MA-CRANE-BOY_EN

Page 1 on 10

Rev: 11/01/2012

CRANE BOY INDICATOR LIMITER

OEM version name: INDI BOY

1. GENERAL INFORMATION .................................................................................................................................................................2

1.1. Introduction ..................................................................................................................................................................................2

1.2. Principle .......................................................................................................................................................................................2

2. INSTALLATION AND ADJUSTMENTS ...............................................................................................................................................3

2.1. Specific CRANE-BOY connections .............................................................................................................................................3

2.2. System calibration .......................................................................................................................................................................3

2.2.1. 1° Configuring the display and commissioning the limiter ..................................................................................................4

2.2.2. 2° Configuration of the triggering thresholds (set points) ....................................................................................................5

2.3. Correct operation test ..................................................................................................................................................................6

2.3.1. Verification of safety if one of the transducer wires breaks .................................................................................................6

2.3.2. Overload, slack cable and load verification .........................................................................................................................7

2.3.3. Periodic verification .............................................................................................................................................................7

2.3.4. Peak values registration ......................................................................................................................................................7

3. TROUBLESHOOTING.........................................................................................................................................................................8

4. EQUIPMENT REFERENCE AND OPTIONS ......................................................................................................................................8

5. SPECIFICATIONS ...............................................................................................................................................................................9

This indicator can only be used for lifting if these instructions are carefully read, strictly applied and if

the legislation in force is respected.

MA-CRANE-BOY_EN

Page 2 on 10

Rev: 11/01/2012

1. GENERAL INFORMATION

This manual describes the procedure to be followed to install and to adjust the CRANE-BOY, an electronic

load system. The information in this manual is applicable for both CRANE-BOY and INDI-BOY. CRANE-BOY

is an INDI-BOY mounted in an IP65 enclosure.

1.1. Introduction

The CRANE-BOY is an electronic system with a digital display and configurable threshold-based triggers. It

has been modified, tested and qualified by SENSY S.A. to provide for a safe lifting operation.

CRANE-BOY has a monitoring circuit to warn the crane operator of a possible break in the measuring wires.

Therefore, it is a self-monitoring device. In the case of a broken wire, a power cut or a short circuit in either the

supply cable and/or in the transducer measuring cable, the device instantly switches into a positive safety

mode.

It is possible to incorporate as options an analogue output (4-20 mA or 0-10V) and serial communication

(RS232). All available options are listed at the end of the manual.

1.2. Principle

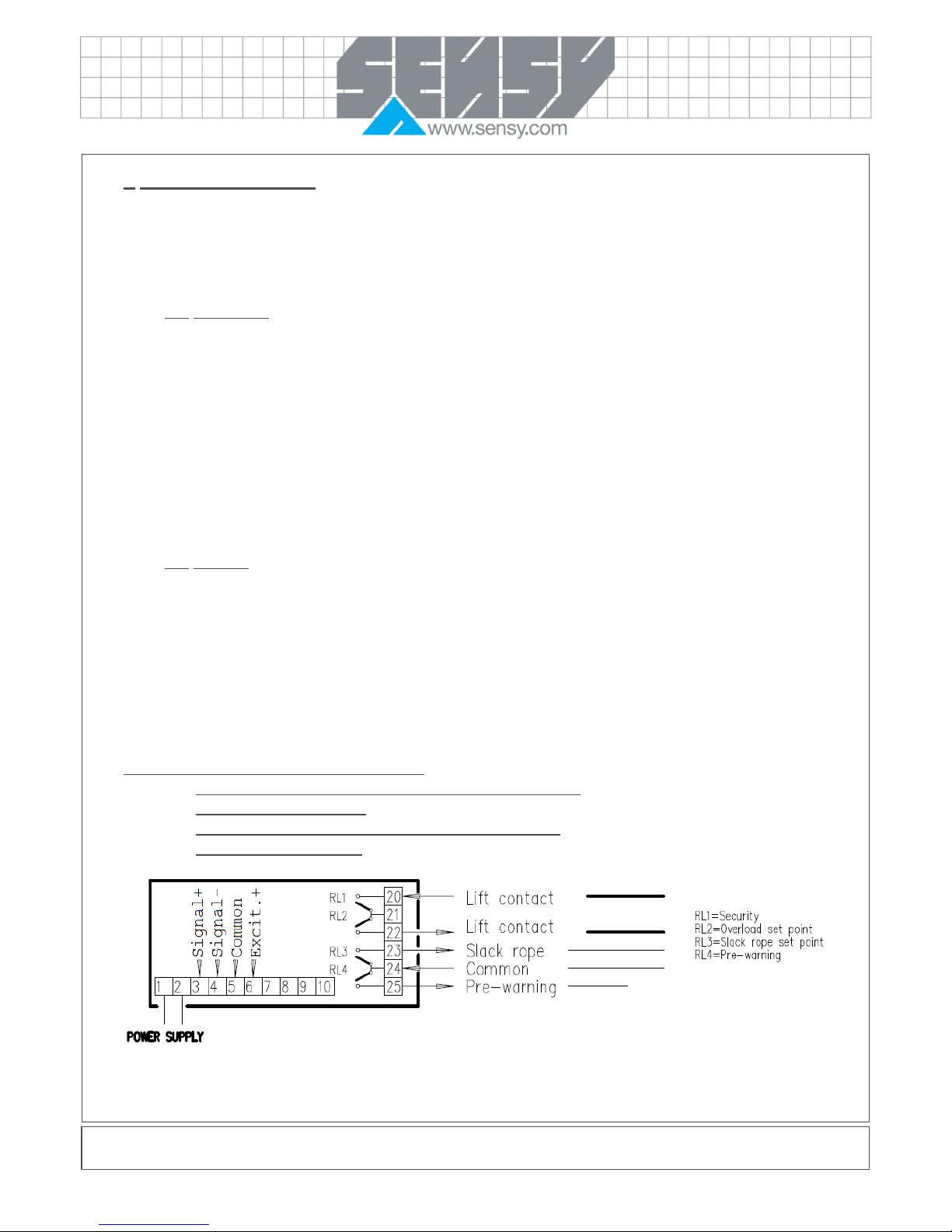

The CRANE-BOY is fitted with a 4-relay board that must be used according to the wiring diagram described

below.

The relays are in the “open” position when the power is shut off (de-energised). When the CRANE-BOY is

turned “on” and the applied load is within the safe operating range, the relays are activated in the "closed"

position (SP1-SP2-SP3-SP4 are displayed in the front panel).

In normal operation, the relays are closed. (SP1-SP2-SP3-(SP4) are displayed in the front panel).

Relay allocation must be strictly respected :

- SP1 (measurement and transducer power supply safety)

- SP2 (overload threshold)

- SP3 (cable slack threshold or intermediate threshold)

- SP4 (optional threshold)

MA-CRANE-BOY_EN

Page 3 on 10

Rev: 11/01/2012

Measuring bridge input

Signal + Green

Signal - White

Excitation - Yellow

Excitation + Brown

2. INSTALLATION AND ADJUSTMENTS

The CRANE-BOY is connected up and adjusted in compliance with the information contained in this manual.

To move around and through the CRANE-BOY's menus, use the buttons or keys on the front panel of the

display.

The PAR key to accept, confirm or enter.

The F1 and F2 keys to go up/down and increase/decrease.

The RST key, in combination with F1 and F2 keys to increase/decrease in steps of 1000 (direct action

on the fourth digit)

The DSP key to quit.

To enter the menus, press the PAR key several times, until CodE appears. Then, using the F1 key, enter the

value of “7”, then press the PAR key. “No” and “Pro” will then appear. You can move from one menu to

another using the F1 and F2 keys.

2.1. Specific CRANE-BOY connections

2.2. System calibration

As the relays that are driven by the different thresholds depend directly on the display, you can only change

some numerical values appearing in menus 1 and 6.

MA-CRANE-BOY_EN

Page 4 on 10

Rev: 11/01/2012

Calibration is carried out in 2 steps:

- 1° display configuration

- 2° threshold configuration

The CRANE BOY programming menu can be accessed via the PAR key. This is organised into function

modules (menus) that group together the parameters associated with each function.

To guarantee that the starting load limitation is correctly followed, the calibration sheet must be duly

completed, dated and signed. Resetting the display is not authorised in any circumstance.

2.2.1. 1° Configuring the display and commissioning the limiter

To configure the display, you must have a known load of at least 70% of the capacity of the transducer’s

Wheatstone bridge or its overload capacity.

Turn the system “on” approximately 15 minutes before starting any adjustment.

If possible, load the system several times to stabilise it mechanically.

Enter menu 1 -INP (using SENSY access code = “7”) and carry out the following operations, using the PAR

key to move on to the next parameter:

DISPLAY

PARAMETER

FACTORY

SETTING

USER SETTING

rANGE

INPUT RANGE

0.02u

. . . . 0,02. . . . .

dECPT

DISPLAY RESOLUTION

0.0

. . . . . . . . .

round

DISPLAY ROUNDING INCREMENT

0.1

. . . . . . . . .

FILtr

FILTER SETTING

1.0

. . . .1.0 . . . .

bANd

FILTER ENABLE BAND

5.0

. . . .5.0 . . . .

Pts

SCALING POINTS

2

. . . . 2 . . . .

StyLE

SCALING STYLE

Select “APPLY” and remove all loads from the crane (in

apply mode, the CRANE-BOY measures the signal of the

load cell).

KEY

. . . APPLY. . .

INP 1

INPUT VALUE 1

1300

Reading at zero (no

load)

dSP 1

DISPLAY VALUE 1

Set to “0”, the value to display when the crane is without

a load (unloaded) by using the F1 and F2 keys and

validate with the PAR key.

0.0

0

INP 2

INPUT VALUE 2

Load the crane with a known load and validate with the

PAR key.

11300

Reading of the signal

under load

dSP 2

DISPLAY VALUE 2

Set to the value to display for the known load and

validate with the PAR key (quit programming mode and

return to display mode)

100.0

Value of the load

MA-CRANE-BOY_EN

Page 5 on 10

Rev: 11/01/2012

Notes :

For each adjustment, INP2 > INP1 and DSP2> DSP1. If this is not the case, check the mounting

direction of the force transducer.

A safe lifting operation is only ensured if the above condition has been satisfied.

After configuring and validating the parameters of your CRANE-BOY, return to display mode (press

the PAR key until “END” appears).

Check that when there is no load, the display is equal to zero and that when the crane is

loaded, the display corresponds to the load that is being lifted.

The details of every parameter are available in the PAXS user guide.

2.2.2. 2° Configuration of the triggering thresholds (set points)

The adjustments in this section are independent of the load lifted at the time of adjustment.

- SP1 is reserved for safety in case either the yellow or brown wire breaks.

- SP2 must be reserved for load limitation: its SP-2 and HYS-2 values will eventually be readjusted to the

characteristics of the transducer’s Wheatstone bridge if this was not carried out at SENSY’s factory.

- SP3 is factory-set to be used for cable slack: its SP-3 and HYS-3 values will eventually be readjusted to

the characteristics of the transducer’s Wheatstone bridge, if this was not carried out at SENSY’s factory.

- SP4 is available to activate a function other than load limitation (but this relay is not protected against a

broken wire). By default, this is not used.

Enter menu “6 –SPt” (SENSY access code = 7) and configure the parameters as shown in the table below.

The SENSY adjustments (factory setting) are such that a lifting system with a force transducer supplying a 1

mV/V signal at nominal capacity (100%) operates in the following way:

- 110% limitation (relay SP2 opens)

- 15% hysteresis (after opening, SP2 closes at 95 %)

- 0% cable slack (SP3 opens)

- 0,1 hysteresis (after opening, SP3 closes at +0,1)

SP2

SP2-Hys

SP3

SP1

MA-CRANE-BOY_EN

Page 6 on 10

Rev: 11/01/2012

The data that must not be changed is written in bold letters

SP1 (security)

SP2 (overload)

SP3 (slack cable)

DISPLAY

PARAMETER

FACTORY

SETTING

USER

SETTING

FACTORY

SETTING

USER

SETTING

FACTORY

SETTING

USER

SETTING

Act - n

SETPOINT ACTION

Ab-LO

Ab-LO

AU-HI

AU-HI

Ab-HI

Ab-HI

SP -n

SETPOINT VALUE

(main)

-3.0%*

Value for a

loose wire (1)

110.0%*

Value for an

overload (2)

0

Value for a

slack cable

(5)

HyS-n

SETPOINT

HYSTERESIS

0.1%*

0.1

15.0%*

15%* (3)

0.1

0.1

tON-n

ON TIME DELAY

0,0

0,0

0,1

0,1 (4)

0,0

0,0

tOF-n

OFF TIME DELAY

0,0

0,0

0,0

0,0

0,0

0,0

out-n

OUTPUT LOGIC

Rev

Rev

Rev

Rev

Nor

Rev

rSt-n

RESET ACTION

AUto

AUto

AUto

AUto

AUto

AUto

Stb-n

STANDBY

OPERATION

No

No

No

No

No

No

Lit-n

SETPOINT

ANNUNCIATORS

Nor

Nor

Nor

Nor

Nor

Nor

* of the nominal capacity

(1) Sufficiently low value to detect a loose wire, by default, -3% of the nominal capacity.

(2) Value at which lifting must be prohibited, according to the legislation in force and the bridge manufacturer's

data.

(3) The hysteresis value may be modified according to the operating conditions. The SP2 activation relay

opens as soon as overloading is reached and only closes when the load is less than the threshold value

minus the hysteresis value.

(4) “tON” (SP2 activation delay) may be modified if the action of lifting a load that is less than the limit load

generates forces (dynamic movements of the load or the “yo-yo” effect) that are greater than those

generated by the static limit load.

(5) Load below which lowering must be prohibited (the SP3 relay opens).

After configuring and validating the parameters of your CRANE-BOY, return to display mode (press the “PAR”

key until “END” appears).

2.3. Correct operation test

The operating test checks that the different relays work and that the wiring is correct, given that the load limiter

must take priority over the commands from the lifting device to prevent any condition that would increase the

overload.

In nominal operation, SP1, SP2 and SP3 are displayed on the front panel.

2.3.1. Verification of safety if one of the transducer wires breaks

For correct verification:

- Disconnect the green wire (+ output) OLOL must be seen on the display and the SP2 overload

relay is off (lifting is impossible)

- Disconnect the white wire (- output) OLOL must be seen on the display and the SP2 overload

relay is off (lifting is impossible)

- Disconnect the brown wire (+ excitation) –xxxxx must be seen on the display and the SP1 and SP3

relays are off (raising and lowering loads are impossible)

- Disconnect the yellow wire (- excitation) –xxxx must be seen on the display and the SP1 and SP3

relays are off (raising and lowering are impossible)

MA-CRANE-BOY_EN

Page 7 on 10

Rev: 11/01/2012

2.3.2. Overload, slack cable and load verification

To verify the overload, first overload and then check that the SP2 relay opens and that lifting is prohibited.

Check that the SP3 relay opens in a slack cable situation and that lowering is prohibited.

Check that the values displayed match the actual values of the loads being handled.

2.3.3. Periodic verification

In compliance with the legislation in force, the lifting force limiter must be regularly checked during periodic

inspections.

This inspection includes a functional test for the triggering limit and the correct condition of the sub-assembly

along with the connections and links. The inspection must be carried out when the equipment is commissioned

then, unless indicated otherwise, at least once a year.

To check the operation of the SP2 overload triggering relay and the display, a test button (*) is fitted on the

load limiter, which destabilises the signal from the force transducer and simulates an overload.

The display offset generated by this test button must be identical to the offset that was obtained when the

equipment was installed and recorded on the calibration sheet.

(*) Push-button in the OEM version: connect the special push-button supplied by SENSY between the signal +

and power supply + terminals (green and brown transducer wires, respectively as standard wire colours).

2.3.4. Peak values registration

Pushing on the DSP key will allow you to visualise the MIN and MAX values the system has recorded while in

operation since the last maintenance check.

In this case, the red LEDS MAX or MIN are “ON” (on the left-hand side of the control panel).

During normal operation (load indication), those LEDS on the left-hand side of the front panel should be off.

CAUTION: using these MIN and MAX values only make sense if you have reset the recorded values by using

the F1 key after the first operation tests and after any subsequent overload simulation by means of the test

button !

MA-CRANE-BOY_EN

Page 8 on 10

Rev: 11/01/2012

3. TROUBLESHOOTING

PROBLEMS

REMEDIES

NO DISPLAY

CHECK: Power level, power connections

PROGRAM LOCKED-OUT

CHECK: Active (lock-out) user input

ENTER: Security access code requested

MAX, MIN, TOT LOCKED-OUT

CHECK: Module 3 programming

INCORRECT INPUT DISPLAY VALUE

CHECK: Module 1 programming, position of the jumper for the input scale, input

connections, input signal level, Module 4 Display Offset is zero, DSP is on Input

Display

PERFORM: Calibration (If the above does not correct the problem.)

“OLOL” in DISPLAY (SIGNAL LOW)

CHECK: Module 1 programming, input connections, position of the jumper for the

input scale, input signal level

“ULUL” in DISPLAY (SIGNAL HIGH)

CHECK: Module 1 programming, input connections, position of the jumper for the

input scale, input signal level

JITTERY DISPLAY

INCREASE: Module 1 filtering, rounding, input scale

CHECK: Wiring is per EMC installation guidelines

MODULES or PARAMETERS NOT ACCESSIBLE

CHECK: Corresponding plug-in card installation

ERROR CODE (Err –n)

Err -1

Err-2

Err-3

Err-4

Err-5

PRESS: RST

Internal hardware fault: A fault of the microprocessor and/or the input circuit has been

detected. Return the CRANE-BOY for repair.

Parameter list memory fault: One or more of set-up parameters has changed value

due to possible electrical glitch or loss of power during parameter save operation.

(during “End” display) Verify all set-up parameters, exit parameter set-up mode and

cycle power the meter to clear error. If the error remains, return meter for repair.

Calibration memory fault: Verify calibration accuracy of meter. If out of tolerance, recalibrate the meter. Otherwise, to clear error, enter and exit parameter set-up mode

and cycle power to meter. If the error remains, return meter for repair.

Analogue output calibration memory fault: Verify calibration accuracy of analogue

output. To clear error, enter and exit parameter set-up mode and cycle power to

meter. If the error remains, replace output card.

Defective keypad: The meter has detected one of the keypad switches is defective.

Inspect keypad for signs of damage or sticking. Cycle power to meter to clear error. If

the error remains, return meter for repair.

For more information, contact SENSY’s helpdesk.

4. EQUIPMENT REFERENCE AND OPTIONS

Supply voltage - 85 to 250VAC Ref.: CRANE-BOY

- 48 VAC Ref.: CRANE-BOY+ option ALIM-48VAC

- 24 VAC Ref.: CRANE-BOY24

- 10 to 30VDC Ref.: CRANE-BOY24

Supply voltage - 85 to 250VAC (OEM) Ref.: DISP-BOY

- 48 VAC (OEM) Ref.: DISP-BOY+ option ALIM-48VAC

- 24 VAC (OEM) Ref.: DISP-BOY24

- 10 to 30VDC (OEM) Ref.: DISP-BOY24

MA-CRANE-BOY_EN

Page 9 on 10

Rev: 11/01/2012

4-20mA or 0-10V Options Ref.: CARD-CDL-10

RS232 options Ref.: CARD-CDC-20

RS485 options Ref.: CARD-CDC-10

IP65 protective cover options Ref.: COVER-PAX

5. SPECIFICATIONS

Display

5 red LED digits 14,2mm (-19999 à 99999)

AC Versions

85 to 250VAC

50/60Hz

15VA

Isolation : 2300 Vrms for 1 min. to all inputs and outputs

Operating temperature : 0 to 50°C (45°C if 3 plug-in cards are

installed)

24VAC

50/60Hz

15VA

Isolation : 500 Vrms for 1 min. to all inputs and outputs

Operating temperature : 0 to 50°C (45°C if 3 plug-in cards are

installed)

DC Version

11 to 36VDC

11W

Operating temperature below 40°C if the power supply is below

15VDC and 3 plug-in cards are installed

Analog/digital

converter

16bits resolution

Bridge excitation

Jumper selectable

5VDC, 65mA max, +/-2%

10VDC, 125mA max, +/-2%

Temperature coefficient (ratio metric): 20ppm/°C max

Custom

linearization

Data point pairs

Selectable from 2 to 16

Display range

from -19999 to 99999

Decimal point

0 to 0.0000

Memory

Nonvolatile EEPROM retains all programmable parameters and display values.

Certifications and

compliances

Electromagnetic immunity:

Conform to EN 50082-2

Electrostatic discharge

EN 61000 - 4 - 2

Level 3: 8 kV air

Electromagnetic RF fields

EN 61000 - 4 - 3

Level 3: 10 V/m 80 MHz to 1GHz

Fast transients (burst)

EN 61000 - 4 - 4

Level 3: 2 kV power

Level 4: 2 kV (I/O)

RF conducted interference

EN 61000 - 4 - 6

Level 3: 10 Vrms de 150 kHz - 80 Mhz

Electromagnetic emission:

Conform to EN 50081 -2

RF interference

EN 55011

Enclosure class A

Power mains class A

Notes: Self-recoverable loss of performance during electromagnetic interference (EMI) at 10 V/m:

measurement error exceeds unit specifications. For operation without loss of performance:

- mount unit in a sheet-metal enclosure (Buckeye SM7013-0 or equivalent)

- route power and I/O cables in metal conduit connected to earth ground.

For more information, refer to guide treatment against the effects of EMC.

Note : In load limitation operation, always lock the device configuration with an access code (the access code

set at the SENSY factory is “7”).

MA-CRANE-BOY_EN

Page 10 on 10

Rev: 11/01/2012

CARD CDC10 (RS485) : PAX’s option card : RS485 Serial communication

- Version RS485

- Field bus RS485

- Screw terminals or connector

CARD CDC20 (RS232) : PAX’s option card: RS232 Serial communication

- Version RS232

- “Half duplex” communication interface

- Screw terminals or connector

CARD CDC50 (Profibus) : PAX’s option card: Profibus communication

- Transmission of data input/output: up to 84 bytes input/output

- Avalable communication speed : 9,6 KB to 12MB with automatic speed detection

CARD CDL (Analogue) : PAX’s option card: Analogue output

- 0-20 mA, 4-20 mA, or 0-10 VDC

- Resolution 1/3500

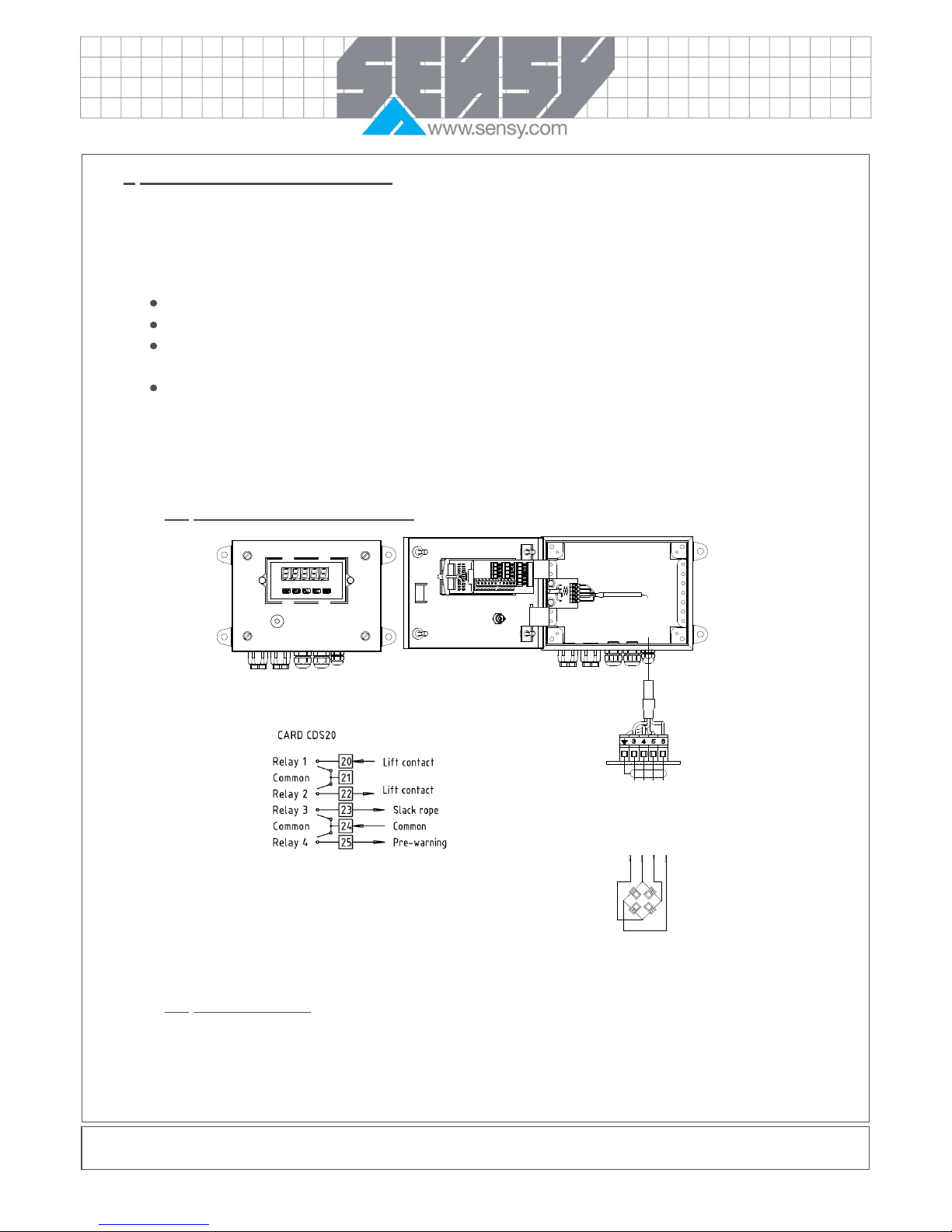

CARD CDS (Set point) : PAX’s option card: Relay output

- 2 versions : 2 or 4 relais

- Open connector in « sinking » or « sourcing » mode

Femelle

PAX

Loading...

Loading...