Page 1

1 of 2

INSTALLATION INSTRUCTIONS

Invensys RadioRead

T

Model 510

MPORTANT

I

The following information contains installation instructions for the

Invensys RadioRead

nections are the same for both inside and pit set installations. Techniques may be different for the actual MXU placement in each type of

installation.

Note: This installation sheet is only for installation of the RadioRead

MXU. For instructions on installing other AMR devices, please request

and refer to the individual installation instructions for those devices.

ECOMMENDED

R

®

●

SR II

security screw socket with 1/4" nut driver or ratchet wrench

●

3M Scotchlok

●

3M Scotchlok

●

Wire stripper tool

●

Screwdrivers (Phillips and standard blade heads)

●

Power drill and bit (1/4")

●

8 x 1" sheet metal screws

●

1/2" Electrical Metallic Tubing (EMT)

●

Conduit cutting tool

●

Hammer

●

Conduit driver (available from Invensys)

●

Three-conductor solid wire (Invensys specification)

T

Meter Transceiver Unit (MXU). The wiring con-

OOLS

T

®

UY-2 butt connector “gel-caps”

®

E-9Y stepped jaw crimping tool with wire cutter

AND

ATERIALS

M

Meter Transceiver Unit (MXU)

The MXU also requires proper programming of each port to match the

device that is connected to the respective port. Refer to Invensys Programming Manual AMR-988.

NSTALLATION

I

The MXU wiring instructions assume the utility meter with an encoder

register or MultiRead module has been installed and the proper wire

has been run to the MXU installation location. Three-conductor, 22

gauge, solid conductor cable is recommended. (For meter installation,

refer to the installation information included in Invensys meter shipping

cartons.)

1. Using the SR II security socket with ratchet wrench or nut driver,

open the MXU enclosure by removing SR II type security screw.

Bottom part of enclosure will contain the MXU battery and top part

the electronics and connection wires. Connect the three wires from

the encoder register or MultiRead module to the matching color

wires on the MXU and the desired port. If not already done, strip

approximately 2"

wire colors for each unit should be

matching color wire ends –

black

into a UY-2 gel-cap with the color button of gel-cap facing

away. (This provides a better view of wire positions inside the clear

plastic gel-cap enabling the installer to see the wires are completely and properly inserted.)

Note: For the Schlumberger Proread encoder, the color coded

wire connections are not standard – For Proread, connect the

MXU red to Proread black, MXU green to Proread red, and MXU

black to Proread green.

Using gel-cap pliers, squeeze the gel-cap. This will splice the two

wires and release the waterproof gel to seal the connection. The

splice can be checked by pulling gently on the gel-cap while holding the wires to be sure they are tight and secure. Repeat Step 2

instructions for the remaining two wire connections. Repeat connections to a second port, if required.

- W

off outer jacket

IRING

red

to

NSTRUCTIONS

I

of the encoder wire cable. The

green

,

red

, and

red

,

green

to

black

green

. Insert two

, and

black

to

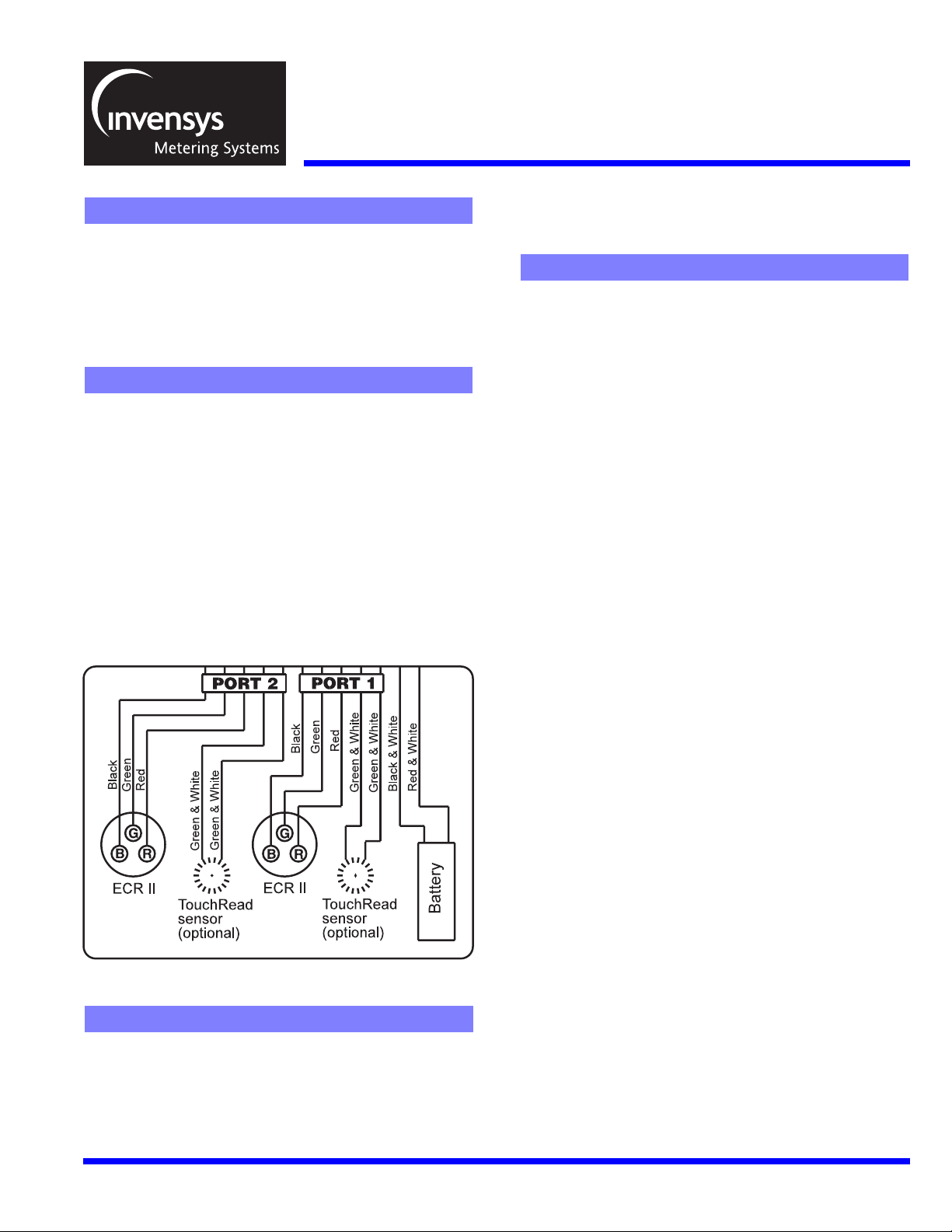

MXU Model 510 - Installation Wiring Diagram

G

ENERAL

The Model 510 MXU incorporates a two-port interface design. Hardwire connections to either port from a compatible utility meter or MultiRead module is the same for each port.

Note: the wiring is different when connecting a Schlumberger

Proread (ARB-VI) encoder to a port.

I

NFORMATION

* If any of the wire connections are not being used they should

be capped at the end with a gel-cap. This is to prevent water

intrusion via wicking through the exposed wire ends. The

green

, and

black

green

with

capped together.

Note: A Schlumberger Proread (ARB VI) register must be connected directly to an MXU port. The Proread register will not work

through a MultiRead module connected to an MXU.

2. Connect the battery to the MXU electronics. Using the gel-cap connecting technique described in Step 2 above, connect the

white stripe

from the MXU electronics. Repeat the procedure for the

white stripe

from the MXU.

Caution: DO NOT cross connect the black and white and red and

white stripe wires of the MXU and battery pack as this may cause

damage to the MXU electronics.

If using the optional TouchRead

skip to Step 4.

3. (Optional) TouchRead

encoders only) – The MXU includes a built-in TouchRead splitter

connection to allow the encoder register to be interrogated by both

RadioRead equipment and a remote TouchRead System sensor.

wires must be gel-capped individually. The

white striped

wire from the battery to the

wire from the battery to the

TouchRead sensor wires can be gel-

red

and

white stripe

black

and

white stripe

®

connection, go to Step 3. If not,

®

Connection (available for Invensys register

red

black

red

and

wire

and

wire

,

Page 2

2 of 2

Wall Mount TouchPad – Using two-conductor or three-conductor

wire cable and gel-caps, connect wires to each of the

white stripe

At the TouchPad connection, connect the same two wires to the

terminal screws on the back of the TouchPad.

Pit-set Mount Sensor – The TouchRead pit-set sensor includes a

factory-sealed three-conductor wire cable. Proper wire connections

are therefore important. To activate the pit-set TouchRead sensor,

use only the

of the cable’s outer jacket must be stripped from its end to access

these wires. Then, using gel-caps, connect the

sensor to one of the

Next, connect the

white stripe wire

ond port if required.

4. Verify MXU operation prior to final assembly: To verify RadioRead

reading, use Radio Frequency Solid State Interrogator (RFSSI) or

Vehicle Transceiver (VXU) to display the register odometer reading(s), register ID number(s), and MXU ID number. (For AMR troubleshooting, refer to bulletin AMR-309.)

-To verify TouchRead reading

to display register odometer reading(s) and register ID number(s).

If MXU does not function, check all wire connections, re-do the

connections or change battery pack. (For complete TouchRead

installation and troubleshooting, see installation bulletins: TR-728,

TR-997, and TR-998.)

5. After wiring connections are completed and MXU operation is verified, align guides of top and bottom parts of MXU and close, bringing the connection wire(s) out the front side, using the wire passthru guides located on either side of the security screw. Secure the

top and bottom parts of the MXU using the security screw.

MXU M

wires from the MXU.

Note: If three-conductor wire cable is used, the third wire is not

utilized for the TouchRead Connection.

Caution: Be sure there is no bare wire-to-wire contact. (The

TouchRead connection is non-polarity sensitive and will w ork as long

as the same color wires are used at both ends of the connection.

If three-conductor wire is used, be sure the third “dead” wire is not

mistakenly connected at either end.) Repeat the connections for a

second port if required.

red

and

black

wires from the sensor. Approximately 2"

green and white stripe

red wire

from the MXU. Repeat the connections for a sec-

Note: When connecting a Schlumberger Proread (ARB VI) register

directly to an MXU port, the TouchRead splitter feature is not available.

Caution: DO NOT over-tighten security screw.

OUNTING

from the sensor to the other

, use a TouchRead visual reader

NSTRUCTIONS

I

black wire

wires from the MXU.

green

and

from the

green

and

For Wall Mounting: (Indoors and Outdoors)

1. Using MXU mounting bracket, find a convenient location for the

MXU mounting. It is recommended that the MXU be mounted in an

upright position so the top part with the Invensys logo is facing up.

The MXU mounting bracket can be mounted to a wall using screws

or fastened to an object using heavy duty wire ties. Grooves have

been placed in the back of the bracket for mounting on either hor izontal or vertical (existing) pipes.

2. After mounting MXU bracket, snap the MXU (which should already

be wired as noted in the preceding wiring instructions) into the

bracket. Be sure the locating tabs on either side of the MXU have

snapped into position in the mounting bracket.The installation is

now complete.

3. TouchPad Mounting (Optional) – If mounting the MXU outdoors and

a TouchRead TouchP ad connection is to be included, mounting

holes can be drilled in the side of the MXU bracket. Using shor t

screws or plastic rivets, mount the TouchPad to the side of the MXU

bracket.

Caution: When using screws, be sure they do not penetrate the

MXU enclosure when mounting the TouchPad. The TouchPad can

also be mounted in a location away from the MXU. Be sure to use

screws that are designed for and applicable to the mounting surface.

For Pit Set Mounting:

1. Use 1/2” EMT. Select a location for the conduit where the MXU’s

installed position will not interfere with the meter and allow the MXU

to be located as high as possible inside the meter box. The MXU

should be kept approximately 1" from the sides of the meter box

and positioned so the meter register odometer remains visible for

visual confirmation readings. Conduit mounting method calls for

driving a length of conduit into the ground at the bottom of the

meter box. (If the bottom of the meter box does not have an opening sufficient for driving the conduit vertically into the ground below,

a different mounting method may need to be developed.) Place

driver on conduit and strike with hammer, driving conduit downward until it is at the desired height. The correct height should be at

the point the driver is level with the top of the meter box in most

cases. When completely installed, the top of the MXU should be

about 1" below the meter box lid.

2. After installation of conduit, position the opening located in the bottom of MXU over the conduit and press into place. Place meter box

cover (lid) into position. Pit set installation is no w complete.

3. TouchRead Sensor Mounting (Optional) – If installing a TouchRead

pit-set module follow the TR/PL mounting instr uctions on Invensys

bulletin TR-997 for mounting in the meter box lid. Place meter box

cover (lid) into position with the TR/PL sensor in place.

FCC C

NOTE: This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or

more of the following measures;

– Reorient or relocate the receiving antenna

– Increase the separation between the equipment and receiver

– Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected

– Consult the dealer or an experienced radio/TV technician

WARNING: No party shall make any modifications or changes to the

MXU Model 510 (the equipment) without the express written consent

of Invensys Metering Systems. Doing so could result in the equipment

becoming non-compliant with the requirements of the Federal Communication Commission Rules CFR47 Part 15 and could void the user’s

authority to operate the equipment.

OMPLIANCE

Invensys Metering Systems

P.O. Box 487

450 N. Gallatin Avenue

Uniontown, PA 15401

1-800-METER-IT

1-800-638-3748

FAX (Direct to Factory)

Local: (724) 439-7729

Toll Free: 1-800-888-2403

Web site: www.ims.invensys.com

select

North American Water

Email: h2oinfo@ims.invensys.com

AUTHORIZED INVENSYS DISTRIBUTOR

Loading...

Loading...