Senstar LM100™

Intelligent Perimeter Lighting and Sensing Solution

Product

Guide

E8DA0102-001 Rev A

December 11, 2017

Senstar Corporation

Website: www.senstar.com

Email address: info@senstar.com

E8DA0102-001 Rev A

December 11, 2017

Senstar and the Senstar logo are registered trademarks, and Silver Network is a trademark of Senstar Corporation. Product

names and Company names included in this document are used only for identification purposes and are the property of, and

may be trademarks of, their respective owners. Copyright © 2017, Senstar Corporation, all rights reserved. Printed in Canada.

The information provided in this guide has been prepared by Senstar Corporation to the best of its ability. Senstar Corporation is

not responsible for any damage or accidents that may occur due to errors or omissions in this guide. Senstar Corporation is not

liable for any damages, or incidental consequences, arising from the use of, or the inability to use, the software and equipment

described in this guide. Senstar Corporation is not responsible for any damage or accidents that may occur due to information

about items of equipment or components manufactured by other companies. Features and specifications are subject to change

without notice.

Any changes or modifications to the software or equipment that are not expressly approved by Senstar Corporation void the

manufacturer’s warranty, and could void the user’s authority to operate the equipment.

The figures included in this document are for illustration purposes only, and may differ from the actual equipment.

Compliance:

This equipment should be installed and operated such that the transmit antenna is 25 mm (1 in.) or more away from any person

during the device’s operation.

Canada: Innovation, Science and Economic Development Canada Certification Number:

1454B-LM100 (Senstar LM100 luminaire)

CAN ICES-3B/NMB-3B

This device complies with Innovation, Science and Economic Development Canada license-exempt RSS standard(s).

Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

Ce dispositif est conforme aux normes CNR Innovation, Sciences et Développement économique Canada applicables aux

appareils radio exempts de licence. Son fonctionnement est sujet aux deux conditions suivantes : 1) le dispositif ne doit pas

produire de brouillage préjudiciable; et 2) il doit accepter tout brouillage reçu, y compris un brouillage susceptible de provoquer

un fonctionnement indésirable.

USA: FCC Identification Number: I5TLM100 (Senstar LM100 luminaire)

Changes or modifications not expressly approved by Senstar Corporation could void the user's authority to operate the

equipment.

FCC Certification - This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Europe:

This device complies with ETSI standard EN 300 440 for European operation.

The use of shielded cables is required for compliance.

Senstar

Corporation’s Quality Management System is ISO 9001:2008 registered.

Page 2 Senstar LM100 Product Guide

Table of Contents

1 System planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Senstar LM100 luminaires - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Senstar LM100 luminaire AP - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Senstar LM100 gateway - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

The Universal Configuration Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Alarm communication options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Relay Output Card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Dry Contact Input Card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Fail-safe relay operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Power source and wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Auxiliary device output power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Power over Ethernet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Grounding considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Alarm monitoring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

NM Mode alarm reporting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Security factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Fence structures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Standard flexible fence types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Chain-link fence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Welded-mesh fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Expanded metal fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Rigid fence types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Palisade fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Climb-over deterrent hardware - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Barbed wire - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Razor ribbon - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Gates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Environment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Site Survey - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Equipment layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Installation overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

2 Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Installing LM100 luminaires - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

At regular fence posts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Senstar LM100 Product Guide Page 3

Tools and equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

At corners or heavy gauge posts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Installing luminaires on welded-mesh fence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Installing luminaires on rigid fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 23

Surface mounting luminaires - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 24

Power cable installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -24

Tools and equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

Installing the luminaire AP - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -27

Installing the LM100 gateway - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -27

Cable entry ports - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Free-standing or fence post mounting the enclosure - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Surface mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

I/O ports - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

I/O port jumpers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 32

Outputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 32

Relay contact ratings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

Auxiliary inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

Gateway wiring connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -34

Silver Network wiring connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -36

Silver Network specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Silver Network data path connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -38

Power supply connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -40

Network power supply - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Local power supply - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Power over Ethernet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Backup power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Using the wireless gate sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -41

3 Calibration & setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

The Universal Configuration Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -43

Senstar LM100 configuration overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -47

Senstar LM100 definitions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -47

Senstar LM100 alarm detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -48

Intrusion detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -49

Cut detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49

Climb detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49

Initial gateway setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -49

Connecting the UCM via USB - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -50

Setting the gateway’s Silver Network address - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -50

Silver Network configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -50

Sequencing the heads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -50

Compiling the Unordered Heads list - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

Compiling the Ordered Heads list - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

Compiling the Head Sequence list - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 53

Senstar LM100 calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -54

The Sensitivity Profile - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -54

Recording the Sensitivity Profile - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 54

Detection parameter setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -55

Defining the luminaire segments and alarm zones - - - - - - - - - - - - - - - - - - - - - - - - - - -56

Defining the initial zone - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 57

Page 4 Senstar LM100 Product Guide

Defining the segments - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 57

Verifying the luminaire segment boundaries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Setting the Threshold - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Segment threshold setting procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 59

Intrusion simulations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 60

Scheduling routine light activation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

Scheduling routine luminaire activation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

Input/output configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 62

Specifying the Auxiliary I/O control mode, I/O type and option card - - - - - - - - - - - - - - 62

Auxiliary (Aux) inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 62

Local control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 62

Remote control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 62

Remote light activation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 63

Input wiring configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 63

Input configuration procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 64

Output relays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 64

Output relay setup (Local control mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 64

Output relay setup (Remote control mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 64

Linking segments to relays (local control mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

System test procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

4 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 67

Recommended maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 67

Preventing weather related nuisance alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 68

Adjusting the Target Filters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 68

Replacing the gateway - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 69

Removing the gateway assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 69

Replacing the gateway assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 69

Updating the Senstar LM100 Firmware - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 69

a Parts list - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -71

b Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 73

Senstar LM100 Product Guide Page 5

Related publications:

The following documents, included on the Senstar LM100 CD, contain information that may be

applicable to the Senstar LM100 system

• E8DA0103-001 Senstar LM100 quickstart instruction

• 00DA0803-001 Installing the network interface card

• 00DA1003-002 UltraLink I/O

• 00DA1203-001 Installing the network interface unit

• 00DA1503-001 Installing I/O cards

• 00DA0109-001 Network Manager overview

• E7DA0103-001 Wireless Gate Sensor

Page 6 Senstar LM100 Product Guide

1 System planning

Description

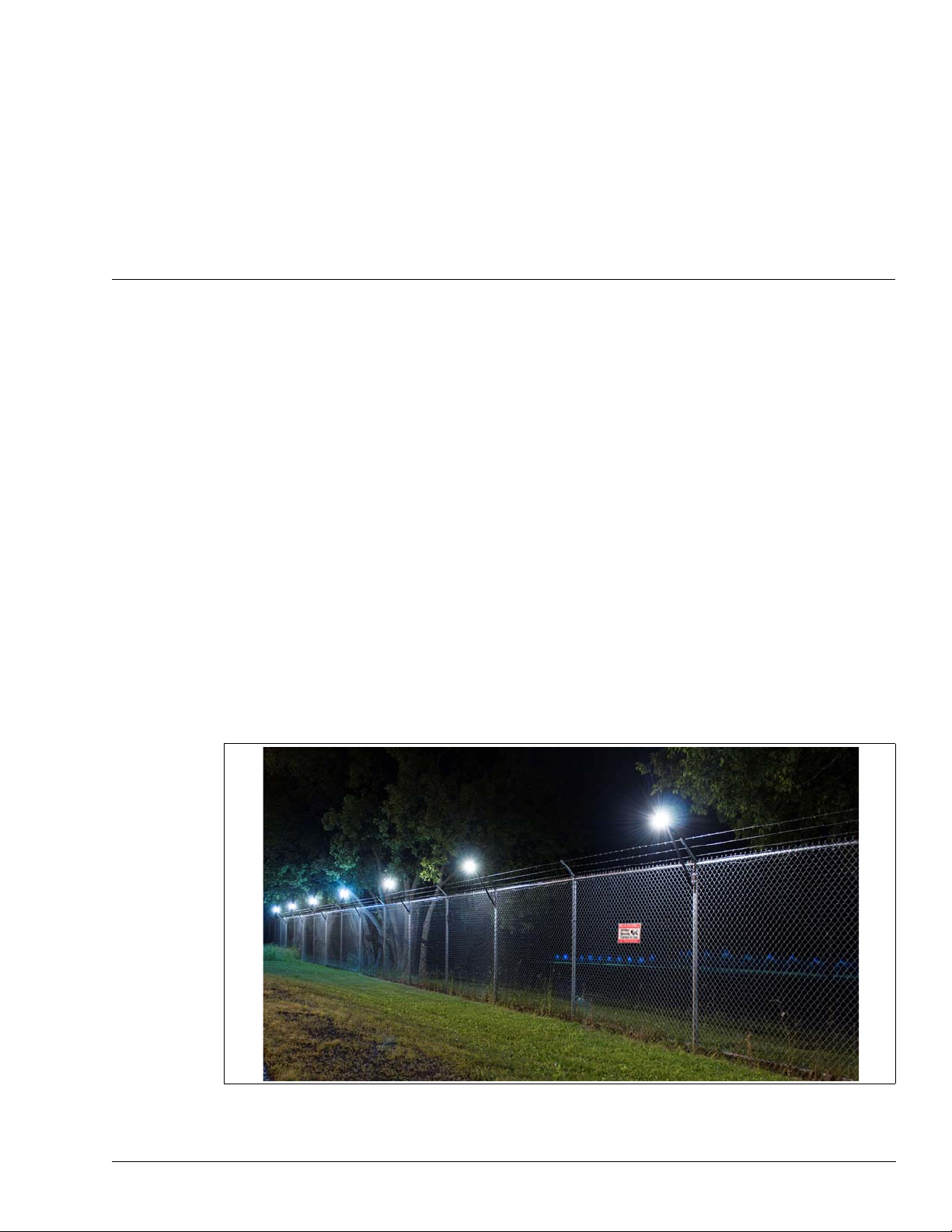

The Senstar LM100 intelligent perimeter lighting and sensing solution combines high-intensity

LED lighting with an accelerometer-based vibration detection sensor. The system is comprised of

a distributed set of LM100 luminaires, which include the LED lights and the vibration detecting

sensor, a gateway device that processes the signals from the luminaires, and a luminaire AP

(access point) that provides an RS-485 half-duplex connection between the RF-based luminaires

and the gateway.

The Senstar LM100 luminaires are typically mounted on the perimeter fence, but can also be

mounted on walls or other surfaces. The luminaires communicate over a proprietary wireless

mesh network transmitting status information and receiving control point commands from the

gateway via the hard-wired connection to the luminaire AP. The gateway provides the user

interface to the distributed luminaires as well as the interface between the luminaires and a

security management system (SMS). The gateway device supports up to 100 luminaires (the

luminaire AP is included in the 100 unit limit for each Senstar LM100 system).

Figure 1: luminaires at night

Senstar LM100 Product Guide Page 7

Description

For optimum performance and the highest probability of detection (Pd) the Senstar LM100

luminaires can be mounted on fences up to 3.6 m (12 ft.) high, with up to 6 m (20 ft.) separation

between luminaires. With 6 m spacing between luminaires, one Senstar LM100 system can

protect up to 600 m (1970 ft.) of perimeter fencing. The luminaires can be mounted at various

heights on the fence posts to avoid contact with barbed wire outriggers at the top of the fence.

Note It may be possible for the Senstar LM100 to protect fences higher than

3.6 m by installing the luminaires at the 3.6 m (12 ft.) point on the fence

posts; or by using the minimum separation between luminaires of 3 m.

However, Senstar strongly recommends a trial installation and testing

the installation thoroughly to ensure the detection sensitivity meets the

site requirements.

The Senstar LM100 system can be configured to protect most types of fences with userconfigurable detection parameters and light activation controls. Each system supports up to 50

distinct alarm zones and each alarm zone can include from 1 to 100 luminaires. In addition to

alarm detection and response, each software defined zone can follow a preset schedule for

routine light activation. The luminaire detection parameters and alarm response are configured

through the LM100 gateway. The lights can be turned ON, OFF, and Strobed in response to an

alarm, individually or grouped by zone. The luminaires can also have their brightness adjusted for

both routine lighting and alarm response.

The LEDs on the Senstar LM100 luminaires are optimized to provide full spectrum lighting, to

ensure high quality images for CCTV coverage. The LEDs provide uniform directional lighting

along the fence line with an elliptical 120º coverage pattern that minimizes light pollution. The LED

lights are fully ON or OFF instantly, without a warm-up period and each luminaire consumes only

2.5 W. The Senstar LM100 system is so energy efficient that a complete system with 100

luminaires consumes about the same amount of power as a single high pressure sodium light.

The Senstar LM100 gateway includes ten I/O ports that are individually selectable as inputs or

outputs with normally open or normally closed contacts. An I/O option card can be added to the

gateway to provide an additional 4 inputs or 4 outputs. The I/O points can be controlled locally by

the gateway with the outputs used to signal alarm and supervision conditions, and the inputs used

to activate luminaire zones. Alternately, the I/O points can be controlled remotely by a security

management system (SMS). In this case the outputs are used to activate auxiliary equipment and

the inputs are used to communicate the status of auxiliary devices to the SMS. The outputs are

individually configurable and can source up to 100 mA to power auxiliary equipment. The inputs to

the gateway must be voltage free. The Senstar LM100 supports the Wireless Gate Sensor (WGS)

to provide coverage for up to 4 gates per system. The WGS requires a receiver module which

mounts on the gateway circuit card assembly (CCA) and at least one gate sensor for each

protected gate.

The Senstar LM100 system can operate as a standalone system which reports alarm conditions

via contact closure outputs. Each luminaire can be configured to respond to alarm conditions and

to automatically turn ON and OFF according to a user-defined schedule, and to activate other

equipment (via gateway outputs). Each luminaire can also be configured to respond to dry contact

inputs from other equipment such as a photo cell for routine li

ght activation.

The Senstar LM100 can be part of a Silver Network based security system. In this case the

gateway requires a Network Interface Card that connects to a PC running Senstar’s Network

Manager (NM) service. The NM interfaces between the Senstar LM100 and a security

management system such as StarNet 2 or the Alarm Integration Module. The Senstar LM100 can

easily be integrated into any SMS that accepts contact closure inputs. There are 16 channels

available to prevent interference between closely located Senstar LM100 systems (400 m

separation is required between Senstar LM100 systems operating on the same channel).

Page 8 Senstar LM100 Product Guide

Senstar LM100 luminaires

luminaire head

6 mm (¼ in.) holes for wall-mounting

clamp slots for post-mounting

2-conductor power cable connection

LED lights and electronics

RS-485 (green A white B)

luminaire AP with power

luminaire AP

luminaire

(red + black -)

power cable (red + black -)

and shielded data connection

The luminaire is both the sensing unit and the lighting unit for the Senstar LM100 system. The

luminaires communicate over a wireless mesh network, relaying status information to the gateway

via the luminaire AP. Luminaires are usually mounted near the tops of the fence posts, and can

also be mounted on walls or other flat surfaces. The luminaire head contains the electronic

components (a MEMs sensor, LED lights and a wireless RF transceiver). Each Senstar LM100

gateway supports up to 100 luminaires (1 luminaire AP + 99 luminaires). The luminaires are

configured remotely through a UCM connection to the gateway. One or more luminaires can be

grouped into segments, and the segments can be grouped into zones (via the UCM software). The

detection parameters are set globally for all luminaires. However, each luminaire segment has an

independent alarm threshold and each luminaire zone can have independent light activation

controls. The global detection parameters include an Event Window, an Event Count and an Alarm

Window. There is also a Target Filter which can be used to screen out some sources of

environmental and mechanical noise. Each luminaire is supervised to protect against tampering

and the removal of the device.

Description

Senstar LM100 Product Guide Page 9

Figure 2: Senstar 100LM luminaire and luminaire AP

The luminaire’s lighting properties are also set globally. This includes brightness, and response to

alarm conditions. There are 5 selectable luminaire alarm responses. Luminaires can be turned

ON, OFF, or strobed individually or in zones. For example, the luminaire that detects an intrusion

attempt can be strobed and the zone it is assigned to can be turned ON. It is also possible to

configure a luminaire zone to follow a routine lighting schedule, with or without providing intrusion

detection. For example, a number of luminaires could be used to provide walkway lighting and

building entrance lighting. These luminaires would be scheduled to turn on at dusk and off at

dawn. Alarm detection is not desired for these luminaires so the detection for this group of

luminaires would be disabled.

Description

Senstar LM100 luminaire AP

The luminaire AP functions as a standard luminaire providing intrusion detection and routine

lighting. It also serves as the access point through which the distributed luminaires communicate

with the gateway device. A two-wire RS-485 connection between the AP and the gateway enables

half-duplex communication between the two devices. Individual luminaires are polled for status

information, and when an alarm condition occurs, the luminaire detecting the alarm transmits the

status change. This information is passed over the wireless mesh network until it is received by the

luminaire AP. The luminaire AP sends the data to the gateway over the RS-485 connection. The

gateway processes the received signals and triggers an alarm when the information indicates a

valid alarm. The luminaire AP includes a 3 m (10 ft.) 4-conductor cable to make the power and

data connection to the gateway. The luminaire AP can be installed up to 100 m (328 ft.) away from

the gateway by splicing in a suitable length of data/power cable. To use the extended cable length

requires a minimum 24 VDC power supply.

Senstar LM100 gateway

The gateway is the central controller for the Senstar LM100 system. It communicates with the

distributed luminaires through a 2-wire RS-485 connection to the luminaire AP. The gateway

receives the alarm and status information from the luminaires, and depending on the method of

alarm reporting, it either passes the data to the Silver Network Manager (NM) or it activates the

onboard outputs to signal alarm conditions and status information. System setup and configuration

for the luminaires is done using the Universal Configuration Module (UCM) through either a direct

USB connection to the gateway device, or remotely through the Silver Network Manager.

The gateway can be mounted outdoors on a post, either on, or separate from, the fence on which

the luminaires are installed. A rigid fixed post is recommended for outdoor applications. The

gateway can also be installed indoors or outdoors on a flat stable surface. Post-mounting

hardware is supplied for post sizes ranging from 4.5 cm to 12.7 cm (1¾ in. to 5 in.). The hardware

required for surface-mounting the gateway is customer-supplied. The gateway enclosure is hinged

on one side and includes a lockable latch (padlock not included).

The gateway includes ten input/output (I/O) ports, each of which can be configured as either an

input or an output. Option cards are available to provide an additional 4 inputs or 4 outputs. There

are two selectable control modes for the gateway’s I/O, local control mode and remote control

mode. The control mode is set in software, via the UCM. The default setting is local control mode,

in which the gateway controls the on-board relays to signal alarm and supervision conditions (user

specified relay activation conditions). In local control mode, the inputs are used to activate userselectable luminaires (i.e., when the input goes high, activate one or more luminaires). In remote

control mode, the alarm data is carried over the Silver Network to a host security management

system (SMS). Remote control mode enables the security management system (SMS) to control

the gateway’s relays as output points to operate other security equipment. The input ports provide

inputs to the host SMS for reporting the status of auxiliary devices. In both modes, you can

configure the gateway’s input/output response according to your site-specific requirements.

• local control mode - hard-wired contact closure alarm data connections and input wiring

connections are made between the gateway and the annunciation equipment

(ten I/O ports in any combination of output relays, dry contact inputs) (the optional Relay

Output card provides 4 additional outputs for reporting alarm conditions; the optional dry

contact input card provides 4 additional inputs)

• remote control mode - the alarm data communications are via the Silver Network: RS-422

copper wire data paths, Ethernet cable, or fiber optic cables connect the gateway to the

Network Manager, which communicates with a host security management system; the outputs

are available as output control points from the host system (the optional Relay Output card

provides 4 additional outputs) the dry contact inputs are available for reporting the status of

auxiliary equipment to the host system (the optional dry contac

additional inputs)

t input card provides 4

Page 10 Senstar LM100 Product Guide

Note For the Senstar LM100 to be part of a Silver Network based security

system, the gateway requires a network interface card.

The gateway can use either an input card or an output card, not both.

The Universal Configuration Module

The Universal Configuration Module (UCM) is a Windows based software application, which

serves as the calibration, setup and maintenance tool for the Senstar LM100 system. The UCM

communicates with the gateway locally through a USB connection, or remotely via the Silver

Network Manager. When the UCM software starts, a window displays that enables you to specify

the device to which you are connecting (Senstar LM100).

Alarm communication options

• contact closure alarm communications (local control mode) up to 14 distinct alarm zones per

Senstar LM100 system (requires optional relay output card)

• Silver Network data communications using RS-422 copper wire data paths, Ethernet cable, or

fiber optic cable

Description

Note Use individually shielded twisted pair with overall shield for RS-422 data

cables.

Note A Silver Network based Senstar LM100 can use local control mode to

operate the gateway’s inputs and outputs.

Relay Output Card

The relay output card (ROC) (P/N 00BA2500) includes four relays to supplement the outputs

available on the gateway. In local control mode the ROC’s outputs indicate user-selectable alarm

and supervision conditions. In remote control mode, the host security management system

operates the ROC’s relays, as output control points, (e.g., to activate sirens, CCTV equipment,

etc.). You can configure the relays as latching (ON by command, OFF by command), in flash mode

(ON-OFF-ON-OFF, etc. by command, then OFF by command), or pulse mode (ON for a period,

then OFF). For flash and pulse modes, the Active/Inactive times are selectable.

Dry Contact Input Card

The dry contact input card (DRIC) (P/N 00BA2400) includes four inputs to supplement the inputs

available on the gateway. In local control mode the DRIC’s inputs are used to activate userspecified luminaires. In remote control mode, the inputs connect auxiliary devices to the host

security management system (e.g., to report the status of other security equipment such as a

microwave or magnetic contact). The Filter Window parameter allows you to set the time period for

which an input must be active, before an event is reported.

Fail-safe relay operation

In the default configuration, the gateway’s relays operate in fail-safe mode. During normal

operation, the relays latch in the non-alarm state. In the event of a total gateway failure all relays

switch to the alarm state.

Senstar LM100 Product Guide Page 11

Description

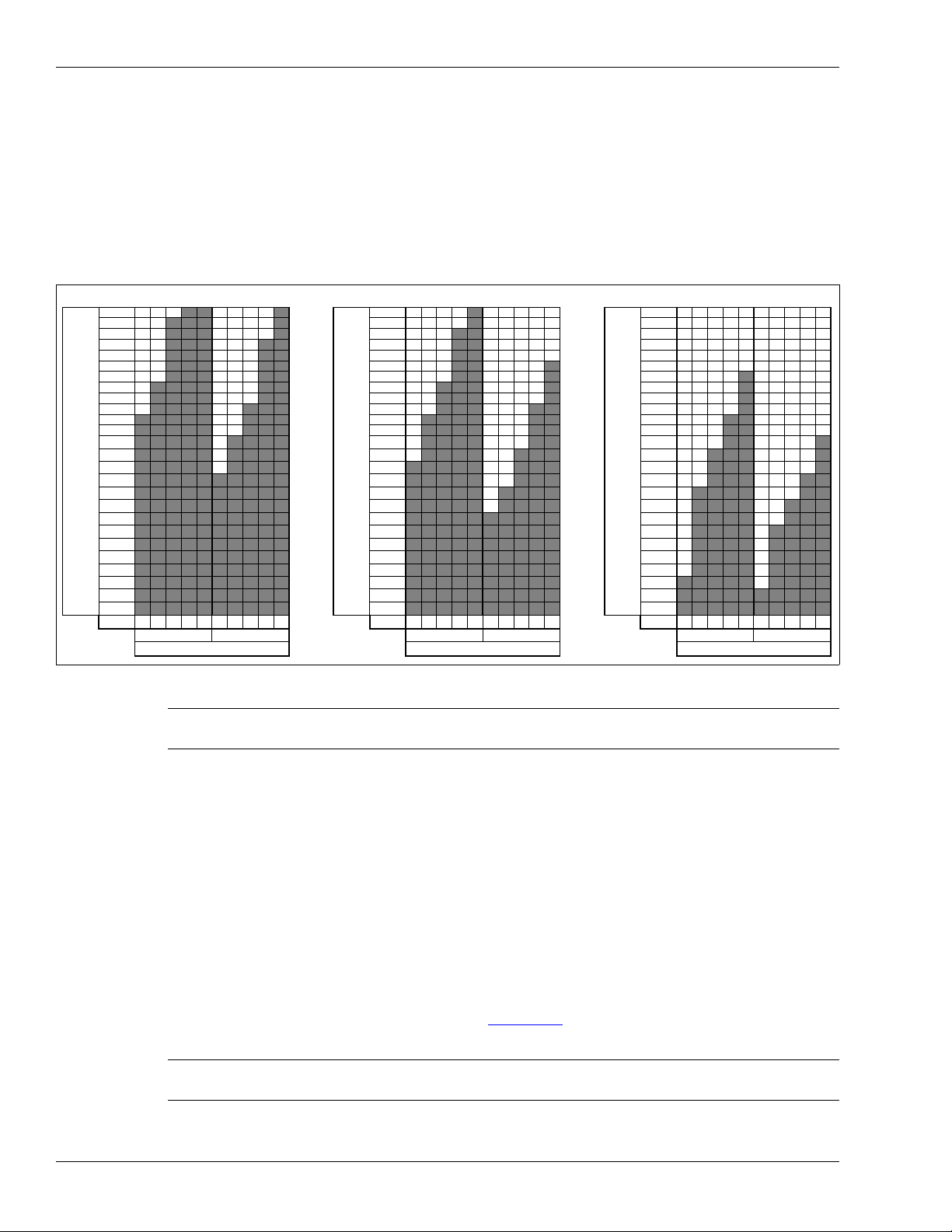

100 100 100

96 96 96

92 92 92

88 88 88

84 84 84

80 80 80

76 76 76

72 72 72

68 68 68

64 64 64

60 60 60

56 56 56

52 52 52

48 48 48

44 44 44

40 40 40

36 36 36

32 32 32

28 28 28

24 24 24

20 20 20

16 16 16

12 12 12

888

444

000

AWG18161412101816141210 AWG18161412101816141210 AWG18161412101816141210

Number of Luminaires

Number of Luminaires

Number of Luminaires

Power source and wiring

The Senstar LM100 system can operate on a wide range of input voltages (12 to 48 VDC). A

12 VDC power supply is suitable for powering the gateway and the luminaire AP, or a single

luminaire. Outdoor rated low voltage power cable is available in 152 m (500 ft.) reels (P/N: 14/2

GW0337-14, 16/2 GW0337-16). The distance covered by a power supply can be extended by

running the power cables in both directions around the perimeter from a central location. The

following figure includes the number of luminaires that can be powered based on power supply

voltage, wire gauge and distance:

48 VDC power supply

Note In locations where AC power may not be stable or reliable, an

36 VDC power supply

6 m/20 ft3 m/10 ft

3 m/10 ft 6 m/20 ft

Luminaire SpacingLuminaire Spacing

Figure 3: Senstar LM100 luminaire power cable recommendations

uninterruptable power supply (UPS) should be used for primary power.

24 VDC power supply

3 m/10 ft 6 m/20 ft

Luminaire Spacing

Auxiliary device output power

The gateway device can source up to 100 mA at the gateway’s input voltage via the onboard

outputs. The outputs can be used to energize high voltage relays or to activate auxiliary security

devices. The gateway’s outputs can also sink up to 100 mA from an auxiliary device.

Power over Ethernet

Silver Network based gateways using Ethernet communications have the option of using Power

over Ethernet. To use this powering option requires a PoE class 3 switch that is located within

100 m (328 ft.) of the gateway, and minimum Category 5 Ethernet cable. Power over Ethernet is

supplied to the gateway’s Network Interface card (NIC) and the power output on the NIC is

Page 12 Senstar LM100 Product Guide

connected to the power input on the gateway. The PoE connection can also supply power to the

luminaire AP (but not to any other luminaires). Figure 43:

illustrates an Ethernet based Silver

Network.

Note Senstar recommends using a fully managed PoE switch, to supply

power to a Senstar LM100 gateway.

Grounding considerations

The Senstar LM100 gateway requires a stable low resistance earth ground connection. Use a

short length of heavy gauge copper wire to connect the ground lug on the bottom of the enclosure

to an approved low resistance earth ground.

CAUTION Consult the local electrical code for grounding information.

Alarm monitoring

Alarm monitoring is site specific and depends on whether you are using relay outputs for alarm

reporting (standalone system, local control mode) or Silver Network based alarm reporting

(networked system, remote control mode). Each gateway has ten user-configurable I/O points

(inputs/outputs). In standalone mode, the outputs are used to signal alarm and supervision

conditions. For network based gateways, alarm data is carried over the network cables and the

outputs are available as output control points from the security management system.

NM Mode alarm reporting

The LM100 gateway can be configured to report alarm and supervision conditions through the

UltraLink modular I/O system. The UltraLink I/O processor, operating in NM Mode, functions as a

Network Manager, providing alarm outputs for a connected network of up to eight Silver Network

compatible devices. In NM Mode, the Silver devices do not require a connection to a PC running

Silver Network Manager software. Sensor alarms and supervision conditions are assigned to

UltraLink I/O outputs. When an alarm occurs on a connected sensor, the corresponding UltraLink

output is activated (see 00DA1003-002 UltraLink I/O for additional details).

Security factors

Security factors

There are many important factors to consider when planning a perimeter security system:

• Fence height - The fence must be high enough to present an effective barrier to climb-over

intrusions. It should also include climb-over deterrent hardware such as barbed wire or razor

ribbon (for flexible fences). Rigid fence types should incorporate a climb over deterrent in their

design (pointed stakes or pales). Senstar recommends that the minimum fence height for a

Senstar LM100 installation on a flexible fence type is 2.5 m (8 ft.). For rigid fence types the

minimum recommended fence height is 2 m (6.5 ft.).

• Fence condition - the Senstar LM100 detects intrusions by sensing the minute vibrations

caused by an intrusion attempt. Therefore, the fence must be in good condition to prevent any

metal on metal contact or vibrations caused by environmental factors. It may be necessary to

upgrade or repair the perimeter fence to ensure it presents a sufficient barrier against climb

over and crawl under intrusions. If you are not sure of the suitability of your fence for a Senstar

LM100 system, Senstar recommends hiring a local fencing contractor to inspect, and if

required, repair the fence.

• Fence length - The length of the fence, the number of fence posts and the fence post spacing

determine the number of luminaires required to provide adequate coverage. The maximum

recommended spacing for luminaires is 6 m (20 ft.). The minimum recommended spacing for

luminaires is 3 m (10 ft.). The minimum spacing provides the highest level of security.

Exceeding the maximum recommended spacing can result in areas with reduced detection

sensitivity and gaps in the lighting.

Senstar LM100 Product Guide Page 13

Fence structures

• Probability of detection (Pd) vs. nuisance alarm rate (NAR) - With a fence-mounted intrusion

detection system there is always a trade-off between the probability of detection and the

nuisance alarm rate. A properly calibrated system will provide a high Pd while minimizing the

NAR.

• Alarm assessment/response - What happens when the system triggers an alarm? Can the

alarm be assessed visually? Does the site include CCTV coverage to verify the event?

Senstar recommends engaging a security consultant to discuss the available methods of

alarm assessment. To ensure maximum confidence in the system you must be able to

distinguish between valid alarms and nuisance alarms.

• Deterrence - The Senstar LM100 can activate or strobe lights at the location where an

intrusion attempt is detected, while the intruder is still outside the perimeter fence. Brightly

illuminating the area of attack serves as a powerful deterrent while also providing high quality

light for CCTV coverage.

Fence structures

To ensure consistent detection, the fence panels should be similar in type and size and be in good

condition. Ensure that there are no loose panels, fittings or metal parts that can move and cause

nuisance alarms. A shake test in which you grip the fence fabric in the middle of a panel and shake

it back and forth with an increasing motion will help identify any loose pieces. Listen for metal-onmetal contact and correct any problems found. Verify that there are no washouts or depressions

under the fence that could allow an intruder access. Ensure that there is no vegetation or other

objects that can make contact with the fence in windy conditions.

Stainless steel post clamps are included for mounting the gateway and the luminaires. The post

clamps fit a wide range of post sizes with outside diameters (ODs) from 4.5 to 13 cm (1¾ to 5 in.).

The clamps will fit rectangular posts measuring up to 10 cm (4 in.) per side. The recommended

luminaire spacing is from 3 to 6 m (10 to 20 ft.) separation. However, The maximum recommended

separation between two luminaires is 20 m (66 ft.) to ensure accurate low power RF

communication between the devices.

Note It is also possible to install luminaires by marking the fence posts,

drilling four holes and using self-tapping screws.

Standard flexible fence types

Chain-link fence

Chain-link fence is usually comprised of steel wires that are bent lengthwise into zig-zag patterns.

The zig-zag wires are vertically woven to form the characteristic diamond pattern. The fence fabric

is attached to fence posts approximately 3 m (10 ft.) apart. Tension wires are often used to stiffen

the fence fabric at the top, bottom and middle of the fence. Chain-link fences are available in

different heights and are sometimes vinyl coated.

Welded-mesh fences

A typical welded-mesh fence section consists of steel wire welded into a grid, with horizontal

spacing differing from vertical spacing. These fence sections are secured to fence posts and often

include top and bottom rails.

Page 14 Senstar LM100 Product Guide

Expanded metal fences

chain-link welded-mesh

expanded metal

Expanded metal mesh is typically comprised of a metal material with diamond shaped holes.

Expanded metal fences are available with a variety of diamond size openings and gauges that can

be attached to a typical fence framework of posts and rails.

Rigid fence types

Palisade fences

Fence structures

Figure 4: Standard flexible fence types

A typical palisade fence panel consists of metal pales fastened onto horizontal rails. These fence

sections are secured to fence posts which are securely anchored to, or into, the ground.

Figure 5: Rigid fence (palisade)

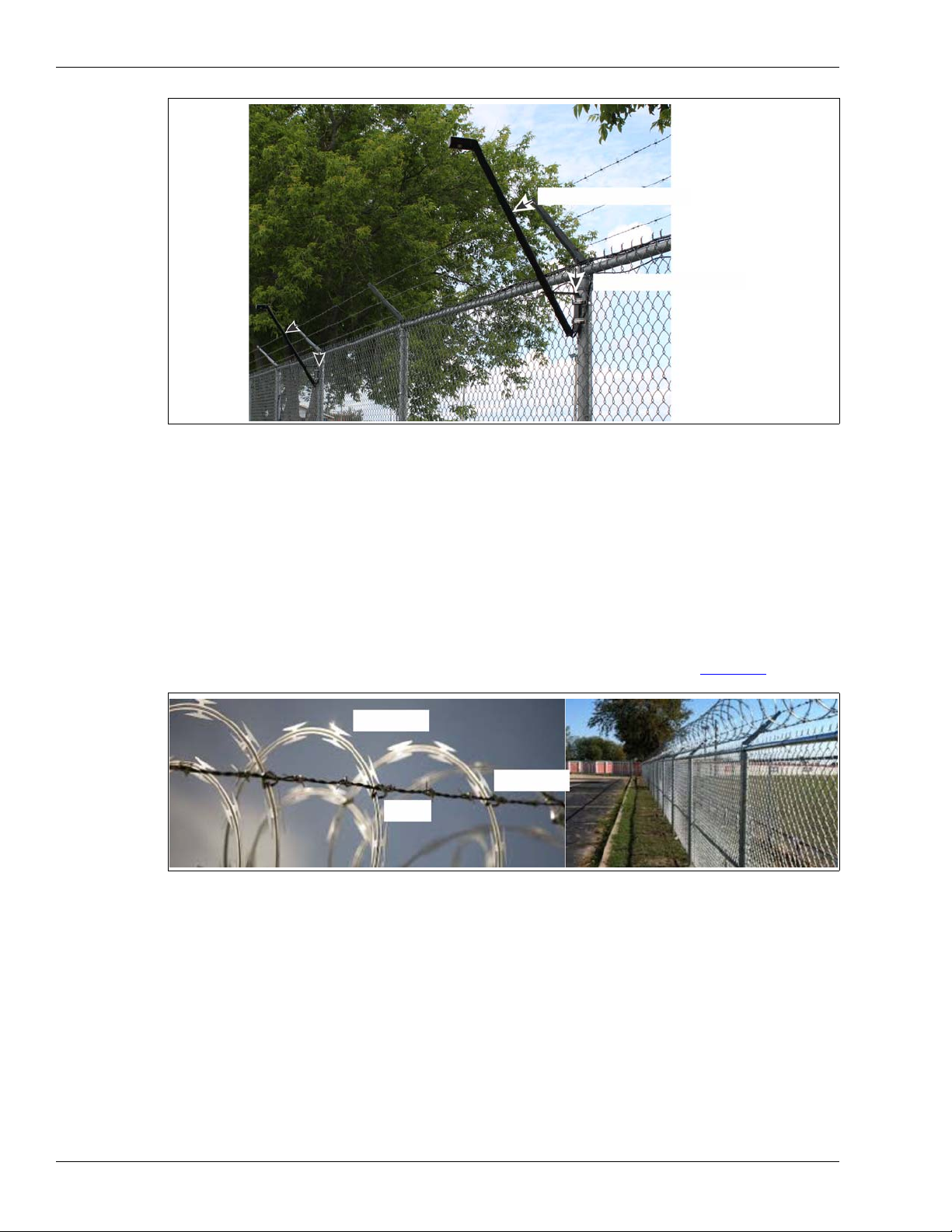

Climb-over deterrent hardware

Note The mounting height of the Senstar LM100 luminaires on the fence

posts may require adjustment to avoid contact with the climb-over

deterrent hardware.

Senstar LM100 Product Guide Page 15

Fence structures

to avoid contact with the barbed wire

lower the luminaires mounting height

razor ribbon

bracing wire

wire tie

Figure 6: Avoiding contact with barbed wire

Barbed wire

Gates

Barbed wire outriggers must be secure to prevent movement due to environmental conditions.

Each barbed wire strand should be taut and tightly secured at each support. Any extension arms

or outriggers attached to post tops should have a tight press-fit or be spot-welded. Fasten and

secure any loose components.

Razor ribbon

The razor ribbon must be secured so that it does not move in the wind. Use bracing wires to

secure the coil and to prevent the razor ribbon from separating if it is cut (see Figure 7:

Figure 7: Razor ribbon

).

There are generally two types of gates used with fences, swinging gates and sliding gates. The

type of gate protection required is determined by:

• the type of gate

• the frequency of gate use

• when the system is active

Gates should consist of fence fabric on a rigid frame that includes horizontal and vertical bracing.

Page 16 Senstar LM100 Product Guide

• Firmly attach all gate hardware accessories (minimum free-play).

• Make sure that double gates have travel stops (rigid anchors).

• Prevent locking hardware from moving in the wind.

• Prevent sliding gate track hardware, supports, guides, etc., from rattling in the wind.

There are two ways to protect gates with the Senstar LM100 system:

• The wireless gate sensor (WGS),

• An alternate technology (e.g., a microwave sensor).

Environment

For installations in environments which include hot sunny periods, install a sun shield to protect the

enclosure from direct sunlight, or install the enclosure in a shady area, or indoors. Extra care must

be taken at sites that experience strong winds on a regular basis. The fence must be wellmaintained to prevent any metal on metal contact caused by the wind. Any objects that can make

contact with the fence should be removed from the perimeter. Heavy vegetation (thick weeds,

brush, trees, etc.) should also be kept away from the fence. Vegetation should not touch or hang

over the fence fabric.

Site Survey

Note The ambient temperature, as measured inside the gateway enclosure,

Site Survey

Conduct a site survey to ensure that site conditions are suitable, and to determine the number of

luminaires required to cover the perimeter fence. Also include any luminaires that will be used

exclusively for lighting purposes. The primary concern of the site survey is the condition of the

fence and gates.

Indicate the following on the site plan:

• The locations of existing structures (include fences, fence posts, heavy fence posts, gates,

buildings, roads, etc.).

• The locations of obstacles including vegetation and trees.

• The length of the fence that is being protected.

• The number of regular fence posts, heavy gauge fence posts, and the fence post spacing.

• Add any surface-mounted luminaires required at the site (in addition to fence-mounted).

must be within the operational range of -40 to +70º C (-40 to +158º F).

Equipment layout

Depending on the height of the fence and the desired level of security, a luminaire is attached to

every fence post (3 m spacing) or every second fence post (6 m spacing). Regardless of the

regular spacing, each tension post, corner post and gate support post, should have a luminaire

attached as these types of posts are usually made of thicker steel and have a wider outside

diameter (OD) than regular fence posts. As a result of the heavier construction, these posts tend to

dampen vibrations.

Senstar LM100 Product Guide Page 17

Equipment layout

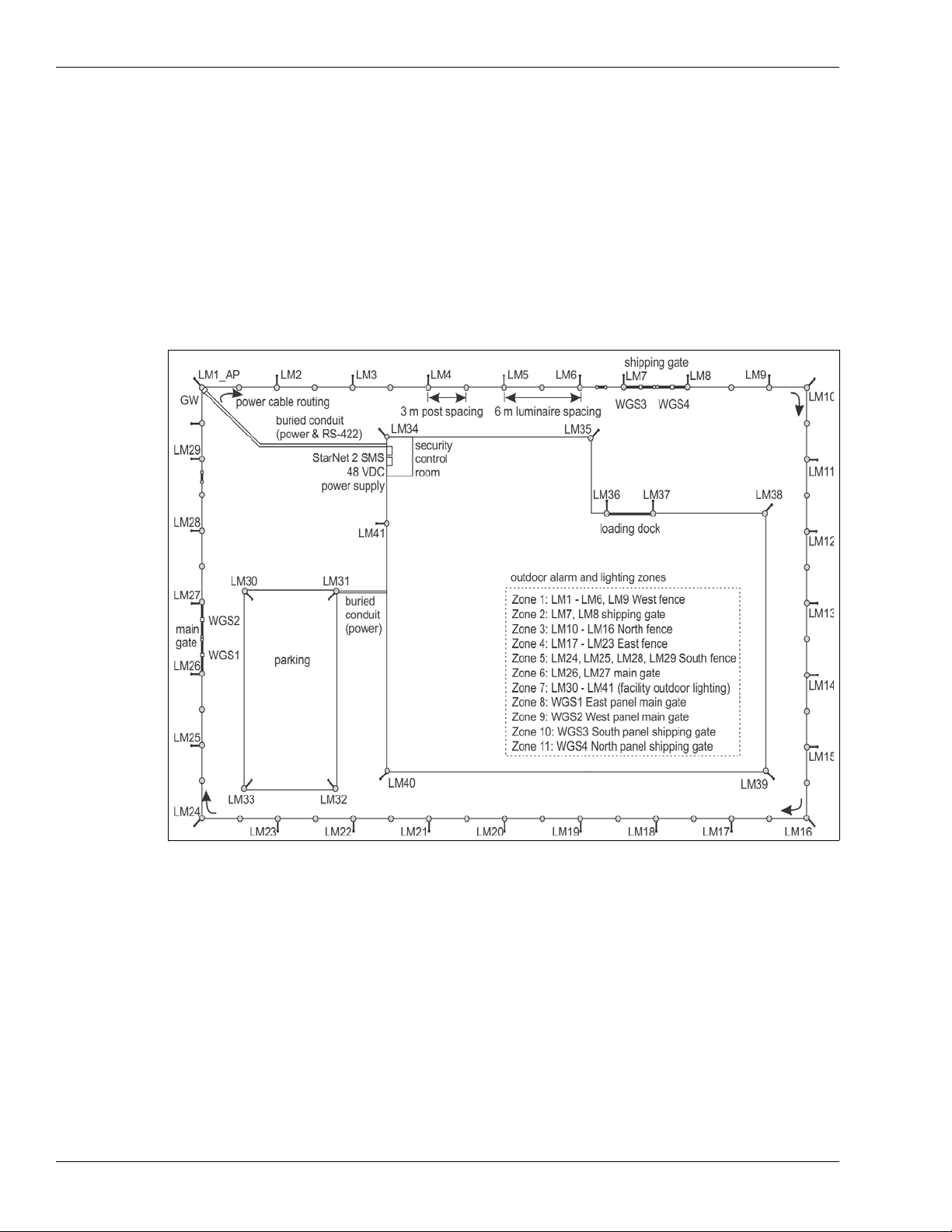

Use a site plan to mark the locations for the Senstar LM100 components:

• LM100 gateway - indicate the location and note the address for network based systems

• LM100 luminaire AP - indicate the location for the Access Point

• LM100 luminaires - indicate the location, the segment groupings, and zone boundaries (on the

site plan, number the luminaires in the order that will be used to form segments)

• Power supply - indicate the type and capacity of power supply and the power distribution plan

• Alarm communication wiring - relay output or network alarm communications

• Power cable - indicate the type and length of power cables that will be used

• Wireless Gate Sensor - the number of protected gates and the number of WGSs required to

cover them

Figure 8: Example site plan

Installation overview

Installing a Senstar LM100 system is a four step process:

1. Inspect and if necessary, repair the fence and the surrounding area.

2. Plan and design the system.

3. Install the Senstar LM100 gateway, luminaire AP and luminaires.

• ground rod

• power supply

• power cable

• data cable

4. Setup and calibrate the system.

Page 18 Senstar LM100 Product Guide

2 Installation

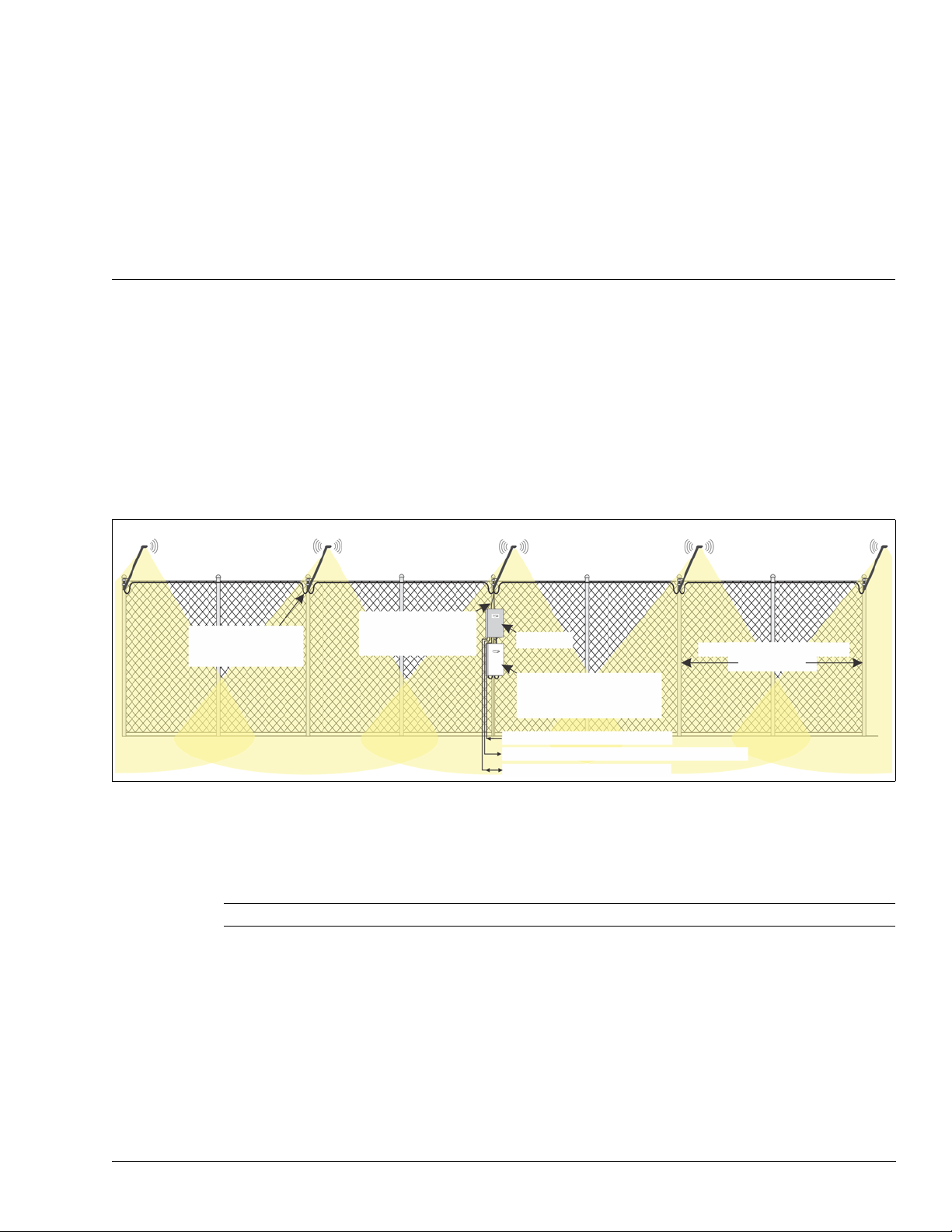

2.4 GHz wireless mesh network (encrypted and supervised)

luminaire AP

luminaire

gateway

48 VDC network

RS-485 connection

low voltage power

to luminaires

typical luminaire spacing

6 m (20 ft.)

cable connection

(up to 100)

(1 required)

discrete inputs (light control)

discrete outputs (alarms / control points)

network interface to SMS

power supply for

gateway and luminaires

between gateway

and luminaire AP

Installing LM100 luminaires

Generally, a luminaire is attached to every second fence post (6 m spacing). In addition, all of the

heavier gauge fence posts should have a luminaire (tension posts, corner posts, gate support

posts). The luminaires should be installed on the side of the fence that faces the perceived threat.

Luminaires are installed so they are perpendicular to the fence line and plumb, with the head

facing directly downward.

Figure 9: Senstar LM100 concept drawing

The first step is mounting the gateway (or indicate the gateway’s installation location if it will be

installed later). Begin with the luminaire AP (the luminaire with a hard-wired connection to the

gateway).

Tip Using a quick-grip clamp will simplify the installation of the luminaires.

At regular fence posts

Tools and equipment

• 8 mm (5/16 in.) nut driver or socket (low torque cordless drill with 8 mm socket recommended)

• ladder or scissor lift suitable for fence height

Senstar LM100 Product Guide Page 19

Installing LM100 luminaires

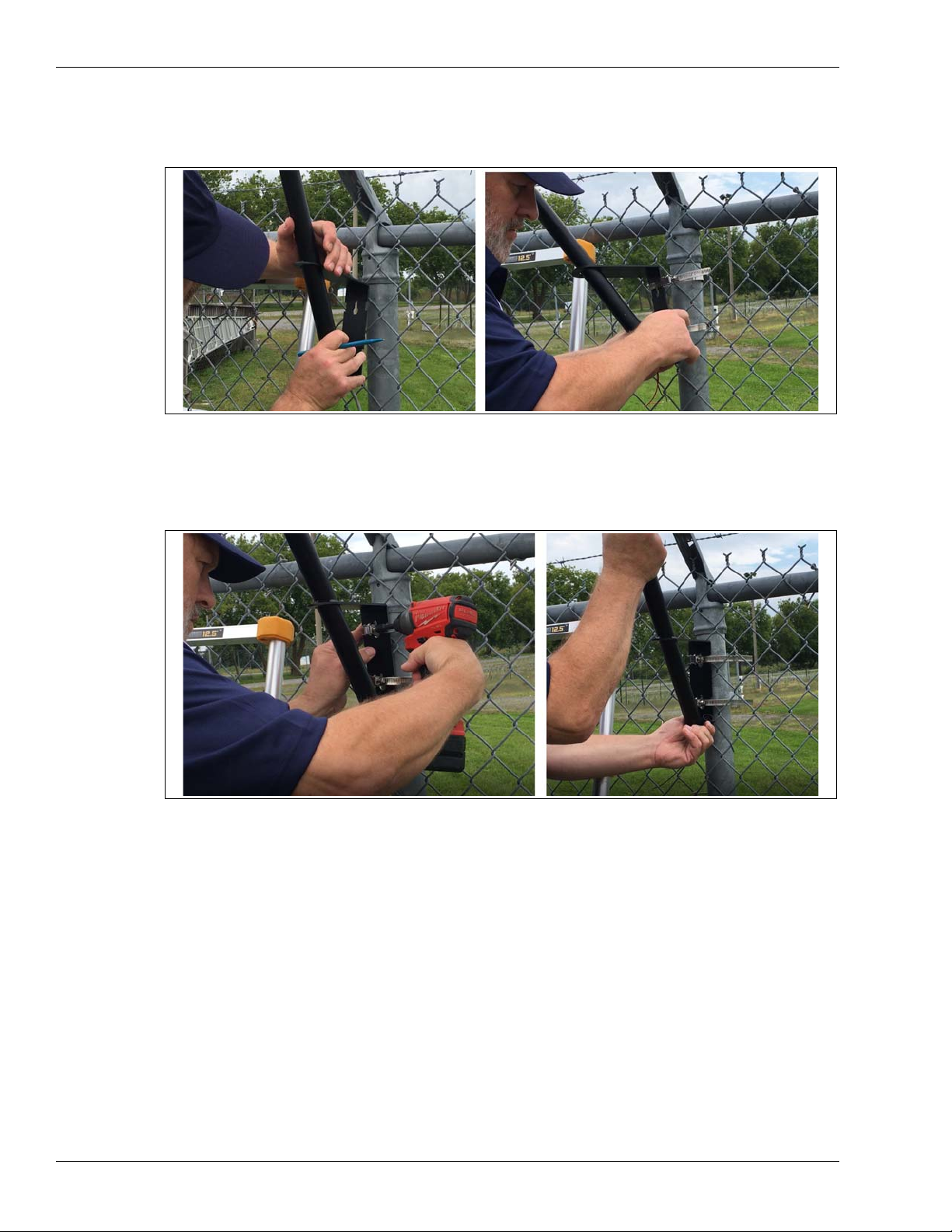

1. Hold the luminaire against the fence post as close to the top of the fence as possible without

2. Wrap the 2 post clamps around the luminaire and fence post to hold the luminaire in place.

3. Tighten the clamps so they fit into the slots on the luminaire’s bracket, and the luminaire is

making contact with the climb over barrier (minimum 25 mm {1 in.} separation between the

luminaire and the barbed wire) and mark the locations for the stainless steel post clamps.

Figure 10: Luminaire installation steps 1 & 2

perpendicular to the fence line and plumb to the ground.

Figure 11: Luminaire installation steps 3 & 4

4. If necessary, adjust the position of the luminaire on the fence post and finish tightening the

clamps until the luminaire is held securely against the fence.

5. Measure the space between the top of the fence post and the luminaire’s bracket and install

the remaining luminaires at the same height.

Page 20 Senstar LM100 Product Guide

Installing LM100 luminaires

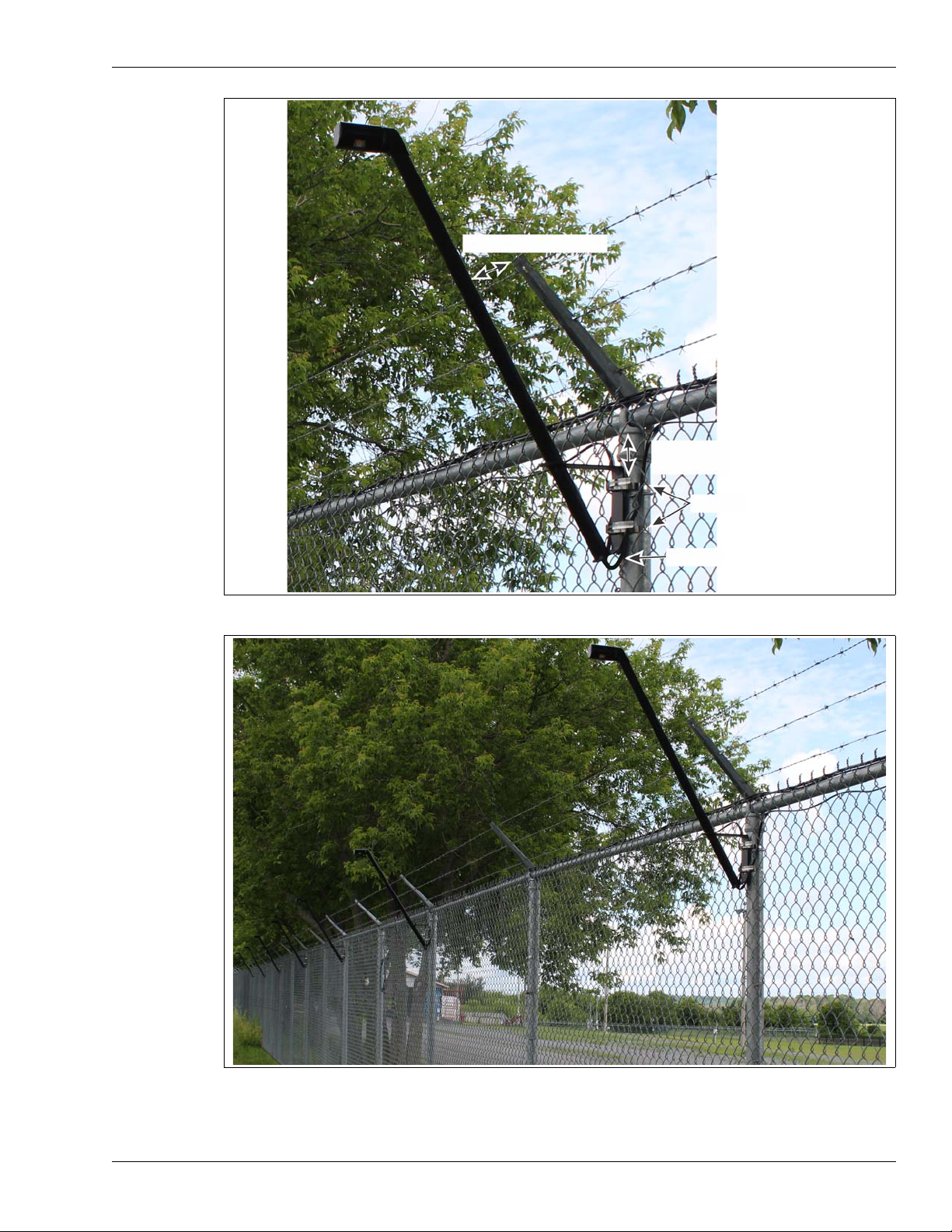

min. 2.5 cm separation

lower the mounting height

2 stainless steel clamps

power cable drip loop

to increase separation

Figure 12: Luminaire installation example

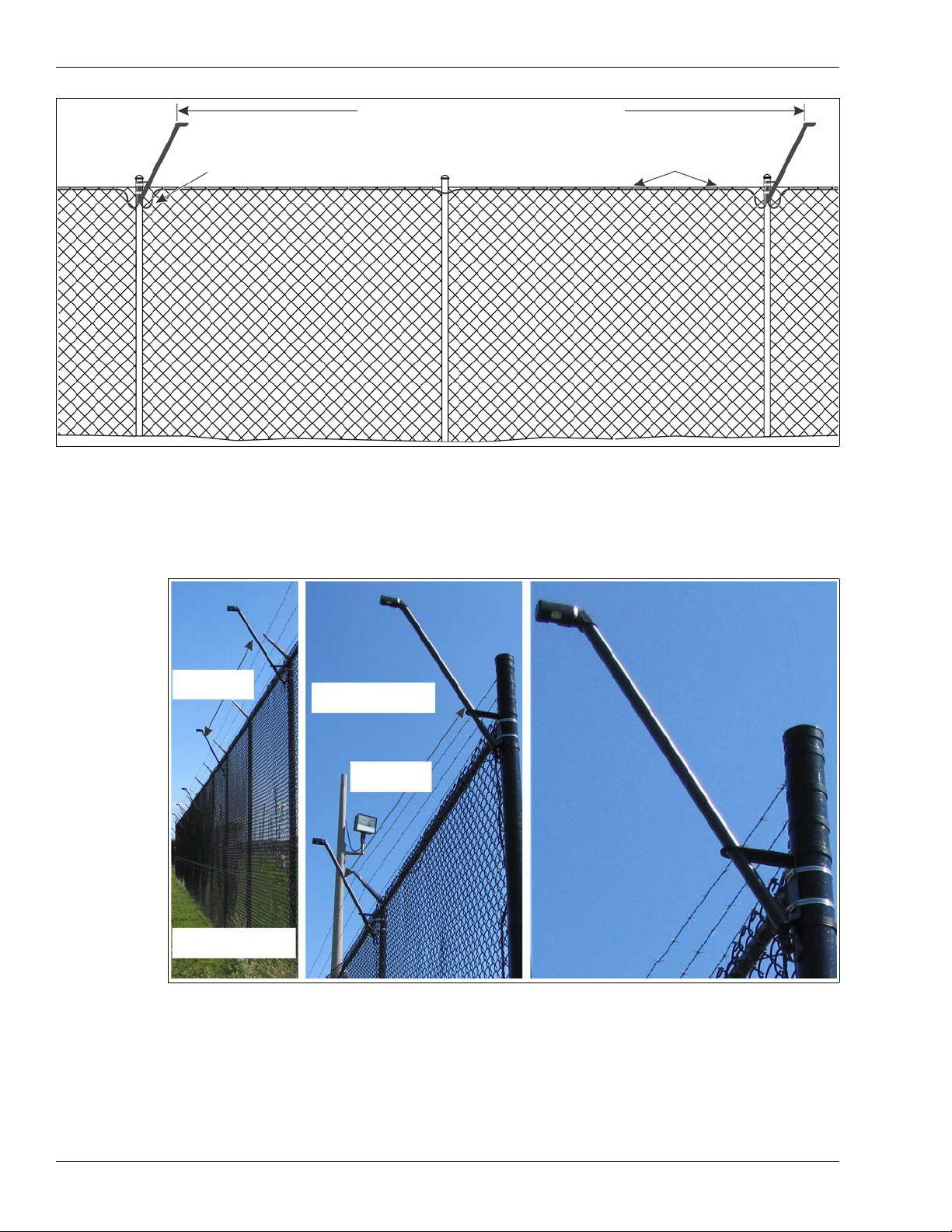

Figure 13: 2.4 m (8 ft.) chain-link fence with luminaires

Senstar LM100 Product Guide Page 21

Installing LM100 luminaires

recommended luminaire spacing

cable ties secure power cable

to upper tension wire or top rail

drip loops

3 to 6 m (10 to 20 ft.)

regular spacing for

standard fence posts

reduced spacing for

heavy gauge posts

3 m (10 ft.)

single panel

6 m (20 ft.)

double panel

Figure 14: Recommended luminaire spacing

At corners or heavy gauge posts

Follow the directions for regular fence posts and install a luminaire on each heavy gauge fence

post.

Page 22 Senstar LM100 Product Guide

Figure 15: Luminaire installation on heavy gauge posts

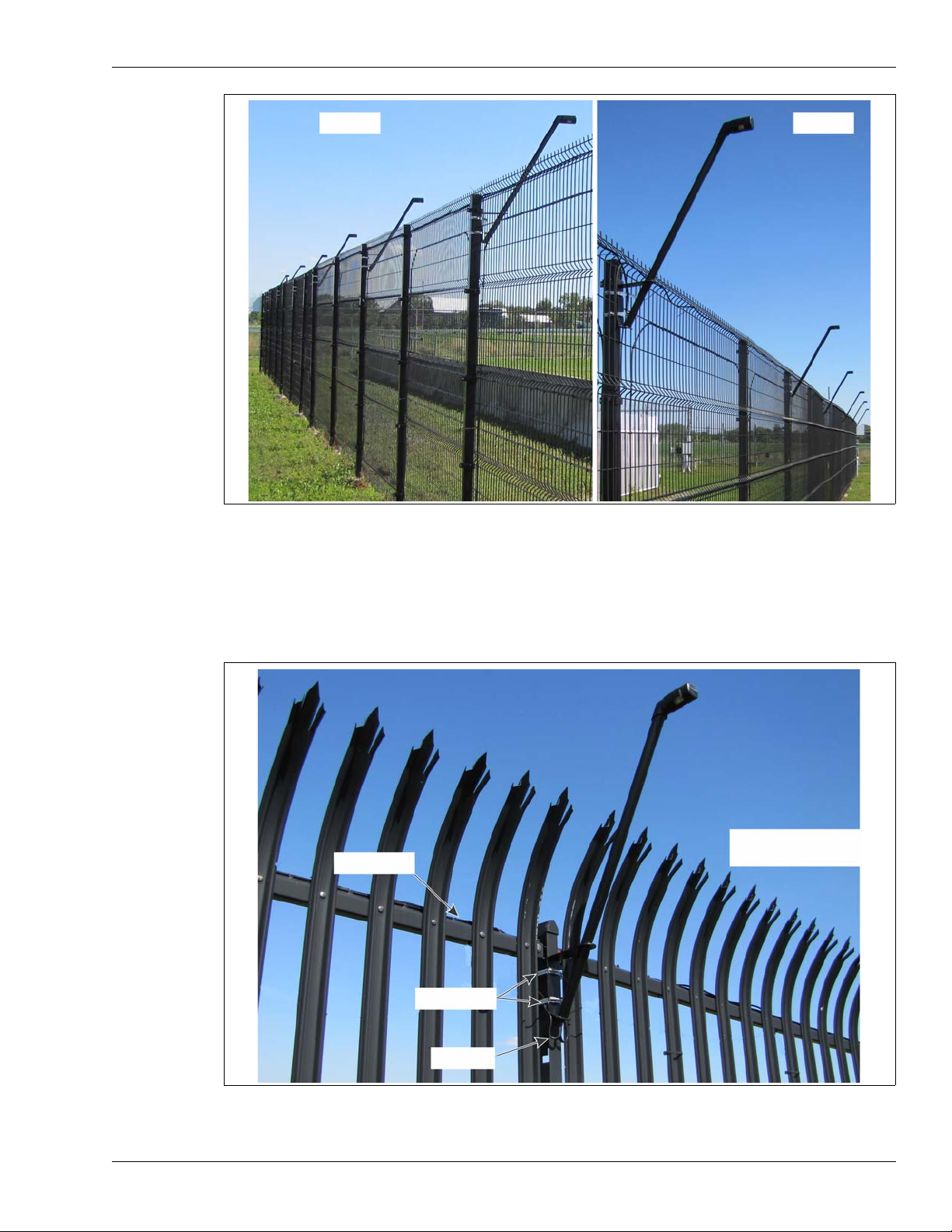

Installing luminaires on welded-mesh fence

Mount the luminaire as high on the fence post as possible on the side of the fence that is facing the

threat.

Installing LM100 luminaires

back side

front side

Impasse® II high-security

palisade fence

power cable

post clamps

drip loops

Figure 16: Welded-mesh fence with luminaires

Installing luminaires on rigid fences

The technique used to install luminaires on rigid fences depends on the type, and brand, of fence.

Mount the luminaire as high on the fence post as possible on the side of the fence that is facing the

threat.

Figure 17: Palisade fence with luminaire

Senstar LM100 Product Guide Page 23

Loading...

Loading...