Page 1

®

FlexZone

Fence-mounted Locating Perimeter Intrusion Detection Sensor

Product

Guide

G6DA0102-001 Rev L

November 14, 2018

Page 2

Senstar Corporation

Website: www.senstar.com

Email address: info@senstar.com

G6DA0102-001 Rev L

November 14, 2018

FlexZone, Senstar and the Senstar logo are registered trademarks, and Silver Network is a trademark of Senstar Corporation.

Product names and Company names included in this document are used only for identification purposes and are the property

of, and may be trademarks of, their respective owners. Copyright © 2017, 2014, Senstar Corporation, all rights reserved.

Printed in Canada.

The information provided in this guide has been prepared by Senstar Corporation to the best of its ability. Senstar Corporation is

not responsible for any damage or accidents that may occur due to errors or omissions in this guide. Senstar Corporation is not

liable for any damages, or incidental consequences, arising from the use of, or the inability to use, the software and equipment

described in this guide. Senstar Corporation is not responsible for any damage or accidents that may occur due to information

about items of equipment or components manufactured by other companies. Features and specifications are subject to change

without notice.

Any changes or modifications to the software or equipment that are not expressly approved by Senstar Corporation void the

manufacturer’s warranty, and could void the user’s authority to operate the equipment.

The figures included in this document are for illustration purposes only, and may differ from the actual equipment.

Approvals

Canada: This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

USA: This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device

may not cause harmful interference, and (2) this device must accept any interference received, including any interference that

may cause undesired operation.

The use of shielded cables is required for compliance.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation.This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

- Reorient or relocate the receiving antenna.

- Increase the separation distance between the equipment and the receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Europe: This device conforms to the protection requirement of council directives 89/336/EEC on the approximation of the laws

of member states relating to Electromagnetic compatibility, amended by directive 93/68/EEC.

The use of shielded cables is required for compliance.

Senstar Corporation’s Quality Management System is ISO 9001:2008 registered.

Page 2 FlexZone Product Guide

Page 3

Table of Contents

1 System planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Installation overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Security factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Fence structures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Standard flexible fence types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Chain-link fence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9

Welded-mesh fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Expanded metal fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Rigid fence types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Palisade fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Climb-over deterrent hardware - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Barbed wire - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Razor ribbon - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Gates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Buildings, walls and other structures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Environment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Site Survey - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Perimeter layout guidelines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

FlexZone sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Cable layout guidelines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Cable length calculator (flexible fences) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Rigid fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Fence height recommendations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Non-detecting cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Fence corners and heavier gauge posts (flexible fences) - - - - - - - - - - - - - - - - - - - - - - - - - 17

Zone demarcation loops (flexible fences) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Service loops (flexible fences) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Drip loops (flexible fences) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Termination loops (flexible fences) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Splice loops (flexible fences) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Gate bypass - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Armored cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Double pass coverage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Processor location guidelines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Power source and wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Power over the sensor cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

FlexZone Product Guide Page 3

Page 4

Auxiliary device output power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Power over Ethernet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

Grounding considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

Alarm communication options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -22

Fail-safe relay operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Relay Output Card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Dry Contact Input Card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Data over the sensor cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -22

Processor synchronization - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -23

Alarm monitoring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -23

NM Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 23

Cable connectors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -23

High security installations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -24

High-security installation rules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 24

2 Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

Installing the sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -25

Cable handling rules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -25

FlexZone sensor cable conditioning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -26

Cable conditioning procedure (part 1 - cable preparation) - - - - - - - - - - - - - - - - - - - - - - - - 26

Cable conditioning procedure (part 2 - cable flossing) - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

Installing cable on chain-link fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -29

Installing cable ties - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Bend radius - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

At fence posts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

At corners or heavy gauge posts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

At software defined zone boundaries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Service loops - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Drip loops - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 32

Termination loops - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 32

Splice loops - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

Installing cable on welded-mesh fence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -34

Double pass cable installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -35

Installing cable on rigid fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -36

Sensor cable connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -36

Cable preparation (all connections) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

Processor connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

Sensor cable splices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

Sensor cable terminations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Using the Wireless Gate Sensor to protect gates - - - - - - - - - - - - - - - - - - - - - - - - - - -42

Installing sensor cable on gates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -42

Gate bypass cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Bypass cable installation instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Installing sensor cable on swinging gates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Gate disconnect assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -44

Installation instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 44

Installing armored FlexZone sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -45

Installing armored FlexZone sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

Installing cable on barbed wire - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -46

On razor ribbon - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

Splicing armored sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

Armored cable terminations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 48

Connecting armored sensor cable to the processor - - - - - - - - - - - - - - - - - - - - - - - - - -50

Page 4 FlexZone Product Guide

Page 5

Installing the FlexZone processor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 51

Cable entry ports - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

Free-standing or fence post mounting the enclosure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 53

Surface mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 54

Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

Relay outputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

Relay contact ratings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

Auxiliary inputs /Self-test inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

Processor wiring connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 56

Silver Network wiring connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Silver Network specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Silver Network data path connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 60

Power connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 63

Power over sensor cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 63

Local power supply - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 63

Power over Ethernet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 64

Auxiliary device power output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 64

Backup power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 64

3 Calibration & setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 67

The Universal Configuration Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 67

FlexZone definitions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 68

Understanding FlexZone alarm detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 68

Intruder detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 69

Intrusion detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 69

Initial processor setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 70

Connecting the UCM via USB - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 70

Setting the processor address - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 70

Network configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 70

Sensor cable supervision - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 71

Adjacent Processor (m) setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 71

Power over sensor cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 72

Processor synchronization - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 73

Audio “listen-in” function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 73

Using the Audio listen-in function via the UCM - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 73

Using the Audio listen-in function via the FlexZone Audio Tool - - - - - - - - - - - - - - - - - - - - - 74

Processor calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 75

The Sensitivity Profile - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 75

Recording the Sensitivity Profile - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 75

Detection parameter setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 77

Defining a zone - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 77

Setting the cable Threshold - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 77

Defining the cable segments and alarm zones - - - - - - - - - - - - - - - - - - - - - - - - - - - - 78

Locating the cable segment boundaries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 78

Defining the cable segment boundaries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 78

Defining sensor cable as non-detecting (setting the start point of detecting cable) - - - - - - - - 79

Defining the detecting cable segments - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 79

Setting the endpoint of detecting cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 80

Setting individual cable segment thresholds - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 81

Setting the segment threshold - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 81

Intrusion simulations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 81

FlexZone Product Guide Page 5

Page 6

Input/output configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -82

Specify the Auxiliary I/O control mode and option card - - - - - - - - - - - - - - - - - - - - - - -82

Auxiliary (Aux) inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -82

Local control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 83

Remote control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 83

Input configuration procedure (Remote control mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - 84

Output relays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -84

Output relay setup (Local control mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 84

Output relay setup (Remote control mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 84

Linking cable segments to relays (local control mode) - - - - - - - - - - - - - - - - - - - - - - - -85

System test procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -85

4 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 87

Recommended maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -87

Preventing weather related nuisance alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 88

Using the SD card function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 88

Testing the fence condition - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 88

Ground faults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 88

Adjusting the Target Filters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 89

Replacing the processor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -90

Removing the processor assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 90

Replacing the processor assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 90

Updating the firmware - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -91

a Parts list - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 93

b Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 97

c NM Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 99

UCM configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -100

Page 6 FlexZone Product Guide

Page 7

1 System planning

Introduction

The FlexZone fence protection system uses loose-tube coaxial sensor cables mounted on a fence

to detect vibrations caused by climbing, cutting, lifting, or otherwise disturbing the fence fabric.

Each FlexZone processor can monitor the activity from one or two sensor cables, each up to

300 m (984 ft.) long, and will report the alarm status of up to 60 software defined sensor zones.

FlexZone will locate the source of a disturbance to within ± 3 m (10 ft.). A single pass of sensor

cable can protect a high quality chain-link fence with no middle rail, up to 4.3 m (14 ft.) high.

Additional passes of sensor cable are recommended for chain-link fences that are higher than

4.3 m.

There are two models of the FlexZone processor available. Both models process alarm data the

same way. However, the FlexZone-4 processor supports up to 4 software defined alarm zones, but

does not report target location. The FlexZone-60 processor supports up to 60 distinct alarm zones

and reports target location.

This Product Guide covers FlexZone installation and setup for chainlink, welded-mesh, expanded

metal and palisade fences.

Installation overview

Installing a FlexZone system is a four step process:

1. Plan and design the system.

2. Inspect and if necessary, repair the fence and the surrounding area.

3. Install the sensor cable, processor and enclosure.

• ground rod (if required)

• alarm communication wiring

• power supply

4. Setup and calibrate the system.

FlexZone Product Guide Page 7

Page 8

Security factors

Security factors

There are many important factors to consider when planning a fence-mounted perimeter security

system:

• Fence height - The fence must be high enough to present an effective barrier to climb-over

intrusions. It should also include climb-over deterrent hardware such as barbed wire or razor

ribbon (for flexible fences). Rigid fence types should incorporate a climb over deterrent in their

design (pointed stakes or pales). Senstar recommends that the minimum fence height for a

FlexZone installation on a flexible fence type is 2.5 m (8 ft.). For rigid fence types the minimum

recommended fence height is 2 m (6.5 ft.).

• Fence condition - FlexZone detects intrusions by picking up the minute vibrations or fence

noise caused by an intrusion attempt. Therefore, the fence must be in good condition to

prevent any metal on metal contact or vibrations caused by environmental factors. It may be

necessary to upgrade the perimeter fences to ensure they present sufficient barriers against

climb over and crawl under intrusions. If you are not sure of the suitability of your fence for a

FlexZone sensor, Senstar recommends hiring a local fencing contractor to inspect, and if

required, repair the fence.

• Probability of detection (Pd) vs. nuisance alarm rate (NAR) - With a fence-mounted intrusion

detection system there is always a trade-off between the probability of detection and the

nuisance alarm rate. A properly calibrated system will provide a high Pd and will minimize the

NAR.

• Alarm assessment/response - What happens when the system triggers an alarm? Can the

alarm be assessed visually? Does the site include CCTV coverage to verify the event?

Senstar recommends engaging a security consultant to discuss the available methods of

alarm assessment. To ensure maximum confidence in the sensor you must be able to

distinguish between valid alarms and nuisance alarms.

Fence structures

To ensure consistent detection, a sensor cable should be mounted on only one type of fence. All of

the fence panels should be similar in type, size and condition. Ensure that there are no loose

panels, fittings or metal parts that can move and cause nuisance alarms. A shake test in which you

grip the fence fabric in the middle of a panel and gently shake it back and forth with an increasing

motion will help identify any loose pieces. Listen for metal-on-metal contact and correct any

problems found. Verify that there are no washouts or depressions under the fence that could allow

an intruder access. Ensure that there is no vegetation or other objects that can make contact with

the fence in windy conditions.

Note Fences that are covered with vinyl privacy slats or other screening

material may not be suitable for the FlexZone sensor due to the

vibration dampening characteristics of the screening materials, and the

additional fence motion caused by wind. It may be necessary to remove

the screening material to ensure optimal FlexZone sensor performance.

Page 8 FlexZone Product Guide

Page 9

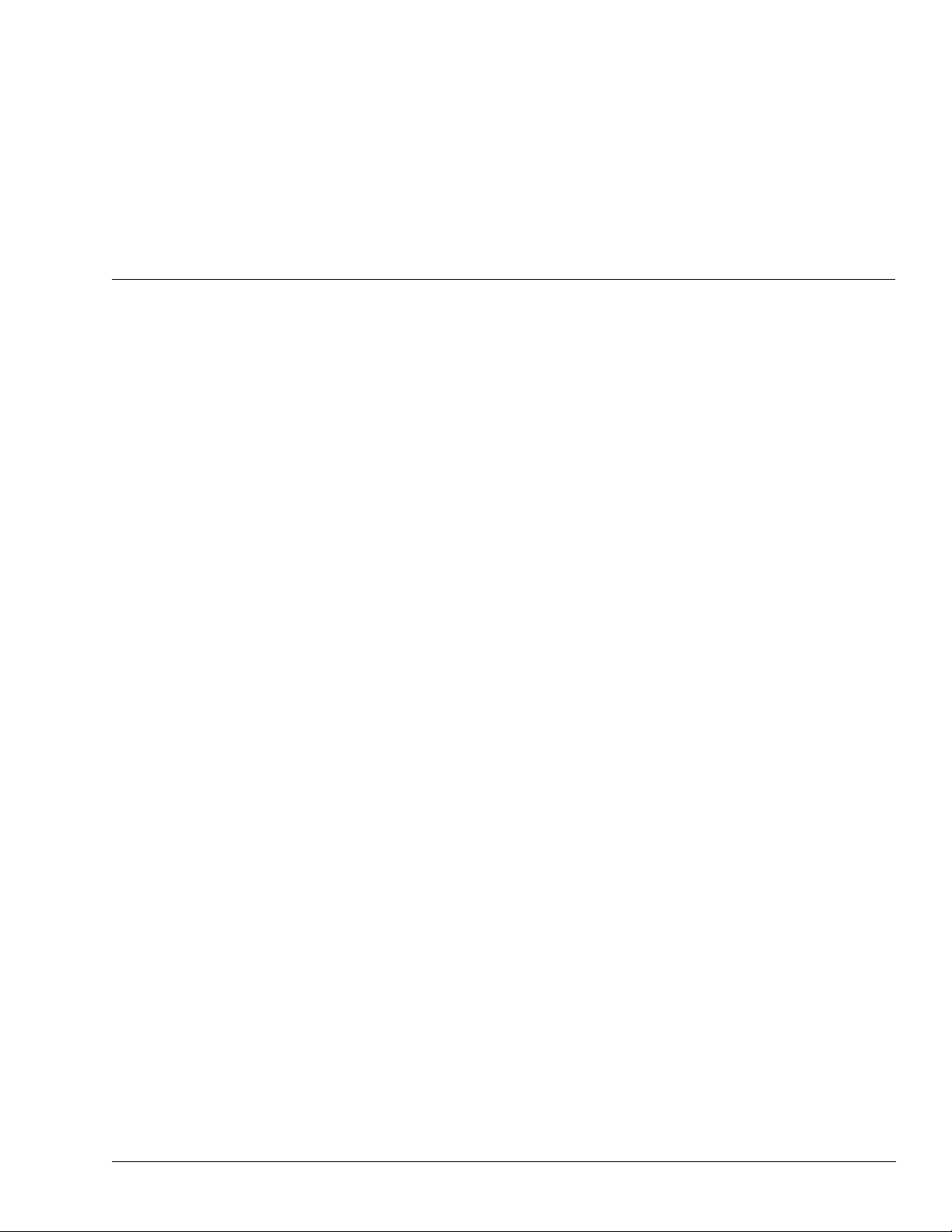

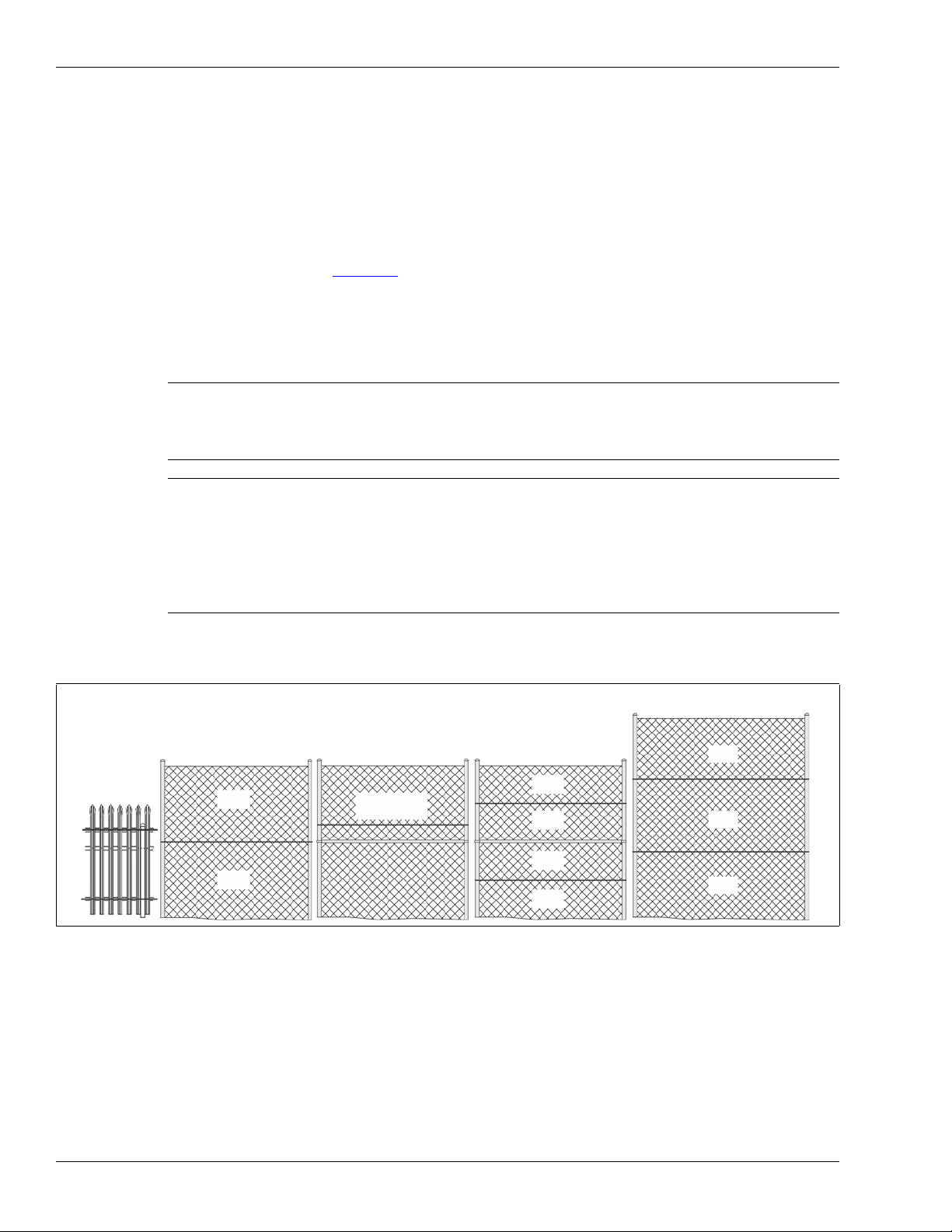

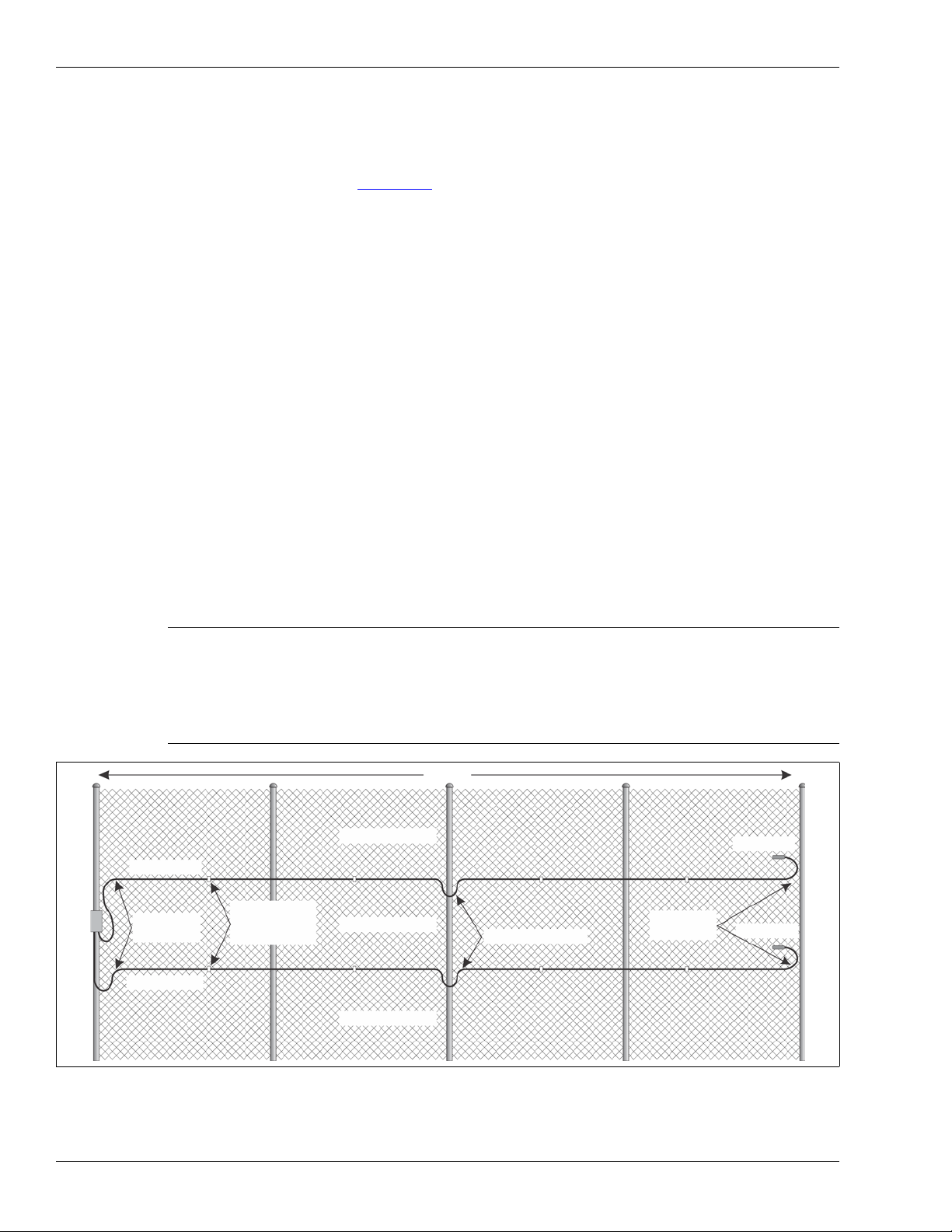

Standard flexible fence types

chain-link welded-mesh

expanded metal

Chain-link fence

Chain-link fence is comprised of steel wires that are bent lengthwise into zig-zag patterns. The

zig-zag wires are vertically woven to form the characteristic diamond pattern. The fence fabric is

attached to fence posts approximately 3 m (10 ft.) apart. Tension wires are often used to stiffen the

fence fabric at the top, bottom and middle of the fence. Chain-link fences are available in different

heights and are sometimes vinyl coated.

Welded-mesh fences

A typical welded-mesh fence section consists of steel wire welded into a grid, with horizontal

spacing differing from vertical spacing. These fence sections are secured to fence posts and often

include top and bottom rails.

Expanded metal fences

Expanded metal mesh is typically comprised of a metal material with diamond shaped holes.

Metals can be expanded in a range of material thickness and to a broad choice of patterns to suit

specific applications. Expanded metal mesh is available with a variety of diamond size openings

and gauges that can be attached to a typical fence framework of round pipe and line rails.

Fence structures

Note High-security welded-mesh and expanded metal fences are comprised

of heavier gauge metal than the standard flexible fence types.

Therefore, these high-security fence types may have to be defined as

Rigid fences via the UCM. Begin testing with the Flexible fence setting

and use the Rigid fence setting only if adequate detection sensitivity

cannot be achieved at the Flexible fence setting.

Figure 1: Standard flexible fence types

FlexZone Product Guide Page 9

Page 10

Fence structures

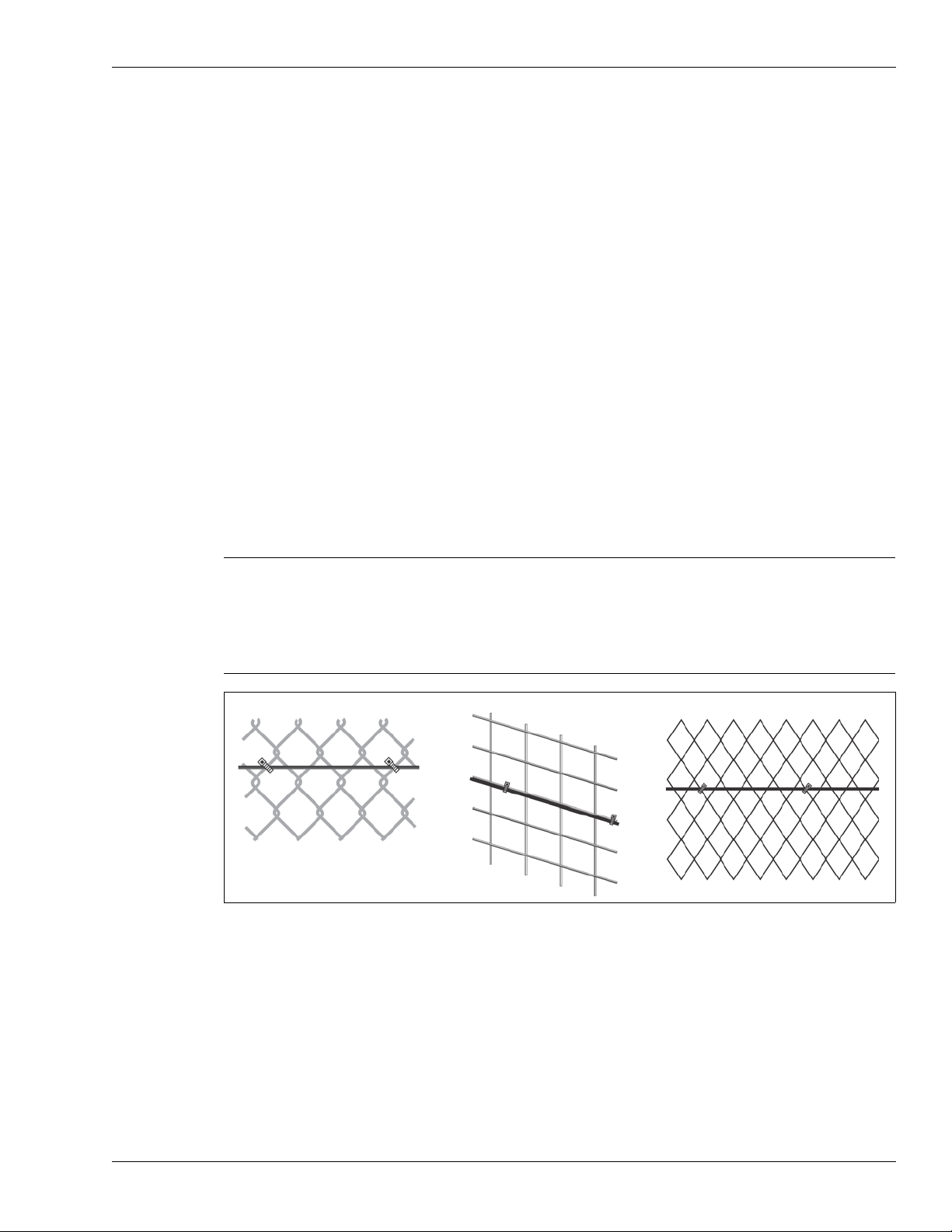

Rigid fence types

Note Rigid fence types do not conduct vibrations as well as flexible fence

types due to their materials and construction. FlexZone provides an

increased sensitivity setting for use with rigid fences. Senstar

recommends installing the FlexZone sensor on a limited length section

of the rigid fence to test and verify that the detection sensitivity meets

the security requirements before installing a full length perimeter.

Palisade fences

A typical palisade fence panel consists of metal pales fastened onto horizontal rails. These fence

sections are secured to fence posts which are securely anchored to, or into, the ground.

Figure 2: Rigid fence (palisade)

Climb-over deterrent hardware

Barbed wire

Senstar recommends using armored sensor cable on barbed wire. Armored cable is comprised of

FlexZone sensor cable inside flexible metal conduit. To protect both the fence and the barbed

wire, use armored cable on the barbed wire, and use sensor cable on the fence fabric. Install

armored cable on both sides of each outrigger and along the top of the fence (see Figure 3:

These configurations allow both sensor cables to be properly calibrated for the specific mounting

surface.

Barbed wire outriggers must be secure to prevent movement due to environmental conditions.

Install bracing wires between the outrigger supports to prevent the barbed wires from spreading

apart. Each barbed wire strand should be taut and tightly secured at each support. Any extension

arms or outriggers attached to post tops should have a tight press-fit or be spot-welded. Remove

or fasten any loose or rattling equipment.

Razor ribbon

Senstar recommends using armored cable on razor ribbon. The razor ribbon must be secured so

that it does not move in the wind. Use tensioning wires to secure the coil and to prevent the razor

ribbon from pulling apart if it is cut (see Figure 4:

).

).

Page 10 FlexZone Product Guide

Page 11

Fence structures

armored cable on barbed wire

sensor cable

bracing wire

barbed wire array

outrigger

cable tie

on fence fabric

razor ribbon

armored sensor cable

tensioning wires (2)

cable tie

Gates

Figure 3: Recommended cable installation on barbed wire

Figure 4: Razor ribbon

There are generally two types of gates used with fences, swinging gates and sliding gates. The

type of gate protection required is determined by:

• the type of gate

• the frequency of gate use

• when the sensor is active

• the type of ground beneath the gate

• the overall protection plan (the number of processors and sensor cables, and their location

relative to the gate in question)

FlexZone Product Guide Page 11

Page 12

Buildings, walls and other structures

Gates should consist of fence fabric on a rigid frame that includes horizontal and vertical bracing.

• Firmly attach all gate hardware accessories (minimum free-play).

• Make sure that double gates have travel stops (rigid anchors).

• Prevent locking hardware from moving in the wind.

• Prevent sliding gate track hardware, supports, guides, etc., from rattling in the wind.

There are three ways to protect gates with the FlexZone sensor system:

• The wireless gate sensor (WGS),

• FlexZone sensor cable,

• An alternate sensor technology (e.g., a microwave sensor).

Gates that are not protected by the wireless gate sensor, or sensor cable, are bypassed via

software (see Figure 48:

side of the gate to the other, and the bypassing cable is set as non-detecting (it does not report

alarms). The sensor cable continues beyond the gate, and another technology is used to provide

protection in the area of the gate.

Occasionally, it is not possible to dig underground to continue the active coverage on the other

side of a gate. There are three standard solutions for this situation:

• Install the cable on the ground surface, under a secured, protective cable mat.

• Terminate the cable at the gate.

• Connect the cable across the gate using quick-disconnect connectors.

). The sensor cable is installed inside conduit, underground, from one

Buildings, walls and other structures

FlexZone can be used to detect intruders attempting to cut, saw, chisel, drill, or smash their way

through building walls, ceilings, roofs, floors, or stock cages. FlexZone sensor cable can be

attached to the structure using commercially available fasteners such as cable ties or nail-clamps

that ensure good contact between the sensor cable and the protected structure. The fastening

devices must not flatten or distort the sensor cable at the attachment points. Sensor cable can also

be installed inside metal conduit, which is attached to the protected surface. Due to the great

variation in building materials used in structures, Senstar recommends a trial installation on a

representative section of the structure before making the full installation.

Environment

For installations in environments which include hot sunny periods, install a sun shield to protect the

enclosure from direct sunlight, or install the enclosure in a shady area. Extra care must be taken at

sites that experience strong winds on a regular basis. The fence must be well-maintained to

prevent any metal to metal contact caused by the wind. All vegetation (weeds, brush, trees, etc.)

must be cleared from around the fence area. Vegetation must not touch or hang over the fence

fabric. Any objects that may contact the fence must also be removed from the perimeter. For sites

that experience snowfalls in the winter, the fence must be kept clear of accumulating snow. Snow

can dampen the vibrations that the FlexZone sensor uses to detect intrusions. Accumulated snow

can also serve as a bridging or tunneling aid for breaching the perimeter fences.

Note The ambient temperature, as measured inside the enclosure, must be

within the range of -40 to +70º C (-40 to +158º F).

Page 12 FlexZone Product Guide

Page 13

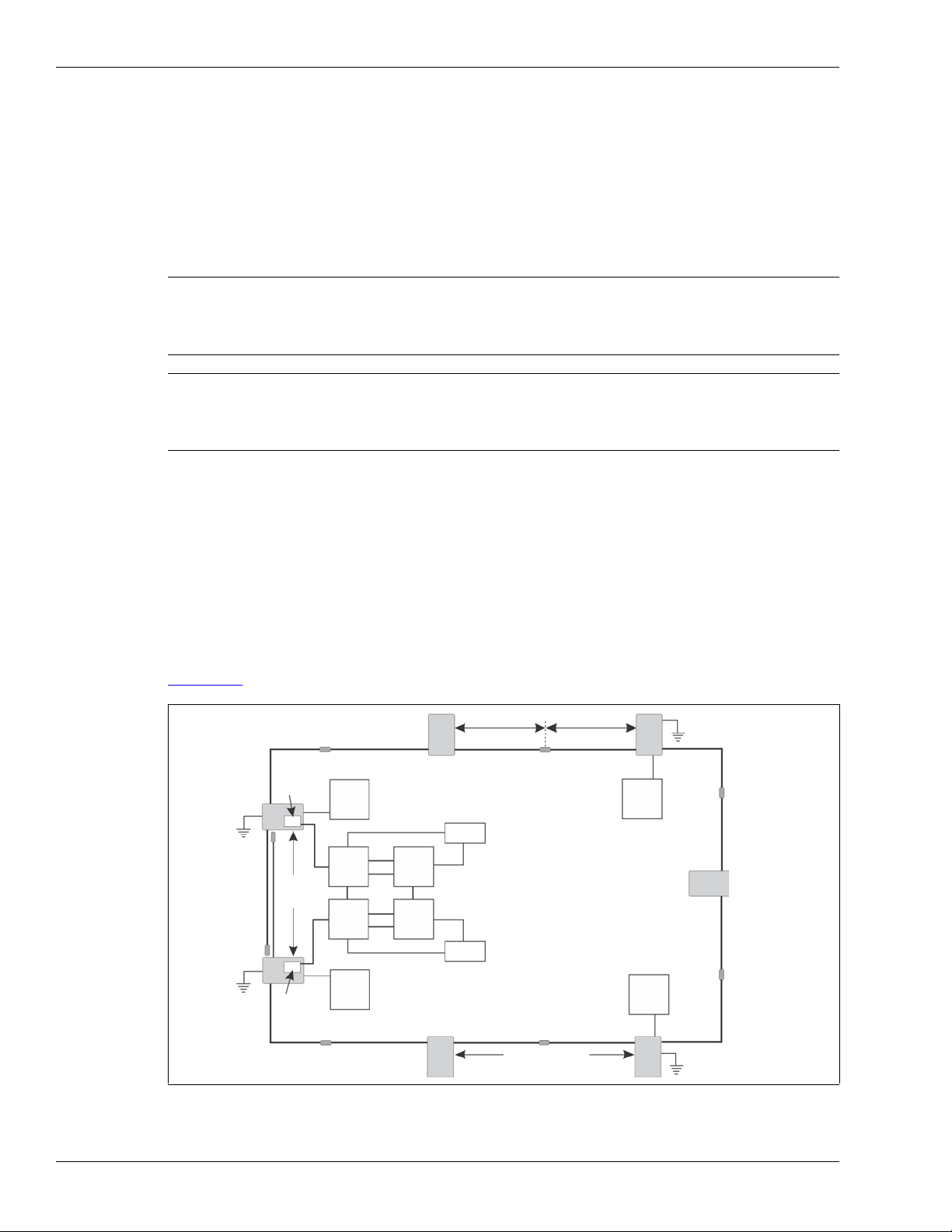

Site Survey

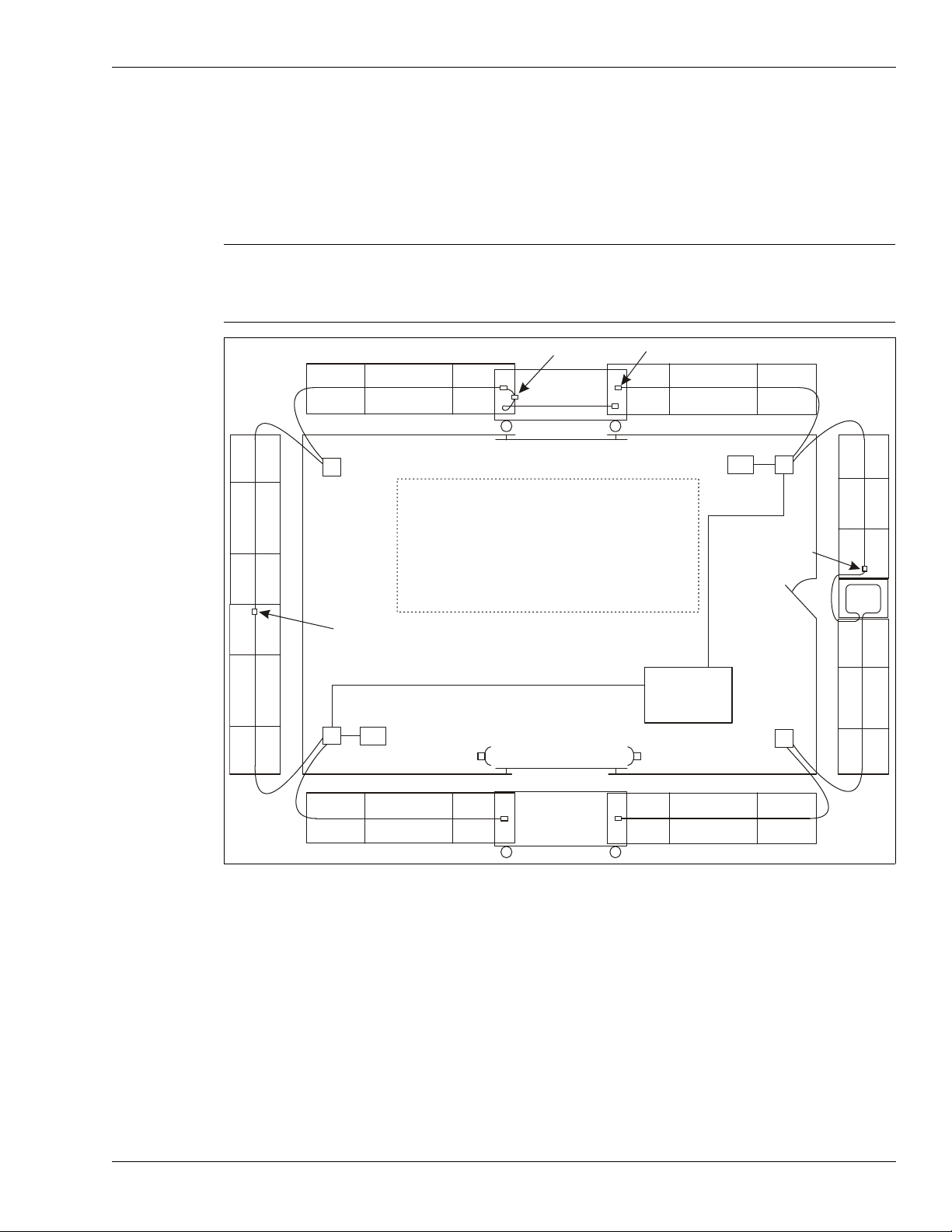

gate disconnect

terminator (typical)

sally port gate

proc #2

swinging gate

proc #1

proc #4

proc #3

power and data over

sensor cable connection

- app. max. fence length per cable 270 m (886 ft.)

microwave sensor

main

building

- drip loops at each splice/termination

- service loop every 50 m

- sensitivity loops at corner posts

sally port

gate

Z15Z12

Z10

48 VDC

48 VDC

Z1

Z2

Z3

Z4

Z5

Z6

Z7

Z8

Z9

Z11

Z13

Z14

Z16

Z17

Z18

Z19

Z20

data cable

data cable

- 19 FlexZone sensor zones (software defined)

- 1 UltraWave microwave zone (Z3)

power and data

over sensor cable

connection

Conduct a site survey to ensure that site conditions are suitable for a FlexZone sensor system.

The primary concern is the condition of the fences and gates. Use the results of the site survey to

create a site plan.

Note Sites that include a fence line that abuts the primary perimeter

Site Survey

fence can be vulnerable to climb over intrusions where the two

fences meet. To increase security in this situation, extend the

FlexZone cable for at least 2 m onto the abutting fence.

Indicate the following on the site plan:

• The locations of existing structures (include fences, gates, buildings, roads, etc.). Verify that

mounting surfaces comply with established standards for installation and stability.

• The locations of obstacles including vegetation and trees.

• The locations for the FlexZone components:

• Sensor cable - indicate the cable layout and zone boundaries for each sensor cable.

• Non-detecting cable - indicate the layout if non-detecting cable is required (at the

processor, or for a bypass).

FlexZone Product Guide Page 13

• Cable connectors - indicate the type of connection (splice, termination).

• FlexZone processors - note the addresses for network based processors.

Figure 5: Sample site plan

Page 14

Perimeter layout guidelines

150 m (492 ft.) reel

FlexZone sensor cable

150 m (492 ft.) reel

armored sensor cable

• Power supply - indicate the type of power supply and the power distribution plan.

• Alarm communication wiring - relay output or network alarm communications.

• Power/data via sensor cables.

• The locations of other perimeter security equipment.

Perimeter layout guidelines

Note A FlexZone perimeter with 1, 2, or 3 processors can be fully closed (all

sensor cables connected through splices). A FlexZone perimeter with 4

or more processors must be open at the ends (first and last sensor

cables must be terminated).

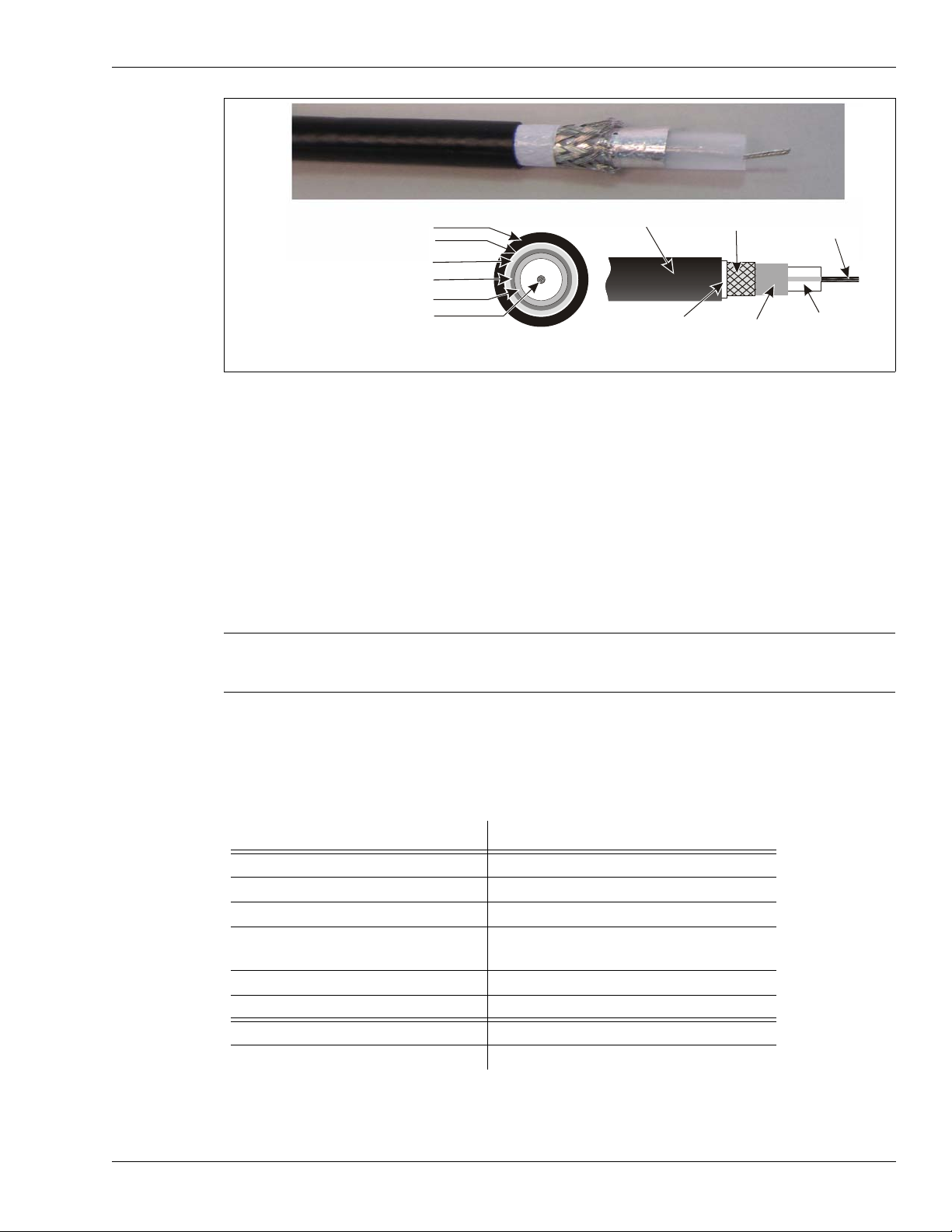

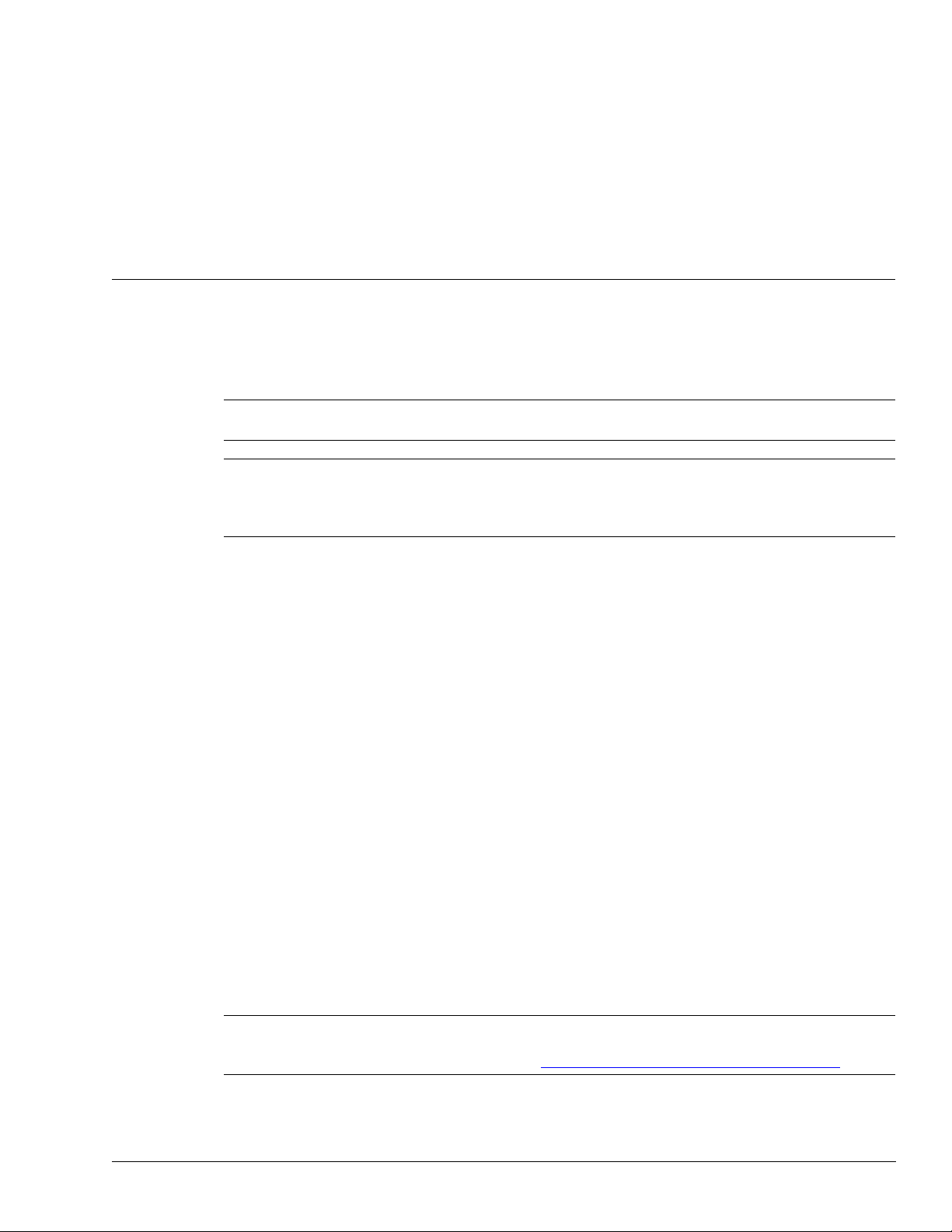

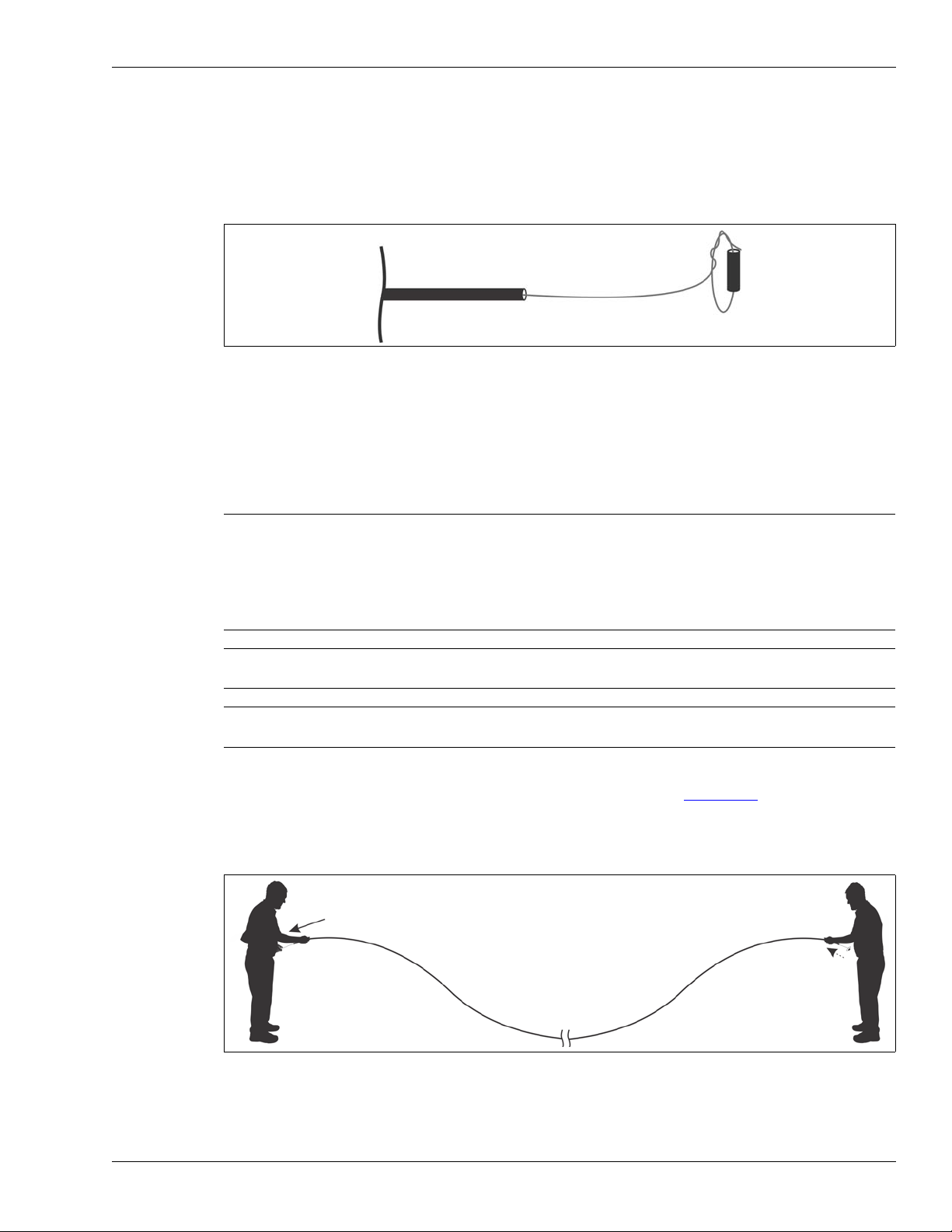

FlexZone sensor cable

There are two types of FlexZone sensor cable, standard and armored. Both Standard FlexZone

sensor cable and Armored FlexZone sensor cable come in 150 m (492 ft.) and 220 m (722 ft.)

lengths. Two lengths can be spliced together to provide up to a 300 m (984 ft.) long sensor cable.

Figure 6: FlexZone and Armored FlexZone sensor cable reels

Page 14 FlexZone Product Guide

Page 15

Cable layout guidelines

polyethylene

jacket

braided

shield

stranded center

conductor

clear tube

foil

clear tube

center conductor

aluminum foil

braided shield

outer black jacket

mylar film*

mylar film*

FlexZone sensor cable may include a mylar film between the outer black jacket and the braided shield.

The mylar film is used in the cable extrusion process and has no effect on the cable’s function.

*

• The full length of sensor cable must be mounted on the same type of surface.

• The maximum length of cable for each side of the processor is 300 meters (984 ft.).

• The smallest allowable bend radius for FlexZone sensor cable is 10 cm (4 in.).

• The smallest allowable bend radius for armored sensor cable is 15 cm (6 in.).

• Keep vertical drops of sensor cable to less than 1 m (3.3 ft.).

• The sensor cable should follow the ground contour to maintain a constant height above the

ground.

Perimeter layout guidelines

Figure 7: FlexZone sensor cable description

Note Senstar strongly recommends installing the sensor cable on the

secure side of the perimeter (the side of the fence opposite the

threat).

Cable length calculator (flexible fences)

Typically, fence coverage requires approximately 10% more cable than the linear fence length.

The following table provides a guideline for calculating the amount of sensor cable required for a

2.44 m (8 ft.) fence (in meters):

zone element required cable length (in meters)

start point + 1 m

service loops + 0.75 m X (linear cable length / 50)

zone demarcation loops + 3 m X number of zone boundaries

sensitivity loops + 3 m X number of corner and heavy

gauge posts

cable terminations and splices + 0.5 m each

linear fence length + _ _ _ _ _ (fence length)

required length of cable per pass = _ _ _ _ _ (total length)

total length X number of passes = _ _ _ _ _ cable length (max. 300 m)

FlexZone Product Guide Page 15

Page 16

Perimeter layout guidelines

max. h = 4.3 m (14 ft.)

1/2 h

1/2 h

1/3 h

1/3 h

1/3 h

single pass

double pass h > 4.3 (14 ft.)

1/4 h

1/4 h

1/4 h

1/4 h

double pass example

fences with a middle rail

h > 2 m (6.5 ft.)

double pass

rigid fences

flexible fences

30 cm (1 ft.)

above rail

single pass example

Rigid fences

Service loops, zone demarcation loops and sensitivity loops are not recommended on rigid fences.

Therefore, the length of cable required on a rigid fence is approximately the length of the fence

plus 5% overage (for each cable pass).

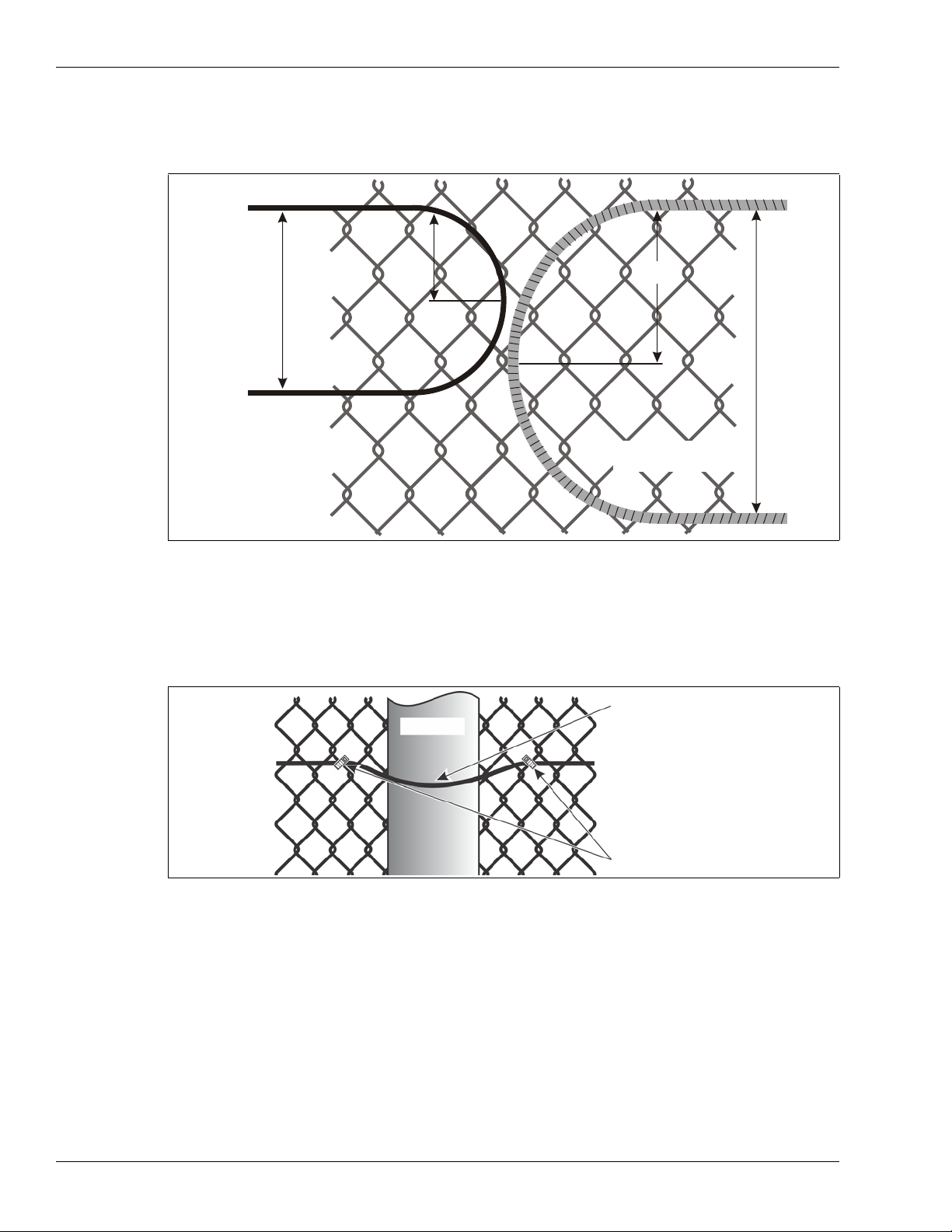

Fence height recommendations

The following cable spacing recommendations will provide a high probability of detection on well

maintained fences (see Figure 8:

• For flexible fences up to 4.3 meters (14 ft.) tall - a single pass of sensor cable at 1/2 the fence

• For flexible fences greater than 4.3 m tall - a double pass of sensor cable at 1/3 and 2/3 the

):

height.

fence height.

Note If the lower edge of the fence fabric is embedded in a concrete

footing, or below ground, an additional cable pass may be required

on the lower section of fence (a double pass at 1/3 and 2/3 fence

height).

Note If the fence framework includes an intermediate (middle) rail, it

may require a double cable pass, with one pass above the rail and

one pass below the rail.

Senstar recommends installing a single pass of cable 30 cm above

the middle rail on a small section of the fence (4 or 5 panels) and

then thoroughly testing the protected section to determine if a

single cable pass meets your detection requirements.

• For rigid fences (minimum recommended fence height 2 m, 6.5 ft.) - a double pass of sensor

cable along the top and bottom rails.

Non-detecting cable

For instances where the processor is located away from the protected fence, outdoor rated,

shielded 75 Ohm coaxial cable with a solid copper center conductor can be used as lead-in cable

(e.g., RG6). For cable bypasses along the perimeter, FlexZone sensor cable is used. The bypass

cable is set to inactive (Zone 0) in software and will not report sensor alarms. Non-detecting

FlexZone cable must be well secured to prevent any cable motion. The length of coaxial cable that

is used for lead-in must be deducted from the detecting cable length

(maximum cable length detecting plus non-detecting = 300 m, 984 ft.).

Figure 8: Cable pass recommendations

Page 16 FlexZone Product Guide

Page 17

Perimeter layout guidelines

Fence corners and heavier gauge posts (flexible fences)

Corner posts and heavier gauge support posts tend to dampen the fence’s vibration transmission

characteristics. Therefore, use cable loops at corner posts and heavy gauge support posts, to

increase the sensitivity. Each sensitivity loop requires approximately 3 m (10 ft.) of sensor cable

(see Figure 23:

).

Zone demarcation loops (flexible fences)

Zone demarcation loops may be used at software defined zone boundaries for improved location

accuracy. It is possible that an alarm that occurs very close to a software defined zone boundary

could be reported in the adjacent zone (± 3 m). Zone demarcation loops add extra sensor cable at

zone boundaries to help ensure that an alarm is reported in the zone in which it occurs. Allot 3 m

(10 ft.) for each zone to adjacent zone boundary (see Figure 24:

). Rather than using extra cable

for zone demarcation loops, overlapping CCTV coverage can provide visual assessment to verify

alarms and alarm location. When setting up the camera views, ensure that there is at least 6 m

(20 ft.) of overlapping coverage at each zone boundary.

Service loops (flexible fences)

Service loops provide extra sensor cable along the fence to make cable repairs. Allot 75 cm

(30 in.) of cable each 50 m (164 ft.) for a service loop. Locate the U-shaped service loops at fence

posts (see Figure 25:

).

Drip loops (flexible fences)

Drip loops raise the connector above the sensor cable to prevent water from running along the

cable and accumulating in the enclosure. Drip loops also relieve strain resulting from temperature

changes that cause the cable to expand and contract. Form the drip loop by raising the connector

15 cm (6 in.) above the level of the cable run. Allot 50 cm (20 in.) of cable for each splice or

termination (see Figure 26:

).

Termination loops (flexible fences)

Termination loops provide extra sensor cable at the end of the protected section of the fence (at

the terminator) to make cable repairs or future sensor cable layout changes. The amount of cable

that can be used for a termination loop depends on the length of sensor cable (plus lead-in cable if

used) connected to the processor (side A or side B, maximum 300 m). Termination loops are

typically comprised of up to 5 coiled loops of sensor cable with a 60 cm (2 ft.) diameter.

Termination loops also include the length of 1 fence panel as the cable uses a double pass on the

final protected panel (see Figure 27:

).

Splice loops (flexible fences)

If there is extra sensor cable at the location of a cable splice, you can save the cable for cable

repairs or future sensor cable layout changes by forming a splice loop instead of cutting the cable

to length (see Figure 28:

). The maximum length of cable per side (300 m) cannot be exceeded,

but up to 10 m of cable can be coiled and attached to the fence at each side of a cable splice. A

10 m splice loop is comprised of 5 coiled loops of sensor cable with a 60 cm (2 ft.) diameter. Each

60 cm diameter coil of sensor cable contains approximately 2 m of cable.

FlexZone Product Guide Page 17

Page 18

Perimeter layout guidelines

1/3 fence height

1/3 fence height

1/3 fence height

A side cable

B side cable

identical features

300 m

matching

start points

matching

end points

terminator

terminator

matching

meter marks

(every 5 m)

Gate bypass

If there is a gate within a FlexZone sensor zone, you require a sufficient amount of inactive cable

to bypass the gate, even if the gate is protected by sensor cable. Secure the bypass cable and

bury it in PVC conduit. See Figure 48:

microwave system to provide security across the gate.

Armored cable

Armored cable is FlexZone sensor cable encased in a flexible metallic conduit. The armor protects

the sensor cable from damage and vandalism, as well as from the sun and weather. Steel cable

ties or wire ties are the recommended fasteners for armored cable. Armored cable is available in

lengths of 150 m (492 ft.). Two lengths can be spliced together to create a 300 m (984 ft.) cable.

Armored cable splices are enclosed inside metal condulet fittings (p/n G6KT0300).

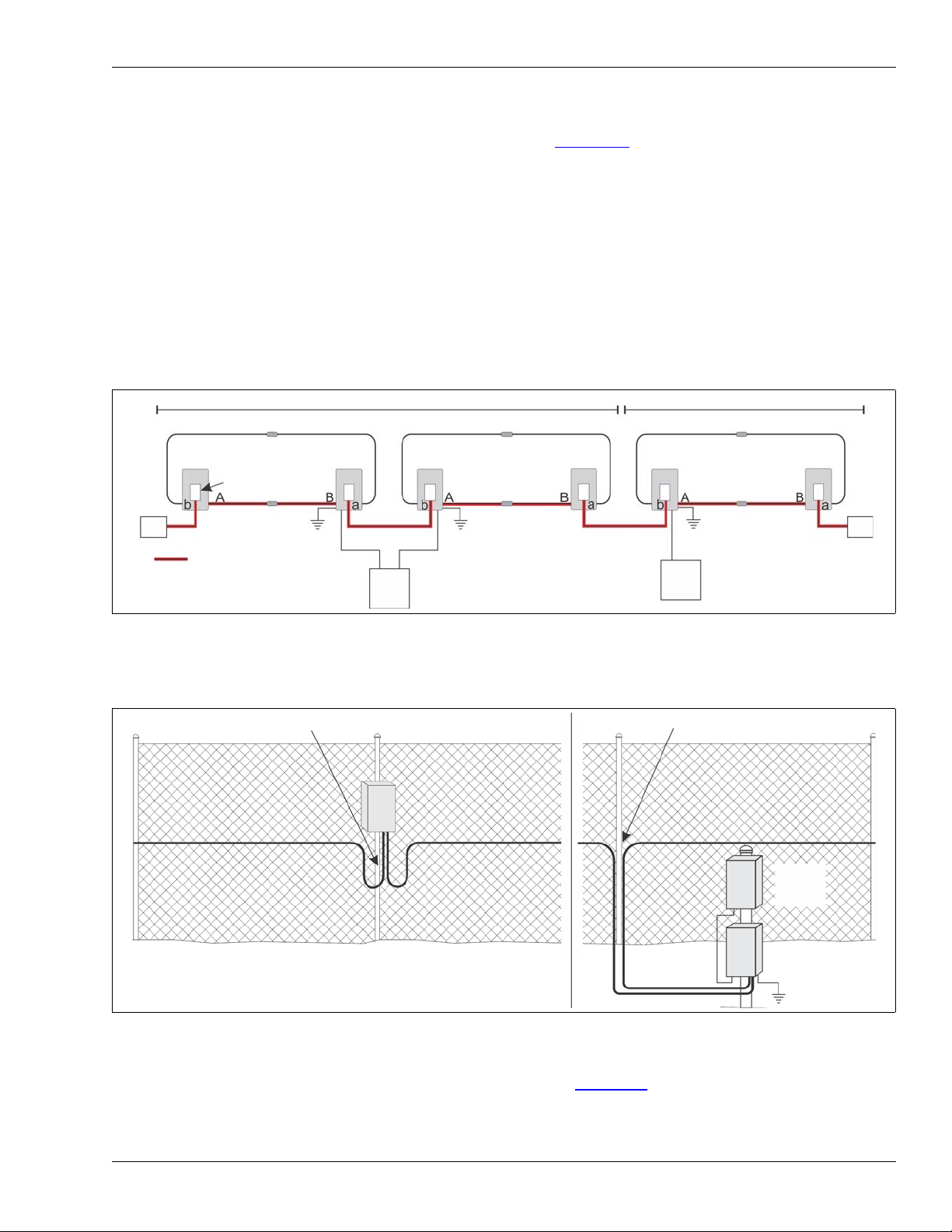

Double pass coverage

For FlexZone installations which require double passes of sensor cable, you use both cable sides

of a processor to provide software zoning and precise target location. To accomplish this the

processor is located at one end and the two sensor cable sides run parallel for up to 300 m along

the fence in an upper and lower cable pass. The ends of the two sensor cables are terminated or

spliced together. To enable precise target location, the detection start points of both cables must

match, and both cables must be of equal length and have identical features (e.g., service loops,

sensitivity loops, etc.). Each FlexZone processor can provide double pass coverage for up to

300 m of cable.

for an example of a bypassed gate, which uses a

Note Senstar recommends that both cables for a double pass installation be

laid out side by side on the ground beside the fence and marked with

tape at 5 m (16 ft.) intervals for the full length of the cable. This will help

ensure that the cables are properly length matched which is essential

for detection sensitivity and location accuracy in a double pass

installation

Figure 9: Single processor, double cable pass configuration

Page 18 FlexZone Product Guide

Page 19

Perimeter layout guidelines

300 m 300 m 300 m 300 m 300 m 300 m

power supply group

power supply group

48

VDC

48

VDC

NIC

processor

FlexZone

bi-directional data flow

power shared between

processors over both sensor cables

NIU

NIU

mmfo NIC

mmfo NIC

service loops for fence-mounted processor

non-detecting

no overlap for post-mounted processor

FlexZone

processor

48 VDC

power

supply

cable

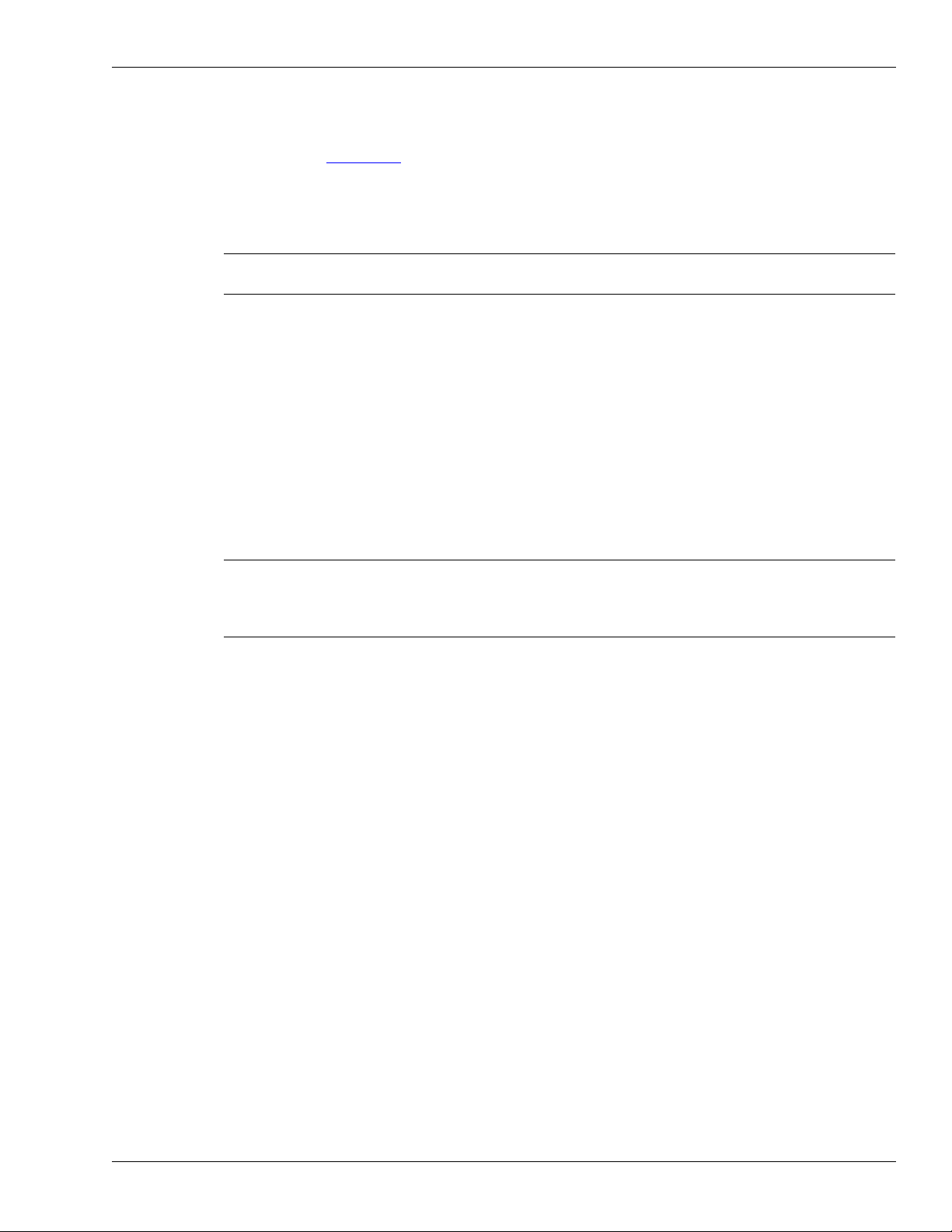

For a multi-processor FlexZone installation with a double pass of sensor cable using software

zoning, precise target locating, as well as power and data over the sensor cables there are a

number of requirements that must be observed. Figure 10:

illustrates a 1.8 km FlexZone

perimeter with six processors and a double pass of sensor cable.

• Each 48 VDC power supply can power to up to five processors over a maximum length of

1.5 km of sensor cable. The power supply must be connected to the central processor.

• The processors must be divided into blocks of two with network interface cards (NIC) carrying

the data between adjacent bocks (use multi-mode fiber optic NICs to isolate the sensor

blocks).

• The detection start points of each processor’s sensor cables must match, and both cables

must be of equal length and have identical features (e.g., service loops, sensitivity loops, zone

demarcation loops, etc.).

• Power flow, data flow and synchronization must be setup for each block of sensors via the

UCM.

Figure 10: Multi-processor, double pass ranging sensors with isolated power groups

Processor location guidelines

Figure 11: Processor location active cable start points

The FlexZone processor can be mounted outdoors on a post, either on, or separate from, the

fence on which the sensor cables are installed (see Figure 11:

for outdoor applications. The FlexZone processor can also be installed indoors or outdoors on a

flat stable surface. Post-mount hardware is supplied for post sizes from 4.5 cm to 12.7 cm

). A rigid fixed post is recommended

FlexZone Product Guide Page 19

Page 20

Perimeter layout guidelines

48

VDC

48

VDC

48

VDC

NIU

SMS

FlexZone processor

NIC

comm channel

splice/termination

cable side

sensor cable with power & data

network wiring

48 VDC power block

sync master

48 VDC power supply

processor network address

sensor cable

(1.75 in. to 5 in.). The hardware required for surface-mounting the processor is customer-supplied.

The FlexZone enclosure is hinged and includes a lockable latch (requires a Customer-supplied

pad lock).

Power source and wiring

The FlexZone processor can operate on a wide range of input voltages (12 to 48 VDC). The power

supply, the number of processors, and the lengths of the power cable runs will determine the

gauge of the power cable wiring that is required. In locations where AC power may not be stable or

reliable, an uninterruptable power supply (UPS) should be used for primary power. Assume a

maximum power consumption of 2.5 W per FlexZone processor (with NIC).

Power over the sensor cables

A group of up to five FlexZone processors can share power via the connected sensor cables. In

this case, the central processor is connected to a 48 VDC power supply. The sensor cables from

the central processor are connected to the two adjacent processors (one on each side). The

processor connected to the power supply requires a stable, low resistance earth ground

connection, which also serves as the ground reference for the connected block of processors.

Power and data distribution is setup via the UCM. Figure 12:

processor FlexZone perimeter with power and data over the sensor cables, and redundant Silver

Network communications.

illustrates a 7.2 km (4.5 mi.) 12

Auxiliary device output power

Processors that are receiving power over the sensor cables can supply up to 2 W of power to an

auxiliary security device through T4, the power connector. The output power is at the same voltage

as the received power input via the sensor cables. The minimum required voltage to enable power

over the sensor cables is 38 VDC. Figure 76:

processor supplying power and carrying alarm data for an UltraWave microwave sensor in both

Page 20 FlexZone Product Guide

Local and Remote control modes.

Figure 12: Power and data distribution via sensor cables

illustrates connection diagrams of a FlexZone

Page 21

Perimeter layout guidelines

Power over Ethernet

Silver Network based processors using Ethernet communications have the option of using Power

over Ethernet (Figure 73:

option requires a PoE class 3 switch that is located within 100 m (328 ft.) of the processor, and

minimum Category 5 network cable. Power over Ethernet is supplied to the processor’s Network

Interface card (NIC) and the power output on the NIC is connected to the power input on the

processor. Each processor receiving PoE requires an earth ground connection.

Note Senstar recommends using a fully managed PoE switch, to supply

Grounding considerations

A stable low resistance earth ground connection is required by each processor that is connected

directly to a power supply. Use a short length of heavy gauge copper wire to connect the ground

lug on the bottom of the processor’s enclosure to an approved earth ground. Processors receiving

PoE also require a ground connection via the enclosure ground lug. Processor’s receiving power

over the sensor cables do not require a direct ground connection. These processors use the

ground of the processor that is connected to the network power supply as their ground reference.

Consult the local electrical code for grounding information.

illustrates an Ethernet based Silver Network). To use this powering

power to a FlexZone processor.

Alarm data communications

Note Senstar recommends setting up a Silver Network, even when using

Local control mode. This enables remote calibration, maintenance

and diagnostic access to your FlexZone processors from a central

control facility.

There are two selectable control modes for the FlexZone processor’s inputs and outputs (I/O) local

control mode and remote control mode. You set the control mode in software, via the Universal

Configuration Module (UCM) which is a Windows-based software application. The default setting

is local control mode, in which the processor controls the on-board relays to signal alarm and

supervision conditions. In local control mode, the two Aux (auxiliary) inputs are self-test inputs to

the processor. In remote control mode, the alarm data is carried over the Silver Network to a host

security management system (SMS). Remote control mode enables the SMS to control the

processor’s relays as output points to operate other security equipment. The two Aux inputs

provide inputs to the host SMS for reporting the status of auxiliary devices. In both modes, you can

configure the processor’s input/output response according to your site-specific requirements.

• local control mode - hard-wired contact closure alarm data connections and self-test input

wiring connections are made between the processor and the annunciation equipment

(4 output relays, 2 self-test inputs) (the optional Relay Output card provides 4 additional

outputs for reporting alarm conditions)

• remote control mode - the alarm data communications are via the Silver Network - EIA-422

copper wire data paths or fiber optic cables connect one or two processors to the Network

Interface Unit (NIU), the remaining processors can be connected via EIA-422 wiring, fiber

optic cable, or data can be carried between processors via the sensor cables the 4 output

relays are available as output control points from the host system (the optional Relay Output

card provides 4 additional relays, which are also available as output control points), the 2

auxiliary device inputs are available for reporting the status of auxiliary equipment to the host

system (the optional dry contact input card provides 4 additional inputs, which are also

available for connecting auxiliary equipment to the host system)

FlexZone Product Guide Page 21

Page 22

Perimeter layout guidelines

Alarm communication options

• contact closure alarm communications (local control mode) up to 8 distinct alarm zones per

• built-in data communication network, secure data passes between processors over the sensor

• Silver Network data communications are daisy-chained to each processor around the

• Silver Network data communications are via Ethernet to each processor using category-5

Fail-safe relay operation

In the default configuration, the processor’s relays operate in fail-safe mode. During normal

operation, the relays latch in the non-alarm state. In the event of a total processor failure all relays

switch to the alarm state. Relays 1 and 2 indicate fail and supervision conditions and relays 3 and

4 report sensor alarms.

processor (requires optional ROC)

cables (one or two processors must have a Silver Network connection to the NIU.)

perimeter using either EIA-422 copper wire data paths or fiber optic cable (Silver Loop)

cable and a PoE switch (Silver Star)

Note You can use a combination of the above methods for powering and

data communications.

Note A Silver Network based processor can use local control mode to

operate its output relays and Aux inputs.

Relay Output Card

The relay output card (ROC) (P/N 00BA2500) includes four relays to supplement the four relays

available on the processor. In remote control mode, the host security management system

operates the ROC’s relays, as output control points, (e.g., to activate lights, doors, sirens, CCTV

equipment, etc.). You can configure the relays as latching (ON by command, OFF by command),

in flash mode (ON-OFF-ON-OFF, etc. by command, then OFF by command), or pulse mode (ON

for a period, then OFF). For flash and pulse modes, the Active/Inactive times are selectable.

Dry Contact Input Card

The dry contact input card (DRIC) (P/N 00BA2400) includes four inputs to supplement the two

inputs available on the processor. In remote control mode, the DRIC’s inputs connect auxiliary

devices to the host security management system (e.g., to report the status of other security

equipment such as a microwave or magnetic contact). The Filter Window parameter allows you to

set the time period for which an input must be active, before an event is reported.

Data over the sensor cables

A group of FlexZone processors can communicate via the connected sensor cables. In this case,

at least one processor requires a network interface card (NIC) to enable Silver Network

communications. The sensor cables from that processor are connected to the two adjacent

processors (one on each side). Processors that are using the sensor cables for data distribution

must be synchronized to prevent mutual interference.

To take advantage of the Silver Network’s redundant communications capability, two of the

connected processors require NICs and connections to a Network interface unit (NIU). In this way

network communications will travel in both directions over the sensor cables, so that a single break

in a sensor cable will not interrupt communications.

Page 22 FlexZone Product Guide

Page 23

Processor synchronization

A group of FlexZone processors that are connected through the sensor cables must be

synchronized to prevent mutual interference. For a fully closed 2 or 3 processor perimeter, one

processor must be set as the Sync Master for the group. The Sync Master generates a

synchronization signal and transmits the signal through its A-side sensor cable. The next

processor receives the Sync signal through its B-side cable, synchronizes itself accordingly and

then sends the Sync signal on to the next connected processor (A-side to B-side). The Sync

Master will not accept a signal from another processor and always restarts the synchronization

process. To set a processor as the Sync Master connect the UCM to the processor and uncheck

the Accept Sync Signal check box.

Note Only one processor in a connected group can be set as the Sync

Master or mutual interference will occur.

For an open loop sensor configuration where at least one sensor cable ends with a terminator (not

connected to another sensor cable) the synchronization process is automatic and requires no

configuration changes. Each processor that is set to Accept Sync Signal will receive the Sync

signal through its B-side cable, synchronize itself accordingly and then send the Sync signal on to

the next connected processor. By default, the processor on the end of the perimeter that is

connected to the next processor through its A-side cable will generate the Sync signal that starts

the synchronization cycle.

Perimeter layout guidelines

Alarm monitoring

Alarm monitoring is site specific and depends on whether you are using relay outputs for alarm

reporting (Local control mode) or Silver Network based alarm reporting (Remote control mode).

Each processor has four user-configurable Form C relay outputs. In Local control mode, the four

relays are used to signal alarm and supervision conditions. For network based processors, alarm

data is carried over the network cables and the four relays are available as output control points

from the security management system (SMS).

NM Mode

The FlexZone processor can be configured to report alarm and supervision conditions through the

UltraLink modular I/O system. In NM Mode, the UltraLink I/O processor acts as the Network

Manager, providing alarm outputs for a connected network of up to eight Silver devices. In NM

Mode, the Silver devices do not require a connection to a PC running Silver Network Manager

software. Sensor alarms and supervision conditions are assigned to UltraLink I/O outputs (relay or

open collector). When an alarm occurs on a connected sensor, the corresponding UltraLink I/O

output is activated (see NM Mode

Cable connectors

The splice kit is used to join two FlexZone cables together, and to join lead-in cable to sensor

cable. The splice kit is also used to make cable repairs. The termination kit is used in situations

where a FlexZone sensor cable is not connected to another FlexZone sensor cable. In this case,

the termination kit is connected to the end of the sensor cable to enable processor supervision.

The cable connectors are mounted horizontally on the fence using two cable ties.

on page 99 for additional details).

Note Senstar recommends limiting cable repair splices to one splice per

150 m (492 ft.) cable length.

FlexZone Product Guide Page 23

Page 24

High security installations

150 m (max.)

150 m (max.)

48

VDC

48

VDC

48

VDC

48

VDC

300 m (max.)

NIU

NIC

NIC

UPS

UPS

NIU

NM

SMS

NM

SMS

P1

P2

P3

P4

P5

P6

P7

300 m

(max.)

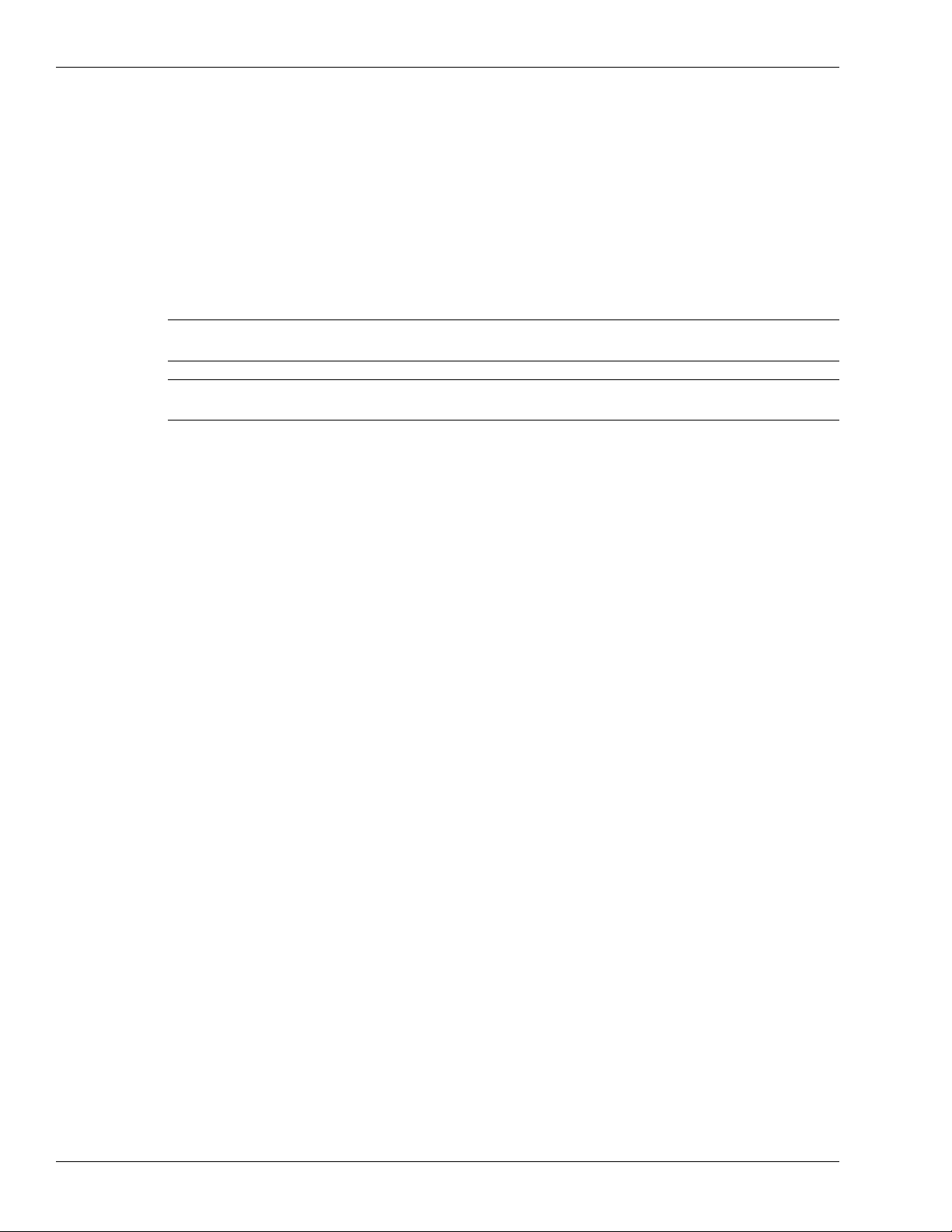

High security installations

The FlexZone sensor can provide redundancy for high-security installations, providing certain

rules are followed. If these rules are followed, then the system will continue to provide perimeter

detection even if one processor fails, or a sensor cable is cut or if one power supply fails. With this

configuration, each 300 m of sensor cable is monitored simultaneously, by two processors.

Note If a sensor cable is cut, location accuracy may be diminished and an

increased system noise level (clutter) and NAR may occur. In the event

of a cut cable, repairs must be made as quickly as possible to return the

system to its full detection capabilities.

Note A fully redundant system requires that there be no single point of failure.

Therefore, the system requires two Network Interface Units, two

Network Manager PCs, two Security Management System PCs (NM

and SMS can reside on one PC) and two UPS systems.

High-security installation rules

• maximum sensor cable length for one side of a processor is 150 m (492 ft.) except terminated

open ends of perimeter (max 300 m)

• maximum length of sensor cable between 2 processors is 300 m (984 ft.)

• a minimum of two 48 VDC power supplies (depending on total number of processors)

• power supplies must be connected to processors on the ends of the perimeter

• two Silver Network connections to two Network Manager PCs at opposite ends of the loop,

OR, star network configuration setup using PoE with redundant switches

Figure 13:

Page 24 FlexZone Product Guide

shows a seven processor high-security perimeter up to 2.1 km (1.3 mi.) in length.

Figure 13: High-security redundancy (2.1 km example)

Page 25

2 Installation

Installing the sensor cable

CAUTION FlexZone sensor cable must be conditioned before it is attached to

the fence.

CAUTION When installing FlexZone sensor cable during periods of freezing

weather (below 0º C, 32º F) extra care must be taken as the sensor

cable is less flexible, and the polypropylene cable ties can be prone to

failure.

Cable handling rules

The FlexZone sensor cable converts minute vibrations in the fence fabric into electrical signals.

Any damage to the cable from mishandling or poor installation practices will have a negative effect

on the system’s performance.

• DO NOT bend, twist, jerk, knot, or kink the sensor cable.

• DO NOT nick or scrape the sensor cable’s outer jacket.

• Avoid tight turns in the sensor cable, the minimum bend radius for FlexZone sensor cable is

10 cm (4 in.) and for armored FlexZone cable is 15 cm (6 in.).

• DO NOT place objects on the sensor cable or allow anyone to stand or walk on the cable.

• DO NOT allow the cable to fall off the side of the cable reel.

• DO NOT apply excessive tension to the sensor cable at any time.

• When using cable ties to attach the sensor cable to a fence, install the ties by hand and pull

them hand-tight until snug.

• DO NOT use mechanical tighteners to attach cable ties to a fence.

• DO NOT allow the sensor cable to be pinched between the fence and a fence post, or any

other object.

• Keep the ends of the sensor cable clean and dry. If water enters the loose tube it can cause

corrosion and potentially freeze in the winter, which will have a negative effect on sensitivity.

Note The number of cable passes required on a fence depends on the

height of the fence, the type of fence, and the required level of

security (see Fence height recommendations

FlexZone Product Guide Page 25

on page 16).

Page 26

Installing the sensor cable

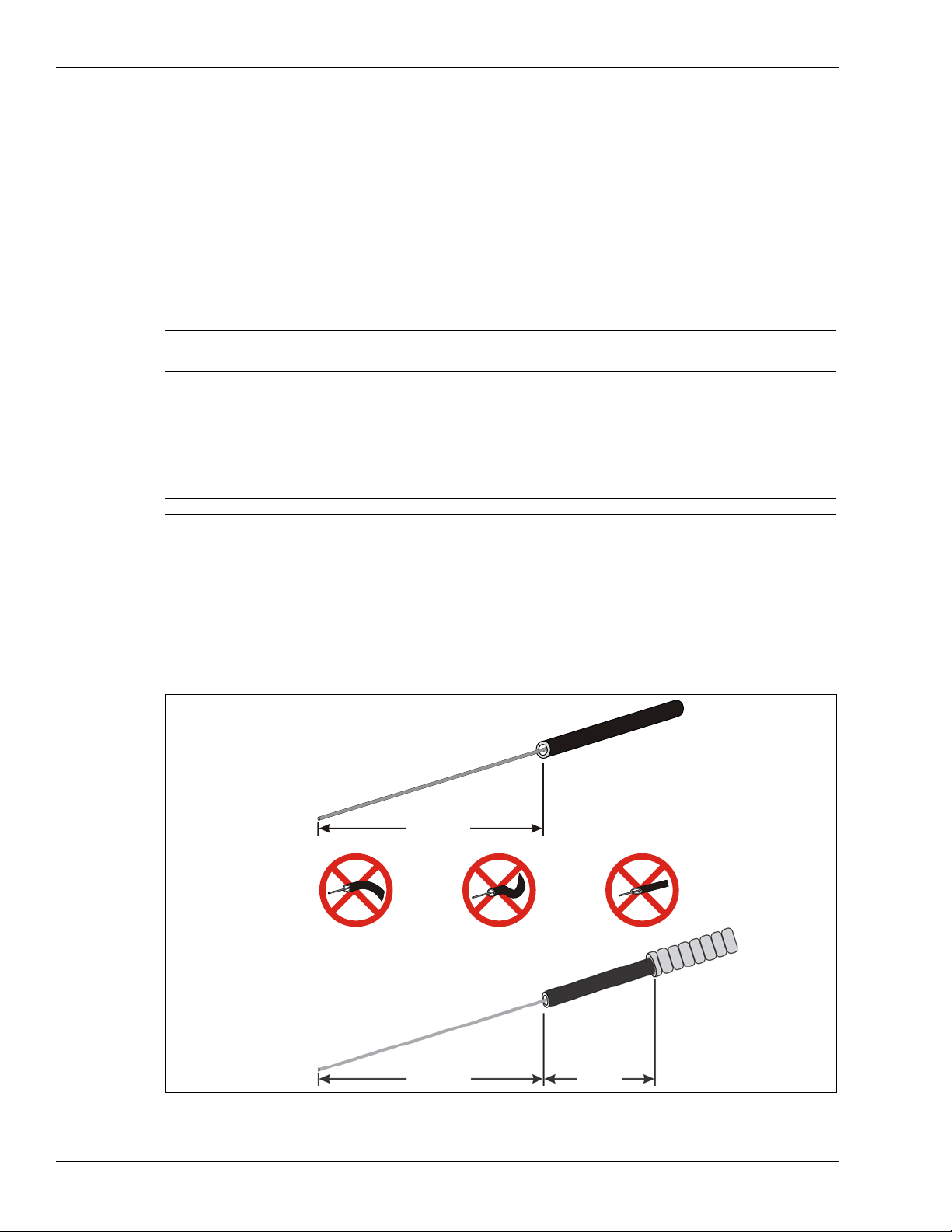

expose 30 cm (12 in.) of the center conductor

ensure the exposed center conductor

is free to extend or retract

30 cm

(12 in.)

remove 45 cm (18 in.) of the armored jacket and

expose 30 cm (12 in.) of the center conductor

armored cable

30 cm

(12 in.)

15 cm

(6 in.)

NOT bent

NOT twisted

NOT flattened

FlexZone sensor cable conditioning

Before installing FlexZone sensor cable, the cable must be conditioned. Prior to conditioning, there

may be excess center conductor in the cable, or the center conductor may be adhered to the cable

side walls after the manufacturing process. Conditioning frees the center conductor and

maximizes its movement, thereby providing the greatest sensitivity. Cable conditioning is best

done by two people and typically takes about 10 minutes for a 150 m sensor cable. FlexZone

cable conditioning can be done by a single person, but it can take significantly longer to complete

due to repeatedly walking back and forth.

Cable conditioning procedure (part 1 - cable preparation)

1. Dispense the sensor cable alongside the fence in a long straight line.

Note This procedure applies to both standard FlexZone sensor cable and

armored FlexZone sensor cable.

Note If site conditions prevent the cable from being laid out in a straight line,

minimize the number of turns and use as large a turn radius as

possible. Turns in the cable will require an increase in the amount of

pulling force needed to move the center conductor back and forth.

Note If the cable is moved to a more open area to be conditioned, move it

2. Carefully remove 30 cm (12 in.) of the black outer jacket, shield and clear tube to expose

30 cm of the center conductor at both ends of the cable. For armored cable, remove 45 cm

(18 in.) of the armor from each end of the cable, then expose 30 cm (12 in.) of center

conductor at each end.

carefully back to the installation location following the process. Avoid

using excessive pulling force and do not pull the cable around corners

or fence posts when it is repositioned.

Page 26 FlexZone Product Guide

Figure 14: Exposing the center conductor

Page 27

Installing the sensor cable

black outer jacket

use the loop to apply tension to the center conductor

second person

first person

hold the cable and apply light

hold the cable by the black jacket

pulling tension to the center conductor

(apply no tension)

3. Check the ends of the cable to verify that the center conductor is free to retract or extend

(i.e., the center conductor is straight and the cable end is not pinched, flattened, twisted, bent,

or distorted). If an end is damaged enough to prevent the free movement of the center

conductor, cut off the damaged section and re-strip the cable.

4. At both ends of the cable, tie a loop through a 2.5 cm (1 in.) piece of the black jacket, to

prevent the center conductor from retracting into the cable during the conditioning procedure.

Figure 15: Securing the center conductor

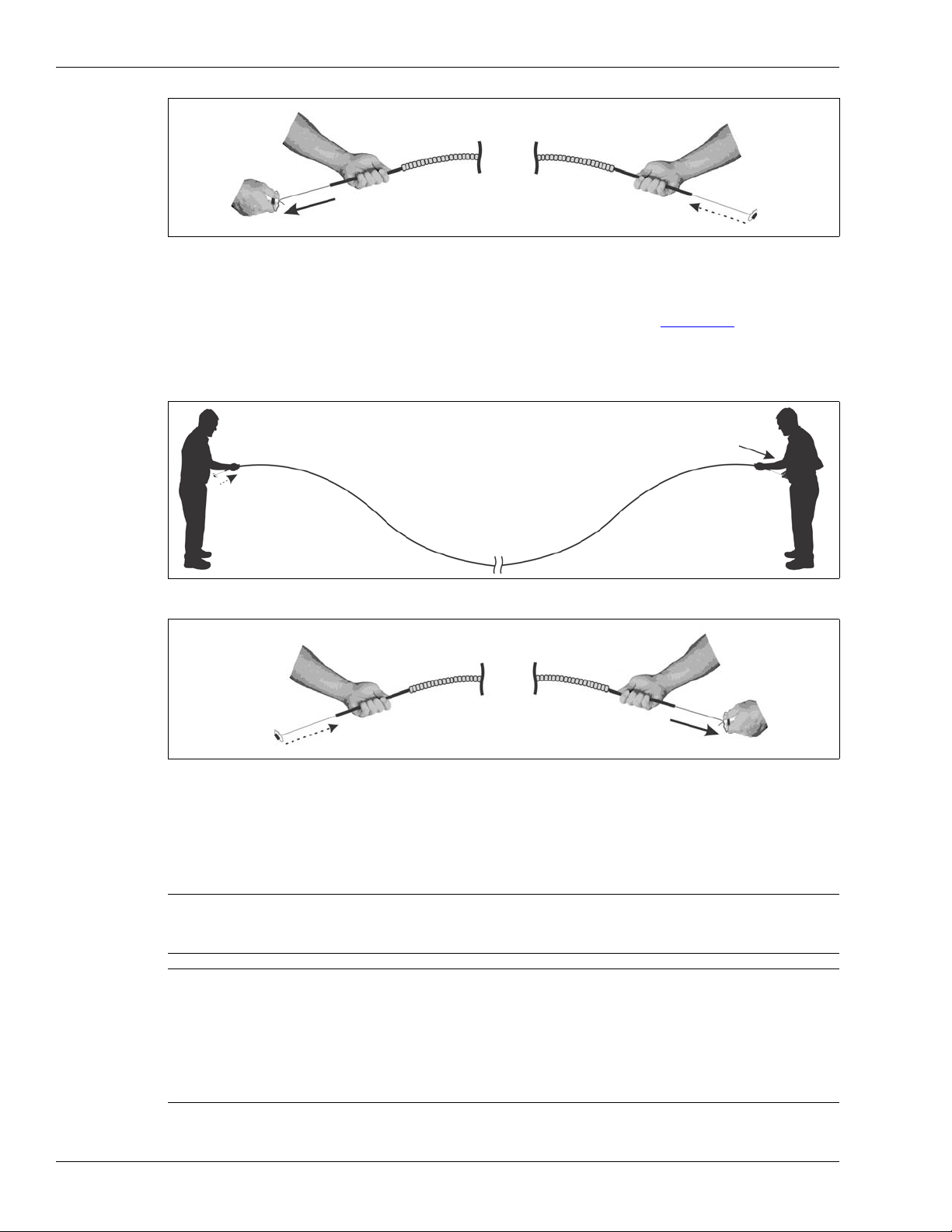

Cable conditioning procedure (part 2 - cable flossing)

Pull the cable by the black jacket to remove any slack and then use a “flossing” motion to pull the

center conductor back and forth to ensure the center conductor is floating freely over the full length

of the sensor cable.

Note Initially, there may be resistance as well as some “stretching” as the

center conductor is freed inside the cable (i.e., the center conductor

pulls out at one end but remains the same length at the other). Once the

center conductor moves back and forth easily so that pulling it out

15 cm (6 in.) at one end causes it to retract 15 cm at the other end, the

conditioning is complete.

Note You can hear the motion of the floating center conductor as it rattles

when you tap a properly conditioned sensor cable.

Note Maintain a firm grip and consistent pulling tension, and keep the sensor

cable taut and in-line during the cable conditioning procedure.

1. The first person begins by holding the cable by the black jacket with one hand and applying

light pulling tension to the center conductor with the other (see Figure 16:

).

The second person holds the cable by the black jacket and allows the center conductor to

move freely (no tension applied).

The first person stops pulling when they encounter an

increase in resistance or the center conductor can be pulled no further.

FlexZone Product Guide Page 27

Figure 16: FlexZone cable conditioning (part 2 cable flossing)

Page 28

Installing the sensor cable

apply light pulling tension

to the center conductor

hold the cable

second person

first person

by the black jacket

second person

first person

pulling tension to the center conductor

hold the cable and apply light

hold the cable by the black jacket

(apply no tension)

apply light pulling tension

to the center conductor

hold the cable

second person

first person

by the black jacket

2. When the second person observes that the center conductor has been pulled to its limit, the

Figure 17: FlexZone armored cable conditioning (part 2 cable flossing)

second person waits 10 seconds and then applies light pulling tension to the center conductor

while holding the cable by the black jacket with the other hand (see Figure 18:

).

The first person holds the cable by the black jacket and allows the center conductor to move

freely (no tension applied).

in resistance or the center conductor can be pulled no further.

The second person stops pulling when they encounter an increase

Figure 18: FlexZone cable conditioning (part 2 cable flossing)

Figure 19: FlexZone armored cable conditioning (part 2 cable flossing)

3. Continue this flossing motion back and forth until the center conductor moves easily with very

little resistance.

4. When the conditioning procedure is complete, release the tension on the center conductor,

and cut off any center conductor that was damaged during conditioning.

Note When conditioning is complete, the center conductor slides easily in both

directions, and it may extend an additional 15 to 30 cm out of the cable

jacket at both ends.

Note If the center conductor does not move back and forth easily (or at all)

during the flossing process, straighten any turns in the cable (relocate the

cable if necessary). Have one person grip the cable at one end and apply

light tension to the center conductor while the second person walks the

length of the cable from the other end shaking and tapping the cable.

Page 28 FlexZone Product Guide

Next, repeat the cable flossing procedure until the center conductor

moves freely and easily.

Page 29

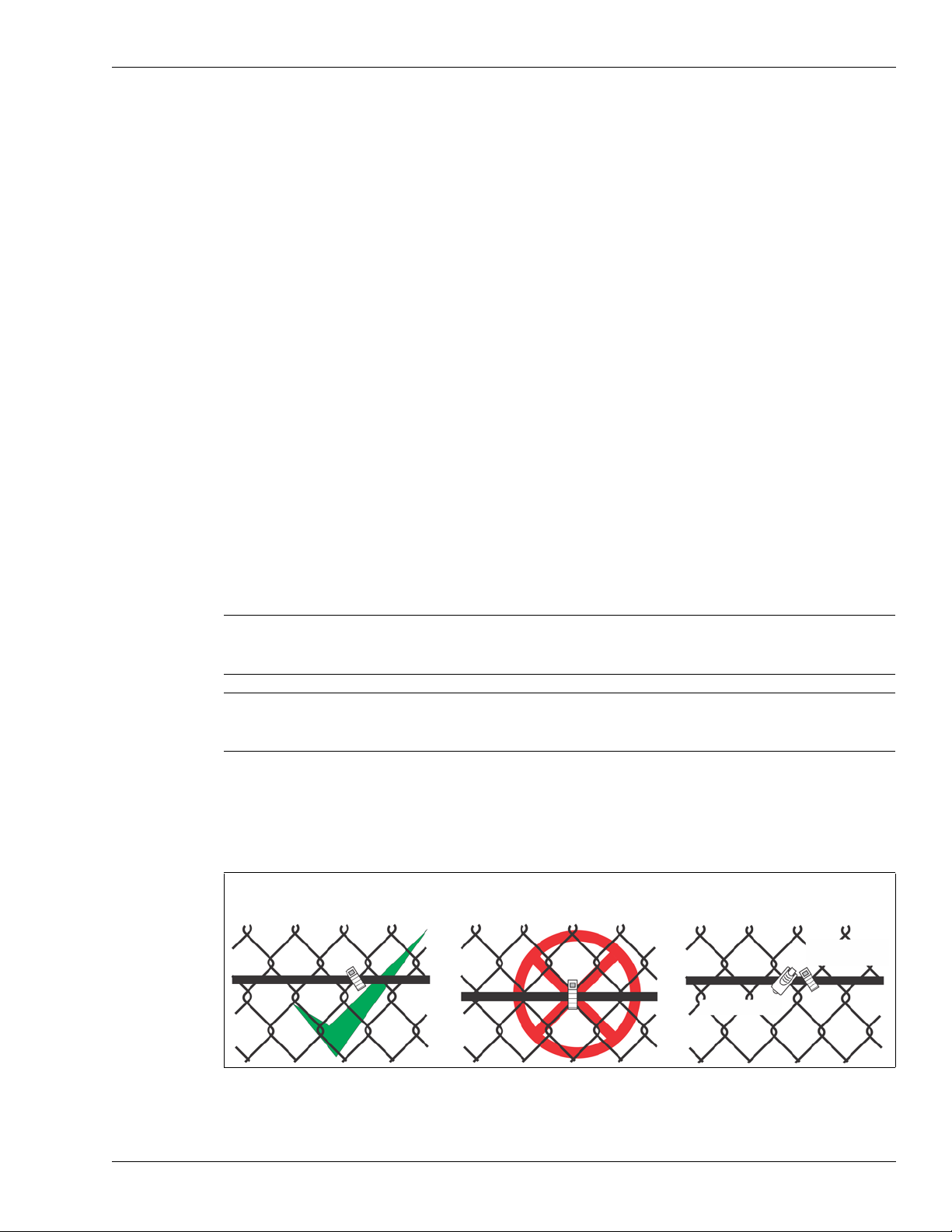

Installing cable on chain-link fences

attach the cable to the fence fabric

in the middle of a fence wire

DO NOT attach the cable to the fence

fabric at the junction of 2 fence wires

use 2 steel cable ties on each fence

polypropylene

cable tie

steel cable tie

panel in addition to the polypropylene

ties for added security

• Attach the sensor cable to the secure side of the fence (the side opposite the threat).