µltraWave

Microwave Detection Sensor

™

Product

Guide

E4DA0402-001 Rev A

March 25, 2011

Senstar Corporation

Web site: www.senstar.com

Email address: info@senstar.com

E4DA0402-001 Rev A

March 25, 2011

Senstar and the Senstar logo are registered trademarks, and µltraWave and Silver Network are trademarks of Senstar

Corporation. Product names and Company names included in this document are used only for identification purposes and are

the property of, and may be trademarks of, their respective owners. Copyright © 2011, Senstar Corporation. All rights reserved.

Printed in Canada.

The information provided in this guide has been prepared by Senstar Corporation to the best of its ability. Senstar Corporation

is not responsible for any damage or accidents that may occur due to errors or omissions in this guide. Senstar Corporation is

not liable for any damages, or incidental consequences, arising from the use of, or the inability to use, the software and

equipment described in this guide. Senstar Corporation is not responsible for any damage or accidents that may occur due to

information about items of equipment or components manufactured by other companies. Features and specifications are

subject to change without notice. Any changes or modifications to the software or equipment that are not expressly approved by

Senstar Corporation void the manufacturer’s warranty, and could void the user’s authority to operate the equipment.

The figures included in this document are for illustration purposes only, and may differ from the actual equipment.

Senstar Corporation’s Quality Management System is ISO 9001:2008 registered.

Compliance:

Canada: Industry Canada Identification Number: transmitter 1454B-E4EM0101; receiver 1454B-E4EM0201

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Ce dispositif est conforme aux normes CNR d’Industrie Canada applicables aux appareils radio exempts de licence. Son

fonctionnement est sujet aux deux conditions suivantes : 1) le dispositif ne doit pas produire de brouillage préjudiciable; et 2) il

doit accepter tout brouillage reçu, y compris un brouillage susceptible de provoquer un fonctionnement indésirable.

USA: FCC Identification Number: transmitter 15T-E4EM0101; receiver 15T-E4EM0201

FCC Certification - This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Europe:

This device complies with ETSI standard EN 300 440 for European operation

The use of shielded cables is required for compliance.

Service statement - We ensure that our products are correctly applied to achieve the maximum benefits for the end-user. We

work hand-in-hand with our customers and remain accessible through all stages of a project - from concept to deployment to

long-term support. We provide design assistance, site surveys, installation support, comprehensive documentation, training,

post-installation annual calibration and maintenance visits, electronics and software extended warranty, rapid factory repair

service and on-call/emergency service. Contact Senstar Corporation to inquire about how a package can be customized for

your unique applications.

µltraWave Product Guide

Table of contents

1 System planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

Site planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Site design - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Zone placement - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Zone length - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Zone height - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Microwave offsets - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Mounting heights - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Power and ground requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Alarm data communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Network wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Relay contact ratings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Cable ports - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Mounting posts/surfaces - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Foundation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

2 Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Mounting the μltraWave units - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Post-mounting procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Post-mount alignment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Surface-mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Surface mounting procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Surface-mount alignment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Transmitter/receiver wiring connections - - - - - - - - - - - - - - - - - - - - - - -15

Relay contact ratings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Auxiliary input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Cable ports - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Making the I/O wiring connections - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Enclosure tamper switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Transmitter/Receiver grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Power supply connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Local power supply - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Silver Network wiring connections - - - - - - - - - - - - - - - - - - - - - - - - 18

Silver Network specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Silver Network connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

3 Setup and calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

Connecting the UCM - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Setting the transmitter/receiver Frequency Pair - - - - - - - - - - - - - - - - 23

Receiver setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 23

Specify the Auxiliary I/O control mode - - - - - - - - - - - - - - - - - - - - - 24

Auxiliary (Aux) inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 24

µltraWaveProductGuide Page1

Input configuration procedure (Remote control mode) - - - - - - - - - - - - - - 25

Output relays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

Output relay setup (Local control mode) - - - - - - - - - - - - - - - - - - - - - - - 25

Output relay setup (Remote control mode) - - - - - - - - - - - - - - - - - - - - - - 25

Setting the receiver’s address - - - - - - - - - - - - - - - - - - - - - - - - - - - 26

a Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

Page2 µltraWaveProductGuide

1 System planning

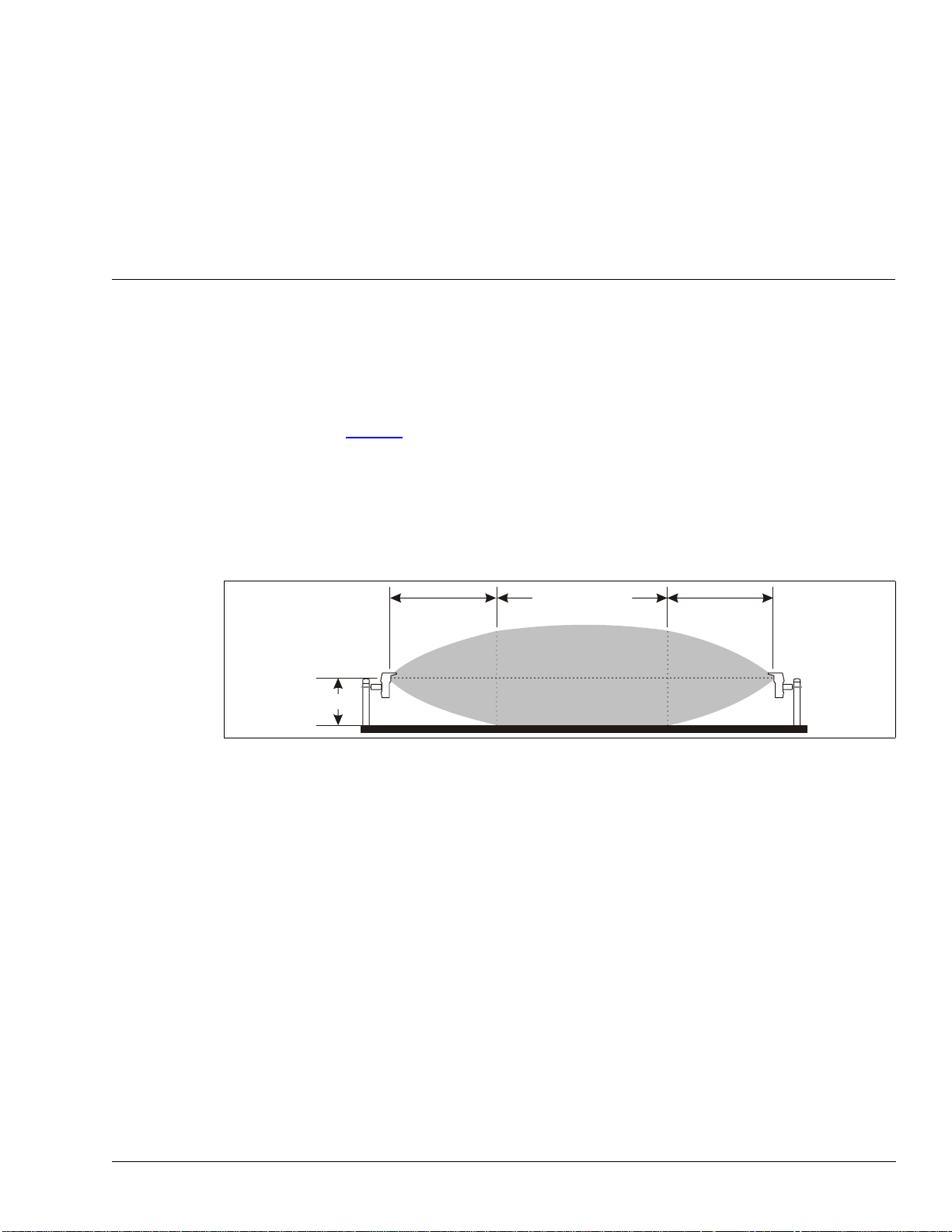

The μltraWave Microwave Detection Sensor is designed for exterior perimeter intrusion detection

applications. μltraWave consists of a microwave transmitter and receiver, which detect motion in a

defined area (see Figure 1

motion in the detection zone causes a variation in the received signal strength. The signal

variations are detected and processed by the receiver, which declares an intrusion alarm when the

received signal meets the criteria for a valid target.

The transmitter and receiver units are housed in weatherproof enclosures. Each enclosure

contains electronic circuitry and an antenna. Both units can be wired to report enclosure tamper

alarms.

). The transmitter sends microwave signals to the receiver, and any

full coverage

partial coverage

detection zone

partial coverage

beam centerline

mounting height

offset area

Figure 1 µltraWave microwave detection sensor

Site planning & design

The amount of site preparation required depends on the level of security. High security

applications require more stringent specifications than do applications where only a beam-break

alarm is required. Use the following definitions to determine the level of security required:

• High Security Zone - detection of an intruder stomach-crawling parallel to the beam.

• Medium Security Zone - detection of an intruder crawling on hands and knees.

• Low Security Zone - detection of an upright walking intruder (beam-break alarm).

The physical specifications for a high security detection zone are:

• maximum transmitter/receiver separation distance of 100 m (328 ft.)

• terrain must be level to grade ± 7.5 cm (3 in.)

• terrain covered with a 10 cm (4 in.) layer of crushed stone (2 cm {0.75 in.} max.) or a paved

zone free of vegetation

offset area

µltraWaveProductGuide Page 3

Site planning & design

Site planning

Conduct a site survey in which you note the physical features of the zone and surrounding area.

Include accurate measurements on a detailed drawing. The following is a list of rules to follow

when planning a microwave zone:

• Line of sight - A direct, unobstructed line of sight is required between the transmitter and

receiver.

• Depressions and deviations in terrain - Drainage ditches and gullies must be avoided or

filled in. These depressions can allow undetected access by an intruder, and occasional

water flow can cause nuisance alarms. Significant deviations from level grade can result in

gaps in the detection zone and detection shadows. Gaps and detection shadows create

unmonitored areas in the zone.

• Vegetation - Trees, bushes, shrubs, tall grass and weeds within the detection zone will

increase the sensor’s nuisance alarm rate and reduce the probability of detection,

especially when the vegetation is wet with rain or dew.

• Objects - Any objects (posts, light standards, stored material, parked vehicles, etc.) within

the detection zone can result in gaps in the microwave field and detection shadows.

• Ensure that there is adequate separation from any object that could be used to jump over

or bridge the detection zone (e.g., fences, trees, storage sheds, etc.).

• Motion - Movement within the detection zone can cause nuisance alarms (trees, brush,

shrubs, weeds, etc.).

The detection zone must not include water, which can cause nuisance alarms when moving

(e.g., puddles, ponds, streams, lakes).

The detection zone must be fenced in to prevent nuisance alarms caused by animals (cats,

dogs, rabbits, deer, livestock, etc.).

The motion of metallic objects (vehicles, buildings, fences, materials, etc.) that are close to the

detection zone can produce nuisance alarms.

• Ground surface - The type of ground surface in the detection zone affects the sensor’s

operation:

Crushed stone is the optimum ground cover. Crushed stone disperses rain and helps to

prevent the formation of puddles. In addition, microwave energy reflects off the rocks,

thereby increasing the zone’s sensitivity.

Paved surface - A paved surface is recommended for detection zones that require snow

removal. Accumulated snow changes the characteristics of the detection zone and can provide

cover for a burrowing intruder.

Other acceptable surfaces for medium and low security applications include closely mowed

grass (7.5 cm {3 in.} or less) and hard-packed dirt or clay.

Site design

Prepare detailed site drawings for the μltraWave system after completing the site survey. Include

dimensions, elevations and the locations of any objects noted during the survey. Once the site

drawings are complete, carefully plot each microwave zone. Zone placement, zone length, and

offsets are critical factors in the design of a microwave sensor system.

Note The Universal Configuration Module includes a tool that calculates

microwave offsets, mounting heights, beam width, and clearance

requirements, based on zone lengths. Use the UCM design tool

when planning an μltrawave zone.

Page 4 µltraWaveProductGuide

Site planning & design

Zone placement

The μltrawave system requires a long, flat, detection zone free of obstacles and depressions. The

minimum distance between the beam centerline and any object (fences, buildings, vehicles, trees,

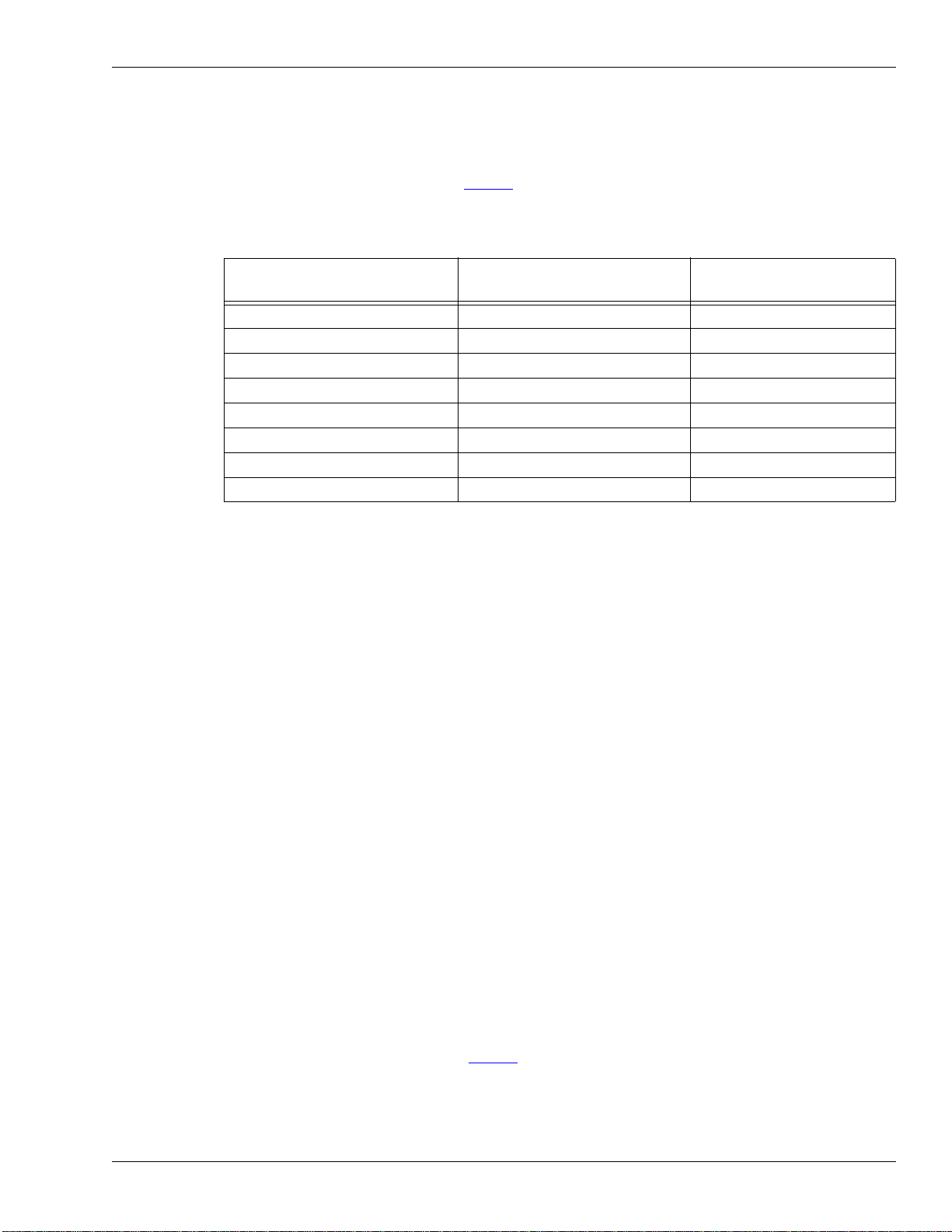

bushes, shrubs, etc.) is outlined in Table 1

. Separation distances are based on typical conditions

and can vary depending on site conditions including zone length, unit mounting height, ground

cover, type of obstacle, etc. The following separation distances are minimum values. Increase the

separation distance between the beam centerline and any objects whenever possible.

transmitter/receiver separation

min. required clearance

(beam centerline to object)

midpoint zone width

30 m (98 ft.) 0.6 m (2 ft.) 1.2 m (4 ft.)

50 m (164 ft.) 1.0 m (3.3 ft.) 2.0 m (6.6 ft.)

75 m (246 ft.) 1.5 m (5 ft.) 3 m (10 ft.)

90 m (295 ft.) 1.8 m (6 ft.) 3.6 m (12 ft.)

100 m (328 ft.) 2.0 m (6.6 ft.) 4.0 m (13.2 ft.)

125 m (410 ft.) 2.5 m (8.2 ft.) 5.0 m (16.4 ft.)

150 m (492 ft.) 3.0 m (10 ft.) 6.0 m (19.7 ft.)

200 m (656 ft.) 4.0 m (13.2 ft.) 8.0 m (26.3 ft.)

Table 1 Unit separation/minimum clearance

You can calculate the required minimum clearance between the beam centerline and an object by

using the following formula:

(transmitter/receiver separation) X 0.02 = (min. distance between beam centerline and object)

The formula can also be used to calculate the maximum separation between the transmitter and

receiver when you know the available clearance between the beam centerline and the nearest

object:

(transmitter/receiver separation) = (min. distance between beam centerline and object) / 0.02

Zone length

The optimum length of each zone depends on several factors:

• the required level of security

• physical constraints (terrain, trees, fences, buildings, etc.)

• available space for the detection zone

For a high security zone, the maximum zone length is 90 m (295 ft.) and the maximum distance

between the transmitter and receiver is 100 m (328 ft.).

For a medium security zone, the maximum zone length is 140 m (459 ft.) and the maximum

distance between the transmitter and receiver is 150 m (492 ft.).

For a low security zone, the maximum zone length is 200 m (656 ft.) and the maximum distance

between the transmitter and receiver is 200 m.

Zone height

The height of the microwave field is approximately equal to the minimum distance between the

beam centerline and an object (see Tab l e 1

) plus the unit mounting height. For applications that

require additional zone height it is possible to stack two or more units on one mounting post.

Stacking μltrawave sensors is described in application note E4DA0109.

µltraWaveProductGuide Page 5

Site planning & design

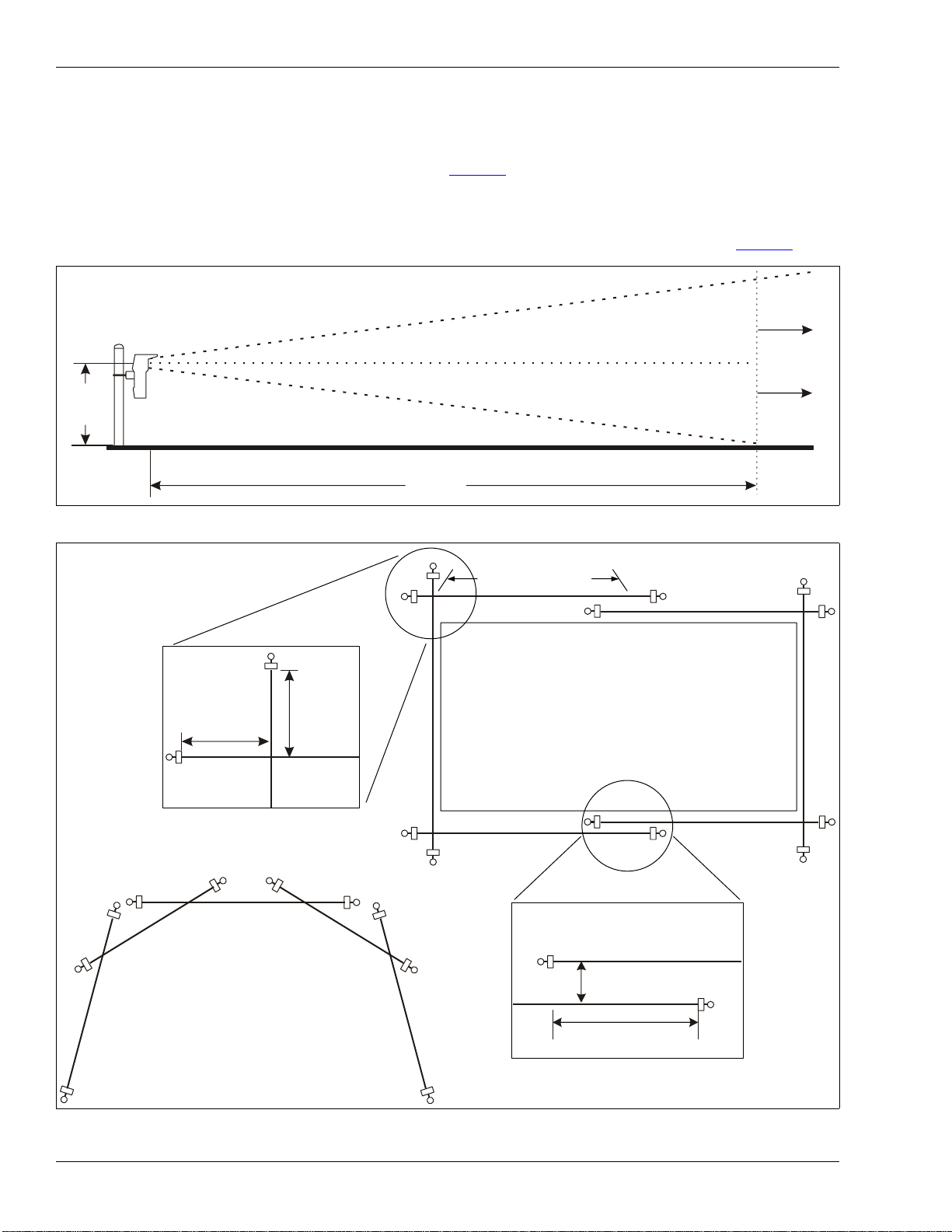

Microwave offsets

The areas immediately above and below the transmitter and receiver antennas are not exposed to

the microwave energy. A microwave offset is used to prevent this unmonitored area from being

vulnerable to undetected intrusions (see Figure 2

). Offsets prevent intruders from crawling under

or jumping over a microwave unit to gain undetected access to the protected area. The offset

distances in the example drawings are based on a 100 m separation between the transmitter and

receiver and a mounting height of 55 cm (21.5 in.) beam centerline to ground. As the mounting

height increases a longer offset is necessary. Different types of offsets are shown in Figure 3

partial coverage

.

55 cm

(21.5 in.)

T

5 m

(16.4 ft.)

partial coverage

T

5 m

(16.4 ft.)

beam

centerline

beam centerline

required offset

5 m

(16.4 ft.)

Figure 2 Offset area

T

detection zone

T

R

protected area

full

coverage

detection

zone

R

T

T

R

R

T

10 m (32.8 ft.)

parallel offset

T

1 m (3.3 ft.)

T

T

corner offset

55 cm (21.5 in.) mounting height

T

R

R

for odd shaped perimeters

T

T

basket weave layout

R

R

R

R

T

T

R

55 cm (21.5 in.) mounting height

Figure 3 Offset arrangement examples

Page 6 µltraWaveProductGuide

Site planning & design

p

Mounting heights

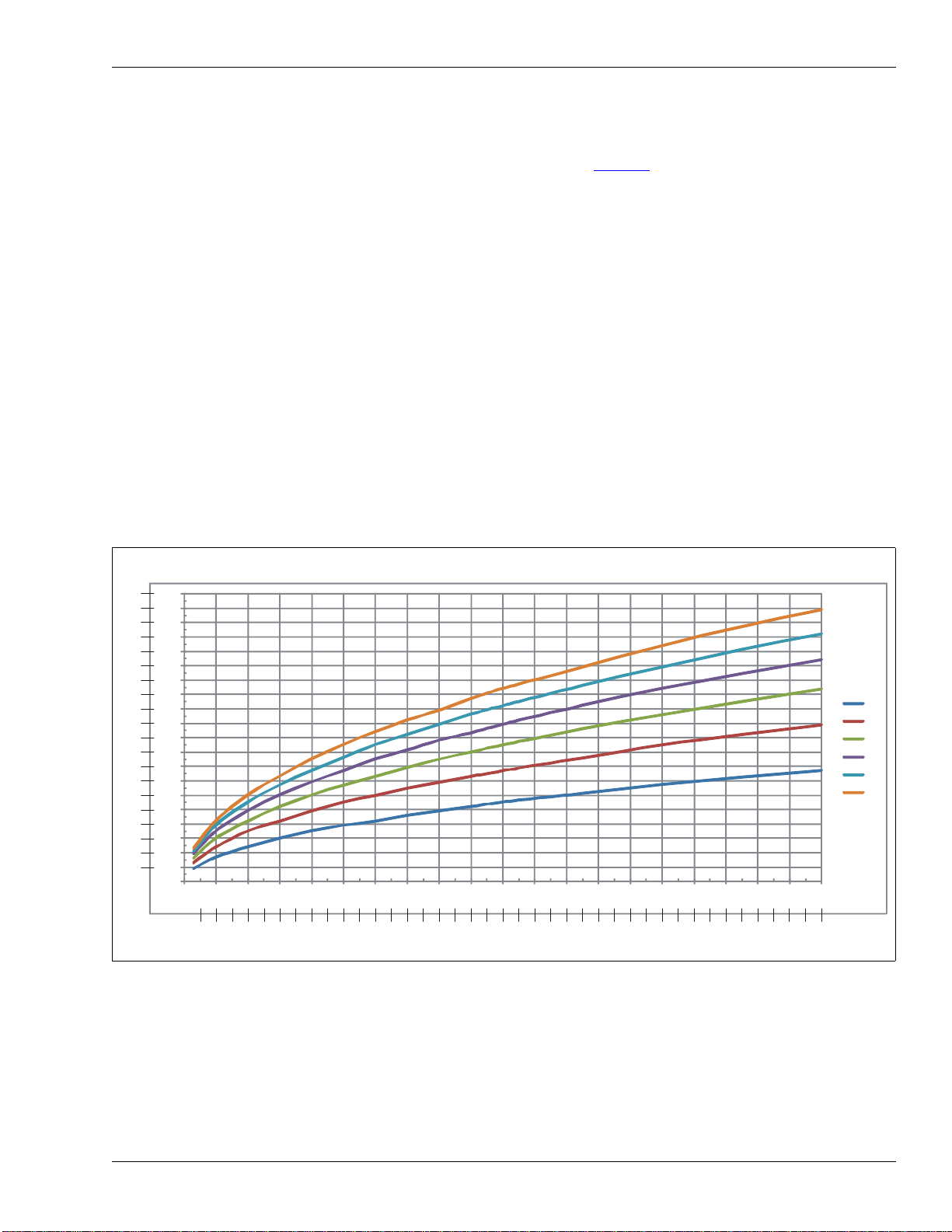

The recommended method for determining the μltraWave unit mounting height is to use the UCM

design tool. However, the mounting height chart (see Figure 4

) can also be used to determine the

optimal mounting height for the transmitter and receiver. The horizontal axis of the chart

represents the separation distance between the transmitter and receiver. The vertical axis

represents the height of the transmitter and receiver from the center of the antenna to the

ground’s surface.

The node curves (N1, N2, N3, N4, N5 and N6) indicate the recommended locations for

coordinating distance (horizontal axis) to mounting height (vertical axis). Coordinate lines that

meet on the node curves provide the highest received signal strength. Avoid the mounting height

and distance coordinates between the node curves. For high security applications, a mounting

height at N1 will provide optimum system operation.

Example:

The distance between the transmitter and receiver is 85 m (279 ft.). Locate this distance on the

height chart's horizontal axis. Plot a vertical line from this distance point across the node curves.

These height measurements represent the best theoretical mounting heights for this example.

They are 50 cm (20 in.) for the N1 curve, 70 cm (28 in.) for the N2 curve, 87 cm (34 in.) for the N3

curve, etc.

mounting height

cminches

200

79

190

75

180

71

170

67

160

63

150

59

140

55

130

51

120

47

110

43

100

39

90

35

80

32

70

28

60

24

50

20

40

16

30

12

8

20

10

4

0

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200

33 66 98 131 164 197 230 263 295

transmitter/receiver se

Figure 4 Mounting height chart

328

361

394

459 492 525 558 591 623 656

427

aration

N6

N5

N4

N3

N2

N1

Node

curves

N1

N2

N3

N4

N5

N6

meters

feet

µltraWaveProductGuide Page 7

Loading...

Loading...