SENSORVISION SpeedDome Ultra Drone, SpeedDome Ultra 8, SpeedDome Ultra Drone III, SpeedDome Optima LT, SpeedDome Ultra Drone II Quick Reference Manual

...

SensorVision® Systems

SpeedDome

Quick Reference Guide

Part of SpeedDome Installation and Service Manual,

8000-0518-01, REV. C.

TABLE OF CONTENTS

Quick Reference Guide: Part I

INDOOR MOUNTS

• Hard Mount Installation.................................................................................................. Q-1

• Hard Mount w/Adj. Bracket Installation..........................................................................Q-2

• 2x2 Tile Mount Installation .............................................................................................Q-4

• Pendant Mount (Standard) Installation ..........................................................................Q-6

• Pendant Mount (I-Beam) Installation..............................................................................Q-7

• Chassis Installation........................................................................................................ Q-8

OUTDOOR MOUNTS

• Over Roof Mount Installation........................................................................................ Q-10

• Wall Mount–Corner Bracket Installation....................................................................... Q-12

• Pole Mount Installation................................................................................................. Q-14

• Ceiling Mount Installation............................................................................................. Q-15

• Housing and Chassis Installation.................................................................................Q-16

INDOOR/OUTDOOR

• Fixed Camera Installation ............................................................................................ Q-18

• Cable Conversions.......................................................................................................Q-19

Quick Reference Guide: Part II

FAULT ISOLATION CHECKLISTS

• Video But No Dome Response / Control ..................................................................... Q-21

• Video / Dome Control But Status Incorrect.................................................................. Q-22

• Loss of Lens Function.................................................................................................. Q-23

• Loss of All Lens Functions ........................................................................................... Q-24

• No Tilt Function ............................................................................................................Q-25

• No Pan Function / Continuous Pan .............................................................................. Q-26

• No Video But All Functions Work .................................................................................Q-27

• Poor Video But All Functions Work .............................................................................. Q-28

• Picture Too Light or Too Dark ...................................................................................... Q-29

• Dome Targeting Incorrect............................................................................................ Q-30

• Dead Dome.................................................................................................................. Q-31

REPLACEMENT PARTS

• Dome CPU Board ........................................................................................................ Q-33

• RS422 Interface Board ................................................................................................ Q-34

• CameralLens Board..................................................................................................... Q-35

• Monochrome Camera.................................................................................................. Q-36

• Color Camera............................................................................................................... Q-37

• Pan, Tilt, Zoom, Iris, and Focus Motors ....................................................................... Q-38

• Clock-Spring Cable ..................................................................................................... Q-39

• Slip-Ring ...................................................................................................................... Q-40

• Power Supply............................................................................................................... Q-41

ADJUSTMENTS

• Back Focus .................................................................................................................. Q-43

• Imager Head Cable ..................................................................................................... Q-44

COMPONENT INTERCONNECTIONS

• Component Interconnections....................................................................................... Q-45

PIN-TO-PIN WIRING

• Pin-to-Pin Wiring .......................................................................................................... Q-46

Sensormatic

SENSORVISION SYSTEMS

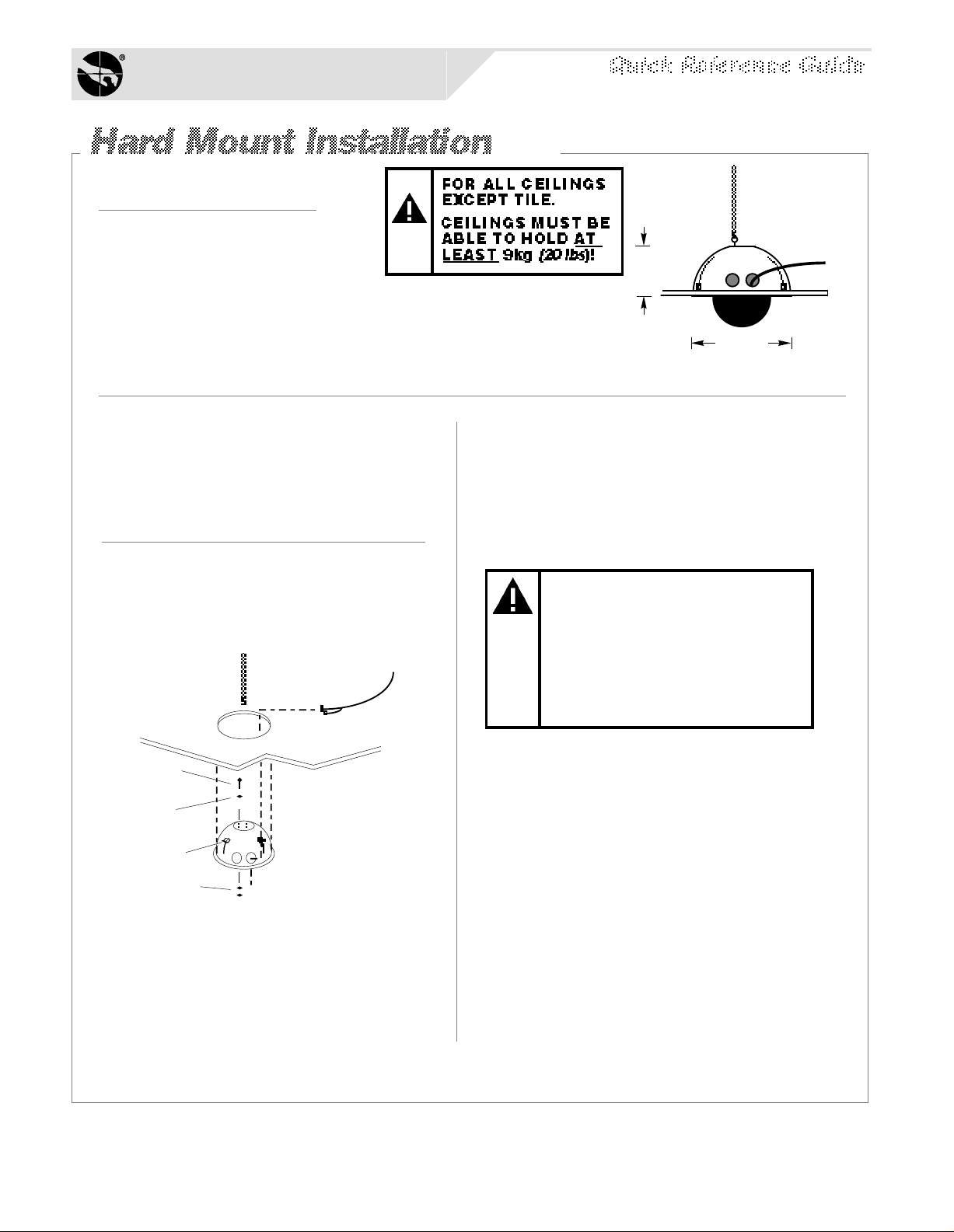

Required Parts

Hard Mount

0351-0393-01

Description Qty. Part No.

"S" hook, open

Chain, Navy link

Eye bolt, 10-24 w/nut

Washer, flat, SS #10

Nut, locking, 10x24

Aluminum tape

2

6

1

2

1

4 FT

2897-0004

2898-0002

2882-0112

2848-8100-17

2838-9154-05

3200-0115-01

20cm

(8")

39.4cm

(15.5")

MAX

3.

Procedure

IMPORTANT: Shipping box contains a

template—do not throw the template out.

1.

Using the template, scribe a 35.6cm

(14")* hole in the ceiling or tile. Cut out

the hole.

[d]

[e]

[b]

[a]

[f]

[c]

2.

Place a washer [a] over the eyebolt

supplied [b]. Insert the eyebolt into a

hole in the top of the housing and

secure using a washer and nut [c].

*U.S. Customary Measurements in italics are rounded off.

Using an S-hook, hang safety chain [d]

from a strong ceiling member and, using

a second S-hook, attach other end of the

chain to the eyebolt. Keep the chain as

taut as possible. Tighten both ends of

each S-hook.

KEEP CHAIN AS TAUT AS

POSSIBLE! CLOSE ENDS

OF EACH S-HOOK!

DO NOT USE SPRINKLER

OR FIRE CONTROL

SYSTEM SECURING THE

SAFETY CHAIN!

4.

Feed video and multiconductor cables [e]

through one of the two holes in the side of

the housing. Then cover all openings in

the housing with the aluminum tape

supplied.

5.

With the three mounting tabs [f] of the

housing in the up position, insert the

housing into the ceiling hole, then from

inside the housing bring the tabs down

and tighten their screws to secure. The

housing is now ready for chassis

installation (page Q-8).

SENSORVISION SpeedDome

Q-1

Sensormatic

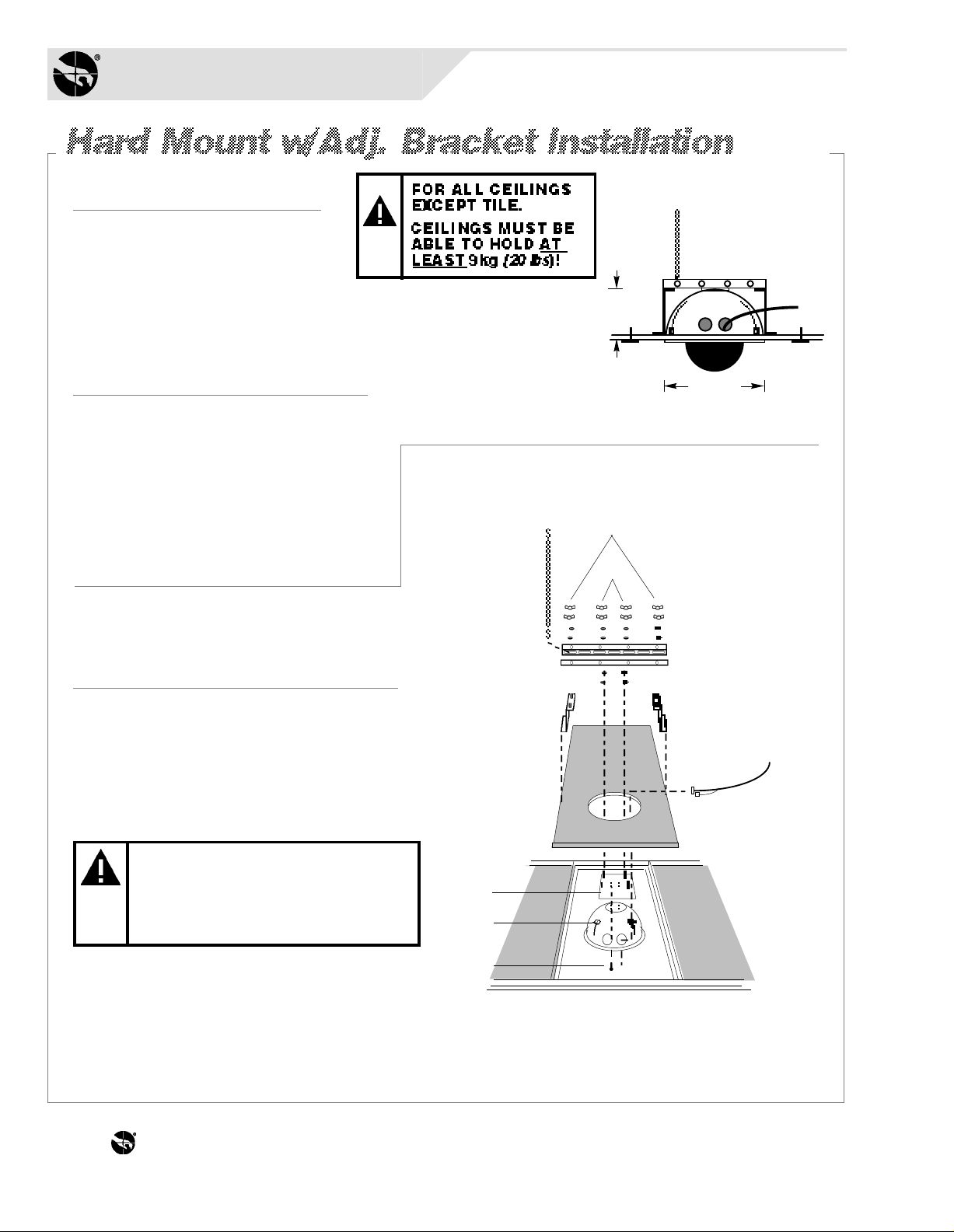

SENSORVISION SYSTEMS

Required Parts

Hard Mount Kit

0351-0393-01

Description Qty. Part No.

"S" hook, open

Chain, Navy link

Eye bolt, 10-24 w/nut

Washer, flat, SS #10

Nut, locking, 10x24

Aluminum tape

2

6

1

2

1

4 FT

Adj. Ceiling Mount Kit

0351-0394-01

Support, L-shape

Support, Z-shape

Washer, flat #10

Nut, wing 10-32

Screw, 10-32x3/4

Spacer, Nylon

Adapter plate

Screw, mach. M6x12

2

2

8

8

2

16

1

4

2897-0004

2898-0002

2882-0112

2848-8100-17

2838-9154-05

3200-0115-01

0500-3439-01

0500-3440-01

2848-6301-23

2834-0007-01

2804-7931-05

3110-0016

0500-3982-01

5801-4074-311

20cm

(7.9")

39.4cm

(15.5")

MAX

[c]

[h]

[i]

Procedure

IMPORTANT: Shipping box contains a

template—do not throw the template out.

1.

Tile ceilings only. Remove the ceiling

tile(s) and inspect the ceiling frame. The

frame must be capable of withstanding 9kg

(20 lbs) of weight and the forces generated

as the dome pans and tilts.

All ceilings. Using the template, scribe a

35.6cm (14") hole in the ceiling or tile. Cut

out the hole.

*U.S. Customary Measurements in italics are rounded off.

*

IF CEILING FRAME

CANNOT SUPPORT DOME,

ASK BUILDING

MAINTENANCE TO INSTALL

ADDITIONAL CEILING

[b]

[f]

[a]

[j]

[e]

[g]

[d]

THE WORLD LEADER IN LOSS PREVENTION Q-2

2.

7.

Place "Z" supports [a] on the ceiling's top

surface. For tile ceilings, make sure the

edge of the supports rests flush with edges

of tile. Refer to diagram on page Q-4.

3.

Place the two "L" supports [b]—cut to

length, if necessary—over the threaded

studs of the "Z" supports and fasten

together using four washers and wing nuts

provided [c].

4.

From inside the housing, insert the four

screws [d] provided through the holes in

the top of the housing and into the

adapter plate [e].

5.

Place enough spacers [f] over each stud

in the adapter plate to compensate for

the thickness of the ceiling.

Bring the three mounting tabs of the

housing down and tighten their screws to

secure. Then secure the plate to the "L"

supports using washers and wing nuts [h].

8.

Using an S-hook, hang safety chain [i]

from a strong ceiling member and, using a

second S-hook, connect the other end of

the chain to one of the "L" supports. Keep

the chain taut. Tighten both ends of each

S-hook.

KEEP CHAIN AS TAUT AS

POSSIBLE! CLOSE ENDS

OF EACH S-HOOK!

DO NOT USE SPRINKLER

OR FIRE CONTROL

SYSTEM SECURING THE

SAFETY CHAIN!

9.

6.

With its three mounting tabs [g] in the up

position, insert the housing into the

ceiling hole until the studs in the plate fit

through the slots in the "L" supports.

Feed video and multiconductor cables [j]

through one of the two holes in the side

of the housing. Then cover all openings

in the housing with the aluminum tape

supplied. The housing is now ready for

chassis installation (page Q-8).

SENSORVISION SpeedDome

Q-3

Sensormatic

SENSORVISION SYSTEMS

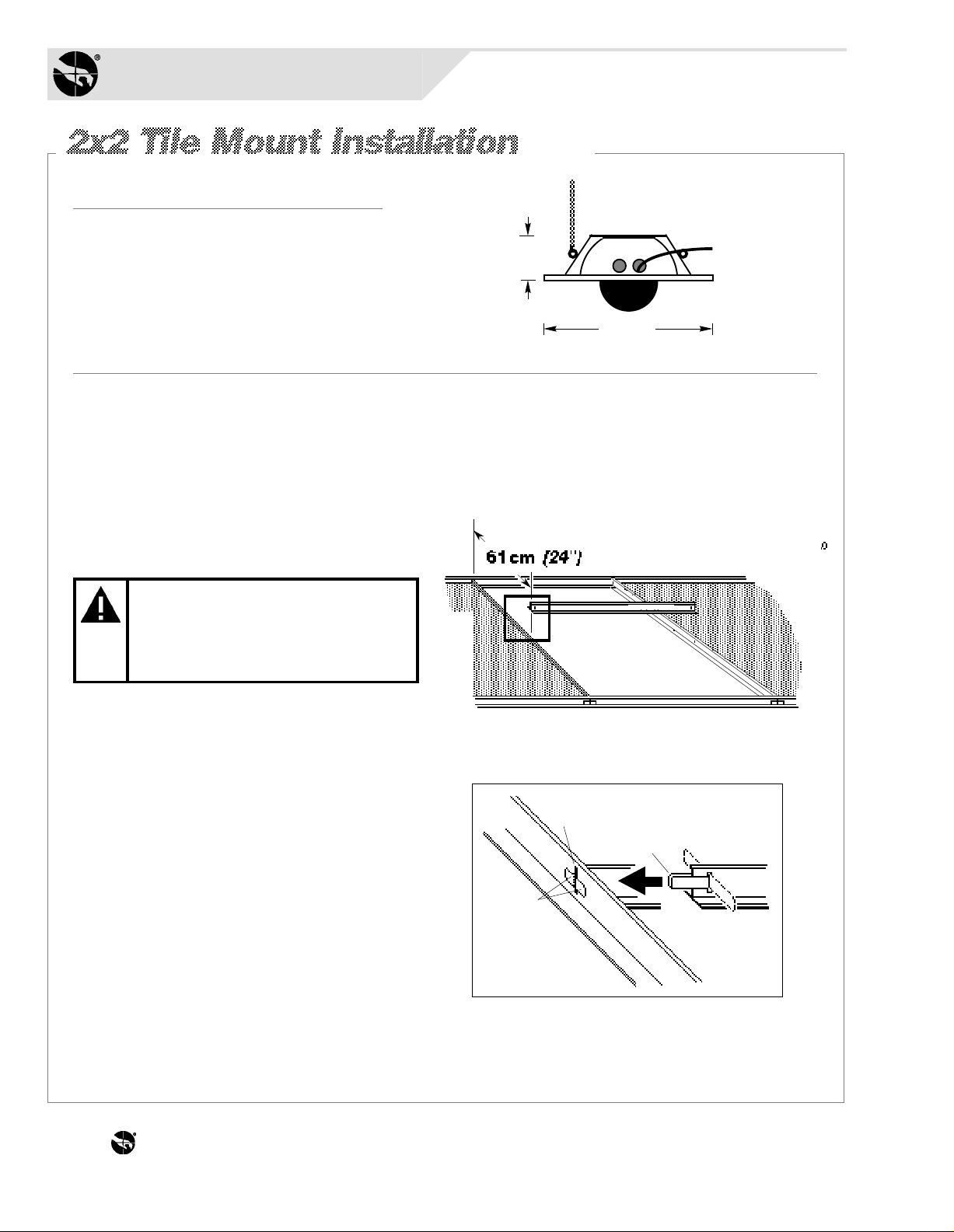

Required Parts

Required Parts

Standard Ceiling Mount

0351-0376-01

Description Qty. Part No.

Bar, ceiling tee

S-hook, open

Chain, Navy link

Tab

Clip, T-bar

1

2

6 FT

2

4

0500-0263-01

2897-0004

2898-0002

0500-0264-04

1400-0033-01

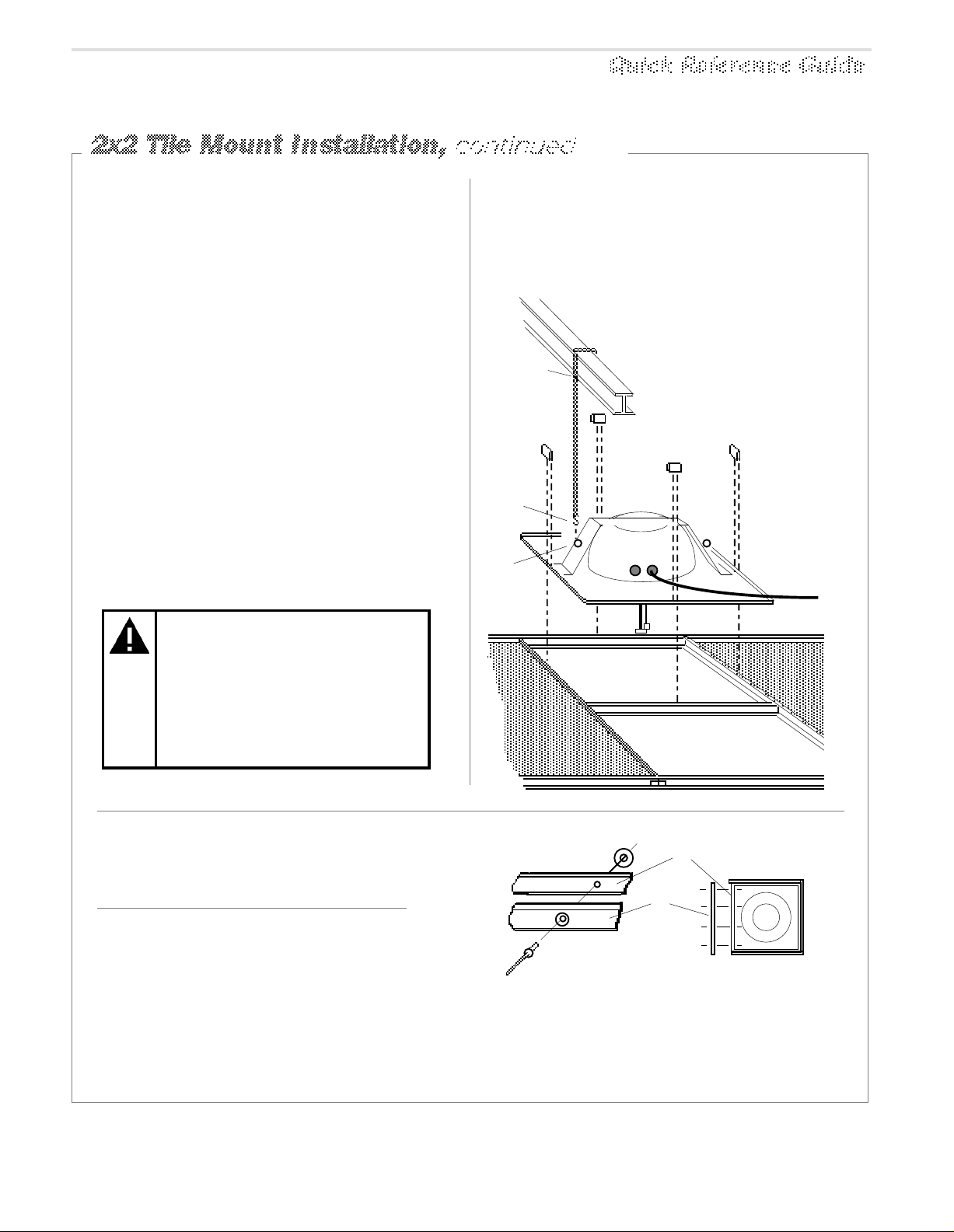

Procedure

1.

Remove the ceiling tile(s) and inspect

the ceiling frame. The frame must be

capable of withstanding 9kg (20 lbs) of

weight and the forces generated as the

dome pans and tilts.

*

19cm

(7.5")

60.7cm

(23.9")

IF CEILING FRAME CANNOT

SUPPORT DOME, ASK

BUILDING MAINTENANCE

TO INSTALL ADDITIONAL

CEILING SUPPORTS.

For 2x2 openings, skip steps 2 and 3.

2.

Cut the 2x4 ceiling tile to 60.3cm (23.75")

using the length of the T-bar supplied [a]

as a guide. Then, attach this T-bar (see

detail) by centering steel tab [b] through

the slot at end of the T-bar. Bend the tab

as shown [c].

3.

Slide the tab through the slot in the

existing frame [d] 61cm (24") from the

T-bar opposite. Bend the ends of the tab

outward [e] to secure. Repeat for the other

end of bar.

[a]

AREA OF DETAIL

[d]

[e]

[c]

[b]

*U.S. Customary Measurements in italics are rounded off.

THE WORLD LEADER IN LOSS PREVENTION Q-4

4.

[f]

[m]

[l]

[k]

[j]

[i]

[h]

[g]

KEEP CHAIN AS TAUT AS

POSSIBLE! CLOSE ENDS

OF EACH S-HOOK!

DO NOT USE SPRINKLER

OR FIRE CONTROL

SYSTEM SECURING THE

SAFETY CHAIN!

Set the housing [f] into the ceiling opening. For slightly larger openings, see box

below. If installing in a 2x2 ceiling, remove

an adjacent ceiling tile to aid installation.

5.

Clamp the housing to the T-bars by snapping a T-bar clip [g] over the raised edge of

the housing and the T-bar. Center this clip

along the edge. Repeat for each side of

housing.

7.

Feed video and multiconductor cables [m]

through one of the two holes in side of the

housing and reinstall the adjacent ceiling

tile. See chassis installation on page Q-8.

6.

Wrap safety chain [h] around a strong

ceiling member [i]; attaching it to itself

using an S- hook [j]. Attach the other end of

the chain to one of two eyelets [k] on the

housing using a second S-hook [l]. Keep

the chain as taut as possible. Close both

ends of each hook.

Add extension bars to the

housing for ceiling openings

slightly larger than 2x2 or 2x4.

[D]

[B]

[A]

Extension Bar

0351-0243-01

Description Qty. Part No.

Bar, extension

Rivet, pop .125x.390

Washer, flat No. 5

Bar, ceiling tee

Tab

Clip, T-bar

4

16

16

1

2

4

0500-3326-01

2873-0004-05

2848-1408-01

0500-0648-01

0500-0264-04

1400-0033-01

side view detail

top view[C]

Extension bars [A] mount to the edge of

the housing [B] to provide a proper fit.

Buttjoint as many bars as required using

pop rivets [C] and washers [D], four per

bar, as shown above. Do not use clips.

SENSORVISION SpeedDome

Q-5

Sensormatic

SENSORVISION SYSTEMS

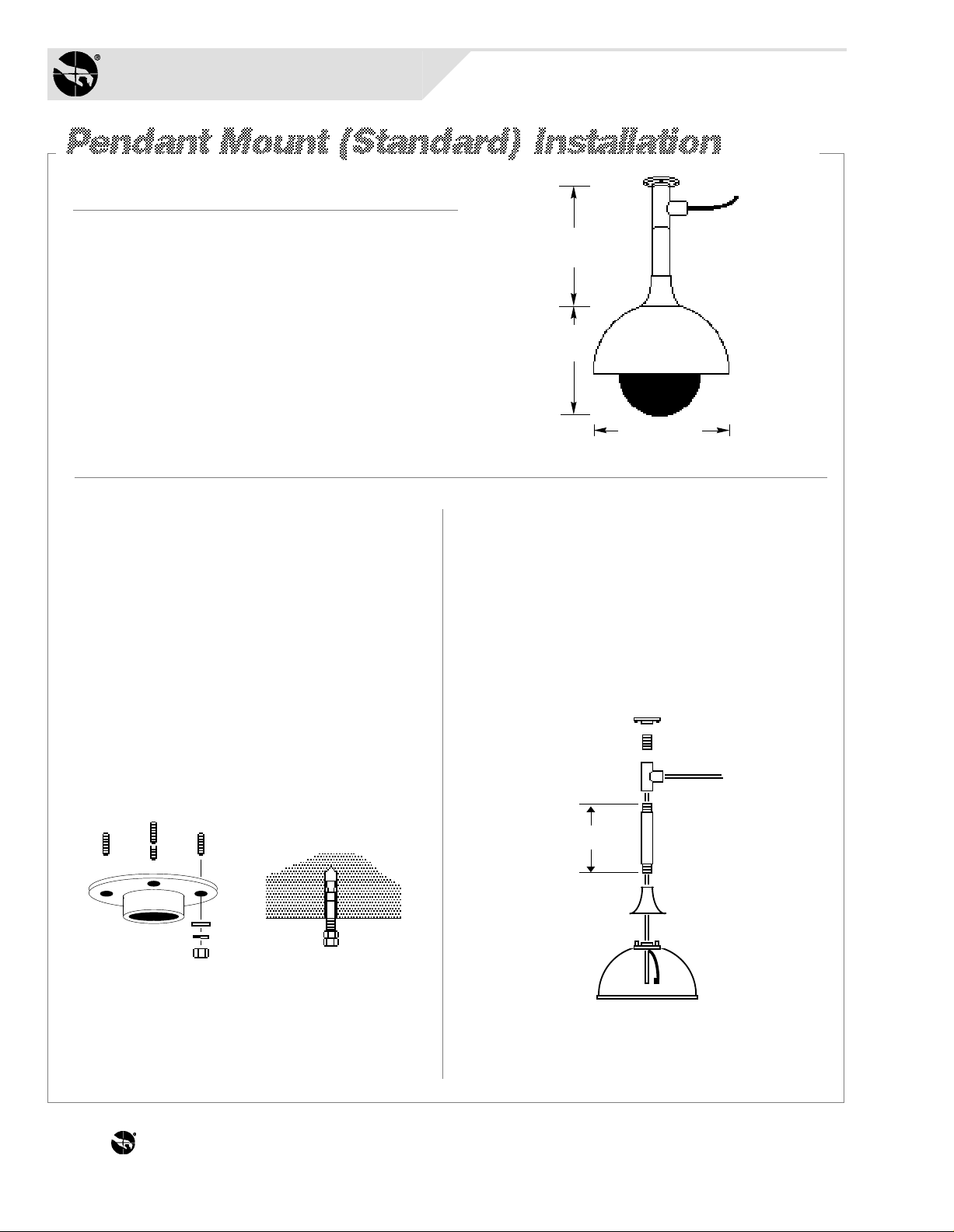

Required PartsRequired Parts

Required Parts

Pendent Mount Kit

0351-0392-01

Description Qty. Part No.

1400-0069-01

Flange, 1-1/4" dia.

Fitting, pipe tee

Nipple, short 1-1/4

Anchor bolt, 1/4x2-1/4

w/hardware

Pipe, 1-1/4", straight, 6m

max, threaded both ends

Cap

1

1

1

4

1

1

1417-0040-01

1417-0041-01

2880-0011

CE supplied

0500-3964-01

Procedure

1.

Using the flange [a] as a template, mark

hole locations on ceiling for four bolts.

Remove the flange and drill four .64cm

*

(1/4") holes to required depth.

For each hole, screw two nuts onto the

anchor bolt provided, with two threads of the

second nut extend- ing over end of the bolt

to protect the bolt threads from damage [b].

Hammer the bolt into ceiling leaving only

its threads exposed. Remove the nuts and

bolt the flange to the ceiling using the flat

washers, lock washers and nuts supplied [c].

6.1M

(20') MAX

30.4cm

(12")

35.6cm (14")

MAX

3.

Feed video and multiconductor cables [h]

through center hole of pipe tee and down

through the pipe. Note: Remove the CinchJones connector, if used, to enter pipe.

Slip the cap [i] onto the pipe, then thread

housing [j] onto the pipe. See chassis

installation on page Q-8.

[g]

[e]

[h]

[f]

[a]

[c]

[b]

2.

Thread the straight pipe [d] (not supplied)

and nipple [e] into pipe tee [f]. Thread the

nipple of the entire assembly into flange [g].

U.S. Customary Measurements in italics are rounded off.

*

THE WORLD LEADER IN LOSS PREVENTION Q-6

6m (20') max

[i]

[d]

[j]

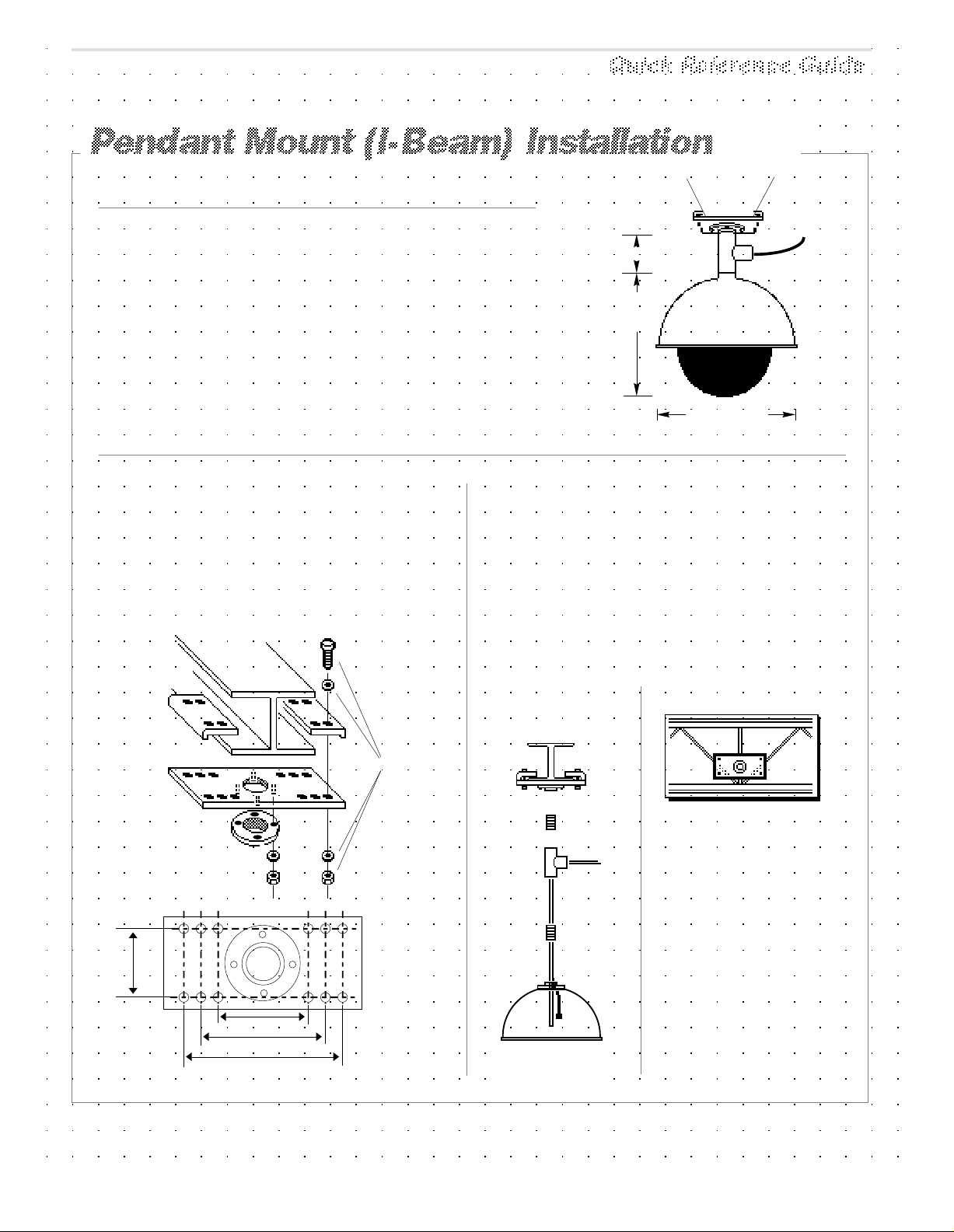

Required Parts

Required PartsRequired Parts

Adjustable I-Beam Clamp Install Kit

0351-0391-01

Description Qty. Part No.

0500-3975-01

12

1

2

4

8

1

1

1

0500-3976-01

5801-4194-311

5840-0500-020

5826-0500-020

1417-0041-01

1417-0040-01

1400-0069-01

Base plate

Clamp plate

Screw, mach. M6x70

Washer, flat

Nut, locking

Fitting, pipe nipple

Fitting, pipe tee

Flange, 1-1/4"

6.1M (20') MAX

30.4cm

(12")

*

35.6cm

(14") MAX

Procedure

I-beam attachment . Set the base plate

[a] against a suitable ceiling member [b].

Secure the plate using clamps [c] and

hardware supplied [d]—see base plate

hole-to-hole dimensions, below. Attach the

flange [e] using hardware supplied [f].

[b]

[c]

[d]

[a]

[e]

Base plate

hole-to-hole

dimensions

[f]

Vertical/Horizontal mounting. Thread

nipples [g] and [h] into the pipe tee [i], and

screw the entire assembly into the base [j].

Next, feed video and multiconductor cables

[k] through center hole of pipe tee. Note:

Remove the Cinch-Jones connector, if used,

to enter pipe.

Finally, thread the housing [l] onto the pipe.

See chassis installation on page Q-8.

Horizontal

Mounting

[j]

[g]

[k]

[i]

Note: If replacing pipe tee

with pipe, cable exiting pipe tee

must be no farther than 15.2cm

(6") from I-beam clamp.

90mm

(3.5")

128mm (5")

179mm (7")

230mm (9")

*

U.S. Customary Measurements in italics are rounded off.

[l]

SENSORVISION SpeedDome

Q-7

Sensormatic

SENSORVISION SYSTEMS

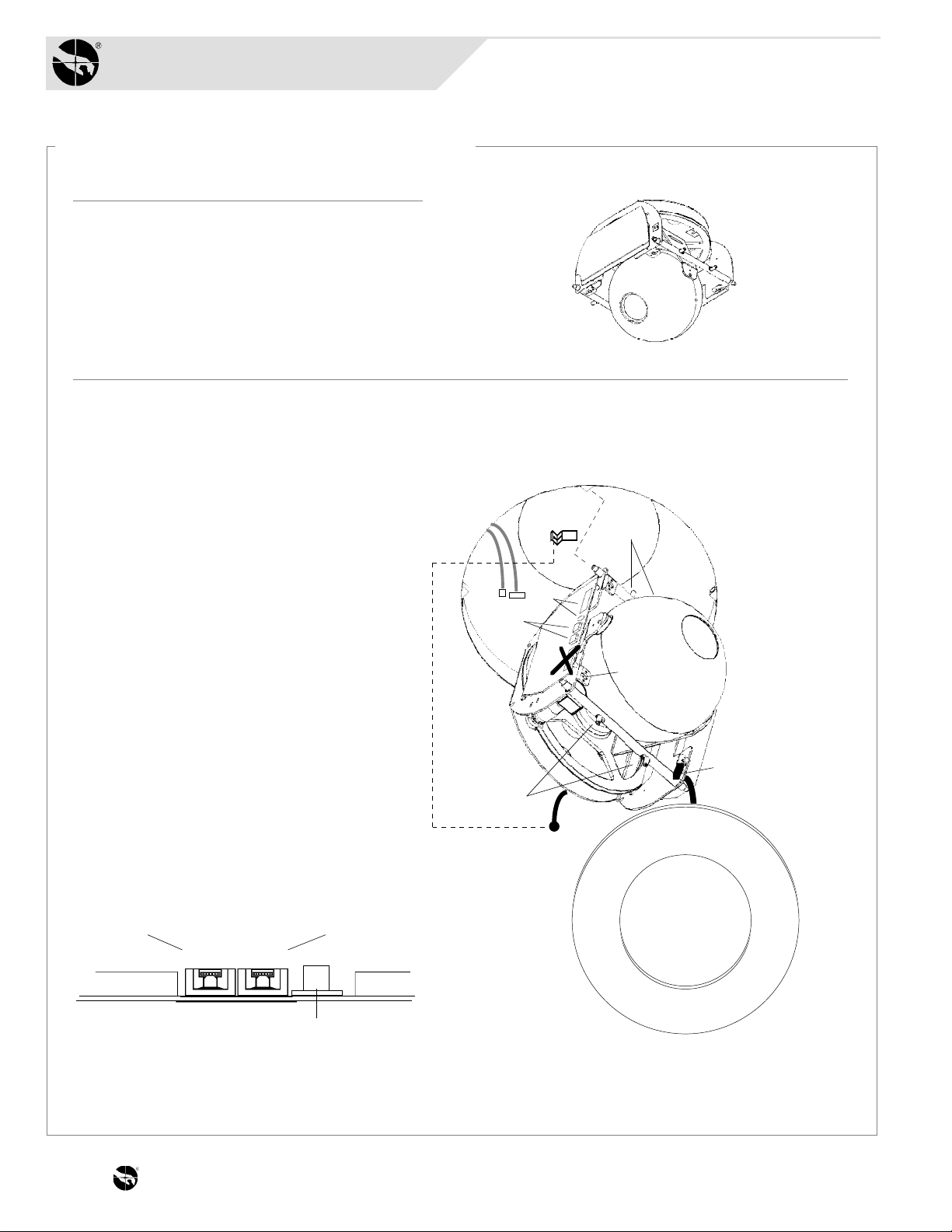

Chassis Installation

Required PartsRequired PartsRequired PartsRequired Parts

SpeedDome Install Kit

0351-0377-01

Description Qty. Part No.

2111-0035-01

Connector, BNC

BNC jack

Nylon Cable Tie

1

1

1

2111-0034-01

6009-0006

Procedure

1.

Snap the ball [a] of the lanyard

hanging from the chassis into the

bracket [b] at the top of the housing.

[b]

[d]

[c]

2.

Squeeze the spring-loaded ejector

pins [c] together to seat the chassis in

the corner receptacles [d]. The PC

board must face the cables exiting

the access holes in the housing.

3.

With the chassis hanging down,

connect the video and multiconductor

cables to their receptacles [e]—refer

to instructions on page Q-19. Do not

use the alarm input connector [f]

unless connecting alarms to domes.

4.

Set the thumbwheel switches [g] to the

appropriate address. Example: for address 16,

Thumbwheel Switches

MSB LSB

P3 P4

1 6

J1

[g]

[j]

[e]

[f]

[a]

[h]

[k]

4 plcs.

[i]

Alarm

Input

AC

Video

THE WORLD LEADER IN LOSS PREVENTION Q-8

and

Data

(continued on page Q-9)

5.

Attach the skirt assembly or optional

bubble assembly [h] to the chassis by

inserting its T-lanyard into a slot [i] on the

chassis until both ends catch securely.

6.

To lock the chassis in the housing,

squeeze ejector pins [j] and swing the

chassis all the way up, while easing the

cables up through the access holes.

Release these pins into the remaining

corner receptacles.

EJECTOR PINS MUST BE

FULLY INSERTED IN

THEIR RECEPTACLES.

7.

Snap the four pins of the skirt (or bubble)

assembly into the four chassis

receptacles [k].

8.

To compensate for accidental jarring

during assembly, recalibrate the dome

as follows:

At the console, call up the

a.

dome address number.

Press and hold the FAST key.

b.

Then—in order—press and

hold the ZOOM OUT,

FOCUS FAR, and IRIS OPEN

keys.

When the dome begins to pan

and tilt, release the keys.

Once calibrated, which takes about

a minute, the dome is ready for use.

Installation is complete.

SENSORVISION SpeedDome

Q-9

Sensormatic

SENSORVISION SYSTEMS

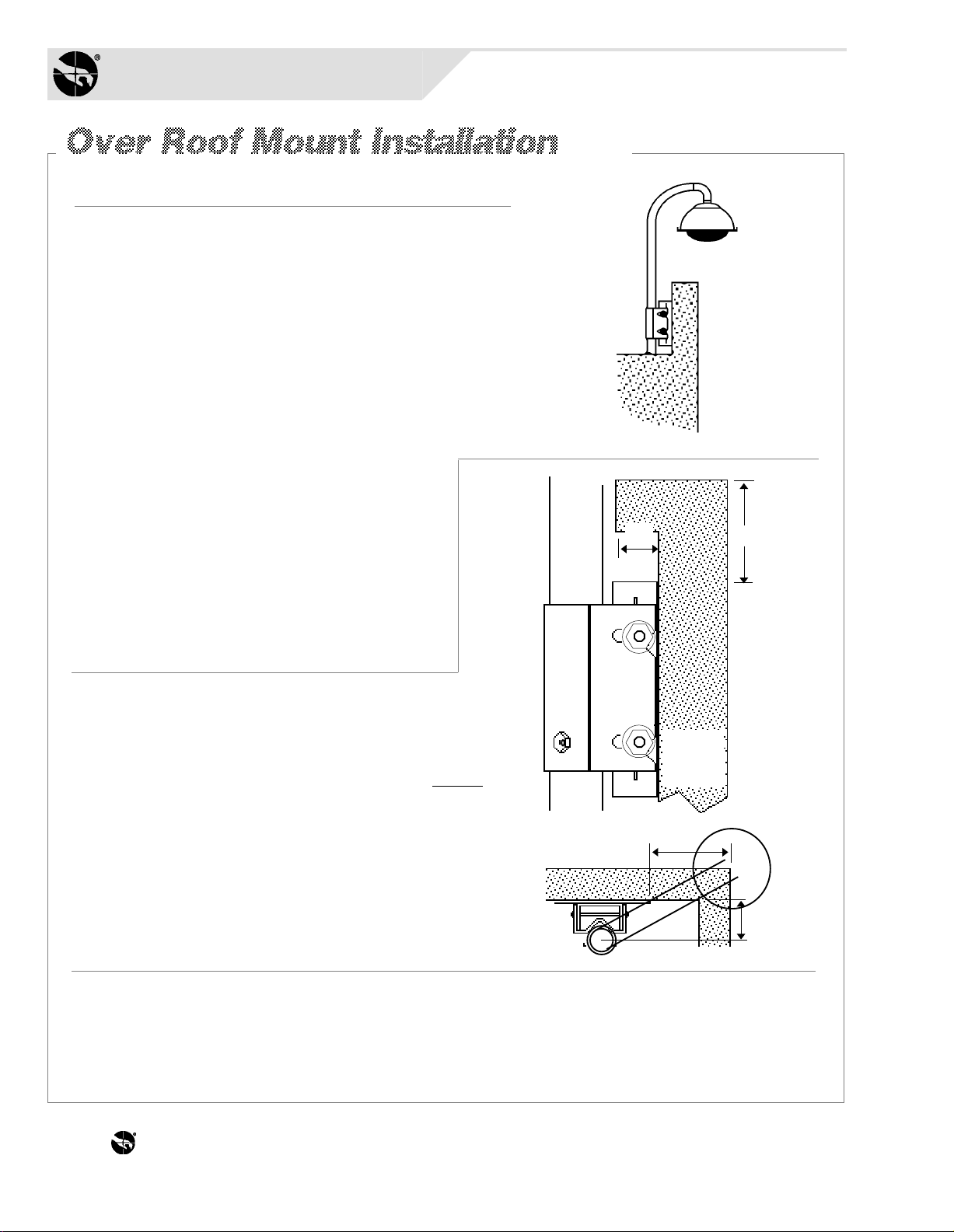

Required Parts

Over Roof Install Kit

0351-0279-01

Description Qty. Part No.

Fitting, 90° pipe

Anchor bolt, 1/2x5 1/2"

Anchor, hollow wall, w/ P

Bolt, hex 1/2-13x4"

Washer, lock1/2"

Cable tie, Nylon, 7.5"

Rod, thread 1/2-13x18"

Nut, Hex 1/2-13"

Washer, flat, SS, P, .531ID X 1.25OD

Washer, flat, ST, Z, .812ID X 2.0OD

RTV compound

Pipe sealant

Washer, flat 5/16"

Nut, hex 5/16-18"

Bolt, hex 3/8-16x3/4"

Adaptor, BNC, male to female

Nut, hex, 1.5" pipe w/seal

1

4

3

1

4

10

1

2

2

1

1

1

8

8

2

1

1

0500-3499-01

2880-0049

2880-0074-01

2880-8917-01

2847-0300

6009-0005

0500-2734-01

2838-9117-04

2848-8101-11

2848-1409-16

1600-0001

1600-0095-01

2848-6301-02

2838-9116-01

2880-0082-01

2113-0004

1417-0042-01

[b]

25cm (10")

Other Parts/Assys

Plate, mounting

Bracket, mounting

Base wall/pole mount

Arm, mounting outdoor

Cover, base (optional)

1

1

1

1

1

0500-3637-01

0500-3638-01

0500-3463-01

0200-0173-01

0500-3668-01

Procedure

Mounting to a solid wall: Mount bracket assembly

[a] to a solid wall or poured concrete cap, where possible.

Mounting to a parapet: Mounting to the inside of

a parapet is preferred. Typically, for the bubble to

clear, mount the base within:

25cm (10") of the top of the parapet.

•

A parapet with a 5cm (2") lip is shown [b].

13cm (5") from the corner of the building [c].

•

Mounting area (including clearance):

Minimum 33cm (13") x 48cm (19").

Note: If the above requirements cannot be

met, mount the dome to the outside of the

wall (a decorative cover can be purchased to

enhance the look of the base). Alternately,

*

(continued on page Q-11)

a 10-inch extender can be screwed into the

end of the pipe, but tell the customer that

increased vibration from wind gusts may

result.

5cm (2")

(top view)

[a]

[c]

(side view)

13cm (5")

Max

8cm (3")

Max

*

U.S. Customary Measurements in italics are rounded off.

THE WORLD LEADER IN LOSS PREVENTION Q-10

Place plate [a] in desired location, level, and mark slots. Plate

MUST BE LEVEL. Remove template, then drill four 1/2-inch

holes to the required depth for

type of wall and hardware used.

TOP

[e][d][c]

[a]

For each hole into solid concrete, screw two nuts

[b] onto an anchor bolt, with two threads of second

nut extending over end of bolt to protect threads.

Hammer bolt into wall leaving 1-1/4 inch exposed.

Remove nuts and attach a 1/2-inch flat washer [c],

lock washer [d] and nut [e]. If voids are

encountered, see NOTE below.

Slip slots of mounting plate [f] over bolts,

togglers, or rods [g] and secure using proper

hardware. Mount base [h] to the plate using

hardware provided—any set of four studs can be

used. Feed cables through bottom of bracket [i].

Slip smooth-end of pipe [j] over cable and into

bracket. Secure pipe by tightening screw [k] and

level by adjusting nuts [l]. If using a decorative

cover [m], slide it over pipe.

Apply pipe sealant to pipe threads [n], then slip

elbow [o] over cable and screw elbow onto pipe.

Once on, elbow opening should face down.

Note: Approximately 36cm (14") of cable must

exit elbow. The mount is now ready for housing

and chassis installation on page Q-16.

[m]

Cover

(optional)

[j]

[i]

[k]

[n]

[f]

[l]

[b]

[o]

36cm (14")

[g]

[a]

NOTE: Voids encountered while drilling...

One void only: Insert toggler (provided) through

hole where void ocurred. Insert associated bolt.

A

B

INSERT

metal

channel

thru hole.

PULL

plastic

tab to

seat

channel

C

D

SLIDE

plastic

cap along

tab until

seated

on wall.

SNAP off

plastic

legs at

cap by

pushing

outward.

Two or more voids: For each void, drill hole

through wall. Then, insert threaded rod (provided)

through hole and attach hardware shown. Purchase

additional rods/hardware as required.

MOUNTING BRACKET

GOES HERE

Lock

Washer

Nut

1/2 inch

Flat Washer

SENSORVISION SpeedDome

1/2 inch

Flat Washer

Nut

3/4 inch

Flat Washer

Q-11

Sensormatic

SENSORVISION SYSTEMS

Required Parts

Wall Mount Install Kit

0351-0283-01

Description Qty. Part No.

Washer, flat ST, Z, .344IDX.875OD

Nut, hex Nylon-LK CAD 5/16-18

Anchor, wedge, bolt, 1/4 X 2.2

Pipe sealant

Plug, 1-7/8 x 1"

RTV compound

Adaptor, BNC, male to female

Nut, hex, 1.5" pipe with seal

Other Parts/Assys

Pipe, 12 in. long

Base, wall/pole

Support, wall/pole

Fitting, 90° pipe

Corner Bracket Mount only:

Corner Brkt, mounting (optional)

4

4

4

1

1

1

1

1

1

1

1

1

1

2848-6301-02

2838-9116-01

2880-0011

1600-0095-01

0649-0685-01

1600-0001

2113-0004

1417-0042-01

0500-3465-01

0500-3463-01

0500-3464-01

0500-3499-01

0500-3636-01

WALL

MOUNT

(side view)

OPTIONAL

CORNER

BRACKET

MOUNT

(top view)

Procedure

Place wall-mount base [a] or corner bracket

[b] in desired location, level, and mark

mounting holes [c].

Drill four 1/4-inch holes to the required

depth. For each hole:

Screw two nuts onto anchor bolt, with two

•

threads of second nut extending over end

of bolt to protect threads [d].

Hammer bolt into wall leaving 1-1/4

•

inch of bolt exposed. Then, remove

nuts.

Slip base shown or corner bracket over bolts

and secure using hardware [e]. Secure base to

studs of corner bracket, if used. Then loosely

thread a washer and nut [f] onto the four

threaded studs of the base [g].

(continued on page Q-13)

[a]

[c]

(front view) (front view)

(side view)

[b]

[d]

[f]

[e]

[g]

(top view)

THE WORLD LEADER IN LOSS PREVENTION Q-12

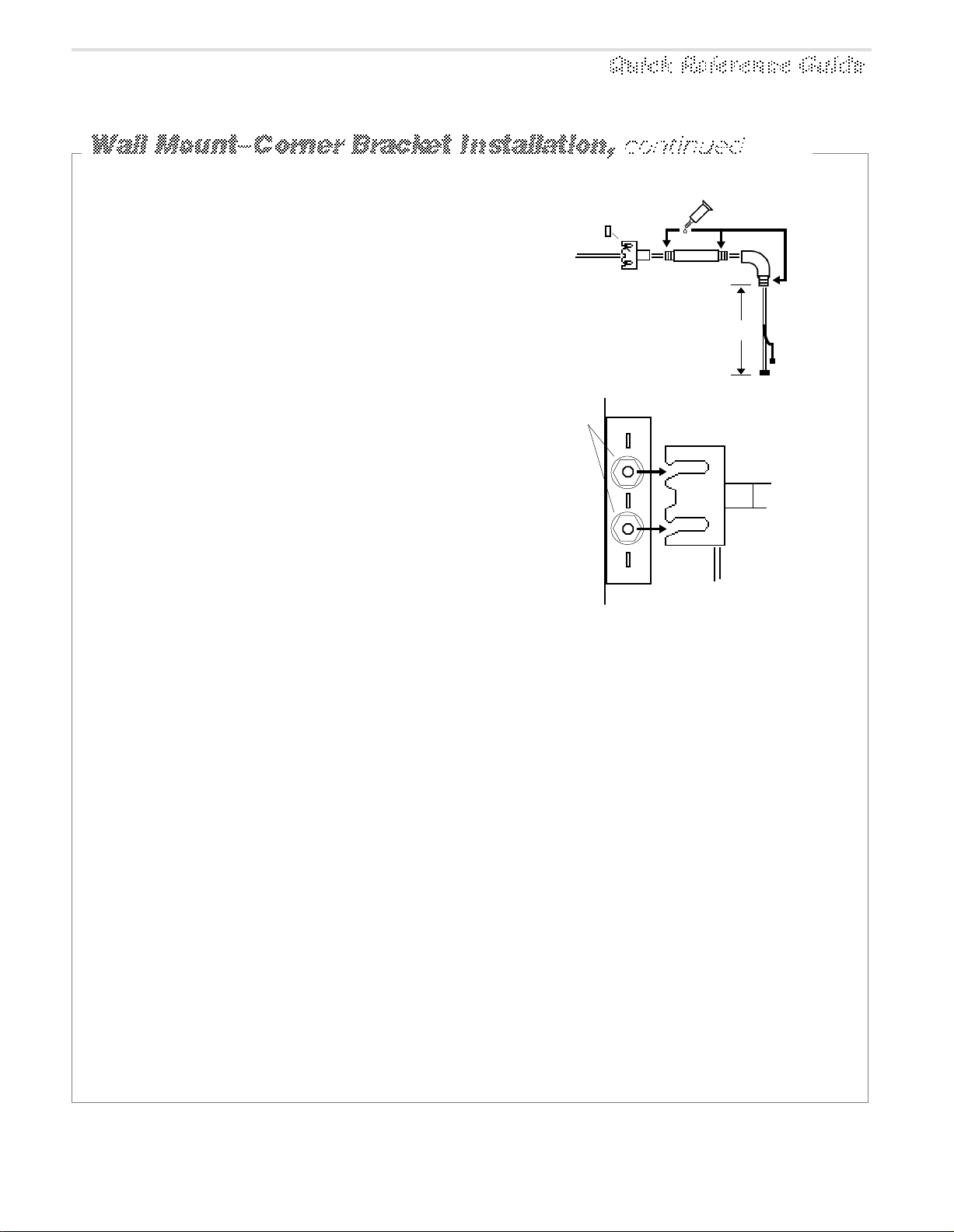

Feed camera dome cables [h] through

mounting bracket (i).

Apply sealant [j] to threads of straight

pipe [k], then slip pipe over cable and

screw pipe into bracket.

Slip elbow [l] over cable and screw elbow

onto pipe. Once on, elbow opening should

face down. Note: Approximately 36cm (14")

of cable must exit elbow. If so, insert plug [m]

and seal with RTV.

[m]

[h]

[i]

*

[j]

[l]

[k]

36cm (14")

Hook bracket [n] on threaded stud between

washer and base [o] while feeding excess

cable [p] back through hole in bracket. Level,

and tighten nuts [q] on both sides of base to

secure.

The mount is now ready for housing and

chassis installation. See page Q-16.

*

U.S. Customary Measurements in italics are rounded off.

[q]

[o]

[n]

[p]

SENSORVISION SpeedDome

Q-13

Sensormatic

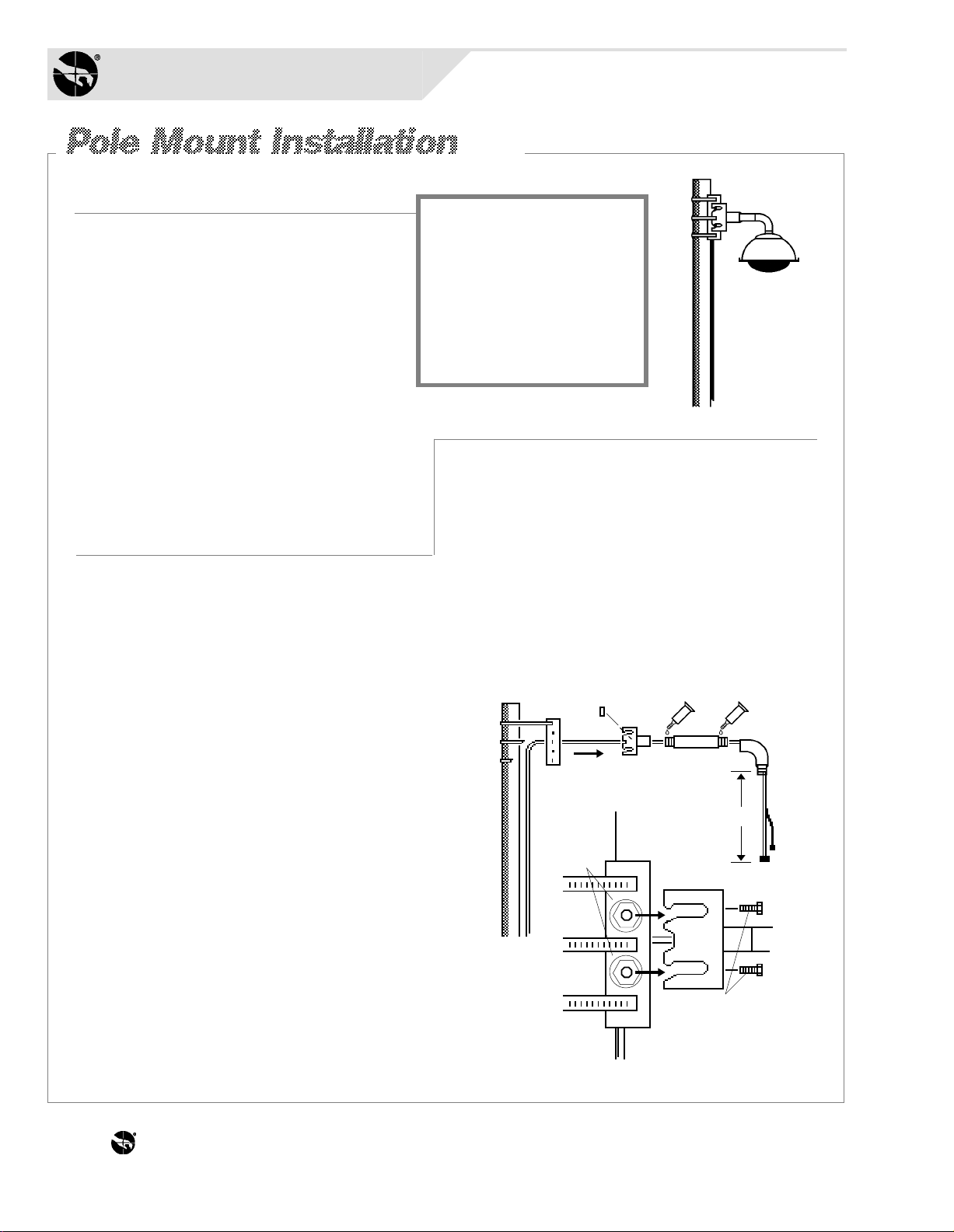

SENSORVISION SYSTEMS

Required Parts

Pole Install Kit

0351-0282-01

Description Qty. Part No.

2848-6301-02

Washer, flat 5/16"

Nut, hex 5/16-18

Screw, M, HXHD, SS, 1/4 - 20 X 1"

RTV compound

Pipe sealant

Plug, 1-7/8 dia. 1" thick

Adaptor, BNC, jack to plug

Nut, hex 1.5" pipe w/seal

Other Parts/Assys

Pipe, 12 in. Long

Base, Wall/Pole

Support, Wall/Pole

Clamp package (see note)

Fitting, 90° pipe

4

4

2

1

1

1

1

1

1

1

1

2

1

2838-9116-01

2802-8401-72

1600-0001

1600-0095-01

0649-0685-01

2113-0004

1417-0042-01

0500-3465-01

0500-3463-01

0500-3464-01

6010-0043-01

0500-3499-01

Note: Two clamp

packages are provided:

one for the dome, one for

the J-box. Straps in each

package are sufficient

for 10cm (4") to 30.5cm

(12") wide poles. For

larger widths, order an

additional package.

Loosely thread washer and nut [i] onto the

four threaded studs of base [j]. Next, insert

two 1/4-20 leveling screws [k] into bracket

[l]. Then, hook bracket on threaded stud

between washer and base while feeding

excess cable [m] back through hole in base.

Procedure

Procedure

Feed camera dome cables [a] through the

large hole in mounting base [b].

Following the directions on back of the

clamp package (see NOTE above), strap

the mounting base securely to the pole [c].

Feed cables exiting base through the hole

in the mounting bracket [d].

Apply sealant [e] to threads of straight pipe [f],

then slip pipe over cable and screw into

bracket.

Slip elbow [g] over cable and screw elbow

onto pipe. Once on, elbow opening should

face down. Note: Approximately 36cm (14")

of cable must exit elbow. If so, insert plug [h]

into bracket and seal with RTV.

*

U.S. Customary Measurements in italics are rounded off.

Use leveling screws to level. Tighten nuts

on both sides of base to secure. The mount

is now ready for housing and chassis

installation. See page Q-16.

[c]

[b]

[h]

[d]

[e]

[f]

[a]

36cm (14")

[i]

[j]

*

[l]

[k]

[m]

[g]

THE WORLD LEADER IN LOSS PREVENTION Q-14

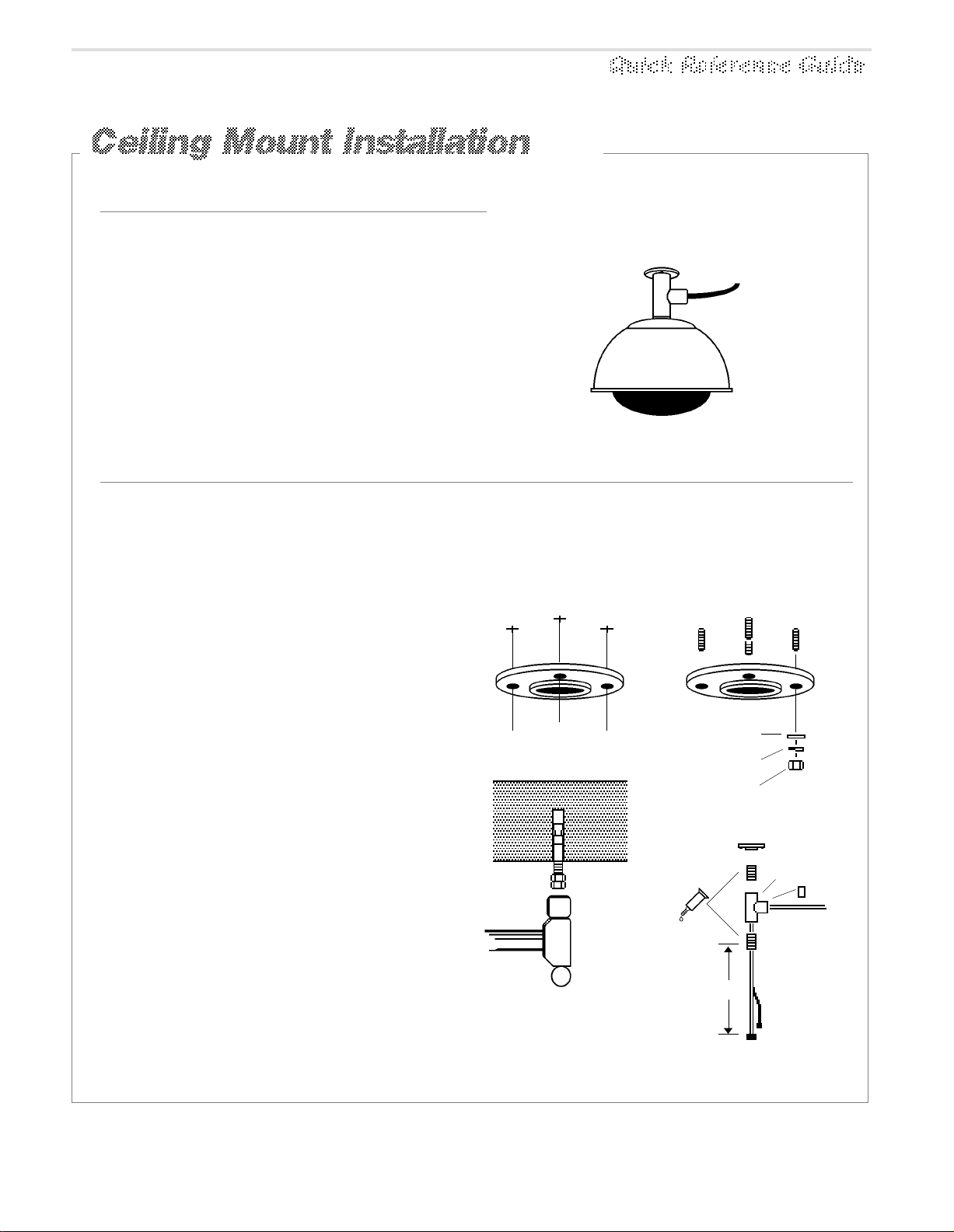

Required Parts

Ceiling Mount Install Kit

0200-0163-01

Description Qty. Part No.

Flange

Fitting, pipe tee

Nipple, short 1-1/2x 2

Anchor bolt, 1/4x2-1/4

w/hardware

Pipe sealant

Plug, 1-7/8 dia., 1" thick

RTV compound

Label, blank, paper, thermal

Adaptor, BNC, male to female

Nut, hex, 1.5" pipe w/seal

1

1

2

4

1

1

1

1

1

1

1400-0058-01

1417-0036-01

1417-0037-01

2880-0011

1600-0095-01

0649-0685-01

1600-0001

2450-0008-01

2113-0004

1417-0042-01

Procedure

Place the mounting flange [a] on the

ceiling in the desired location. Then, using

the flange as a template, mark locations for

four bolt holes. Remove the flange.

Drill four 1/4-inch holes to the required

depth. For each hole, screw two nuts

onto an anchor bolt, with two threads of

second nut extending over end of bolt to

protect threads [b].

Hammer the bolt into the ceiling leaving

1-1/4 inch of bolt exposed. Remove nuts.

Bolt the mounting flange to the ceiling

using a 1/2-inch flat washer [c], lock

washer [d], and nut [e].

Apply pipe sealant to nipples [f], then

screw nipples into the pipe tee [g].

Screw the entire assembly into the flange

[h]. Then, feed the camera dome cables [i]

through the center hole of the pipe tee.

Note: Approximately 36cm (14") of cable

*

must exit the nipple. If so, insert plug [j]

and seal with RTV.

The mount is now ready for housing and

chassis installation. See page Q-16.

[a]

[c]

[d]

[e]

[h]

[b]

[f]

36cm (14")

[g]

[j]

[i]

U.S. Customary Measurements in italics are rounded

*

SENSORVISION SpeedDome

Q-15

Sensormatic

SENSORVISION SYSTEMS

1

[a]

Using tamper-proof tool

(T-20), remove captive

bubble attachment screws [a]

from housing, then remove

bubble [b].

[b]

[e]

2

[c]

[d]

[f]

[g]

[h]

Screw 1.5" hex nut [c], with its white (or

yellow) seal facing the cap [d], onto the

pipe. Next, apply pipe sealant [e] to

threads of elbow (or nipple, if this is a

ceiling mount). Then feed the composite cable (f) through the SpeedDome

cap [d] and through the housing [g].

Thread the dome housing onto the

elbow (or nipple), compressing the cap

against the housing until tight. Level as

shown [h]. Apply RTV around the hex

nut.

[j]

3

FEMALE

COMPRESSION-TYPE

CONNECTOR

PN 2109-0254-06

Existing composite cable

from J-Box

Referring to the chart below, replace

the Cinch-Jones connector [i] with

female compression connector [j]

(located at P4 on the SpeedDome

chassis).

Female Compression-Type

Connector

PIN CONNECTIONS

1

brown

2

yellow

3

black

4

red

5

white

6

green

7

orange

7

DESCRIPTIONPI

data out (Lo)

data out (Hi)

ac

Gnd.

ac

data in (Lo)

data in (Hi)

1

[i]

4

[k]

Next, connect the composite cable

compression connector [k] to J2, and the video

connector to J1, on the Outdoor Interface

Board [l], mounted on the outside of the

bracket. Make sure when connecting to this

board, that the screws of the compression

connector are turned toward the inner black

assembly. Tie wrap the composite cable to the

bracket assembly to make way for chassis

installation.

THE WORLD LEADER IN LOSS PREVENTION Q-16

[l]

5

[m]

[n]

Snap the ball of

the lanyard [m]

in- to the

bracket [n] at

the top of the

housing.

(continued on page Q-17)

6

Squeeze the spring-loaded ejector pins [n] together to

seat the chassis in the corner receptacles [o]. The

RS422 board [p] must face the SpeedDome interface

board cables [q] inside the housing.

7

Set the thumbwheel switches [r] to the appropriate

address. Example: for address 16,

MSB LSB

P3 P4

1 6

J1

To connect alarm to

an outdoor SpeedDome, add lightning

protection using a

dataline protector,

PN 4815-0021-01.

Alarm

Input

AC and

DataVideo

8

Then, with the camera chassis hanging down,

connect the video and data SpeedDome Interface

Board cables [q] to their receptacles [s]. Do not

use the alarm input connector [t].

9

To lock the chassis in the housing, squeeze ejector

pins [u] and swing the chassis all the way up, while

easing the cables into place. Release these pins

into the remaining corner receptacles.

ENSURE EJECTOR PINS ARE FULLY

INSERTED IN THE RECEPTACLES.

10

Snap the four pins of the skirt assembly [v] into the four

chassis receptacles [w]. Then screw the attachment screws

of the bubble [x] into the three housing receptacles [y].

11

To compensate for accidental jarring during assembly,

recalibrate the dome as follows:

At the console, call up the dome address

a.

number.

Press and hold the fast key. Then—in order—press

b.

and hold the zoom out, focus far, and iris open keys.

[n]

[w]

[o]

[q]

[y]

[p]

[t]

[r]

[s]

[u]

[v]

[x]

When the dome begins to pan and tilt, release the keys.

Once calibrated, which takes about a minute, the dome

is ready for use.

DOME INSTALLATION IS COMPLETE.

SENSORVISION SpeedDome

Q-17

Sensormatic

SENSORVISION SYSTEMS

Required Parts

Parts/Assys

Description Qty. Part No.

0400-0529-01

Chassis, Fixed/Drone

Shroud, Fixed

Bubble Kit, Smoked, 9-Inch

Clamp Kit, Adjust. I-Beam

2x2 Indoor Housing

Pendant Indoor Housing

Hard Mount Indoor Housing

1

1

1

1

1

1

1

0500-4218-01

0351-0386-03

0351-0391-01

0200-0176-01

0200-0177-01

0200-0178-01

Procedure

1.

Snap the ball of the lanyard [a] into the

bracket at the top of the housing. Then flex

the chassis [b] to insert its mounting studs

into the four corner mounts of the dome

housing to be used: Hard Mount (page Q-1),

2x2 (page Q-4), or I-Beam (page Q-7).

2.

Attach the fixed camera [c] to the swivel

mount. If necessary, move bracket [d] to

turn the camera horizontally (it is not

necessary to loosen the wing nut [e]).

Note: Cover the camera’s LED “on”

indicator with electrical tape.

3.

Using a video test cable and portable monitor,

adjust the camera’s focus and iris using

information provided with the camera. Then,

connect camera video to the console room.

[a]

[e]

[b]

[d]

Swivel Mount

[c]

LED Indicator

[g]

4.

With the studs of the bubble [f] aligned with

the holes in the chassis, nest the shroud [g]

in the bubble and turn its viewing slot so that

the camera lens can see out. Then fasten the

shroud and bubble assembly to the chassis

by placing its studs against the chassis

holes and pressing firmly on the bubble.

THE WORLD LEADER IN LOSS PREVENTION Q-18

[f]

Adapting a Composite Cable

for SpeedDome

Replace Cinch-Jones with

female compression-type

connector (supplied with

dome).

FEMALE COMPRESSION-TYPECONNECTOR

PN 2109-0254-06

Existing composite cable

from J-Box

1

7

Female Compression-Type Connector

PIN CONNECTIONS

DESCRIPTIONPI

1

2

3

4

5

6

7

brown

yellow

black

red

white

green

orange

data out (Lo)

data out (Hi)

ac

Gnd.

ac

data in (Lo)

data in (Hi)

WARNING:

Disconnect cable from

power source when

performing cable

conversions.

...or add Patch

PATCH CABLE

PN 0650-0657-01

Extending a

SpeedDome Cable

Add to a length of bulk

composite cable, male and

female compression-type

connectors and male and female

BNCs from SpeedDome Cable

Conversion Kit, 0351-0403-01.

MALE COMPRESSION-TYPECONNECTOR

PN 2109-0271-07

Existing SpeedDome

cable from J-Box

Adapting a SpeedDome

Cable for a Mini-Dome, etc.

Replace female compressiontype connector with

Cinch-Jones connector.

Existing SpeedDome

1

FEMALE BNC

CONNECTOR

PN 2111-0034-01

6

8

(front view)

cable from J-Box

Male and Female

Compression-Type Connectors

PIN CONNECTIONS

DESCRIPTIONPI

1

brown

2

yellow

3

black

4

red

5

white

6

green

7

orange

7

FEMALE

CINCH-JONES

PN 2107-0005-01

12

34

5

7

data out (Lo)

data out (Hi)

ac

Gnd.

ac

data in (Lo)

data in (Hi)

PI

1

2

3

4

5

6

7

8

FEMALE COMPRESSION-TYPECONNECTOR

1

PN 2109-0254-06

7

MALE BNC

CONNECTOR

PN 2111-0033-01

Female Cinch-Jones

PIN CONNECTIONS

DESCRIPTION

orange

green

black

red

white

drain

brown

yellow

data in (Hi)

data in (Lo)

ac

Gnd.

ac

N.C.

data out (Lo)

data out (Hi)

To SpeedDome

SENSORVISION SpeedDome

Q-19

THE WORLD LEADER IN LOSS PREVENTION Q-20

4.0

4.0

Service

Service

Fault Isolation Checklists, Replacement Parts, Adjustments, and Component

Interconnections in this section:

• Fault Isolation Checklists ..................................................................... Q-21

Video But No Dome Response / Control................................... Q-21

Video / Dome Control But Status Incorrect ............................... Q-22

Loss of Lens Function ............................................................... Q-23

Loss of All Lens Functions ........................................................ Q-24

No Tilt Function ......................................................................... Q-25

No Pan Function / Continuous Pan ........................................... Q-26

No Video But All Functions Work .............................................. Q-27

Poor Video But All Functions Work ........................................... Q-28

Picture Too Light or Too Dark ................................................... Q-29

Dome Targeting Incorrect......................................................... Q-30

Dead Dome............................................................................... Q-31

• Replacement Parts...............................................................................Q-33

Dome CPU Board...................................................................... Q-33

RS422 Interface Board.............................................................. Q-34

Camera/Lens Board.................................................................. Q-35

Monochrome Camera ............................................................... Q-36

Color Camera............................................................................ Q-37

Pan, Tilt, Zoom, Iris, and Focus Motors..................................... Q-38

Clock-Spring Cable...................................................................Q-39

Slip-Ring.................................................................................... Q-40

Power Supply ............................................................................ Q-41

• Adjustments......................................................................................... Q-43

Back Focus ............................................................................... Q-43

Imager Head Cable Reinsertion................................................ Q-44

• Component Interconnections............................................................... Q-45

• Pin-to-Pin Wiring ..................................................................................Q-46

SENSORVISION SpeedDome 4-1

4-2 THE WORLD LEADER IN LOSS PREVENTION

Sensormatic

SENSORVISION SYSTEMS

Video But No Dome Response / Control

What to check. What to do.

1.

Dome status.

2.

Data at J-Box.

Check the dome # in question for the correct

dome type and condition. If the dome # is

incorrect, reset the dome.

For a new installation, check data wiring at P4

on the RS422 board on the dome.

Use a data tester to test the data line out of

the J-Box. Ensure that the LED status

indicators show good data at each data port. If

an LED indicates bad data, check the data path

back to the control box for improper wiring.

3.

Inside dome.

a. boards and cables.

b. address.

4.

Data into dome.

Make a visual inspection of the inside of the

dome. Ensure that the power and data cables

are properly connected and the boards are

properly seated.

Ensure that the dome is correctly addressed.

Use a data tester to test the data at pins 6

(data Lo) and 7 (data Hi). If data is not present

going into the dome, check the data path back

to the J-Box for improper wiring.

If data is present, replace the RS422 interface

board. If that does not solve the problem,

replace the CPU board. If replacing both

boards does not solve the problem, unplug the

slip-ring connector at JP4 from the CPU board

to ensure that the eyeball connection is not

loading down the system. If this does not solve

the problem, replace the chassis.

NOTE: Testing a chassis at a known working

location will isolate a bad chassis or a bad

connector/cable/J-Box. If a working dome fails

in the bad dome location, the problem is with

the connector/cable/J-Box.

5.

Pan, tilt.

See Q-25 and Q-26.

SENSORVISION SpeedDome

Q-21

Sensormatic

SENSORVISION SYSTEMS

Video / Dome Control But Status Incorrect

What to check. What to do.

1.

Dome status.

2.

Data at J-Box.

Check the dome # in question for the correct

dome type and condition. If the dome # is

incorrect, reset the dome.

Disconnect all domes from the J-Box except

the problem dome. Use a data tester to test

the data line out of the J-Box. Ensure that the

LED status indicator shows good data. If the

data tester indicates bad data, check the

wiring path back to the control box for

improper connections.

3.

Data from dome to J-Box.

Use a data tester to test the data at pins 1

(data Lo) and 2 (data Hi) of P4 on the RS422

interface board. If data is not present, replace

the board.

If that does not solve the problem, replace the

CPU board. If replacing both boards does not

solve the problem, unplug the slip-ring

connector at JP4 from the CPU board to

ensure that the eyeball connection is not

loading down the system. If this does not solve

the problem, replace the chassis.

NOTE: Testing a chassis at a known working

location will isolate a bad chassis or a bad

connector/cable/J-Box. If a working dome fails

in the bad dome location, the problem is with

the connector/cable/J-Box.

THE WORLD LEADER IN LOSS PREVENTION Q-22

Loss of Lens Function

What to check. What to do.

1.

Connection to camera/lens board.

Verify that the failed operation is isolated to

the suspect dome.

Ensure that the clock spring ribbon cable is

properly connected to the camera/lens board

plug J5.

If the dome does not zoom, focus, iris, or tilt,

replace the camera/lens board with a known

working camera/lens board. Retest.

If some but not all motors are working, replace

the motor in question with a known working

motor. If this solves the problem, replace the

motor.

NOTE: Only zoom/focus/iris motors are

interchangeable.

If the lens functions do not have a full range of

motion, then re-align the motor(s).

2.

RS422 interface board.

3.

Voltage on camera/lens board.

4.

Camera focus.

On the S1 switch pack of the RS422 interface

board, switch position 3 to ON.

If the lens rotation is not smooth with voltage

applied and the lens motor disabled, then

replace the camera lens.

If the dome does not have power, check the

input voltage to the RS422 board. Also check

the DC voltage coming from the dome power

supply to the CPU board. If 12Vdc and 5Vdc are

not present out of the dome power supply,

replace it. If 12Vdc and 5Vdc are present out of

the dome power supply, replace the

camera/lens board.

If the camera does not focus properly while

zooming in and out, adjust the back focus. See

page Q-43.

SENSORVISION SpeedDome

Q-23

Sensormatic

SENSORVISION SYSTEMS

Loss of All Lens Functions

What to check. What to do.

1.

Dome switches.

2.

Camera/lens board.

3.

Sprockets.

Ensure that the position of SW3 on S1 of the

RS422 interface board is set to OFF for

enabling lens functions.

Ensure that all connectors to and from the

camera/lens board are properly seated. If

that does not solve the problem, replace the

camera/lens board.

Check to see if the sprockets are hung up and

adjust them accordingly. If the motor gears

are too tight, adjust the gaps of the sprockets

and gears with a 1/4 watt resistor lead. See

page Q-37.

THE WORLD LEADER IN LOSS PREVENTION Q-24

No Tilt Function

What to check. What to do.

1.

Connection to P1.

2.

Sprocket.

3.

Tilt motor when the tilt function is

commanded.

4.

Data when the tilt function is

commanded.

Reset the dome and observe the orientation

(tilt). Verify that the motor is connected to P1

on the camera/lens board.

Check to see if the sprocket moves freely and

adjust it accordingly. If the motor gear is too

tight, adjust the gap distance of the sprocket

and gear with a 1/4 watt resistor lead. See

page Q-38.

Plug a known working tilt motor into P1. If the

motor works with the tilt command, replace

the tilt motor. If the tilt motor does not work,

replace the camera/lens board.

If no data is present, check the data path for

improper wiring.

NOTE: Tilt motors are not interchangeable

with other motors.

SENSORVISION SpeedDome

Q-25

Sensormatic

SENSORVISION SYSTEMS

No Pan Function / Continuous Pan

What to check. What to do.

1.

Connection to P3.

2.

Sprocket.

3.

Pan motor when the pan function

is commanded.

Reset the dome and observe the orientation

(pan). Verify that the motor is connected to

P3 on the CPU board.

Check to see if the sprocket moves freely and

adjust it accordingly. If the motor gear is too

tight, adjust the gap distance with a 1/4 watt

resistor lead. Ensure that it rotates smoothly

without power applied to the dome.

Plug a known working pan motor into P3. If

the motor works with the pan command,

replace the pan motor. If the pan motor does

not work, replace the dome CPU board.

4.

Data when the pan function is

commanded.

5.

Slip-ring assembly.

If no data is present, check the data path for

improper wiring.

If the camera continuously pans when the

stop or reset command is issued, replace the

slip-ring assembly.

NOTE: Pan motors are not interchangeable

with other motors.

THE WORLD LEADER IN LOSS PREVENTION Q-26

No Video But All Functions Work

What to check. What to do.

1.

Iris adjustment from controller.

2.

RS422 board.

3.

Clock spring ribbon cable.

4.

Voltages/zoom, focus, and iris

functions.

Open the iris and verify that video is present.

Check for the presence of video out of the

RS422 board. If video is coming out of the

RS422 board, check the J-Box, composite/

video cable and monitors for the problem.

If video is not coming from the RS422 board,

check for visual damage to the ribbon cables

and verify that the iris is operating.

Ensure that the clock spring ribbon cable is

correctly connected to the camera lens

board.

If voltages are not present and/or the zoom,

focus, and iris functions are not working,

replace the camera/lens board.

If replacing the camera/lens board does not

solve the problem, replace the camera.

SENSORVISION SpeedDome

Q-27

Sensormatic

SENSORVISION SYSTEMS

Poor Video But All Functions Work

What to check. What to do.

1.2.Video, gray "Humbar."

Monitor

Video, no sync.

If the monitor is a dedicated (full time)

monitor, remove the looping video and set the

termination switch to 75 ohms.

If that does not correct the problem, isolate

the ground lug on the monitor power cord

using a 2-cond extension cord. DO NOT cut or

damage the line cord. If isolation of the

ground lug corrects the problem, order and

install a ground loop transformer (isolation

transformer).

If the video coming in directly from the dome

is poor, set the switches on the RS422

interface board to LL, SW5 on S1.

If the video coming in directly from the dome

is good, but the customer monitor video is

poor, check monitor, cabling, and connectors

for improper connections.

NOTE: Keep at least 1.5m (5') from high

voltage lines, flourescent lights, neon lights,

etc. when installing video and data cables. If

you must cross a 110Vac line, do so at right

Monitor

THE WORLD LEADER IN LOSS PREVENTION Q-28

angles to the cable.

NOTE: Use a quality coaxial cable (Beldon

8241 or equivalent).

Picture Too Light or Too Dark

What to check. What to do.

1.

Iris adjustment at controller.

2.

S1 switch pack.

3.

Iris control.

4.

Video cable.

Open or close the iris at the controller to suit

or reset the iris to auto function by holding

the iris open and close buttons at the same

time.

Ensure that the settings of the S1 switch

pack on the RS422 board are 3 and 4 (off).

Verify that the iris control is working properly.

If the motor sprocket is jammed, make the

appropriate adjustments to the sprocket. See

page Q-38.

Plug the focus motor into the iris motor jack.

If the camera focuses when you use the iris

control, replace the iris motor. If the camera

does not focus when you use the iris control,

replace the camera/lens board.

If the video cable has been spliced too many

times, it could adversley effect the video

signal.

The dome looses approximately 3db of video

signal for each splice.

5.

Terminations.

The maximum allowable distance for video

cable between a dome and monitor is 305m

(1000').

Ensure that the video lines are properly

terminated.

SENSORVISION SpeedDome

Q-29

Sensormatic

SENSORVISION SYSTEMS

Dome Targeting Incorrect

What to check. What to do.

1. Check the service history of the dome to see

Dome service history.

if it has been replaced recently. Re-download

the software from the console to the dome.

The dome may have been put back into the

housing in reverse. Also check to see if the

dome is shifting in the ceiling. If it is shifting,

install the necessary clips. If it is a pendant

mount, you may need to secure it with wires

to keep it from swinging or swaying.

THE WORLD LEADER IN LOSS PREVENTION Q-30

Dead Dome

What to check. What to do.

1.

Composite cable at J-Box.

2.

Voltage on RS422 interface board.

3.

Voltage on CPU board.

Make a visual inspection of the J-Box to

ensure that the composite cable is connected

properly. Unplug the cable and wait 45 sec.

Plug the cable back in and test dome

operation.

Check the voltage (22Vac min.) at pins 3 and

5 of P4 on the RS422 interface board. If

voltage is not present, check the J-Box for

improper wiring and the dome power supply.

If that does not solve the problem, check

voltage (22Vac min.) at pins 1 and 3 of P5 on

the RS422 interface board. If voltage is not

present, replace the board.

Check pins 2 and 3 of P2 on the CPU board for

12Vdc and pins 1 and 2 for 5Vdc. If voltage is

not present, replace the fuse on the dome

power supply. If that does not solve the

problem, replace the dome power supply

assembly.

If that does not solve the problem, disconnect

JP4 from the CPU board. Check the dome for

pan control. If it does not have pan control,

replace the CPU board.

4.

Camera/lens board.

Disconnect J5 on the camera/lens board.

Check the dome for pan control. If it does not

have pan control, replace the clock spring

assembly and/or the slip-ring assembly.

If that does not solve the problem, replace

the camera/lens board. If that does not solve

the problem, replace the chassis.

SENSORVISION SpeedDome

Q-31

THE WORLD LEADER IN LOSS PREVENTION Q-32

WARNING: Unexpected pan

and tilt can cause injury or

damage the dome during

servicing. To prevent such

movement, always disconnect

power/data connector P4 from

the RS422 interface board

1.

[a]

[e]

[d]

JP4

Remove the RS422

interface board (page

Q-34). Then remove the

CPU board by first

disconnecting

the slip ring [a], pan

motor [b], and power

supply cables [c], then

removing two M3x10

screws

[d] and two standoffs [e].

[d]

[e]

2.

Secure the new board using the

screws and standoffs. Then

connect the following three cables:

• Slip ring cable to JP4,

• Pan motor cable to P3,

• Power supply cable to P2.

DOME CPU BOARD REPLACEMENT IS COMPLETE.

Dome CPU Board

0301-0478-01

[c]

P2

[b]

P3

3.

Reinstall the RS422 interface board

(go to page Q-34).

SENSORVISION SpeedDome

Q-33

Sensormatic

SENSORVISION SYSTEMS

WARNING: Unexpected pan

and tilt can cause injury or

damage the dome during

servicing. To prevent such

movement, always disconnect

power/data connector P4 from

the RS422 interface board

1.

Disconnect all cables from the RS422

interface board.

2.

On the new board, set S1 DIP switches to

the same settings (if different) as the

board to be replaced.

P2

S1

P5

P1

Note: S1 factory settings are listed on

a label affixed to the chassis.

3.

Disconnect this board from the dome

CPU board by removing its two M3x10

mounting screws [a].

Note: If removing the RS422

interface board in order to

replace the dome CPU board,

go to page Q-33, then return to

this page and complete step 4.

4.

Noting its orientation, plug in the new

board and reinstall the two mounting screws.

Then reconnect cables in the following order:

• Video cable to J1,

• AC power out cable to P5,

• External sync, if used, to P1,

• Alarm out cable, if used, to P2,

• Alarm in cable, if used, to P3, and last

• AC power/data cable to P4 (see WARNING).

Dome CPU Board

P4P3 J1

[a]

WARNING: Connecting the AC

power/data cable will cause the

dome to immediately pan and

tilt.

THE WORLD LEADER IN LOSS PREVENTION Q-34

5.

Reassemble the SpeedDome chassis

and recalibrate.

WARNING: Unexpected pan

and tilt can cause injury or

damage the dome during

servicing. To prevent such

movement, always disconnect

power/data connector P4 from

the RS422 interface board

1.

Remove the lens and camera shrouds (four

screws each). Then disconnect all six cables

from the old camera/lens board [a]. Next, remove

the three M3x10 screws [b]from the board and

the M3x10 screw and nut [c]connecting the

voltage regulator to the eyeball casting.

2.

To avoid pulling the voltage regulator out of

the board, first secure the new board to the

eyeball casting using three screws [b]. Then

reattach the regulator to the eyeball casting

using the M3x10 screw and nut. Finally,

reconnect the following six cables (dressing

them as shown):

• Tilt motor cable to P1.

• Zoom motor cable to J2.

• Focus motor cable to J3.

• Iris motor cable to J4.

• Camera cable to P6.

• Clock spring cable to J5.

Reassemble the lens and camera shrouds

using the eight screws. CAMERA/LENS

BOARD REPLACEMENT IS COMPLETE.

[b]

Screw connecting

regulator to

eyeball casting

[c]

J5

[b]

[c]

J3

[b]

Camera/Lens Board

0301-0204-01

J2

P6

[a]

J4

Iris Ring

Zoom Ring

Focus Ring

P1

3.

Reassemble the SpeedDome chassis and

recalibrate.

SENSORVISION SpeedDome

Q-35

Sensormatic

SENSORVISION SYSTEMS

WARNING: Unexpected pan

and tilt can cause injury or

damage the dome during

servicing. To prevent such

movement, always disconnect

power/data connector P4 from

the RS422 interface board

WARNING: The camera is

sensitive to ESD. Use a ground

strap when installing.

1.

Remove the lens and camera shrouds (four

screws each). Then remove two M3x8 screws

[a] from the back of the camera [b] and

unplug its connector from P6 on the

camera/lens board [c].

2.

Lift the camera off the back of the lens and

replace it with a new one. Reinstall the two

screws and reconnect its cable to P6 on the

camera/lens board.

3.

Restore power by plugging connector P4 into the

dome. The dome will return to its home position.

4.

Check backfocus by zooming in on a distant

object and focusing as clearly as possible, then

zooming out. If the picture is out of focus, see Back

Focus Adjustment, page Q-43. If OK, continue.

P6

[a]

[c]

Monochrome

Camera

1/2" CCD EIA, 60Hz

2003-0026-01

1/2" CCD CCIR, 50Hz

2003-0026-02

[b]

Iris Ring

Zoom Ring

5.

Reassemble the lens and camera shrouds using

the eight screws. CAMERA REPLACEMENT IS

COMPLETE.

6.

Reassemble the SpeedDome chassis and

recalibrate.

THE WORLD LEADER IN LOSS PREVENTION Q-36

Focus Ring

WARNING: Unexpected pan

and tilt can cause injury or

damage the dome during

servicing. To prevent such

movement, always disconnect

power/data connector P4 from

the RS422 interface board

WARNING: The color camera

imager head is both delicate

and sensitive to ESD. Use a

ground strap when installing.

Be careful not to dislodge its

ribbon cable from the camera.

1.

Remove the lens and camera shrouds (four screws

each). Then remove the old camera [a] by first

unplugging its grey ribbon cable [b] from P6 on the

camera/ lens board, by removing four M3x10

screws [c], and finally, removing the two M2x6

screws [d] securing the imager head to the lens.

Gently lift the camera away from the casting.

2.

Detach the PCI board from the old camera by

removing two M3x10 screws [e], and unplug the

J3 cable. Reassemble this board into the new

camera using the same two screws.

3.

With the grey ribbon cable hugging its chassis,

gently position the new camera into the eyeball

casting. Secure the camera using the four

previously removed screws. Connect the grey

ribbon cable to P6 on the camera/lens board.

4.

Noting how the imager head cable is looped, plug

the imager head onto the back of the lens. Then,

using the two previously removed screws to secure

the imager head.

5.

Restore power by plugging connector P4 into the

dome. The dome will return to its home position.

Color Cameras

1/2" CCD NTSC, 60Hz

2003-0027-01

1/2" CCD PAL, 50Hz

2003-0027-02

[c]

Imager

Head

Note how

imager

head ribbon

cable is

looped.

[d]

[a]

[b]

PCI Board

P6

Focus Ring

6.

Check backfocus by zooming in on a distant object

and focusing as clearly as possible, then zooming

out. If the picture is out of focus, see Back Focus

Adjustment, page Q-43. If OK, continue.

7.

Reassemble the camera and lens shrouds using

the eight screws. CAMERA REPLACEMENT IS

COMPLETE.

8.

Reassemble the SpeedDome chassis and

recalibrate.

Camera

cable must

hug

camera

chassis as

camera is

positioned

into eyeball

casting.

[e]

Iris Ring

Zoom Ring

SENSORVISION SpeedDome

Q-37

Sensormatic

SENSORVISION SYSTEMS

WARNING: Unexpected pan

and tilt can cause injury or

damage the dome during

servicing. To prevent such

movement, always disconnect

power/data connector P4 from

the RS422 interface board

Remove the lens and camera shrouds (four screws each). Then

remove the motor suspected of being defective. Tilt, zoom, focus

and iris motors secure to the eyeball casting using two M3x10

screws each. The pan motor secures to the carriage assembly.

Refer to the notes and diagrams for exact motor placement.

Note: Outline the bracket of the old motor with a pencil

before removing to simplify the alignment of the new motor.

Note: When installing screws in the zoom, focus and

iris motors, use the round hole [a] to align the motor,

then use the oblong hole [b] to adjust the gear mesh.

Note: Calibrate gear mesh using a 1/4-watt

resistor or .05mm (.02") dia. drill rod.

Iris Ring

Zoom Ring

Focus Ring

Note: Zoom, focus and iris motors are identical

and can be exchanged when troubleshooting.

Unless only the pan motor was replaced, reassemble

the lens and camera shrouds using the eight screws.

Then reassemble the SpeedDome chassis and

recalibrate.

Zoom Motor

3501-0008-01

[a]

[b]

Pan Motor

3501-0009-01

Focus

Tilt Motor

3501-0010-01

Motor

3501-0008-0

Iris Motor

3501-0008-01

THE WORLD LEADER IN LOSS PREVENTION Q-38

Remove the lens and camera shrouds (four

screws each). Next, detach the old clockspring cable by unplugging it from the J5

connector on the camera/ lens board [a] and

by removing two M3x10 screws [b] securing it

to the base of the yoke bracket. Then unplug

the cable from the slip ring connector [c],

unwind it, and slip it out of the retainer/spool

assembly [d].

2.

The new cable has an inked marking [e] on

it. Crease the cable along this marking to

form a 90° bend. Holding the cable’s male

connector [f] in your hand, insert the bend

into the retainer as shown in the detail.

Connect the cable’s male connector to the

slip ring connector at the base of the yoke

bracket and secure it using the previously

removed screws. Dress the cable’s female

end [g] clockwise around the spool approximately 1-1/2 times and connect its connector to J5 on the camera/lens board.

3.

Reassemble the SpeedDome chassis and

recalibrate.

5.

WARNING: Unexpected pan

and tilt can cause injury or

damage the dome during

servicing. To prevent such

movement, always disconnect

power/data connector P4 from

the RS422 interface board

before servicing.

IMPORTANT:

It is not necessary

to disassemble the

eyeball assembly

from the carriage

assembly to

perform this task.

Eyeball assembly is

shown

disassembled for

explanation

purposes only.

[a]

[d]

[c]

[b]

1.

AREA OF DETAIL

Bend

Retainer/

Spool Assy.

To slip ring

connector at

yoke bracket.

To J5,

cam./lens bd.

Male Connector

Female

Connector [g]

[f]

[e]

Reassemble the lens and camera shrouds

using the eight screws. CABLE REPLACEMENT IS COMPLETE.

Cable Assy.

0650-0623-01

4.

SENSORVISION SpeedDome

Q-39

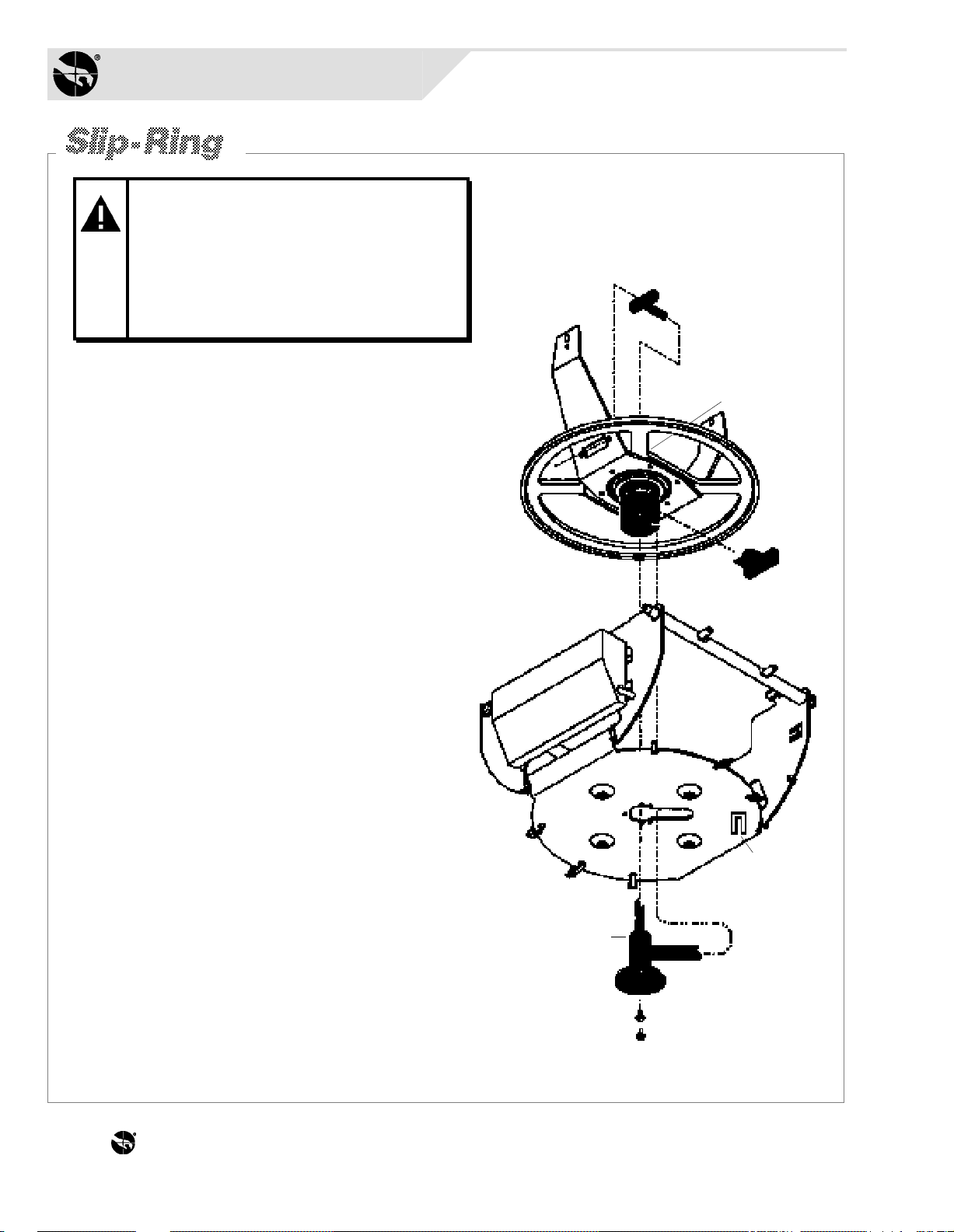

Sensormatic

[e]

[g]

[c]

[a]

[b]

[d]

Slip Ring Assy.

2100-0004-01

[f]

[h]

SENSORVISION SYSTEMS

WARNING: Unexpected pan

and tilt can cause injury or

damage the dome during

servicing. To prevent such

movement, always disconnect

power/data connector P4 from

the RS422 interface board

1.

Ready the old slip-ring assembly for removal by unplugging its

female connector [a] from the clock-spring cable connector

at the yoke bracket, unplugging its ribbon cable [b] from JP4

of the dome CPU board, and by removing its two M3x8

screws [c] from at the base of the carriage assembly.

2.

Cut the tie wrap [d] and remove the old slip ring [e] and

washer [f] while carefully feeding its female connector

down through the slip-ring receptacle [g].

3.

Insert the new slip ring by carefully inserting its female

cable connector through the receptacle (making sure

the washer [f] stays at the end of the slip ring as it

enters the receptacle). Then position the slip-ring

ribbon cable in the slot of the receptacle and slowly

turn the slip ring clockwise approx. 3/4-turn until its

flange [e] firmly seats against the carriage assembly.

Secure the slip ring using the two screws.

4.

Connect the cable exiting the end of the receptacle

to the clock-spring cable connector and tie wrap it

[d] to the chassis. Then slip the ribbon cable into its

retaining notch [h] and connect it to JP4 of the dome

CPU board.

SLIP-RING ASSY. REPLACEMENT IS COMPLETE.

5.

Reassemble the SpeedDome chassis and recalibrate.

THE WORLD LEADER IN LOSS PREVENTION Q-40

WARNING: Unexpected pan

and tilt can cause injury or

damage the dome during

servicing. To prevent such

movement, always disconnect

power/data connector P4 from

the RS422 interface board

1.

Disconnect power supply cables from P5 [a]

on the RS422 interface board and from P2 [b]

on the dome CPU board.

2.

Cut the tie wraps [c] to release the

cables from the chassis.

[a]

3.

Detach the supply by removing four

M3x10 screws [d] from the corner tabs.

4.

Attach the new supply to the chassis

using the four screws previously

removed. Then secure its cables along

the chassis, as shown, using six new tie

wraps.

[b]

[c]

6 Places

5.

Plug the cable having the large connector into

P5 on the RS422 interface board and the other

cable into P2 on the dome CPU board.

POWER SUPPLY REPLACEMENT IS COMPLETE.

6.

Reassemble the SpeedDome chassis and

recalibrate.

Power Supply

5606-0002-02

SENSORVISION SpeedDome

[d]

Q-41

THE WORLD LEADER IN LOSS PREVENTION Q-42

WARNING: Unexpected pan

and tilt can cause injury or

damage the dome during

servicing. To prevent such

movement, always disconnect

power/data connector P4 from

the RS422 interface board

WARNING: If servicing a color

camera, be careful not to

disturb the copper-colored

imager cable exiting the imager

Before you begin:

Does the dome use a bubble? If so, remove

the contact eye (if used) and adjust the back focus

of the camera through the bubble. If not, adjust

back focus of the camera through the contact eye.

Focus Ring

Zoom Ring

Iris Ring

Please note: Cameras should not require

adjustment in the field. However, if a camera

image that is focused when zooming in does not

stay in focus when zooming out, perform the

following mechanical adjustment.

1.

Remove the lens and camera shrouds (four screws

each). Then, using the appropriate tool*, loosen the

back focus setscrew (just beneath the back focus

wheel). This screw keeps the wheel stationary.

2.

Restore power by plugging connector P4 into the

dome. The dome will return to its home position.

3.

Disable the lens motors for manual adjustment by

flipping S1, switch 3 on the RS422 board to ON

(disable).

4.

Connect a monitor to the video out BNC (J1 on

RS422 interface board) and manually open the

iris completely.

.035 Allen Wrench for set screw (old version) or

*

screwdriver for Phillips Head screw (new version).

Back focus

Screw

Back focus

Wheel

5.

Manually zoom in on a distant object, focus as

clearly as possible, then zoom out. Next, focus

the picture by turning the back focus wheel

clockwise or counterclockwise for best picture.

Repeat this procedure until the camera stays in

focus through the entire zoom range.

6.

Turn S1, switch 3 on the RS422 interface board

to OFF (enable).

7.

Reassemble the lens and camera shrouds using

the eight screws. BACK FOCUS ADJUSTMENT

IS COMPLETE.

8.

Reassemble the SpeedDome chassis and

recalibrate.

SENSORVISION SpeedDome

Q-43

Sensormatic

SENSORVISION SYSTEMS

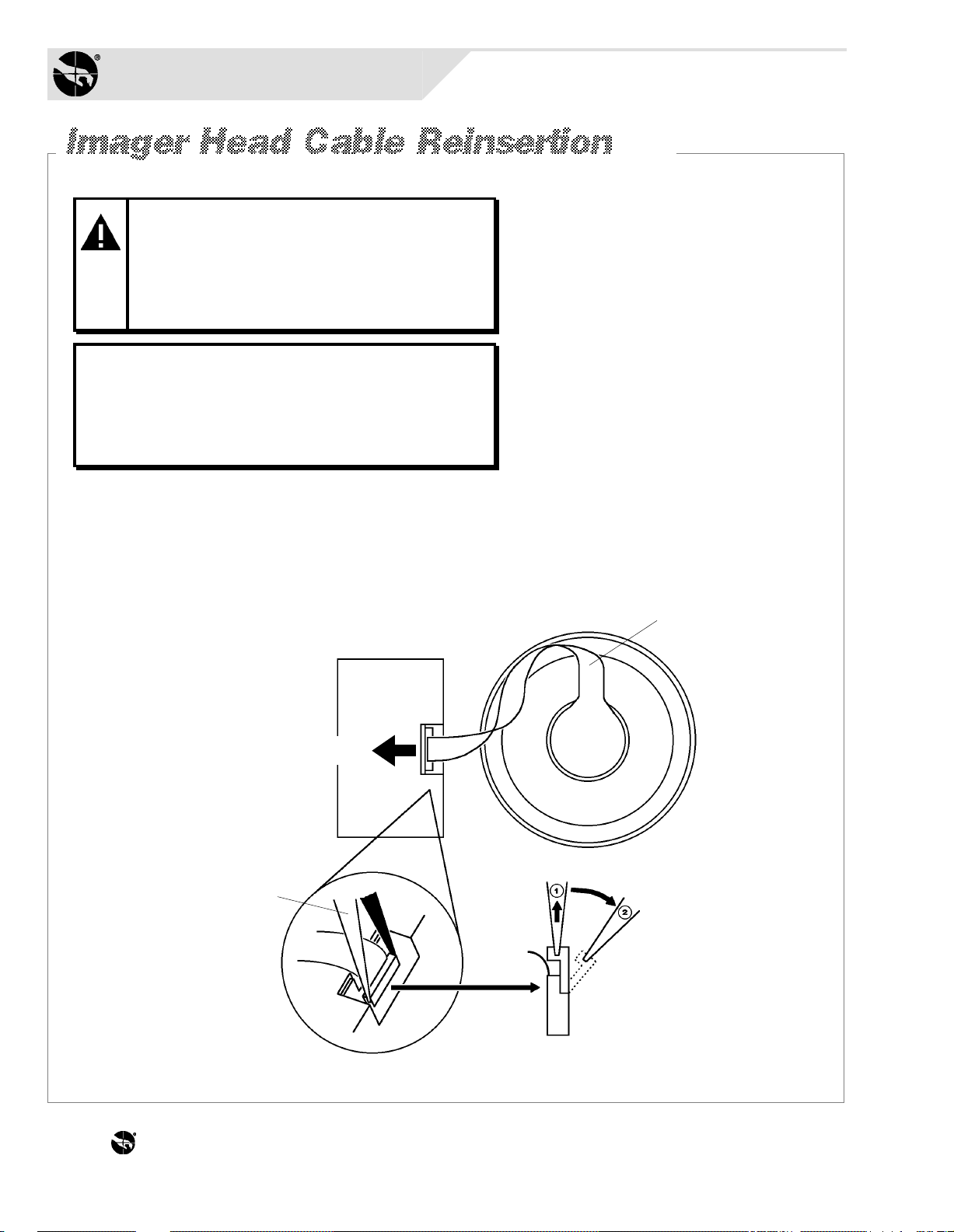

COLOR CAMERAS ONLY!

WARNING: Perform this

procedure ONLY if the imager head

cable was dislodged from the

camera while performing the back

focus adjust- ment procedure or

while replacing the color camera.

IMPORTANT: Note the orientation of

the ribbon cable as it is seated in the

camera. The exposed contacts of the

cable provide the connection between

the camera and the imager head.

Procedure

Using a pair of needle nose pliers, grab the ends of

the camera cable clamp [a] and gently pull it up until

it swings to one side [b]. Next, noting how the ribbon

cable is looped [c], reseat the cable into the

connector. Finally, using the pliers,

push the top of the clamp down to

lock the cable in place.

Color Camera

Ribbon Cable

Cable contacts face this way.

Needle Nose Pliers

[c]

Imager

Head

Lens Body

[b]

[a]

THE WORLD LEADER IN LOSS PREVENTION Q-44

Monochrome

Monochrome

Camera Options:

1/2" CCD EIA, 60Hz

2003-0026-01

1/2" CCD CCIR, 50Hz

2003-0026-02

NOTE: Monochrome

camera uses cable PN

0650-0666-01. Color

camera has cable

permanently attached

to the PCI board.

Camera Lens*Camera Lens*

Camera

J1 J3

J2

P6 P1 J2 J3 J4

J5

Clock-Spring

Ribbon Cable Assy.

0650-0623-01

Color

Camera

1/2" CCD NTSC, 60Hz

2003-0027-01

1/2" CCD PAL, 50Hz

2003-0027-02

*

Outdoor Lens Options:

(Monochrome/Color)

1/2" F1.2, 8-80mm

2004-0051-03

1/2" F1.8, 12-120mm

2004-0051-04

DC OUTPUT

P2

5606-0002-02

P5

Power Supply

AC INPUT

AC/DATA FROM

INDOOR J-BOX OR

OIB*, PAGE 48.

Receives female 7-pin

compression-type

connector

2109-0254-06

JP4

JP2 JP3

JP1 JP2

P4

P3

ALARM INPUT

Receives female 8-pin

compression-type

connector

2109-0254-07

P2

AUX. OUTPUT

Receives female

6-pin connector

2109-0108-05

P1

EXT. SYNC

Receives female 2-pin

compression-type

connector

2109-0254-01

P3

J1

VIDEO OUTPUT

TO INDOOR

MONITOR OR

OIB*, PAGE 48.

BNC Connector

p/n 2112-0009-01

*Outdoor Interface Board (outdoor version only).

SENSORVISION SpeedDome

Q-45