Infrared Temperature Switch (Hot Metal Detector)

Polaris PS09 / PI16

User Manual

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Content

2

Content

1 General ............................................................................................................................................... 3

1.1 Information to this Manual ......................................................................................................... 3

1.2 CE Conformity and Standards .................................................................................................. 3

1.3 Limitation of Liability .................................................................................................................. 3

1.4 Terms of Warranty .................................................................................................................... 3

1.5 Copyright ................................................................................................................................... 3

1.6 Explanation of Symbols ............................................................................................................ 4

1.7 Disposal .................................................................................................................................... 4

1.8 Intended Use ............................................................................................................................. 4

1.9 Scope of Delivery ...................................................................................................................... 4

1.10 Model Design ............................................................................................................................ 4

2 Safety .................................................................................................................................................. 5

2.1 General ..................................................................................................................................... 5

2.2 Electrical Connection ................................................................................................................ 5

2.3 Laser Targeting Light ................................................................................................................ 5

2.4 Device Labels............................................................................................................................ 5

2.5 Responsibility of the Operators ................................................................................................. 5

3 Electrical Connection........................................................................................................................ 6

3.1 Cable Colors and Pin Assignment ............................................................................................ 6

3.1.1 Power Supply ....................................................................................................................... 6

3.1.1.1 Factory Settings ...............................................................................................................6

3.1.2 Switching Outputs ................................................................................................................ 7

3.1.3 Serial Interface RS232 or RS485 ........................................................................................ 7

3.1.3.1 Interface Converter (Accessory) ......................................................................................8

4 Mechanical Installation ..................................................................................................................... 8

4.1 Mounting ................................................................................................................................... 8

4.2 Ambient Temperature ............................................................................................................... 8

4.3 Alignment onto the Measuring Object ....................................................................................... 8

4.3.1 Alignment with the Laser Targeting Light ............................................................................ 9

4.4 Setting the Measuring / Focus Distance ................................................................................... 9

4.5 Spot Size Tables ..................................................................................................................... 10

4.5.1 Calculation of the Spot Size Diameter outside the Focused Distance .............................. 10

4.6 Parameters / Settings ............................................................................................................. 11

4.6.1 Emissivity ε ........................................................................................................................ 11

4.6.2 Response Time t90 ............................................................................................................. 12

4.6.3 Simulate a Switching Temperature .................................................................................... 12

4.6.4 Baud Rate .......................................................................................................................... 12

4.6.5 Address .............................................................................................................................. 12

4.6.6 Interface Delay (Answer Delay) ......................................................................................... 12

5 Configuring via SensorTools Software ......................................................................................... 13

5.1 Program Start .......................................................................................................................... 13

5.1.1 Connecting the Polaris ....................................................................................................... 13

5.2 Setting Window ....................................................................................................................... 13

6 Technical Data ................................................................................................................................. 15

6.1 Storage .................................................................................................................................... 15

6.2 Dimensions ............................................................................................................................. 15

6.3 Composition of the Type Number ........................................................................................... 16

6.4 Accessories ............................................................................................................................. 16

7 Maintenance ..................................................................................................................................... 17

7.1 Cleaning .................................................................................................................................. 17

7.2 Calibration ............................................................................................................................... 17

8 Communication via Serial Interface / Interface Commands ....................................................... 17

Index ......................................................................................................................................................... 19

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

General

3

1 General

1.1 Information to this Manual

This manual enables the safe and efficient use with the device. The manual is part of the instrument and

has to be kept in a location where users always have access to.

Read this manual carefully before operating. For secure working all security notes and operation procedures in this manual has to be followed.

Additionally the local accident prevention regulations and common safety regulations of the instruments’

operational area are valid.

The descriptions may differ from the current delivery status, since the device is continuously developed.

Illustrations in this manual are for basic understanding and can differ from the actual construction.

1.2 CE Conformity and Standards

The product conforms to the following standards:

CE conformity: DIN EN 61326-1 (electromagnetic compatibility)

Laser safety: IEC 60825-1, laser class 2

RoHS: 2011/65/EU

1.3 Limitation of Liability

All information and notes in this manual are made under consideration of valid standards and rules,

state of technology and our expert knowledge for many years.

The producer assume no liability for damages due to:

Non-observance of this manual

Usage out of intended use

Assignment of unskilled personnel

Unauthorized modifications

Technical modifications

Usage of spare parts not approved

The responsibilities of the delivery contract are valid as well as our general terms and conditions and

terms of delivery and the valid statutory rule at date of the conclusion of contract.

1.4 Terms of Warranty

A warranty period is 24 months from date of shipment form the Sensortherm facility. The seller will repair or replace the device at its own discretion. Further claims of the buyer against the seller or its

agents are excluded, especially claims for damages that are not incurred in the delivery itself. This shall

not apply in cases of intent, gross negligence, or the absence of assured properties. Damage or misuse

of the product will be determined and void the warranty coverage. Repairs paid by the customer will include a 180 days warranty from date of shipment. Transportation costs are to be paid by the customer.

Any claims for damage caused by misuse, neglect or tampering with the sensor are excluded.

1.5 Copyright

This manual is protected by copyrights and are intended solely for internal purposes.

It is not permitted to transfer these instructions to third parties, duplication in any kind and form - including excerpts - as well as recovery and / or notification of contents without written permission of the manufacturer, except are internal purposes.

Contraventions are liable for damages. All other rights reserved.

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

General

4

1.6 Explanation of Symbols

The following symbols are used in this manual for restrictions, preventive measures and security notes.

Please pay attention to this symbols for safety reasons.

CAUTION: This combination of symbol and signal word indicates a potentially dangerous

situation that can result in minor or moderate injury if not avoided.

CAUTION, LASER RADIATION: This combination of laser radiation symbol and signal

word indicates the dangers of a laser targeting light.

INFO: This symbol indicates useful tips, recommendations and information for efficient and

trouble free operation.

1.7 Disposal

Dispose of the product properly when it is no longer usable: infrared measuring devices include electrical and electronic waste and have to be recycled or disposed environmentally friendly or to send to the

manufacturer for disposal.

1.8 Intended Use

The infrared temperature switches Polaris are mainly used for non-contact detection of hot metal parts

and triggering a switching operation. They are equipped with 2 switching contacts with adjustable

switching temperatures. Also the switching status is indicated by LEDs on the rear panel. A laser targeting light can be used to align the devices to the measuring object.

Polaris-temperature switches measure in the short wave spectral range and are therefore mainly used

for measuring of metals, ceramics, graphite, etc.

A serial interface connection to to a PC is required configure the devices. The configuration itself will be

done via PC and SensorTools software or via interface commands.

1.9 Scope of Delivery

Infrared switch, SensorTools software, allen key 1.5 mm, user manual.

(A connection cables is not included in scope of delivery and has to be ordered separately).

1.10 Model Design

Focusable optics

Mounting thread

with mounting nut

M 40 x 1.5

Type label

LEDs to indicate system ready (middle)

or active switching outputs (left / right)

Laser targeting light button

Power supply and switching outputs

Serial interface connection

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Safety

5

2 Safety

2.1 General

Any person who is tasked to carry out work with the device must have read and understood the operating instructions before beginning. Operation and maintenance of the system may only be performed by

trained personnel.

2.2 Electrical Connection

When connecting or when working on the mains voltage, the general safety guidelines are observed,

e.g. when connecting power transformers. Supply voltage can be lethal when touching. Improper installation can cause serious injury or physical damage. Only qualified personnel are allowed to work with

mains voltage.

2.3 Laser Targeting Light

For easy alignment, the devices are equipped with a laser targeting light, Laser Class 2 (according to

IEC 60825-1-3-4) and has a sticker shown on the right. The laser emits a visible red light with a maximum power of < 1 mW and a wavelength around 650 nm.

Safety precautions:

Never look into the direct or reflected laser beam.

Do not point the laser to anyone.

If laser radiation hits the eye, the eyes must be intentional-

ly closed and the head immediately moved out of the

beam.

2.4 Device Labels

A nameplate and a laser targeting light warning label is to find on the Polaris housing.

The device must be mounted in a manner that the labels after installation are still clearly visible.

Keep the warning signs in always legible condition

Replace damaged labels

2.5 Responsibility of the Operators

If the device is used in the commercial sector the operator is subject to the legal responsibilities for

workplace safety.

In addition to the safety instructions in this manual follow the regulations of safety, accident prevention

and environmental protection.

Laser

beam

direction

Laser warning label

on top of the device

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Electrical Connection

6

0 V

Brown

Blue

+24 V

AK30

3 Electrical Connection

3.1 Cable Colors and Pin Assignment

The electrical connection of the Polaris (supply voltage and switching signals) will be done via the connectors on the rear panel. For

this purpose, connection cables are available as accessory (see

6.4 Accessories). To prevent accidental short circuits, not used

cable wires need to be placed, for example to the supplied screw

terminals.

Cable AK32: Power Supply and Switching Output Connector

Cable color

Function

Pin

Brown

+ 24 V DC power supply (possible range 12–30 V DC)

(to be fused by 250 mA slow blow)

1

View on device

plug

Blue

0 V DC power supply (ground)

3

White

Output 1

Each transistor output switches the positive

supply voltage to the output (positive switching),

max. current 30 mA

2

Black

Output 2

4

Cable AK31: Serial Interface Connector

Cable color

Function

Pin

Pin

Brown

RS232: TxD (to PC receive line RxD)

RS485: A (-)

2

1

View on device

socket

Black

RS232: RxD (to PC send line TxD)

RS485: B (+)

3 4 Blue

DGND (ground, electrically isolated)

5

3

3.1.1 Power Supply

With connection of the supply voltage (standard 24 V DC, possible range 12–

30 V) the unit is ready for operation with the following factory settings (changing

the settings is possible via software (see 5) or interface commands (see 8).

Interrupt the power supply to turn off the device, e.g. by disconnecting the connector.

Status LEDs:

Green (middle) when the device is ready to use.

Yellow (left and right) illuminates when the corresponding

transistor output is switched.

3.1.1.1 Factory Settings

Data transmission speed (baud rate) .... 19.2 kBd

Emissivity ε............................................ 100%

Response time t90 ................................. 4 ms

Device address ..................................... 00

Lower switch temperature output 1 ....... 790°C

Upper switch temperature output 1 ....... 800°C

Lower switch temperature output 2 ....... 890°C

Upper switch temperature output 2 ....... 900°C

4 1 3

Pin 5

Pin 3

Pin 2

4 3 1

2

AK31: Serial

interface

AK32: Power supply /

switching outputs

LED Output 1

LED Operating

status

LED Output 2

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Electrical Connection

7

Max. 30 mA

0 V

Output

+24 V

100 k

Ω

Brown

Blue

0 V

100 k

Ω

White

Max. 30 mA

Black

Output

3.1.2 Switching Outputs

The switching outputs are used to detect if a certain temperature

threshold is exceeded or falling below.

The output logic is invertible, see under 5.2 Setting window in the

SensorTools Software).

3.1.3 Serial Interface RS232 or RS485

Polaris are available with RS232 or RS485 interface, the built-in version is to find on the device label.

The serial interface is used for digital communication of the device with another computer, for example a

PC for data transmission to the software SensorTools.

The maximum transmission speed (in Baud) is limited by the cable length, it is halved with each doubling of the transmission path.

RS232: about 7 m cable length with 19.2 Bd. Adjustable are values from 1.2 and 57.6 kBd.

RS485: about 2 km with 19.2 kBd. Adjustable are values between 1.2 and 57.6 kBd.

Connecting one Polaris

via RS232 or RS485:

In a short RS232 or RS485 connection to the master (computer receiving the data), the Polaris is

connected directly as a point-to-point connection

with the master.

Connecting several Polaris via RS485:

For a reflection-free operation with longer cables, pay attention to the correct cable termination. Termination at the physical bus is on front and rear.

Master at the

beginning:

Master in the

middle:

When operating multiple devices (up to 32 are possible), each device needs to assign its own address

(directly on the device or via software SensorTools), under which it can be addressed later. For this

purpose, initially, each device must be connected individually and provided with an address (00-97). After that, all devices can be connected.

If specific parameters for all devices should be changed simultaneously, the global address 98 is used

(there is no response from the device). If the address of a device is unknown, you have the opportunity

to address each device independently of the set address with the global address 99 (connect only one

device).

RxD

TxD

GND

TxD Brown

RxD Black

DGND Blue

RS232 (PC)

Pin 2

Pin 3

Pin 5

A (-)

B (+)

GND

A (-) Brown

B (+) Black

DGND Blue

RS485

(Master /

PC)

Master

A (-)

B (+)

DGND

120 Ω

... Device

Terminating

resistor 120 Ω

Device 2

Device 1

Terminating

resistor 120 Ω

in the master

or manually

A B GND A B

GND A B

GND A B

GND B A B A

120 Ω

... Device n

Terminating

resistor 120 Ω

Device 1

A B GND B A B A

120 Ω

Master

A (-)

B (+)

DGND

A B GND

Terminating

resistor 120 Ω

GND

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Mechanical Installation

8

3.1.3.1 Interface Converter (Accessory)

Using an interface converter DK3000 or DK4000 (RS232USB or RS485USB) is a quick and easy

way to connect the infrared switch to a PC (see 6.4 Accessories). Via the sub-D connector this is simply connected to the cable AK31.

Depending on the operating system, suitable drivers are installed automatically or can be found on the

CD supplied with the software SensorTools in the directory Drivers FTDI_USB_COM, or after installing SensorTools in the installation directory (updated driver for Windows from the FTDI website:

http://www.ftdichip.com/Drivers/VCP.htm).

4 Mechanical Installation

4.1 Mounting

Note that the installation lecation is free of vibrations. If necessary, helps the use of rubber absorbers

when mounting.

The device can be mounted in a drilling hole of 41 mm Ø and fixed with the included nuts (M40x1.5).

For easy installation a mounting angle is available as accessory (see 6.4 Accessories).

4.2 Ambient Temperature

Polaris switches are designed for ambient temperatures between 0 and 70°C. Operation outside this

temperature leads to incorrect measurements and may damage the unit.

To comply with the permitted ambient temperature, sufficient distance from the (hot) object to detect is

observed.

To prevent laser targeting light overheating, the targeting light is deactivated at a device temperature

from 55°C. Below that temperature it can be used again

Accessory: The use in ambient temperatures outside the permissible ambient temperature is possible

with an additional cooling housing (see 6.4 Accessories).

4.3 Alignment onto the Measuring Object

To detect the temperature correctly, the infrared switch must be aligned properly to the measuring object. In the focus point of the optics (focus distance) the spot size diameter is the smallest. Also measurements in the defocused area can be done to determine the average temperature of a bigger spot. If

the target under measurement is smaller than the spot size produced by the lens, the colder or warmer

border is also measured and results in a lower or higher temperature.

The optical path between infrared switch and the target must be free of interfering objects and va-

pors, fumes or dust (if necessary, use air purge or sight tube).

A viewing window between Polaris and the measured

object should have constant transmission properties in

the spectral range of the Polaris (e.g. BK7 crown

glass). The transmission loss must be compensated

by correction of the emissivity.

If the target is smaller than the spot size, there will be

measuring errors because background temperatures

go with the measurement.

Spot size smaller than measured object, measurement OK

Measuring object

Spot size larger than measured

object, enter fill factor, observe

background radiation!

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Mechanical Installation

9

4.3.1 Alignment with the Laser Targeting Light

The laser targeting light is a conical red laser beam with

the largest diameter directly at the lens and the smallest

and sharpest in the focused distance, i.e. at the point

where the measuring field is the smallest.

The focus distance (=measuring distance at the smallest

spot size) is easy to find where the laser dot is the smallest.

INFO: The size of the laser point does not match to the spot size, spot sizes are given in the

spot size tables (see 4.5)

CAUTION, Laser Radiation, Laser Class 2:

Never look into the direct or reflected laser beam.

Do not point the laser to anyone.

If laser radiation hits the eye, the eyes must be intentionally closed and the head immedi-

ately moved out of the beam.

Turn on / off via the targeting light button on the rear side or via Sen-

sorTols software (see 5.2).

The targeting lightwill automatically switched off after 2 minutes (if not

switched off manually).

INFO: The laser targeting light is turned off at a device

temperature above 55°C.

If the targeting light does not turn on, probably the device's

internal temperature is too high. In this case, the installation

place should be checked (excessive heat radiated from the

measuring object). When temperature falls below 55°C the

laser is working again.

4.4 Setting the Measuring / Focus Distance

The focal distance is the distance at which the optics achieves its smallest spot size. In most cases, this

distance is also the required measuring distance.

With the focusable optics the focus distance can be changed continuously within a predetermined range

(see 4.5 Spot size tables), so the smallest possible spot size is always achieved.

Loosen locking screws (allen key 1.5 mm)

Adjust measuring distance by turning the optics in or out un-

til the measuring distance is found

- Optics screwed out: short measuring distances

- Optics screwed in: long measuring distances

Fix locking screws (hand-screwed).

Optics locking

screws

Focus point

Spot size and

Laser dot bigger

Laser targeting

light button

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Mechanical Installation

10

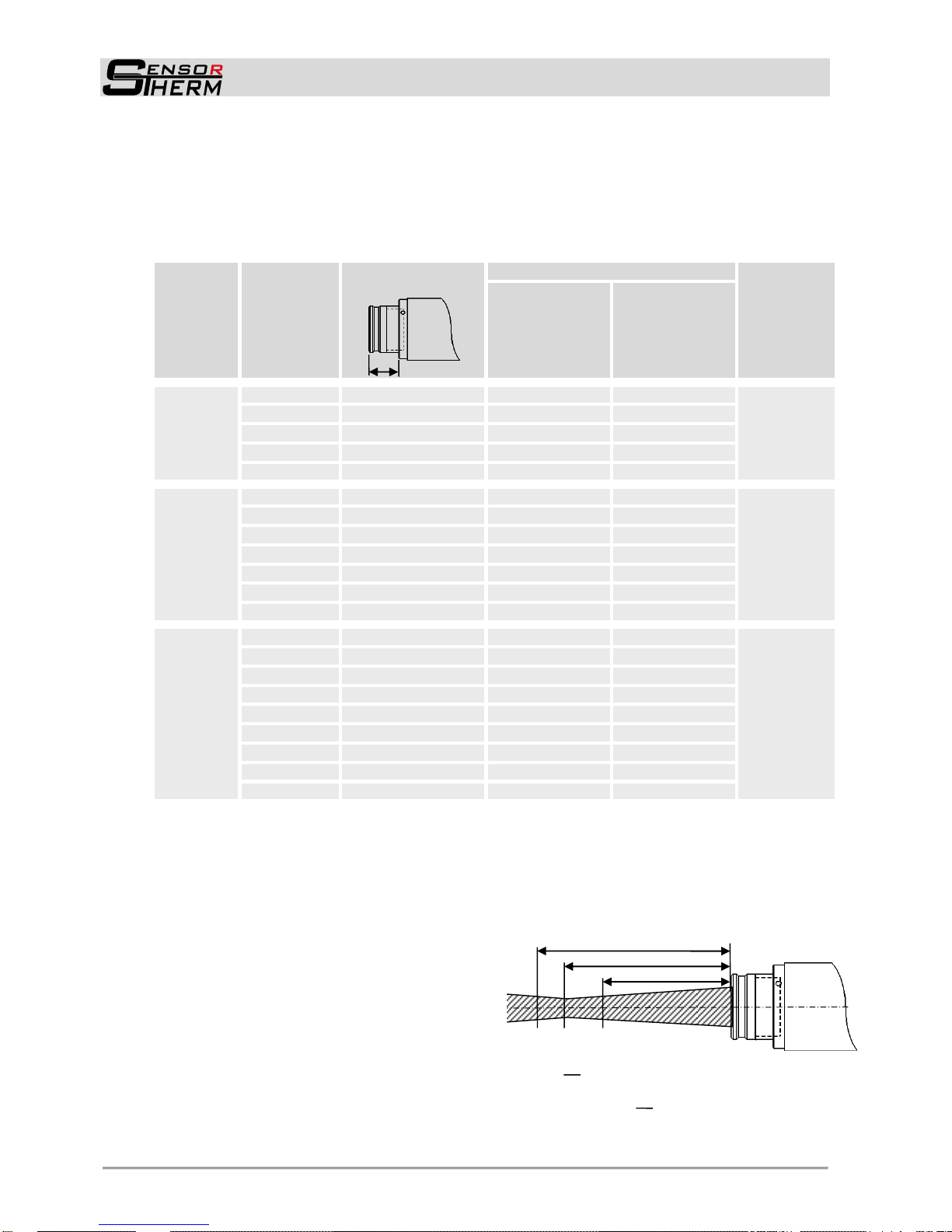

4.5 Spot Size Tables

The following tables show the optical data of the different device types. The values in the tables are exemplary, intermediate measurement distances must be determined by interpolation. If the measuring

distance differs from the adjusted or specified, a measurement is also possible, but the spot size

changes (usually it is larger, see 4.5.1 Calculation of the Spot Size Diameter outside the Focused

Distance). The measuring distances are specified from lens front.

Optics

Measuring

(focus)

distance

a [mm]

Optics pull-out

S [mm]

Spot size M [mm]

Aperture Ø

D [mm]

PI16

250–1000°C

PS09 and PI16

all other

temp. ranges

OP09-A0

170

16

1.7

1.3

14 mm

185

14.7

1.8

1.35

200

13.4

1.9

1.4

220

12.1

1.95

1.45

245

11

2

1.5

OP09-B0

260

16

2.1

1.6

14 mm

280

15

2.4

1.85

300

13.3

2.7

2.1

350

12.9

2.9

2.25

400

12.1

3.3

2.5

450

11.2

3.7

2.9

500

11

4.3

3.2

OP09-C0

480

16

4

3.3

14 mm

500

15.7

4.3

3.2

600

14.6

4.8

3.6

800

13.3

6.1

4.6

1000

12.5 8 6

1250

11.9

9.3

7

1500

11.5

11

8.3

1750

11.2

13

10

2000

11

14.5

11

4.5.1 Calculation of the Spot Size Diameter outside the Focused Distance

The spt size diameter determines the area on the measurement object from which 90% of the temperature radiation is detected by the pyrometer; therefore the spot size tables specify spot sizes for different

measuring distances (or focused distances).

For calculating intermediate values in front of and behind the focused measuring distance, the following

formula can be used or the Spot size calculator integrated in SensorTools (under 5.2):

a Focused distance

M Spot size diameter in the focused measuring

distance

a1 Measuring distance longer than focused meas-

uring distance

M1 Resulting spot size on measuring distance a1

a2 Measuring distance shorter than focused

measuring distance

M2 Resulting spot size on measuring distance a

2

D Aperture (specifies the spot size directly on the

optics’ lens, it differs depending on the optics

pull-out. The largest value applies at a fully extended optics, the lowest value is with inserted lens)

S

M

M2

M1

a2

a

a1

M1= (M+D)-D

a

1

a

M2= (M-D)+D

a

2

a

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Mechanical Installation

11

4.6 Parameters / Settings

4.6.1 Emissivity ε

The emissivity indicates the radiation

capacity of an object to be measured

relative to a calibration source with the

same temperature. To obtain correct

readings, the emissivity must be taken

into account in the measurement and

adapted for the respective measuring

material on the infrared switch. Each

material has a max. emissivity of 1.00

(=100%) which can be set.

In principle applies: to measure metals

in a short-wavelength spectral range as

possible, as here the emissivity is higher than in the long-wave range.

The specified values are guide values,

which were determined in the laboratory

and confirmed in application-oriented

measurements. They can vary due to

material-dependent conditions, as in

metals additionally to the surface texture alloy components play an important

role for the emissivity.

Is a range given, this is related to dif-

ferences in the nature of the surface

from smooth to rough, rough surfaces

have higher emissivities (for determining the correct emissivity also a

comparison measurement can be

performed with a thermocouple).

“n.s.“ means that no values exist for

this wavelength range (not specified),

e.g. because a reasonable measurement in this wavelength or temperature range is not possible.

The emissivities with "shiny" refer to

applications that are performed under

an inert gas or in a vacuum.

Measuring object

Emissivity [%]

PS09

PI16

Calibration source

1

1

Aluminum, shiny

n.s.

0.05-0.2

Aluminum, oxidized

n.s.

0.3-0.4

Aluminum, sandblasted, rough

n.s.

0.4-0.5

Aluminum, black anodized

n.s.

0.9

Lead oxidized

n.s.

n.s.

Bronze

0.2-0.4

0.2-0.4

Iron, liquid

0.15-0.3

0.1-0.25

Iron, shiny

0.3-0.4

n.s.

Iron, oxidized

0.7-0.9

0.65-0.85

Graphite

0.8-0.92

0.8-0.9

Gold, shiny

0.02-0.05

0.02-0.05

Inconel, shiny

0.35-0.45

0.4

Inconel, oxidized

0.65-0.75

0.6-0.7

Copper, shiny

0.10

0.05-0.1

Copper, oxidized

0.3-0.7

0.2-0.8

Magnesium, shiny

n.s.

0.15-0.2

Magnesium, oxidized

n.s.

0.3-0.5

Brass, shiny

0.5-0.7

0.5-0.7

Brass, oxidized

0.6-0.8

0.6-0.7

Molybdenum, oxidized

0.7-0.9

0.7-0.85

Nickel

0.22

0.15-0.2

Porcelain, glazed

0.6

0.6

Porcelain, rough

0.8-0.9

0.8-0.9

Platinum

0.4

0.35

Soot

0.95

0.95

Chamotte

0.45-0.6

0.45-0.6

Slag

0.85

0.8-0.85

Silver, shiny

n.s.

n.s.

Silver, oxidized

0.1-0.2

0.05-0.2

Steel, shiny

0.4-0.55

0.3-0.45

Steel, oxidized

0.8-0.9

0.7-0.9

Steel, rolled

0.8-0.9

0.8-0.9

Stoneware, glazed

0.86-0.9

0.8-0.9

Stainless steel

0.4-0.9

0.4-0.9

Titanium, shiny

0.35-0.45

0.3-0.4

Titanium, oxidized

0.55-0.85

0.55-0.85

Tungsten, shiny

0.3-0.4

0.3-0.4

Tungsten, oxidized

0.7-0.9

0.7-0.85

Brick

0.85-0.9

0.8-0.9

Zinc

0.45-0.58

0.45-0.55

Measurement deviations at a 10% false set emissivity

at a temperature of 700°C:

+10%

6.5°C

10.5°C

-10%

7°C

11.5°C

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Mechanical Installation

12

4.6.2 Response Time t90

The response time specifies the time that an infrared measuring device requires to track 90% of a

sudden temperature change on the signal output.

The response time depends on the requirements of the respective measuring task and can be adjusted.

If a short response time is selected, the temperature measurement follows the actual temperature

curve accurately. Short setting thus allowing the detection of briefly occurring temperature peaks,

which occur especially in fast heating processes or fast moving samples.

At longer response times, the measurement signal is smoothed and average values for temperature

fluctuations are formed caused by the inertial measurement.

4.6.3 Simulate a Switching Temperature

The switching outputs can be checked by simulating a switching temperature.

4.6.4 Baud Rate

The baud rate can be set between 1.2 and 57.6 kBd.

4.6.5 Address

In bus operation with RS485, an address between 00 and 97 can be assigned.

4.6.6 Interface Delay (Answer Delay)

During operation of the infrared switch via RS485, it may happen that the connection is not fast enough

to detect the response of the infrared switch to a command from the master, e.g. because the line is still

busy with sending before receiving. This sometimes occurs in older PCs or interface adapters or by

slow switching times of interface adapters and manifests itself in transmission errors of interface commands, so errors when parameters are changed or of measured values transmission.

In this case a delay for delaying the data transfer can be entered, the value specifies the main circulating time and can be set from 00-20. The transmission of commands to the connected device is thus

somewhat delayed, but it can work with existing peripherals.

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Configuring via SensorTools Software

13

5 Configuring via SensorTools Software

5.1 Program Start

Starting the software opens

the main window of the program. The Polaris is not connected automatically.

Since the Polaris is not a

measuring instrument, the

temperature reading functions in the main window of SensorTools are not functional.

5.1.1 Connecting the Polaris

For successful communication with the Polaris it has to be connected first.

Select the computer’s com port the device is connected to. Also a COM port must be

selected when connecting via an USB converter.

Press the search button if the com port is unknown. The device will be connected

automatically if the port is found.

Press the connect button to connect the device to the software. All device settings will

be read out and displayed in the software.

The button changes to “Disconnect” when connected. Click to disconnect.

The status line informs about device and connection status.

5.2 Setting Window

The setting window will appear as soon as the connection

is established.

The response time t90 (see 4.6.2) can be adapted to the

measurement conditions.

Selecting "Minimal" the Polaris works with the shortest

possible devices response time of 4 ms.

Under "User definded", times up to 10 s can be entered.

The Emissivity (see 4.6.1) is used for adaptations to the

material surface properties.

Limit switches:

- Limit value: Activates the corresponding output (Port)

at the entered limit value.

- Hysteresis: The hysteresis is the value at how many

degree below the limit value the output is switched

back.

- Logic: The state of the digital outputs can be set:

- NO (normally open): outputs have in active state 24

volts (precicely the power supply voltage, output

max. 30 mA) to the pins and in inactive state 0 V.

- NC (normally closed): outputs have in active state 0 volts to the pins and in inactive state 24 V

(precicely the power supply voltage, output max. 30 mA)

Laser targeting light: turns on and off the laser targeting light.

CAUTION, Laser Radiation, Laser Class 2:

Never look into the direct or reflected laser beam.

Do not point the laser to anyone.

If laser radiation hits the eye, the eyes must be intentionally closed and the head im-

mediately moved out of the beam.

Select PC

interface

or search

automatically

Connect with

software

Status line

Homepage link

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Configuring via SensorTools Software

14

Port test:

Enables testing of the outputs by simulating a switching temperature.

The simulation automatically stops after 3 seconds.

Interface:

For setting the baud rate (see 4.6.4), device address (see 4.6.5)

and interface delay (see 4.6.6).

Service functions

To back up, for printing or restore device parameters or create service files for

remote diagnosis of problems.

- Create configuration file: A configuration file includes all device settings made by user. This can

be used e.g. to setup a new device with the same values

and settings or to save the current status in case of a device replacement.

- Load Configuration file: load a previously saved configu-

ration data in the device.

- Print parameters: Prints the parameters of the currently

connected device.

- Print configuration file: Prints a saved file.

- Create service file: A service file includes all device data

and all software settings made by user. Creating such a file

can be useful if a problem can’t be solved and help from

our service could be useful.

- Upload service file: Transmitting a (possibly modified) file

to the device it was created from.

Spot size calculator

The spot size calculator (from the

main window) is used to calculate

the spot size diameter in front and

behind the focused measuring distance (see 4.5.1). To do this, fill the

white fields with the basic data (see

4.5 spot size tables), then values

in the gray fields can be calculated.

Start simulation

Specify simulation

temperature

Check output state

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Technical Data

15

6 Technical Data

Model

PS09 PI16

Temperature ranges

550–1400°C

650–1800°C

250–1000°C

300–1300°C

350–1800°C

Spectral range

0.7–1.1 µm

1.45–1.8 µm

Switch temperatures

Can be set within the limits of the temperature range

Signal processing

Digital

Measurement uncertainty

± 1% of adjusted switching point temperature (TA=23°C, ε=1, t90=1 s)

Repeatability

0.5% of adjusted switching point temperature (TA=23°C, ε=1, t90=1 s)

Response time t90

4 ms, adjustable to 10 s

Emissivity ε

20–100%

Power supply

24 V DC (possible range 12 – 30 V DC)

Power consumption

Max. 0.5 VA (without switching output current)

Switching outputs

2 transistor outputs, switches the positive supply voltage to the output

(positive switching), max. current 30 mA

Digital interface

RS232 or RS485, addressable, baud rate 1.2–57.6 kBd,

galvanically isolated

Parameters

changeable and readable via serial interface:

switching temperature, emissivity, response time, device temperature,

address, baud rate

Sighting

Laser targeting light (laser class 2, max. output power 1 mW, 635 nm)

Operation indicator

Green LED

Switching indicator

2 yellow LEDs

Weight

300 g

Protection class

IP65 (according to DIN 40 050) with mounted connection cables

Ambient temperature

0–70°C

Storage temperature

-20–70°C

Rel. humidity

No condensing conditions

CE label

According to EU directives for electromagnetic immunity

6.1 Storage

Store packages under the following conditions:

Do not store outdoors

Store dry and dust-free

Do not exposed to corrosive media

Protect from direct sunlight

Avoid mechanical vibrations

Storage temperature: -20 to 85°C

Relative humidity: max. 95%,

no condensing conditions

6.2 Dimensions

Dimensions in mm

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Technical Data

16

6.3 Composition of the Type Number

The equipment version of the Polaris is encoded in the 18-digit model number as follows

(Example type number PS09 with 550–1400°C; laser targeting light, 2 switch outputs):

Digit

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

Expl.:

P S 0 9 0 5 5 0 1 4 0 0 1 1 2 4 3

2 Digit

Indication of the various points

Code

Meaning / Example

01-02

Series Polaris

PS

Polaris with Silicon detector

PI

Polaris with Indium-Gallium-Arsenid detector

03-04

Spectral range

09

0.7–1.1 µm (Si)

16

1.45–1.8 µm (InGaS)

05-08

Beginning of temperature range [°C]

0550

550°C

09-12

End of temperature range [°C]

1400

1400°C

13

Sighting

1

Laser targeting light

14

Serial interface

1

RS232

2

RS485

15

Lens type

2

Focusable optics

16-17

Minimum response time

43

4 ms

18

Outputs

2

2 transistor outputs

Measuring distance / Optics

A

Optics A (170-245 mm)

B

Optics B (260 - 500 mm)

C

Optics C (480 - 2000 mm)

6.4 Accessories

Ref. number

Meaning

AK32-02

Connection cable 2 m

AK32-05

Connection cable 5 m

AK31-02

Interface cable 2 m, including SensorTools software

AK31-05

Interface cable 5 m, including SensorTools software

DK4000

Interface converter RS485USB, 1.7 m cable, 9-pin Sub-D-connector

DK3000

Interface converter RS232USB, 1.7 m cable, 9-pin Sub-D-connector

NG12-00

Din-rail power supply 24 V DC, 1.6 A

NG15-00

Desktop power supply 24 V DC, 2.5 A

HA11-00

Stainless steel mounting bracket

BL11-00

Air purge accessory

KG60-00

Water cooling jacket for temperatures up to 140°C

HA10-10

Mounting bracket to be used with cooling housing KG60

HA21-00

Ball and socket swivel mount for water cooling jacket KG60

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Maintenance

17

7 Maintenance

CAUTION, switch off supply voltage.

Before beginning any maintenance, switch off power supply or pull connector on the Polaris to prevent injury by accidentally activated laser targeting light!

7.1 Cleaning

Clean the lens with a soft cloth and a little alcohol or acetone. Use only high-purity acetone to avoid residues.

The objective lens is not

to clean with solvents that contain acid

immerse in water or other liquids to clean

7.2 Calibration

To obtain the measurement accuracy, we recommend to re-calibrate the Polaris at Sensortherm periodically (annually) with the help of calibration sources.

8 Communication via Serial Interface / Interface Commands

Interface commands are used to communicate directly with a Sensortherm device. Commands can be

used to write an own access control or can be entered in the terminal field of the software SensorTools

(in the main window in the tab “miscellaneous”) or entered via a terminal software. Data is exchanged in

ASCII format with the following transmission parameters: 8 bit, 1 stop bit, even parity (8,1,e).

Command structure:

For successful communication the following sequence of a command is used:

Device Address - Command - Parameter

Device address: all interface commands are starting with the 2-digit device address (exception: in

the terminal field of the SensorTools software no address is required). In factory setting the device

address is 00 but can be change per command.

Device addresses from 00 to 99 are valid but 98 and 99 are with special functions. The global address 99 can be used to communicate with every device, independent of the set address. This allows

communication with devices which have unknown addresses. The address 98 is a group address

used for RS485 devices. Devices do not answer with this address, useful to change parameters of all

connected devices at the same time.

Command: command have to be completed with a carriage return <CR> (decimal 13).

Parameter (Unless otherwise specified, coded hexadecimal):

without parameter the command reads out the current set value. The answer at request commands

is the set value of the device corresponding to the possible settings described in the table. Answers

are normally finished with a <CR>. Deviating read commands are in parentheses in the respective

write commands.

With parameter the parameter will be set into the device. A setting command answers with

ok+<CR>, this means the command is accepted.

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Communication via Serial Interface / Interface Commands

18

Command

Parameter

Description / Settings

bn Read reference number (18-digit ASCII sequence)

Meaning: see 6.3 Type number

br X Baud rate (1-digit dec.)

X = 0-4, 6

0 = 1200 Baud 2 = 4800 Baud 4 = 19200 Baud

1 = 2400 Baud 3 = 9600 Baud 6 = 57600 Baud

em

XXXX

Emissivity (4-digit. dec.)

XXXX = 0020–1000 in ‰ (= Emissivity 2–100%)

ez X Einstellzeit t90 (1-stell. Dez.)

X = 0-6

0 = inherent time constant of the device

1 = 0.01 s 3 = 0.25 s 5 = 3 s

2 = 0.05 s 4 = 1 s 6 = 10 s

ga

XX Device address (2-digit decimal number)

00–97 = individual device address

99 = global address with answer

98 = global address without answer

gt Read device temperature (2-digit decimal number in °C)

XX=00–98°C

mb Read temperature range (8-digit hexadecimal number)

First four digits: beginning of temperature range in °C

Last four digits: end of temperature range in °C

sw1

XXXXYYYY

Switch temperature 1 (8-digit hex.)

XXXX=lower switch temperature in °C

YYYY=upper switch temperature in °C

sw2

XXXXYYYY

Switch temperature 2 (8-digit hex.)

XXXX=lower switch temperature in °C

YYYY=upper switch temperature in °C

sn Read serial number (5-digit decimal number)

tm Read Maximum device temperature (2-digit decimal number),

XX=00–98°C

ve Read device type and software version (6-digit decimal number)

1. and 2. digit: Device type Polaris PS/PI

3. and 4. digit: Month of software version

5. and 6. digit: Year of software version

Infrared Temperature Switch (Hot Metal Detector) Polaris PS09 / PI16

Index

19

Index

A

Accessories ......................................................... 16

Address ................................................................ 12

Alignment onto the measuring object .................... 8

Alignment with the laser targeting light .................. 9

Ambient temperature ............................................. 8

Answer Delay ....................................................... 12

B

Baud rate ............................................................. 12

C

Cable colors and pin assignment .......................... 6

Calibration ............................................................ 17

Cleaning ............................................................... 17

Communication via serial interface ...................... 17

Configuring via SensorTools software ................. 13

Connecting the Polaris......................................... 13

E

Electrical connection .............................................. 6

Emissivity ε .......................................................... 11

F

Factory settings ..................................................... 6

I

Intended use .......................................................... 4

Interface commands ............................................ 17

Interface converter (accessory) ............................. 8

Interface delay ..................................................... 12

Interface settings ................................................. 14

L

Laser targeting light .......................................... 9, 13

M

Maintenance ......................................................... 17

Mechanical installation ........................................... 8

Mounting ................................................................. 8

P

Parameters / settings ........................................... 11

Power supply .......................................................... 6

R

Response time t90 ................................................. 12

S

Scope of Delivery ................................................... 4

Serial Interface RS232 or RS485 ........................... 7

Service functions .................................................. 14

Setting the measuring / focus distance .................. 9

Setting window ..................................................... 13

Simulate a switching temperature ........................ 12

Software SensorTools .......................................... 13

Spot size calculation ............................................. 10

Spot size calculator .............................................. 14

Spot size tables .................................................... 10

Status LEDs ........................................................... 6

Switching outputs ................................................... 7

T

Technical data ...................................................... 15

Type number ........................................................ 16

Sensortherm GmbH

Hauptstraße 123

65843 Sulzbach

Tel: +49 (0)6196 64065-80

Fax: +49 (0)6196 64065-89

E-Mail: info@sensortherm.com

Internet: www.sensortherm.com

© Sensortherm GmbH Polaris_PS09_PI16 (May 11, 2017)

Loading...

Loading...