ST-2200 Sensor

with Attached Electronics

Installation Instructions

© Sensortech Systems, Inc. 2016 Page 1 of 16 Rev.7-2016

Sensortech Systems, Inc.

2221 E. Celsius Avenue Unit B

Oxnard, California USA 93030

805-981-3735 main

805-981-3738 fax

www.sensortech.com

ST-2200 Sensor System:

Figure

2. ST-2200

Sensor

The two main components in the system are:

1. ST-2200 Processor Unit (Processor) – an intelligent measurement and control unit that

connects to the Sensor Electronics Unit and provides moisture measurements via serial, 420mA and front panel LED display. The Processor is also referred to as the Signal Processor.

Figure 1. ST-2200 Processor Unit

2. ST-2200 Sensor with Attached Sensor Electronics (Sensor) – a NEMA12 rated metal

enclosure containing the moisture measurement and RF switching electronics is attached to

the bottom side of the open-frame planar sensor. The Sensor is mounted in-line on the

outside of the dryer. The Sensor with Attached Sensor Electronics is also referred to as the

Antenna.

© Sensortech Systems, Inc. 2016 Page 2 of 16 Rev.7-2016

with Attached Electronics Unit

ST-2200 Sensor System Installation Guidelines

Locating the Sensor:

Select a location to install the ST-2200 Sensor where the board will remain flat over the Sensor

for the full length or width of board travel over the Sensor.

Avoid locations where the air gap between the board and Sensor may change during board travel

due to changing slope or roller height on Dry End Transfer conveyor or Takeoff Cascade.

Preventing board bounce while arriving, travelling over and leaving the Sensor results in the best

measurement accuracy. In addition, it is desirable to prevent a board impacting the Sensor due to

board bounce or changing angle of approach or departure from the Sensor.

The spacing between the top of the Sensor to the bottom of a board is critical for good

measurement accuracy. The specification for the air gap between the board and Sensor is 0.25

inches (6.35mm). A typical ST-2200 Sensor is installed on a Mounting Beam centered between

level rollers 12-18 inches (30-45cm) apart.

When measuring board traveling over the Sensor for the full length of the board, the

recommended minimum distance from the end of the Take-off Cascade is calculated as follows:

Sensor Location = Longest Board Length + 1 Roller (from the Take-off Cascade)

i.e. if the Longest Board Length = 14 feet (4.3m) and the roller spacing is 12-18 inches (30-

45cm) then the mounting beam for the Sensor should be installed greater than 15 feet

(4.6m) from the end of the Take-off Cascade.

When measuring board traveling over the Sensor for the full width of the board, the

recommended minimum distance from the Inverter on the Dry End Transfer is calculated as

follows:

Sensor Location = Widest Board Width + 1 Roller (from the Inverter)

i.e. if the Widest Board Width = 4 feet (1.22m) and the roller spacing is 12-18 inches (30-

45cm) then the mounting beam for the Sensor should be installed greater than 5 feet

(1.5m) before the Inverter.

© Sensortech Systems, Inc. 2016 Page 3 of 16 Rev.7-2016

Preparing for the installation:

1. Fabricate and install a height adjustable beam for installing the Sensor after the kiln or dryer

between the rollers. Ensure the adjustment range allows the Sensor to be positioned at 0.25

inch (6.35mm) spacing from bottom of board when resting on rollers.

2. Run a 10-16 AWG Earth Ground wire from local ground source to Sensor mounting location.

3. Mount the Processor Unit in the desired location per supplied drawings (see Figure 7 & 8). It

is recommended to mount the Processor Unit near the Sensor mounting location and run the

4-20mA cable for moisture output to the control room Process Controller / PLC.

4. Install conduit or cable run for Processor Cable from the Sensor to the Processor Unit.

5. Provide AC plug receptacle for main AC power to Processor Unit (110-240VAC 20A Service).

6. Run an Earth Ground wire from local ground source to Processor Unit mounting location.

7. Install any external equipment / PLC cabling to Processor Unit terminal block signals (RS-232

serial link, 4-20mA loop, external alarms, product detectors, etc.).

Important:

Do not mount the Sensor with attached Sensor Electronics Unit where excessive heat

transfer will occur. Ensure that Sensor is located away from exhaust gases venting from

the dyer to prevent measurement drift or electronics failure due to the attached Sensor

Electronics Unit over-heating.

Provide an Earth Ground for the Sensor. Ensure a side plate of the Sensor is connected to

local Earth Ground. Add a 10-16 AWG direct wire connection from the Sensor with

attached Sensor Electronics to a local Earth Ground potential. Ensure sensor frame is

grounded to process frame or conveyor frame, etc. This is not a safety requirement, but

may influence instrument performance.

© Sensortech Systems, Inc. 2016 Page 4 of 16 Rev.7-2016

© Sensortech Systems, Inc. 2016 Page 5 of 16 Rev.7-2016

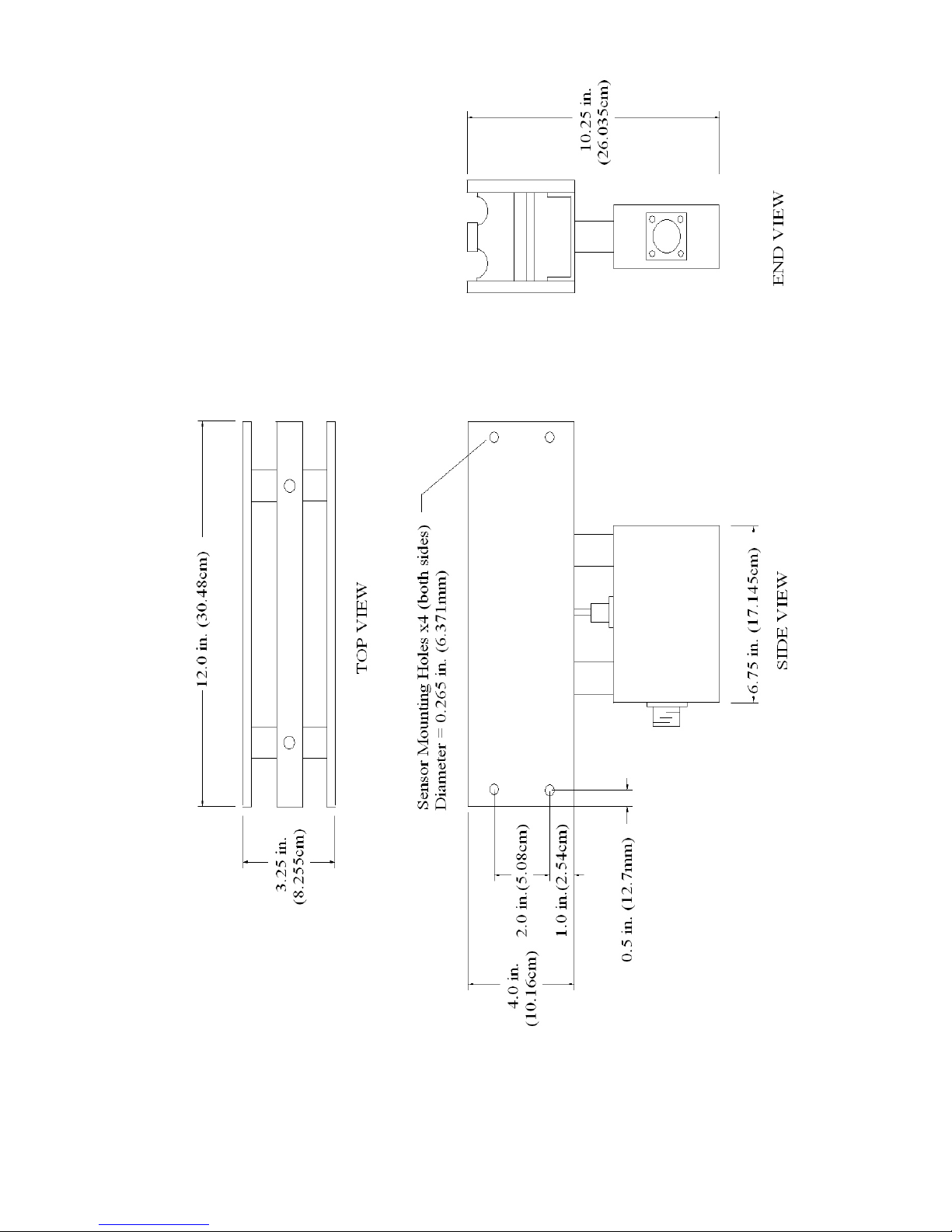

Figure 3. 12

-

inch (30.48cm) Sensor Dimensions

© Sensortech Systems, Inc. 2016 Page 6 of 16 Rev.7-2016

Figure

4

. 36-inch

(91.44cm)

Sensor Dimensions

Mounting the Sensor:

The Sensor is typically mounted after the dryer between rollers or under a conveyor surface. The

Sensor with attached Sensor Electronics Unit is rated from 0°C to 50°C ambient temperature and

should be on a low vibration steel channel or angle beam mounted to the floor. A less desirable

mounting approach due to increased vibration is to install the sensor on a steel channel or angle

beam mounted to the existing roller support frame. The Sensor is attached to the beam using the

four mounting holes on the ends of the Sensor frame (see Figure 5 & 6). The open-frame Sensor

construction allows debris to fall through the Sensor and the bottom of the Sensor should not be

blocked by the beam to allow debris to exit.

A critical dimension for a roller conveyor process is the 0.25 inch (6.35mm) product to Sensor air

gap between the top of the Sensor to the bottom of a board across the board width. The air gap

distance can be checked with anything that is 0.25 in. (6.35mm) in diameter (a drill bit, 1/4inch bar

stock, etc.) and a straight edge that rides on top of the conveyance system (rollers, belt, etc.). The

concept most important here is that the Sensor is coplanar and parallel to the product. If one end

of the Sensor is further from the product, it will be less sensitive to changes in moisture than the

opposite end that is closer. This can be further aggravated if the product does not have uniform

moisture distribution. See Parallel Antenna Verification below. The antenna and sensor should

also be isolated as much as possible from vibration. Vibration can loosen nuts, bolts, and

electronic components.

The Processor Cable, a multi-conductor shielded twisted pair cable is used to connect the Sensor

Electronics Unit to the Processor Unit. The standard Processor Cable is 25 ft. x 0.5 in. (7.62m x

12.7mm) in length. The Processor Cable is rated from -40°C to +85°C ambient temperature.

Custom processor cable lengths up to 1000 ft. (300m) are available and higher temperature rated

cable is available by special order.

Parallel Antenna Verification (on roller conveyors):

This procedure should be done with factory default settings. Place a Standardization Plate (or

board product with approximate dimensions of 24 in. x 24 in. (61cm x 61cm) covering one half of

the Sensor. Note moisture display value. Move the Standardization Plate over one half of the

other end of the Sensor. Make sure to use the same section of plate with same orientation. Note

moisture display value. If there is a difference in moisture display values, the antenna is not

parallel to the product. The side that displayed higher readings is closer to the product than the

other end of the Sensor. The mounting beam or Sensor mounting bolts will need to be adjusted

up or down until both ends of the Sensor are at 0.25 in. (6.35mm) air gap spacing and moisture

values are similar within +/- 1 are displayed when the Standardization Plate is placed covering

one half at each end of the Sensor.

© Sensortech Systems, Inc. 2016 Page 7 of 16 Rev.7-2016

Leveling the Rollers:

Lay a level or straight edge across the six rollers near their ends.

Sensor

IMPS Sensors

The maximum runout for each of the three rollers preceding

and following the sensors is 0.02 inches (0.5 mm).

The top surface of the IMPS Sensors should be 0.25 +/- 0.02 inches (6 +/- 0.5mm) from the bottom of the board.

Mount the sensor 0.125 inches (3mm) down from the surface of the bracket. This protects the sensor from the

leading board edge.

Shim the two outer rollers’ bearing assemblies so that they are level.

Shim the remaining four rollers’ bearing assemblies so that each roller is within 0.01 inches

(.25mm) of level.

Lay the level along the first roller. Shim its bearing assembly on the other side so that it is level

lengthwise.

Lay a level across the six rollers near their ends.

Shim the last roller’s bearing assembly so that it is level with the first roller.

Shim the remaining four rollers’ bearing assemblies so that each roller is within 0.01 inches

(.25mm) of level.

Use a feeler gauge to measure the space from the top of Sensor to bottom of a board or use the

ST-2200 Standardization Plate for board alignment. To make a feeler gauge for air gap

alignment, cut two 12 in. (30 cm) lengths of 0.25 in. (6.35 mm) square or round rod and place on

Sensor below the Standardization Plate and adjust the beam until the rods just touch the bottom

of the Standardization Plate. Ensure both ends of the Standardization Plate are coplanar to the

tops of the Sensor. Adjust the Sensor mounting Beam and adjacent 4-6 rollers until the Sensor is

coplanar to the rollers and the rollers are level to each other.

© Sensortech Systems, Inc. 2016 Page 8 of 16 Rev.7-2016

Level

Rollers

Roller

Conveyor

Frame

Level

Bearing

Shim

© Sensortech Systems, Inc. 2016 Page 9 of 16 Rev.7-2016

Figure 5. Detail of Sensor Installed on a Mounting Beam

© Sensortech Systems, Inc. 2016 Page 10 of 16 Rev.7-2016

Figure 6. Example of 36-inch (91.44cm) Sensor Installed on a Mounting Beam

© Sensortech Systems, Inc. 2016 Page 11 of 16 Rev.7-2016

Mounting the Processor Unit:

Figure

7

. Processor Unit Dimensions

The ST-2200 Processor Unit (Processor) is typically panel mounted in an enclosure next to the

line for ease of access during maintenance calibration or in a control room within the Processor

Cable length to the Sensor.

To panel mount the Processor, remove the front plastic bezel and attach the Processor

mounting brackets, provided with the Processor Unit, to the Processor housing. It is

necessary to loosen the Processor front panel in order to install the mounting brackets

onto the housing.

When locating the Processor, allow sufficient depth for the length of the unit plus at least 3inches (76mm) to accommodate cables at rear of unit.

© Sensortech Systems, Inc. 2016 Page 12 of 16 Rev.7-2016

Figure

8

. Processor Panel Cut

-

out Dimensions

To panel mount the Processor, use the panel cut-out mounting diagram below to cut out a

rectangular hole for the front panel. Drill four thru holes to install bolts to attach to the Processor

mounting brackets.

© Sensortech Systems, Inc. 2016 Page 13 of 16 Rev.7-2016

ST-2200 System Power-up:

Figure

9

. Processor Unit Rear Panel Connections

Please verify the following before applying power to the ST-2200 Processor:

1. Securely tighten the black Amphenol connector located on the side of the Sensor.

2. Ensure the nine wires on the Processor Cable from the Sensor Electronics Unit are

wired into the terminal block labeled SENSOR INPUT on the rear of the Processor. The

wires are labeled 1 thru 9, and should be installed in sequential order, starting with wire

labeled #1 on the left side terminal block connector labeled +12V. Continue installing

each wire in number sequence ending with wire labeled #9 on the right terminal block

connector labeled AIO- (see Figure 9).

3. Ensure the Processor and Sensor are moisture free and the ambient temperature

environment is between 0°C to +50°C.

Note: Do not over tighten the terminal block screws.

For additional technical support, email us at

support@sensortech.com

or call 805-981-3735 M-F between 8AM-4:30PM Pacific Standard Time

© Sensortech Systems, Inc. 2016 Page 14 of 16 Rev.7-2016

ST-2200 PROCESSOR COMMANDS - QUICK REFERENCE

Function

Number

00

01 Product code 1 10 1

02 Password ****** ****** ******

03 Sample Rate 1 1S 10ms

04 Damping 0 120 0

05 Decimal selection 0 2 1

06 Pre-zero

07 Standardization 25

08 Sampling Mode 0 4 1

09 Batch Average mode No Yes No

10 Void Time 1

11 ATRO No

19 New Password ******

20 Limits

21 Low moisture limit -5.0 99.9 -5.0

22 High moisture limit 0 9999 100

23 4 mA out moisture 0 100 0

24 20 mA out moisture 0 100 100

25 Auto product loss 0 9999 0

26 Auto product return 0 9999 9999

27 Timed sampling fill time 0 99 1

28 Timed sampling purge time 0 10 1

29 Reference 0 100 15

30 Dielectric

31 Dielectric mode 1 3 1

32 Dielectric span -99.999 99.999 1

33 Dielectric zero -999.99 999.99 0

40 Temperature

41 Temperature compensation No Yes No

42 Temperature coefficient...Kt1 -99.999 99.999 0

43 Temperature coefficient...Kt2 -99.999 99.999 0

44 Temperature nominal -999.99 999.99 0

50 Weight

51 Weight compensation No Yes No

52 Weight coefficient...Kw N/A N/A 0

53 Weight nominal -999.99 999.99 0

54 Weight...keyboard entry 0 999.9 0

60 Distance

61 Distance compensation Off On Off

62 Distance coefficient...Kd -99.999 99.999 0

63 Distance nominal N/A N/A 0

Function

Description

General

Range

Low

Range

Range

High

Range

Default

© Sensortech Systems, Inc. 2016 Page 15 of 16 Rev.7-2016

Number

100 Utilities

101 Default CAUTION!!

102 Code Copy

120 I/O Configuration

121 Temperature span -99.999 99.999 1

122 Temperature zero -999.99 999.99 0

123 Weight span -99.999 99.999 1

124 Weight zero -999.99 999.99 0

125 Distance span -99.999 99.999 1

126 Distance zero -999.99 999.99 0

127 4 mA calibration

128 20 mA calibration

129 Equal High referencing No Yes No

130 Alpha-numeric display intensity 00 77 33

131 Numeric Display minimum -999.99 999.99 -.2

132 Numeric Display maximum 0 9999 9999

133 Host Interface Baud Rate 300 19200 9600

134 Host Interface Device Address 0 99 0

135 Communication Type RS232 RS485 RS485

136 Host Options 0 255 56

137 Product Code No Yes Yes

138 Safe Alarm No Yes No

139 Compensation WTD 1 6 WTD (1)

140 Diagnostics

141 Voltmeter Display

142 Antenna frequency Display

143 Low frequency Display

144 High frequency Display

145 Raw Dielectric Display

146 Dielectric pre-zero value 0.0000

147 Dielectric standardization value 50.00

148 Dielectric loss input Display

155 Raw temperature Display

156 Raw weight Display

157 Raw distance Display

158 Delta frequency Display

160 Display test Display

161 Keyboard test Display

162 Software Version 210

Description

Low High

Default

© Sensortech Systems, Inc. 2016 Page 16 of 16 Rev.7-2016

Loading...

Loading...