Sensortechnik Meinsberg TM 40, AM 40, LF 40 Operating Instructions Manual

edition 13/11

Sensortechnik Meinsber g G mbH

Quality System certified to DIN EN ISO 9001

Meinsberg, Kurt-Schwabe-Straße 6

D-04736 Waldheim/Germany

Internet: www.meinsberg.de

Tel.: +49 (0) 34327 623 0

Fax: +49 (0) 34327 623 79

Draft

Operating Instruction

Manual

pH/Redox/ISE Meter

TM 40

Oxygen Meter

AM 40

Conductivity Meter

LF 40

1. Safety ..................................................................................................................................................................... 4

2.

Sockets ................................................................................................................................................................... 5

2.1 Battery .......................................................................................................................................................... 5

3. Button, Display, M enu structure, Password protection ........................................................................................ 6

3.1 Operation elements ..................................................................................................................................... 6

4. Configuration the basic settings “General” ........................................................................................................... 7

4.1 Configuration Backlight ............................................................................................................................... 7

4.2 Configuration pass word ............................................................................................................................. 8

4.3 Configuration clock ...................................................................................................................................... 8

4.4 Configuration language ............................................................................................................................... 8

4.5 Configuration off time .................................................................................................................................. 8

4.6 Data logger .................................................................................................................................................. 9

5. Info ........................................................................................................................................................................ 10

6. Interface HMG USB ............................................................................................................................................. 10

7. Maintenance, Disposal ........................................................................................................................................ 10

8. TM 40 ................................................................................................................................................................... 11

8.1 Application Fields TM 40 ........................................................................................................................... 11

8.2 Construction TM 40 ................................................................................................................................... 11

8.3 pH-Sensor EGA 142/TM 40 ...................................................................................................................... 11

8.4 Menu structure TM 40 ............................................................................................................................... 11

8.5 Calibration pH ............................................................................................................................................ 13

8.5.1 Data input ..................................................................................................................................... 13

8.5.2 Settings of the temperature offset ............................................................................................... 14

8.5.3 Two-point-Calibration “two point“ ................................................................................................ 14

8.5.4 Automatic Calibration .................................................................................................................. 14

8.5.5 Calibration error ........................................................................................................................... 15

8.6 Calibration Redox ...................................................................................................................................... 15

8.6.1 Data input ..................................................................................................................................... 15

8.6.2 Setting of the temperature offset ................................................................................................ 15

8.7 Calibration ISE ........................................................................................................................................... 15

8.7.1 Data input ..................................................................................................................................... 15

8.7.2 Settings of the temperature offset ............................................................................................... 15

8.7.3 Two-point Calibration „Two point“ ............................................................................................... 16

8.8 Configuration TM 40 .................................................................................................................................. 16

8.8.1 Configuration of the fix temperature ........................................................................................... 16

8.8.2 Configuration of the sensor type ................................................................................................. 17

9. AM 40 ................................................................................................................................................................... 17

9.1 Application Fields AM 40 ........................................................................................................................... 17

9.2 Construction AM 40 ................................................................................................................................... 17

9.3 Dissolved Oxygen Sensor MF 41-N/AM 40 ............................................................................................. 17

9.4 Menu structure AM 40 ............................................................................................................................... 18

9.5 Calibration oxygen ..................................................................................................................................... 19

9.5.1 Data input ..................................................................................................................................... 19

9.5.2 Settings of the Temperature Offset ............................................................................................ 20

9.5.3 Single-Point Calibration „one point“ ............................................................................................ 20

9.5.4 Automatic Calibration .................................................................................................................. 20

9.5.5 Calibration error ........................................................................................................................... 20

9.6 Configuration AM 40.................................................................................................................................. 21

9.6.1 Configuration of the fix temperature ........................................................................................... 21

9.6.2 Configuration of the main value .................................................................................................. 21

10. LF 40 .................................................................................................................................................................... 22

10.1 Application Fields LF 40 ............................................................................................................................ 22

10.2 Construction LF 40 .................................................................................................................................... 22

10.3 Conductivity Sensor LTC 0,35/LF 40 ....................................................................................................... 22

10.4 Menu structure LF 40 ................................................................................................................................ 22

10.5 Calibration conductivity ............................................................................................................................. 23

10.5.1 Data input ..................................................................................................................................... 23

10.5.2 Settings of the temperature offset ............................................................................................... 24

10.5.3 One-point-Calibration „one point“ ............................................................................................... 24

10.5.4 Automatic calibration „Automatic“ ............................................................................................... 25

10.5.5 Calibration error ........................................................................................................................... 25

10.6 Configuration ............................................................................................................................................. 25

10.6.1 Configuration of the fix temperature ........................................................................................... 25

10.6.2 Configuration of the measuring range „meas. range“ ............................................................... 25

11. Specifications ....................................................................................................................................................... 26

12. Delivery volume ................................................................................................................................................... 27

13. Accessories .......................................................................................................................................................... 27

4/27

1. Safety

This Operating Instructions Manual contains fundamental information that should be observed in connection with the

installation, start-up, operation and maintenance of the instrument in connection with the sensor. Therefore, it is absolutely

vital for the user to read this manual prior to workin g with it.

User qualification

The meter has been designed for analytical measurements. It is assumed that the user/operator and the maintenance

personnel have the proper professional skills and experience to know the specific properties of analytical measuring

systems, master the safe handling of chemicals, for example, in the maintenance of electrodes/sensors, and can assess

any dangers and risks resulting thereof. The user must ensure that the national legislation and procedures concerning the

maintenance of industrial health and safety standards, the accident preventions and the handling of chemicals are

observed.

Installation and getting started

The perfect functioning and operational safety of the instrument can only be maintained under the climatic conditions

specified in the section "Specification" of this manual. When the instrument is moved from cold to warm surroundings,

condensate may occur and interfere with the functioning of the instrument. In such case, the user should wait until the

temperature of the instrument has adapted to t he ambient temperature b efore using the instru ment again.

Use the sensor and interface cables recommended by the manufacturer only. For the sensors and accessories, the

instructions and regulations given in the respective operating instructions manuals and specification sheets will apply. The

instrument can only be operated with the battery specified in the section “ Specification”.

Be careful when connecting other instruments (e.g. via interface). Connections with external instruments may cause not

permissible potentials inside the instrument (e.g. connections between GND and earth). These potentials may result in

operational influences or malf unctions in the instrum ent itself or the ext ernal devices conne cted.

Proper usage

The meter and the sensor are intended for measuring and docu mentation of analy sis parameters. T aking into consideration

the “Specification” paragraph, operating and using the unit for this application is the proper usage. Any application beyond

this and individual modifications or extensions are improper and will lead to loss of entitlement to the warranty. When

connecting the unit with electrochemical sensors, always take into account their life and natural wear as this may result in

malfunctioning of the measuring system and the regulation or control associated therewith. The user must take suitable

measures to limit harmful effects of such malfunctioning.

General safety instructions

The complete meter has been manufactured and tested in accordance with the relevant guidelines and standards for

electronic measuring equipment. It has left the fact ory in technically unobj ectionable condition.

The perfect functioning and operational safety of the instrument and the accompanying components will only be ensured if

the user observes the normal safety precautions as well as the specific safety guidelines stated in the present manual and

in the relevant operating instruction manuals of the components. If there is reason to assume that the instrument can no

longer be employed without a risk, it must be set aside a nd appropriately marked to prevent further use.

The safety of the user may be endangered, e.g. if the instrument or one of its components

•

shows visible damage,

•

no longer operates as specified,

•

has been stored over a longer period under unsuitable conditions,

•

has been subjected to difficult conditions during transport.

If in doubt, please contact your supplier and sent back t he instrument to the manuf acturer for repair and maintenance.

5/27

2. Sockets

2 sockets for connecting the sensor and the” Interface HMG USB” are located on the front side of the instrument. Please

use only the delivered original cable for the interface with the PC. For protecting the sockets against moisture and to avoid

corrosion, the sensor should always b e con nected to the i nstrument and the “Interface HMG USB” so cket shoul d be seale d

by means of the protection cap if it is not in use. The “Interface HMG USB” is not included in the deliv ery.

Cable Sockets

2.1 Battery

Please open the battery chamber on the back sid e of the instrument an d insert the battery correctly into the cham ber.

Battery Chamber

Please use batteries from the type AA, IEC R6, LR6 only. After connecting and inserting the battery, please close the

battery chamber carefully an d correctly, to avoid moistu re coming inside t he device.

If the battery is in low condition, the device shows these with only 1 bar in battery indicator display. A change of the battery

is recommended. If there is no bar in the display, t he battery must be cha nged immediately.

Only for AM 40:

After changing battery or sensor please note the wait time before a new calibration. We recommend a new

calibration after battery change, because the permanent polarisation of the sensor was interrupted by

disconnecting the sensor from the battery.

6/27

3. Button, Display, Menu structure, Password p rotection

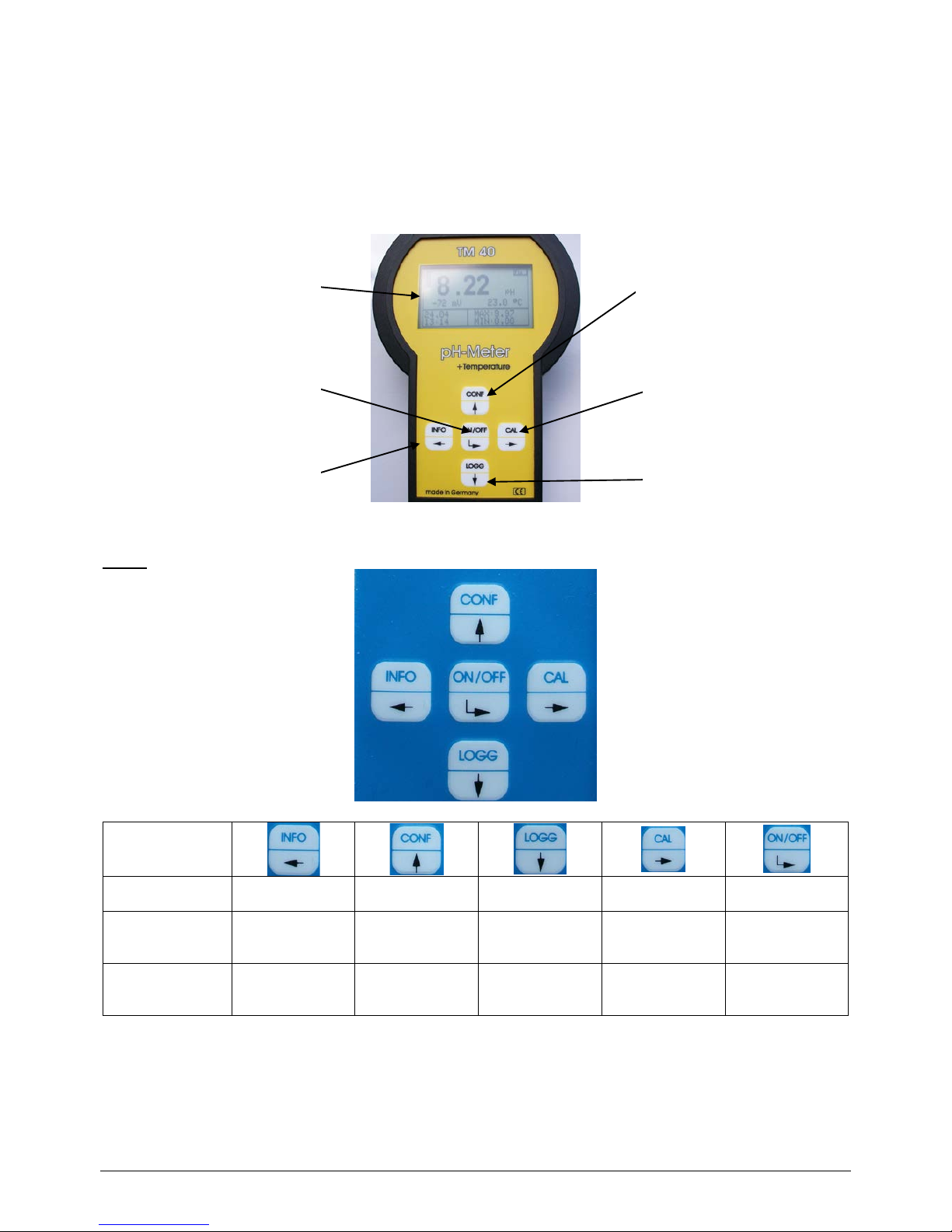

3.1 Operation elements

The instrument features easy operation by mean s of 5 buttons only and a plain text menu structure.

Button

Open a menu Information Configuration Data logger Calibration On / Off

navigation in the

menu

Cursor left Cursor up Cursor down Cursor right

selection /

ENTER

input / change

values

Cursor left position value +1 position value -1 Cursor right

confirm / save

value

By pressing the button “ON/OFF“ the meter switches on. The meter switches off either automatically after a

preset time-out or by long (approximately 3 seconds) pressing th e “ON/OFF“ button.

Only for AM 40:

Also when the AM 40 is switched off, the connected O2-Sensor is supplied with the necessary polarisation

voltage and so the system is directly after switching on always ready to measure.

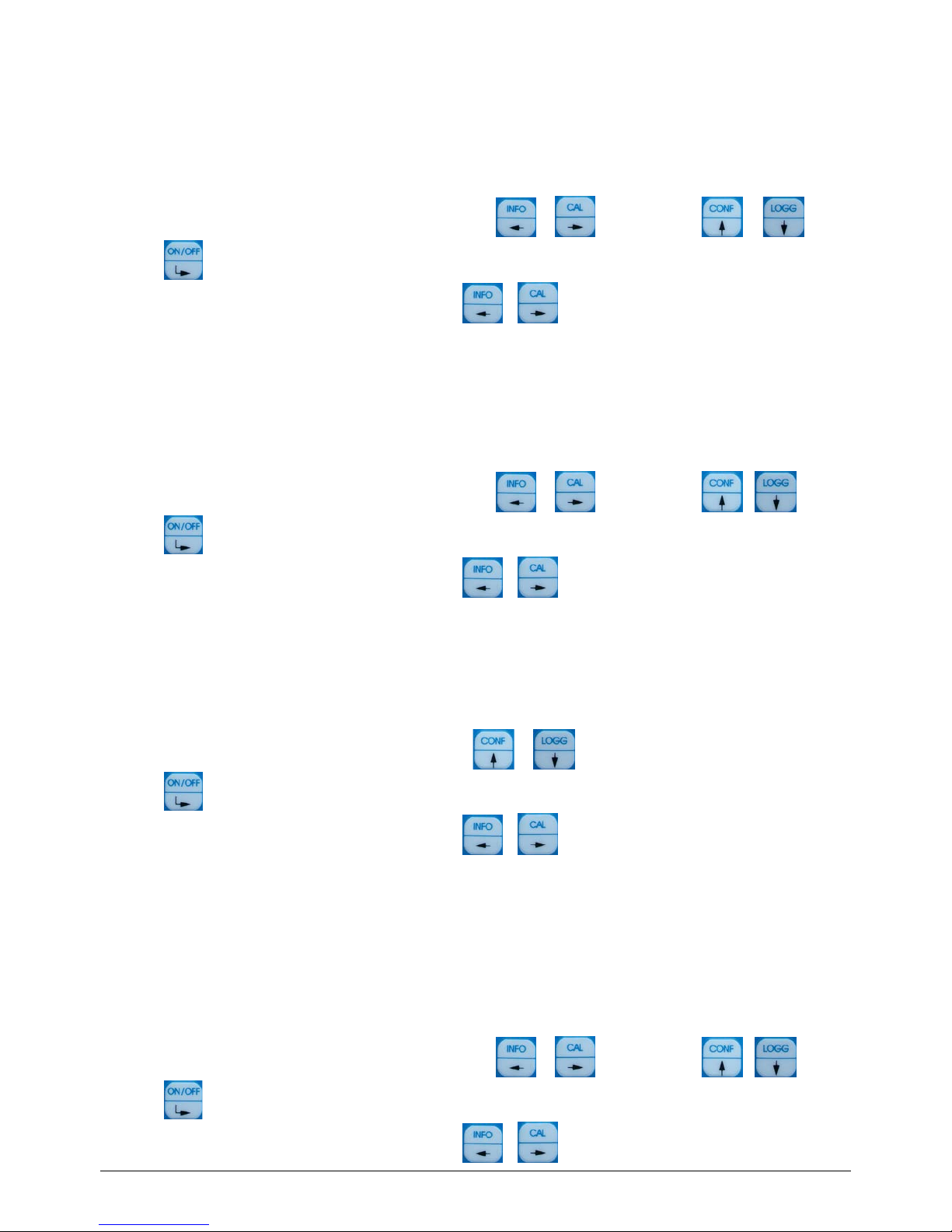

Configuration

Navigation <up>

Calibration

Navigation <right>

Data logger

Navigation <down>

Graphic display On/Off

Enter

Information

Navigation <left>

7/27

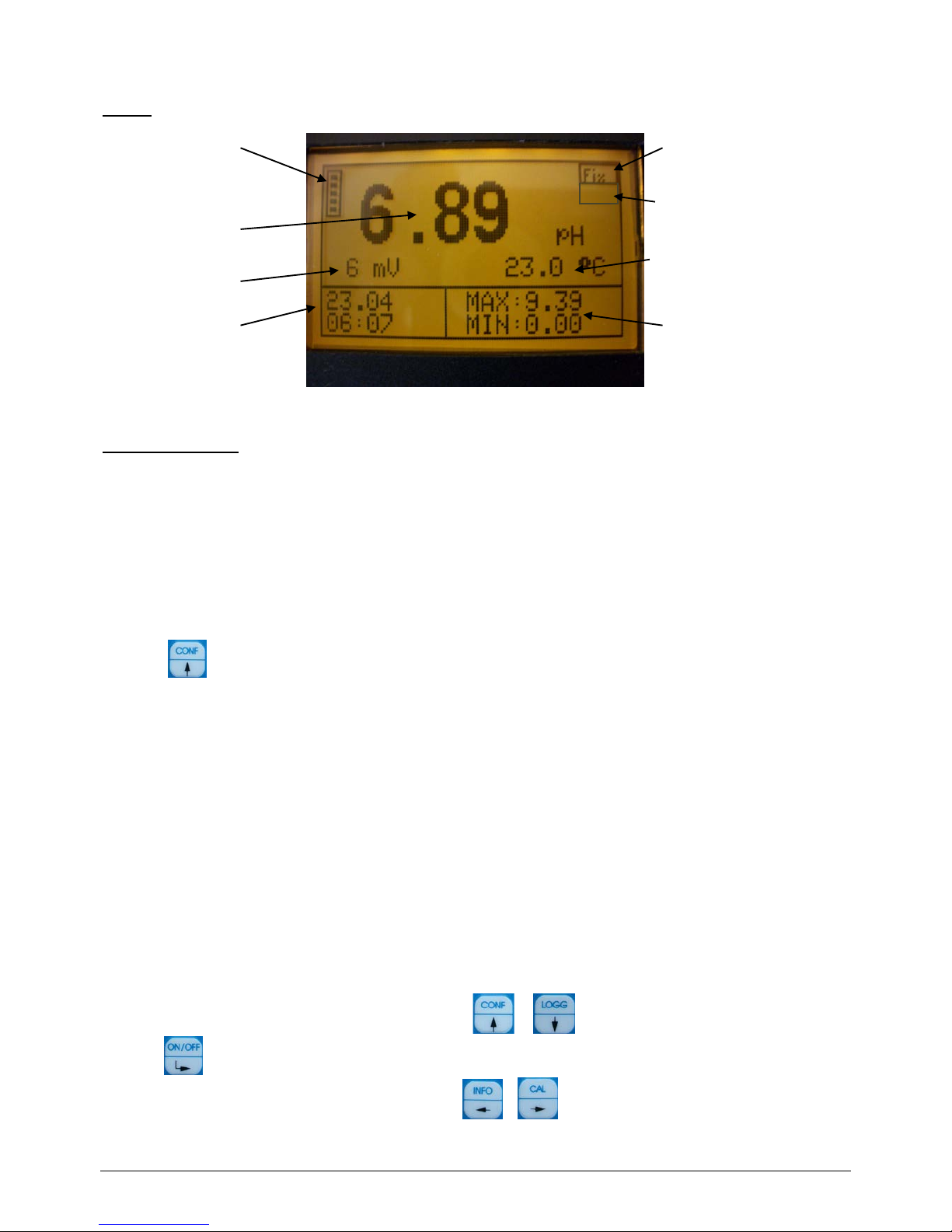

Display

Password protection

The calibration menu (CAL) and the configuration me nu (CONF) are password-protected.

The default password for opening these menus is 1.

4. Configuration the basic settings “General”

Open with

+ password t he configuration menu.

Select the menu item you would like to configure.

Backlight

Password

Clock

Language

Off time

Back

4.1 Configuration Backlight

On the device the backlight for display can be switched o n or off.

For configuration of the backlight do the following step s:

1. Open menu „general“

2. Select „Backlight“ disable/enable

Select the position you would like to use by using the buttons

or .

Press the -button to accept and save the entry.

To cancel the input dialogue without saving the value pre ss

+ .

Battery bar

display

Main

Measurement value

Second

Measurement value

Date / Time

Fix temperature active

Temperature

Min / Max

Main Measurement value

only LF 40:

Temperature compensation

nLF

8/27

4.2 Configuration pass word

For configuration of the password do the following steps:

1. Open menu „general“

2. Select „Pass word“ and enter your new pass word

3. Retry the new pass word

Select the position you would like to change by using the b uttons

or and change with or .

Press the -button to accept and save the entry.

To cancel the input dialogue without saving the val ue press

+ .

4.3 Configurati on clock

For configuration of the clock do the following steps:

1. Open menu „general“

2. Select „clock“ and enter the time and date

Select the position you would like to change by using the buttons

or and change with or .

Press the -button to accept and save the entry.

To cancel the input dialogue without saving the value press

+ .

4.4 Configuration language

For configuration of the language do the following steps:

1. Open menu „general“

2. Select “language“ and enter the language

Select the position you would like to use by using the but tons

or

Press the -button to accept and save the entry.

To cancel the input dialogue without saving the val ue press

+ .

4.5 Configuration off time

You can set the time when the meter switch es off automatically. The data logger will continue to log, if it is set in para 4.6

(Data logger).

To configuration the off tim e do the following step s:

1. Open menu „general“

2. Select “off time“ and enter the time

Select the position you would like to change by using the buttons

or and change with or .

Press the -button to accept and save the entry.

To cancel the input dialogue without saving the val ue press

+ .

9/27

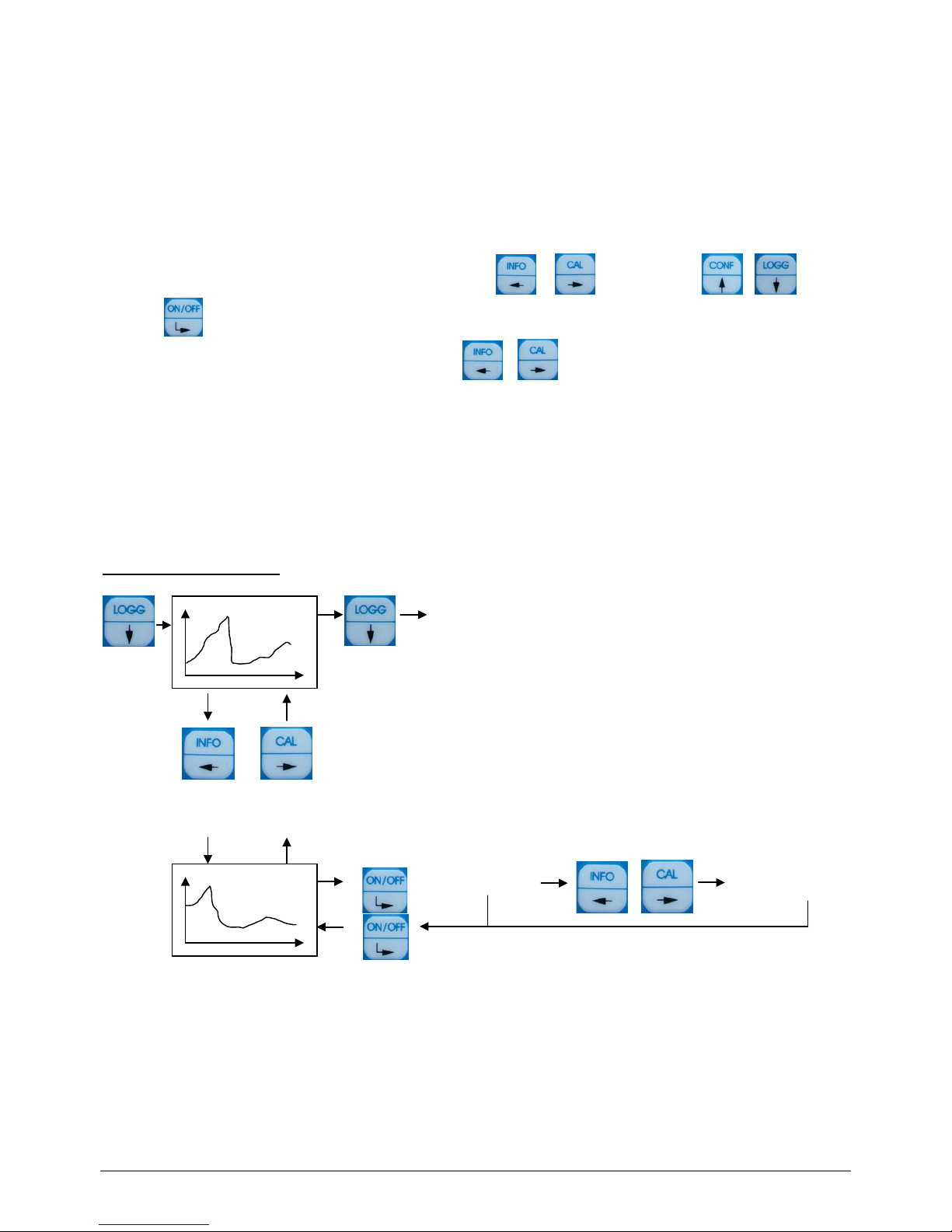

4.6 Data logger

The device has an integrated data logger with real-time clock. So it is possible to save the last about 4.000 data sets (date,

time, main measurement value, second measurement value, temperature ).

The saved data can be either displayed directly in the device display or t ransferred by the USB-interface.

To configuration the data logger d o the following steps:

1. Open menu „general“

2. Enter the time interval in the menu it em „ interval“

Select the position you would like to change by using the buttons

or and change with or .

Press the -button to accept and save the entry.

To cancel the input dialogue without saving the value pre ss

+ .

Data logger Automatic:

If the automatic is switched off, the logger logs only by switched on device. (plea se note also the off time)

If the automatic is switched on, the logger logs continue. (long time logging)

For correct logger function set the real time clock.

During view the logged data’s the recording is stopped.

Menu structure data logger

measuring-info

next period

1 period

back

back to Measuring

next measuring-info

Loading...

Loading...