ZMD31050

Advanced Differential Sensor Signal Conditioner

Application Note PRELIMINARY

1. Startup

First you have to install driver and software form CD - refer KIT2 installation description

“CB_descr_*.pdf” (former name “tech_desr_comm._board_revxxx.pdf”) in folder “Manual Evaluation Kit

2.0” on CD for details.

For a demo application without hardware access it is not necessary to install the USB port driver. After

the end of software installation procedure you find two additional icons on your desktop or programs in

program menu:

• ZMD31050 (former ZMD31050 EV KIT)

• ZMD31050_SSC2 (former ZMD31050 EV KIT2)

ZMD31050 is tool supporting all features and functions in detail – recommended for being familiar with

the ZMD31050, design in a sensor, developing and verifying a configuration/application.

ZMD31050_SSC2 is tool, which is made for pre series calibration work. The configuration is displayed

as configuration words only, but this tool supports “ZMD SSC Kit command language” (SSC_CML).

SSC_CML enables to write command procedures for full automated calibration of sensor modules.

SSC_CML is in development now. Additional ZMD31050_SSC2 software enables mass calibration

using “ZMD SSC Mass Calibration Board” – a mass calibration solution, which calibrates up to 120

sensor modules in one batch.

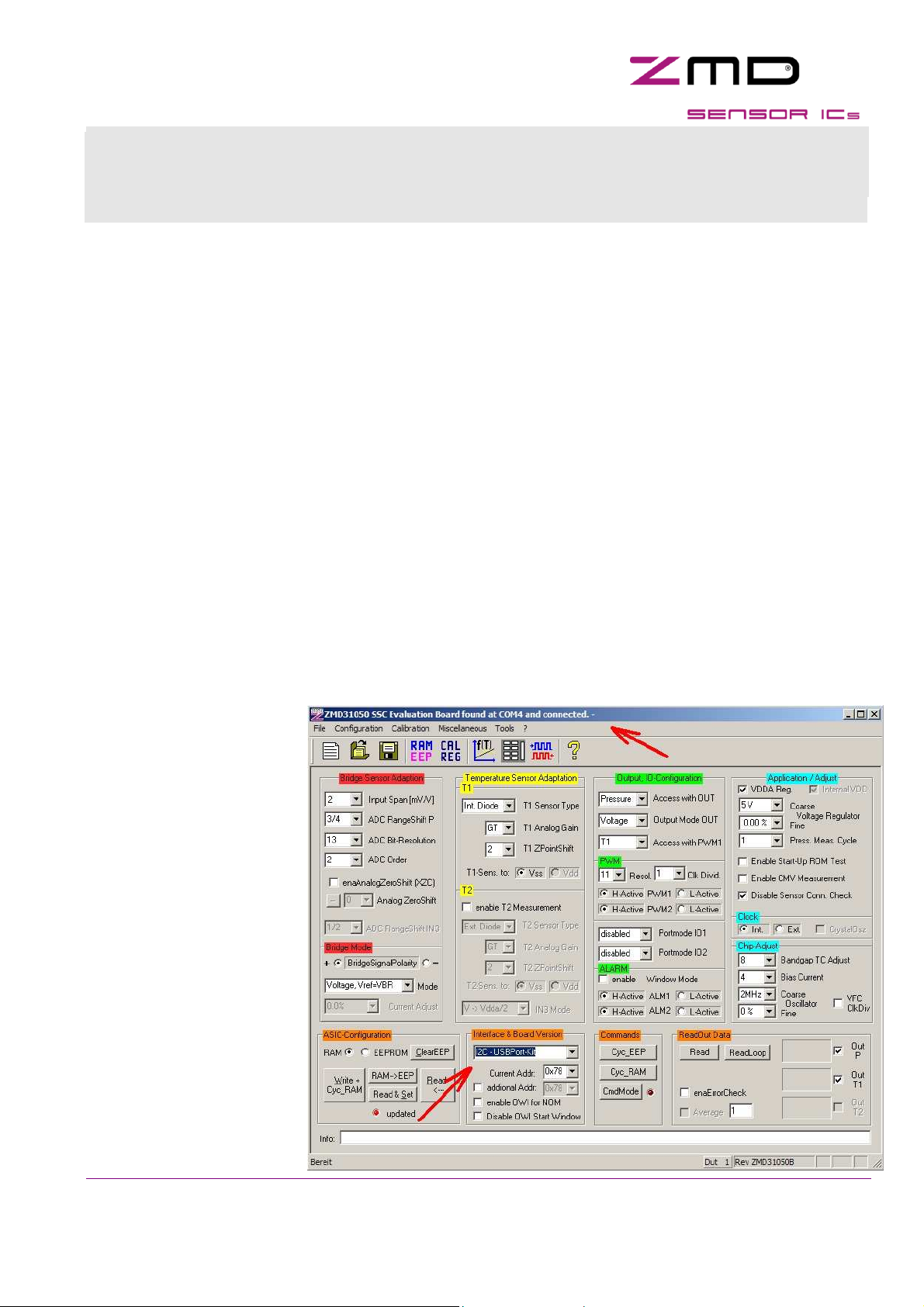

1.1 ZMD31050 software

After starting ZMD31050

software has to be select

desired interface (lower

arrow).

ZMD31050 software is

applicable for KIT1 (in

software called

“ParallelPort-Kit”) and

KIT2 (“USBPort-Kit”).

ZMD recommends for first

steps I2C interface.

Founded hardware and

port is messaged in top of

the window, if

“Communication Board”

and “ZMD31050 SSC

Board” is connected at

the computer and was

found by the software

(upper arrow). ZMD31050

circuit revision number is

displayed in status line.

Copyright © 2005, ZMD AG, 2005-05-17

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

1/8

ZMD31050

Advanced Differential Sensor Signal Conditioner

Application Note PRELIMINARY

To change type of interface select first “NULL” and then a new one. To verify command mode press

“CmdMode” button, if applicable the “LED” near the “CmdMode” button is flashing green for some

seconds.

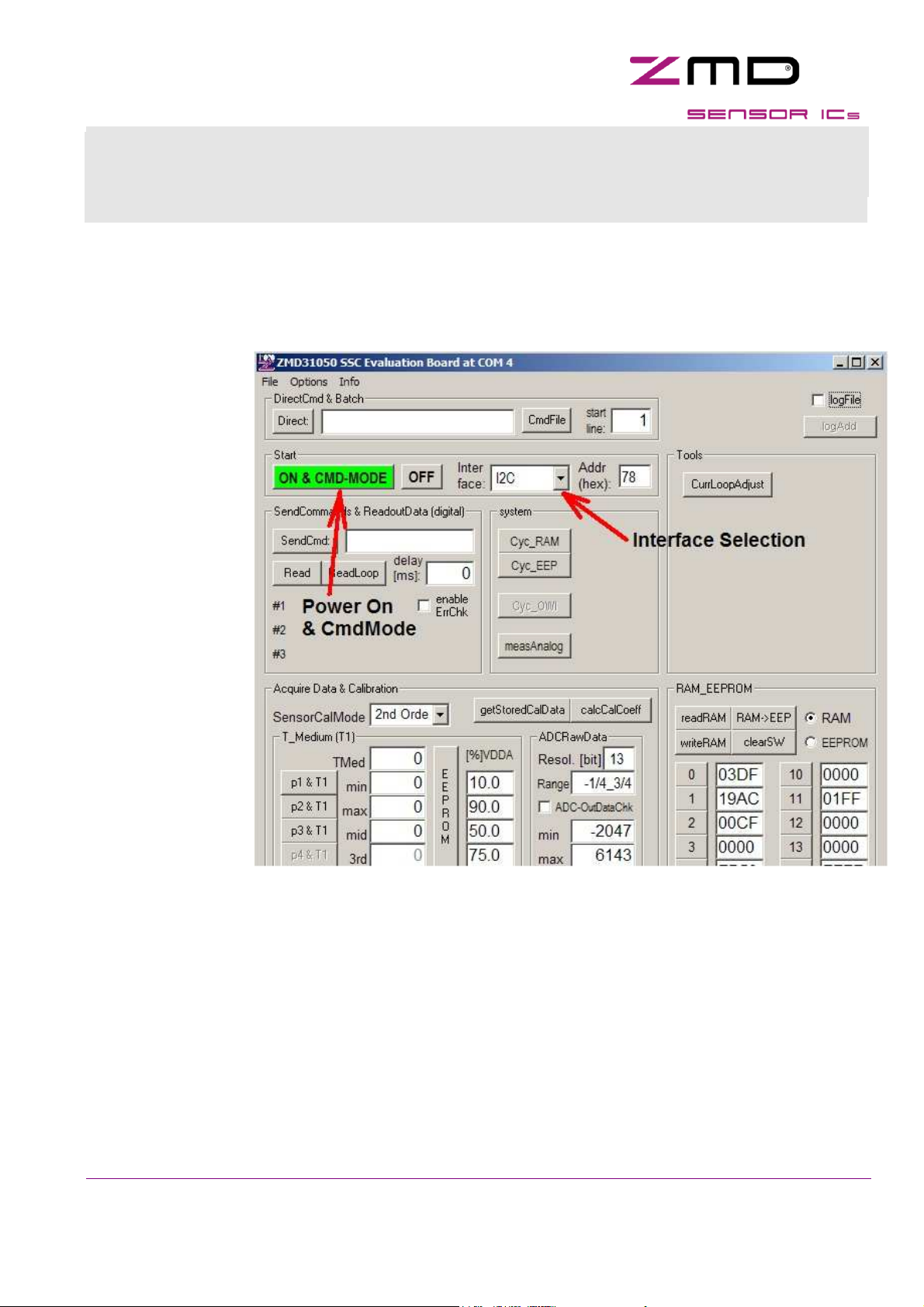

1.2 ZMD31050_SSC software

ZMD31050_SSC

software supports

only KIT2 (USB).

After starting

ZMD31050_SSC

software

connection status

is displayed in

header of window.

To access

ZMD31050 has to

be select desired

interface and then

power on.

Supply LED on

SSC Board is

flashing, if this

successful and

indicates, that

ZMD31050 IC is

supplied correct.

As next step

current register

content can be

read out by

pressing the “readRAM” button in RAM_EEPROM frame. RAM content is displayed then RAM register

fields #1...31.

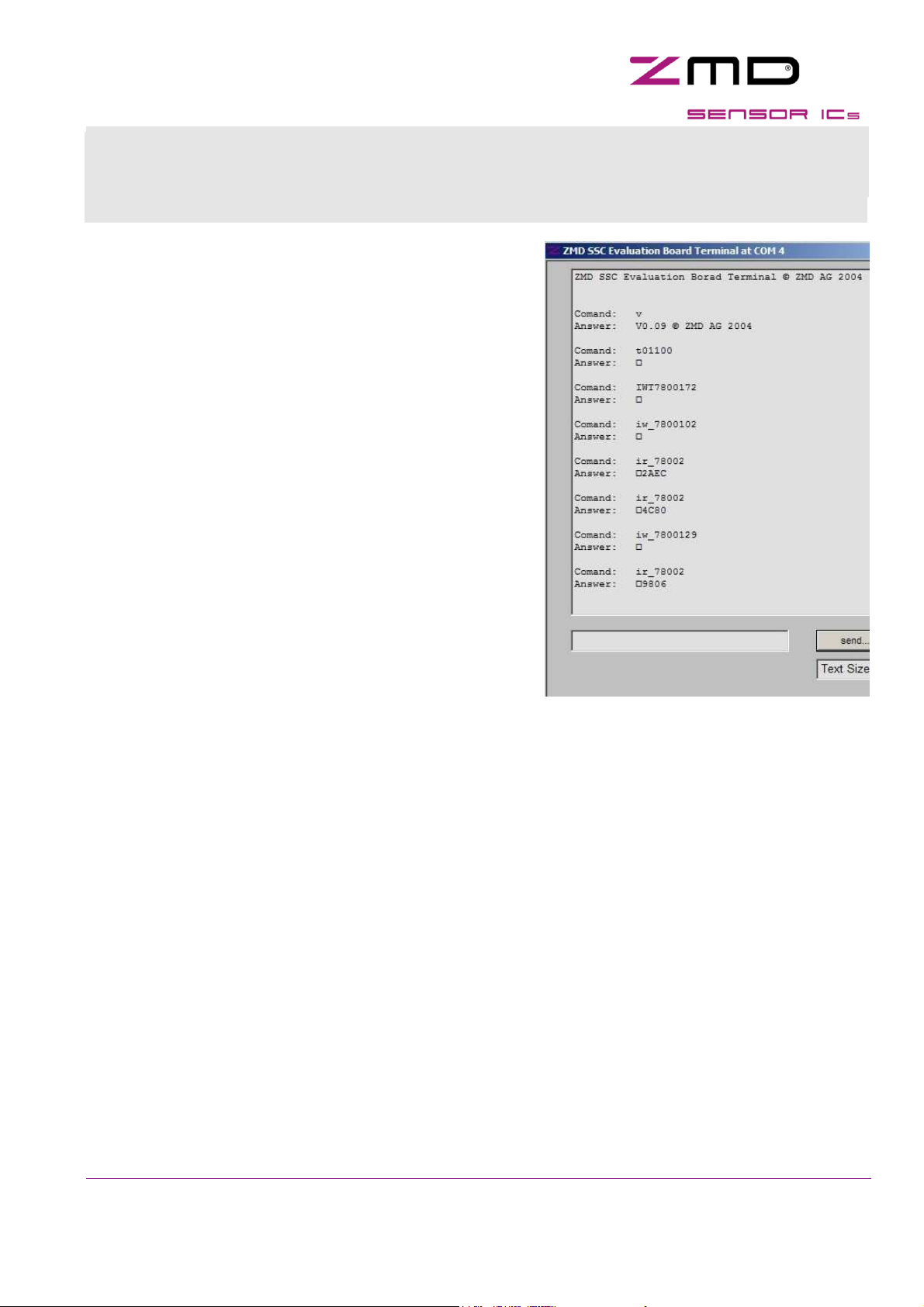

1.3 ZMD SSC Terminal

ZMD SSC terminal is the lowest level of communication, which transfers commands direct to

communication board (CB) microcontroller. Controller command language is used for this and is

described in “CB_descr_*.pdf” chapter 7 & 8.

Input a command in input line and press <CR> or “send”. Sent command and answer is displayed in

terminal window. A practical communication example is displayed terminal program screenshot.

Copyright © 2005, ZMD AG, 2005-05-17

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

2/8

ZMD31050

Advanced Differential Sensor Signal Conditioner

Application Note PRELIMINARY

T01100 set trigger, communication should start

100ms after power on

IWT7800172 I2C, power on & send cmd: "72"

= activate ZMD31050 command mode

IW_7800102 I2C, send cmd: "02" = start cylce ram

IR_78002 I2C, read 2 bytes of SIF output register

=> 0x2AEC digital readout result of conditioning

change adjustment of potentiometer on sensor

replacement board now => changed input signal

IR_78002 I2C, read 2 bytes of SIF output register

=> 0x4C80 digital readout result of conditioning

changed input signal delivers also other output signal

IW_7800129 I2C, send cmd: "29"

= read content fof RAM register 0x19

content of addressed register is copied to SIF output,

continuous conditioning (“cycle_ram”) is stopped

IR_78002 I2C, read 2 bytes of SIF output register

=> 0x9806 register content of RAM register 0x19

ZMC SSC Terminal

1.4 Troubleshooting

Communication problems:

• If software don’t found the communication board check in “system control” of your computer for

accessible COM ports etc. – refer “CB_descr_*.pdf” for details)

• If software get no access to ZMD31050 (e.g. message “… Command Mode failed …”) verify power

supply of the ZMD31050 (wrapped jumpers, measure supply voltage @ K10 Vsupply-GND, …).

Software can detect type of connected SSC board - in headline of software type of founded SSC

board is messaged. Verify board type …

• Try it again with other software (ZMD31050_SSC2.exe).

• A error code is displayed in case of communication errors in software. ZMD31050_SSC2 messages

errors in “SendCommand & ReadoutData” frame. An error code is an “e” with a number of three

digits e.g. “e032”. Refer “tech_desr_comm._board_revxxx.pdf” for detailed error description. At

using ZMD31050-software press “Read” button in “ReadOut Data” frame of main window “ or open

“RAM-Register” dialogue (RAM_EEP-icon) and press also “Read” button. Error code is displayed

in related output data fields.

• If all this doesn’t help send problem description with screenshots of software, software version

(about dialogue), error code etc. to ZMD support. Use mail task in about/support dialogue for this.

Copyright © 2005, ZMD AG, 2005-05-17

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

3/8

ZMD31050

Advanced Differential Sensor Signal Conditioner

Application Note PRELIMINARY

2. First Example

The following example describes first

steps being familiar with KIT2 and

ZMD31050-software and ZMD31050.

• Plug all 3 delivered PCBs in order

Communication Board (CB) –

Sensor Signal Conditioner Board

(SSC) - Sensor Replacement Board

(SR) together and connect these to

the USB port of your computer

• Verify wrapped jumper connection

at SSC: K5 (Vsupply), K10 (Bridge

Mode Voltage) and at SR: K4 (BR)

• Start ZMD31050 software and

activate USB Port access via I2C

interface (refer chapter 1.1) and

verify accessed board and

command mode

• Open File menu and load

“31050_kit_default.31050” configuration. These file contains needed programming data for

ZMD31050 circuit to adjust/configure the ZMD31050 for application completely. These file or set of

data is called following “config”.

Loading a saved configuration

“31050_kit2_default.31050” config is loaded in software now.

These config is made for KIT2 to learn basics in handling of

KIT and ZMD31050. A short description of the loaded config

is displayed as info text. These config gain the input signal generated by the sensor replacement (SR) and was

calibrated to deliver 0.5/4.5V for SR potentiometer top/down

end adjustment. To verify this you have to do:

• Connect a DMM to the analog out of the ZMD31050. Use

“SSC: K10 – pin OUT“ and “SSC: K10 – pin GND”

measure point for this. Now the DMM measures the

analog output signal (VOUT). Refer ZMD31050 SSC

Board description for details.

Write to 31050 and starting a config

• Adjust SR – potentiometer (poti) in middle position.

• Press “Write+Cyc_RAM” button: Loaded config is written

(Write) to ZMD31050 and started (Cyc_RAM) now.

• Check measured VOUT at the DMM: VOUT should be

approx. 2.5V and should be alter at changing SR – poti

adjustment.

• Measure VOUT for top and bottom position of the poti.

Copyright © 2005, ZMD AG, 2005-05-17

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

Open “Sensor calibration“ dialogue

4/8

ZMD31050

Advanced Differential Sensor Signal Conditioner

Application Note PRELIMINARY

These values should be 0.5/4.5V. In most cases this wouldn’t be so and is caused by tolerances of all

components/elements at the PCBs – calibration is necessary. This is the next step.

• Open “Sensor-Calibration” dialogue (last picture)

• A two point calibration

(poti top & down) should be

done.

“Calibration Mode” is

linear, no temperature

behaviour. Adjust this like

displayed in screenshot.

Tooltips in software give

you additional help for use.

“Targets” are the output

aims for calibration. In

example output voltage

should be 0.5/4.5V for

minimum/maximum input

signal. All targets are

inputted proportionally to

VDDA, complete calibration

is done proportionally to

VDDA. For VDDA=5V is a

required output voltage of 0.5/4.5V => target is 10/90%. This has to be inputted in target frame for

minimum and maximum.

“Acquire Raw Data” frame is used to collect data of all

needed measurement points for calibration. In minimum 2

input fields and acquire buttons are enabled depending on

selected “Calibration Mode”.

Sensor-Calibration: Target input fields and acquire raw data buttons

• Adjust SR poti to top end and press “P1M” button.

The current analogue input signal is gained and AD-converted

now, the result is displayed in the input field beside the button.

• Adjust SR poti to down end and press “P2M” button.

Both required data points for calibration are acquired now,

calculation of calibration coefficients can be done now.

Calibration results

• Press “calcCoeff” button in “Sensor Calibration” dialogue.

Software messages success of coefficients calculation.

Founded calibration coefficients are copied to RAM register

block. To verify this open “RAM-Register” dialogue by

pressing the “RAM_EEP” icon in icon list of software.

• Press “Write+Cyc_RAM” button in main window now.

Calibration results are transferred to ZMD31050 and activated

Copyright © 2005, ZMD AG, 2005-05-17

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

RAM Register dialogue

5/8

ZMD31050

Advanced Differential Sensor Signal Conditioner

Application Note PRELIMINARY

now. New calibration is ready and result can be verified now.

• Measure VOUT for top and bottom position of the poti.

You should measure 0.5V for poti down end 4.5V for poti top end now.

• Repeat the same procedure with reverse acquiring (pressing P2M instead P1M and otherwise).

You will get a mirrored output function for this case. We see, the output signal can be inverted by

calibration for the same input signal.

3. ZMD31050 Software Description

Main window is split in 8 frames:

• “ASIC-Configuration” configures memory access. Configuration data can be written into RAM or

EEPROM. All modifications can be done in and activated from RAM. Write new configuration into

EEPROM, if changes should be made non-volatile. To do this, ZMD recommends to write first all

data into RAM and then copy into EEPROM by pressing “RAM->EEP” button. The “LED” indicates

whether the displayed information in software are identical to ZMD31050 circuit or not.

• “Bridge Sensor Adaptation” enables config of basic “Sensor Design-In” and “ADC” parameters

• “Temperature Sensor Adaptation” enables configuration of temperature measurement for

conditioning (T1) and additional temperature measurement

• “Output, IO-Configuration” configures analogue and PWM output and IO channel

• “Application/Adjust” configures supply voltage regulator, safety feature, bandgap voltage and TC.

Additional clock frequency and biasing can be adapted/modified.

• “Interface & Board Version” is used to select interface type, board and addressing.

• “Commands” enables to start signal conditioning using RAM or EEPROM data. Enabled

“Command Mode” can be verified and is displayed by a green flashing “LED”.

• “ReadOut Data” enables digital readout via serial communication interface (SIF). If continuous

readout is activated averaging mode can be enabled. Via the SIF can be read output data for

pressure and temperature 1 & 2 channel. A description of data is displayed beside the output fields.

Info line enables to add a short description of application to configuration data. Additional in status line

is displayed revision number of accessed ZMD31050 circuit. Refer detailed software description for

further information and examples.

Copyright © 2005, ZMD AG, 2005-05-17

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

6/8

ZMD31050

Advanced Differential Sensor Signal Conditioner

Application Note PRELIMINARY

4. Calibration Examples

4.1 Conditioning a Pressure Signal

4.2 Conditioning a Temperature Signal

4.3

1st step - acquire calibration data

temperature out calibration target:

• 0.5V at 0deg = 10%

• 4.5V at 100deg = 90%

and/or digital:

• 3277 (10% of 32768) at 0deg

• 29491 (90% of 32768) at 100deg

--- room temperature = 25deg

Temperature-Calibration Example

OW_78001D9 => acquiring T1

OR_78002 => you get first acquired raw data for current temperature calibration point now (1) in example: 1000

--- change of temperature =50deg

OW_78001D9 => acquiring T1

OR_78002 => you get second acquired raw data for current temperature calibration point now (2) in example: 2000

=> calculate coefficients now and write calibration data to RAM/EEPROM

OW_7800102 => start cycle RAM

OR_78004 => readout of 4 bytes, @ 25deg you should read 9830

Copyright © 2005, ZMD AG, 2005-05-17

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

7/8

ZMD31050

Advanced Differential Sensor Signal Conditioner

Application Note PRELIMINARY

The information furnished here by ZMD is believed to be correct and accurate. However, ZMD shall not be liable

to any licensee or third party for any damages, including, but not limited to, personal injury, property damage, loss

of profits, loss of use, interruption of business or indirect, special, incidental, or consequential damages of any

kind in connection with or arising out of the furnishing, performance, or use of this technical data. No obligation or

liability to any licensee or third party shall result from ZMD’s rendering of technical or other services.

For further

information:

ZMD Stuttgart Office

Nord-West-Ring 34

70974 Filderstadt - Bernhausen

Tel.: +49 (0)711.674.517-0

Fax: +49 (0)711.674.517-99

sales@zmd.de

www.zmd.biz

ZMD AG

Grenzstrasse 28

01109 Dresden, Germany

Tel.: +49 (0)351.8822.310

Fax: +49 (0)351.8822.337

sales@zmd.de

www.zmd.biz

ZMD America Inc.

201 Old Country Road, Suite 204

Melville, NY 11747

Tel.: (631) 549-2666

Fax: (631) 549-2882

sensors@zmda.com

www.zmd.biz

Copyright © 2005, ZMD AG, 2005-05-17

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

8/8

Loading...

Loading...