&;

Conductivity Transmitter CX2000 S/N: 123456789

ACT

B.L.

10.00

ʳ Intelligent

ʳ ʳ Conductivity

Transmitter

Operation

Manual

Lin

10.00

PM 12:00

2013/04/10

SETUP

Conductivity Transmitter CX2000 S/N: 123456789

CAL

MODE

mS/cm

MTC

25.0 C

ENTER

ACT

B.L.

1

Precautions for installation

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

Wrong wiring will lead to breakdown or electrical shock of the instrument, please read this

operation manual clearly before installation.

zMake sure to remove AC power from the controller before wiring input, output connections,

and remove it before opening the controller housing.

zThe installation site of the controller should be a well ventiled area and out of direct sunlight.

zThe material of signal cable should be special coaxial cable. We strongly recommend using our

coaxial cable.

zAvoid electrical surges when using power, especially when using three-phase power. Use

ground wire correctly.

zThe internal relay contact of the instruments is for alarm or control function. To ensure safety,

please connect to external relay which can withstand enough amperage to allow safe

operation of the instruments.˄Please refer to chapter 3.6ʳ“Illustration of electrical

connectionϙ˅

CONTENTS

Precautions for installation

Brief Instruction 1

1. Specifications 4

2. Assembly and installation

2.1 Transmitter installation 5

2.2 Illustration of panel mounting 5

2.3 Illustration of Wall mounting and pipe mounting 6

3. Overview of conductivity / resistivity transmitter EC-4110

3.1 Illustration of rear panel 7

3.2 Illustration of terminal function ˊ

3.3 Description of terminal function ˋ

3.4 Wiring of cable ˌ

3.5 Circuit of cable ˌ

3.6 Illustration of electrical connection 10

4. Configuration

4.1 Illustration of front panel 11

4.2 Keypad 11

4.3 LED indicators 11

4.4 Display 12

5. Operation

5.1 Measurement mode 13

5.2 Set-up menu 13

5.3 Calibration menu 13

5.4 Shortcuts 13

5.5 Reset 13

5.5.1 Set-up reset 13

5.5.2 Calibration reset 13

6. Settings

Block diagram of settings 14

6.1 Entry of set-up menu 16

6.2 Security code of settings(Code) 17

6.3 ˟˴˺˴˺˸

6.4 Measurement parameters(Mode)

6.5 Product Adjustment 20

6.6 Temperature 21

6.7 Compensation 22

18

19

6.8 Relay 1 23

6.9 Relay 2

6.10 Wash time(Clean) 25

6.11 Analog output 1 (Cond/Res) 26

6.12 Analog output 2 (˧emperature)

6.13 Date/Time (Clock) 28

6.14 Sample average of measurements (Digital filter) 29

6.15 Backlight settings 30

6.16 Contrast settings 31

6.17 Power frequency (Freq.) 32

6.18 Automatically back to measurement mode(Return) 33

7. Calibration

Block diagram of Calibration 34

7.1 Entry of calibration menu 35

7.2 Automatically back to measurement mode(Return) 36

7.3 Security password of calibration 37

7.4 Cell constant calibration (CELL Const.) 38

7.4.1 Resistivity (Res) 38

24

27

7.4.2 Conductivity (Cond) 39

7.5 Standard solution calibration (Std. Sol.) 40

8. Error messages (Error code) 41

9. Installation of cells

9. Correct installation 42

9. Incorrect installation 43

Brief Instruction

1

Description of set-up settings (see chapter 6 for details) ʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳ

Press and simultaneously to see the overview of the set-up settings. Then press I

if you would like to modify set-up settings.

.H\SDGIndex

.eypad )XQFWLRQ Description

Back to upper lHYHO

Choose change to left page

Increase digit

Choose change to right page

Decrease digit

Confirm settings after modifications and then go WR nextVWHS

Selection of set-up items

.eypad )XQFWLRQ 'escription

Mode Measurement mode, to choose Resistivity (Res) or Conductivity

(Cond) measurement

Temperature Temperature measurement and compensation, including MTC,

PTC, NTC MTC---Manual temperature compensation,

PTC/NTC--- auto temperature compensation

Relay 1 First relay setting, to select OFF or Hi/Lo alarm

Relay 2 Second relay setting, to select OFF or Hi/Lo alarm

Clean Automatic wash time setting, to choose electrode clean

equipment’s ON and OFF duration

Analog 1 Current output -Res or Cond

Analog 2 Current output -temperature

Clock

2

Clock setting ('XULQJORVV of power the

instrument’s time

will return to the facory setting)

Black-light Backlight setting, to set Auto/ON/OFF backlight, brightness,

and sensitivity

Contrast Contrast of screen setting

Digital Filter Takes every serial 1~60 measurements and averages them

continuously and displays the average readings

Return Setting of returning to the measurement mode

Code Security code of set-up mode. The factory default is 1111, and a

designated user can change the code.

Description of calibration settings (see chapter 7 for details)ʳ ʳʳʳʳʳʳʳʳʳʳʳʳʳ

3

Press and simultaneously to see the last calibration information. Then press if you

would like to make a new calibration or modify setting of calibration. Press keypad according to

index of keypad on the screen.

Index of keypad:

keypad Accordingly item Description

Back to upper layer

CKDnge to left page

Increase digit

CKange to right page

Decrease digit

Confirm settings after modifications and then go through next

step

Selection of calibration items (up to three-point calibration)

keypad Accordingly item Description

Code Security code of calibration mode. The factory default is 1100.

Return Time interval setting of returning to the measurement mode

Cell Constant To adjust the instrument cell constant setting WRPDWFK the

YDOXHRIWKH cell constant of the sensor

Solution Use the appropriate standard solution to calibrate the system

Note ʳ

Sensorex reserves the right to change the figure of icons and contents. For the actual icons and contents

please refer to the instruments.

1. Specifications

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

4

Model!

Measuring modes

Ranges

Resolutions

Accuracy

Temperature

Compensation

Calibration mode

Ambient Temp.

Resistivity

Conductivity

Tem p.

Resistivity

Conductivity

Tem p.

Resistivity

Conductivity

Tem p.

CX2000

0.00 S/cm~200.0 mS/cm manual or auto range selectable

Manual temperature compensation selectable

(1)Cell constant adjustment (2)Standard solution calibration

Resistivity/Conductivity/Temp.

0.00 M·cm~20.00 M·cm

-30.0~130.0C

0.01 M·cm

0.01 S/cm

0.1C

±1% ± 1Digit

±1% ± 1Digit

±0.2C± 1Digit

NTC30K or PT1000 or

0~50 C

Storage Temp.

Cell Constant

Temperature Coefficient

Display

Analog output 1

Analog output 2

Contact

Settings

Activate

Wash

Certification

Power Supply

Installation

-10~70 C

0.01, 0.05, 0.1, 0.5, 10.00 cm

freely selectable 0.008~19.99 cm

Linear temperature compensation from (0.00%~ 40.00%)

and Non-Linear compensation

Large LCD display with environment light sensor

auto/manual illumination function

Isolated DC 0/4~20mA corresponding to main measurement,

max. load 500:

Isolated DC 0/4~20mA corresponding to Temp., max. load 500:

RELAY contactΔ240VAC 0.5A Max.(recommend)

Two sets of individual HIGH or LOW programmable control

RELAY contact: ON 0~99min. 59sec. / OFF 0~999hr 59min.

IP65 (NEMA 4)

100V~240VAC±10%Δ50/60HzΔ5W max.

Wall or Pipe or Panel Mounting

-1

fixed,

-1

Dimensions

Cut off Dimensions

Weight

Note: The specifications are subject to change without notice.

96m × 96mm × 132mm (HuWuD)

93 mm u 93 mm (HuW)

0.5Kg

2. Assembly and installation

m

m

5

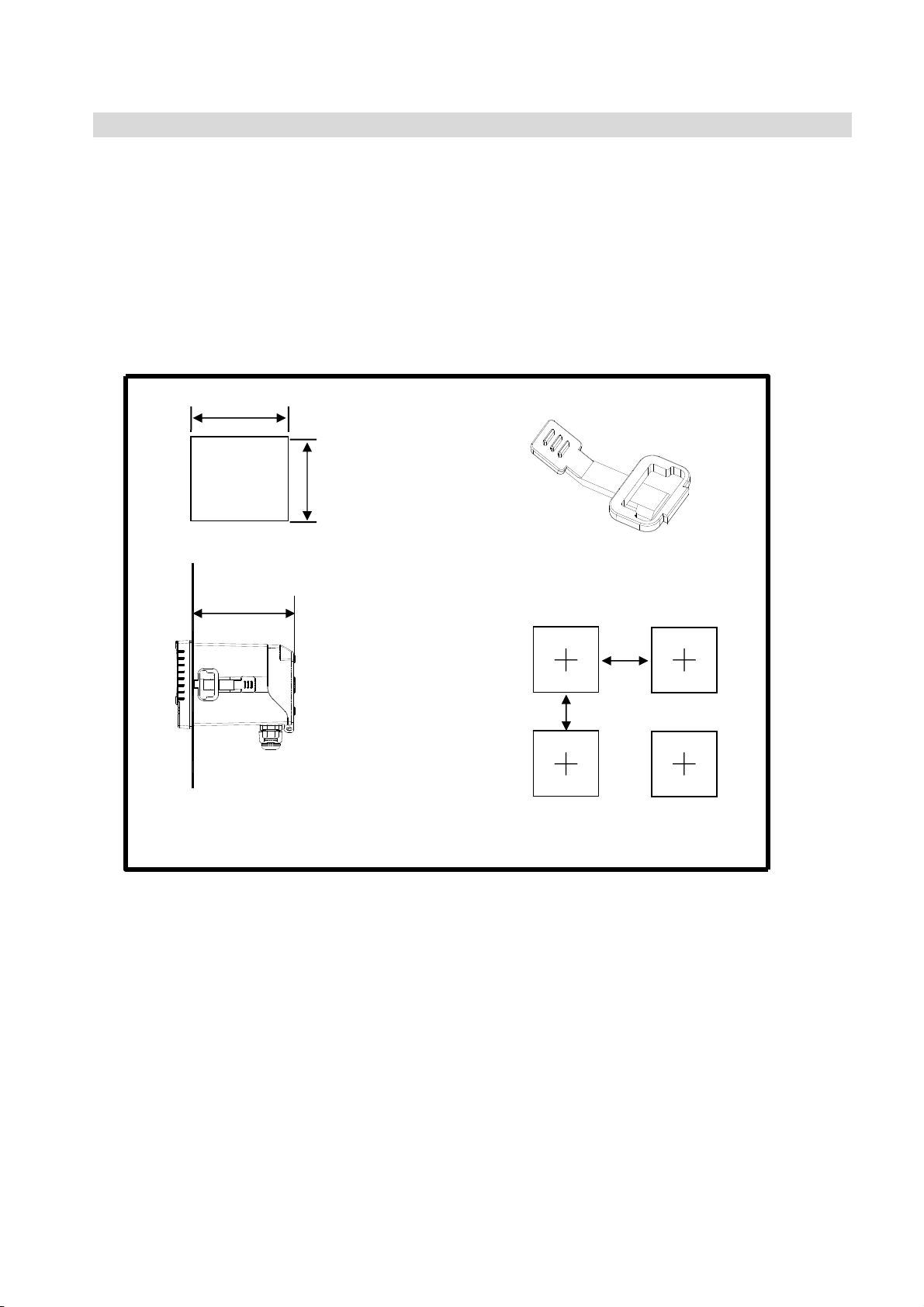

2.1 Transmitter installation: This Transmitter can be installed through panel mounting, wall

mounting and pipe mounting.

Installation of panel mounting: Firstʿ prepare a square hole of 93 x 93mm on the panel box,

and then insert the controller directly into the panel box. Insert the accessorial mounting bracket

from the rear, until it is locked into pickup groove.

2.2 Illustration of panel mounting:

93 m

93 mm

Hole size

112 m

Illustration of panel mounting,

fixed with mounting bracketʳ

Mounting bracket

Ѐ

87 mm

87 mm

Ѐ

Hole distances on the panel box

Ѐ

Ѐ

3.3 Description of terminal function:

ѽѾ

ѽѿ

ѽҀ

ѽҁ

ѽ҂

ѽ҃

҄

ѽ҅

ѽ҆ ʳ

Ѿѽ

ѾѾ ʳ

Ѿѿ

ѾҀ

Ѿҁ

Ѿ҂

Ѿ҃

Ѿ҄

Ѿ҅

Ѿ҆

ѿѽ ʳ

ѿѾʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ

ѿѿʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ

ѿҀʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ

ѿҁʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ

8

REL1ΚExternal relay terminal first control

REL2ΚExternal relay terminal second control

WA SHΚExternal wash relay terminal

ѽ҄

ʳ NCΚNone contact

100~240ACΚPower supply terminal

NCΚNone contact

ʳ 100~240ACΚPower supply terminal

SHIELDΚThe transparent cell connection line

CELL1ΚThe cell connection line: Current electrode 1

CELL3ΚThe cell connection line: Voltage electrode 2

CELL4ΚThe cell connection line: Current electrode 2

ʳ

CELL2ΚThe cell connection line: Voltage electrode 1

SGΚNC

TPΚConnect the cell connection line of temperature probe

SGΚNC

4~20mAЀterminalΚMaster measure current output terminal +, for external

recorder or PLC control

4~20mAЁterminalΚMaster measure current output terminal -, for external

recorder or PLC control

4~20mAЀterminal / D+(B)ΚTemperature current output terminal +, for

external recorder or PLC control

4~20mAЁterminal / GΚTemperature current output terminal -, for external

recorder or PLC control

NC / D-ΰAαΚNC

3.6 Illustration of electrical connection:

10

100 ~ 240VAC

Transmitter

Surge absorber

Surge absorber

Surge absorber

Washing device

Dose feeder

Dose feeder

Surge absorber

External relay

Surge absorber

External relay

Surge absorber

External relay

4. Configuration:

ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ

11

Conductivity Transmitter CX2000 S/N: 123456789

ACT

B.L.

10.00

4.1 Illustration of front panel:

10.00

PM 12:00

2013/04/10

Lin

mS/cm

MTC

25.0 C

ACT

B.L.

SETUP

CAL

Conductivity Transmitter CX2000 S/N: 123456789

MODE

ENTER

4.2 Keypad:

In order to prevent inappropriate operation by others, before the parameter setting and

calibration, the operation applies multi-keysʿʳand coding protection if necessary. Description of

the key functions is in the following:

ΚIn the parameter set-up mode, pressing this key allows you exit parameter set-up mode

and back to Measurement mode.

ˍ In the Calibration mode, pressing this key allows you exit Calibration mode and back to

Measurement mode.

Κ1. In the parameter set-up mode and Calibration mode, pressing this key to select

leftward or change to another page.

2. When adjusting value, press this key to increase the value.

Κ1. In the parameter set-up mode and Calibration mode, pressing this key to select

rightward or change to another page.

2. When adjusting value, press this key to decrease the value.

ΚKey for confirmation; pressing this key is essential when modifying data value or

selecting the parameter setting items in the window.

4.3 LED indicators:

ACTΚWashing device operation indicator ˴˷ʳ˶ontrolling operation indicator (Relay 1ΕRelay 2)

B.L. : Light sensor; in the automatic display backlit mode, the lamp will light or go out as the

change of environmental brightness.

4.4 Display:

12

:Measurement mode

:Set-up mode

:Calibration mode

Control function

on hold

Clock

RELʳ1ʳhighʳʳ

˿ point alarm

RELʳ˅ʳhighʳʳ

˿ point alarm

Analog 1 output

current over range

alarm

Analog 2 output

current over range

alarm

Compensation unit

Meaurementʳ˼

Temperature

compensation mode

(MTC/ATC)

Temperature valueʳ

˴˷ʳ˼

Wash device in

action condition

Note: 1. When the wash device is turned on, the display shows and flashes the description, “Clean

Running”. At the same time, the ACT indicator LED lights up, and the transmitter

automatically turns off Relay 1 and Relay 2 function. After finishing cleaning, elay 1

and Relay 2 will automatically return to normal status.

2. When Relay 1 which is set in high setting point is in action, the display shows and flashes

the description, “REL 1_Hi”, and ACT indicator LED lights up. When Relay 1 which is set

in low setting point is in action, the display shows and flashes the description, “REL 1_Lo”,

and ACT indicator LED lights up.

3.When Relay 2 which is set in high setting point is in action, the display shows and flashes

the description, “REL 2_Hi”, and ACT indicator LED lights up. When Relay 2 which is set

in low setting point is in action, the display shows and flashes the description, “REL 2_Lo”,

and ACT indicator LED lights up.

4. When under measurement mode, if the temperature compensation mode is set in MTC

(Manual adjustment), press or to adjust the MTC temperature manual.

5. Operation

ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ

13

5.1 Measurement mode:

ʳʳʳAfter all electrical connections are finished and tested, connect the instrument to the power

supply and turn it on. The transmitter will automatically enter measurement mode with the

factory default settings or the last settings from user.

5.2 Set-up menu:

ʳʳʳPlease refer to the set-up instructions in Chapter 6. Press and simultaneously to

enter into set-up menu, and press toʳgo press to back to measurementʳmode.

5.3 Calibration menu:

ʳʳʳPlease refer to the calibration instructions in Chapter 7. Press and

simultaneously to enter into calibration menu, and press to go back to measurementʳmode.

5.4 Shortcuts: In the measurement mode, if selecting MTC for temperature compensation mode, you

may press and to adjust MTC temperature value.ʳ

5.5 Reset:

5.5.1 Master reset:ʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳʳ

Measurement mode: Conductivity, Auto-Range

Temperature compensation: MTC 25ć

Temperature Coefficient: Lin, 2.00%

Relay 1ΚHigh point alarm: AUTOʿʳSP1= 100.0mSΔDB=10.0mS

Relay 2ΚLow point alarm: AUTOʿʳSP2 =10.0 mSΔDB= 1.00 mS

Wash time: OFF

Analog 1 current output (Cond/Res)Κ420 mAΔ0.00199.9mS

Analog 2 current output (Temp)Κ(Temp)Κ420 mAΔ0100.0C

Display backlit:ʳOFF

Contrast: 0

Code: OFF

Date & TimeΚ2010/1/1 00:00:00

Auto back: Auto, 3 minutes

5.5.2 Calibration reset:

Cal TimeΚ2010/01/01

Cal TypeΚNo Cal

Cell ConstantΚ0.5000

Cal Temp.Κnone

Auto back: Auto, 3 minutes

Note: The factory default of calibration presetting is “No Cal”, and the cell constant setting is “0.5000”.

It means that the user has not calibrated the sensor with the transmitter yet. When selecting

standard solution to finish calibration, the display shows cell constant of the cell and the value of

the standard solution.

6. Settings

ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ ʳ

14

Block diagram of settings 1:

Settings

Overview

Return

Setting

Code

Setting

Code Input

OFF ON

New

Code

Setting

Ɠ

Ɠ

Ɠ

Setting Mode

Mode

Setting

Res/Cond

mode select

Cond

Range

select

5HVLVWLYLW\

PRGHRQO\

Product Adj.

Setting

OFFON

ResCond

MTC

ATC

Value

Value

correc

correc

-tiont

-tion

Modify

CF

Temperature

Setting

Compensation

mode

MTC PTC

Value

input

Value

correct

NTC

Value

correct

Lin

T.C.

value

input

T.C.

Setting

Non-Lins

Relay1

Setting

Relay1

ON/Off

select

Relay 1

Hi/Lo select

Relay 1

SP input

Relay 1

DB input

Relay 1

Test

Relay2

Setting

Relay2

ON/Off

select

Relay 2

Hi/Lo select

Relay 2

SP input

Relay 2

DB input

Relay 2

Test

Clean

Setting

Clean

ON/Off

select

Clean ON

time input

Clean OFF

time input

Clean

DB input

Clean

Test

Cond/Res

Settom g

Continued on next page

˕˴˶˾ʳʳ˻˸ʳ˸˼

˶˿˴ʳ˂ʳ˴˶˼ˍ

Continued on next page

Block diagram of settings 2:

15

Connected with previous page

Clean

Setting

Cond/Res

current

output 1

0/20 or

4/20mA

mode select

Relative

value to 0 or

4mA

Relative

value to

20mA

Κ

Κ

Temp

current

output 2

0/20 or

4/20mA

mode select

Relative

value to 0 or

4mA

Relative

value to

20mA

Clock

Setting

Year

Input

Date

Input

Time

Input

Digital

Filter

Setting

Signal

average

Auto ON OFF

Bright-

ness

setting

Sensi-

tivity

setting

Backlight

Setting

Mode

select

Bright-

ness

setting

Contrast

Setting

Contrast

Input

Freq.

Setting

Freq.

Select

Auto

Return

time

input

Return

Setting

Method

select

Code

Setting

Manual

Connected with previous page

Κ

Back to the previous

class / action:

16

6.1 Entry of set-up menu

In the measurement mode, pressing the two keys and simultaneously allows

you enter the overview of current setting, and press to enter the set-up mode to

modify the setting if necessary.

“Measurement (Mode)”

Pressʳʳor

Pressʳʳor

Pressʳʳto confirm it

Enter set-up menu

Pressʳʳ

17

6.2 Security code of settings:

After entering set-up mode, select “code” item, press to enter into code

procedure. The pre-set code is 1111.

Note: Set the code of setting mode prior to the code for calibration. That means that

the code of setting mode can be used for the code of calibration mode.

When a wrong password

is keyed in, the display

shows “Error 5”, press

to re-key in it, or press

to exit.

(Select to turn on or turn off

code protection function. If

you select turn on, please

key in a new code. There

will be a code requirement

showing in display when you

re-enter to the setup mode.

Key in the correct password

to enter into setup mode.)

Press to confirm it.

Press to confirm it.

Press or

或 鍵

The first ‘0” of digits ‘0000” start

to twinkle. Press or to

adjust the value, and then press

to confirm it and continually key

in the next digit, and so on.

Press to confirm it.

Key in new password

Press to confirm it.

Enter “Language” Setup

18

6.3 Language

Enter Language setup menu, select the system language from English, Traditional

Chinese and Simplified Chinese.

Press to confirm it.

Pressʳ or ʳʳ

to select language

type.

Press to confirm it.

Enter “Measurement Mode” Setup

19

6.4 Mode

Enter setup of “Mode”. Select between “Conductivity (Cond)” or “Resistivity

(Res)” measurement. If select “Conductivity”, then the range limit needs to be selected

from AUTO, 20.00S, 200.0S, 2000S, 20.00mS or 200.0mS.

Select “Res”.

Press to confirm it.

Press to confirm it.

Select “Cond”.

Press to confirm it.

Select “mS/cm”.

Press to confirm it.

Select “GEAR”.

Press to confirm it.

Select “S/cm”.

Press to confirm it.

Select “GEAR”.

Press to confirm it.

Select “AUTO”.

Press to confirm it.

Enter ”Temperature” Setup

Enter ”Product Adjustment” Setup

20

6.5 Product Adjustment (Resistivity mode only)

Enter setup of product Adjustment to make the fine adjustment of the measurement

reading. For ultra-pure water application, the function can increase the resolution of cell

constant, and it makes users to adjust the cell constant through a Cell Factor (CF

adjustable range: 0.7000~1.3000). It also allows two decimal of the temperature display

which increases the sensitivity of cell constant and temperature change and achieves the

fine adjustment of reading up to 0.01Meg ohm. It helps the users to see the small

change of reading or trend in ultra-pure water application.

Press to confirm it.

Press or

to switch

on or switch off.

ATC Mode MTC Mode

Use standard

thermometer to test

the actual temperature

of the solution, and

press or

to input the correct

temperature value.

Users may compare the reading with the

actual measured resistivity value. Press

or to adjust the Cell Factor( a

cell constant’s multiplier) in the main

display in order to modify the reading of

If necessary, compare

with the actual

temperature value

tested by standard

thermometer.

Press or

to input the modified

value.

measurement which shows in the bottom

part of display.

Enter “Temperature” Setup

21

6.6 Temperature

Enter setup of “Temperature” to select temperature compensation mode. Select from

NTC(NTC 30K), PTC(PT 1K) or MTC(Manual adjustment), or you may press &

simultaneously to back to default setting. In the measurement mode, if selecting MTC

for temperature compensation mode, you may press or to adjust MTC

temperature value.

Press to confirm it.

Press

or to select

Press to confirm it.

Press

or to select

Press to confirm it.

Use standard thermometer to test

the actual temperature of the

solution, and press or

to input the correct temperature

value.

If necessary, compare with

the actual temperature value

tested by standard

thermometer.

Press or to

input the modified value.

Press to confirm it.

Enter “Compensation” Setup

22

6.7 Compensation

Enter setup of compensation mode, and select Linear Compensation or Non-linear

compensation mode. According to your measurement need for temperature coefficient,

you may select linear (Lin), non-linear (nLin), or non-compensated (Lin 0.00%).

Normally, select linear compensation for conductivity measurement(Cond)(Range:

0.00%~40.00%), and select non-linear compensation for Resistivity measurement.

Temperature coefficient (hereinafter referred to as TC): Conductivity of solution

increases with temperature increase. The relationship is as follows:

C

Ct

T

Conductivity at 25C

25

Conductivity at TC

Measured solution temperature

Formula 1ΚCt = C

Formula 2Κ= ( CtЁC25 ) / { C25 ( TЁ25 )}

{ 1+( TЁ25 ) }

25

Temperature compensation

How to get TC of solution: For obtaining higher accuracy of measurement, you may

calculate the TC value according to the formulas above and set an appropriate TC value

for the instrument. Take an example for 0.01N KCl. Set the TC of the instrument to

non-compensatedΰLin, 0.00иα, and control the temperature at 25C and at 20C.ʳC

means the measurement value at 25C(Such as C

measurement value at 20C(Such as C

= 1278S). According to the formulas above,

25

= 1413S). Ct means the

25

25

Ј1.91%.

Press to confirm it.

Pressʳ or ʳʳ

to select Linear or

Non-linear

com

pensation.

Press to confirm it.

The range of linear compensation:

0.00% ~ 40.00%

Pressʳ or ʳʳ

to set percentage

Linear compensation.

MAX: 40.00%

Default: 2.00%

Enter “Relay 1” Setup

23

6.8 Relay 1

Enter setup of Relay 1. Select the item to turn on or turn of the relay 1 function. If you

select to turn on the relay 1, then select for using relay 1 as “Hi set-point” alarm or

“Low set-point” alarm. Set the value of set-point (SP) and dead-band (DB). The range

for set-point isʳ00.00M~19.99 M/00.00s~1999mS; while the range for DB is

00.00M~2.00 M/00.00s~19.99mS.ʳ(The measurement unit is depending on the use

of measuring range)

Press to confirm it.

Press to confirm it.

Press or to adjust

set-point (SP) value.

If the measuring range of

conductivity measurement is set

as AUTO, then it needs to be set

unit((S /cm or mS/cm), value,

and decimal point by order.

Press ʳ or

to select to activate

REL1 or not. If

not, the guide

menu goes to setup

of Relay 2.

Press or to adjust

dead-band(DB) value

Press to confirm it. Press to confirm it.

Press ʳ or

to select use REL1

as Hi point or Lo

point alarm.

Press ʳ or

to select to activate

a test of REL1 or

not. If “ON”, the

relay 1 is in action,

and the “ACT”

indication light

will light up.

Press to confirm it.

Press to confirm it.

Enter “Relay 2” Setup

24

6.9 Relay 2

Enter setup of Relay 2. Select the item to turn on or turn off the relay 2 function. If you

select to turn on the relay 2, then select relay 2 as “Hi set-point” alarm or

“Low set-point” alarm. Set the value of set-point (SP) and dead-band (DB). The range

for set-point isʳ00.00M~19.99 M/00.00s~1999mS; while the range for DB is

00.00M~2.00 M/00.00s~19.99mS.ʳ(The measurement unit is depending on the use

of measuring range)

Press to confirm it.

Press to confirm it.

Press or to adjust

set-point (SP) value.

If the measuring range of

conductivity measurement is set

as AUTO, then it needs to be set

to S /cm or mS/cm value,

and decimal point by order.

Press to confirm it.

Press to confirm it.

Press ʳ or

to select to activate

REL2 or not. If

not, the guide

menu goes to setup

of Clean.

Press ʳ or

to select use REL2

as Hi point or Lo

point alarm.

Press or to adjust

dead-band(DB) value

Press to confirm it.

Press ʳ or

to select to activate

a test of REL2 or

not. If “ON”, the

relay 2 is in action,

and the “ACT”

indication light

will light up.

Press to confirm it.

Enter “Clean” Setup

25

6.10 Clean

Enter setup of “Clean” function. Select the icon to turn on or turn off the clean function.

If you select “Auto” turning on, this sets the timer of the clean function including

automatically turning on time and turning off time, and the bead-band value(DB).

Note: When the clean function is turned on, if any value is set to 0, the instrument

will automatically turn off this function.

Press or to adjust

set-point(SP) value

Press to confirm it. Press to confirm it.

Press ʳ or

to select to activate

Clean or not. If

not, the guide

menu goes to setup

of Analog 1.

Press or to adjust

dead-band(DB) value

Press to confirm it.

Press ʳ or

to adjust the auto

turning on time.

Press to

confirm the

minute part, and

move to adjust

the second part.

Press to confirm it.

Press to confirm it.

Press ʳ or

to select to activate

a test of Clean or

not. If “ON”, the

Clean function is in

action, and the

“ACT” indication

light will light up.

Press to confirm it.

Enter “Analog 1” Setup

26

6.11 Analog output 1 (Cond/Res):

Enter setup of Analog 1. Select 0~20mA or 4~20mA current output. Set the related

value to the range of Cond./Res. measurement. If the range of the Cond./Res.

measurement is set smaller, the resolution of current output is higher. When the

measurement value exceeds the upper limit of setting range, the current output remains

at around 22mA. When the measurement value exceeds the lower limit of setting range,

the current output remains at 0mA under 0~20mA mode, or the current output remains

at around 2mA under 4~20mA mode. The phenomenon can be used as a judgment

reference of abnormality. If under HOLD status, the current output will remain at last

current output value before the HOLD status is activated. For the convenience of

connecting external recorder or PLC controller, the current output will remain 0/4mA or

20mA while setting its relative measurement value.

Press to confirm it.

Press to confirm it.

Press ʳ or

to select to current

output range,

0-20mA or

4-20mA.

Press or to

set the lower limit of

Cond. value relative to

4.0mA output signal. If

the measuring range of

conductivity

measurement is set as

AUTO, then it needs to

be set unit((S /cm or

mS/cm), value, and

decimal point by order.

Press to confirm it.

Press or to

set the upper limit of

pH value relative to

20.0mA output signal.

Press to confirm it.

Press or to

set the lower limit of

Cond. value relative to

0.0mA output signal. If

the measuring range of

conductivity

measurement is set as

AUTO, then it needs to

be set unit((S /cm or

mS/cm), value, and

decimal point by order.

Press to confirm it.

Enter “Analog 2” Setup(Temperature)

27

6.12 Analog output 2 (Temperature):

Enter setup of Analog 2. Select 0~20mA or 4~20mA current output. Set the related

value to the range of temperature measurement. If the range or the temperature

measurement is smaller, the resolution of current output is higher. When the

measurement value exceeds the upper limit of setting range, the current output remains

at around 22mA. When the measurement value exceeds the lower limit of setting range,

the current output remains at 0mA under 0~20mA mode, or the current output remains

at around 2mA under 4~20mA mode. If under HOLD status, the current output will remain at the last

current output value before the HOLD status is activated.

Press to confirm it.

Press to confirm it.

Press ʳ or

to select to current

output range,

0-20mA or

4-20mA.

Press or to

set the lower limit of

Temp. value relative to

4.0mA output signal.

Press or to

set the lower limit of

Temp. value relative to

0.0mA output signal.

Press to confirm it.

Press or to

set the upper limit of

Temp. value relative to

20.0mA output signal.

Press to confirm it.

Enter “Date/Time(Clock)” Setup

28

6.13 Date/Time(Clock)

Enter setup of Date/Time(Clock). Set the “Year”, “Month”, “Date”, “Hour”, and

“Minute” time. Note: The clock needs to be reset in the event of a power failure.

Press to confirm it.

Press or to

set the year.

Press to confirm it.

Press or to

set the month part, and

press to move to

adjust the date part.

Press to confirm it.

Press or to

set the hour part, and

press to move to

adjust the minute part.

Enter “ Sample average of measurements

(Digital Filter) ” Setup

29

6.14 Sample averaging of measurements (Digital Filter)

Enter the setup of Digital filter. You may select the number of samples to be averaged

each time to increase the stability of measurement.

Press to confirm it.

Press or to

set the number of

sample to be averaged.

Press to confirm it.

Enter “Back Light” Setup

30

6.15 Backlight settings

Enter setup of backlight display. As needed, you can set the brightness of

display(-2~2, dark~ bright) and sensitivity of the baclight sensor(-2~2, insensitive~

sensitive).

ON: Backlight light up OFF: Backlight turns off & Touch-on mode

AUTO: According to ambient condition turn on & off automatically & Touch-on mode

Press to confirm it.

Press or

to select

backlight mode.

Press to confirm it.

Pressʳ or ʳʳ

to

select -2, -1, 0,

1, 2, five

Backlit

Brightness

levels

Press to confirm it.

Pressʳ or ʳʳ

to select

-2, -1, 0, 1, 2, five

Backlit sensitization

levels.

Press or

to select

backlight mode.

Press to confirm it.

Pressʳ or ʳʳ

to

select -2, -1, 0,

1, 2, five

Backlit

Brightness

levels

Press to confirm it.

Press to confirm it.

Press to confirm it.

Enter “Contrast” Setup

Press to confirm it.

31

6.16 Contrast settings

Enter setup of display contrast. You can set the contrast of display according to your

need.

Press to confirm it.

Pressʳ or ʳʳ

to select display

contrast level.

Press to confirm it.

Enter “Power frequency (Freq)” Setup

32

6.17 Power frequency (Freq.)

Enter setup of power frequency. You may select power frequency setting of the

instrument 50Hz or 60Hz according to the local power frequency.

Note: This setting significantly affects the normal measurement of instrument, thus, be

sure to make the setting correctly.

Press to confirm it.

Pressʳ or ʳʳ

to select power frequency.

Press to confirm it. Press to confirm it.

Enter ”Auto return mode (Return)” Setup

33

6.18 Return

Enter setup of auto return mode (Return) to set the function that the instrument

automatically exit the setup menu after a period of time without pressing any key. The

“Manual Exit” means that it needs to exit setup menu manually, while “Auto” means

that the display automatically exit the setup menu and back to measurement mode after

a period of time without pressing any key.

Press to confirm it.

Pressʳ or ʳʳ

to select Auto return

or manual exit.

Press to confirm it.

Pressʳ or ʳʳ

to adjust “minute”

part, and press

to confirm it and

move to” second” part.

Press to confirm it.

Return to “Password (Code)”Setup

Press to confirm it.

7. Calibration

34

Block diagram of Calibration

Cal. Info.

Cal. mode

MTC

Temp.

adjust

CELL

Const.

CELL

constant

select

ATC

CELL

constant

adjust

Auto

Time

input

Return

setting

Manual

Exit

Std. Sol.

Std. Sol.

select

Std. Sol.

MTC

Temp.

adjust

Κ

Κ

adjust

ATC

calibrate

Indicate

CELL

constant

Code

setting

Code

input

OFF ON

New Code

input

Κ

Back to the previous class / action

or the end of the procedure:

35

7.1 Entry of calibration menu

In the measurement mode, pressing the two keys and simultaneously

allows you enter theʳCalibration Information. If you do not need to re-calibrate the

measurement system, press to go back to measurement mode. If you need to

re-calibrate the system, press to enter to the calibration setup menu.

Measurement mode

Press and simultaneously

ʳ

Press to confirm it.

Enter Calibration setup menu

36

7.2 Return

Enter setup of auto return mode (Return) to set the function that the instrument

automatically exit the setup menu after a period of time without pressing any key. The

“Manual Exit” means that it needs to exit calibration setup menu manually, while

“Auto” means that the display automatically exit the calibration setup menu and back

to measurement mode after a period of time without pressing any key.

Note: the return function of setup menu and calibration setup menu are independent

settings.

Press to confirm it.

Pressʳ or ʳʳ

to select Auto return

or manual exit.

Press to confirm it.

Pressʳ or ʳʳ

to adjust “minute”

part, and press

to confirm it and

move to ”second” part.

Press to confirm it.

Press to confirm it.

Enter “Password (Code)” Setup

37

7.3 Security password of calibration (Code)

Select the Code (password) icon after entering calibration setup mode. Select to

activate code function or not. The default Calibration setting code is “1100”.

If you input a wrong code,

then the display shows a

“Error 5” message. Press

to restart inputting another

code, or press to

exit the calibration menu.

Press to confirm it.

The first ‘0” of digits ‘0000” start

to IODVK. Pressor to

adjust th

to confirm it and continually key

in the next digit, and so on.

Press to confirm it.

e value, and th

en press

(Select to turn on or turn off

code protection function. If

you select turn on, please

key in a new code. There

will be a code requirement

showing in display when you

re-enter to the setup mode.

Key in the correct password

to enter into calibration setup

menu.)

If you input a wrong code,

then the display shows a

“Error 5” message. Press

to restart inputting another

code, or press to

exit the calibration menu.

Press or

Press to confirm it.

Input new code

Press to confirm it.

Enter “Cell Constant Calibration

(CELL Const.)”Setup

38

7.4 Cell constant calibration (CELL Const.)

7.4.1 Resistivity (Res)

Enter setup of cell constant to directly set cell constant. Press or to

select the preset value closest to your sensor's one. There are three sets of preset value

(0.01, 0.05, 0.10). Select the most appropriate cell constant value and press to

confirm it and enter to the next screen. At the time, the cell constant starts to flash.

Press or to adjust the cell constant value. Correct the measurement value to

known standard solution value by adjusting the cell constant, or setting the known cell constant

directly. Press to confirm it.

Resistivity cell constant setting range:

0.0100 Adjustable range: 0.0080 ~ 0.0120

0.0500 Adjustable range: 0.0400 ~ 0.0600

0.1000 Adjustable range: 0.0800 ~ 0.1200

Press to confirm it.

According to the cell constant of the

resistivity sensor, press or

to select the nearest preset value.

Press to confirm it.

Under MTC temperature mode, press

or to adjust temperature value.

If under ATC temperature mode(PTC or

NTC), the temperature value is read

automatically, and the instrument

directly goes to next screen.

Press to confirm it.

According to labeled cell constant of the

resistivity sensor, press or to

adjust to the corresponding value. Press

to confirm it.

Press to confirm it.

Enter “Standard solution calibtaion” mode

39

7.4.2 Conductivity (Cond)

Enter setup of cell constant to directly set cell constant. Press or to

select the preset value to near an appropriate one. There are four sets of preset values

(0.01, 0.10, 0.50, 10.00). Select the most appropriate cell constant value and press

to confirm it and enter to the next screen. At thLV time, the cell constant starts to )ODVK

. Press or to adjust the cell constant value. Correct the measurement

value to known standard solution value by adjustLQJWKH cell constant, or set the known cell

constant directly. Press to confirm it.

Conductivity cell constant setting range:

0.0100 Adjustable range: 0.0080Д0.1200

0.1000 Adjustable range: 0.0400Д0.6000

0.500 Adjustable range: 0.0800Д1.999

10.00 Adjustable range: 2.00Д19.99

Press to confirm it.

According to the cell constant of the

resistivity sensor, press or

to select the nearest preset value.

Press to confirm it.

Under MTC temperature mode, press

or to adjust temperature value.

If under ATC temperature mode(PTC or

NTC), the temperature value is read

automatically, and the instrument

directly goes to next screen.

Press to confirm it.

According to labeled cell constant of the

conductivity sensor, press or

to adjust to the corresponding value.

Press to to confirm it.

Enter “Standard solution calibtaion” mode

Press to confirm it.

40

7.5 Standard solution calibration (Std. Sol.)

Applying known standard solution for calibration is only suitable for

conductivity measurement mode. Press or to select from preset standard

solution value. There are three preset value from 84.0S/cm, 1413S/cm, to

12.88mS/cm. After selecting proper preset value, put the cleaned conductivity sensor

into standard solution, and press to enter the calibration screen. At the time, the

conductivity value can be adjusted according to standard solution value. Press to

initiate the calibration. The display shows the sign , and it starts the auto

calibration procedure. After finishing calibration, the display automatically shows the

cell constant after calibration. Press to exit.

Press to confirm it.

Press or to select it.

Press or to adjust the

standard solution value. Press

to confirm it.

Under MTC temperature mode, press

or to adjust temperature value.

If under ATC temperature mode(PTC or

NTC), the temperature value is read

automatically, and the instrument

directly goes to next screen.

The system measure the

standard solution. Press to

show the reading, or wait for

the reading which shows

automatically.

Display shows calculated

cell constant value

Enter ”Auto return

mode (Return)” Setup

41

8. Error messages (Error code)

Messages Reason Dispositions

Error9

Error3

Error2

Error1

Serious error that does

not permit any further

measuring

Please call Customer service.

Wrong password Re-enter a password

Cell constant of the electrode

exceeds the upper or lower

limit

The readout is unstable when

calibration

1. Replace with new standard

solution

2. Maintain the electrode or

change to a new electrode, and

make another calibration

1. Replace with new standard

solution

2. Maintain the electrode or

change to a new electrode, and

make another calibration

42

9. Installation of cells

9.1 Correct installation of cells

43

9.2Incorrect installation

9.2 .1 Insufficient immersion: This installation can result in stagnant water inside

the cell and thus lead to measurement error.

9.2.2 Insufficient water flow: This installation is prone to error due to

insufficient water flow.

9.2.3 Insufficient immersion: This installation can result in stagnant water inside

the cell and thus lead to measurement error.

Loading...

Loading...