Preliminary Information

RF by

DX80 Gateway Installation & Operation Manual

The gateway and endpoint nodes communicate over multiple wireless channels within the 902-928MHz

ISM Spectrum. Different configurations of internal & external antennas and different RF power options

allow you to customize the wireless range from a few feet to > 10000’. The implementation of FHSS

methodology allows for reliable communications even in harsh industrial environments. The gateway

station and endpoint nodes communicate with acknowledge handshaking to verify reception of data. Error

checking is also performed to validate the data transmission.

The Gateway and Endpoint node communications always collect signal strength information. The

collected data can help gauge the strength and performance of the wireless signals. The received signal

strength can be adjusted by various parameters such as the TX power settings and Receiver Sensitivity

Modes. Hardware configurations can also impact the signal strength, such as internal / external antenna and

antenna placement.

Features

• Operates in 902-928MHz ISM

Spectrum

• FHSS operation

• RF configurations – up to 150 mw

• External antenna connection

• RS232 / RS485

• 2 Analog In (4-20ma)

• 2 Analog Out (4-20ma)

• 2 Digital In

• 2 Digital Out

• 10-30v DC

• LCD, Control buttons, LED

indicators

• Stand alone operation

• DX80 - NEMA 6, IP67 enclosure

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

1 of 18 www.sensonix.com • 763.519.7042

Preliminary Information

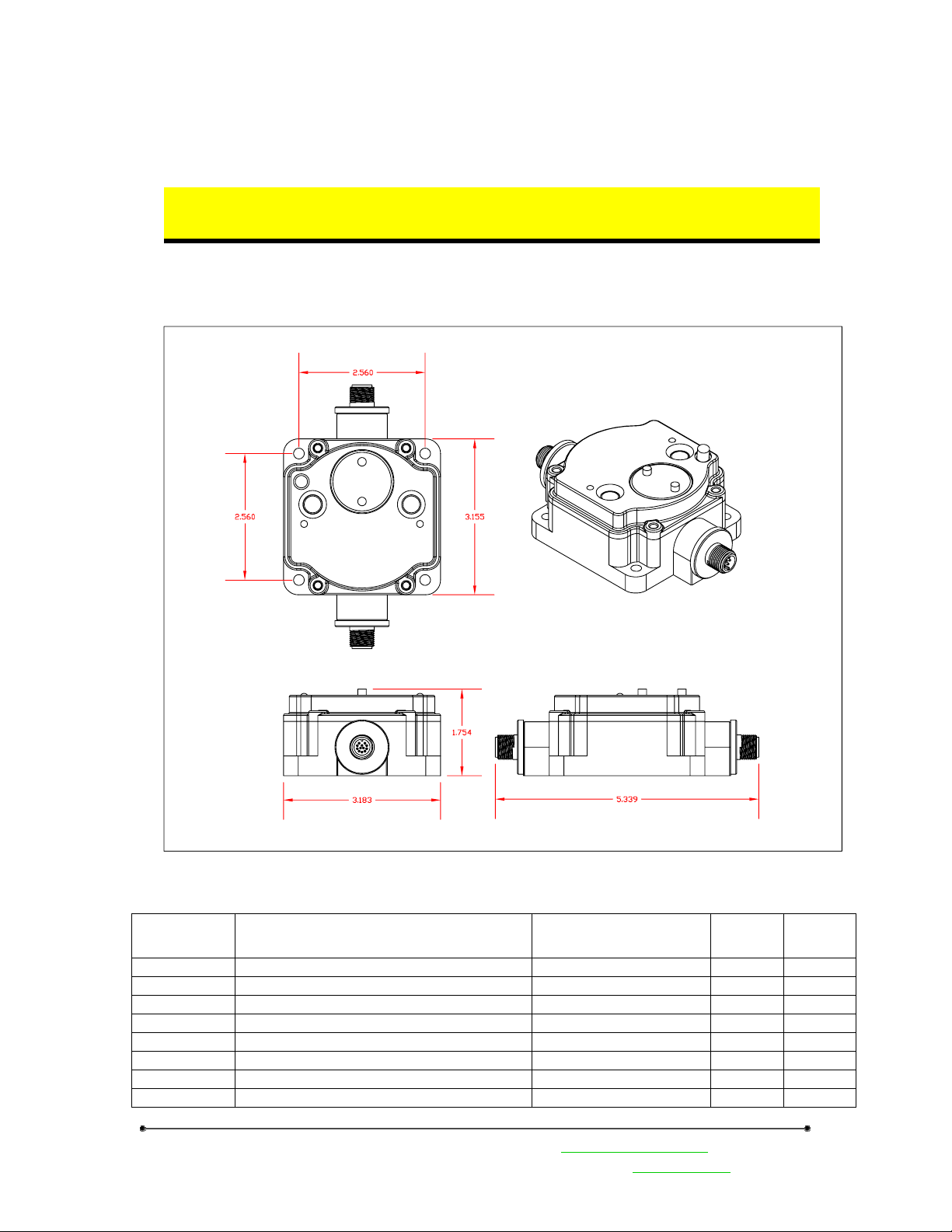

1 Mechanical

Low Profile DX80 enclosure, a two connector model is shown. A DX80 gateway unit

in a single connector model is also available

All DX80 mechanical enclosures

Model # Description Euro Connectors High

Profile

LPGW1 Line Powered Gateway 1 female, 1 male X

LPGW2 Line Powered Gateway 1 male, 8 pin X

LPEN1 Line Powered Endpoint Node 1 female, 1 male X

BPDEN1 Battery Powered Endpoint Node 1 male, 8 pin X

BPMIEN1 Battery Powered Endpoint Node 1 female connector X

BPTMPEN1 Battery, RTD Endpoint Node 2 female connectors X

BPTMPEN2 Battery, Thermocouple Endpoint Node 1 female connector X

BPMG1 Battery, Magnetic Endpoint Node No connectors X

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

2 of 18 www.sensonix.com • 763.519.7042

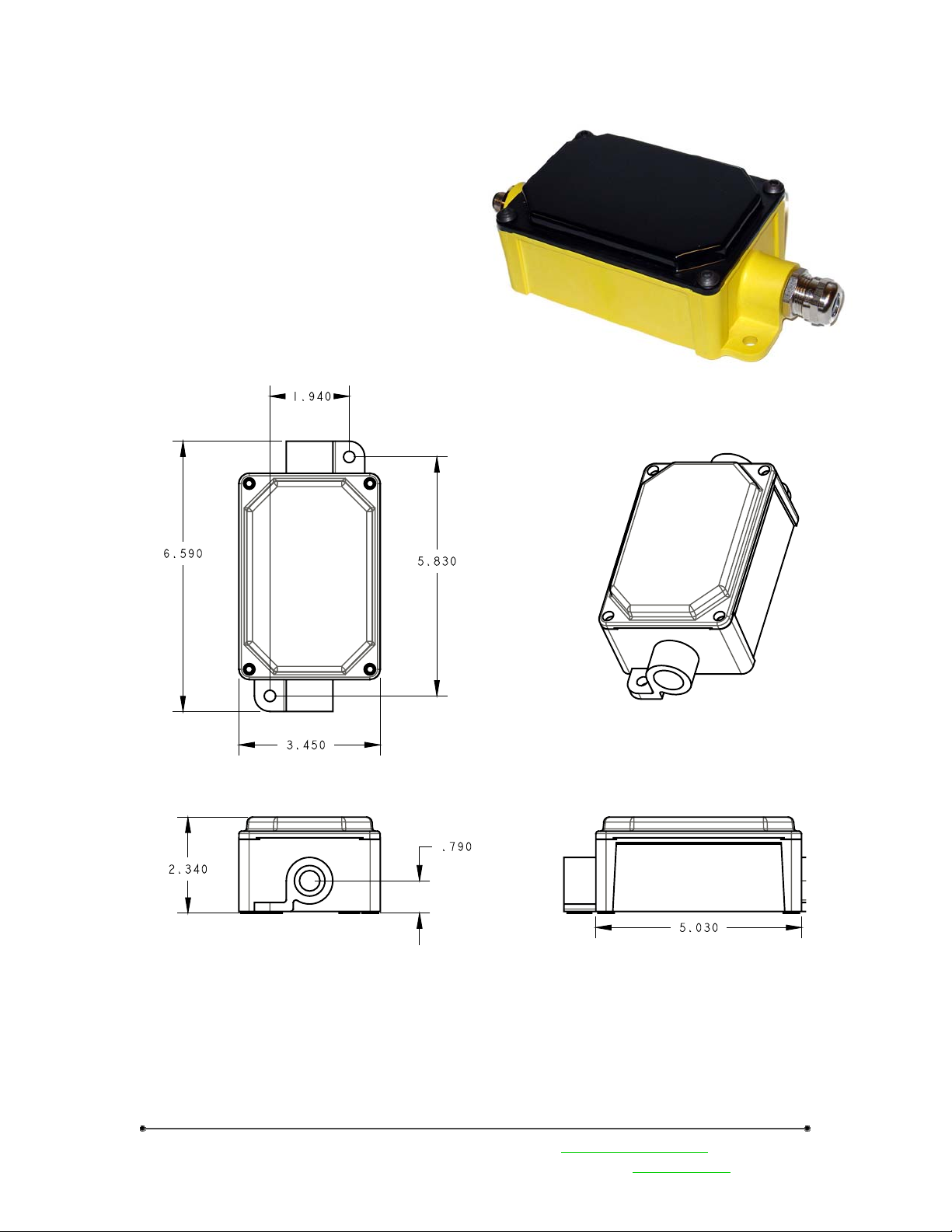

Low

Profile

Junction Box

Junction box models – euro connectors, glands,

Euro-style connector or glands?

Mounting holes

Wiring diagram

PC Board with Terminals to identify connection.

Preliminary Information

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

3 of 18 www.sensonix.com • 763.519.7042

Preliminary Information

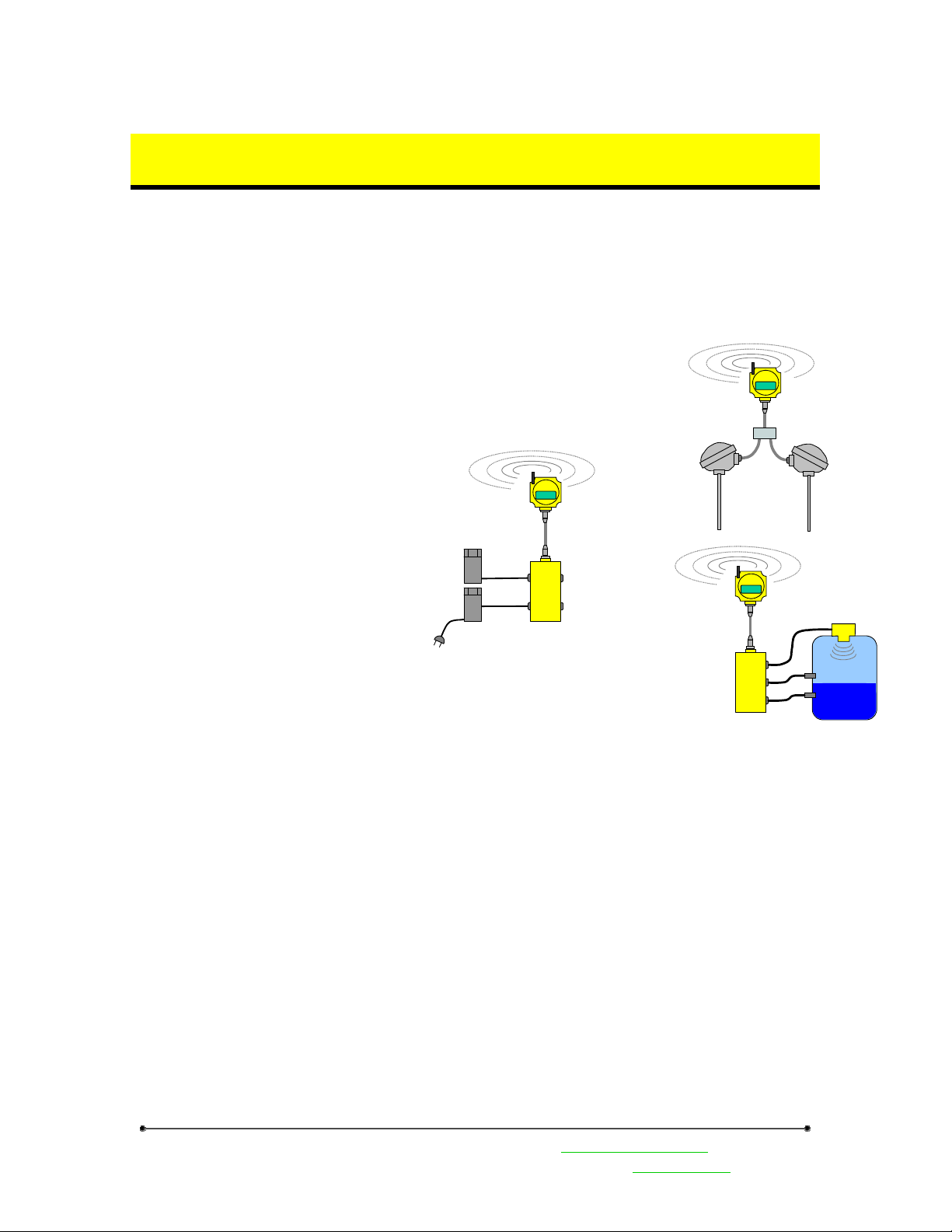

2 Mounting & Electrical Connections

2.1 Placement

A wireless network can be hindered by radio interference as well has obstructions in the path of the

receiver and transmitter. When planning for the best location to install the wireless gateway or endpoint

node, it is best to be able to monitor the signal strength relative to the positions of the devices. A built in

diagnostic called ‘site survey’ continuously monitors signal strength and displays the information on the

gateway front panel LCD. Use this diagnostic tool to confirm signal quality before fixing devices for

permanent installation. (Refer to the

section on Front Panel Operation.)

Avoid placement of the wireless

units in extreme temperatures, high

vibration and high shock areas. The

DX80 is IP67 compliant and designed for

all types of environments but continued

exposure to harsh environments will

shorten the product life.

Although the DX80 devices are

considered maintenance free, try to avoid

installation in an unserviceable location.

Only place the DX80 devices in

ambient operating temperatures of -40°C

to 85°C.

Third

Party

PLC

24Vdc

power

supply

Serial

Interface

123456

Junction

Box

DX80 Line

powered

gateway

2.2 External Antenna

For optimal RF communications the

external antenna should be vertically

mounted. A clear line of sight between

gateway and nodes is ideal.

Only Banner approved external

antenna should be connected to DX80 devices. Unsuitab le antenna may void th e user’s autho rity to op erate

the equipment. The approved antennas are listed in the accessory section.

2

123456

DX80 Battery

powered TC

endpoint node

Thermocouple &

Compensation

Thermistor

1

123456

Junction

Box

Digital sensors

for tank hi/lo

DX80 Battery

powered

endpoint node

QT50

2.3 Mounting hardware requirements

DX80 devices have four #10 screw holes used for mounting the device vertically or horizontally. The

screws should not be tightened more that XX ft/lbs.

Keep in mind sufficient clearances for the external antenna, euro-style connectors and for viewing the

LCD display. The bottom unit dimensions are supplied in the mechanical section of this document.

2.4 Mounting accessories

DIN rail mounting hardware

Antenna mounting hardware, cables

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

4 of 18 www.sensonix.com • 763.519.7042

Preliminary Information

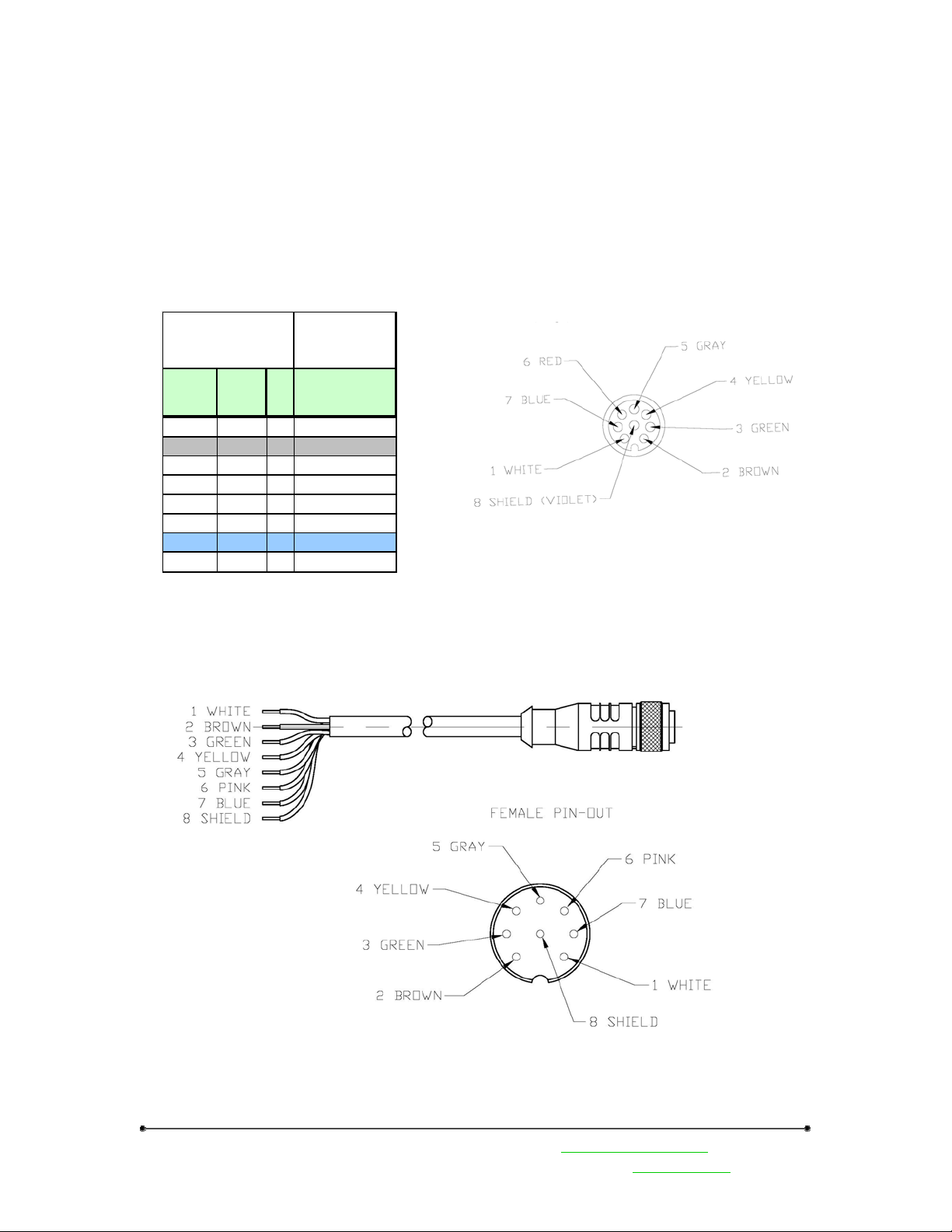

2.5 Euro-Style Connectors

The Gateway devices have 8-pin or 12-pin euro-style connectors. The pin numbering and wire color is

identified below. The signal wire to pin number association table identifies all wires for the DX80

Gateway.

2.5.1 8-pin Euro-Style Wiring (models LPGW2, BPDEN1)

Signal to pin association for 8-pin Euro-Sty l e connectors. DX80 Gateway models

DX80 internal 8-pin Euro Style Connector

(male)

* Looking at the pin end

Euro-Style

Connector

Internal

Wire

Color

White White 1

Brown Brown 2 10-30Vdc

Green Gr een 3 Di gital I nput

Yellow Yellow 4 Courtesy Ground

Gra y Gra y 5 NM OS Ou tp ut

Blue Blue 7 Ground

Vio le t wire 8

Cable

Pin

Wire

Color

Red Pink 6

#

8-Pin Euro-Style Cable

LPGW2 –

Line Powe red

Gate wa y

Euro Q D1 male

Shield

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

5 of 18 www.sensonix.com • 763.519.7042

2.5.2 12-pin Euro-Style Wiring

Signal to pin association for 12-pin Euro-Style connectors. DX80 Gateway models

Euro-Sty le Connector

LPGW1 –

Internal

Wire Color

White White 1 -

Bro wn Bro wn 2 10-30Vdc Outpu t 10-30V dc Input

Green Green 3 Analog In1 (4-20mA) RS485 Yellow Yellow 4 Analog Out1 (4-20mA) RS485 +

Grey Grey 5 Analog In2 (4-20mA) RS485 Signal Gnd

White/Red Pink 6 Analog Out2 (4-20mA) -

Blue Blue 7 Ground Ground

Red Red 8 - RS232Tx

Orange Orange 9 Di gital I n1 RS 232R x

White/Bl ack Tan 10 Digital Out1 -

Black Black 11 Di gital I n2 -

Violet Violet 12 Digital Out 2 -

Cable

Wire

Color

Pin # Euro QD1 female Euro QD2 male

Line Powered Gateway

Looking at the connection pin end

Preliminary Information

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

6 of 18 www.sensonix.com • 763.519.7042

Preliminary Information

2.6 ModBus Communications, RS232 / 485 (model LPGW1)

The gateway interface is controlled using the Modbus RTU protocol. The gateway device operates as

a Modbus slave device with a programmable slave address in the range of 01-99. The serial interface is set

up with factory default parameters of 19.2k baud, one start bit, two stop bits, no flow control and a slave

address of ‘01’.

The following Modbus function codes are supported. For DX80 configuration commands and DX80

user commands refer to the DX80 Inte rf ace Prot ocol document.

Type

Modbus Cmd 1 0x1 Read Coils, 1 – 2000 contiguous status of coils

Modbus Cmd 2 0x2 Read Discrete Inputs, 1 – 2000 cont i g u ous st at us of discret e inputs

Modbus Cmd 3 0x3 Read Holding Regist ers, 1 – 12 5, cont i g uo u s bl ock of holding regs.

Modbus Cmd 4 0x4 Read Input Registers, 1 – 125, contiguous block of input registers

Modbus Cmd 5 0x5 Write Single Coil

Modbus Cmd 6 0x6 Write Single Register

Modbus Cmd 15 0xF Write Multiple Coils, 1 – 0x7B0 force multiple coils, ON or OFF

Modbus Cmd 16 0x10 Write Multiple Registers, 1 – 0x78, contiguous block of registers

The gateway front panel LED’s are used to display information about the Modbus serial

communications.

LED1

• ‘GREEN’ when power is applied and the gateway is operational.

• ‘RED’ indicates a system error has occurred. Review the LCD display for further

information.

LED2

• ‘YELLOW’ signifies a frame reception or sending.

• ‘RED’ signals an internal Modbus error has occurred.

• Flashing ‘RED’ indicates a communications fault or configuration error.

The RS485 connections are on the 12-pin euro-style male connector QD2 on the gateway. See the Euro

Connector Diagram section in this manual

Function

Code

Description

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

7 of 18 www.sensonix.com • 763.519.7042

Preliminary Information

3 Setup & Operation

3.1 DX80 Front Panel

The DX80 front panel picture helps identify

each switch, button and LED. The rotary switches in

the middle of the round window are identified as a

10’s switch (left switch) and a 1’s switch (right

switch). The value for each rotary switch is 0 – 9.

The rotary switches define different parameters

depending upon the current operating state and

whether the device is a gateway or node.

During Run Mode the gateway rotary switches

define the device information to display; the node

switches indicate the node ID number.

During configuration of the Network ID, the

rotary switches indicate the network ID number on

both the gateway and the node.

During configuration of the Modbus slave

number the gateway rotary switches indicate the

Modbus slave number 01-99.

During Site Survey operations the gateway

switches define the node ID number; the node rotary

switches define the node ID number.

The gateway front panel LED’s are used to display information about the Modbus serial

communications

LED1

• ‘GREEN’ when power is applied and the gateway is operational.

• ‘RED’ indicates a system error has occurred. Review the LCD display for further

information.

LED2

• ‘YELLOW’ signifies a frame reception or sending.

• ‘RED’ signals an internal Modbus error has occurred.

• Flashing ‘RED’ indicates a communications fault or configuration error.

The gateway LCD panel will display a variety of information about the gateway and wireless system.

3.2 Power on / Power Off

The gateway and nodes can be powered up or powered down with button 1. When the device is

powered down (sleep mode), depress button 1 for 2-3 seconds, the device will activate. Holding down

button1 for 2-3 seconds when the device is active will cause the device to power off. The wireless devices

are not operational when in Sleep Mode.

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

8 of 18 www.sensonix.com • 763.519.7042

Preliminary Information

3.3 Set-up / Configuration

The gateway and nodes must be configured to create a communications link. A properly running

wireless network will be indicated on each endpoint node by LED1 flashing green every second. (The

gateway LED’s monitor the Modbus host link)

Complete the following configuration steps to set up the wireless link.

DC power or Battery power applied to all devices and powered up. (out of sleep mode) (See 4.2 Power

on / Power off)

Gateway Set-up –

• Rotary switches = ‘00’

• Network ID set to a common value for the entire wireless network. The factory default is ‘01’

and will work for most single network installations. (See Setting the Network ID to change

the network ID)

• The Modbus slave number must be set to a unique number compared to other slaves on the

serial host bus. This is only required if using a host interface with the gateway.

Node / Endpoint Set-up –

• Rotary switches = unique number for each node in the wireless network. 01-99, 00 is not valid

• LED1 will blink GREEN every second when a RF communications link is established.

• LED1 will blink RED every 3 seconds when a node is not communicating with the gateway.

*Some endpoint nodes may require up to 20 seconds after power-on to synchronize with the gateway.

3.4 LabView Configuration

Node configuration, Sensor configuration,

System Parameters – dynamic TDMA

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

9 of 18 www.sensonix.com • 763.519.7042

Preliminary Information

3.5 Front Panel Operation

The front panel rotary switches and push button switches control the display information and

configuration of the DX80 devices. The flow diagram below shows the button sequences and operational

flow for what is possible with the DX80 Gateway.

Sleep

Mode

hold.1

ModBus Slave ID

hold.1

ModBus Baud

Network ID

RF Baud

sc1

RUN

Run Mode

Rotary switches

define device

Sys Warn / Err

Dev Warn / Err

Point 0 status

Point 1 status

Point N status

sc.1

DEVINF

Device Info

sc.2

Rotary switches

define device

Name A

Name B

Name C

RF Msg

Dev Warn / Err

dc.2

sc.1

S/W Cm rev high

FACTRY

Factory

sc.2

Rotary switches

define device

S/N high

S/N low

Mod high

Mod low

S/W RF rev high

S/W RF rev low

S/W Cm rev low

Production high

Production low

dc.2

sc.1

Site Survey Start

DIAG

Diagnostics

sc.2

Password

protect,

Rotary Sw

sc.1

dc.2

CONFIG

Config

sc.2

Password

protect,

Rotary Sw

Config Start

dc.2

hold.1 = press and hold button 1 for 2-3 seconds

sc.1 = single click button 1

sc.2 = single click button 2

dc.2 = double click button 2

From a powered-off state, press and hold button 1 for 2-3 seconds will turn on the Gateway or Node.

From any state, press and hold button 1 for 2-3 seconds will turn off the Gateway or Node. Configuration

steps not fully completed before going into sleep mode will be lost.

3.5.1 Operating States

Sleep Mode – This is the off state for all devices. Sleep mode can be entered or exited by holding

button 1 for 2-3 seconds regardless of the current state. All LED’s will be turned off in this state. (The LCD

display will be turned off for DX80 devices with an LCD display)

Run Mode – (LCD display = ‘RUN’) This is the default operating state for normal operation. Out of

sleep mode the device will transition into run mode. If no buttons changes are detected the gateway will

display device information. The rotary switches on th e gateway will define which device information to

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

10 of 18 www.sensonix.com • 763.519.7042

Preliminary Information

display on the LCD. If the rotary switches are set to ‘04’ the information for endpoint node ’04 will be

displayed. The gateway can only display device information if they are defined with Modbus registers.

The LCD will display any system warnings or errors, any device warnings or errors and the state of

each I/O point defined for that device. The LCD display will continuously cycle through this information

until the rotary switches change or a button change is detected.

Device Information (LCD display = ‘DEVINF’) From the Run mode state, single click button 1 to get

to the Device Information selection. Single click button 2 will begin displaying the information for the

device defined by the rotary switches. The LCD will display ‘NAME A’, ‘NAME B’, ‘NAME C’, RF

Message and Device warnings / errors.

The NAME A, B and C fields are a user defined name that can be associated with each device. A total

of 18 characters can be used. The name fields can be defined under the CONFIG menu.

The RF message can be one of several informational messages about the RF link between the gateway

and node. ‘NO RF’, ‘RF OFF’, ‘RF SYNC’ and ‘RF OK’ are the RF messages. ‘NO RF’ indicates there is

no communication link between the device defined by the rotary switches and the gateway. ‘RF OFF’

indicates the device has been disabled. ‘RF SYNC’ indicates that the node and the gateway are in the

process of trying to synchronize communications. All devices should synchronize within 20 seconds of

being enabled. ‘RF OK’ indicates the wireless communications between the gateway and node are

operating normally.

The device warnings and error messages displayed will be for the device defined by the rotary

switches. See the ‘Warnings & Error Messages’ section for full explanations of each message.

To exit the device information state, double click button 2

Factory Settings (LCD display = ‘FACTRY’) From the run mode state, single click button 1 and then

single click button 1 again to arrive at the factory settings display. To begin the cycle through the factory

information display single click button 2. The display information will include: serial number, model

number, software version for the RF processor, software version for the communications processor and the

production date.

To exit the factory settings state, double click button 2.

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

11 of 18 www.sensonix.com • 763.519.7042

Preliminary Information

Diagnostics (LCD display = ‘DIAG’) The diagnostic menu is a password protected area. A 4-digit

password must be entered before the system will enter into the diagnostics menus. The default password is

‘0000’. The password is entered starting at the right most character; use the right rotary switch to enter the

proper digit, then single click button 2 to move to the next digit. When all four digits have been properly

entered, double click button 2 to enter the site survey diagnostic.

The Site Survey mode can be used to judge the quality of the RF communications link between the

gateway and any node. Site Survey mode can only be activated from the gateway menu.

The gateway LED1 and LED2 will alternately blink RED to indicate you are now in Site Survey Start.

Now set the rotary switches to a node number to perform the Site Survey testing. Then single click button 1

to activate the node defined by the rotary switches.

dc.1

Deactivate

Device & Reset

Totals

Excellent Reception Total

Site Survey Start

Rotary switches

define device

Good Reception Total

Poor Reception Total

Missed Packet Total

dc.2

sc.1

Activate Device &

Reset Totals

This will cause the LCD on the front panel of both devices (gateway and node) to display the signal

strength for the wireless RF link. A group of 100 data packets are sent at different frequencies between the

gateway and the node. The LCD display will show the breakdown of total missed packets, total poor

reception packets, total good reception packets and the total number of excellent reception packets.

After 100 data packets the whole process is repeated. The LCD display is continually updated with the

running totals for each category.

When testing the communication signal link using site survey, make sure to ke ep all wireless units

separated by at least 3 feet.

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

12 of 18 www.sensonix.com • 763.519.7042

Preliminary Information

Configuration (LCD display = ‘CONFIG’) To set the network ID or Modbus Slave nu mber, from

Run Mode single click button 1 until the LCD display reads ‘CONFIG’, now single clock button 2. The

configuration menus are a password protected area. A 4-digit password must be entered before the system

will enter into the configuration menus. The default password is ‘0000’. The password is entered starting at

the right most character; use the right rotary switch to enter the proper digit, then single click button 2 t o

move to the next digit.. Double click button 2 when all four digits have been entered. This will allow access

into the configuration menus.

dc.2

Config Start

sc.1

switches define

Network ID

LCD Display

Current value, Switch value

Enter new value

LCD Display

Current value, Switch value

NET ID

Config

sc.2

Rotary

sc.2

sc.1

sc.1

MODSLV

Config

sc.2

Rotary switches

define Modbus

Slave #

LCD Display

Current value, Switch value

sc.2

Enter new value

LCD Display

Current value, Switch value

sc.1

sc.1

Current value, Switch value

Current value, Switch value

SETPWD

Config

sc.2

Use Rotary

Switches to

Set PW

LCD Display

sc.2

Enter new value

LCD Display

sc.1

sc.1

dc.2

Current value, Switch value

SETNAM

Config

sc.2

Use Button 1

to Set

NAME3,2,1

LCD Display

Display Name3,2,1

sc.2

Enter new value

LCD Display

sc.1

GATWAY

Config

sc.1

NODE

Config

The configuration menu is made up of 4 sub menus: Network ID, Modbus Slave number, Gateway and

Node. Select the appropriate sub menu by single clicking button 2.

Configuration: Network ID. The network ID is a parameter used to define the sequence of RF

channel hops and used to create a unique network ID that will allow devices to communicate with each

other as a wireless network. A wireless network comprised of a gateway and nodes need to be programmed

using the same network ID. For co-locating multiple wireless networks within range of each other, choose

unique network IDs for each wireless network group. The default Network ID setting from the factory is

‘01’.

The network ID is set with the rotary switches. The rotary switches are defined as a 10’s switch and a

1’s switch. For example, if the 10’s switch is set to ‘6’ and the 1’s switch is set to ‘2’ the resulting value is

read as ‘62’.

From within the configuration menu, single click button 1 until the LCD display reads ‘NETID’ and

then single click button 2. The LCD will display the current value of the Network ID and the rotary switch

values. When the rotary switches are set correctly for the new Network ID, enter the new value by a single

click of button 2. The LCD will briefly display the new Network ID before exiting back to the Netwo rk ID

top menu.

If you change the network ID on one device, gateway or node, all devices intended for that

wireless network need to be changed to the same network ID.

Double click button 2 to put the device back into Run Mode.

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

13 of 18 www.sensonix.com • 763.519.7042

Preliminary Information

Configuration: Modbus Slave Number. The DX80 gateway can have a Modbus slave address from 1

to 99. Each member of a Modbus RTU serial network must have a unique slave number.

From within the configuration menu, single click button 1 until the LCD display reads ‘MODSLV’ and

then single click button 2. The LCD will display the current value of the Modbus Slave number and the

rotary switch values. When the rotary switches are set correctly for the new Modbus Slave number, enter

the new value by a single click of button 2. The LCD will briefly display the new Modbus Slave number

before exiting back to the Modbus Slave top menu.

Double click button 2 to put the device back into Run Mode.

Set Password: The password is defined as a 4-digit number used to protect the configuration and

diagnostic areas of the menu system.

Set Name: A user name can be applied to each device. Up to 16 alphanumeric characters can be

stored.

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

14 of 18 www.sensonix.com • 763.519.7042

Preliminary Information

4 Maintenance

The DX80 family of products is designed to be IP67 compliant and maintenance free. Annual cleaning

and inspection is always recommended. When inspecting the equipment watch for housing cracks, residue

build-up or corrosion on connectors. It is also a good idea to verify the mechanical connections are tight

and still in good condition.

5 Trouble shooting

Network setup

A table of all LCD messages

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

15 of 18 www.sensonix.com • 763.519.7042

6 Specifications

RS232 / 485 Serial Interface

Interface RS-232 / RS-485

Baud Rates 19.2k

Data Format 8 data, no parity, 2 stop bit

Protocol ModBus RTU

Radio Specifications

Range

Frequency 902 – 928 MHZ ISM band

Transmit Power Variable

Channel Hopping

Rx Sensitivity To -110 dBm

Antenna Connector

Operating Temperature Range

Electronics

LCD -30C to +70C

LCD reduced visibility

Configurable – few feet to >

10000’

FHSS – configurable # of

channels

External Reverse Polarity

SMA – 50 ohms

-40C to +85C

-40C to +85C

Preliminary Information

Ethernet Interface

Interface Ethernet 10/100

Connection RJ-45 / Hardwired

General

Power 10-30V DC

Power Consumption XX mW

Wiring Connections Two 12-pin Euro-Style Connectors

Mounting

Dimensions 3.15” x 3.15”

Case Material ABS, polycarbonate

Weight

Temperature Ratings -40 to +85ºC

Approvals

Environmental Ratings NEMA 6, IP67

LED Indicators (2) LED

Switches (2) Push Button Switches

LCD 6 Character LCD

DX80 enclosure – horizontal or

vertical mount.

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

16 of 18 www.sensonix.com • 763.519.7042

Preliminary Information

Care should be taken to maintain the minimum separation distances specified between the antenna and

nearby persons.

7 Agency Certifications

7.1 FCC

This device compiles with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

This equipment compiles with part 15 of the FCC rules. Any changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate the equipment.

Antenna usage: This device should be used with the antennas listed on page 17 of this manual.

7.2 UL

913

Intrinsically Safe –

7.3 Environmental Rating

NEMA 6

IP67

8 Accessories

Qualified Antennas

Part

Manufacturer

Nearson S321AH-915 ¼ wave, 3” antenna 0.0 dBi Fixed / Mobile 20 cm

Nearson S463AH-915

Nearson S467AH-915S

Number

Type Gain Application

1/2 wave fixed

antenna

1/2 wave Swivel

antenna

2.0 dBi Fixed / Mobile 20 cm

2.0 dBi Fixed / Mobile 20 cm

Cables

Mounting Brackets

Min. Separation

Distance

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

17 of 18 www.sensonix.com • 763.519.7042

Preliminary Information

9 Messages

Endpoint Node

RF link status messages

• RF OK –

• RF Sync –

• RF OFF –

• NO RF –

Warning / Error Messages

LOWBAT – Low battery condition, replace battery.

S FLT – Sensor response is outside of normal operating parameters.

P FLT – Parameter error in processing sensor status.

Gateway

ModBus errors

Banner Engineering Corp • Minneapolis, MN USA www.bannerengineering.com • Tel: 763.544.3164

Sensonix Incorporated • Plymouth, MN USA

18 of 18 www.sensonix.com • 763.519.7042

Loading...

Loading...