| DR45 SERIES

AC SINGLE PHASE OUTPUT DIN RAIL MOUNT SSRS

Introduction

The DR45 is a powerful and compact solid state relay in a DIN rail 45mm wide package with an output rating up to 60 Amps

@ 40°C offering mounting flexibility (on panel or DIN rail) and convenient input connection options. Its high I²t capability

and optional built-in overvoltage protection make it suitable for demanding heating, motion and lighting applications.

Its contactor configuration and large cage clamp terminals allow connecting wires up to 3 AWG size on the output without

the use of any additional accessories making them truly ready-to-use devices, therefore reducing installation cost and

time.

UL Listed and VDE certified, the DR45 is a safe and versatile solid state relay with superior performance when compared to

previous generation and competitor products in similar sized packages.

Features

• Output ratings up to 60 Amps at 600 VAC

• Built-in overvoltage protection

• Integral heat sink eliminates the need for complex

thermal calculations

• Cage clamp terminal type accept up to 3 AWG wire size

• IP20 touch-safe housing

• Contactor configuration

• AC or DC control

• C-UL-US Listed and VDE approved

Applications

• Plastic injection molding equipment

• Packaging equipment

• Industrial ovens

• Lighting control

• Pump control

• Conveyor drives

• HVAC&R

• Railway vehicles

PRODUCT SELECTION

Control Voltage 45A

90-280 VAC/VDC DR4560A45x

4-32 VDC

60A

DR4560A60x

DR4560D60xDR4560D45x

Copyright © 2017 Sensata Technologies Inc.

Page 1

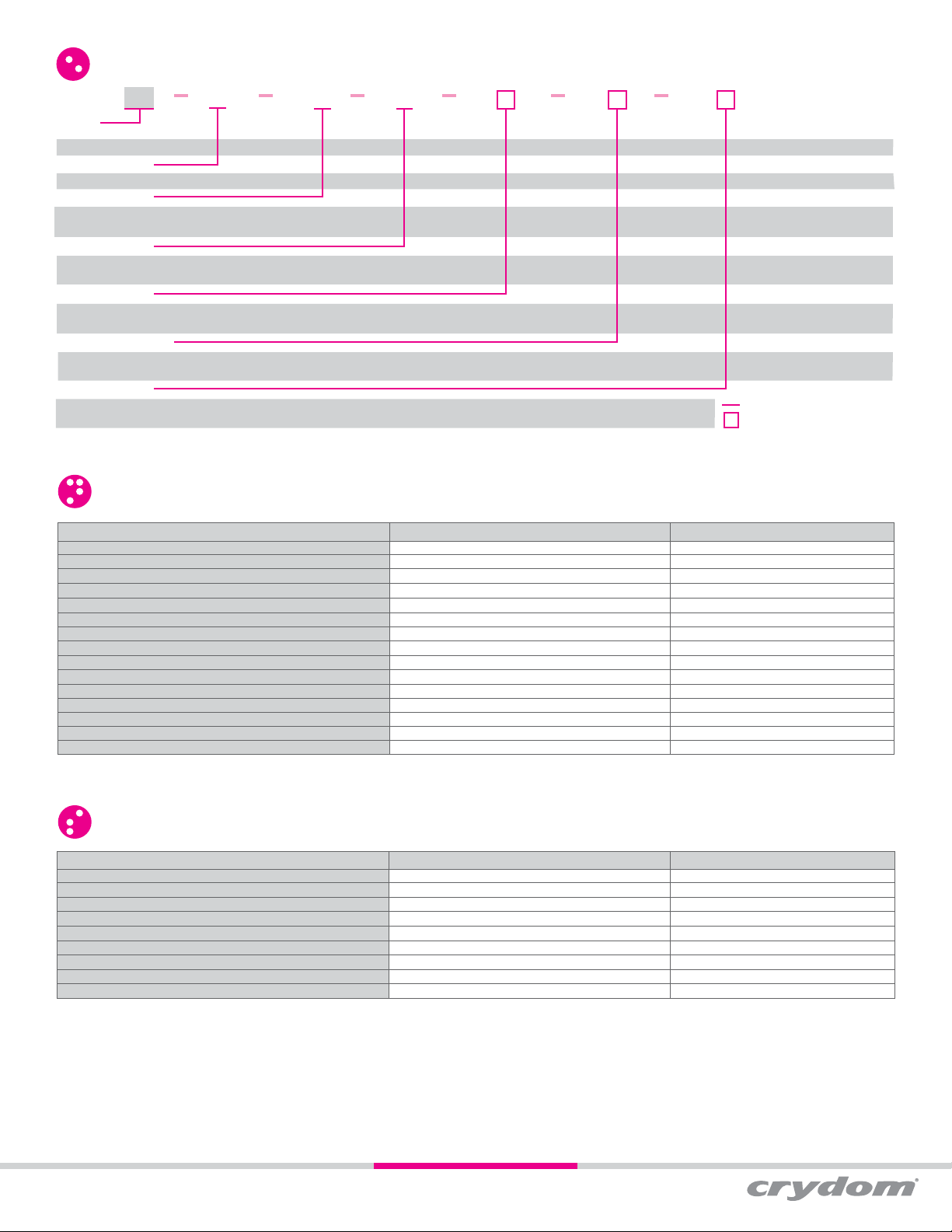

ORDERING OPTIONS

DR45

60 A 45 R JP

Series

DR45

Operating Voltage

60: 48-600 VAC

Control Voltage (1)

A: 90-280 VAC/VDC

D: 4-32 VDC

Rated Load Current

45: 45 Amps

60: 60 Amps

Switching Type

Blank: Zero Voltage Turn-On

R: Instantaneous Turn-On (Motor Rating Certified)

Overvoltage Protection

Blank: Not Included

P: Included

Input Connector

Blank: Screw Terminal

J: Spring Terminal

OUTPUT SPECIFICATIONS

(2)

Description 45A

Operating Voltage (45-65Hz) [VRMS] 48-600

Transient Overvoltage [Vpk]

Maximum Off-State Leakage Current @ Rated Voltage [mA

Minimum Off-State dV/dt @ Maximum Rated Voltage [V/μsec] 500

Load Current, General Use UL508/LC A IEC62314 @ 40°C [A

Load Current, Motor Starting UL508 FLA/LC B IEC62314 @ 40°C [ARMS] 14/7.6

Minimum Load Current [mA

Maximum 1 Cycle Surge Current (50/60Hz) [Apk] 716/750

Maximum On-State Voltage Drop @ Rated Current [V

Maximum 1/2 Cycle I² t for Fusing (50/60Hz) [A² sec] 2563/2343

Maximum Power Dissipation @ Rated Current [W] 52

Minimum Power Factor (at Maximum Load)

Motor Rating UL 508/IEC62314 [HP (kW)]: 120 VAC 1 (0.74)

Motor Rating UL 508/IEC62314 [HP (kW)]: 240 VAC 3 (2.2)

Motor Rating UL 508/IEC62314 [HP (kW)]: 480 VAC 5 (3.7)

(3) 1200

RMS] 1

RMS] 45

RMS] 100

RMS] 1.25

(4) 0.5

Required for valid part number

For options only and not

required for valid part number

60A

48-600

1200

1

500

60

26/14

150

1290/1350

1.15

8320/7593

69

0.5

2 (1.5)

5 (3.73)

10 (7.4)

INPUT SPECIFICATIONS

Description DR4560Axxx

Control Voltage Range 90-280 VAC/VDC

Maximum Reverse Voltage Minimum Turn-On Voltage 90 VAC/VDC

Must Turn-Off Voltage 5 VAC/VDC

Minimum Input Current (for on-state) 3 mA

Maximum Input Current 4 mA

Nominal Input Impedance Switch Mode

Maximum Turn-On Time [msec] 20

Maximum Turn-Off Time [msec] 30

(2)

DR4560Dxxx

4-32 VDC

(5)

-32 VDC

4 VDC

1 VDC

10 mA

15 mA

Current Limited

1/2 Cycle

1/2 Cycle

(6)

Copyright © 2017 Sensata Technologies Inc.

Page 2

GENERAL SPECIFICATIONS

(2)

Dielectric Strength, Input to Output (50/60Hz) 4000 V

Dielectric Strength, Input/Output to Case (50/60Hz)

Minimum Insulation Resistance (@ 500 VDC)

Maximum Capacitance, Input/Output 8 pF

Ambient Operating Temperature Range -40 to 80 °C

Ambient Storage Temperature Range

Short Circuit Current Rating

(7)

(8)

Weight (typical) 17.63 oz (500 g)

Housing Material UL94 V-0

Heat Sink Material Aluminum

DIN Rail Clip Material Zinc Plated Steel

Hardware Finish Nickel Plating

Input Terminal Screw Torque Range (lb-in/Nm) 5/0.5

Load Terminal Screw Torque Range (lb-in/Nm) 18-20/2-2.2

Humidity per IEC 60068-2-78 93% non-condensing

LED Input Status Indicator Green

Overvoltage Category III

Impulse Withstand Voltage According to IEC 60664-1 6kV

RMS

4000 V

RMS

109 Ohms

-40 to 100 °C

100kA

INPUT CURRENT INFORMATION

4-32 VDC Input

14

12

10

8

6

4

Input Current (mA)

2

0

ParametersDescription

0 5 10 15 20 25 30 35

Input Voltage (VDC)

SURGE CURRENT INFORMATION

DR4560x45x

700

600

500

400

300

200

100

Surge Current (Amp) AC Peak

0

0.01 0.1 1 10

THERMAL DERATE INFORMATION

DR4560x45x

60

50

40

30

20

10

Load Current (Amps)

Single unit

0

20 30 40 50 60 70 80

Ambient Temperature (ºC)

Surge Duration (sec)

(10)

Multiple units, no spacing

Single Pulse (9)

1400

1200

1000

800

600

400

200

Surge Current (Amp) AC Peak

0

0.01 0.1 1 10

DR4560x60x

80

70

60

50

40

30

20

Load Current (Amps)

10

Single unit

0

20 30 40 50 60 70 80

Ambient Temperature (ºC)

Multiple units, no spacing

DR4560x60x

Surge Duration (sec)

Page 3

Copyright © 2017 Sensata Technologies Inc.

EQUIVALENT CIRCUIT BLOCK DIAGRAMS/WIRING DIAGRAMS

* TVS option available in “P” version

+3/A1

INPUT

-4/A2

Current

Limiter

* TVS option available in “P” version

+3/A1

AC/DC

Converter

INPUT

-4/A2

Current

Limiter

Trigger

Circuit

Trigger

Circuit

AC/DC

DC Control

+

V

DC

-

AC/DC Control

+/

V

-/

INSTALLATION INSTRUCTIONS

Mounting on DIN Rail

• Locate rail and align with non moveable end of DR45 DIN clip.

• Using reasonable force, push DR45 in the direction of the arrow (as shown in fig.1).

• For removal pull release tag in direction of arrow using blade of screwdriver and

pull it away from DIN rail.

Mounting on Panel

• Locate the panel section on which the DR45 SSR will be mounted on (as shown in

fig.2)

• DIN clip includes tabs for this type of mounting. Tab holes have a diameter of 4.5 mm.

You will need three screws (not included) no larger than that to mount the SSR onto

panel.

• Align SSR tabs with panel surface and screw both top and bottom sides.

Recommended torque is 12 in-lbs (1.36 Nm).

Wiring Instructions

• Recommended wire sizes as shown in TABLE 1

• Maximum terminal screw torque input terminal 5 lb-in (0.5 Nm) (screw terminal only)

• Maximum terminal screw torque load terminal 18-20 lb-in (2.0-2.2 Nm)

• If multiple units are installed be sure to follow derating curves

Load

1/L1

*

2/T1

Load can be wired in position A or B

1/L1

*

2/T1

Load can be wired in position A or B

OUTPUT

OUTPUT

Load

Load

Load

A

AC

V

B

A

ACV

B

TABLE 1. Wire Size & Pull Out Strenght

Terminal

Configuration

Output

Screw

Input

Spring

* Tests performed on Stranded wire

WARNING! Removing product from 35 mm rail incorrectly by not using the

appropriate tool would damage the latching system.

Recommended Wire Size

(Solid / Stranded)

2

1 x 18 AWG (1 mm

) [minimum]

1 x 8 AWG (10 mm2) [maximum]

2 x 8 AWG (10 mm2) [maximum]

1 x 3 AWG (26.67 mm2) [maximum]

30 AWG (0.05 mm2) [minimum]

12 AWG (3.3 mm2) [maximum]

26 AWG (0.13 mm2) [minimum]

12 AWG (3.3 mm2) [maximum]

Wire Pull-Out

Strength (lb)[N]

20 [88]

90 [400]

80 [355]

90 [400]

4.5 [20]

30 [133]

5 [22]

5 [22]

*

To install

on DIN rail

To remove

from DIN rail

fig. 1 SSR mounted on DIN rail

Copyright © 2017 Sensata Technologies Inc.

DIN rail

(35mm)

fig. 2 SSR mounted on Panel Mount

Page 4

MECHANICAL SPECIFICATIONS

Tolerances: ±0.02 in / 0.5 mm

All dimensions are in: inches [millimeters]

1.43

[36.4]

1.88

2.94

[47.8]

[74.8]

ACCESSORIES

Recommended Accessories

Connectors

CP201

Screw Terminal

CP202

Spring Terminal

ID Marker

Blank Strips

Numbered 1 to 10 Strips

Numbered 11 to 20 Strips

1.77

[45]

CNLB

CNLN

CNL2

0.91

[23.1]

3.62

[92]

4.39

[111.5]

5.36

[136]

6.08

[154.4]

Protective Earth Connection

Protective earth (PE) screw type recommended

is 10-32 UNC standard not provided with SSR.

Through the use of a DIN rail ground (protective

conductor) terminal block, the DIN rail itself

can be used as the grounding bus bar. In this

case, the zinc plated steel material used for the

DIN rail clip of DR45 models, permits a secure

path to ground and avoid the need of a further

PE connection.

10-32

Thread

Copyright © 2017 Sensata Technologies Inc.

Page 5

AGENCY APPROVALS, CONFORMANCES, ENVIRONMENTAL AND EMC

Copyright © 2017 Sensata Technologies Inc.

Approvals (Tested and Certified according To)

E116949

UL 508 and C22.2 No. 14

Vibration and Shock

Resistance

IEC 61373: Category 1,

Class B

Generic

Standard

Electrostatic Discharge

IEC 61000-4-2

Fast transients (burst)

IEC 61000-6-2

Immunity for

IEC 61000-4-4

Industrial

Environments

Surge

IEC 61000-4-5

REG-Nr. xxxxxx

EN 62314

Conformances Environmental

Designed in

accordance with

Resistances to heat

and fire

IEC 60950-1 IEC 60335-1, Section 30 Directive 2006/95/EC Directive 2011/65/EU GBT 26572-2011

Electromagnetic Compatibility

Immunity Tests Test Specification Level

8kV air discharge

6kV contact discharge

Output 2kV, 5kHz, 100kHz

Input 1kV, 5kHz, 100kHz

1kV Line to Line

Output

2kV Line to Earth

AC Input Option

1kV Line to Line

2kV Line to Earth

Performance

Criterion A

Criterion A

Criterion B

Criterion B

Criterion B

Criterion B

Criterion A

Criterion A

50

GENERAL NOTES

(1) Control voltage 18-52 VAC/VDC is available upon request.

(2) All parameters at 25°C unless otherwise specified.

(3) “P” option output will self trigger between 900-1200 Vpk, not suitable for capacitive loads.

(4) High inductive loads requires nominal control voltage; AC input models only.

(5) Increase minimum voltage by 1 V for operations from -20 to -40°C.

(6) Turn-on time for Instantaneous turn-on versions is 0.1 msec.

(7) No freezing or condensation allowed.

(8) When protected with the appropriate class and rated fuse. For detailed info please contact Crydom Technical Support.

(9) For single surge pulse Tc=25°C; Tj=125°C. For AC Output SSRs, AC RMS value of surge current equals the peak value divided by √2 (1.414).

(10) UL approved rating is the one that intersects at 40°C.

Sensata Technologies, Inc. (“Sensata”) data sheets are solely intended to assist designers (“Buyers”) who are developing systems that

incorporate Sensata products (also referred to herein as “components”). Buyer understands and agrees that Buyer remains responsible

for using its independent analysis, evaluation and judgment in designing Buyer’s systems and products. Sensata data sheets have been

created using standard laboratory conditions and engineering practices. Sensata has not conducted any testing other than that

specifically described in the published documentation for a particular data sheet. Sensata may make corrections, enhancements,

improvements and other changes to its data sheets or components without notice.

Buyers are authorized to use Sensata data sheets with the Sensata component(s) identified in each particular data sheet. HOWEVER, NO

OTHER LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE TO ANY OTHER SENSATA INTELLECTUAL PROPERTY RIGHT,

AND NO LICENSE TO ANY THIRD PARTY TECHNOLOGY OR INTELLECTUAL PROPERTY RIGHT, IS GRANTED HEREIN. SENSATA DATA

SHEETS ARE PROVIDED “AS IS”. SENSATA MAKES NO WARRANTIES OR REPRESENTATIONS WITH REGARD TO THE DATA SHEETS

OR USE OF THE DATA SHEETS, EXPRESS, IMPLIED OR STATUTORY, INCLUDING ACCURACY OR COMPLETENESS. SENSATA

DISCLAIMS ANY WARRANTY OF TITLE AND ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, QUIET ENJOYMENT, QUIET POSSESSION, AND NON-INFRINGEMENT OF ANY THIRD PARTY INTELLECTUAL PROPERTY

RIGHTS WITH REGARD TO SENSATA DATA SHEETS OR USE THEREOF.

All products are sold subject to Sensata’s terms and conditions of sale supplied at www.sensata.com SENSATA ASSUMES NO

LIABILITY FOR APPLICATIONS ASSISTANCE OR THE DESIGN OF BUYERS’ PRODUCTS. BUYER ACKNOWLEDGES AND AGREES THAT IT

IS SOLELY RESPONSIBLE FOR COMPLIANCE WITH ALL LEGAL, REGULATORY AND SAFETY-RELATED REQUIREMENTS CONCERNING ITS

PRODUCTS, AND ANY USE OF SENSATA COMPONENTS IN ITS APPLICATIONS, NOTWITHSTANDING ANY APPLICATIONS-RELATED

INFORMATION OR SUPPORT THAT MAY BE PROVIDED BY SENSATA.

Mailing Address: Sensata Technologies, Inc., 529 Pleasant Street, Attleboro, MA 02703, USA.

Rev. 011618 ECN 20312 FDE-07-01 Rev. B

Page 5

Loading...

Loading...