Page 1

M550/M551 Level 3 Service Manual Page1

MM555500//MM555511 SSEERRVVIICCEE MMAANNUUAALL LLEEVVEELL 33

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 2

M550/M551 Level 3 Service Manual Page2

Contents:

Section 1. Introduction

Section 2. Repair Precautions

Sendo guidelines for safe and productive repair work.

Section 3. Product Features and Specifications

General features, technical specifications and warranty details for the

M550.

Section 4. Product Architecture

Functional block diagrams of the RF and logic circuit architecture. Board

layouts are also provided which highlight the main functional areas such as

audio, power supplies and RF circuitry.

Section 5. Product Servicing and Rework Guide

Level 3 repair items, recommended rework equipment and guidelines. Also

included are the assembly-disassembly instructions.

Section 6. Trouble Shooting

Detailed circuit description and repair information to help debug problems

and faults.

Section 7. Software Download

The service centre software download set-up process and its operation.

Section 8. Parts Info

The M550 Parts list including exploded view.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 3

M550/M551 Level 3 Service Manual Page3

Section 1. Introduction

Welcome to the level 3 Service Manual for the Sendo M550/M551. This manual

will guide you to repairing the modules used in the Sendo M550/M551 models.

The M551 is the United States variant – for GSM 850/1900 Mhz.

This manual will help guide you through all repair aspects of the M550/M551 and

provide detailed information on the product.

X102 32 Khz Xtal

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 4

M550/M551 Level 3 Service Manual Page4

Section 2

Repair Precautions

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 5

M550/M551 Level 3 Service Manual Page5

Important!

Please read the following cautions, notes and warnings

before progressing through this manual or undertaking

any repair action. Remember: SAFETY

FIRST!

AC Main Lead/Power Cord:

Always ensure that ALL AC mains leads used in the repair area are in good condition

and checked regularly. Care must be taken not to damage the lead as this could result

in fire or electric shock.

Battery Pack:

ONLY use original Sendo supplied batteries and chargers with the M550/M551.

DO NOT short the battery terminals together.

Keep the battery pack away from fire and sources of ignition.

Remember to recharge the battery pack after each use.

Before YOU Power up the M550/M551:

• Only switch on the telephone’s power once the test or installation set-up is complete.

• Switching on at the wrong time may result in electric shock or damage to system

components.

• Always ensure that the power is switched off before making connections /

disconnection’s.

• It is important to check that the correct DC voltage is applied to the M550/M551 to

prevent electrical damage.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 6

M550/M551 Level 3 Service Manual Page6

Component Polarity +/-

Always check the polarity of connections and components before soldering.

Particular attention must be paid to I.C’s, diodes, transistors, capacitors and

any other semiconductor device that is polarity dependent.

Electrostatic Damage (ESD):

Semiconductor devices are easily damaged by electrostatic discharge. Many of the

procedures detailed in this manual involve disassembly of the equipment and therefore

handling of the printed circuit boards.

To protect these devices from ESD a wrist strap connected to ground must be worn. In

addition to this the work surface must be covered with an anti-electrostatic mat, which

should also be grounded.

If printed circuit boards are to be stored without being re-assembled into

their equipment, then they must be kept in an anti-electrostatic bag.

Grounding:

Each piece of test equipment should be electrically grounded. A third

(grounding) pin is provided as a safety feature. Ensure that the electrical

outlet also contains this feature.

Cosmetic Protection during Repair Work:

Always ensure that the working surface is kept clean and free from abrasive materials.

The LCD is very susceptible to scratches and damage. It should be

covered with clear adhesive vinyl while the equipment is disassembled.

Storage of Faulty Components:

Any components that are replaced due to failure should be kept safely in an

anti-electrostatic container. Sendo’s Quality or Research & Development

Departments may require them to make quality and reliability investigations.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 7

M550/M551 Level 3 Service Manual Page7

No Fault Found Equipment:

In some cases the reported symptom may not be apparent. You may subject the

equipment to a controlled amount of stress, vibration and temperature variation to see if

the fault occurs.

Care should be taken not to apply excessive stress or vibration or extreme temperature

variations as further faults may develop.

Soldering and Disordering :

Fast, accurate and high quality soldering is required to minimise the risk of heat

damage to the electronic components. ALL rework must follow methods set out in IPC-

7711 (Rewpork of Electrical Assemblies). NO joint should be touched up more than

twice. Wire modifications are not permitted. BGA or fine pitch devices may not be

reflowed more than once.

Short Circuits:

Care must be taken to avoid short circuits. Soldering, solder dust, screws, metal

clippings, metal wrist watches etc. can cause short circuits on PCBs which may result in

component damage.

Test Equipment Calibration:

Your test equipment should be calibrated before use. Frequent calibration is essential

to ensure high quality and reliable repairs.

Cleaning:

Before cleaning ensure that the telephone is switched off and disconnected

from the power source. Cleaning should be done using a soft dry cloth. If

the equipment is heavily soiled a soft cloth soaked in a mild synthetic

detergent diluted in water may be used.

Never use benzene or any other chemicals to clean the equipment.

RF Shielding:

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 8

M550/M551 Level 3 Service Manual Page8

It is advisable to carry out detailed measurements and repair (in particular

RX) in a shielded area to minimise RF interference.

AC Adapter and Battery Charger:

The AC adapter and battery chargers are for indoor use only. Ensure that

the devices are not exposed to rain or moisture.

Electrical Safety:

Electrical equipment is hazardous if misused. Any repairs must be carried out with care

and only by authorised personnel.

Ensure all power sources are switched off and power cords removed before

undertaking any repairs.

Hazardous Waste:

The battery pack, if incorrectly disposed of, is an environmental hazard. It must be

disposed of in accordance with the regulations of the country concerned.

Never dispose of the battery pack in fire or water.

Confidentiality:

The circuitry within this equipment contains several components that are

regarded as company confidential. Only use Sendo authorised parts as

replacements.

RF Injury:

To avoid RF injury, direct exposure to radio frequency energy should be

avoided. In particular, exposed parts of your body (especially the eyes and

face) should not come into contact with the antenna while the equipment is

transmitting.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 9

M550/M551 Level 3 Service Manual Page9

Storage Conditions:

It is recommended that the following storage conditions should be avoided to prevent

damage to the equipment: Dusty.

Humid.

Near to magnetic equipment.

In direct sunlight.

Ventilation:

Repair areas should be well ventilated and fume extraction systems should

be installed where necessary. Potential hazardous substances are solder

fumes, flux, alcohol etc.

PCB Handling:

It is recommend that cotton or latex gloves are worn during repair work. This is to

protect your hands from chemical contamination and to protect the PCBs from

fingerprints and humidity.

SIM Card:

• Do not bend.

• Clean by using a soft dry cloth.

• Please note that a modified SIM card will be required to perform conducted rf

measurements via the rf switch. See section 5. Product Servicing and Rework Guide.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 10

M550/M551 Level 3 Service Manual Page10

Section 3

Product Features and

Specifications

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 11

M550/M551 Level 3 Service Manual Page11

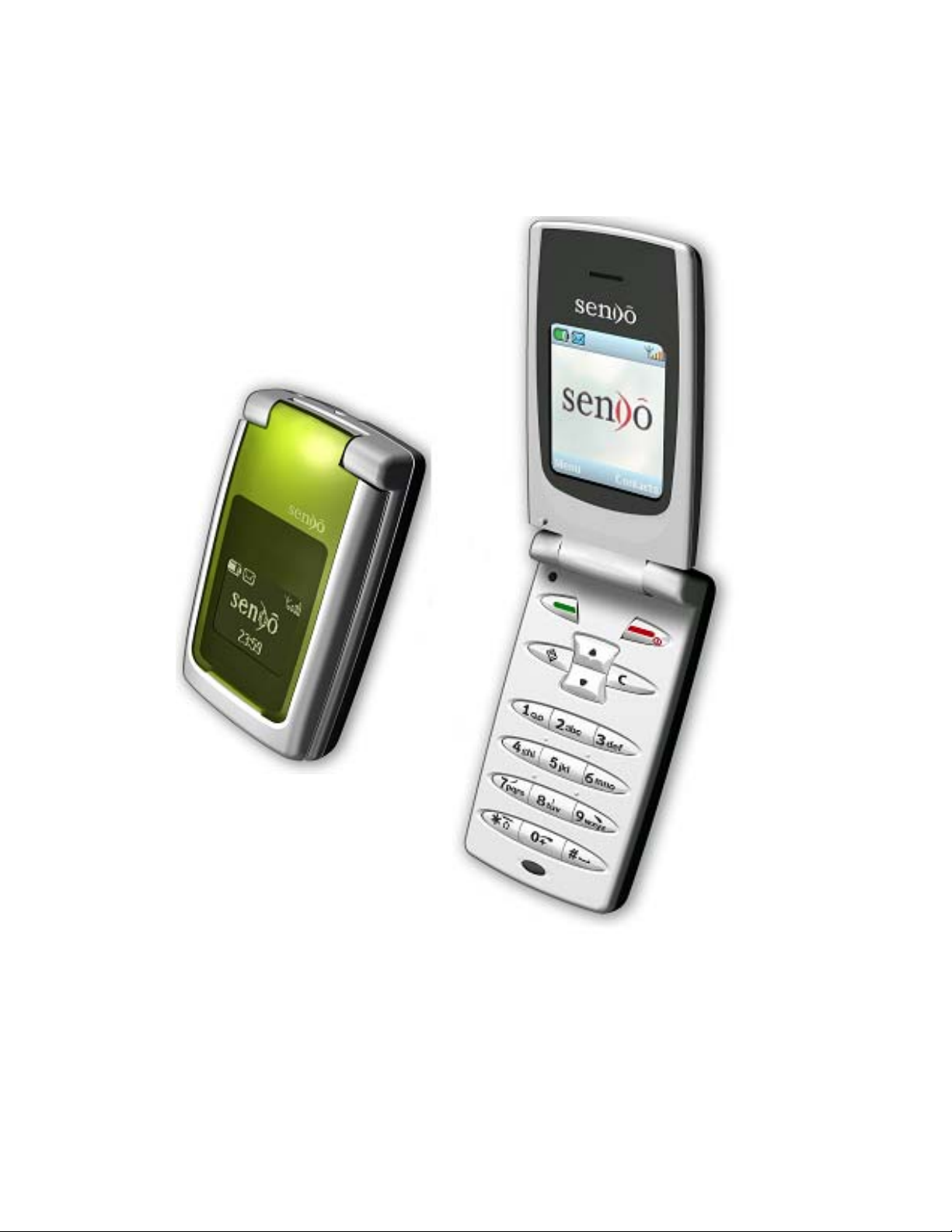

PPrroodduucctt DDeessccrriippttiioonnss

M550 IMEI TAC code: 35188400 (M551:001031A)

Model Type: SND550/SND551

NNeettwwoorrkk SSeerrvviicceess

Dual Band E-GSM 900 / GSM 1800 - M550

Dual Band GSM 850 / GSM 1900 - M551

Automatic switching between bands

Manual and automatic network selection

HR / FR / EFR codec for GSM 900 / 1800

M551 includes AMR FR and AMR HR

DDiimmeennssiioonnss aanndd WWeeiigghht

Length (a)

Width (b) 19.6mm at widest point

Depth (c) 45mm at thickest point

82mm at longest point

t

a

Weight 77g

Volume 68cc

PPoowweerr MMaannaaggeemmeennt

Talk Time: Up to 180-400 mins*

Standby Time: Up to 120-300 hours*

Game-Play up to 3 hours*

Sim Type:

Charging time: <2 hours

Battery: Li-Ion cell - 650Ah, 3.7vdc

Linear charger (240v Euro plug, 240v UK plug, 220v China plug, 110v US

plug or 220v Australian plug)

* Battery life is Network dependent; variations may occur.

The M550/M551 works closely with the network and the standby and talk

times achieved depend upon this. In particular the location of the HHP

within the network, the type of SIM, reception of area messages, the use of

Micro 3V or 5V SIM

t

c

b

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 12

M550/M551 Level 3 Service Manual Page12

Full Rate speech or Enhanced Full rate speech and other factors will affect

both standby and talk times.

MM555500 CCoorree FFeeaattuurrees

s

Product Features

Clamshell design with internal antenna

Size: 77g, weight: 68cc

Dual display, outer: reverse video, 96x64 pixels

Inner colour display – up to 4096 colours

Customizable colour themes

On phone dynamic memory-up to 500 phone book entries

Colour EMS

Wap 1.2.1 colour browser and GPRS class 8

Colour games

Tegic T9 text input, built in SMS chat and SMS templates

Animated graphics and sound

Dual Band (M550:E-GSM 900/1800, M551:GSM850/1900

Stand by time up to 180-400 hours*

Talk time up to 120-300 mins*

Gameplay up to 3 hours*

*talktime and standby times depend upon network conditions and the way you use the phone.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 13

M550/M551 Level 3 Service Manual Page13

WWaarrrraannttyy DDeettaaiills

s

Limited Warranty

Sendo International Limited (“Sendo”) warrants, subject to the exclusions and limitations set forth below, that your

cellular phone, battery and accessories (collectively “Product”) is free from defects in materials and workmanship

according to the following terms and conditions:

1. The limited warranty for the Product commences on the date of purchase and continues for a period of one

(1) year from that date. Upon request from Sendo, you, (the “Consumer”) must prove the date of the original

purchase of the Products by dated itemised receipt.

2. The limited warranty extends to the original purchaser of the Product, the Consumer, and is not assignable

or transferable to any subsequent purchaser or user.

3. The warranty extends only to Consumers who purchase the Product in the market for its intended sale.

4. During the limited warranty period, Sendo will repair, or replace, at Sendo's sole option, any defective parts, or any

parts that will not properly operate for their intended use with new or refurbished replacement items if such repair or

replacement is needed because of a malfunction or failure of the Product during normal usage. No charge will be

made to the Consumer for any such parts. Sendo will also pay for the labour charges incurred by Sendo in repairing

or replacing the defective parts. This warranty does not apply to any damage or failure to operate caused by use of

the Product other than in accordance with the instructions contained in the User Manual, or for periodic maintenance

or repair due to normal wear and tear. Sendo's limit of liability under the limited warranty shall be the actual cash

value of the Product at the time the Consumer returns the Product for repair, determined by the price paid by the

Consumer for the Product less a reasonable amount for usage. Sendo shall not be liable for any other losses or

damages. These remedies are the Consumer's exclusive remedies for breach of warranty

5. The warranty will be invalidated if any of the following circumstances are applicable:

a) The Product has been subject to abnormal use, abnormal conditions, improper storage, exposure to

moisture or dampness, unauthorized modifications, unauthorized connections, unauthorized repair, misuse,

neglect, abuse, accident, alteration, improper installation, or other acts which are not the fault of Sendo,

including damage caused by shipping.

b) Physical damage to the surface of the Product, including scratches or cracks in or to the outside casing or

Liquid Crystal Display, or damages caused by dropping the Product.

c) The Product has been damaged from external causes such as liquid, water, collision with an object, or from

fire, flooding, sand, dirt, windstorm, lightening, earthquake or damage from exposure to weather conditions,

an Act of God, or battery leakage, theft, blown fuse, or improper use of any electrical source, damage

caused by computer or internet viruses, bugs, worms, Trojan Horses, cancelbots or damage caused by the

connection to other products not recommended for interconnection by Sendo.

d) The Product has been altered or repaired by anyone other than an authorised Sendo service centre or if it

has been used with unapproved accessories or other ancillary items.

e) For adaptations or adjustments made to the Product to comply with local standards in any country other than

one for which the Product was designed and manufactured.

f) Loss of integrity of any user data stored in the Product or any storage device used in conjunction with the

Product at any time

g) The Sendo authorised service centre was not advised by the Consumer in writing of the alleged defect or

malfunction of the Product within fourteen (14) days after the expiration of the applicable limited warranty

period.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 14

M550/M551 Level 3 Service Manual Page14

h) The Product serial number plate or the accessory data code has been removed, defaced or altered.

i) The defect or failure to operate was caused by the defective function of the cellular system or by inadequate

signal reception.

6. Any implied warranty of satisfactory quality, merchantability, or fitness for a particular purpose or use, shall be

limited to the duration of the foregoing written warranty. Otherwise, the foregoing warranty is the Consumer’s sole

and exclusive remedy and is in lieu of all other warranties, express or implied. Sendo does not warrant uninterrupted

or error free internet or data connections. Sendo shall not be liable for special, incidental or consequential damages,

including but not limited to, loss of anticipated benefits or profits, loss of savings or revenue, punitive damages, loss of

use of the product or any associated equipment, loss of data, cost of capital, cost of any substitute equipment or

facilities, downtime, the claims of any third parties, including customers, and injury to property, resulting from the

purchase or use of the product or arising from breach of the warranty, breach of contract, negligence, strict tort, or any

other legal or equitable theory, even if Sendo knew of the likelihood of such damages. Sendo shall not be liable for

delay in rendering service under the limited warranty, or loss of use during the period that the product is being

repaired or loss of data.

7. Some jurisdictions do not allow limitation of how long an express or implied warranty lasts and so the one year

warranty period referred to above may not apply, to you, the Consumer. Some jurisdictions do not allow the exclusion

or limitation of incidental and consequential damages and so to the extent that such limitations are not allowed, the

above limitations or exclusions may not apply, to you, the Consumer. This limited warranty gives the Consumer

specific legal rights and the Consumer may also have other legal rights under the legislation of some jurisdictions.

These legal rights vary from jurisdiction to jurisdiction and are not prejudiced by anything contained in this limited

warranty. It also means that in some jurisdictions our responsibility to you the Consumer may be more extensive than

in other jurisdictions.

8. The Consumer shall take the following steps to make a claim under this limited warranty:

a) Please do not ship the Product for service without first contacting the nearest Sendo Authorised Service

Centre.

b) Contact information for the world-wide network of Sendo authorised service centres is available at

www.sendo.com

c) If the Product qualifies for in-warranty service, the Consumer must prove the date of the original purchase of

the Products by a dated proof of purchase.

d) Back up all data. If the Consumer has sensitive information stored on the Product copy it to another device

and delete it from the Product before repair.

e) The Consumer must ship the Product prepaid and insured. Expenses related to removing the Product from

an installation are not covered under this limited warranty.

f) If the Product is returned for service and the Product is deemed out of warranty under the terms and

conditions of this warranty, the Consumer will be notified and given an estimate of the applicable charges. If

the estimate is refused a minimum service fee for collection, inspection and quotation of said product would

be due.

9. Subject to any more extensive legal rights granted to the Consumer by law of the Consumer’s jurisdiction, Sendo

neither assumes nor authorizes any authorised service centre or any other person or entity to assume for it any other

obligation or liability beyond that which is expressly provided for in this limited warranty including the provider or seller

of any extended warranty or service agreement.

10. This is the entire warranty between Sendo and the Consumer, and supersedes all prior and contemporaneous

agreements or understandings, oral or written, and all communications relating to the Product, and no representation,

promise or condition not contained herein shall modify these terms.

11. This limited warranty allocates the risk of failure of the Product between the Consumer and Sendo. The allocation

is recognized by the Consumer and is reflected in the purchase price of the Product.

12. Diagnostic instructions and other service information is available free of charge at www.sendo.com

out of warranty repair costs and charges is available at www.sendo.com

. Information on

.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 15

M550/M551 Level 3 Service Manual Page15

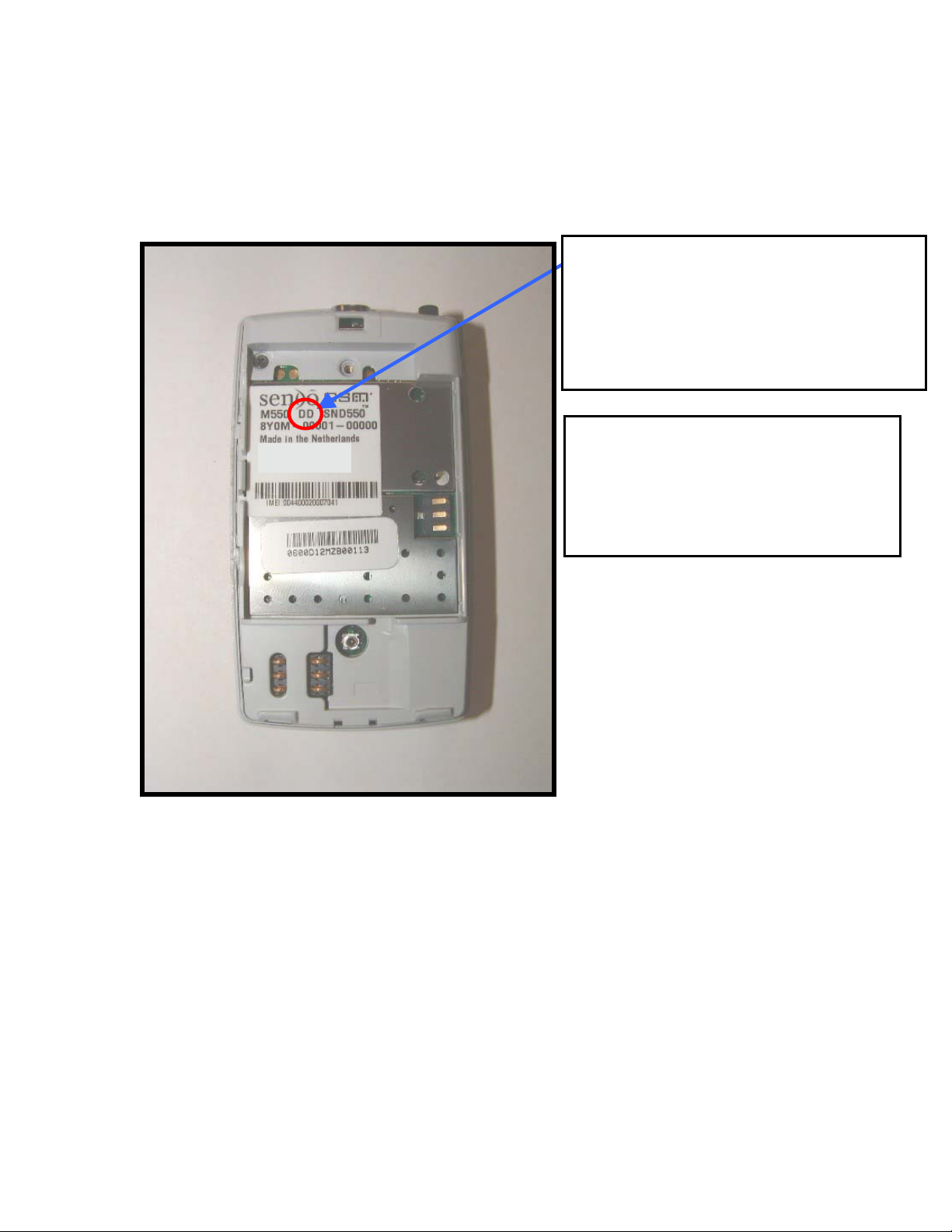

Warranty Details

Identifying the manufacturing date on a unit.

EXAMPLE,

First LETTER = YEAR

Second LETTER = MONTH

DD = 2003, April

NOTE:

THE CODES HAVE ONLY BEEN

ISSUED ON MANUFACTURED

UNITS AFTER SEPTEMBER 2001.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 16

M550/M551 Level 3 Service Manual Page16

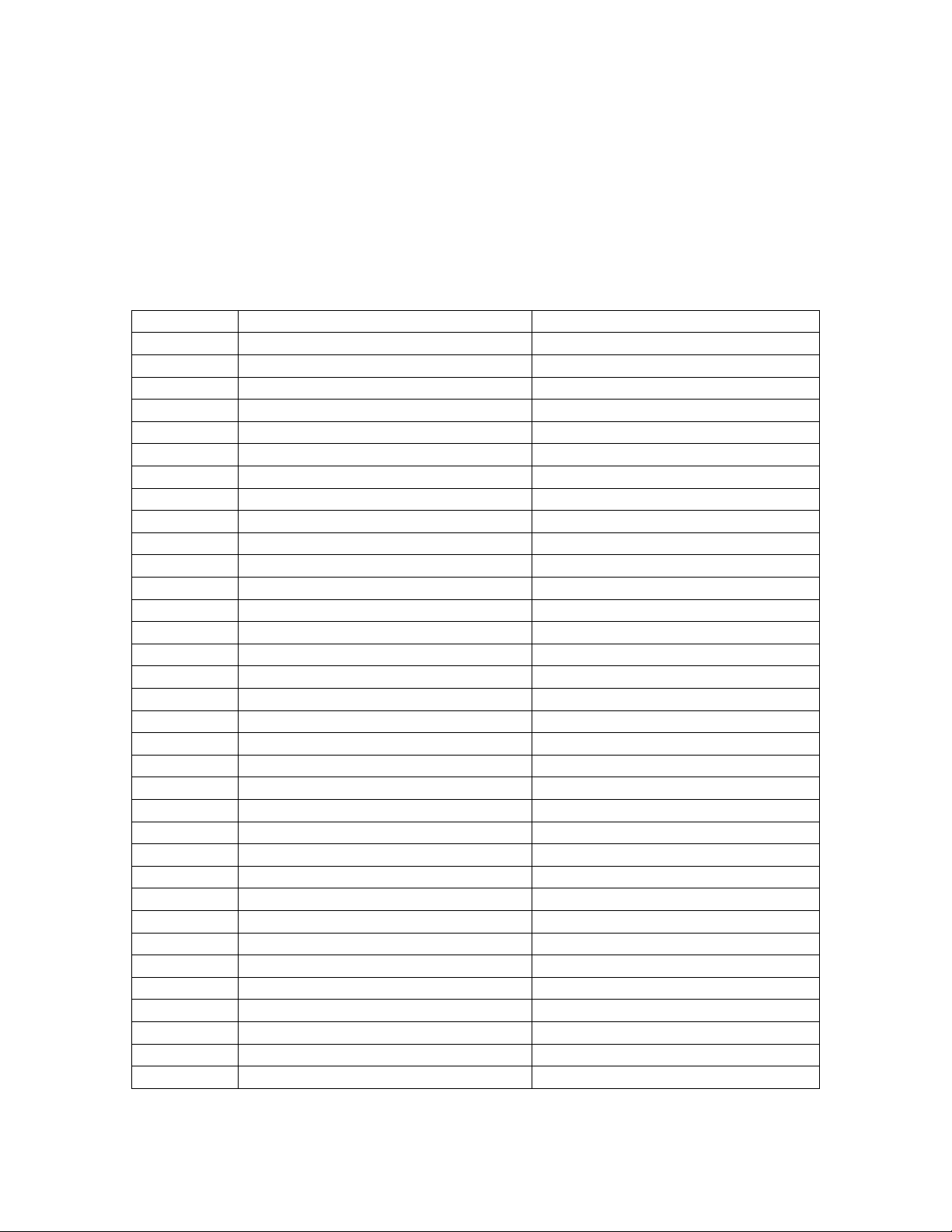

The Table below shows the manufacturing dates and their codes.

WWaarrrraannttyy TTaabbllee

CODE MANUFACTURED DATE OUT OF WARRENTY END OF

BI

BJ

BK

BL

CA

CB

CC

CD

CE

CF

CG

CH

CI

CJ

CK

CL

DA

DB

DC

DD

DE

DF

DG

DH

DI

DJ

DK

DL

EA

EB

EC

ED

EE

EF

SEPT 2001 NOV 2002

OCT 2001 DEC 2002

NOV 2001 JAN 2003

DEC 2001 FEB 2003

JAN 2002 MAR 2003

FEB 2002 APR 2003

MAR 2002 MAY 2003

APR 2002 JUNE 2003

MAY 2002 JULY 2003

JUNE 2002 AUG 2003

JULY 2002 SEPT 2003

AUG 2002 OCT 2003

SEPT 2002 NOV 2003

OCT 2002 DEC 2003

NOV 2002 JAN 2004

DEC 2002 FEB 2004

JAN 2003 MAR 2004

FEB 2003 APR 2004

MAR 2003 MAY 2004

APR 2003 JUNE 2004

MAY 2003 JULY 2004

JUNE 2003 AUG 2004

JULY 2003 SEPT 2004

AUG 2003 OCT 2004

SEPT 2003 NOV 2004

OCT 2003 DEC 2004

NOV 2003 JAN 2005

DEC 2003 FEB 2005

JAN 2004 MAR 2005

FEB 2004 APR 2005

MAR 2004 MAY 2005

APR 2004 JUNE 2005

MAY 2004 JULY 2005

JUNE 2004 AUG 2005

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 17

M550/M551 Level 3 Service Manual Page17

Section 4

Product Architecture

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 18

M550/M551 Level 3 Service Manual Page18

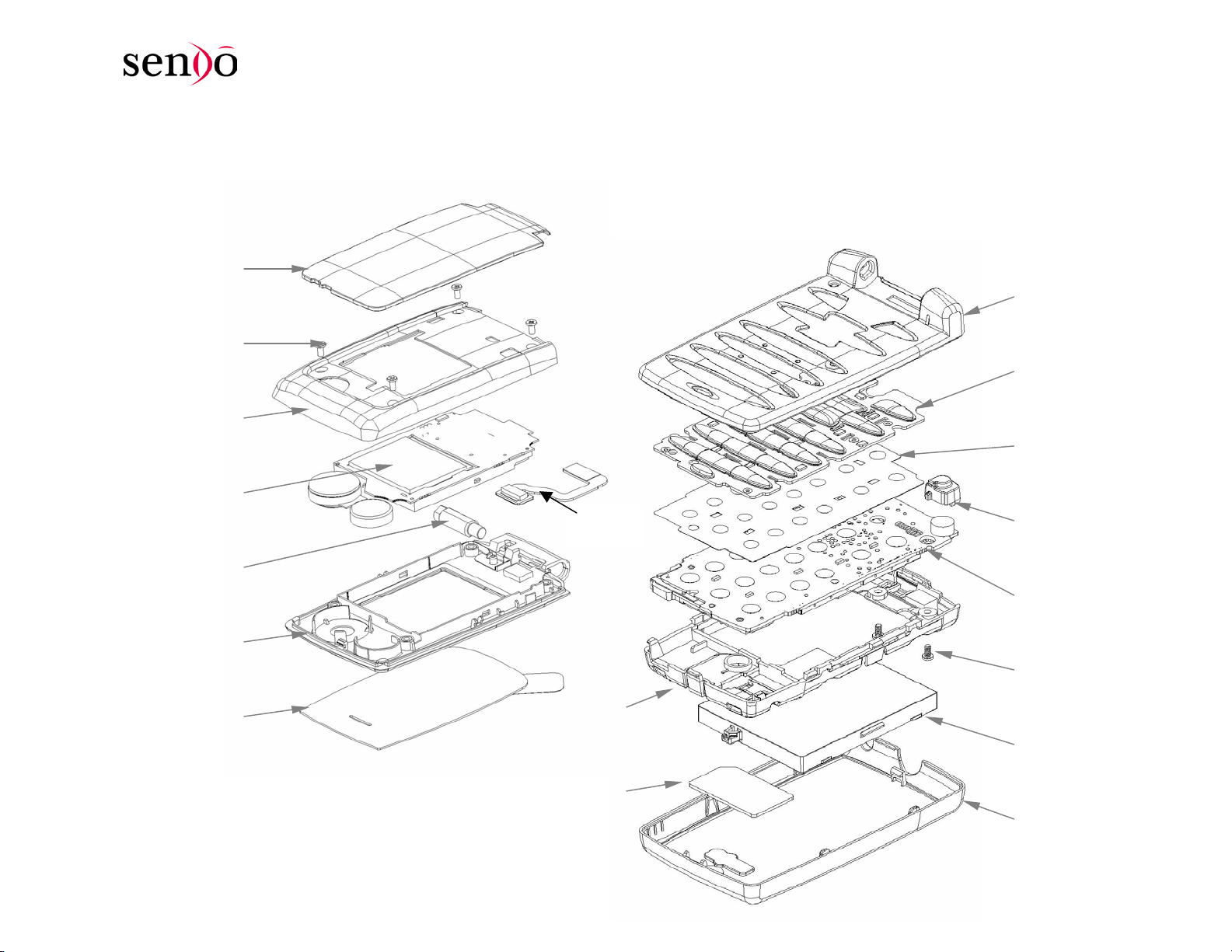

r

Section.1: M550 Product Structure – Exploded view

Outer Lens Assy

Screw (4pc)

Outer Ring Assy

LCD Module

FPC

Front Hsg Assy

Keypad

Metal-dome

Mic Gasket

Inner Hsg Assy

Lens Assy

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Hinge

Battery

Holde

SIM

PCBA

Screw (2pc)

Battery

Battery Cover

Page 19

M550/M551 Level 3 Service Manual Page19

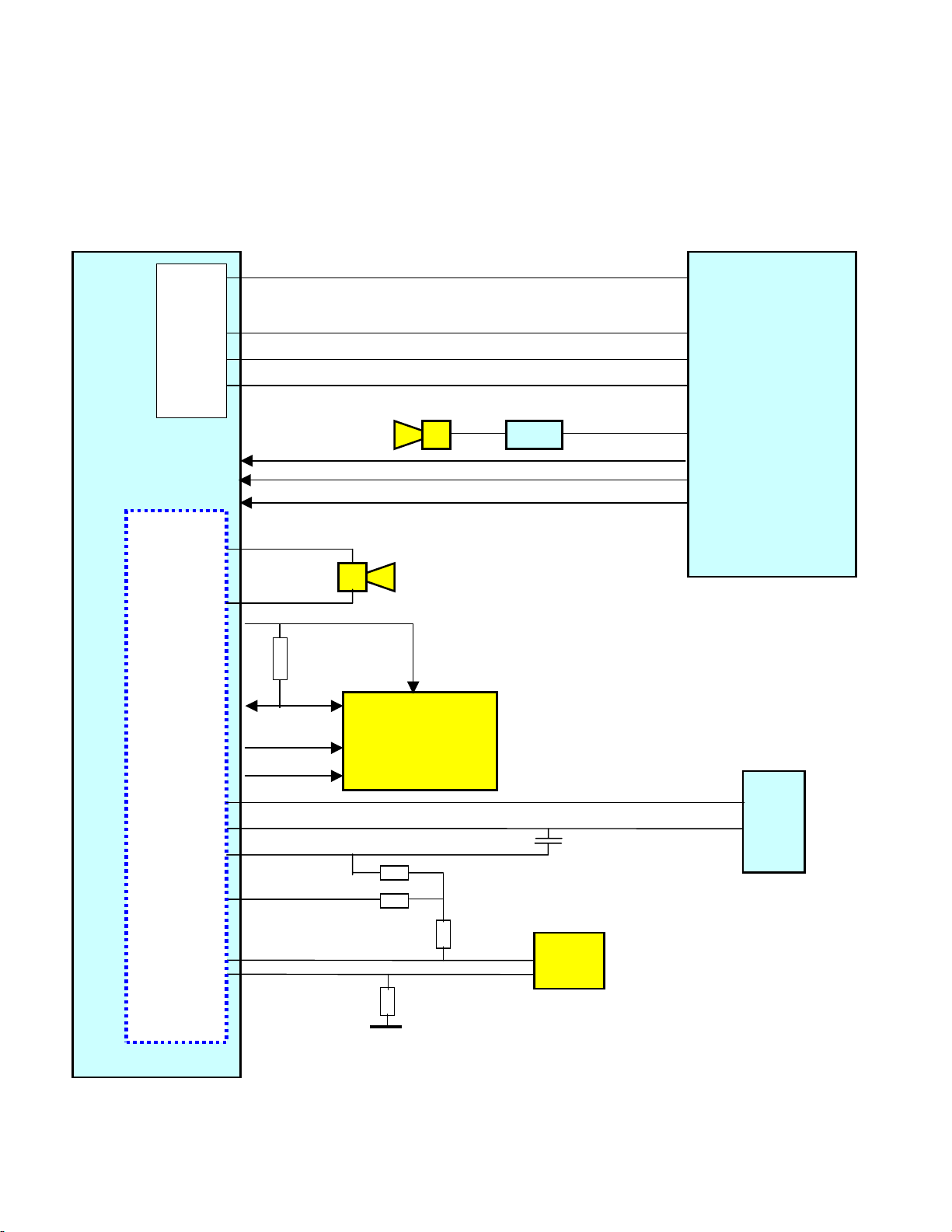

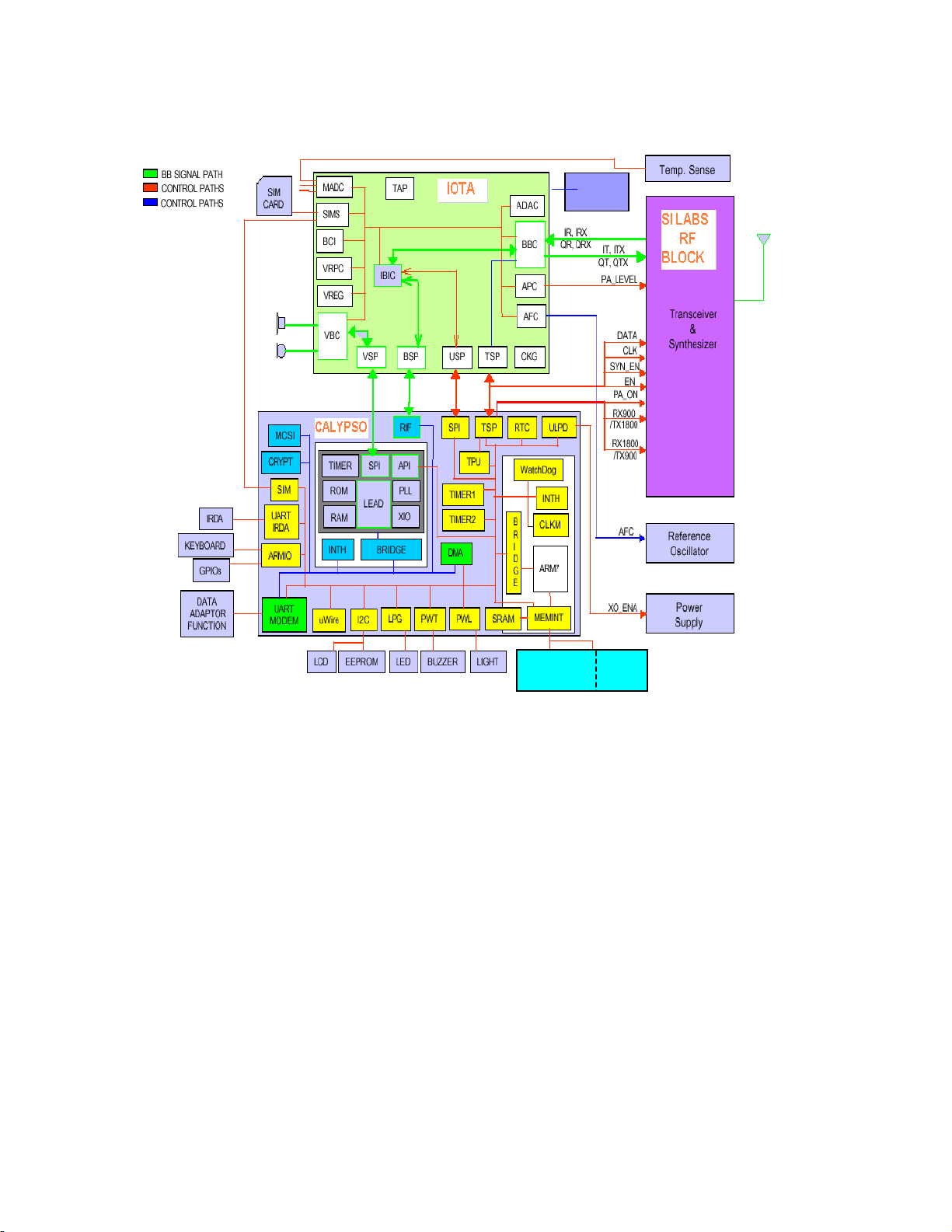

Logic circuit Architecture

Part a: Audio Circuits and SIM Interface

IOTA

IC200

VOICE

BAND

SERIAL

PORT

K3

G5

H5

F5

VOIC

BAND

CODER/

DECODER

J9

J10

E

SIM_IO

SIM_CLK

SIM_RST

K9

C7

G7

J8

J7

H7

BB_VCLK

BB_VFS

BB_VDX

BB_VDR

(Buzzer)

BB_EARP

BB_EARN

(Ear Piece)

SIM_VCC

IO VDD

CLK

RST

BB_MIC_REF_P

BB_MICP

BB_MICN

BUZZ_EN

T401

BB_SIM_IO

BB_SIM_CLK

BB_SIM_RST

SIM Reader (X402)

BB_AUX_MIC

MIC

N12

M13

N13

P14

CALYPSO

K7

IC100

X200

(Audio Jack)

AUXOP

3

2

Part b:

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 20

M550/M551 Level 3 Service Manual Page20

Part b: Logic Circuit Block Diagram

CHGR

IC200

IC100

(X102 – 32Khz)

The main functional blocks of Calypso (IC100) are:

• ARM Megamodule (ARM7TDMIE)

• DSP Megamodule (S28C128)

• Memory Interface & Memory Protection Unit

• Interrupt Handler (INTH)

• Clock Management (CLKM)

• Timers

• General Purpose IO (ARMIO)

• UART – IRDA and UART – MODEM

• UWire Interface (UWIRE)

• I2C Master Serial Interface (I2C)

• Serial Port Interface (SPI)

• Pulse Width Tones (PWT)

• Pulse Width Light (PWL)

• Light Pulse Generator (LPG)

• Debug Unit (DU)

The main functional blocks of IOTA (IC200) are:

• Automatic Frequency Control Unit

• Auxiliary Drivers

• Automatic Power Control Unit

• Baseband Codec

• Back up Battery Switch, Battery Charger Control

• Baseband Up / Down Link, Baseband Serial Port

• Clock Generator

• LDO Voltage Regulators, Voltage Reference, Power Control

• Monitoring Analogue to Digital Converter

• SIM interface

• Time Serial Port, Test Access Port

• Microcontroller Serial Port

• Voice band Codec

• Voice Serial Port

Flash

SRAM

IC300

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 21

M550/M551 Level 3 Service Manual Page21

A

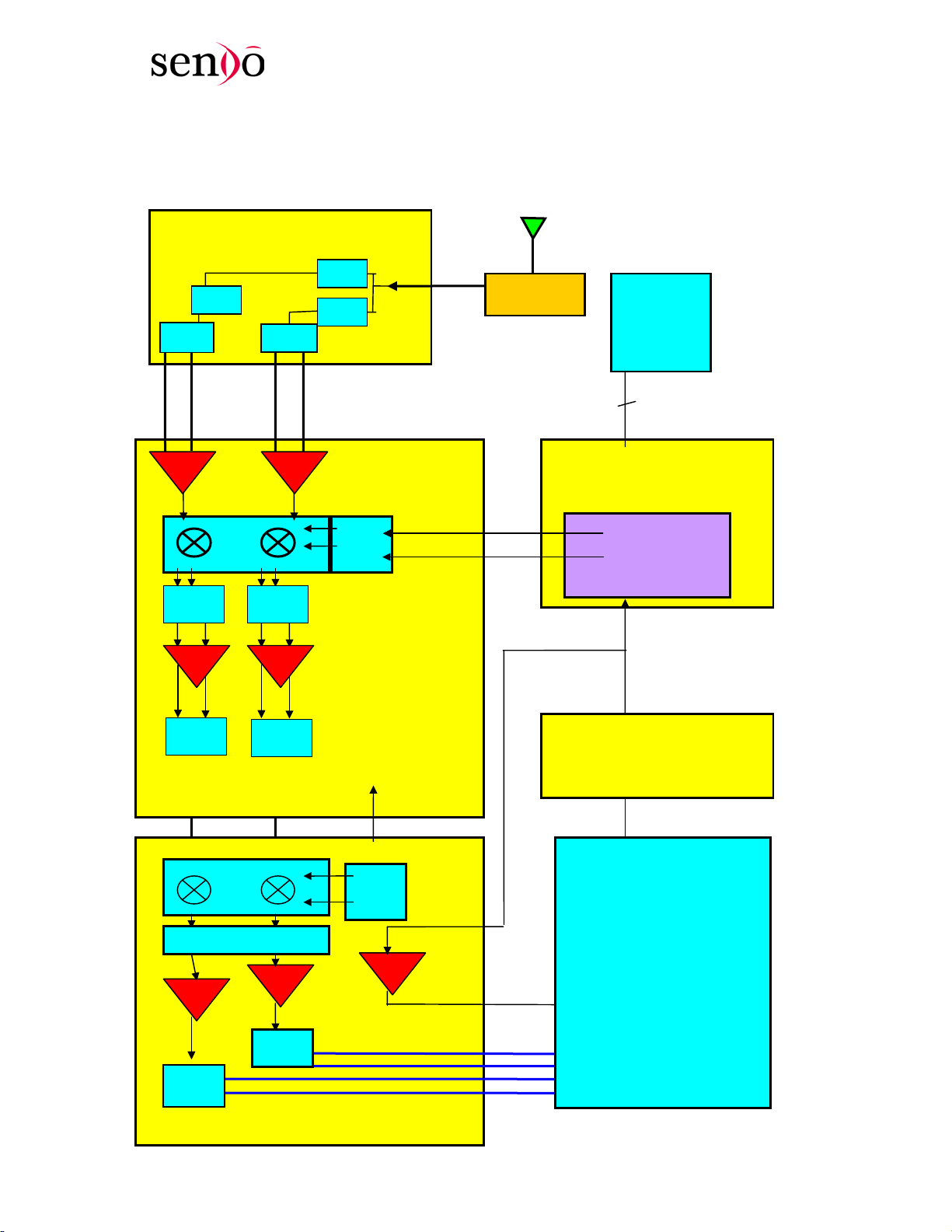

Section.2: Radio Architecture

Part a: Receiver Block Diagram

IC500 RF Switch

SW

saw

6 7 9 10

PCS GSM

20 19 22 21

saw

LPF

LPF

ADC

ADC

1 2

ION IOP

12 11

Channel filter

DAC

DAC

IC600

Doc M550/M551 Revision June 2

©2003 Sendo Ltd. Confidential and Proprietary

Demodulator

HPF

LPF

Π/2

IC601

IF Mixer

IOP

ION

CLKP

CLKN

100

KHz

NT

13 RF_LON 23

12 RF_LOP 24

7

RF_CLK_13M

4

5

2

3

D9

D10

C9

C10

003

IC100

CALYPSO

PDNB

RF_TPU_DATA_OUT (SDO)

3

RF_TPU_DATA IN (SDI)

IC602

Synthesiser

RF PLL

7

3

IICC660033

((1133MMhhzz))

RF_AFC

IICC220000

IOTA

RF_IP

RF_IN

RX = I+Q

RF_QP

RF_QN

Page 22

M550/M551 Level 3 Service Manual Page22

)

part b: Transmitter Block Diagram

RF_PA_CTL_EN

3

QP QN IP IN

VCCOUT

9 10 11

7 6 1

VRAMP

÷1 DCS

÷2 GSM

(IC200)

TX_VCO_GSM TX_V CO_PCS

IC700

25 24

IC601

LPF

∅detector

LPF

OFFSET PLL

÷

TX = I+Q

IICC220000 ((IIOOTTAA))

©2003 Sendo Ltd. Confidential and Proprietary

EGSM_PA_TX

PCS_PA_TX

Power Amps

(PA

13 RF_LON 24

14 RF_LOP 23

10 IF_ LON 27

11 IF_ LOP 28

IOP

ION

CLKP

CLKN

M550/M551 Doc SP11498 Rev:01 Aug03

1

11

IC500 RF Switch

LPF

LPF

HPF LP F

ANT

RF_AFC (IC200)

MF501

IICC660033

13Mhz Reference

RF PLL

IC602

IF PLL

3

IICC660000

9

2

V

CXO_13MHZ

3

7

PDNB

RF_TPU_DATA_OUT (SDO)

RF_TPU_DATA IN (SDI)

Page 23

M550/M551 Level 3 Service Manual Page23

)

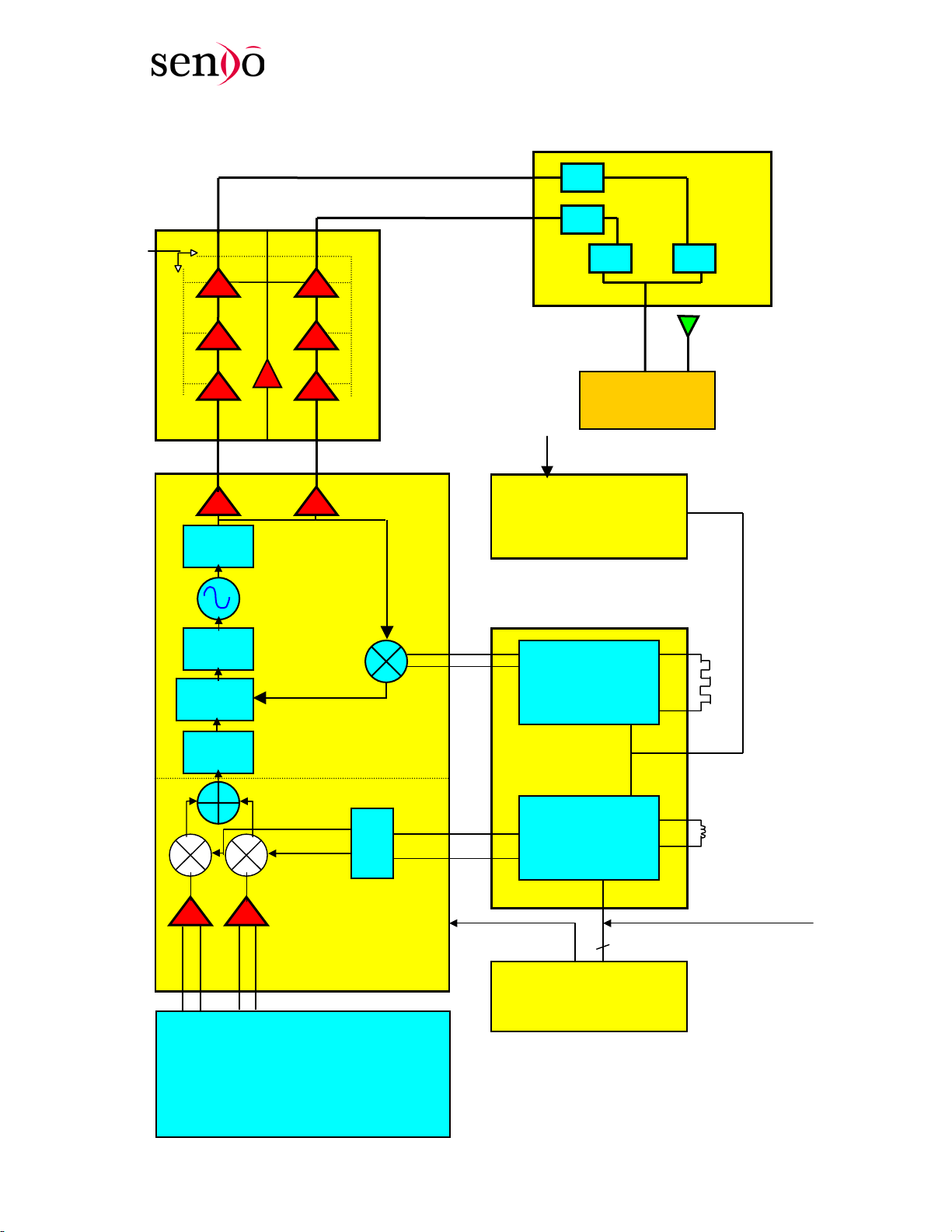

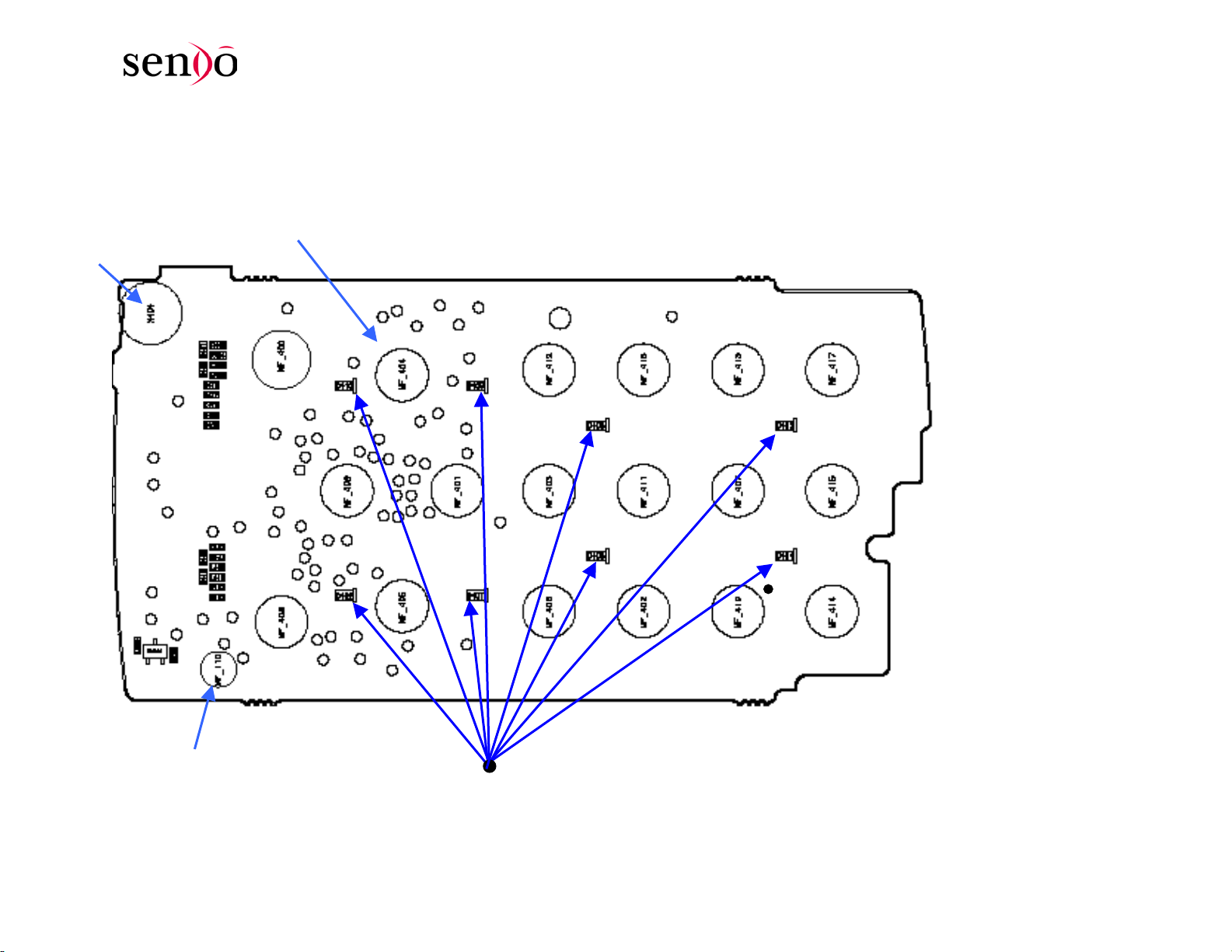

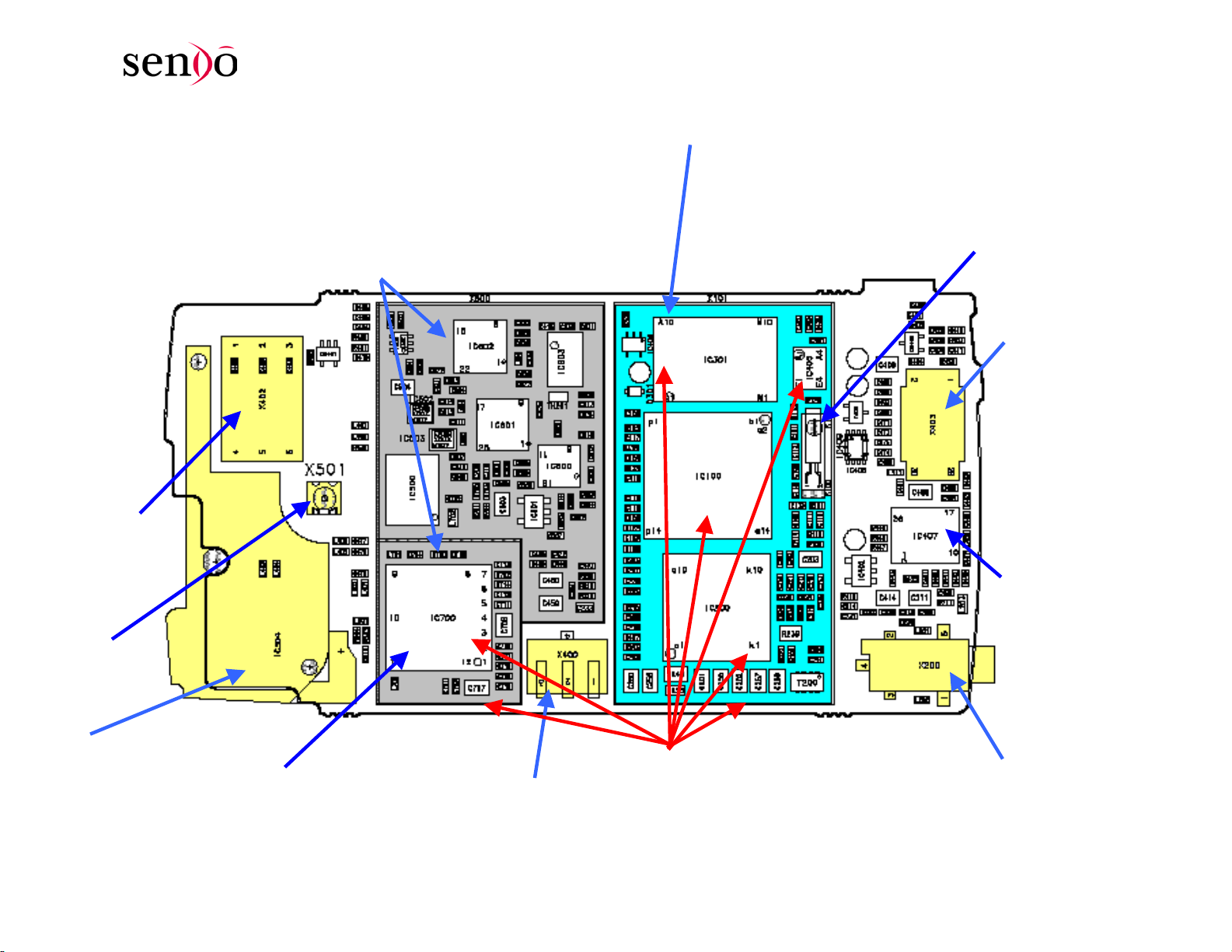

Section.3: M550 Functional Areas

Part a: Keypad, MIC and Backlight Area’s

In this section are shown the locations of the main keypad, backlight and Mic locations.

Side.1

X404: MIC

Keypad Area (Shown without Metaldome sheet fitted

MF_110: Flip detect contact pad

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Backlight LED’s (D402-D410)

Page 24

M550/M551 Level 3 Service Manual Page24

p

Section.3: Functional Areas – Cont’d

Part b: RF and Logic functional blocks

Here are shown the main functional parts of the logic and RF circuits.

Baseband Circuitry area (in blue)

Side.2

X402 - SIM Interface

X501 – Antenna

RF Switch

RF Circuitry areas (in grey)

X403 Connector

(Connects PCB to

LCD Module via

*FPC).

IC407 Sound Synthesiser

PA

IC504 - Antenna

IC700 – TX Power Amplifier

and associated circuit.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

X400 - Battery Connector

and DC

ower supply

Non-replaceable Parts

IC100 “Calypso” (BGA-Underfilled)

IC200 “IOTA (BGA –Underfilled)

IC301 Flash/SRAM – Underfilled)

IC405 LCD Driver

IC700 Power Amplifier

Shielding Frames (BB & RF)

X200 - Audio Jack and

charging socket.

Page 25

M550/M551 Level 3 Service Manual Page25

IC603 13Mhz Clock

Main RF Circuit devices:

IC500: TX/RX path switching IC

IC501: RF 2.8V POWER SUPPLY (VCC_2V8_RF)

IC600: RX Demodulator

IC601: IF+RF Modulator and Mixer

IC602: IF+RF Synthesisor (PLL- Phase Locked Loop)

X501: Mechanical rf switch

IC603:13Mhz Clock

IC502: GSM1800 Rx band pass filter

IC503: GSM900 Rx band pass filter

IC504: Antenna

X102 32 Khz Xtal

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 26

Page:26

M550/M551 Level 3 Service Manual

Section 5

Product Servicing

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 27

Page:27

M550/M551 Level 3 Service Manual

5.1 Level 1-2 Repair Items

Administration Checks

- Warranty Check

- Phone and Accessories

- DOA Filter Analysis (if required)

- Checking Fault report from customer

Level 1

- NFF

- SWAP

- Outer Bezel

- Inner Bezel

- Battery Cover

- Charger

- Battery

- Accessories

Level 2

- Labels

- Software Upgrade/Blocked Units

- Battery Holder

- Inner Housing

- Outer Ring

- Front Housing

- Keypad

- Board to Board FPC (Flexible Plastic Connector)

- Shielding can covers (Baseband+RF)

- Hinge assembly

- Metaldome

- Mic Gasket

- LCD Module (Replacement only)

- PCB cleaning

- Discreet components which just require soldering to replace

o Charger Socket

o Sim Connector

o Battery Connector

o Mic

o Buzzer, Vibrator and Earpiece (Speaker)

o Backlight LED’s

o Antenna

Level 3

- Components that need replacing after test equipment de-bug analysis

- Internal DAC level calibration, setting internally in phone

- Re-programming IMEI – Security

NOTE : Level 3 repair is restricted on the SND550 as some IC’s are under filled.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 28

Page:28

M550/M551 Level 3 Service Manual

5.2 General Quality Guidelines for Rework

The following guidelines should be followed when either reworking joints or replacing

electronic parts.

• All rework must follow the methods described in part 5.3b – “Prefered rework

methods” and to standard IPC-7711 (Rework of Electric/Electronic Assemblies).

• No joint may be touched-up more than twice.

• Wire modifications are not permitted.

• Any BGA devices on M550, which are underfilled must not be reworked or

replaced.

5.3a Recommended Equipment for Repair

Rework Tools

Soldering Iron: - Lockable temperature-regulated soldering iron station.

E.g. JBC AM6000, Weller WSD80 or Metcal MX-500

Hand Tweezers: - ESD safe flat rounded point

Solder Braid: - Multicore AA or Chemtronics 60-2-10 (size #2)

Solder: - Tin/Copper Lead Free (0.5 – 1.0mm diameter)

Flux: - Cobar 390RX

Flux Applicator: - Boncote BON-102

Torque Driver:- Calibrated to 10Ncm (+/- 1cNm) with bit Posidrive size “0”

Protective Gloves:- Disposable Latex gloves / Finger Cots.

Cover opening Tool* - Available from Sendo.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Cover Opening tool

Page 29

Page:29

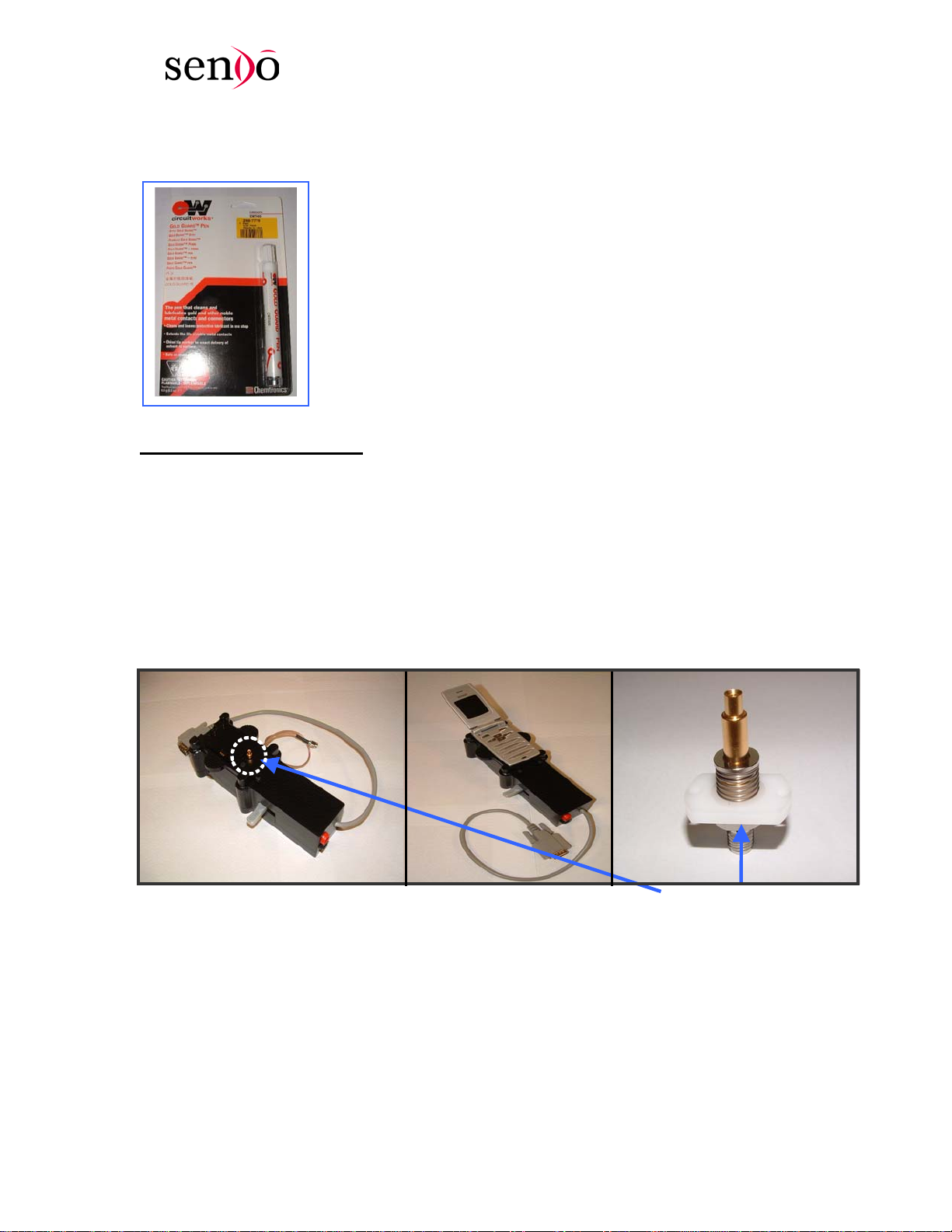

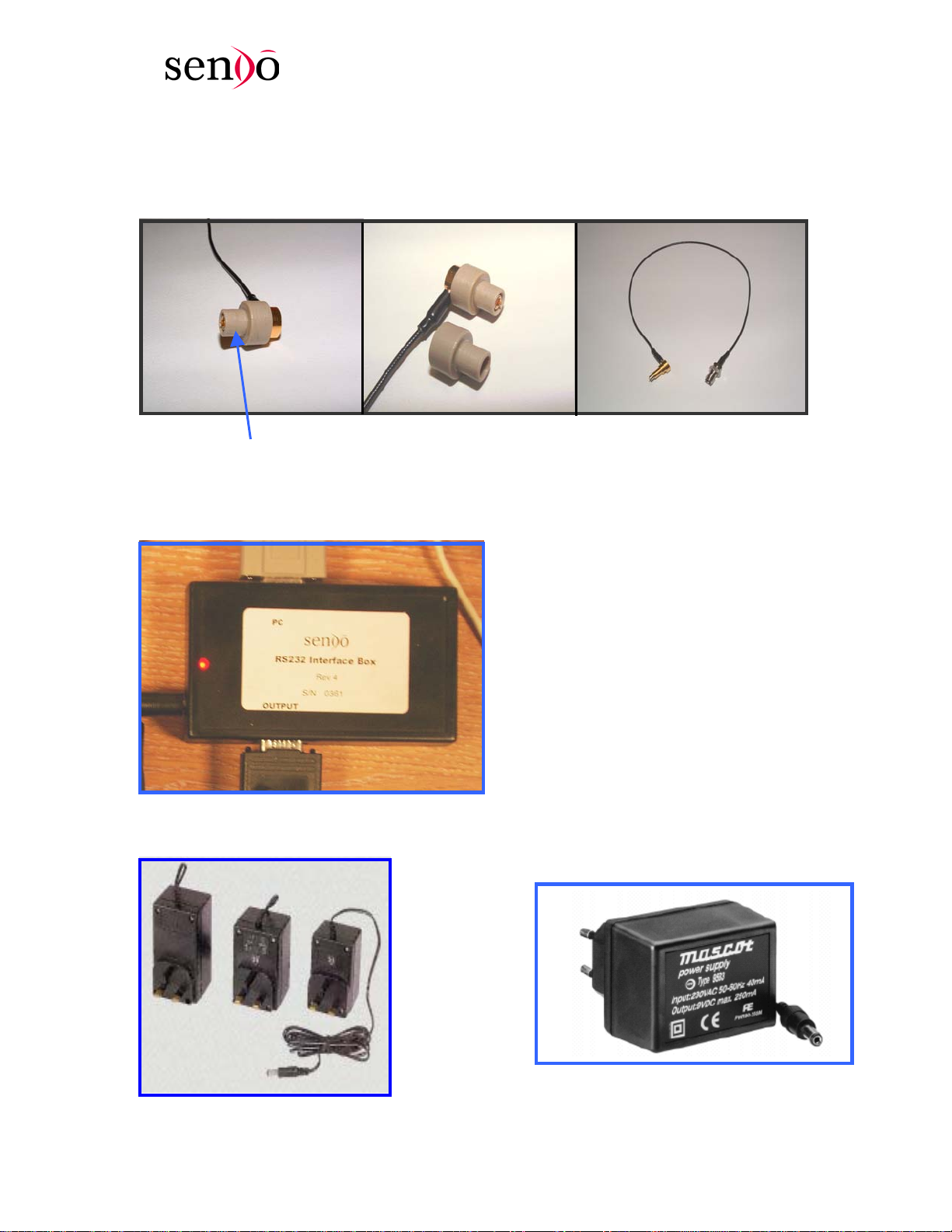

Adaptor fitted to battery eliminator.

RF Note: Can only be used with

battery eliminator.

Gold Guard Pen:- (for cleaning all contact pads) as below:-

M550/M551 Level 3 Service Manual

This item is available from: RS Components

Ltd (Part no: 298-7779), Website:rswww.com

Electronic Equipment

Digital Multimeter (DMM)

5V DC Power Supply

GSM Test Set

PC with Windows XP or 2000

Battery Eliminator* :- For software downloading and powering unit. Can also be used

to perform RF measurements**.

**RF adaptor (optional) must also be fitted to

perform measurements).

* Please contact Sendo for Details of aquiring these items

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 30

Page:30

M550/M551 Level 3 Service Manual

Leaded RF adaptor fitted with support collar*:- for performing RF measurements of

M550/M551 if using standard battery. Plugs directly into rear of M550/M551.

Collar fitted to RF adaptor

Leaded RF adaptor “without" Collar

RS232 Interface Box with 9 VDC power supply and serial cable*

Regulated 9vdc Power Supply for RS232 interface box.

Used to provide DC power to the RS232 Interface Box.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

UK Type

EU Type

Page 31

Page:31

DC Jack/bannana Leads * For power connection from 5V DC power supply to

battery eliminator.

GSM Test SIM :- To perform RF tests on the unit a modified test SIM must be used. A

portion of the test SIM needs to be removed as per the diagram below:-

This enables the RF adaptor(s) access to the RF switch (X501) on the rear of the unit.

* Please contact Sendo for Details of aquiring these items

This portion is removed

M550/M551 Level 3 Service Manual

M550/551 Handling Precautions

Whenever the M5** is either disassembled or assembled extreme care

must be taken in handling any of its parts. Special attention must be paid

when handling the colour LCD module, which can easily be scratched or

damaged. Soft cotton gloves should be worn AT ALL TIMES when

handling any of the M5XXs parts.

For your own safety and to protect the product from damage please

observe the guidelines listed in Section 1: Repair Precautions.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 32

Page:32

M550/M551 Level 3 Service Manual

5.3b Preferred Rework Methods

Part to be Replaced: Microphone (Through-hole device)

Removal

Replacement

Insert legs of mic through holes in pcb and position as in above

picture. Apply iron tip to both leg and pad and apply solder to leg.

keep tip in Place for 3-5 secs to ensure solder melted evenly. Remove

tip and allow to cool, then inspect and clean.

Removal Method

Microphone

For standard through-hole devices, remove any adjacent parts

that are heat sensitive i.e. key pad assembly etc. Set station

temperature to approx 350 degrees and select a suitable hand

piece. Add flux to the solder joints with brush applicator. Tin the tip

with solder and lower over the solder connection. Ensure complete

solder melt and apply the vacuum whilst using a rotating motion of

the hand piece. Keep the hand piece on the pad for no longer than

5 secs at any one time. Remove the mic from the joint, leaving the

vacuum on for a further 3 seconds to clear molten solder from the

head. Repeat for both mic pins and carefully remove device.

Using fluxed solder braid and standard soldering iron, clean

excess solder off pad. If no vacuum system is available then

alternatively use a soldering iron.

Recommended Equipment

Continuous Vacuum De-soldering System

Soldering Iron

Solder Braid

Flux

Flux-Cored Solder

(Alternative approach is 2 irons or hot tweezers for devices not

suitable for a de-solder system)

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 33

Page:33

Part to be Replaced: Battery, SIM Connectors and Three Pole Audio Jack

M550/M551 Level 3 Service Manual

Three pole audio Jack

Battery Connector

SIM Connector

Removal Method

Set the heater temperature to approx 425

the device in question. Add flux to the solder joints with Boncote brush

applicator and position the air tip approx 0.5cm away from the component.

Direct the hot air over the component until complete solder melt is achieved

(air guides can be used where appropriate). Grasp the component with

tweezers and remove from the PCB.

Using a fluxed solder braid and standard soldering iron, clean excess solder

off pad.

Note: If replacing the SIM connector using an hot air pencil, the antenna

must first be removed. This is to prevent the hot air from damaging the

plastic antenna body.

Recommended Equipment

Hot Air Pencil with suitable tip.

Soldering Iron

Solder Braid

Flux

Tweezers

Flux-Cored Solder

degrees and install a suitable tip for

Replacement

Set iron temperature to 350 degrees +/- 5% and ensure the iron has been on for the manufacturers recommended warm up period.

Thermal shock the tip on a moist sponge and re-tin the tip. Position the component accurately to the PCB. Apply flux and tack

solder two adjacent corner leads. Apply flux to the remaining leads and individually hand solder each lead in turn. Clean contacts

and solder area if required. Note: Care must be taken not to damage the plastic parts of the connectors or ANY parts

located near the item being replaced.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 34

Page:34

r

Outer Lens

Screw

(4pc)

Outer Ring

LCD

Hinge

Inner Hsg

Lens

M550/M551 Level 3 Service Manual

5.4 Mechanical Assembly Parts

RF

Adaptor

fitted to

battery

Battery

Holde

FPC

SIM

Front Hsg

Keypad

Metal-dome

Mic Gasket

PCBA

Screw (2pc)

Battery

Battery

Cover

Part Descrtion:

1. Inner Hsg Assy:

2. Populated PCBA: Not supplied as a spare part

3. Hinge

4. Screws

5. Mic Gasket

6. LCD Assy

7. Keypad Assy

8. Metal Dome:

9. Front Housing

10. Battery Holder

11. Outer Ring

12. FPC: BOARD TO BOARD FPC

13. Lens

14. Battery Cover

15. Outer Lens

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 35

Page:35

M550/M551 Level 3 Service Manual

5.5 Dis-Assembly Procedure

5.5a Battery Holder Cover Removal

Note: Before the M550/M551 can be dis-assembled, the battery and battery cover

must firstly be removed.

BU: Bottom Unit

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Note:

When dis-assembling the product great care must be

taken while opening the covers, as they can easily be

damaged if not handled correctly. Always ensure the

fixing locks/hooking features are released correctly.

Insert the separator tool between BU

front and the Battery holder plastics to

pry open the lower end of the assy both

left and right hand sides.

Remove two screws

securing the Battery

Holder.

Page 36

Page:36

M550/M551 Level 3 Service Manual

5.5a Battery Holder Cover Removal

Continue to pry the left and right

sides to working the tool further

along the housing edge to release all

the side locks.

Note:

To minimise damage to battery

holder and front housing care must

be taken not to damage the side

locks/hooking features on the battery

holder.

With the side locks released, the

battery holder will hinge off the BU

front housing.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 37

Page:37

M550/M551 Level 3 Service Manual

5.5b PCB Removal

Keypad

Disconnect the FPC from the

connector on the pcb. Always remove

the FPC gently as the connector may

be damaged if not handled correctly.

Now the main PCB can be removed

from the front housing. The rubber

keypad can also be removed from the

front housing if required.

ALWAYS ENSURE THAT THE FPC

IS HANDLED CORRECLTY AND IS

NEVER CREASED AS THIS CAN

CAUSE DAMAGE TO ITS

INTERNAL LAYERS.

IMPORTANT NOTICE

Now the Mic gasket can be

removed using tweezers.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 38

Page:38

p

M550/M551 Level 3 Service Manual

5.5c Dis-assembling the top unit from the front housing

The top unit (TU) can be disconnected from the front housing as shown below.

90 deg

TU (Top Unit)

TU angled @ 90 deg relative to Front cover

Angle the unit as shown so the TU and front

housing are at an angle of 90 deg. This is

because the hinge assembly can only be disassembled/assembled when in this

IMPORTANT NOTICE

osition.

Push centre of hinge body

in arrow direction shown in

RED.

Hinge body

Spring ground

contact “In Position”

Position screwdriver head here.

To separate the TU from the front housing, the hinge body must be pushed backwards

through the locating hole in the front housing. Using a small flat blade screwdriver

(size:3mm), position it as shown above. The head of the screwdriver should be positioned

between the sprung contact and the centre of the hinge body. Care must be taken not to

damage the spring contact when pushing the hinge body backwards through the

locating hole. When the hinge has been pushed through the locating hole the TU and front

housing can then be separated. While separating the TU and front housing, they must be

kept at 90deg as shown above.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 39

Page:39

M550/M551 Level 3 Service Manual

Separating the TU and front housing units.

IMPORTANT: Take care when easing the

FPC through the locating slot in front

housing.

Front Housing

Locating slot

5.5d Dis-assembling the top unit 5.5d Dis-assembling the top unit

Using the opening tool as shown

above carefully remove the outer lens.

This will then give access to the four

screws on the outer bezel.

Note: A new outer lens will have to

be fitted when assembling the unit.

TU

Remove the four fixing screws.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 40

Page:40

M550/M551 Level 3 Service Manual

5.5d Dis-assembling the top unit

Carefully insert the opening tool

between the outer ring and inner

housing as shown above. Slide the

tool down the length of the joint on

both sides and gently ease the

parts apart.

Before fully separating the outer bezel from the

inner housing carefully slide the bezel in the

direction shown. This is so to release the hook

features located on the inner housing from the

bezel.

IMPORTANT: Take care when dis-assembling

the bezel and housing as they can be

damaged if not opened in the correct way.

5.5e Removing the LCD assembly from the inner housing

LCD Assy

Disconnecting the FPC

Using the opening tool gently insert

the one end between the LCD assy

and FPC connector as shown. Then

prise the connector away from the

LCD assy to disconnect it.

Disconnecting the FPC

Now the FPC can be removed via the slot

in the inner housing.

IMPORTANT: Take care not to snag the

FPC or its connector on the inner

housing when removing it.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 41

Page:41

y

A

r

Disconnecting Vibrator, Earpiece+ Polyphonic speaker assembly

Again using the opening tool gently insert the one end between the base

of the vibrator body and inner housing as shown. Then gently prise the

vibrator away from the housing to remove it. The same method can be

used to remove the earpiece/speaker unit. Once these parts have been

disconnected from the inner housing the LCD module can then be

removed. IMPORTANT: Always use gloves when handling the LCD

module as both LCD screens can be easil

5.5f

Replacing the vibrator and earpiece + polyphonic speaker assembly

dhesive backing tape*

E/P+P-Spkr

Remove resin encapsulate

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Vibrator

M550/M551 Level 3 Service Manual

Earpiece+P-Speaker

scratched/damaged.

Vibrato

With the LCD module removed from the inner

housing both the vibrator and speaker assembly

must be de-soldered before removal.

Only replace the vibrator/speakers if faulty. The

LCD module can also be replaced separately to

the vibrator or speakers if required.

IMPORTANT

Before these parts can be de-soldered, the

protective resin, which covers the wires needs to

be removed. The resin can be removed by using

tweezers to carefully detach it from the LCD pcb.

* Replacement vibrator and speaker units are

supplied with an adhesive backing tape used for

fixing them to the inner housing. Always replace the

backing tape if the parts are detached from the

housing.

Page 42

Page:42

1

M550/M551 Level 3 Service Manual

5.6 Assembly Procedure

Assembly of the M550/551 is the reverse of the dis-assembly procedure,

except for the following care points.

5.6a Removing/Replacing the hinge assembly

Gnd Contact point with hinge

Gnd Contact

Hinge Assy

Resistance measurement points: <1 ohm

The hinge can be removed either by hand or tweezers, by gently pulling it out from the cavity on the

inner housing in the direction shown in red. When re-fitting the hinge push fit back into the cavity in the

reverse direction, ensuring it is fully located in position.

IMPORTANT:

Whenever the hinge is removed and re-fitted a resistance measurement must be taken to ensure that

there is good electrical continuity between the ground contact (shown above) and the centre of the

hinge. Using a digital multi-meter measure at the points shown above. The value measured should

be < 1ohm. If this value is >1 ohm, then check/clean hinge body and inspect the end of the ground

contact where it connects to the hinge body.

5.6b Refitting the LCD module (including the vibrator/speaker assy)

Vibrator Fitting

2

1) Refit the FPC onto the LCD module. Then Align the Vibrator with the location feature on inner

housing. Ensure that the wires do not become trapped under the LCD module.

2) Manoeuvre the LCD module toward Left hand side of inner housing and guide the FPC through

the slot feature in the housing as shown above.

IMPORTANT: always ensure the adhesive backing tape is removed from the vibrator/speaker

assy before they are placed in position on the inner housing. Also check that the FPC is not bent

or creased before assembly.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 43

Page:43

12 3

2

3

A

1

M550/M551 Level 3 Service Manual

Speaker Assy and LCD Fitting

Use tweezers dress wires fold back the speaker over

the LCD module - remo

adhesive backing.

IMPORTANT:

The FPC is fragile and should under no circumstances be allowed to crease.

Take care not to trap the Vibrator or earpiece wires during assy.

Avoid applying excessive pressure on the earpiece gauze.

ALWAYS observe anti static precautions when handling the PCB or LCD Assy.

Assembling the Top unit (TU) to the Bottom unit (BU)

ve

Turn the speaker through 180

degs so the adhesive is face

down – then rotate in direction

indicated.

Gently press earpiece into front

housing and dress wires

between the vibrator and

speaker.

RH Hinge pivot

Slot feature

Align the FPC with the slot

feature on the BU Front

housing. Carefully pass the

FPC through the slot. Slide

the TU assy over the BU

front housing hinge cover to

mate with the RH hinge

pivot .

Push Hinge down

Push here

Use the opening tool to

depress the spring loaded

hinge - press down as

shown. Then push the BU (in

direction/location shown)

towards the TU so the hinge

engages in position in the

BU.

The spring loaded hinge will finally

self centre when the module flip is

fully opened.

positive engagement lock will be

observed when the TU assy is

rotated as shown.

IMPORTANT

Test the flip operates

smoothly - no abnormal

clicking noise or stiffness.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 44

Page:44

A

g

Fitting the Battery Holder to the Bottom unit

Cantilever Lock

Hook Feature

The assembly sequence and

method are important to avoid

scrap or rework.

Angle the battery holder onto

the BU front housing as

shown above. Slide into

position the two hook features

left and right and one centre

cantilever lock .

M550/M551 Level 3 Service Manual

Snap fit the 5 lock features on

the battery holder by pressing

where shown above.

Replacing the Metal dome Key sheet

Finally press fit the upper lock

features where indicated above.

The two fixing screws can then be

fitted.

MPORTANT

Check that all the clips have fully

engaged. Also Check that the

FPC does not protrude from the

assembled housings.

Carefully remove the

original metal dome. Inspect

the pcb contacts and ensure

surface is free from

contamination and dust.

Clean the pcb contact

pads with the gold guard

pen to ensure they are

clean.

Backlight cut outs

lign along pcb edge.

Peel the protective backing

from the new metal dome

sheet. Align the sheet with the

edge of the pcb and cut outs

for the LED backli

hts.

Smooth over dome sheet

with fingers to ensure it is

fully adhered to the pcb. Also

check that the metal domes

are aligned with the keypad

contacts on the pcb.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 45

Page:45

M550/M551 Level 3 Service Manual

Section 6

Troubleshooting Guide

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 46

Page:46

M550/M551 Level 3 Service Manual

Important!

Please read the following cautions, notes and

warnings before progressing through this

manual or undertaking any repair action.

Remember: SAFETY FIRST!

Part 6a. General troubleshooting

Troubleshooting:

Customers appreciate people with good product knowledge and

someone who can solve any problems quickly and conveniently.

Read each of the tips below to find out how to solve the most common problems that

some customers experience.

We suggest you also print a copy of the troubleshooting guide in the user manual,

which together will enable you to solve most customers problems immediately

Customer Issues

Phone does not switch on…

Wipe clean the battery contacts on the phone and on the battery itself. Try a battery

from a working phone. If the phone powers on OK, the problem may be that the

battery is not charging so refer to the next topic for some tips on checking charging

problems

Phone will not charge…

The charging function can be confirmed by inserting a known good charger into the

phone. Wait for at least ten minutes for the charging icon to appear.

You can also connect the customers’ charger to a known working phone. If the phone

does not charge, the charger will need to be replaced.

Battery does not Last…

The standby time and talk time figures that are quoted in our sales literature are

made according to strict industry standards that give the best possible guide to

battery performance and product comparisons. Many factors in the customers own

day-to-day use of the phone effect the actual battery life.

Sending text messages or playing games activates the display backlights, which

greatly affect the battery life. Another example is the areas network coverage. A

strong network signal uses significantly less battery power from the phone than a

weaker network signal.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 47

Page:47

M550/M551 Level 3 Service Manual

It is also important to remember the relationship between standby times and talk

time. As a rough guide, for every minute the phone is in a call, the standby time

remaining reduces by two hours.

Other tips to get the most battery life out of the phone are to ensure the battery is

charged for at least 12 hours before using the phone for the first time, and customers

should occasionally allow their battery to fully discharge until the phone switches

itself off, before recharging it.

No signal or Network…

Try another SIM card in the phone. If the network name appears on the display, the

customer may have an invalid SIM card, and should contact their service provider.

Can’t make/receive calls…

Make a live call in-store. If there is no connection at all, try another SIM card. If calls

can then be made OK, the customer may have an invalid SIM or call barring is

enabled, and the customer will need to contact their service provider.

If calls in-store are OK, the customer may be experiencing network congestion at

certain times of the day, or limited coverage in certain areas.

Customer Fault Codes

There are 21 fault codes, which are used to record the reported fault from the

customer, please see them listed below. Under each fault codes are some general

troubleshooting tips, which may help you determine the cause of the problem. If

these do not rectify the problem then further detailed inspection and fault finding will

be required. There are detailed circuit descriptions and debug techniques described

in parts “ 6b Base band troubleshooting” and “6c RF troubleshooting”.

1 Liquid Damage/ Corrosion

2 Cosmetic

3 No Signal

4 Drops calls / Poor Rx Tx

5 Display Fault- Blank – Monochrome screen

6 Display fault- lines missing-Monochrome screen

7 Backlight

8 Keys not functioning

9 Power On / Off Faults

10 Charging Fault

11 Audio Fault

12 SIM Reader Fault

13 Software Fault

14 Battery Fault

15 No Fault Found

16 Vibrator Fault

17 Buzzer (ring tone) fault

18 Other

19 Display Fault-Blank – Colour screen

20 Display Fault- Lines missing – Colour screen

21 Hinge / Flip problem

The 21 Reported fault codes

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 48

Page:48

(

)

A

M550/M551 Level 3 Service Manual

1 ) Liquid Damage

Check for water/liquid

ingress around the

following areas, keypad,

charging jack, SIM

connector, battery

contacts, LCD module and

also the PCB. Any liquid

ingress found will instantly

void the Sendo warranty

that is given with a Sendo

product. Please find

attached picture for

example of liquid ingress.

Note

ALWAYS CHECK BOTH THE BOTTOM PCB AND LCD MODULE FOR

LIQUID CONTAMINATION AS THIS INVALIDATES THE WARRANTY OF

THE PRODUCT.

2) Cosmetic

Cosmetic damage/ scratches to a Sendo product are NOT covered by a warranty

that is given with a Sendo produ

ct.

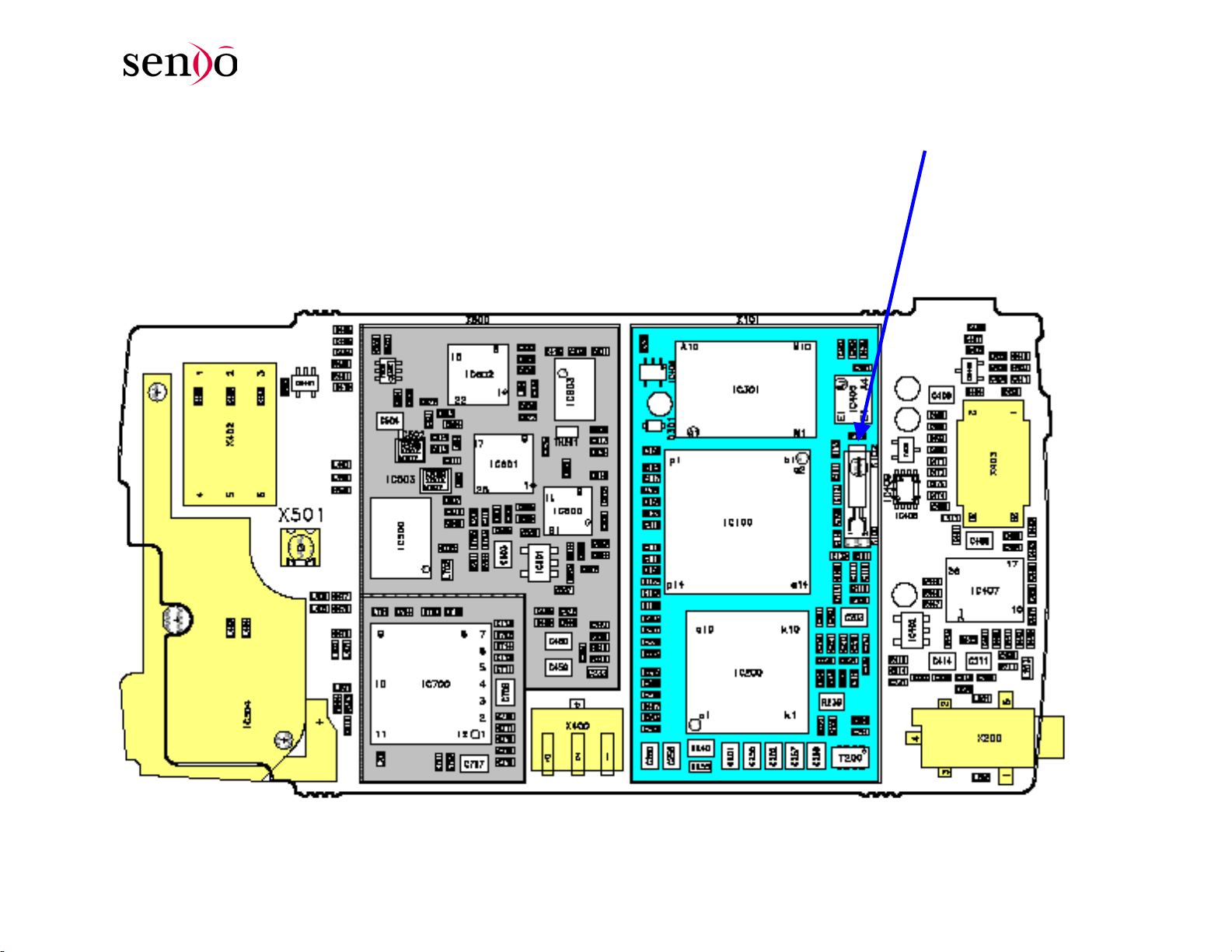

3) No Signal/Network

If a Sendo phone is returned with ‘ No

Signal’, the first test should be to put

a test SIM card into the phone and

complete some call testing on test

equipment to determine whether or

not the phone is able to make/receive

a call. If the phone is unable to get a

signal then both the antenna and its

soldering should be inspected. Also

clean/check the RF switch “X501”(see

picture). Also check the condition of

the grounding contacts in both the

RF Switch

X501

top unit and bottom unit. (See pictures

on next page for details

).

ntenna Solder point

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 49

Page:49

Check sprung

grounding contacts.

4) Drops Calls / Poor Rx/Tx

Place test SIM card into phone and complete

GSM tests on test equipment, this will

evaluate phone to see if phone is operating

within GSM spec. If unit fails check the

antenna/X501 as above. Also check the

antenna grounding contacts. Only Level 3

centres will be able to adjust RF settings.

Checking Antenna Grounding Contacts

M550/M551 Level 3 Service Manual

B

A

To ensure that the ground contacts are making

good contact check the resistance between point

A-B. The Resistance should be less <1ohm.

If > 1ohm then check:

1) All grounding contacts (circled) for

condition/damage.

2) Clean all contacts including contact pad on

lower pcb.

3) Check/clean hinge body.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 50

Page:50

M550/M551 Level 3 Service Manual

5) Display Fault

Blank Display

If either the outer or inner LCD’s are blank, then check:

IMPORTANT: LCD Damage: Inspect both LCD’s for physical damage. If LCD

shows signs of physical damage (see picture) then the Sendo warranty is void

for this repair.

If there is no sign of physical damage then try the following:-

4) FPC: Inspect the FPC connection at both ends. Ensure that the FPC is seated in

its socket and that the foam retaining pad is in position on inner housing. Also

check the condition of the FPC itself for damage or any obvious signs of failure –

especially check for cracks in the FPC and the soldering of the connector plugs.

5) Cleaning: Before replacing any parts try cleaning the FPC connector/ sockets

with a suitable cleaning agent.

6) FPC/LCD: Try connecting another “good” one to prove if the FPC is the cause of

the fault. If the FPC is ok, then try connecting another LCD module to establish

whether the original module is faulty.

LCD Damage

Foam Retaining Pad

(In correct Position)

Lcd damage

FPC

Check: FPC Condition

• Connectors

• Flexi

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 51

Page:51

M550/M551 Level 3 Service Manual

Check: FPC/Connection/Clean

6) Display Fault

missing Lines on display

If either the outer or inner LCD’s are blank, then check:

If there is no sign of physical damage then try the following:-

1) FPC: Inspect the FPC connection at both ends. Ensure that the FPC is seated in

its socket and that the foam retaining pad is in position on inner housing. Also

check the condition of the FPC itself for damage or any obvious signs of failure –

especially check for cracks in the FPC and the soldering of the connector plugs.

2) Cleaning: Before replacing any parts try cleaning the FPC connector/ sockets

with a suitable cleaning agent.

3) FPC/LCD: Try connecting another “good” one to prove if the FPC is the cause of

the fault. If the FPC is ok, then try connecting another LCD module to establish

whether the original module is faulty.

Note:

The LCD module IS NOT a repairable item and must only be replaced. NEVER rework

it or attempt to repair it. FAULTY LCD MODULES MUST BE QUARANTINED ON

BEHALF OF SENDO.

Missing lines on inner display

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 52

Page:52

f

7) Backlight.

Things to check:

1) Check whether backlight LED’s are working and i

soldering is ok. Replace/resolder faulty LED if

required.

2) Inspect the soldering (circled red) for defects as

these are the backlight drive circuit area’s.

M550/M551 Level 3 Service Manual

8) Keys Not Functioning.

Things to check:

Check polydomes on keypad (see picture).

Check keyboard contacts on main PCB. Clean

contacts if required.

Keypad Area

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 53

Page:53

M550/M551 Level 3 Service Manual

9) Power On/Offs faults.

Check battery voltage and condition of contacts on battery.

Test the phone on battery eliminator (see picture), see if fault occurs.

If fault occurs then check/clean battery connector (X400) soldering and also

contacts.

X400 – Battery connector

10) Charging Fault

Check that the Battery isn’t

causing the problem.

Make sure the Charger

Connector (circled) is not

damaged/faulty and there is

not a dry joint on any of the

solder points, if this is the

case re-solder all of them

when repairing the fault.

Check the battery contacts

to make sure there is a

connection to the battery

Check the circled area’s on

the pcb for soldering

defects.

Solder Points

Check soldering

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 54

Page:54

g

11) Audio Fault

Check both the Speaker and Mic for

dry joints or obvious damage. On

Speaker especially check that its

wires are not broken or damaged.

Check FPC condition and both the

connectors are clean and soldering is

good.

Check PCB components (circled) for

visual dama

e and soldering defects.

12) SIM Reader Fault

Clean the SIM contacts and check for

soldering defects on the X402 SIM reader.

Check components circled above.

Ensure the connection pins on X402 are not

bent or broken.

Also ensure that the front housing and

battery holder are clipped together correctly

as the SIM card will not be retained against

the contacts if the covers are not fitted

together.

M550/M551 Level 3 Service Manual

Audio components

Check

FPC/X403

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 55

Page:55

13) Software Fault

Please update any unit to the latest version on Software

The Software updates will be issued to the service

centres via mail or Internet. There will be a technical

bulletin with each issue.

Software upgrade will also default the unit back to factory

configuration settings. Sometime the customer will adjust

the phone and think they have caused a fault.

(Please re-software these units to reset them)

Units which have ‘BLOCKED’ show, check the following:-

- check the handset has an IMEI, this can be done

- If the unit has a IMEI, then the unit is blocked

14) Battery Fault

Check that the voltage in the battery is above 3.3V, if

not then put the battery on charge for an hour to see

if it rises and the phone charge indicator lights up

Check for corrosion and damage to the battery

Ensure the battery contacts on the phone are not

faulty or dirty.

NOTE: To ensure professional battery testing

please use an astrotec battery checker ( Info

from Sendo )

by typing *#06#, the IMEI will be shown on the

screen, if it has *?????????????, then send it to a

Level 3 repair center.

because the NCK code was typed in wrong more

than 6-12 times, re-software the phone will reset

the counters, NOT unlock the phone

Astratec “Expresscheck” battery tester

http://www.astratec.co.uk

M550/M551 Level 3 Service Manual

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 56

Page:56

15) No Fault Found (NFF)

Most NFF can be down to the Network Service Quality in the location where customer live,

Also units can wrongly be diagnosed and NFF can be made of a variety of returns

Please ensure that the Service Centres carries out the following tests on a NFF

- Checks the modules radio performance, with making live calls on the customers

- The phones menu functions are tested to ensure that the phone runs without

- The phone is quality checked, by powering on/off various times, checking network

16) Vibrator

Check in the user menus that the

vibrator option is selected to ON, some

operators may have this switched off fo

factory s

Check the connection wires to the

vibrator are good and the soldering is ok.

Ensure that the contacts are not

damaged or bent and are clean

Check the vibrator works by changing it

with a know good one, Level 3 service

centre can put a voltage load across it to

check it works

17) Buzzer (ring tone) fault

Ensure that the user has not muted the

buzzer in the phones menu

Check the Buzzer has not been

damaged,

Make sure that there are no dry joints on

the contacts and there is nothing

blocking the buzzer output in the case

and cover of the phone

network (GSM test set)

problems

connection, ringer and audio.

et

ting

M550/M551 Level 3 Service Manual

Vibrator Checks:

1) Connection wires

2) Soldering of joints

r

3) PFC/X403 connector

4) Try another known good vibrator to

verify if it is faulty or the LCD module.

Buzzer Checks:

1) Connection wires

2) Soldering of joints

3) PFC/X403 connector

4) Try another known good buzzer to verify

if it is faulty or the LCD module.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 57

Page: 57 M550/M551 Level 3 Service Manual

6b Base band Circuit Description and De-bug

FUNCTIONAL BLOCK DIAGRAM OF CORAL

M550 is a ‘clam shell’ phone. There are two pieces of pcbs in M550. The main

baseband and RF circuitries are on the main pcb assembly while the LCD

module assembly is on the lcd pcb. The following diagram illustrates the

functional blocks located on the two pcb assemblies.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 58

Page: 58 M550/M551 Level 3 Service Manual

t

r

A

A

A

pag

Audio Description

Please refer to the circuit below and on pages 2,4 Schematic; 8J60-0M000-02000-SCH. BB_EARP and BB_EARN

are the positive and negative differential inputs to the internal speaker fitted to the LCD module.

When the handsfree connector is inserted BB_AUX_MIC detects the insertion by the impedance change. This is

detected by IC200 on pin C7 (BB_AUX_MIC). This is line will change state and hence the audio route will change.

X200 is the audio jack. Pin 3 is the audio output from IC200 and pin 2 is the audio in.

X404 is the microphone. Its two outputs are BB_MICP and BB_MICN. These differential outputs are fed to the Iota chip

on pins J7, H7. The biasing for the microphone is from AVDD_MIC (which is derived from BB_MIC_REF_P, from

IC200-#J8), and is only present during a call or loop back.

Between the voice band serial port in IC200 and the IC100, we have the data link. The four lines are BB_VCLK,

BB_VFS, BB_VDX, and BB_VDR. VCLK is the voice band serial port clock. The other three are the SPI bus and are

Voice band serial Frame Synchronisation (VFS), Voice band serial port Data Transmit (VDX), and Voice band Data

Receive (VDR).

Aux-Mic call control

When a Headset is fitted into system connector, BB_AUX_MIC is pulled low. Iota (IC200 #C7) samples it on inpu

ADIN3. This ADC input is linked to IO connector X200 pin 2 via R208. It is pulled high by the mic-bias potential. (Afte

MIC_REF_P passes through R406, it is named AVDD_MIC.

Note: A block schematic diagram showing the related audio, SIM reader and audio jack circuits can be found in:

“Section 4. Part a: Audio Circuits and SIM Interface”

udio Out from IC200

#K9 to X200 jack

udio In from Mic to (IC200

#H7-J7)

BB_AUX_MIC

To: IC200 #C7.

Pulled low when

headset connected.

Not used

udio input from

microphone X404.

See next

Charger input: 5v.d.c

X200-Audio jack

To X403 connector

(#25-27) and then

earpiece.

e.

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 59

Page: 59 M550/M551 Level 3 Service Manual

A

o

o

o IC100 #

r

Biasing voltage for Microphone – IC200 #J8.

udio In from Mic (X404) to (IC200

#H7-J7)

IC407 is the device which generates the ring tones on M550/M551. It can generate up to 16

voices with different tones. It contains a decorder and FM synthesiser. IC407 also contains an

amplifier with an output of around 500mW. The 13Mhz clock is used as the master clock for

the PLL inside IC407. Data from IC100 is from the parallel bus along lines D0-D7. There are

also RnW,Chip Select, and Clock lines from IC100 to control the data transmission. The

signal VIBR_EN from IC407 pin19 goes high to enable the vibrator. The vibrator is located

inside the upper plastics with its drive circuits. VIBR_EN is connected to the vibrator via X403

pin22.

Data Lines from IC100

m IC409 #3

Fr

From IC100 #D3,M4,E2

m IC100 #F12

Fr

T

Microphone Circuit

(Voltage supply to X200 – Jack socket circuit)

X404 -Mic

IC407 - Ring tone generator and Vibrator control IC

To X403

connecto

Not used

Not used

IC407

Not used

Not used

P1

From IC100 #P8

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 60

Page: 60 M550/M551 Level 3 Service Manual

Keyboard and LCD Backlight Control

Backlight Operation

To operate the backlights,IC100-#L7 takes the control line KB_BKLT_EN high. KB_BKLT_EN

will switch T400 on allowing the current to flow through the diodes. The diodes are supplied

using LCD_VBKLT (supplied from LCD display via X403 - #12). The current output is

regulated by R448/R454.

Keyboard Operation

When a key is pressed, the corresponding row and column lines are shorted together. To

allow key press detection, all input pins (KB_ROW) are pulled up to VCC and all output pins

(KB_COL) are driven to a low state. Any activation of a key will short together the

corresponding column and row address lines and form an interrupt within IC100, which

constantly scans these lines to detect a key press.

LCD_VBKLT – from X403 #12

KB_BKLT_EN–from IC100 # L7

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 61

Page: 61 M550/M551 Level 3 Service Manual

On/Off Power Key – Pulsed low when key pressed

To IC100 # K5-P5

To IC200 “IOTA” #F8

M550 Power up Sequence and power supplies

1. When the battery is connected “VBAT” is applied to the board from the

battery.

2. When the power key is pressed “PWR_ON” is taken low temporarily,

Then IC200 generates the following power supplies:VCORE 1.8VDC TP202

VIO 2.8VDC TP200

VMEMORY 2.8VDC TP205

AVDD 2.8VDC TP203

VUPR Approx. VBATR237

IBIAS 1.2VDC R205

VMEMRAM 2.8VDC TP210

VREF 1.2VDC C225

VRTC_IOTA C255

3. The 32KHz clock (X102) will now start, measured at C110/C111

4. Control line BB_nRESET, from (IC200) IOTA (TP206) goes high, taking

calypso (IC100) out of reset.

5. Control line BB_ON_NOFF, from IOTA (#-E3) to Calypso (#-F10) goes

high. (TP109)

6. Now Calypso will enable the radio circuits:

7. Calypso takes RF_REF_ON (C502, IC501 pin 3), high. This turns on

radio regulators.

From IC100 # K6-P6

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 62

Page: 62 M550/M551 Level 3 Service Manual

8. The 13MHz Oscillator (IC603) now generates the 13MHz signal, which

is fed to the Calypso (#-E13). The signal “RF_CLK13M” is then passed

from the calypso (IC100-#F12) to the Iota (IC200-E4).

9. The calypso is now executing code from memory, and the backlight

LED’s should illuminate.

Note. The Flash Part is a 64Mbit (8Mbyte) Flash with a 4Mbit SRAM

attachment.

Additional power supply “VCC_2V8_RF” for RF circuits generated by IC501

Signal “LB_nOPC” (from IC100-#A13)

“Calypso” enables IC501.

Power supplies generated by IC200 “IOTA”

IC200 “IOTA”

IC501 – 2.85v Power supply for RF circuitry

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 63

Page: 63 M550/M551 Level 3 Service Manual

Power supply and control signal interconnection table

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

Page 64

Page: 64

M550/M551 Level 3 Service Manual

Probing Test-Point (side 1)

AVDD

2.8V

VIO

2.8V

VMEMRAM_IOTA

2.8V

VCORE

1.8V

VMEMORY_IOTA

2.8V

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

BB_ON_nOFF

Check HIGH “1” to

enable RADIO

BB_nRESET

High “1” when

IC200 is OK

Page 65

Page: 65

M550/M551 Level 3 Service Manual

Probing Test-Point (side 2)

RF_REF_ON

High “1”

VREF

1.2VDC

13 MHz Crystal

Master Clock

32 KHz (RTC)

Real Time

Clock

IBIA

1.2VDC

M550/M551 Doc SP11498 Rev:01 Aug03

©2003 Sendo Ltd. Confidential and Proprietary

VUPR

VBATT 3.7V

VRTC_IOTA

1.5 V

Page 66

Page: 66 M550/M551 Level 3 Service Manual

SIM INTERFACE

The SIM Card circuitry first comprises of a four wire parallel interface between the

SIM Card holder (X402) and the IOTA (IC200). The four lines comprise of the

following: The power supply SIM_VCC (X402, 1-IC200, B4), the reset line SIM_RST

(X402, 2-IC200, D4), the clock line SIM_CLK (X402, 3-IC200, C4) and the serial data

line SIM_IO (X402, 6-IC200, B3). X400, 4 is grounded. The SIM_IO is biased by