Page 1

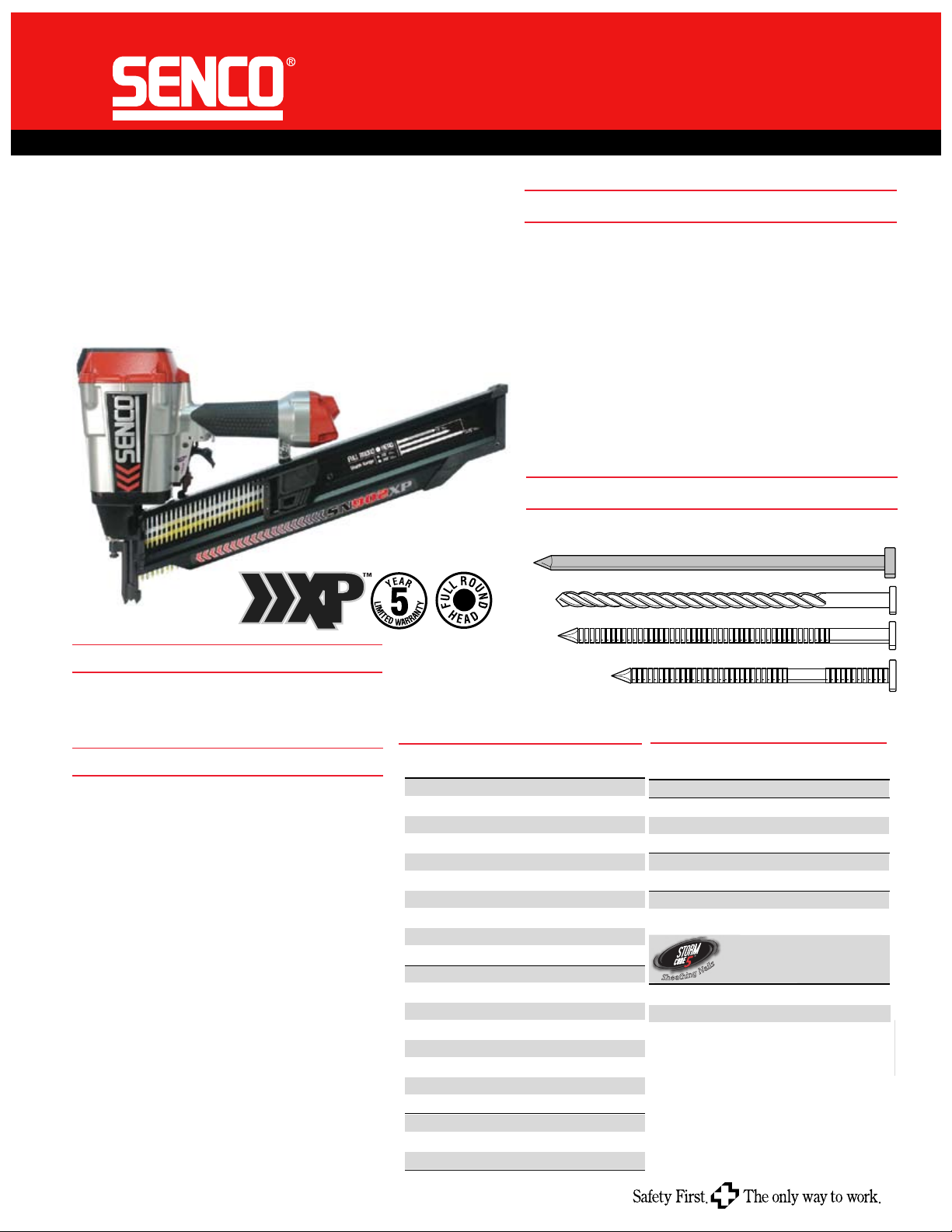

Framing Nailer

Full Round Head SN902XP

This well-balanced lightweight XP framing nailer packs plenty of

power and won't leave you fatigued at the end of the day. Drives ring,

screw, and smooth-shank full round head nails for tough fastening

jobs. SENCO XP tools are specifically engineered for demanding pros

and demanding environments. Built with enhanced features and

superior components – SENCO’s XP tools always provide the best

performance and longest life backed by a 5-year limited warranty.

Tool Specifications:

Item #: 4H0001N

Tool Weight: 7.4 lbs. (3.4 kg)

Height: 11.65" (296 mm)

Length: 20.3" (516 mm)

Width: 4.5" (114 mm)

Collation: 20˚ strip

Capacity: 60 nails

Operating Pressure: 70-120 p.s.i.g. (4.8-8.3 bar)

Mode of Operation: Selectable trigger mechanism allows either

sequential or contact actuation.

Air Inlet: 3/8" NPT

UPC: 741474060335

Packaged Dimensions: L: 21", H: 14.75", W: 5.25", Wt: 8.5 lbs.

Fastener Specifications:

Drives .113 – .148, Smooth 2"– 3¼", Screw 2 ½" – 3", Ring 2" – 3"

GD (.113) HD (.120) KD (.131) MD (.148)

(.120)

GL (.113) HL (.120)

Applications:

Framing, sheathing, truss building, sub-flooring and

decks. Other applications include crate and box assembly,

pallet making, furniture frame assembly and fencing.

Features and Benefits:

• Well balanced and lightweight – 7.4 lbs.

• Uses up to 15% less air – Highly efficient internal

design

• Reduced jams and mis-feeds – Patented TrueDrive™

magazine

• Easily fits between studs and joists – Low profile

design

• Contact or sequential trigger actuation – Patented drive

selector

©2008 Senco Products, Inc.

STORMCODE 5* GT (.113) KT (.131)

Genuine SENCO Fasteners Available:

Smooth-Shank

Length Item Code

2 x .113 GD21APBSN 5.M Bright

2¼ x .148 MD23APBSN 4.M Bright

23⁄8 x .113 GD24APBSN 5.M Bright

2½ x .113 GD25APBSN 5.M Bright

3 x .120 HD27APBSN 4.M Bright

3 x .131 KD27APBSN 4.M Bright

3 x .148 MD27APBSN 4.M Bright

3¼ x .120 HD28APBSN 4.M Bright

3¼ x .131 KD28APBSN 4.M Bright

3¼ x .148 MD28APBSN 4.M Bright

2 x .113 GD21AABSN 4.M Galv

2½ x .113 GD25AABSN 5.M Galv

2½ x .113 M002098 2.5M Galv

2½ x .131 KD25AABS 2.5M Galv

3 x .131 KD27AABSN 4.M Galv

3 x .131 M002046 2.5M Galv

3¼ x .131 KD28AABSN 4.M Galv

3¼ x .131 M002047 2.5M Galv

23⁄8 x .113 GD24ASBS 2.5M Hot Dip

3 x .131 KD27ASBS 2.5M Hot Dip

3¼ x .131 KD28ASBS 2.5M Hot Dip

3¼ x .131 KD28AGBS 1.M Stainless

www.senco.com

Carton

Count

Finish

Ring-Shank

Length Item Code

23⁄8 x.113 GL24APBSN 5.M Bright

23⁄8 x.113 GL24AABSN 5.M Galv

23⁄8 x.113 M002042 5.M Galv

3 x.120 HL27AABSN 4.M Galv

23⁄8 x.113 GL24ASBS 2.5M Hot Dip

3 x.120 HL27ASBS 2.5M Hot Dip

23⁄8 x.113 GL24AGBS 1.M Stainless

3 x.120 HL27AGBS 1.M Stainless

s

l

i

a

N

g

n

i

h

t

S

a

h

e

2½ x.131 GT25APAS 5.M Bright

2½ x.131 KT25APAS 5.M Bright

Carton

Count

Finish

STORM CODE 5 Nails feature a unique patented

design with proprietary shank and increased

head diameter for use in severe weather regions.

®

Page 2

Framing Nailer

Full Round Head SN902XP

Unique Features of the SN902XP

Low Profile Design –

Easily fits between studs & joists

Cap Exhaust –

Directs exhaust downward

Aluminum Housing –

Lightweight,

superior durability

Uses Up to 15% Less AIr –

Highly efficient internal design,

runs great with 1/4” line fittings

Thumbwheel Adjustable

Depth-of-Drive –

Drives nails to a consistent

and controllable depth

Full Comfort Grip –

Resilient grip reduces fatigue

Rear Two-Step Loading –

Quick and easy for right or

left handers

Contact or Sequential Trigger

Actuation Switch – Patented drive

selector*

Aggressive Toenail Safety –

Teeth grip studs with real bite for

precise positioning

*Choose the right actuation mode!

Sequential Actuation (also known as restrictive trigger or trigger fire) operates in

the following a sequence - depress the safety element at the nose of tool against the

work surface then pull the trigger. After each fastener is driven, release the trigger

and lift the tool off the work surface before starting the sequence again. This trigger

is recommended and acceptable for most applications.

Contact Actuation (also known as dual action, bounce or bottom fire) operates in

the following sequence- pull the trigger first and keep the trigger pulled while

moving the tool along the work surface with a bouncing motion, depressing the

safety element at the nose of the tool against the work surface where the fastener is

to be driven. This trigger is recommended for use by trained professionals only in

high production or volume applications.

©2008 Senco Products, Inc.

www.senco.com

Patented TrueDriveTM Magazine –

Reduced jams and mis-feeds

Always read the Operators Manual and Safety Instructions with all tools to

ensure proper use and safety precautions. For additional information on

trigger systems and how SENCO will save you time, reduce costs, and

increase quality, call our toll-free Action Line 800-543-4596, or visit our

web site at www.senco.com.

®

Loading...

Loading...