Page 1

Framing Nailers SN60 SN65 SN65C

Pneunatically driven true round head framing nailers for

manufactured housing, on-site building construction,

and pallet assembly. The SN65C has been designed

for earthquake, hurricane, and tornado-prone areas,

where codes call for common nails.

The SENCO SN60, SN65, and SN65C drive a wide

range of full round head nails for a variety of tool

applications. Excellent balance and power-to-weight

ratio, along with a comfort-grip handle, helps reduce

fatigue and increase productivity. Built to exceed

SENCO’s proven standard of reliability, the SN60,

SN65, and SN65C provide high-quality performance

through our depth-of-drive control which allows the

user to achieve the right countersink. Toenail safety,

no-mar pad, and the angled magazine increase

flexibility for nail placement.

R

Applications:

Manufactured Housing, On-site and Mobile Home

Construction:

• Framing

• Subflooring

• Sidewall sheathing

• Decking construction

• Siding

• Roof deck construction

• Truss building

Also for Crate, Box, and Pallet Assembly

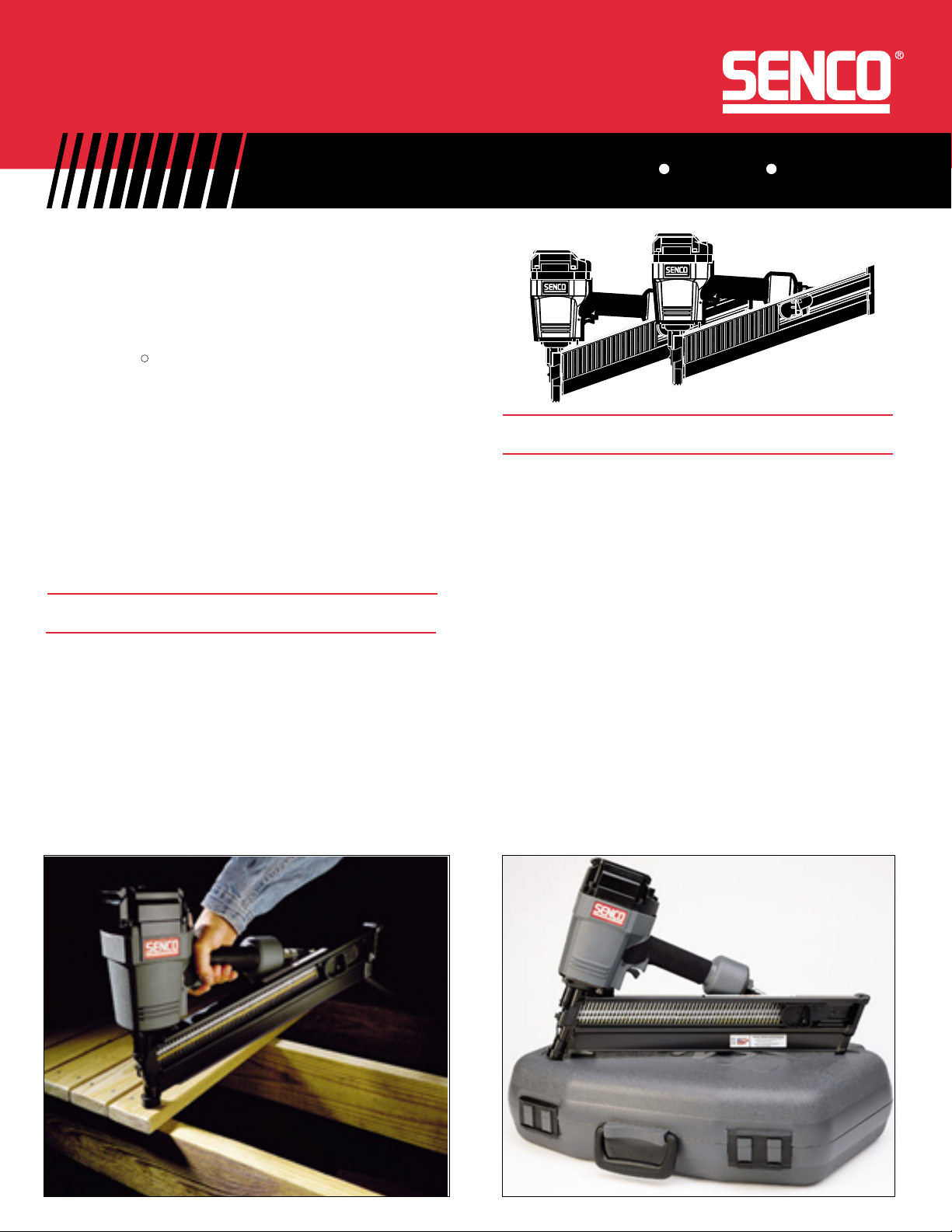

SN65/65C

SN60

Features:

• Drives a wide range of true round head framing

nails.

• The SN65C drives 2½", 3", and 3½" common nails.

• Reduces fatigue though excellent balance and

power-to-weight ratio, as well as a comfort-grip

handle.

• Toenail safety, streamlined nose area, and angled

magazine aid in nail placement.

• Depth-of-drive control and standard no-mar pad

attachment improves craftsmanship by ensuring the

right countersink while keeping the work surface

mar-free when necessary.

• EZ- Clear design allows quick clearing of infrequent

nail jams.

• Two-step rear loading makes loading quicker and

easier, for right-handed or left-handed users.

• SN65’s have 15% more power than SN60 for those

extra-tough jobs.

Page 2

Framing Nailers SN60 SN65 SN65C

Tool Specifications:

Tool Weight: SN60: 7.7 lbs. (3.5 kg)

SN65’s: 8.1 lbs. (3.7 kg)

Height: SN60: 13" (330 mm)

5

SN65’s: 13 " (346 mm)

/

8

Length: 19¾" (502 mm)

3

/

Lip Length: " (10 mm)

8

Magazine Capacity: 60

Operating Pressure: 70-120 psig (4.8 - 8.3 bar)

Mode of Operation: Tools are available with either

“Restrictive Trigger” or “Dual Action” activating

mechanism. **

3

/

Hose Fitting: " (10mm)

8

Fastener Specifications:

Drive full round-head framing nails, ranging from 2"

3½" in length (50 - 90 mm)

3

3

/

2

(GD21)

2¼

/

2

8

8

(GD24)

2½

(KD25)

2½

(GD25)

3

(MD27)

3

(HD27)

3

(KD27)

3¼

(HD28)

3¼

(KD28)

3½

(KD29)

3½

(ND29)

2

(GL21)

3

3

/

/

2

2 32 2¼ 2 2½ 2½ 3 3 3 3¼ 3¼ 3½ 3½ 2

8

8

(GL24)

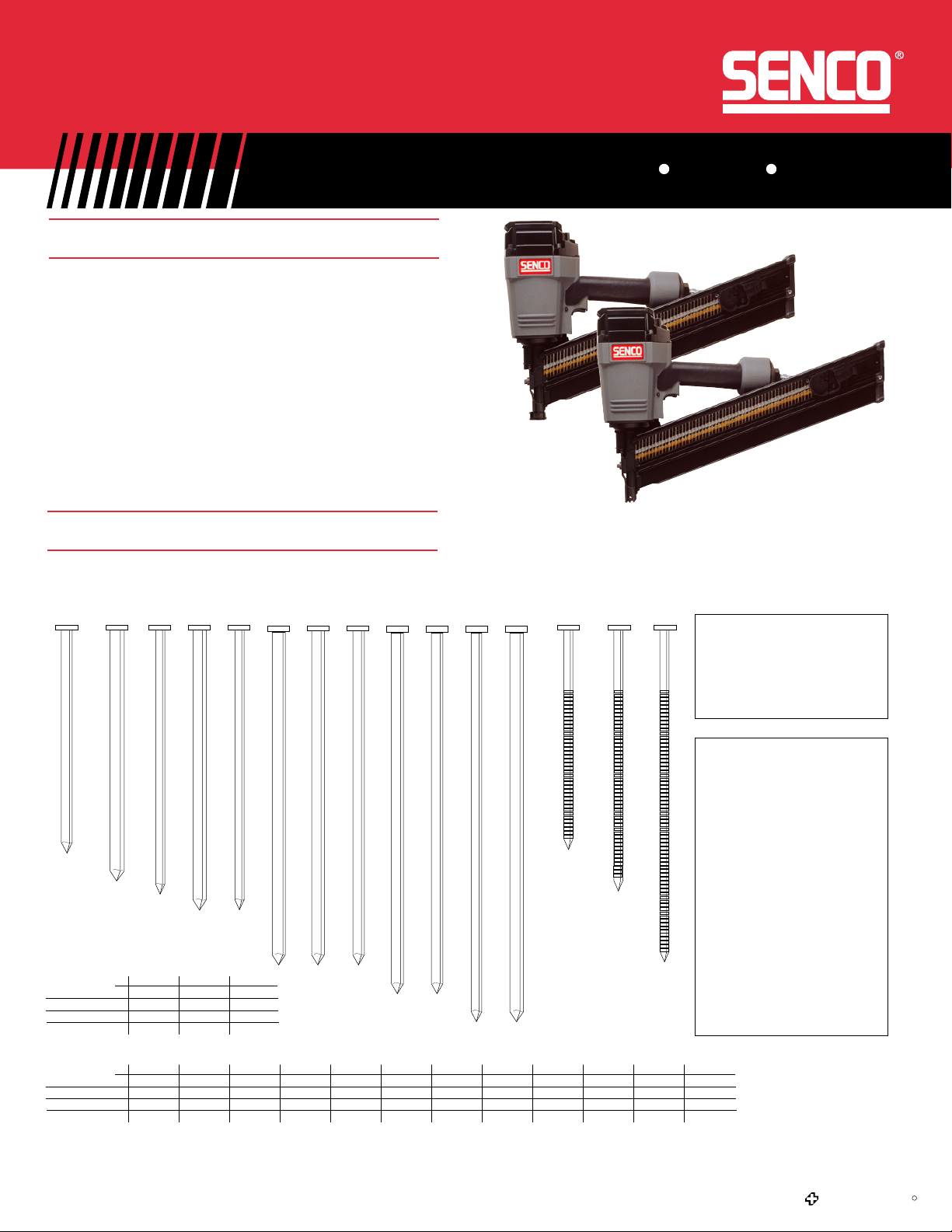

SN65/65C

3

SECNO round head nails are designed to

provide maximum fastening performance in

partnership with the SN60, SN65, and

SN65C. These quality nails are made to

specs that meet codes and industry or

manufacturer requirements. Check your

SENCO rep or Authorized Dealer regarding

(HL27)

availability of galvanized and Bright Basic

nails.

SN60

(MD23) 10d short

.113

.148

.113

.113

.113

Ring Shank

Lengths

Shank

Reorder Number

Nails/Strip

Inches

Millimeters

2" 2"2 "

50

.113**

GL21APBS GL24APBS HL27AABS

28 28 28

3

/

8

60 75

.113** .120**

Smooth Shank

Lengths

Shank

Reorder Number

Nails/Strip

Note: The 2" GD21APBS smooth shank is for the SN60 and SN65 only.

The 3" MD27APBS and the 3½" ND29APBS smooth shank is for the SN65C only.

The 2" GL21APBS ring shank is for the SN60 only.

For additional information on how Senco fastening systems will save you time, reduce costs, and increase quality, call your nearest Authorized Senco Dealer or Distributor listed in the Yellow Pages under

“Staples,” or call our toll-free Action Line: 1-800-543-4596.

©1998 by Senco Products, Inc. Order MK322 (10AMP798) Litho in U.S.A. Visit our website at www.senco.com

Inches

Millimeters

2" 2 "

50

.113**

GD21APBS MD23APBS GD24APBS

28 28 28

2¼ 2½" 2½" 3" 3" 3" 3¼" 3¼"

55 60 65

.148** .113**

.148

.120

3

/

8

.113**

GD25APBS KD25APBS HD27APBS

28 28 28

65 75 75

.113* .120**

.131

.120

.131

.131

.162

**Dimensions shown may be converted to metric on basis of 1" = 25.40 millimeters (mm) rounded to the nearest 5 mm.

.131**

KD27APBS MD27APBS HD28APBS

28 28 28

75 85 85

.148** .120**

.113

.113

.131**

KD28APBS KD29APBS ND29APBS

.131** .162**

28 28 28

* “Restrictive Trigger” activated tools are

used for applications where precision nail or

staple placement is desired. You must first

depress the safety element where you want to

drive a nail or staple and then pull the trigger.

After each nail or staple is driven, completely

release the trigger and lift the tool off the work

surface.

“Dual Action” activated tools are used for

applications where high-production work is

desired. There are two modes of operation:

1. Bottom Fire Method: This method of

operation is sometimes called bounce firing.

You must keep the trigger pulled while moving

the tool along the work surface with a

bouncing motion, depressing the

safety element where you want to drive a nail

or staple.

2. Trigger Fire Method: First depress the

safety element where you want to drive a nail

or staple and then pull the trigger.

.120

For instructions on safe use of tools with

either of these activating mechanisms, please

refer to the Operating Instructions or

Customer Satisfaction and Safety Reminder

contained in your tool carton.

3½"

90 90

3½"

Safety First. The only way to work.

R

Loading...

Loading...