Page 1

Parani-ESD100/110/200/210

User Guide

Version 1.0.0

2006-08-14

1

Page 2

User Guide for the Parani-ESD100/110/200/210

Version 1.0.0

Firmware version 1.0.X

Last revised on June 14, 2006

Printed in Korea

Copyright

Copyright 2002, Sena Technologies, Inc. All rights reserved.

Sena Technologies reserves the right to make changes and improvements to its product without

providing notice.

Trademark

Parani™ is a trademark of Sena Technologies, Inc.

Windows® is a registered trademark of Microsoft Corporation.

Ethernet® is a registered trademark of XEROX Corporation.

Notice to Users

When a system failure may cause serious consequences, protecting life and property against such

consequences with a backup system or safety device is essential. The user agrees that protection

against consequences resulting from system failure is the user's responsibility.

This device is not approved for life-support or medical systems.

Changes or modifications to this device not explicitly approved by Sena Technologies will void the

user's authority to operate this device.

Precautions and Safety

Electricity

Use only the supplie d AC a dapter . Use of un author ize d power ad apter is no t reco mm ended. Electr ica l

shock may result.

Do not kink or cr ease the po wer cab le or plac e he avy obj ects on th e po wer cab le. Fire c an resu lt fr om

damaged power cables.

Do not handle power plug and adapter with wet hands. Electrical shock may result.

Immediately power of f the pr oduct and u nplug the AC adapter if s m oke or odor s em it from the product

and adapter. Fire can result from improper use.

Immediately power off the produc t an d unp lu g the A C adap ter if water or other l iquids ar e pres e nt. Fire

can result from improper use.

Product

Parani-ESD meets th e RS-232 standards. Do not wire with non-standard produ cts. Damage to your

products may result from improper use.

Do not drop or subject the device to impact. Damage to your products may result from improper use.

Keep away from harsh environments including humid, dusty, and smoky areas. Damage to your

products may result from improper use.

Do not use excessive force on the buttons or attempt to disassemble the device. Damage to your

products may result from improper use.

Do not place heavy objects on the product. Damage to your products may result from improper use.

Technical Support

Sena Technologies, Inc.

210 Yangjae-dong, Seocho - gu

Seoul 137-130, Korea

Tel: (+82-2) 573-5422

Fax: (+82-2) 573-7710

E-Mail: support@sena.com

Website: http://www.sena.com

2

Page 3

Contents

1. Introduction 6

1.1. Overview ...................................................................................................................................6

1.2. Package Check List ...................................................................................................................6

1.3. Product Specification..................................................................................................................7

2. Getting Started 8

2.1. Panel Layout ..............................................................................................................................8

2.2. Connecting the Hardware ..........................................................................................................8

2.2.1. Connecting Parani-ESD to Jig Board ..............................................................................9

2.2.2. Connecting Power to Jig Board .......................................................................................9

2.2.3. Connecting a Device to Jig Board .................................................................................10

3. Configuration 11

3.1. Operation Modes......................................................................................................................11

3.2. Serial Ports...............................................................................................................................12

3.2.1. Data Bit ..........................................................................................................................12

3.2.2. Hardware Flow Control ..................................................................................................12

3.2.3. Software and Utility........................................................................................................12

3.2.4. ParaniWIN......................................................................................................................13

3.2.5. ParaniUpdater................................................................................................................19

3.2.6. Terminal Program ..........................................................................................................19

4. Approval Information 21

4.1. FCC .................................................................................................................................21

4.1.1. FCC Compliance Statement..........................................................................................21

4.1.2. RF Exposure Statement .................................................................................................21

4.1.3. Do not.............................................................................................................................21

4.2. CE .................................................................................................................................21

4.2.1. EC-R&TTE Directive......................................................................................................21

5. RF Information 22

5.1. Radio Frequency Range..........................................................................................................22

5.2. Number of Frequency Channel................................................................................................22

5.3. Transmission Method...............................................................................................................22

5.4. Modulation Method...................................................................................................................22

5.5. Radio Output Power.................................................................................................................22

5.6. Receiving Sensitivity ................................................................................................................22

5.7. Power Supply...........................................................................................................................23

Appendix A: Connections 24

A.1. Pin Assignment........................................................................................................................24

A.1.1. Parani-ESD100/110.......................................................................................................24

A.1.2. Parani-ESD200/210.......................................................................................................25

A.1.3. DCD Signal....................................................................................................................25

A.1.4. RST Signal.....................................................................................................................26

A.1.5. Pairing Signal (only for Parani-ESD100/110)................................................................26

A.2. Connection Diagram................................................................................................................27

A.2.1. Parani-ESD100/110.......................................................................................................27

A.2.2. Parani-ESD200/210.......................................................................................................29

Appendix B: AT Commands 31

B.1. Terminology..............................................................................................................................31

B.1.1. AT Command.................................................................................................................31

B.1.1. AT Response .................................................................................................................31

B.1.2. Operation Mode.............................................................................................................31

B.1.3. Operation Status............................................................................................................31

B.1.4. Security..........................................................................................................................31

B.1.5. Symbols.........................................................................................................................32

B.2. Command Category.................................................................................................................32

B.3. Command Description .............................................................................................................33

3

Page 4

B.3.1. ATZ ..............................................................................................................................33

B.3.2. AT&F ............................................................................................................................33

B.3.3. AT .................................................................................................................................33

B.3.4. AT+UARTCONFIG ,Baudrate,Parity ,S topbit,Hwfc ........................................................33

B.3.5. AT+USEDIP? ...............................................................................................................34

B.3.6. AT+BTINFO? ...............................................................................................................34

B.3.7. AT+BTINQ? ..................................................................................................................34

B.3.8. AT+BTLAST? ...............................................................................................................34

B.3.9. AT+BTVER? ................................................................................................................35

B.3.10. AT+BTRSSI,n ............................................................................................................35

B.3.11. AT+BTMODE,n ..........................................................................................................35

B.3.12. +++ .............................................................................................................................35

B.3.13. AT+SETESC,nn .........................................................................................................36

B.3.14. ATO ............................................................................................................................36

B.3.15. AT+BTCANCEL .........................................................................................................36

B.3.16. AT+BTSCAN ..............................................................................................................36

B.3.17. AT+BTSCAN,n,to .......................................................................................................37

B.3.18. AT+BTSCAN1 12233445566,to ..................................................................................37

B.3.19. ATD ............................................................................................................................37

B.3.20. ATD1 12233445566 ....................................................................................................38

B.3.21. ATH ............................................................................................................................38

B.3.22. AT+BTKEY=$string ....................................................................................................38

B.3.23. AT+BTSD? ................................................................................................................39

B.3.24. AT+BTCSD ................................................................................................................39

B.3.25. AT+BTFP,n

B.3.26. AT+BTSEC,Authentication,Encryption ......................................................................39

B.3.27. AT+BTNAME=$string ................................................................................................39

B.3.28. AT+BTLPM,n .............................................................................................................40

B.3.29. AT+DFU .....................................................................................................................40

B.3.30. AT&V ..........................................................................................................................40

B.3.31. ATSnn? .....................................................................................................................40

B.3.32. ATSnn=mm ................................................................................................................41

B.4. Command Validity....................................................................................................................41

.................................................................................................................39

Appendix C: S-Register 43

C.1. S1: Force to Reconnect (default 1)..........................................................................................43

C.2. S2: Enable Hardware Flow Control (default 1)........................................................................43

C.3. S3: Stream UART Policy (default 0)........................................................................................43

C.4. S4: Enable Remote Name Query (default 1)...........................................................................43

C.5. S6: Enable Low Power Mode (default 0).................................................................................44

C.6. S10: Enable SD Response (default 1) ....................................................................................44

C.7. S11: Enable Escape (default 1)...............................................................................................44

C.8. S12: Clear Data Buffer When Disconnected (default 0)..........................................................44

C.9. S14: Enable DTR Transfer (default 1) .....................................................................................44

C.10. S15: Enable Disconn ect by DTR (default 0)..........................................................................44

C.11. S22: Fast Connect (default 0)................................................................................................44

C.12. S24: Maximum Number of Inquiry Result (default 10) ..........................................................45

C.13. S28: Escape Sequence Character (default 43).....................................................................45

C.14. S31: Page Timeout (default 300)...........................................................................................45

C.15. S33: Inquiry Timeout (default 30) ..........................................................................................45

C.16. S37: Supervision Timeout (default 16000)............................................................................45

C.17. S46: BD Address of Last Connected Device.........................................................................45

Appendix D: Trouble Shooting 46

D.1 No Data Transmission ..............................................................................................................46

D.1.1 COM Port Settings .........................................................................................................46

D.2 Data Loss or Malfunctioning.....................................................................................................46

D.2.1Hardware Flow Control....................................................................................................46

4

Page 5

D.2.2 SD Response .................................................................................................................46

D.3 Transmission Delay ..................................................................................................................47

D.3.1 RF Processing Delay......................................................................................................47

D.3.2 RF Transmission Environment.......................................................................................47

Appendix E: How make a RS232 interface Jig Board 48

5

Page 6

1. Introduction

1.1. Overview

Parani-ESD is a m odule device f or wireless serial com munication us ing the Bluet ooth technolo gy that

is international standard of short range wireless communications. Parani-ESD accomplishes more

reliable wireless comm unication. As P arani-ESD c an comm unicate with oth er Blueto oth devices, user

may construct various communications with it.

Parani-ESD provides several models with different communication ranges from 30m (ParaniESD200/210) up to 100m (Parani-ESD100/110) for user’s various applications. In terms of noise,

Parani-ESD delivers better quality of communication than standard RS232 cables.

Parani-ESD has the m ost compact design of the sam e kind devices and can be placed convenientl y

into any devices or e qui pm ents. Its d etacha bl e a nte nn a of v ar iety optimizes the q ual ity and distance of

wireless communications.

Parani-ESD can be configured and controlled by typical AT commands. User can easily configure

Parani-ESD on the terminal program such as HyperTerminal and implements the wireless

communication without modifying user’s existing serial communication program. In addition to the

basic AT commands, Parani-ESD provides som e expanded AT comm ands for its various functions.

User friendly ParaniWizard and ParaniWIN are also provided for easy setup on Microsoft Windows.

The FHSS (Frequenc y Hopping Spread Spectrum) techniq ue of Bluetooth lets Parani-ESD h ave less

radio interference and no danger of hack ing in air. Parani-ESD also supports aut hentication an d data

encryption.

1.2. Package Check List

- Parani-ESD100/110/200/210

- A hardcopy of

- CD-ROM including the HelloDevice Manager and User Guide

Quick Start Guide

6

Page 7

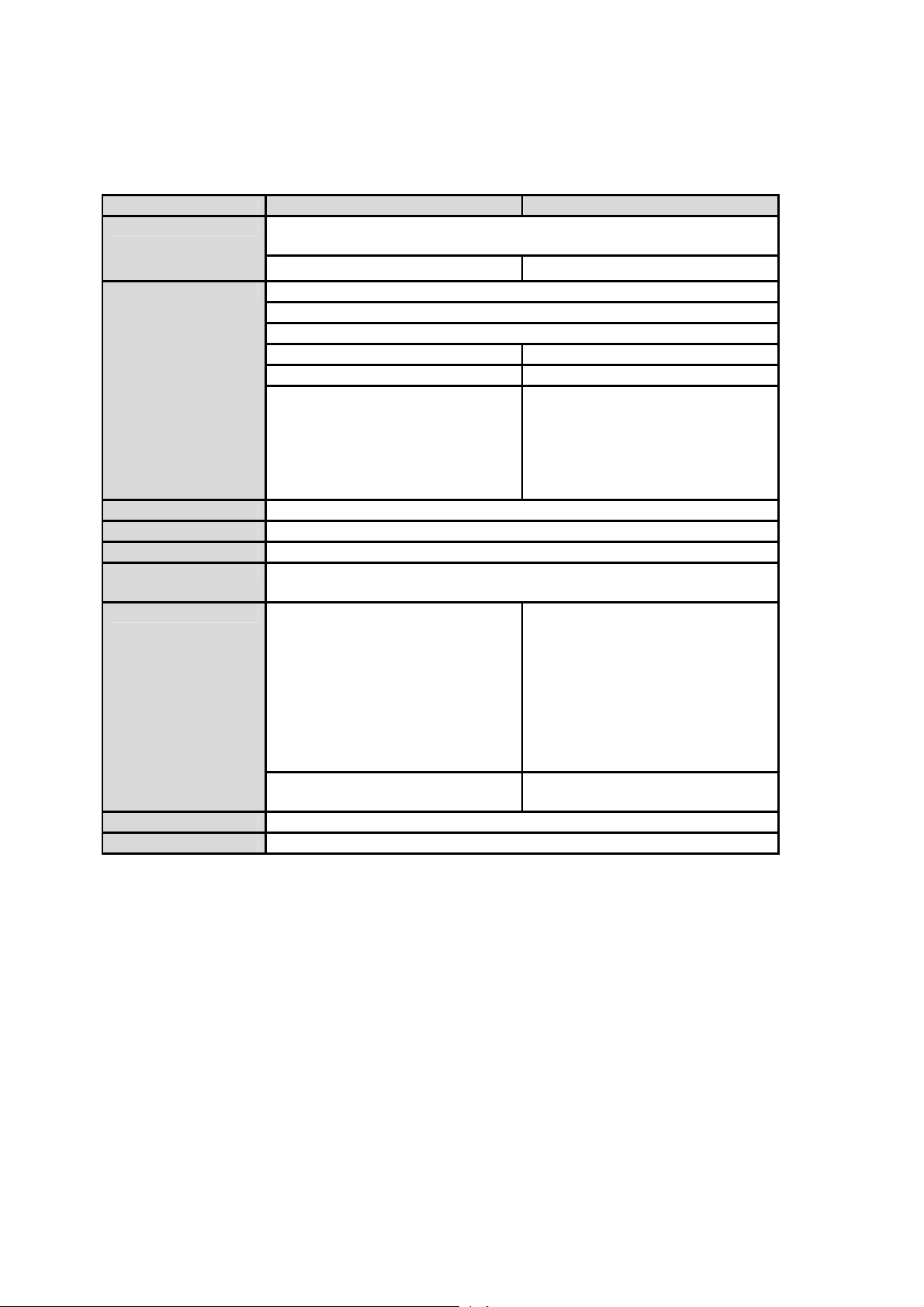

1.3. Product Specification

ESD100/110 ESD200/210

Serial Interface

Bluetooth Interface

Serial speeds 1200bps to 230400bps

Flow Control: None, Hardware RTS/CTS

2.54mm Header 2X6 2.54mm Header 1X4X2

Bluetooth v1.2

Protocol: RFCOMM, L2CAP, SDP

Profile: General Acc es s Profile, Ser i al Por t Pr of il e

Class 1 Class 2

Level: 18dBm Level: 2dBm

ESD100-Working distance:

Nominal 100m

ESD110-Working distance:

Up to 100m

ESD210-Working distance:

Nominal 30m

ESD210-Working distance:

Up to 30m

Configuration

Firmware Update

Power

Environmental

Physical properties

Approvals

Warranty

ParaniWIN, ParaniWizard, Modem AT command set

ParaniUpdater for SD&ESD

Supply voltage: DC3.3V

Operating temperature: -20 ~ 70

Humidity : 95% (Non-condensing)

Dimension

- ESD100

27.5 mm L (1.08 in.)

27.7 mm W (1.09 in.)

14.0 mm H (0.55 in.)

- ESD110

27.5 mm L (1.08 in.)

30.0 mm W (1.18 in.)

14.0 mm H (0.55 in.)

Weight

5 g

FCC, MIC

1-year limited warrant y

o

C

Dimension

- ESD200

- ESD210

Weight

18.0 mm L (0.7 in.)

20.0 mm W (0.78 in.)

11.7 mm H (0.47 in.)

18.0 mm L (0.7 in.)

20.0 mm W (0.78 in.)

11.7 mm H (0.47 in.)

2 g

7

Page 8

2. Getting Started

This chapter describes how to set up the Parani-ESD Series for the first time.

- 2.1 Panel Layout explains the panel layout.

- 2.2 Conn ecting the Hardware descr ibes how to connect the Paran i-ESD Series, the power, a nd the

serial device to the Jig Board.

Following items are pre-required to get started.

- One Jig Board (included in the Starter Kit package).

- One DC power adapter or one USB power cable (included in the Starter Kit package).

- One serial console cable for configuration (included in the Starter Kit package).

- One PC with RS232 serial port.

- Terminal emulation program running on the PC

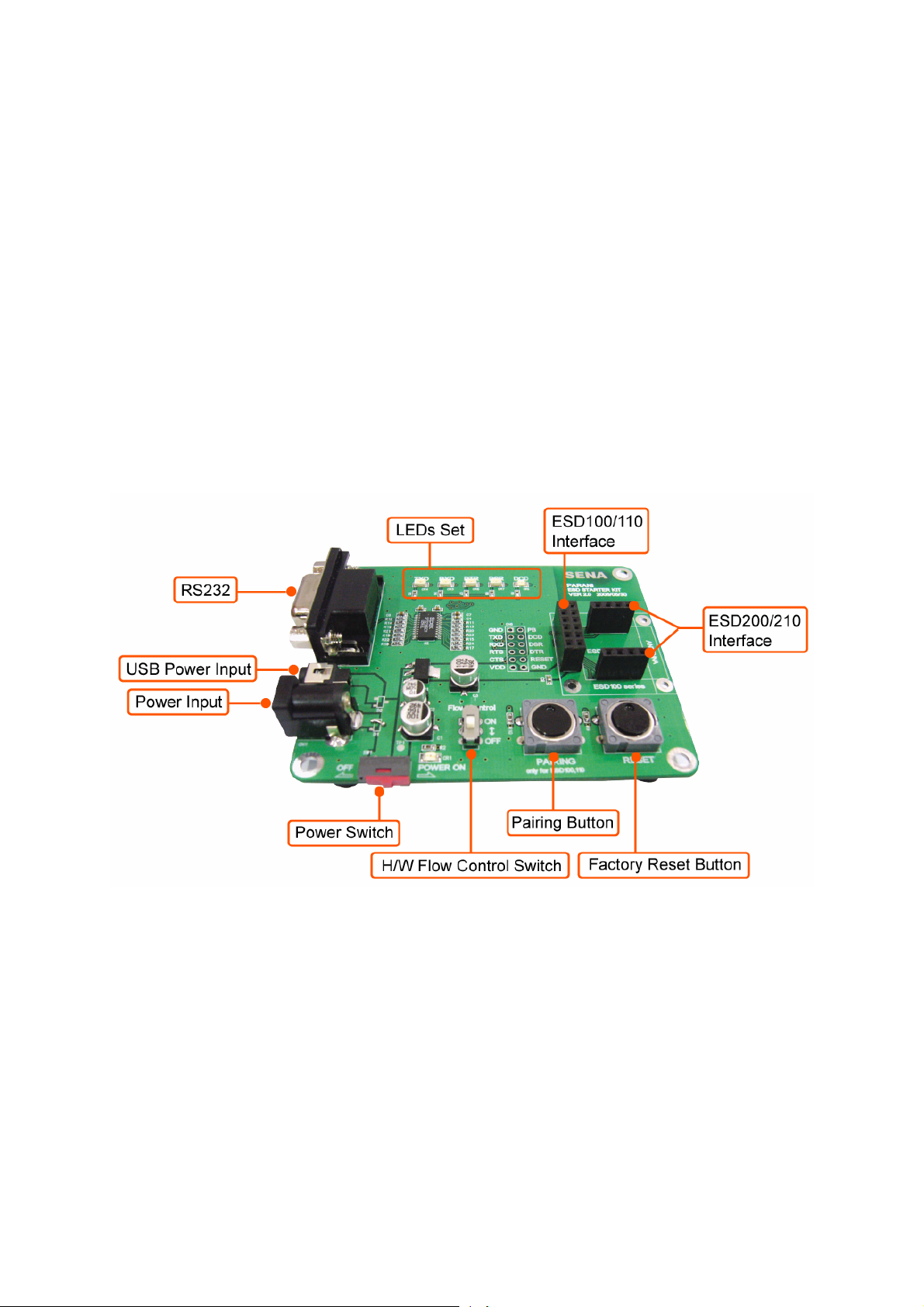

2.1. Panel Layout

This section describes the panel layout of the Jig Board.

Figure 2-1 The panel layout of Jig Board

2.2. Connecting the Hardware

This section descr ibes how to connect the Par ani-ESD Series to the Jig Boar d and the Jig Board to

the serial device for initial testing.

- Connect the Parani-ESD Series to Jig Board.

- Connect a power source to Jig Board for the Parani-ESD Series.

- Connect Jig Board for the Parani-ESD Series to a serial device.

8

Page 9

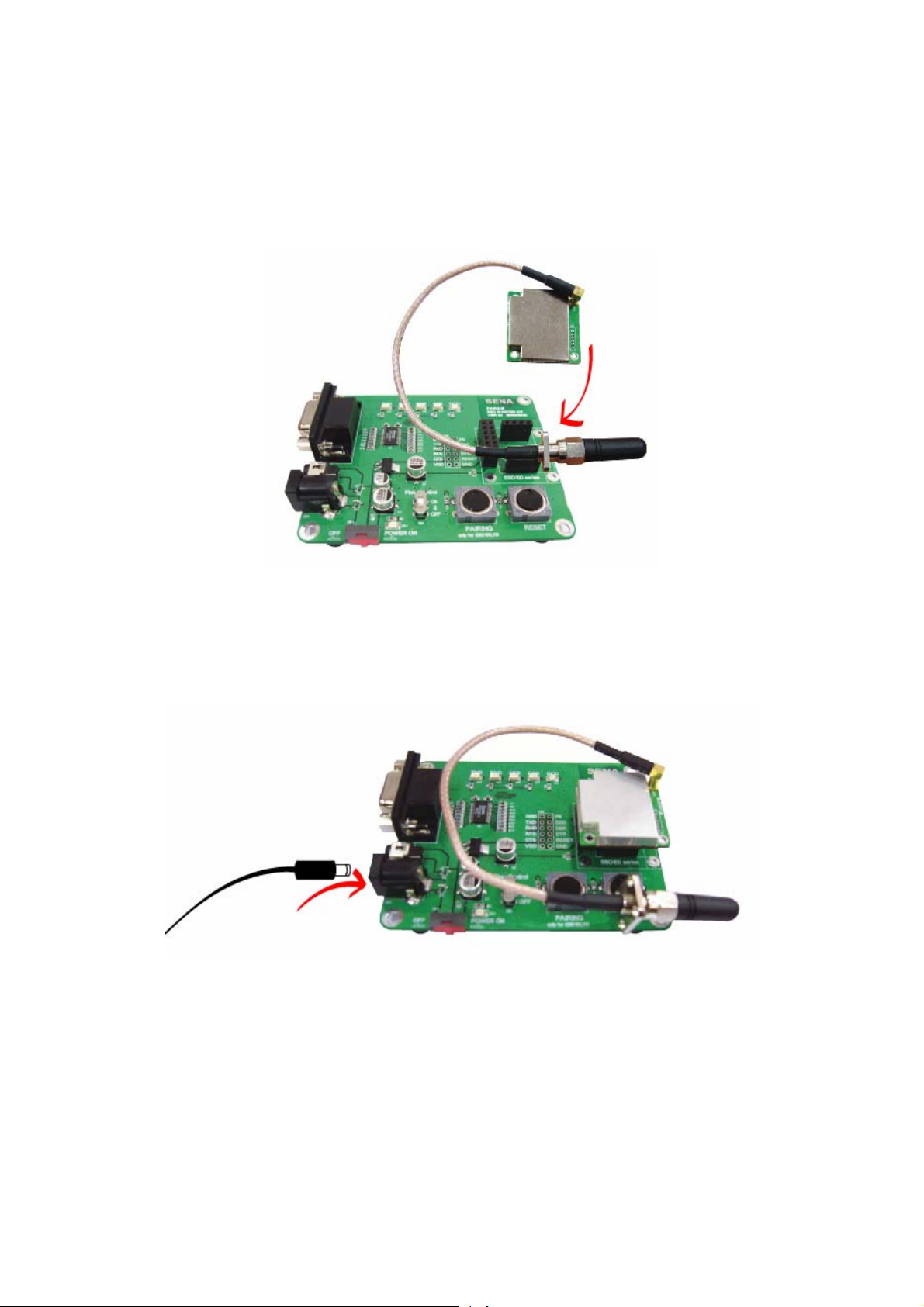

2.2.1. Connecting Parani-ESD to Jig Board

Connect the Parani-ESD Series to the Jig Board as shown below.

Figure 2-2 Connecting Parani-ESD to Jig Board

2.2.2. Connecting Power to Jig Board

Connect the power jac k to the power c onnector of the Jig Board for the Parani-ESD Ser ies using the

DC power adapter or USB power cable that is included in the package.

Figure 2-3 Connecting Power to Jig Board

9

Page 10

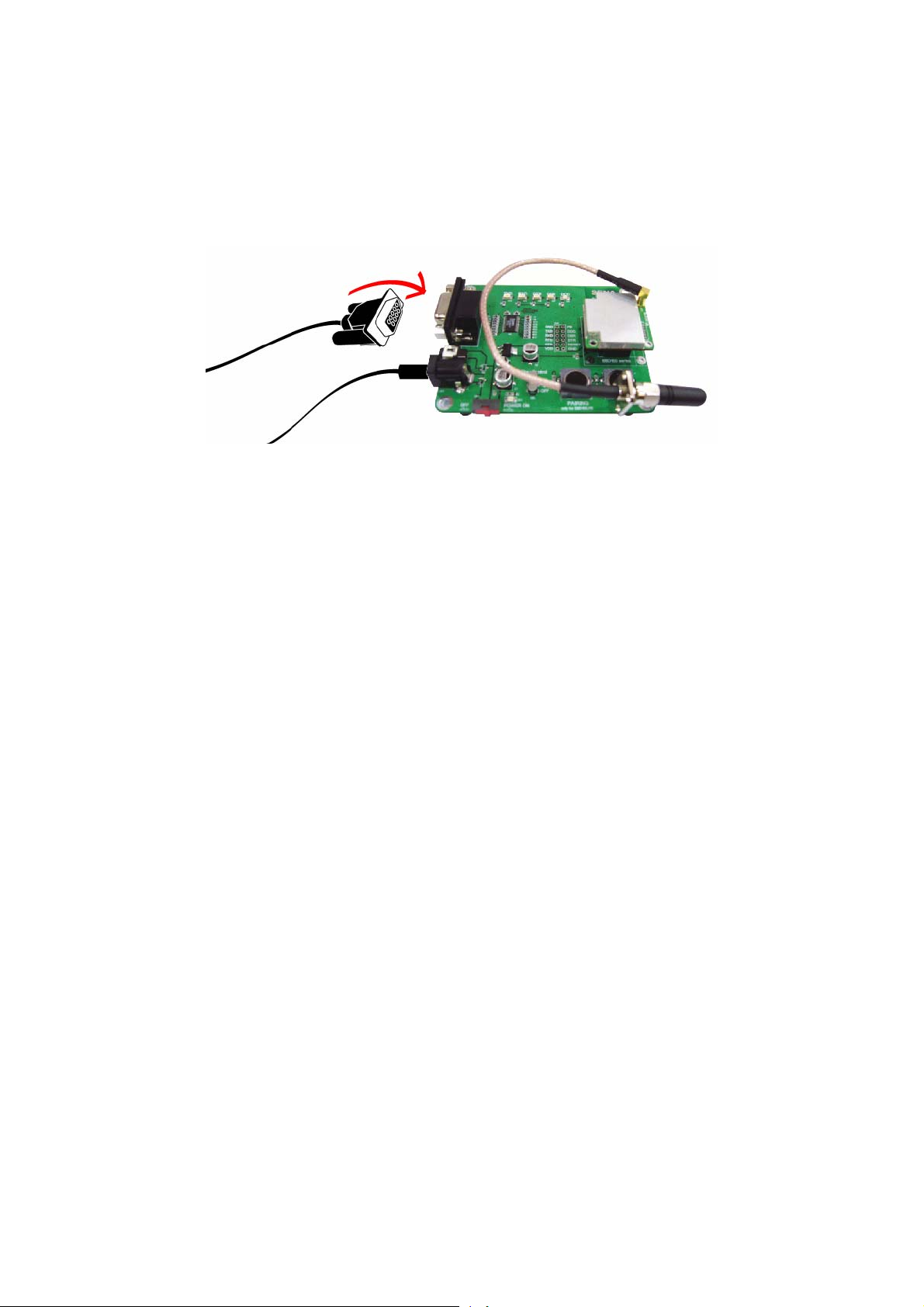

2.2.3. Connecting a Device to Jig Board

Connect the serial data c able between the Jig Board and the serial device. If neces sary, s upply the

power to the serial device attached to the Jig Board.

Figure 2-4 Connecting a Device to Jig Board

10

Page 11

3. Configuration

3.1. Operation Modes

In addition to the s erial port configuratio ns such as bit/second, data b it, parity, stop bit, flow co ntrol,

Parani-ESD has some configurations for Bluetooth. For getting the most out of Parani-ESD, user

should understand the following Bluetooth connection schemes.

A Bluetooth device can play a role as a master or slave. Master tries to connect itself to other

Bluetooth device, and slave is waiting to be connected from other Bluetooth devices. A Bluetooth

connection is al ways made b y a pair of m aster and sl ave. A slave can be in t wo modes , Inquiry Scan

or Page Scan m ode. Inquiry Sc an mode is waiting the pack et of inquir y from other Bluet ooth devices

and Page Scan mode is waiting the packet of connection from other Bluetooth devices. Every

Bluetooth device h as its uni que ad dress , calle d BD ( Bl uetooth Device) ad dress , whic h is com posed of

12 hexa-decimal numbers.

Parani-ESD has 4 oper ation modes as follows. Eac h mode can be identified with LED indicators as

illustrated in next section.

Table 3-1 The Parani-ESD Operati on Mod es

Mode Description

Mode0

Mode1

Mode2

Mode3

Parani-ESD must be in Mode0, when it is directly controlled by AT commands.

In this mode, there is no response when power on or software reset, and Parani-ESD is just

waiting for AT command input. Neither master nor slave is assigned to Parani-ESD in mode0.

User can change the configurations of Parani-ESD in this mode.

The factory default is set to Mode0.

Parani-ESD tries to connect the last connected Bluetooth device.

Parani-ESD in Mode1 is to be a master and tries to connect the last connected Bluetooth

device. Parani-ESD always stores the BD address of the Bluetooth device to which ParaniESD has connected last time. When Parani-ESD is initially used or after hardware reset, there

is no BD address stored in Parani-ESD. In this case, Mode1 does not make any sense and

mode change from other operation modes to Mode1 is not allowed. The mode change to

Mode1 can be made after Parani-ESD succeeds to connect to other Bluetooth device in

Mode0. Once changed to Mode1, Parani-ESD will try to connect automatically the last

connected Bluetooth device whenever power on or software reset.

Parani-ESD in Mode1 cannot be discovered or connected by other Bluetooth devices.

Parani-ESD is waiting for the connection from the last connected Bluetooth device.

Parani-ESD in Mode2 is to be a slave and waiting for the connection only from the last

connected Bluetooth device. Just like Mode1, if there is no BD address stored in Parani-ESD,

the mode change from other operation modes to Mode2 is not allowed. Once changed to

Mode2, Parani-ESD will wait for the connection from the last connected Bluetooth device

whenever power on or software reset.

Parani-ESD in Mode2 cannot be discovered or connected to Bluetooth devices other than the

last connected device.

Parani-ESD is waiting for the connection from any other Bluetooth devices.

Parani-ESD in Mode3 acts like in Mode2, but allows any connection from other Bluetooth

device. Most of general Bluetooth device is set to Mode3.

Parani-ESD in Mode3 can be discovered and connected from any other Bluetooth devices.

11

Page 12

3.2. Serial Ports

The applicable settings for serial ports are as follows.

Table 3-2 The Parani-ESD Seri al Por t Sett in gs

Serial Port Settings Values

Baud rate

Data bite

Parity

Stop bit

Hardware Flow Control

1200, 2400, 4800, 9600, 19200, 38200, 57600, 115200, 230400

8

No parity, Even parity, Odd parity

1, 2

Use, No Use

The values in box ar e the factory defaults. The flow contr ol setting is configurable only thro ugh dip

switch.

3.2.1. Data Bit

Parani-ESD supports only 8 data bit. In the case of 7 data bit, please contact the technical support.

3.2.2. Hardware Flow Control

Parani-ESD plugg ed into its host system transmits data from host to t he other side Bluetooth device.

These data is saved temporarily in the internal buffer of Parani-ESD and sent repeatedly until the

transmission is completed packet by packet. When the radio transmission condition is not good

enough to send data prom ptly, it can cause the transm ission dela y. If the host sends more data when

the buffer is full, buffer ove rflow will make Parani-E SD malfunction conseq uently. In order to prevent

this buffer overflow, Parani-ESD works as follows.

In case of using har dware flow control, Parani-ESD mak es RTS be ‘disable’ to stop receiv ing further

data from the host when the buffer becom es full. RTS will be ‘a ble’ to begin receiving data again f rom

the host when the buffer has some room for more data.

In case of not using hard ware flow control, Paran i-ESD clears the buffer to s ecure the room for next

data when the buffer becom es full. This means the l oss of data. As the transmiss ion data becomes

large, the possibility of data loss goes higher.

For large data transmission, use of hardware flow control is highly recommended.

3.2.3. Software and Utility

This configuration software and uti lity for firm ware update c omes with the product, wh ich also can be

downloaded from http://www.sena.com

Table 3-3 Configuration Software

Software Purpose Operating System

ParaniWIN Configuration MS Windows 98SE or Higher

ParaniWizard Pairing Configuration

ParaniUpdater Firmware Update MS Windows 98SE or Higher

12

Page 13

3.2.4. ParaniWIN

ParaniWIN is a program running on Microsoft Windows for the configuration of Parani-ESD. Install

ParaniWIN on your computer. Plug a Parani- ESD into the s erial port of the computer and turn on t he

power. Run ParaniWIN.

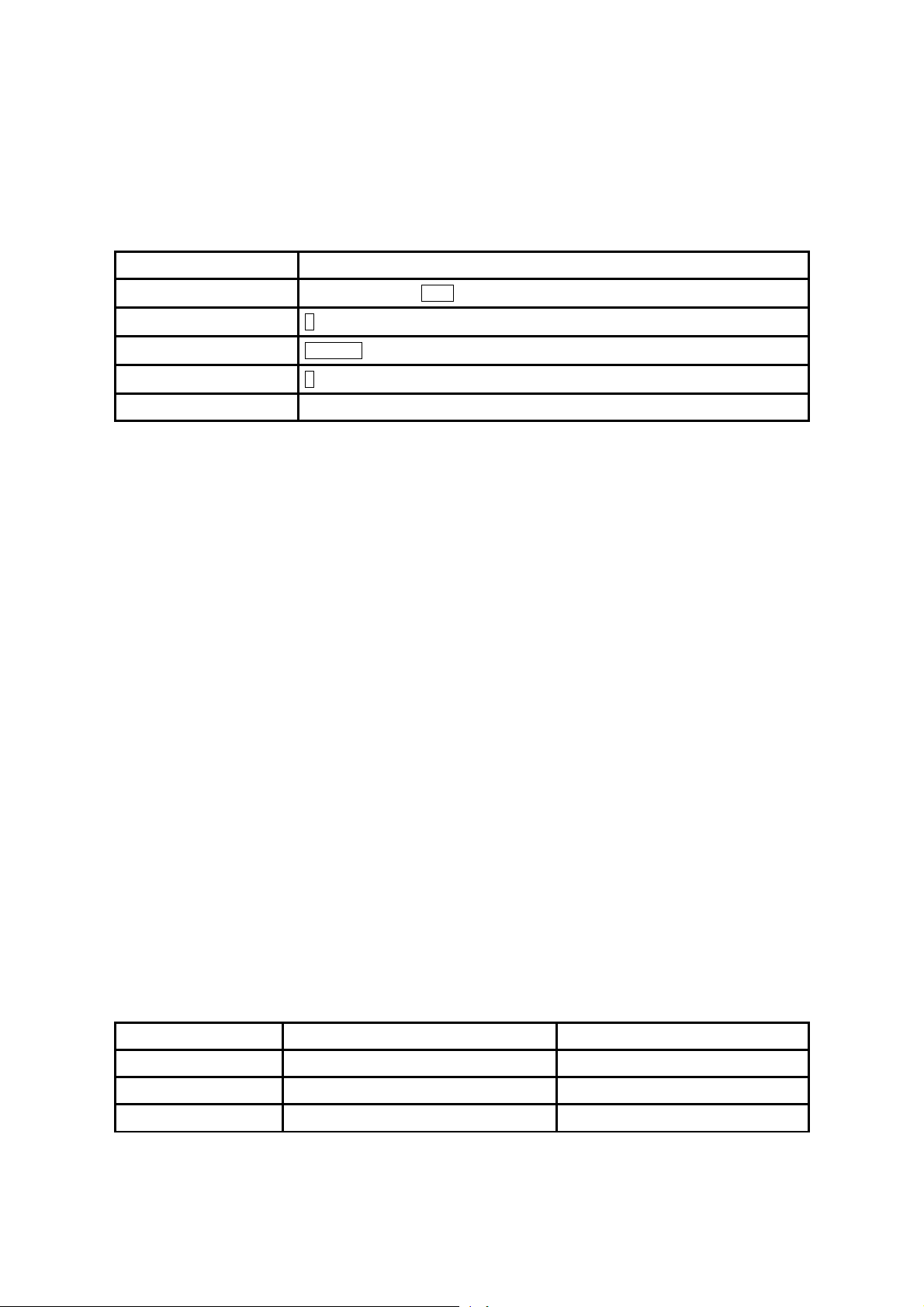

Figure 3-1 Serial Port Setting

Set each option properl y and click [Confirm]. If the settings are differ ent from the host c omputer, error

message will pop up. If the Parani-ESD is in t he status of connection, warning message will po p up.

Then the current connection can be cancelled by [Disconnect] button on the main window.

Figure 3-2 Error Message Box

13

Page 14

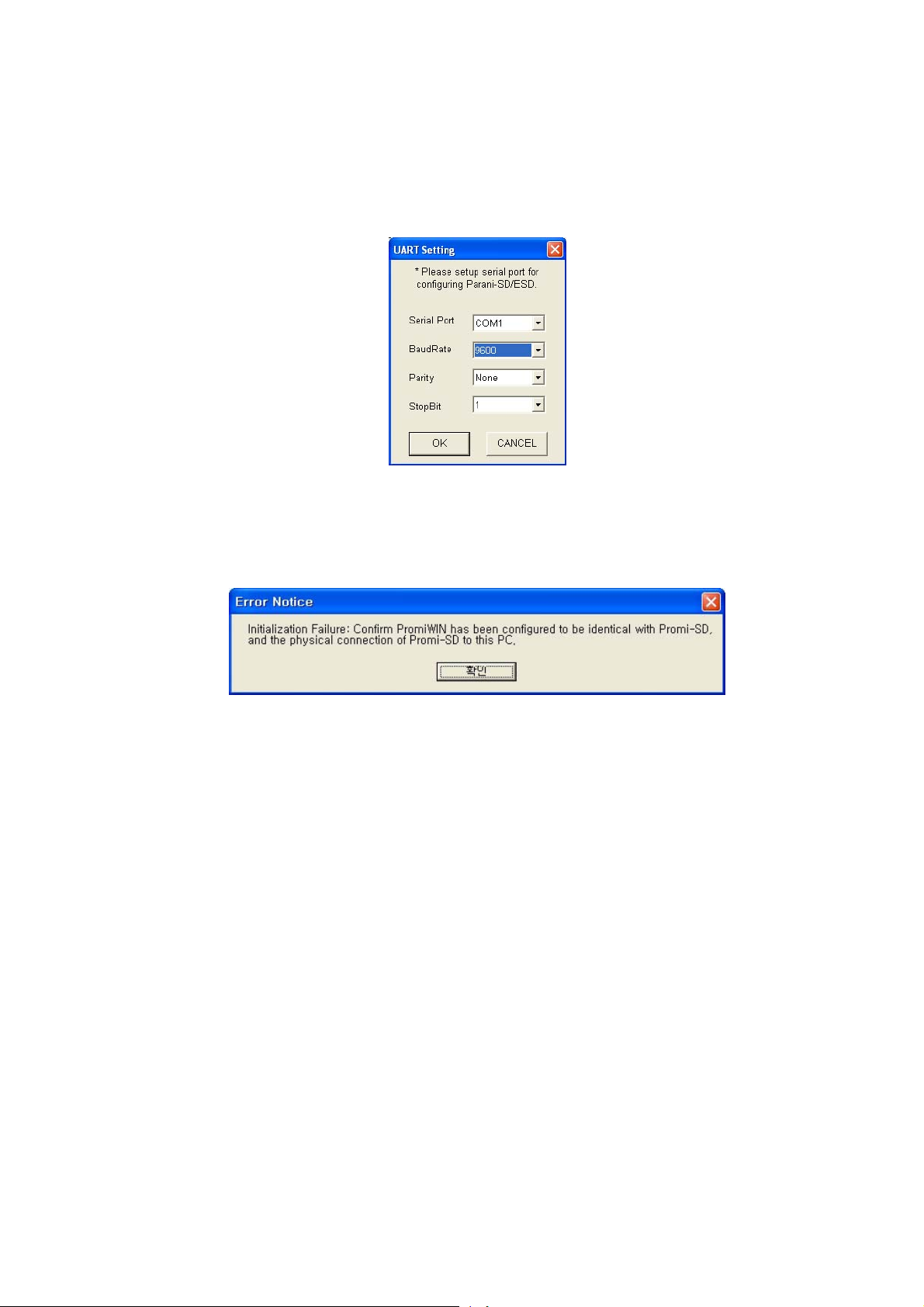

Figure 3-3 Main Window

14

Page 15

Figure 3-4 Information Window

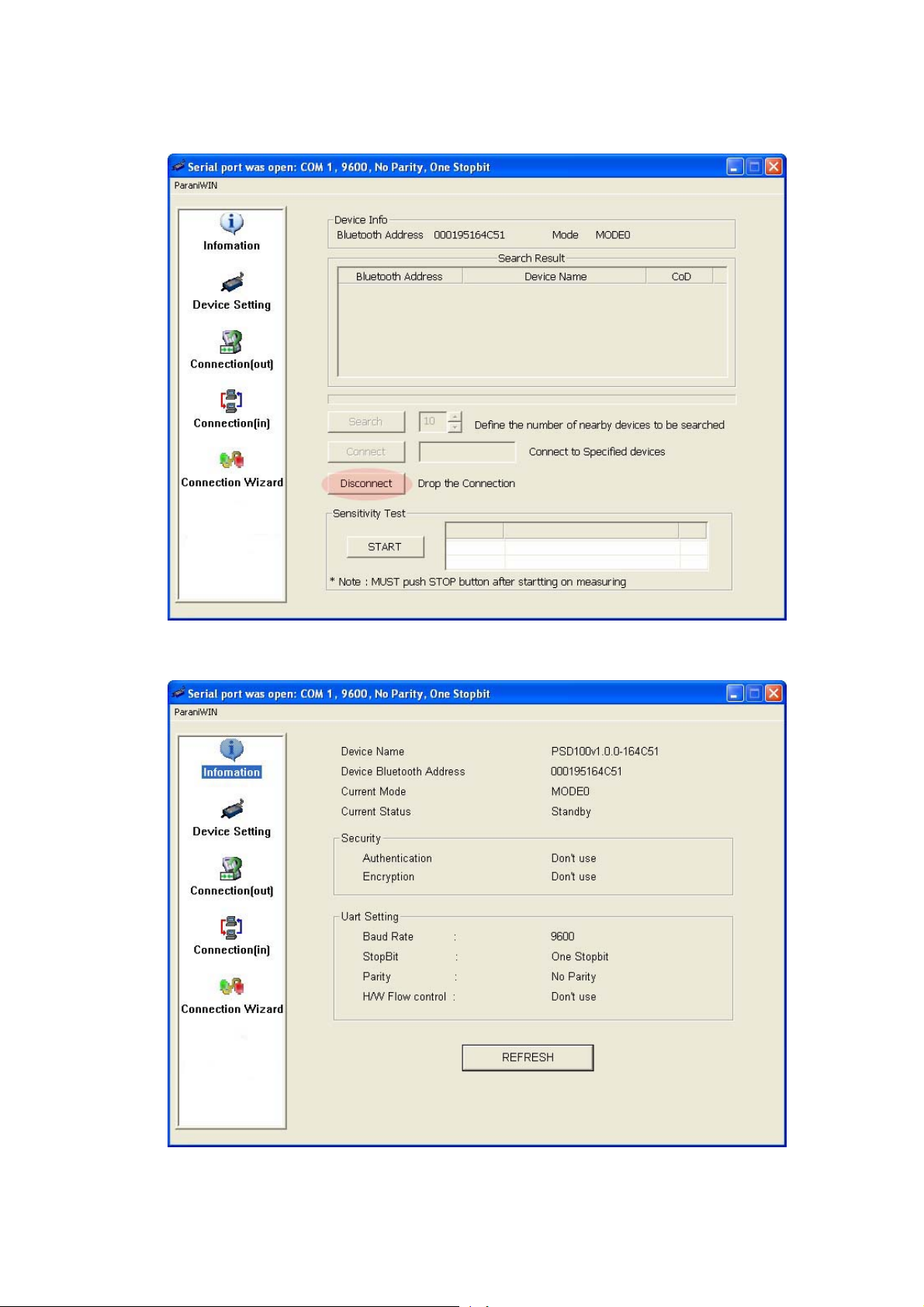

Serial port settings can be changed by <Start Configuration> and <ParaniWIN Configuration> of

ParaniWIN in the menu bar at upper left corner of the window without re-running the ParaniWIN

program.

Figure 3-5 Menu Bar at Upper Left corner of ParaniWIN

The icons in the left side window come to the corresponding windows.

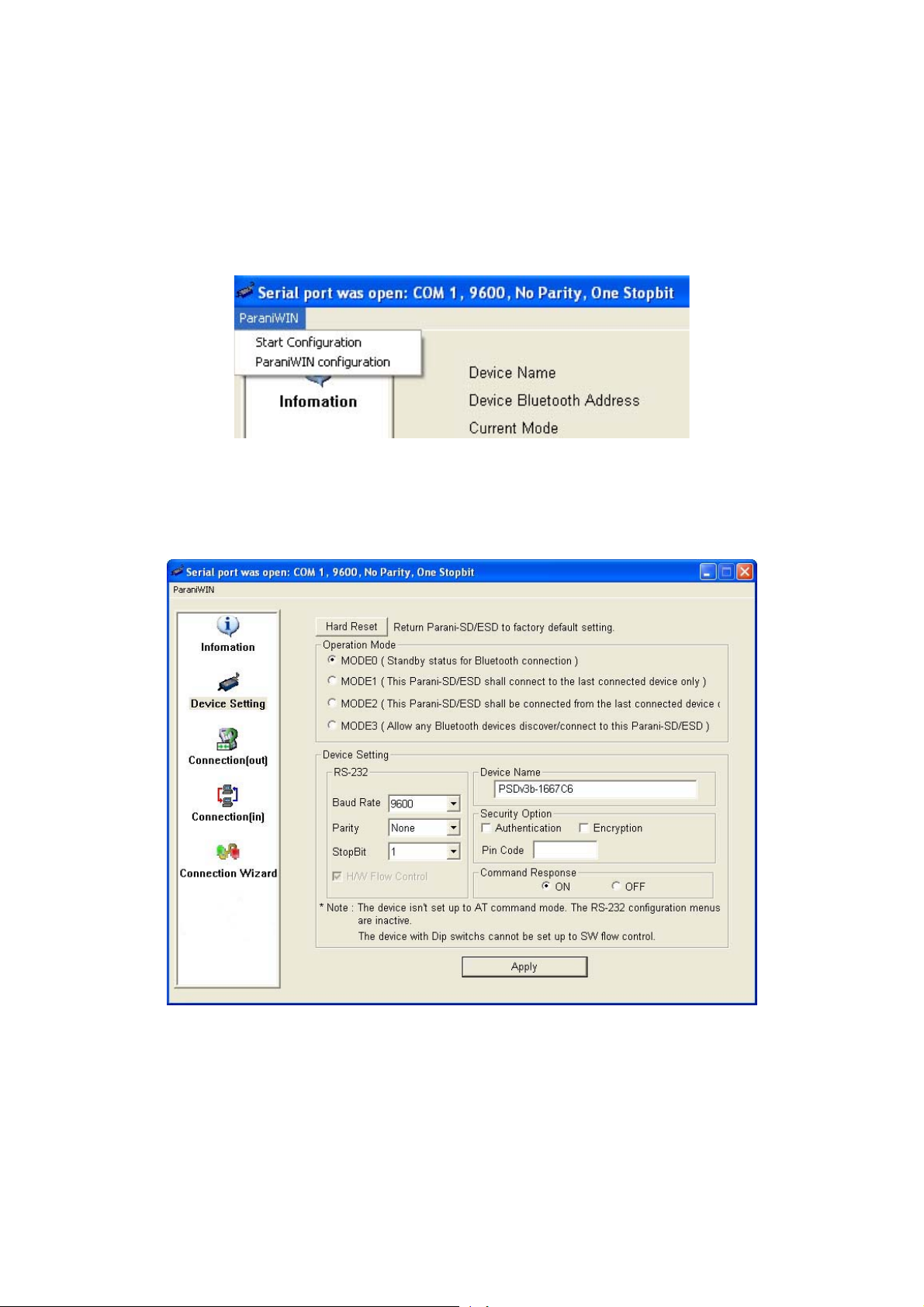

In device configurat ion window, hardware reset can be ex ecuted or operation m ode and RS232 can

be configured as well. Securit y option als o can be confi gur ed in this win do w.

Figure 3-6 Device Setting Window

Parani-ESD supports two security options, Authentication and Encryption. If you check the

Authentication op tion, you must also ent er the Pin Code valu e. If the authenticatio n is activated, the

connection, onl y between the Master and Slave dev ice that sh are the sam e Pin Code, is establish ed.

In case that Parani-ESD connects to other Bluetooth device that enables authentication, you must

know the other device’s Pin Code. In general Bluetooth devic es, 1234 or 0000 is used as a defaul t

15

Page 16

value. If you check Encryption option, the Parani-ESD encrypts packets and sends them. The

Encryption options works well in case that only one between Master and Slave uses this option.

Parani-ESD has 4 resp onse messages, ‘OK’, ‘ERROR’, ‘CO NNECT’, and ‘DISCONNECT’. In som e

cases, these responses can affect the host system unexpectedly. To prevent this, user can set the

Command response to ON or OFF.

Click [Apply] button to reflect the given options to Parani-ESD actually.

Connect(out) icon will show the following window to search and connect other Bluetooth devices.

Figure 3-7 Connect(out) Window

Click [Search] button to search nearby Bluetooth devices. The maximum number of devices to be

searched can be controlled. Select one of the devices searched and click [Connect] button. The

selected Bluetooth device must be in Page scan mode. Click [Disconnect] button to cancel the

connection normally.

After the connection is established, you are able to test sensitivity by pushing the START button.

16

Page 17

Figure 3-8 Sensitivity Tes t

The sensitivity test shows LInkQuality and RSSI values. The sensitivity is fine, If the LinkQuality is

closer to 255 and RSSI is c loser to 0. In general, the sensitivit y is the best when the distance is 10

meters. You can push the ST OP button in order t o terminate the sensiti vit y tes t. The sensitivity test will

continue until the STOP button is pushed. If you close the ParaniW IN Window without pushing th e

STOP button, you must restart Parani-ESD to terminate the test.

Connection(in) icon will sh ow the foll owing win dow to mak e Parani-ESD wait to a connec tion fr om the

other Bluetooth devic e. The waiting time in seconds can be controlled. With 0 input for this waiting

time, Parani-ESD keeps waiting for connection until [Cancel] button is clicked.

17

Page 18

Figure 3-9 Connection(in) Window

If the Connection Wizard icon is clicked, an easy pairing menu to use appears as follows:

Figure 3-10 Connection Wizard Wind ow

18

Page 19

This menu make easy pairing configuration of Parani-ESD. To use this menu, follow next steps.

Step 1. Connect the first ESD and then push the START button.

Step 2. Disconnect the f irs t ESD, c o nnect the second ESD an d t hen p us h t he Ne xt butt on after s etti ng

up Slave configuration.

Step 3. Disconnect the second ESD, once again connect the first ESD and then push the Finish

button. The pairing conf iguration finis hed. From no w, when the ESD restarts the pairing connect ion

will be established automatically.

3.2.5. ParaniUpdater

Parani-ESD support firmware update. You can download new firmwares of Parani-ESD at

http://www.sena.com

firmware image file and pushing Start button.

* Note: DO NOT power off Para ni-ESD while t he firmware update is progressing. It m ay damage the

firmware seriously.

. With ParaniUpdater, you can u pdate firmware of Parani-ESD by selecting the

Figure 3-11 ParaniUpdater Window

.

3.2.6. Terminal Program

A terminal program is an appl ication that will enable a PC to communicate dir ectly with a m odem. If

you are using Windo ws 98SE or higher versio n of Windows, HyperTerminal program as it is includ ed

as part of the operating system. Parani-ESD provides some extended AT commands for its

configurations on terminal program.

This manual will exp lain the method using Hyper Terminal. If you need to install HyperTerminal, click

start>setting>control pane l>add/remove pr ograms . For more precise information, ple ase refer to Hel p

of Microsoft Windows.

Attach Parani-ESD to serial port of host computer and power on.

19

Page 20

Launch HyperTerminal. It can be found in start >programs >accessories >communication

>HyperTerminal. Select the Serial port t hat Para ni-ESD will be connected to.

Input the same settings into Serial port configuration window as Parani-ESD settings.

The settings need to be set correctly, otherwise, err or message may be shown up on the screen or

cause malfunctioning of Parani-ESD.

Figure 3-12 HyperTreminal

Choose the settings in File->Properties->Settings->ASCII setup that let you turn echo on in

HyperTerminal; this will show the response Parani-ESD sends on the screen.

You now get the HyperTerminal window where you are able t o c ontrol Parani-ESD with AT commands.

For expanded AT commands that Parani-ESD provides, please refer to Appendix A. AT commands.

Example of AT commands:

AT+BTINFO?

000B53000509,PSDv3b-000509,MODE0,STANDBY,0,0,HWFC

OK

AT+BTINQ?

000B5320007E,PSDv2a-20007E,001F00

0004B300E205,AP2002:1 #0,020300

OK

ATD000B53000509

OK

CONNECT 000B53000509

20

Page 21

4. Approval Information

4.1. FCC

4.1.1. FCC Compliance Statement

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received,

Including interference that may cause undesired operation

Information to User

This equipment has been t ested and found to com ply with the l imits f or a Class B digital device,

Pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio Frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications.

However, there is no guarantee that interference wil l not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separat ion b etween the equipm ent a nd rec eiv er- Con nec t the eq ui pment into an

outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

4.1.2. RF Exposure Statement

The equipment complies with FCC RF radiation exposure limits set forth for an uncontrolled

environment. T his device and its ante nna must not be c o-located or operati on in conjunction with

any other antenna or transmitter.

4.1.3. Do not

Any changes or modifications to the equ ipment not expressl y appro v ed b y the par t y respo nsib le f or

compliance could void user’s authority to operate the equipment.

4.2. CE

4.2.1. EC-R&TTE Directive

EN 50385

EN 60950

EN 301 489-1/-17

EN 300 328

21

Page 22

5. RF Information

5.1. Radio Frequency Range

2.402~2.480GHz

5.2. Number of Frequency Channel

79 channels

5.3. Transmission Method

FHSS(Frequenc y Hopping Spread Spectrum)

5.4. Modulation Method

GFSK(Gaussian-filtered Frequency Shift Keying)

5.5. Radio Output Power

Products Radio Output Power

ESD100 +18dBm

ESD110 +18dBm

ESD200 +4dBm

ESD210 +4dBm

5.6. Receiving Sensitivity

Products Radio Output Power

ESD100 -88dBm

ESD110 -88dBm

ESD200 -80dBm

ESD210 -80dBm

22

Page 23

5.7. Power Supply

Products Radio Output Power

ESD100 DC3.3V

ESD110 DC3.3V

ESD200 DC3.3V

ESD210 DC3.3V

23

Page 24

Appendix A: Connections

A.1. Pin Assignment

A.1.1. Parani-ESD100/110

Figure A-1 Pin Assignment of Parani- ESD 10 0/1 10

Table A-1. Pin Assignment of Parani-ESD100/110

Pin # Signal Direction Description Signal Level

1

2

3

4

5

6

7

8

9

10

11

GND - Power Ground Ground

TxD Output UART Data Output TTL

RxD Input UART Data Input TTL

RTS Output UART Ready to Send TTL

CTS Input UART Clear to Send TTL

VDD Input DC Input (3.0~3.3V) Ground

Pairing Input Pairing Input TTL

Status Output Bluetooth Connect Detect (Active Low) TTL

DSR Input Data Set Ready TTL

DTR Output Data Terminal Ready TTL

RST Input Reset (Active Low) TTL

12

GND - Power Ground Ground

24

Page 25

A.1.2. Parani-ESD200/210

Antenna

1

2

3

4

Figure A-2 Pin Assignment of Parani- ESD 20 0/2 10

Table A-2 Pin Assignment of Paran i- ESD 20 0/2 10

Pin # Signal Direction Description Signal Level

1

GND - Power Ground Ground

5

6

7

8

2

3

4

5

6

2

3

VDD Input DC Input (3.0~3.3V) Ground

Status Output Bluetooth Connect Detect (Active Low) TTL

RST Input Reset (Active Low) TTL

CTS Input UART Clear to Send TTL

RTS Output UART Ready to Send TTL

TxD Output UART Data Output TTL

RxD Input UART Data Input TTL

A.1.3. DCD Signal

Status of Bluetooth connection will be delivered to Host PC via DCD line. When Bluetooth

connection is m ade, DCD signal will be in state OFF. For disconnection of Bl uetooth, DCD signal

will become state ON.

Connection Module Æ low signal

25

Page 26

A.1.4. RST Signal

RST signal will be used f or initializatio n of Parani-ESD. RST should be on 0V status f or at least 1

second for this.

A.1.5. Pairing Signal (only for Parani-ESD100/110)

Parani-ESD100/110 provides pairing sign al input for instant configurat ion without PC to make an

automatic connecti on between two Parani-ESDs . For convenience sake, nam e two Parani-ESDs

as ESD1 and ESD2 respectively.

Step 1. Turn off all the nearby Parani-ESD

Step 2. Turn on ESD1 and ESD2 and hardware reset both of them by using RST signal.

Step 3. Drop the pairing signal of ESD1 to low state and keep it for 2 seconds. Keep the power ON.

Step 4. Drop the pairing signa l of ESD2 to low state and k eep it for 2 seconds. Rais e the pairing

signal of ESD2 to high state and keep it for 2 seconds. Now drop again the pairing signal of

ESD2 to low state and keep it for 2 seconds

Step 5. Wait for ESD1 & ESD2 to be c onnected for a while. It takes about 10 seconds to m ake a

connection. If there are many Bluetooth devices nearby, it will take a little bit more.

Step 6. Now a pair of Parani-SD is configured to m ake automatic conn ection, whenever p ower off

and on.

Just use this pair of Parani-SD like virtual serial cable.

* Note: While pairing is progressing by the pairing signal, the Command Response will be

inactivated automatically. Then, Parani-ESD will not send the response messages such as OK,

Connect and Disconnect.

Table 0-1 Pairing Process by Pairing Signal

ESD100/110 Status Pairing Signal ESD200/210 Status Paring Signal

1. Hard reset Mode0 HIGH 1. Hard reset Mode0 HIGH

2. Drop pairing

signal

Mode3 LOW 2. Drop pairing

signal

Mode3 LOW

3.Restore

pairing signal

4. Drop pairing

5.Restore

6. Connected Slave HIGH 6. Connected Master HIGH

Mode3 HIGH 3.Restore

pairing signal

signal

pairing signal

Mode3 HIGH

Mode1 LOW

Mode1 HIGH

26

Page 27

A.2. Connection Diagram

A.2.1. Parani-ESD100/110

A.2.1.1. When TTL level of MICOM is 3.3V

MICOM

MICRO-VDD

MICOM-DCD

MICOM-TXD

MICOM-RXD

MICOM-RTS

MICOM-CTS

MICOM-DTR

MICOM-DSR

MICOM-RST

MICOM-GND

DC 3.3V

PROMI-ESD01

VDD

Status

RXD

TXD

CTS

RTS

DSR

DTR

RST

GND

A.2.1.2. When TTL level of MICOM is 3.3V and Hardware Flow Control is not used

27

Page 28

A.2.1.3. When TTL level of MICOM is 5V

MICOM

MICRO-VDD

MICOM-DCD

MICOM-TXD

MICOM-RXD

MICOM-RTS

MICOM-CTS

MICOM-DTR

MICOM-DSR

MICOM-RST

MICOM-GND

DC 3.3V

68K 115K

68K 115K

68K 115K

68K 115K

PROMI-ESD01

VDD

Status

RXD

TXD

CTS

RTS

DSR

DTR

RST

GND

28

Page 29

A.2.2. Parani-ESD200/210

A.2.2.1. When TTL level of MICOM is 3.3V

A.2.2.2. When TTL level of MICOM is 3.3V and Hardware Flow Control is not used

29

Page 30

A.2.2.3. When TTL level of MICOM is 3.3V and Hardware Flow Control is not used

30

Page 31

Appendix B: AT Commands

B.1. Terminology

B.1.1. AT Command

AT command set is the

developed by

HTHayesTH and is recognized by virtually all HTpersonal computerTH modems. Parani-ESD

HTde facto standardTH HTlanguageTH for control ling HTmodemsTH. The AT command set was

provides the extended AT command set to control and configur e the serial parameter s and Bluetooth

connection.

B.1.1. AT Response

Parani-ESD replies to AT commands with 4 kinds of message, ‘OK’, ‘ERROR’, ‘CONNECT’ and

‘DISCONNECT’.

B.1.2. Operation Mode

Mode Description

Mode0

Mode1

Mode2

Mode3

Waiting for AT commands

Attempting to connect the last connected Bluetooth device

Waiting for the connection from the last connected Bluetooth device

Waiting for the connection from any other Bluetooth device

B.1.3. Operation Status

Status Description

Standby

Pending

Connect

Waiting for AT commands

Executing tasks

Executing tasks

B.1.4. Security

Security Description

Authentication

Encryption

Pin Code (or Pass key)

Data encryption

31

Page 32

B.1.5. Symbols

The symbols are used for the description of command syntax as follows:

Symbols Meaning ASCII Code

N or m One digit decimal number

to Timeout in seconds

Carriage return 0x0D

Line feed 0x0A

Carriage return + Line feed

Bluetooth device address

B.2. Command Category

Command Category Index AT Commands

RESET 1

SERIAL PORT 3

BLUETOOTH

Information 6

2

4

5

7

8

ATZ

AT&F

AT

AT+UARTCONFIG,b,p,s,h

AT+USEDIP?

AT+BTINFO?

AT+BTINQ?

AT+BTLAST

Mode 9 AT+BTMODEn

Status 10

11

12

13

14

15

16

Connection 17

18

19

Security 20

21

22

23

24

Miscellaneous 25

26

S-REGISTER 27

28

29

+++

AT+SETESC,nn

ATO

AT+BTCANCEL

AT+BTSCAN

AT+BTSCAN,n,to

AT+BTSCAN112233445566,to

ATD

ATD112233445566

ATH

AT+BTKEY=$string

AT+BTSD?

AT+BTCSD

AT+BTFP,n

AT+BTSEC,a,e

AT+BTNAME=$string

AT+BTLPM,n

AT&V

ATSnn?

ATSnn=mm

32

Page 33

B.3. Command Description

B.3.1. ATZ

SD Response

Purpose

Description

Reference

B.3.2. AT&F

SD Response

Purpose

Description

Reference

B.3.3. AT

OK

Software Reset

This is the same effect as power off and on.

This command disconnects B l uetoot h devi ce, and sto p s ong oing task. After rebooting, the

status is decided by the preset operation mode.

Some AT commands need ATZ to take effect.

A T&F, AT+BTCSD, AT+UARTCONFIG

OK

Hardware reset

This is the same effect as initialization by reset button.

All parameters are initialized to factory defaults. The storage of Parani-ESD is cleared

completely.

ATZ

SD Response

Purpose

Description

Reference

OK

Check the connection status with host equipment

Check if the connection to host equipment is normal. The serial parameters of Parani-ESD

must be same as those of host equipment. If not, SD response is none or ‘ERROR’ or

abnormal sequence of strings.

AT+UARTCONFIG, ATZ, AT&F

B.3.4. AT+UARTCONFIG,Baudrate,Parity,Stopbit,Hwfc

SD Response

Purpose

Parameters

Description

Reference

Example

OK

Set Serial parameters

Baudrate=1200/2400/9600/14400/19200/38400/57600/115200/230400 (Default=9600)

Parity=N/E/O (Default=N)

Stopbit=1/2 (Default=1)

Hwfc(Hardware Flow Control)=0/1 (Default=1)

The Serial parameters can be set or changed. The factory default is 9600, N, 1.

To take effect of this command, ATZ or power off and on.

AT, ATZ, AT&F, ATS

AT+UARTCONFIF,9600,N,1

33

Page 34

B.3.5. AT+USEDIP?

SD Response

Purpose

Description

Reference

m

Check the Baud rate set by dip switch

m=0: Set to ‘AT cmd’

m=1: Set to other than ‘AT cmd’

AT, ATZ, AT&F, ATS

B.3.6. AT+BTINFO?

SD Response

Purpose

Description

112233445566,DeviceName,Mode,Status,Auth,Encryp,FlowControl

OK

Display Bluetooth settings

The current Bluetooth settings are displayed including BD address, Device name,

Operation mode, Operation status, Authentication, Data Encryption, and Hardware Flow

Control. The initial value of Device name is ‘PSD100v1.0.0-445566’. PSD stands for

Parani-ESD, v1.0.0 for the version of firmware, and 445566 for the last 6 digits of BD

address.

Mode=MODE0/MODE1/MODE2/MODE3

Status=STANDBY/PENDING/CONNECT

Auth=0/1 (Authentication is not activated when 0)

Encrypt=0/1 (Encryption is not activated when 0)

FlowControl=HWFC/NoFC

Reference

Example

A T+BTNAME, AT+BTMODE, AT+BTSEC, A T S14?

000B530011FF,SENA,MODE0,PENDING,1,1,HWFC

B.3.7. AT+BTINQ?

SD Response

Purpose

Description

Reference

112233445566,FriendlyName,CoD

112233445566,FriendlyName,CoD

112233445566,FriendlyName,CoD

OK

Search Bluetooth devices nearby

The Bluetooth devices in Inquiry scan mode nearby are displayed with their BD addresses,

Device names, and Class of device.

Maximum 10 devices are scanned for 30 seconds.

A T+BTSCAN, A TD, AT+BTINFO?

B.3.8. AT+BTLAST?

SD Response

Purpose

112233445566

Display the BD address of the last connected device

Description

Reference

The Bluetooth device connected to this Parani-ESD last time is displayed with its BD

address.

A T+BTSCAN, A TD, AT+BTINFO?, AT+BTINQ?

34

Page 35

B.3.9. AT+BTVER?

SD Response

Purpose

Description

Reference

SD100v1.0.0

OK

Display device firmware version

Display device firmware ver sion

AT+BTINFO?

B.3.10. AT+BTRSSI,n

SD Response

Purpose

Parameters

Description

Example

OK

0,255,0,0 (repeatedly)

Test sensitivity

n=0: Start sensitivity test

n=1: Stop sensitivity test

When Bluetooth connection is est a bli she d, you can use this c omm and in Stanby sta t us .

The sensitivity will be displayed repeatedly in order of Status, LinkQuality, Status, RSSI. If

the LinkQuality is close to 255 and RSSI is close to 0, the sensitivity is not bad.

+++

AT+BTRSSI,1

OK

0,255,0,0

B.3.11. AT+BTMODE,n

SD Response

Purpose

Parameters

Description

Reference

Example

OK

Set operation mode

n=0: MODE0 (Default)

n=1: MODE1

n=2: MODE2

n=3: MODE3

When the operation status is ‘Pending’ currently, change the status to ‘Standby’ with

AT+BTCANCEL prior to this command.

To take effect of this command, ATZ or power off and on

AT+BTINFO?

AT+BTMODE,2

OK

ATZ

B.3.12. +++

SD Response

Purpose

OK

Convert the operation status of ‘Connect’ to ‘Standby’

35

Page 36

Description

Reference

In ‘Connect’ status, data from host is transmitted to the other side Bluetooth device, and

any AT command is not accepted but this command, which is not echoed on the screen.

When Parani-ESD encounters a character ‘+’ from host, it stops the data transmission and

waits for next 2 characters. If the next 2 characters aren’t both ‘+’, it restart to transmit data

including the first ‘+’ as well. If not, it converts the operation status to ‘Standby’.

If the data from host includes ‘+++’, it will convert the operation status to ‘Standby’

unexpectedly. Notice that Parani-ESD holds data transmission when it encounters ‘+’, until

receiving next character.

‘+’ is an escape sequence character by default, which is changeable by AT+SETESC.

AT+SETESC, ATO, AT+BTCANCEL

B.3.13. AT+SETESC,nn

SD Response

Purpose

Description

Reference

Example

OK

Change the escape sequence character

Escape sequence character set to ‘+’ by default is changeable.

The parameter nn must be a printable char act er.

+++, A TO

AT+SETESC,42

B.3.14. ATO

SD Response

Purpose

Description

Reference

None

Convert the operation status of ‘Standby’ to ‘Connect’

You can convert the operation status of ‘Standby’ to ‘Connect’ ready to transmit data.

+++, A T+SETESC

B.3.15. AT+BTCANCEL

SD Response

Purpose

Description

Reference

OK

Terminate a current executing task

This terminates a current executing task, such as Inquiry scan and Page scan, then

converts the operation status to ‘Standby’

A T+BTSCAN, A TD, AT+BTINQ?

B.3.16. AT+BTSCAN

SD Response

Purpose

Description

OK

CONNECT 112233445566

Wait for inquiry and connection from other Bluetooth devices

This allows the inquiry and connection from the other Bluetooth devices. The operation

status will be in ‘Pending’ after this command. When connection is made and released, the

operation status is back to ‘Pending’. To convert the operation status to ‘Standby’

AT+BTCANCEL must be used.

36

Page 37

This has the same effect as AT+BTSCAN,3,0.

When connection is made with other Bluetooth device, SD response will be ‘CONNECT’

with its BD address.

Reference

A TD, A T+BTINQ?, A T +BTCANCEL

B.3.17. AT+BTSCAN,n,to

SD Response

Purpose

Parameters

Description

Reference

Example

OK

CONNECT 112233445566

or

OK

ERROR

Wait for inquiry and connection from other Bluetooth devices for a given duration

n=1: Allows Inquiry scan

n=2: Allows Page scan

n=3: Allows both of Inquiry scan and Page scan

to= Time duration in seconds

For the given to, Parani-ESD is waiting for the inquiry and connection from other Bluetooth

devices. If the parameter of to is 0, it will wait forever.

When connection is made with other Bluetooth device, SD response will be ‘CONNECT’

with its BD address. If there is no connection made within this time duration, SD response

is ‘ERROR’ and the operation status becomes to ‘Standby’.

A TD, A T+BTINQ?, A T +BTCANCEL

AT+BTSCAN,2,30

B.3.18. AT+BTSCAN112233445566,to

SD Response

Purpose

Parameters

Description

Reference

Example

OK

CONNECT 112233445566

or

OK

ERROR

Wait for connection by the Bluetooth device with given BD address

112233445566=BD address

to= time duration in seconds

For the given to, Parani-ESD is waiting for the connection from the Bluetooth device with

the given BD address. If the parameter of to is 0, it will wait forever.

When connection is made with the Bluetooth device, SD response will be ‘CONNECT’ with

its BD address. If there is no connection made within this time duration, SD response is

‘ERROR’ and the operation status becomes to ‘Standby’.

A TD, A T+BTINQ?, A T +BTCANCEL

AT+BTSCAN000B530011FF,30

B.3.19. ATD

SD Response

OK

CONNECT 112233445566

or

37

Page 38

OK

ERROR

Purpose

Description

Reference

Connect to the last connected Bluetooth device

Parani-ESD saves the BD address of the Bluetooth device most recently connected. ATD

can make connection to it without input its BD address.

If it fails to make connection, SD response is ‘ERROR’.

A T+BTINQ?, A T+BTSCAN

B.3.20. ATD112233445566

SD Response

Purpose

Parameters

Description

Reference

Example

OK

CONNECT 112233445566

or

OK

ERROR

Connect to the Bluetooth device with given BD address

112233445566=BD address

Parani-ESD attempts to connect to the Bluetooth device with the given BD address. To

make successful connection, the Bluetooth device must be in Page scan. This attempt

continues for 5 minutes.

If it fails to make connection, SD response is ‘ERROR’.

A T+BTINQ?, A T+BTSCAN

ATD000B530011FF

B.3.21. ATH

SD Response

Purpose

Description

Reference

OK

DISCONNECT

Release the current connection

The current Bluetooth connection is released normally. It takes about 30 seconds to detect

an abnormal disconnection such as power off and moving out of service range.

A TD, A T+BTSCAN

B.3.22. AT+BTKEY=$string

SD Response

Purpose

Parameters

Description

Reference

OK

Change pin code

$string= New pin code (Default=”1234”)

Pin code is a string, which allows 16 alpha-numeric characters maximum. Based on this pin

code, Parani-ESD generates a link key which is used in actual authentication process

A T+BTCSD, A T +BTFP, AT+BTSD?, AT+BTSEC, ATZ, AT&F

Example

AT+BTKEY=”apple”

38

Page 39

B.3.23. AT+BTSD?

SD Response

Purpose

Description

Reference

112233445566

OK

Display the list of Bluetooth devices shar ing the pin cod e

Once a connection is made with pin code, Parani-ESD saves the Bluetooth device with its

link key generated by pin code. The connection to a device listed in Parani-ESD can be

made automatically without authentication process. The maximum number of the list is 5.

AT+BTCSD, AT+BTFP, AT+BTKEY , AT+BTSEC, ATZ, AT&F

B.3.24. AT+BTCSD

SD Response

Purpose

Description

Reference

OK

Clear the list of Bluetooth devices sharing the pin code

This clears the list of Bluetooth devices with link key in flash memory. To take effect of this

command, ATZ or power off and on because the main memory still has the list.

A T+BTFP, AT+BTK EY, AT+BTSD?, AT+BTSEC, ATZ, AT&F

B.3.25. AT+BTFP,n

SD Response

Purpose

Parameters

Description

Reference

OK

Set generation of link key every time of connection

n=0: Inactivate (Default)

n=1: Activate

If n is set to 1, Parani-ESD asks pin code every time of connection. This is used to level up

the security.

AT+BTCSD, AT+BTKEY, AT+BTSD?, AT+BTSEC, ATD, ATZ, AT&F

B.3.26. AT+BTSEC,Authentication,Encryption

SD Response

Purpose

Parameters

Description

Reference

OK

Set authentication and data encryption

Authentication=0: Inactivate (D efault)

Authentication=1: Activate

Encryption=0: Inactivate (Default)

Encryption=1: Activate

If the authentication is activated, the pin code must be set by AT+BTKEY command. Data

encryption cannot be used when authentication is not activated, i.e. Authentication=0 and

Encryption=1 is not valid.

A T+BTCSD, A T +BTFP, AT+BTSD?, AT+BTSD?, ATZ, A T &F

B.3.27. AT+BTNAME=$string

39

Page 40

SD Response

Purpose

Parameters

Description

Reference

Example

OK

Change device name

$string= New device name (Default=”PSDv3b-445566”)

Parani-ESD can have a user friendly name to identify easily. The name allows 30 alpha-

numeric characters max imum .

A T+BTINFO?, A T +BTINQ?

AT+BTNAME=”My-Parani-ESD”

B.3.28. AT+BTLPM,n

SD Response

Purpose

Parameters

Description

OK

Set low power mode

n=0: Inactivate (Default)

n=1: Activate

During no data transmission, Parani-ESD can be in low power mode to save the power

consumption. It takes a few seconds to wake up Parani-ESD in low power mode.

B.3.29. AT+DFU

SD Response

Purpose

Description

B.3.30. AT&V

SD Response

Purpose

Description

Reference

(Display garbage messages repeatedly)

Device firmware update

DO NOT use this command in console. Because the Parani-ESD enter into firmware

update mode, garbage messages will appear. This command is used by ParaniWIN’s

firmware update menu.

S0:m0;S1:m1; …Sn:mn

OK

Display all the S-register

All parameters are stored at S-register in flash memory. These values are sustained until

hardware reset.

ATS

B.3.31. ATSnn?

SD Response

value

OK

40

Page 41

Purpose

Parameters

Description

Reference

Display a given S-register

nn= Address of S-register

A specific S-register is displayed.

AT&V

B.3.32. ATSnn=mm

SD Response

Purpose

Parameters

Description

Reference

Example

OK

Change S-register value

nn= Address of S-register

mm= New value of S-register

Some S-registers are optimized for the overall performance and protected from an arbitrary

change by user. When users try to change these S-registers, SD response is ‘ERROR’.

For details of S-register, refer Appendix. B.

AT&V

ATS10=0

B.4. Command Validity

Operation Status AT Command

AT

ATZ

AT&F

AT+BINQ?

ATD112233445566

ATD

AT+BTSCAN

AT+BTSCAN,n,to

AT+BTSCAN112233445566,to

AT+BTCANCEL ○

+++

AT+SETESC

ATO

Standby Pending Connect

○ ○

○ ○

○ ○

◎

◎

◎

◎

◎

◎

◎

●

○

ATH

AT+BTSEC,Auth,Encr

AT+BTLAST?

●

◎

○ ○

41

Page 42

AT+BTMODEn

AT+BTNAME=”Name”

AT+BTKEY=”nnnn”

AT+BTINFO?

AT+BTLPM,n

AT+BTSD?

AT+BTCSD

AT+BTFP,n

AT+UARTCONFIG,b,p,s,h

AT+USEDIP?

AT+BTVER?

AT+DFU

AT+BTRSSI,n

◎

◎

◎

○

◎

○ ○

◎

◎

◎

○ ○

○ ○

◎ ◎

●

◎ Valid only when Parani-ESD is not connected to other Bluetooth device.

● Valid only when Paran i-ESD is connected to other Bluetooth devic e.

42

Page 43

Appendix C: S-Register

S-registers contain 46 parameters of Parani-ESD. These are stored in flash memory and sustained the

values unless h ard ware re set is ex ecut ed. T he va lue o f S-regis ter c an be acc essed a nd c hanged with

ATS command b y user. Some S-register s not shown below are set to maximize the perf ormance of

Parani-ESD. Thus it is not recommended to change these S-registers.

Change the value of S-register onl y in Standby status.

C.1. S1: Force to Reconnect (default 1)

S1=0, Parani-ESD in Mode1 does not try reconnection when disconnected.

S1=1, Parani-ESD in Mode1 keeps trying reconnection when disconnected.

C.2. S2: Enable Hardware Flow Control (default 1)

S2=0, Parani-ESD’s hardware flow control is off.

S2=1, Parani-ESD’s hardware flow control is on.

In case of SD Series, it can be changed only through dip switch.

C.3. S3: Stream UART Policy (default 0)

S3=0, the priority of UART streaming is throughput.

S3=1, the priorit y is latenc y, which minim izes the delay of data transm ission. This is useful in cas e of

transmiting very small data quickly.

This value decides the way of handlin g str eam data from UART. When this value i s 1, in ord er tha t SD

minimizes the late nc y, SD sends the received data im m ediately. When this value is 0, in order t hat SD

maximizes throughput, SD stores received data for a short time and sends a large packet. If the

packet length is less than100 b ytes, latency-or iented way is better. But if the packet length is more

than 100 bytes, throughput-oriented way is recommended. Also if you want to use high baudrate,

throughput-oriented way is more effective. Just for reference, the buffer length for receiving is 2 Kbytes.

C.4. S4: Enable Remote Name Query (default 1)

S4=0, Parani-ESD inquires only BD address. This speeds up the inquiry process.

S4=1, Parani-ESD inquire BD address, device name and class of device.

This value dec ides whether SD finds friendly nam e of Bluetooth device or not. W hen this value is 1,

SD finds not onl y BD addr es s but als o fr iendl y nam e. When this value is 0 , SD f inds onl y BD addr ess.

Without finding friendly name, a searching is quick to respond. If you want to search the other

Bluetooth devices quic kly, set this value to 0. In case of using pairing b utton, find ing friendl y name will

be omitted automatically.

43

Page 44

C.5. S6: Enable Low Power Mode (default 0)

S10=0, deactivate Low Power Mode.

S10=1, activate Low Power Mode.

This value decides whether SD works in Low Power Mode or not. When this value is 0, SD works only in

active power mode. When SD works in Low Power mode, delay in transferring data may occur.

C.6. S10: Enable SD Response (default 1)

S10=0, Parani-ESD does not send SD responses to host system.

S10=1, Parani-ESD send SD responses to host system.

This value decides whether SD sends response messages such as OK, ERROR, CONNECT, DISCONNECT

or not. When this value is 0, SD sends no response messages. If the response messages cause troubles

in host programs or devices that is connected to SD, change this value to 0.

C.7. S11: Enable Escape (default 1)

S11=0, Parani-ESD does not allow escape sequence character. The operation status of Connect cannot be

changed to Standby. As Parani-ESD skips the process detecting escape sequence character, the more

efficient data transmission is expected.

S11=1, Parani-ESD allow escape sequence character. Whenever it is needed, the Connect status can be

changed to Standby.

C.8. S12: Clear Data Buffer When Disconnected (default 0)

S12=0, Parani-ESD does not clear the data buffer received from host system when disconnected.

S12=1, Parani-ESD clears the data buffer when disconnected.

C.9. S14: Enable DTR Transfer (default 1)

S14=0, DTR/DSR signal is transferred to loop-back.

S14=1, DTR signal is transferred to DSR of remote device.

C.10. S15: Enable Disconnect by DTR (default 0)

S15=0, DTR signal cannot release the connection.

S15=1, The Bluetooth connection can be released when DTR signal is off.

This value decides whether Bluetooth connection is released when DTR signal drops or not. If this value

is 1, you can use DTR signal in order to disconnect Bluetooth connection.

C.11. S22: Fast Connect (default 0)

S22=0, none

S22=1, page scan

S22=2, inquiry scan

S22=3, page/inquiry scan

44

Page 45

C.12. S24: Maximum Number of Inquiry Result (default 10)

The maximum number of inquiry list can be controlled. This value is up to 15,

C.13. S28: Escape Sequence Character (default 43)

The decimal number of the ASCII code of escape sequence character c an be controlled. The initial

value is 43, the ASCII code of ‘+’.

C.14. S31: Page Timeout (default 300)

This is the timeout in seconds to attempt connection with ATD command. After this timeout expires, the

SD will restart automatically. If this value is 0, SD will attempt to connect without restarting

C.15. S33: Inquiry Timeout (default 30)

This is the timeout in seconds to execute inquiry scan.

C.16. S37: Supervision Timeout (default 16000)

This is the timeout in 625µsec to presume disconnection, which is set to 16000 initially.

16000¯625µsec=10sec)

The smaller the value be comes, the m ore quic kly Parani- ESD can det ect an a bnorm al disconnection .

But when the co mmunication is suspende d for some environm ental reasons, it may be regar ded as

disconnection.

C.17. S46: BD Address of Last Connected Device

This saves the BD address of the Bluetooth device connected most recently.

45

Page 46

Appendix D: Trouble Shooting

D.1 No Data Transmission

D.1.1 COM Port Settings

Check whether the Baud rate of Parani-ESD is same as t hat of its host equipment. If you don’t know

the current Baud rate, initialize it to 9600 by resetting

Check whether the Data bit is s et to 8. Parani-ESD supports onl y 8 Data bit. If your host equipment

uses 7 Data bit and even or odd parity, it can work as if it uses 8 Data bit an d No parity. This is valid

only when both DCE devic es ar e Parani-E SD. In this c ase, set both P aran i-ESD s to 8 Data bit and No

parity. If one of DCE devices is other Bluetoot h device suc h as Bluetooth U SB dongle, please c ontact

Technical Support.

Check whether the Par ity and Stop bit of Parani-ESD are same as those of its host equipm ent. Par an iESD supports No parity, Even parity and Odd parity, 1 and 2 Stop bit.

Check whether the host equipment of Par a ni- E SD us e s Hard war e F l o w Con tr ol. Par an i- E SD is in iti al ly

set to Use of Hardware Flo w Contro l. If your host equipm ent does not us e Hardw are Flo w Contr ol, set

the Hardware Flow Control of Parani-ESD to No use.

Parani-ESD does not support RS-232 break signal.

D.2 Data Loss or Malfunctioning

D.2.1Hardware Flow Control

When transmitting lar ge data with No use of Hardware F low Control, Parani-ESD will c lear the data

buffer unexpectedly. This possibility goes higher as the RF transmission environment is bad.

D.2.2 SD Response

The messages of AT response may affect the function of host system. Set ATS10=0 not to send AT

response to host system and try again. Refer Appendix B. for details.

46

Page 47

D.3 Transmission Delay

D.3.1 RF Processing Delay

It takes 30msec approxim ately for a Parani-ESD to com plete the data transmission to the other side

Bluetooth device. This time delay cannot be reduced and would be bigger as the RF transmission

environment is bad. Do not use Parani-ESD If your applications cannot allow this time delay.

D.3.2 RF Transmission Environment

If there are lots of Blue tooth device working in a sm all area and/or the RF communicat ion distance is

too long and/or there are some obstacles affecting RF performance, Parani-ESD repeats the

transmission packet by packet due to interferences and/or low RF performance. This leads the

transmission time delay .

47

Page 48

Appendix E: How make a RS232 interface Jig Board

48

Loading...

Loading...