LOW VOLTAGE, BOOST DC-DC

CONTROLLER

SC1408

August 22, 2000

TEL:805-498-2111 FAX:805-498-3804 WEB:http://www.semtech.com

DESCRIPTION

The SC1408 is a low voltage boost controller that operates from a 1.8V to 16.5V input range. A shutdown pin

allows the user to turn the controller off reducing supply current to less than 2µA typical. Output voltage can

be preset to 5V or is adjustable from 3V to 16.5V with

a resistor divider. The controller changes frequency in

low load conditions to improve efficiency.

The SC1408 was designed for two cell Alkaline or single cell Lithium Ion battery applications. With the

proper external components it can be used as a boost

converter or a buck/boost converter.

A current sense is implemented with an external resistor that is not in the load current path.

The SC1408 operates in “bootstrapped” mode. When

the input voltage to the device is less than 2.5V during

startup, a low voltage 50% fixed duty cycle oscillator is

switched in to initiate boost action.

FEATURES

•= 1.8V to 16.5V input range

•= Up to 10W output power

•= Preset 5V or adjustable output

•= Up to 300kHz switching frequency

•= 10µA max shutdown current

•= Industrial temperature range

•= SO-8 or MSOP-8 package

APPLICATIONS

PDA Power supplies

•=

•= Battery powered applications

•= Positive LCD Bias generator

•= Portable communications (cellular phones)

•= Peripheral card supplies

•= Industrial power supplies

ORDERING INFORMATION

Part Number

SC1408IS.TR SO-8 -40° to +85°C

(1)

Package Temp. Range (TA)

SC1408IMS.TR MSOP-8

Note:

(1) Only available in tape and reel packaging. A reel

contains 2500 devices.

TYPICAL APPLICATION - BOOST CONFIGURATION

U1

2

4

SHDN

5

REF

7

GND

SC1408IS

L1

GATEBST

ISENSE

FB

AGND

1

8

3

6

Vin (1.8V to 16.5V) Vout (3V to 16.5V)

+

C2

C5

Q1

R2

D1

R3

R4

+

C3

1

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

LOW VOLTAGE, BOOST DC-DC

SC1408

CONTROLLER

August 22, 2000

ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Maximum Units

Input Voltage BST to GND -0.3 to 18 V

Small Signal Ground to Power Ground GND to AGND ±0.1 V

GATE to GND -0.3 to VBST+0.3 V

FB, SHDN, REF, ISENSE to GND -0.3 to min. of VBST+0.3 or 5 V

Operating Temperature T

Junction Temperature Range T

Storage Temperature T

Lead Temperature (Soldering) 10 seconds T

Thermal Resistance, Junction to Ambient

SO-8

θ=JA

MSOP-8

Thermal Resistance, Junction to Case

SO-8/MSOP-8

ELECTRICAL CHARACTERISTICS

Unless specified: V

OUT

= 5V; I

= 0mA; TA = +25°C

LOAD

(1)

θ=JC

PARAMETER SYM CONDITIONS MIN TYP MAX UNITS

Input Voltage T

T

Supply Current V

= 16.5V,

OUT

= 25°C 1.8 16.5 V

A

= -40°C to +85°C 1.8 16.5 V

A

SHDN ≤=0.4V

V

= 10V,

OUT

1.6V ≤=SHDN ≤=5V

A

J

STG

L

-40 to +85 °C

-40 to +150 °C

-65 to +160 °C

+300 °C

165

°C/W

206

40 °C/W

TA = -40°C to +85°C 110 140 uA

TA = -40°C to +85°C 2 10 µA

Output Voltage V

Load Regulation V

Line Regulation V

= 2.0V to 5.0V, TA = -40°C to +85°C 4.800 5.0 5.200 V

IN

= 2.0V, V

IN

= 2.7V to 4.0V, V

IN

OUT

= 5V, I

OUT

= 0mA to 500mA 60 mV/A

LOAD

= 5V, I

= 500mA 7 mV/V

LOAD

Minimum Start Up Voltage No load 1.8 V

Maximum Swit ch On Time T

Minimum Switch Of f Time T

Efficiency V

Reference Voltage V

ON

OFF

REF

= 4V, V

IN

I

= 0µA TA = -40°C to +85°C 1.176 1.200 1.224 V

REF

OUT

Reference Load Regulation 0µA <

Reference Line Regulation 5V <

FB Trip Point Voltage V

FB Input Current I

FM

FB

= -40°C to +85°C 1.176

T

A

= -40°C to +85°C

T

A

= 5V, I

I

< 100µA -4 10 mV

REF

V

OUT

= 500mA 87 %

LOAD

< 16.5V 40 100 µV/V

TA = 25°C

TA = 25°C

9.6 16 22.4 µs

1.4 2.3 3.2 µs

1.200

V

1.224

-4

nA

+ 40

2

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

August 22, 2000

ELECTRICAL CHARACTERISTICS

LOW VOLTAGE, BOOST DC-DC

CONTROLLER

(1)

SC1408

Unless specified: V

OUT

= 5V; I

= 0mA; TA = +25°C

LOAD

PARAMETER SYM CONDITIONS MIN TYP MAX UNITS

SHDN Input High Voltage V

SHDN Input Low Voltage V

SHDN Input Current I

Current Limit Trip Level V

ISENSE Input Current I

IH

IL

IN

CS

SENSE

V

OUT

GATE Rise Time V

GATE Fall Time V

= 3V to 16.5V TA = 25°C

V

= 2.7V to 16.5V 1.6 V

OUT

V

= 2.7V to 16.5V 0.4 V

OUT

V

= 16.5V, SHDN = 0V or 5V + 1µA

OUT

8580100 115

= -40°C to +85°C

T

A

120

0.01 + 1µA

= 5V, 1nF from GATE to GND 50 ns

OUT

= 5V, 1nF from GATE to GND 50

OUT

GATE On Resistance GATE = high or low 15 30

NOTE:

(1) This device is ESD sensitive. Use of standard ESD handling precautions is required.

mV

Ω

3

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

August 22, 2000

BLOCK DIAGRAM

LOW VOLTAGE, BOOST DC-DC

CONTROLLER

SC1408

1.20V

REFERENCE

TRIG Q

MAX ON TIME

ONE SHOT

AGND

16uS

ERROR

COMP

+

-

MIN OFF TIME

ONE SHOT

TRIG Q

2.3uS

REF

S

R

LOW

VOLTAGE

OSCILLATOR

Q

MODE

DETECT

+

CURRENT

SENSE AMP

START

UP

COMP

FB

INTERNAL BIAS

50mV

BIAS

+

SHDN

BST

-

2.5V

GATE

GND

+

ISENSE

-

0.1V

PIN CONFIGURATION

PIN DESCRIPTION

Pin # Pin Name Pin Function

Top View

1 GATE Gate drive output.

2 BST Supply voltage.

3 FB Voltage feedback.

4 SHDN Logic high shuts down the converter.

5 REF Reference output pin.

6 AGND Small signal analog and digital ground.

(SO-8/MSOP-8)

7 GND Power ground.

8 ISENSE Current sense pin.

4

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

LOW VOLTAGE, BOOST DC-DC

CONTROLLER

August 22, 2000

Fig. 1: Typical Application - Boost Configuration

SC1408

Vin=3.3V

C2

100uF

L1 22uH

COILCRAFT DO3316P-223

U1

FB

12

8

3

67

GATEBST

4

+

SHDN

5

REF

ISENSE

AGNDGND

C5

SC1408IS

D1

B130T

Q1

IRLR024N

R2

0.05Ohm

R3

31.6k

R4

10.0k

0.1uF

(1) See Component Selection

Fig. 2: Typical Application - Buck/Boost (SEPIC) Configuration

D2 1N4148

C9

(1)

+

C3

100uF

Vout=5V

+

C8

100uF

Vin=2.7V to 6V

C2

+

100uF

C4

0.1uF

L1A 22uH

U1

4

5

C5

0.1uF

L1A/L1B IS COUPLED INDUCTOR

PULSE PE-53718 OR

EQUIVALENT

SHDN

REF

SC1408IS

ISENSE

AGNDGND

12

12

GATEBST

8

3

FB

67

C1

+

Q1

IRLL3303

R2

0.05Ohm

100uF

D1

B130T

R3

31.6k

4

L1B

22uH

3

(1) See Component Selection

R4

10.0k

C9

(1)

+

C3

100uF

Vout=5V

+

C8

100uF

5

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

LOW VOLTAGE, BOOST DC-DC

CONTROLLER

August 22, 2000

Fig. 3: Achieving output voltages greater than 16.5V

SC1408

D4

1N4148

R6 470

L1 22uH

3.3V IN

U1

Q1

IRL3103S

C2

100uF

FB

12

8

3

67

GATEBST

C4

0.1uF

+

4

SHDN

5

REF

ISENSE

AGNDGND

SC1408IS

D3

C5

0.1uF

12V

Fig. 4: Implementing shutdown with input/output isolation

D1

B130T

200k

R2

0.05Ohm

R3

R4

10.0k

+

C3

100uF

25V OUT

+

C8

100uF

Q2

SHORT = RUN

OPEN = SHUTDOWN

3.3V IN

J1

R5

5.1k

1

2

Si2301DS

C2

100uF

C4

0.1uF

+

C5

0.1uF

4

5

L1 22uH

U1

SHDN

REF

SC1408IS

GATEBST

ISENSE

AGNDGND

FB

D1

B130T

R3

12

8

3

67

Q1

IRLL3303

R2

0.05Ohm

90k

R4

10.0k

+

C3

100uF

12V OUT

+

C8

100uF

6

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

August 22, 2000

LOW VOLTAGE, BOOST DC-DC

CONTROLLER

SC1408

THEORY OF OPERATION

The SC1408 is a modified hysteretic boost converter

controller. The power switch is turned on when the output voltage falls slightly below it’s setpoint. It remains on

for approximately 16µs, or until the inductor current

reaches limit, whichever occurs first. The power switch is

then turned off for 2.3µs, or until the output voltage once

again falls below setpoint, whichever occurs last.

The SC1408 is normally powered from the output voltage. Internal circuitry, such as the bandgap, comparators and one shots will not function properly until the BST

pin voltage reaches 2.5V. To ensure startup at low input

voltages, the normal control circuitry is disabled and a

special, low voltage start up oscillator generates an approximate square wave at the GATE pin, initiating boost

action. When the output voltage reaches 2.5V, the normal control circuitry is enabled and the start up oscillator

shuts down.

To conserve power, a SHDN pin is provided which,

when pulled high, shuts down most internal circuitry. The

output voltage will then be one diode drop below the input.

COMPONENT SELECTION

Boost Converter

SENSE

R

The value of the sense resistor is the primary determining factor for maximum output current. The SC1408 has

a fixed current limit voltage threshold, which is developed by the peak inductor current flowing through

SENSE. RSENSE may be determined either from the maxi-

R

mum output current curves or from the equation below:

æ

V

CS

I

)MAX(O

R

−

ç

1

−=

ç

SENSE

è

æ

t

()( )

ç

ç

L2

è

−+

:Where

=

F

=

FET

ö

VVV

−+

INFO

÷

÷

VVV

−+

FETFO

ö

VVVVV

−+−

INFOFETINoff

VVV

FETFO

Drop VoltageForward Diode Output V

SENSE

pin to GND, or to any voltage in the 3.0V to 16.5V range

using external divider resistors.

The bottom resistor in the divider chain (R4) should be

300kΩ or less and the top resistor (R3 in the application

circuits) can be calculated from:

æ

ç

4R3R

ç

V

è

V

REF

ö

O

−= 1

Inductor

The SC1408 will work with a wide range of inductor values. A good choice for most applications is 22µH.

Smaller inductor values result in higher peak currents

and increased output ripple, while larger values will result in slower loop response.

Transistor Selection

Normally the power switch will be an N-channel MOSFET, although in certain circumstances an NPN bipolar

may be substituted.

The choice of FET can be critical, especially in battery

powered applications where the converter must be able

to use all of the available energy in the battery. This requires that the converter be capable of starting up from

very low input voltages. For example a two cell alkaline

system’s terminal voltage will drop to 1.8V as it approaches full discharge. For these demanding applications, a FET with low V

thumb is that V

should be at least 0.5V less than the

GS(th)

is required. A good rule of

GS(th)

minimum input voltage.

Diode

For most applications, a Schottky diode should be used

as the output rectifier. It will be subjected to reverse voltages of at least V

, and average current will be equal to

O

the output current. Industry standard 1N5817 series or

an equivalent surface mount part would be suitable.

Output Capacitors

Output capacitors should be low ESR to minimize ripple

voltage and maximize efficiency. Low ESR tantalums,

OSCONs or the newer Polymer capacitors should be

DCR Inductor and R FET, across VoltageV

used. Ripple voltage will be approximately:

In the equation above, the use of 2.3µs for t

to slightly optimistic current values for low V

The theoretical curves use the actual value of t

=0.5V, V

V

F

=0.3V and VCS=0.08V and are generated

FET

for L=22µH.

may lead

off

ratios.

O/VIN

,

off

R*V

V =

RIPPLE

R

ESRCS

SENSE

Input Capacitors

Input capacitors on a boost converter are less critical

than the output capacitors, since there are no fast cur-

Output Voltage

Output voltage can be set to 5V by connecting the FB

rent pulses drawn from the input supply. A 100µF tantalum will be adequate for most applications.

7

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

August 22, 2000

LOW VOLTAGE, BOOST DC-DC

CONTROLLER

SC1408

Feed Forward Capacitor

Although converters based on the SC1408 are stable,

with no possibility of oscillation, they are susceptable to

“mode switching” at intermediate current levels. This

leads to increased ripple voltage and slightly reduced

efficiency. Mode switching can be eliminated by a suitable choice of C9. It is possible to empirically select C9.

Start with a value of about 100pF and adjust until all low

frequency output ripple is eliminated at the desired output current.

See AN99-15 “SC1408 Operating Modes” for a full discussion of the origins of “Mode switching” and a more

analytical approach to the selection of C9.

COMPONENT SELECTION

SEPIC Converter

SENSE

R

Again, with the SEPIC topology, the value of the sense

resistor is the primary determining factor for maximum

output current. The simplest approach to select R

is to add Vin to Vo and use this value as the output voltage in the output current curves or in the equation for

Boost converter.

Output Voltage

Output voltage setting works exactly the same in SEPIC

topology as in Boost, including the ability to set to 5V by

connecting the FB pin to GND. Care must be taken to

ensure that the IC supply (pin2; BST) does not exceed

its 16.5V rating. In the circuit of Fig.2: This requires maximum output voltage to be limited to 16.5V-Vin. Higher

output voltages are possible with different IC supply

strategies.

Inductor

The SEPIC topology requires a coupled inductor. Again

a good choice for most applications is 22uH. Smaller inductor values result in higher peak currents and increase

output ripple, while larger values will result in slower loop

response.

Transistor Selection

The choice of FET can be critical, especially in battery

powered applications where the converter must be able

to use all of the available energy in the battery. This requires that the converter be capable of starting up from

very low input voltages. For example a two cell alkaline

system’s terminal voltage will drop to 1.8V as it approaches full discharge. For these demanding applications, a FET with low V

thumb is that V

should be at least 0.5V less than the

GS(th)

is required. A good rule of

GS(th)

minimum input voltage.

SENSE

Diode

For most applications, a Schottky diode should be used

as the output rectifier. It will be subjected to reverse voltages of at least V

and average current equal to the

O +VIN

output current. Industry standard 1N5817 series or an

equivalent surface mount part would be suitable.

Output Capacitors

Output capacitors should be low ESR to minimize ripple

voltage and maximize efficiency. Low ESR tantalums,

OSCONs or the newer Polymer capacitors should be

used.

Input Capacitors

Input capacitors on a SEPIC converter are less critical

than the output capacitors, since there are no fast current pulses drawn from the input supply. A 100µF tantalum will be adequate for most applications.

Series Capacitors

The Series capacitor(s) must be capable of handling an

RMS current given by:-

5.0VII+

O

=

ORMS

V

IN

Feed Forward Capacitor

The feed forward capacitor should be selected in the

same way as for a Boost application.

LAYOUT GUIDELINES

The SC1408 is fairly insensitive to layout, however following some simple guidelines will help ensure successful implementation.

Whenever possible, lay the circuitry out over a ground

plane. Connect AGND and GND together at the IC and

return to the ground plane with one or two vias. Place

the current sense resistor (R2), the REF decoupling capacitor (C5) and the divider resistors (R3 and R4) close

to the IC, Return the ground side of these components

to the ground plane close to the AGND/GND pin vias.

Connect the top side of the sense resistor to ISENSE

with a short trace and the source of Q1 directly to the

sense resistor. Make the output loop Q1, D1 and the

output capacitors (C3, C8) as small as possible to minimize EMI.

8

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

LOW VOLTAGE, BOOST DC-DC

CONTROLLER

August 22, 2000

3.5

3.0

2.5

Vo=3.3V

L=22uH

20mOhm

25mOhm

2.0

Io (A)

1.5

1.0

0.5

35mOhm

50mOhm

100mOhm

0.0

2.0 2.2 2.4 2.6 2.8 3.0 3.2

3.5

Vo=12V

3.0

L=22uH

2.5

2.0

Io (A)

1.5

1.0

0.5

0.0

2.0 4.0 6.0 8.0 10.0 12.0

Vin (V)

20mOhm

25mOhm

35mOhm

50mOhm

100mOhm

Vin (V)

Figs. 5 - 8: Maximum output current vs. input voltage and sense resistor value. (Boost Mode)

3.5

Vo=5V

L=22uH

3.0

2.5

2.0

Io (A)

1.5

1.0

0.5

0.0

2.0 2.5 3.0 3.5 4.0 4.5 5.0

4.0

Vo=15V

3.5

L=22uH

3.0

2.5

2.0

Io (A)

1.5

1.0

0.5

0.0

2.0 4.0 6.0 8.0 10.0 12.0 14.0 16.0

Vin (V)

Vin (V)

SC1408

20mOhm

25mOhm

35mOhm

50mOhm

100mOhm

20mOhm

25mOhm

35mOhm

50mOhm

100mOhm

100%

Vo=5V

90%

80%

Efficiency (%)

70%

60%

1 10 100 1000

100%

Vo=15V

90%

80%

Efficiency (%)

70%

60%

1 10 100 1000

Io (mA)

Io (mA)

Vin=5.0V

Vin=4.0V

Vin=3.3V

Vin=3.0V

Vin=12V

Vin=9.0V

Vin=5.0V

Vin=3.0V

Vin=1.8V

100%

Vo=12V

90%

80%

Efficiency (%)

70%

60%

1 10 100 1000

Io (mA)

Vin=5.0V

Vin=3.0V

Vin=1.8V

Figs. 9-11:Efficiency in the Boost Application circuit of Fig.1

9

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

August 22, 2000

LOW VOLTAGE, BOOST DC-DC

CONTROLLER

SC1408

Output Ripple Voltage; Vin=3V, Vo=5V, Io=470mA

Ch1 = Output Ripple

Ch2 = Voltage at GATE pin

Output Ripple Voltage; Vin=3V, Vo=5V, Io=810mA

Ch1 = Output Ripple

Ch2 = Voltage at GATE pin

Load Transient; Vin=3V, Vo=5V, Io=0 to 500mA

Ch1 = Output Voltage

Ch2 = Load Current (0.5A/div)

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

Load Transient; Vin=2V, Vo=5V, Io=0 to 500mA

Ch1 = Output Voltage

Ch2 = Load Current (0.5A/div)

10

August 22, 2000

OUTLINE DRAWING - SO-8

LOW VOLTAGE, BOOST DC-DC

CONTROLLER

SC1408

JEDEC

REF: MS-012AA

LAND PATTERN - SO-8

11

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

August 22, 2000

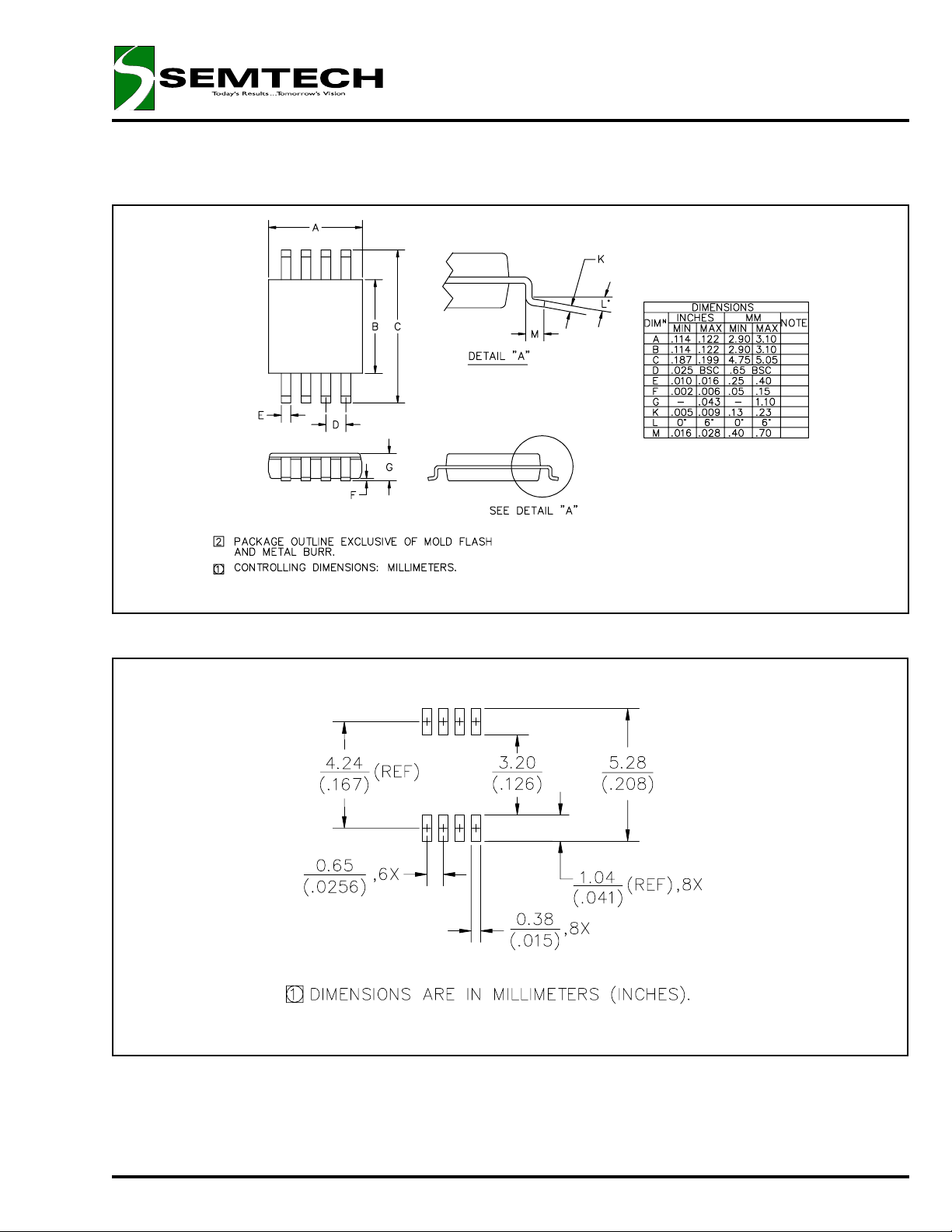

OUTLINE DRAWING - MSOP-8

LOW VOLTAGE, BOOST DC-DC

CONTROLLER

SC1408

LAND PATTERN - MSOP-8

ECN00-1275

12

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

Loading...

Loading...