SINK AND SOURCE DC/DC CONTROLLER FOR

TERMINATION POWER SUPPLY APPLICATIONS

SC1110

PRELIMINARY - October 9, 2000

TEL:805-498-2111 FAX:805-498-3804 WEB:http://www.semtech.com

DESCRIPTION

The SC1110 is a low-cost, full featured, synchronous

voltage-mode controller designed to generate termination voltage in double data rate (DDR) memory systems and other applications where wide data bus need

to be actively terminated. Synchronous control of the

MOSFET half bridge allows power flowing bidirectionally. The termination voltage can be tightly

regulated to track the chipset voltage, i.e. to be exactly

50% of that at all times.

The SC1110 is ideal for low cost implementation of termination voltage supplies. SC1110 features include

temperature compensated voltage reference, triangle

wave oscillator and current sense comparator circuitry,

and allows the use of inexpensive N-channel power

switches.

The SC1110 operates at a fixed 250kHz, providing an

optimum compromise between efficiency, transient

performance, external component size, and cost.

FEATURES

•= Generates termination voltages for active termina-

tion schemes

•= 1% set point accuracy

•= For ±7A output current, transient regulation is bet-

ter than ±80mV

•= V

•= Buffered V

•= R

pin available

REFIN

sensing for over current protection in hiccup

DSON

for system usage

REFOUT

mode

•= Soft start and logic input enabling

•= 250kHz switching for best transient and efficiency

performance

•= Gate drive capable for 0.5A sourcing and sinking

APPLICATIONS

•= For DDR memory systems

•= For active termination schemes in high speed logic

systems

ORDERING INFORMATION

DEVICE

(1)

PACKAGE TEMP. RANGE (TJ)

TYPICAL APPLICATION CIRCUIT

REFOUT

SS/ENBL

PWRGD

C1

R1

5k

R2

0.01

1.24k

C3

0.1

C25

0.1

R3

10

C2

0.1

U1

SC1110

1

VCC

2

SS/ENBL

3

OCSET

4

PWRGD

5

GND

6

PHASE

7

DL

C10-14: Sanyo, 4SP560M

C8,9,15-24: TDK, CC3216AX5R0J106K

L1: Panasonic, ETQP6F0R8L or Falco, QPIP1205-809-3

Q1,Q2 options: Si9426DY, FDS6890A, IRF7401

D1: ON Semi (Motorola)

REFOUT

REFIN

SENSE

COMP

BSTL

BSTH

SC1110CSTR SO-14 0 - 125°C

Note:

(1) Only available in tape and reel packaging. A reel

contains 2500 devices.

+5Vcc

+

C10,11

C8,9

Q1

Si9426DY

Q2

Si9426DY

C7

1.0

C6

1.0

2 x 10uF

800 nH

L1

C12-14

3 x 560uF

2 x 560uF

R4

C4

1k

14

13

12

11

10

9

8

DH

0.022

R5

1k

C5

R6

0.047

4.7k

D1

MBRM120

R7

2.2

R8

2.2

C15-24

10 x 10uF

Vin 2.5V

_

+

Vout = 1.25V @ 7A

_

1

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

SINK AND SOURCE DC/DC CONTROLLER FOR

SC1110

TERMINATION POWER SUPPLY APPLICATIONS

PRELIMINARY - October 9, 2000

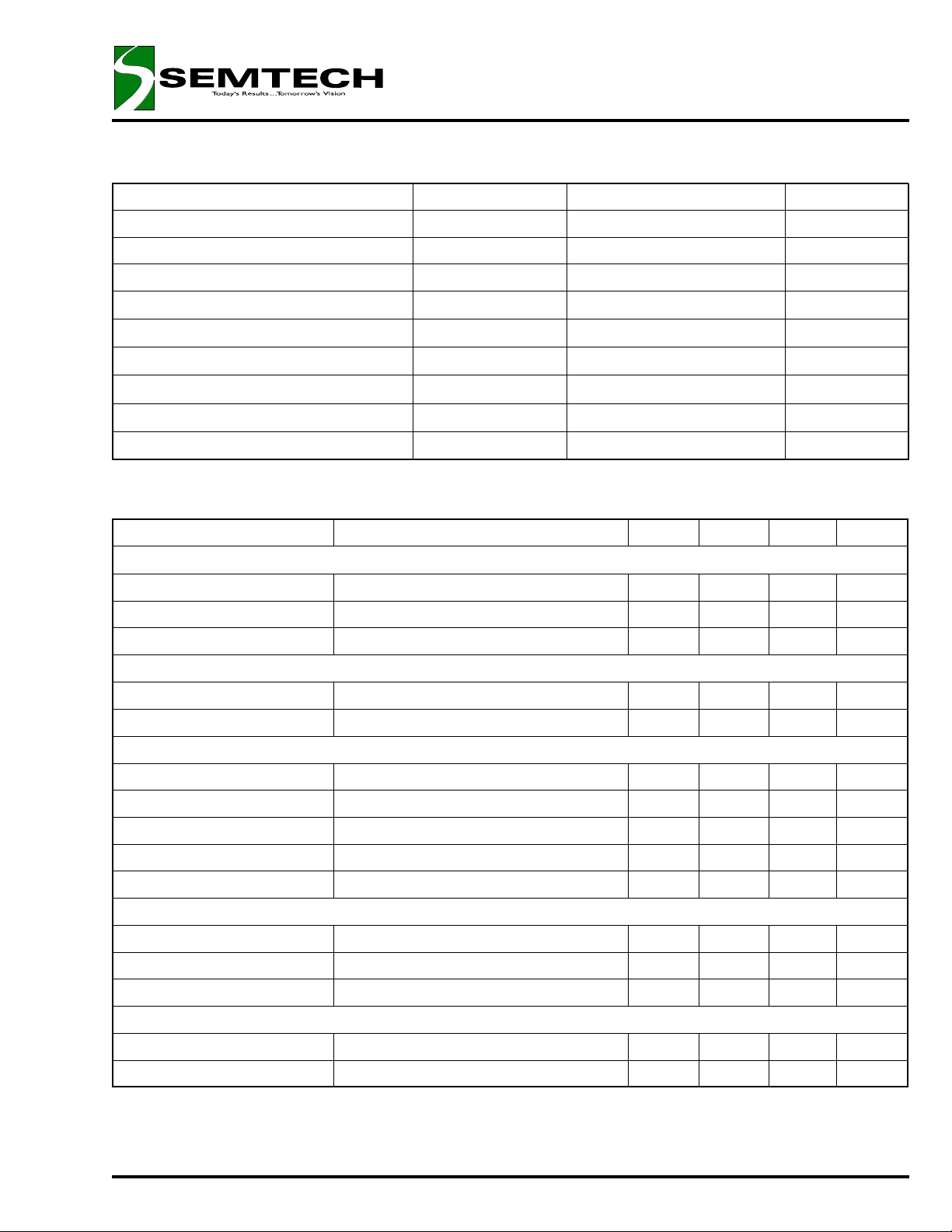

ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Maximum Units

V

, BSTL to GND V

CC

IN

PGND to GND ± 0.5 V

PHASE to GND -0.5 to 18 V

BSTH to PHASE 14 V

-0.5 to 14 V

Thermal Resistance Junction to Case

Thermal Resistance Junction to Ambient

Operating Temperature Range T

Storage Temperature Range T

Lead Temperature (Soldering) 10 sec T

θ

JC

θ

JA

STG

LEAD

A

45 °C/W

115 °C/W

0 to 70 °C

-65 to +150 °C

300 °C

ELECTRICAL CHARACTERISTICS

Unless specified: VCC = 4.75V to 12.6V; GND = PGND = 0V; FB = VO; V

PARAMETER CONDITIONS MIN TYP MAX UNITS

POWER SUPPLY

Supply Voltage V

Supply Current EN = V

Line Regulation V

= 2.5 ± 0.5V, VO = VIN/2 @ 0A 0.5 %

IN

CC

CC

UNDER VOLTAGE LOCKOUT

Turn-On Threshold TBD 4.2 TBD V

Turn-Off Threshold TBD 4.0 TBD V

ERROR AMPLIFIER

Transconductance 2 mS

BSTL

= 12V; V

BSTH-PHASE

= 12V; TJ = 25oC

4.4 12.6 V

8mA

Open Loop DC Gain 50 dB

Bandwidth -3dB 500 kHz

COMP Source Capability ±250 µA

Input Bias 58µA

OSCILLATOR

Oscillator Frequency 225 250 275 kHz

Oscillator Max Duty Cycle 90 95 %

Ramp Height 1V

TIMING

Minimum Off-Time 100 ns

Dead Time 80 ns

2

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

SINK AND SOURCE DC/DC CONTROLLER FOR

SC1110

TERMINATION POWER SUPPLY APPLICATIONS

PRELIMINARY - October 9, 2000

ELECTRICAL CHARACTERISTICS

Unless specified: VCC = 4.75V to 12.6V; GND = PGND = 0V; FB = VO; V

PARAMETER CONDITIONS MIN TYP MAX UNITS

MOSFET DRIVERS

Peak DH Sink/Source Current BSTH - DH = 4.5V, DH - PHASE = 3.0V 0.5 A

DH - PHASE = 1.5V 0.1

Peak DL Sink/Source Current BSTL - DL = 4.5V, DL - GND = 3.0V 0.5 A

DL - GND = 1.5V 0.1

PROTECTION

BSTL

= 12V; V

BSTH-PHASE

= 12V; TJ = 25oC

Over Current Set Isource V

= 4.5V 180 200 220 µA

OCSET

SOFT START

Charge Current V

Discharge Current V

= 1.5V 10 µA

SS

= 1.5V 2 µA

SS

POWER GOOD

Upper Threshold 112 %

Lower Threshold 88 %

PWRGD Voltage Low I

= 2mA 0.5 V

PWRGD

REFERENCE

REFOUT Source Current 3 mA

Input Bias 58µA

NOTE:

(1) Specification refers to application circuit (Figure 1.).

BLOCK DIAGRAM

3

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

PRELIMINARY - October 9, 2000

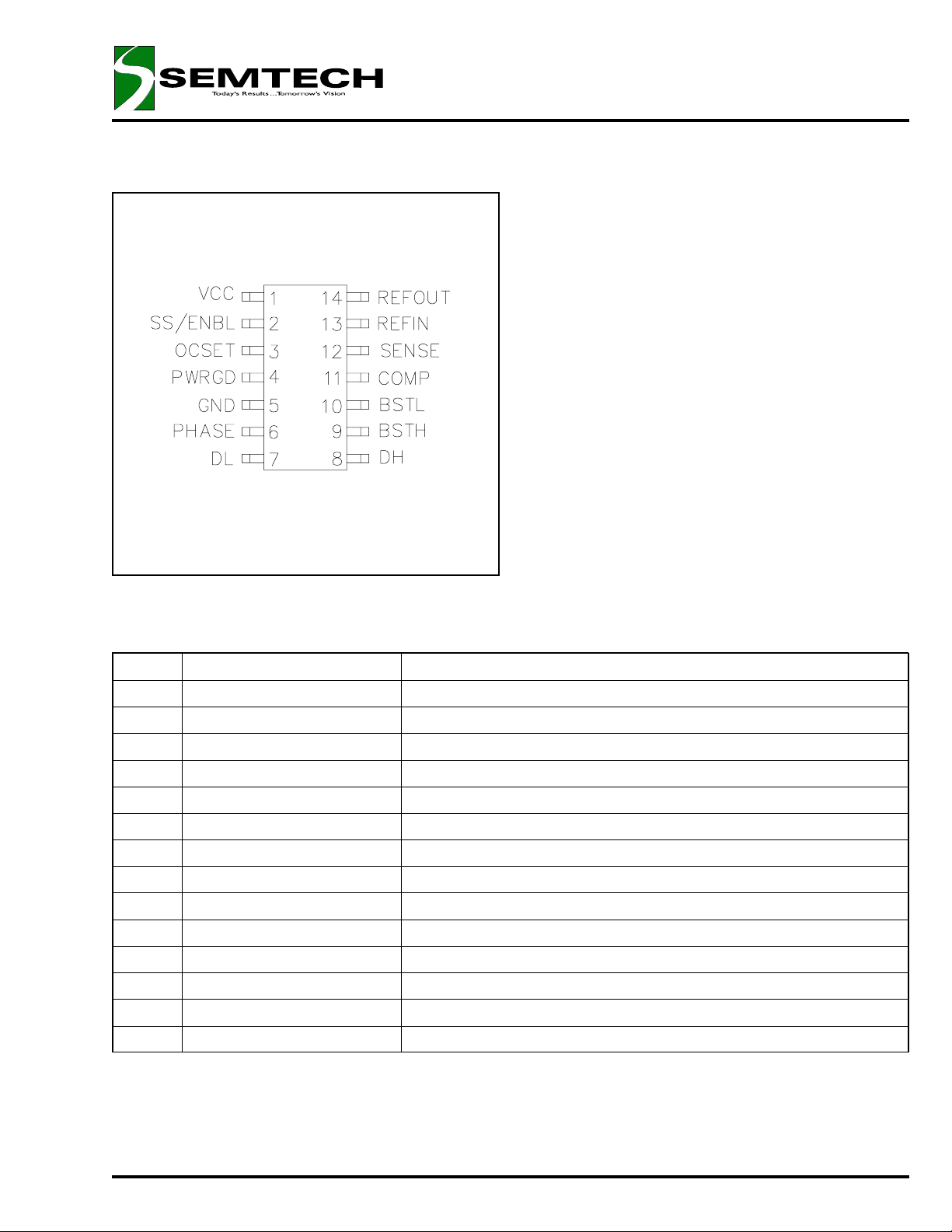

PIN CONFIGURATION

Top View

(14-Pin SOIC)

SINK AND SOURCE DC/DC CONTROLLER FOR

TERMINATION POWER SUPPLY APPLICATIONS

SC1110

PIN DESCRIPTION

Pin # Pin Name Pin Function

1 VCC Chip supply voltage.

2 SS/ENBL Soft start/Enable.

3 OCSET Current limit set point.

4 PWRGD Logic high indicates correct output.

5 GND Ground.

6 PHASE Phase node connection between MOSFET’s.

7 DL Low side driver output.

8 DH High side driver output.

9 BSTH High side drive supply.

10 BSTL Low side drive supply.

11 COMP Error amplifier output, compensation.

12 SENSE Error amplifier negative input.

13 REFIN Error amplifier positive input.

14 REFOUT Buffered reference voltage.

NOTE:

(1) All logic level inputs and outputs are open collector TTL compatible.

4

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

SINK AND SOURCE DC/DC CONTROLLER FOR

TERMINATION POWER SUPPLY APPLICATIONS

PRELIMINARY - October 9, 2000

THEORY OF OPERATION

Synchronous Buck Converter

V

TERMINATION

voltage-mode pulse width modulated (PWM) controller.

This section has all the features required to build a

high efficiency synchronous buck converter for termination of power application.

The output voltage of the synchronous converter is set

and controlled by the output of the error amplifier. The

resistive divider generates reference voltage for the

error amplifier from an external chipset voltage which

is usually 2.5V. The inverting input of the error amplifier

receives its voltage from the SENSE pin.

power is provided by a synchronous,

SC1110

R

Current Limiting

DS(ON)

The current limit threshold is set by connecting an external resistor from the V

age drop across this resistor is due to the 200µA internal sink sets the voltage at the pin. This voltage is

compared to the voltage at the PHASE node. This

comparison is made only when the high-side drive is

high to avoid false current limit triggering due to uncontributing measurements from the MOSFET’s offvoltage. When the voltage at PHASE is less than the

voltage at OCSET, an overcurrent condition occurs

and the soft start cycle is initiated. The synchronous

switcher turns off and SS/ENABLE starts to sink 2µA.

When SS/ENABLE reaches 0.8V, it then starts to

source 10µA and a new cycle begins.

supply to OCSET. The volt-

CC

The internal oscillator uses an on-chip capacitor and

trimmed precision current sources to set the oscillation

frequency to 250kHz. The triangular output of the oscillator sets the reference voltage at the inverting input

of the PWM comparator. The non-inverting input of the

comparator receives it’s input voltage from the error

amplifier. When the oscillator output voltage drops below the error amplifier output voltage, the comparator

output goes high. This pulls DL low, turning off the lowside FET, and DH is pulled high, turning on the highside FET (once the cross-current control allows it).

When the oscillator voltage rises back above the error

amplifier output voltage, the comparator output goes

low. This pulls DH low, turning off the high-side FET,

and DL is pulled high, turning on the low-side FET

(once the cross-current control allows it).

As SENSE increases, the output voltage of the error

amplifier decreases. This causes a reduction in the ontime of the high-side MOSFET connected to DH,

hence lowering the output voltage.

Under Voltage Lockout

The under voltage lockout circuit of the SC1110 assures that both the high-side MOSFET driver outputs

remain in the off state whenever the supply voltage

CC

falls

CC

rises

drops below set parameters. Lockout occurs if V

below 4.0V. Normal operation resumes once V

above 4.2V.

Soft Start

Initially, SS/ENABLE sources 10µA of current to

charge an external capacitor. The outputs of the error

amplifiers are clamped to a voltage proportional to the

voltage on SS/ENABLE. This limits the on-time of the

high-side MOSFETs, thus leading to a controlled rampup of the output voltages.

Hiccup Mode

During power up, the SS/ENABLE pin is internally

pulled low until VCC reaches the undervoltage lockout

level of 4.2V. Once V

has reached 4.2V, the SS/EN-

CC

ABLE pin is released and begins to source 10µA of

current to the external soft-start capacitor. As the softstart voltage rises, the output of the internal error amplifier is clamped to this voltage. When the error signal

reaches the level of the internal triangular oscillator,

which swings from 1V to 2V at a fixed frequency of 250

kHz, switching occurs. As the error signal crosses

over the oscillator signal, the duty cycle of the PWM

signal continues to increase until the output comes into

regulation. If an over-current condition has not occurred the soft-start voltage will continue to rise and

level off at about 2.2V.

An over-current condition occurs when the high-side

drive is turned on, but the PHASE node does not

reach the voltage level set at the OCSET pin. The

PHASE node is sampled only once per cycle during the

valley of the triangular oscillator. Once an over-current

occurs, both the high-side and low-side drivers turn off

and the SS/ENABLE pin begins to sink 2uA. The softstart voltage will begin to decrease as the 2uA of current discharges the external capacitor. When the softstart voltage reaches 0.8V, the SS/ENABLE pin will begin to source 10uA and begin to charge the external

capacitor causing the soft-start voltage to rise again.

Again, when the soft-start voltage reaches the level of

the internal oscillator, switching will occur.

If the over-current condition is no longer present, normal operation will continue. If the over-current condition is still present, the SS/ENABLE pin will again begin

to sink 2uA. This cycle will continue indefinitely until

the over-current condition is removed.

5

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

PRELIMINARY - October 9, 2000

SIMULATION WAVEFORMS

2.5V and 1.25V ramp up

SINK AND SOURCE DC/DC CONTROLLER FOR

TERMINATION POWER SUPPLY APPLICATIONS

SC1110

Output current of the VTT supply

6

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

PRELIMINARY - October 9, 2000

OUTLINE DRAWING SO-14

SINK AND SOURCE DC/DC CONTROLLER FOR

TERMINATION POWER SUPPLY APPLICATIONS

SC1110

ECN00-1363

7

© 2000 SEMTECH CORP. 652 MITCHELL ROAD NEWBURY PARK CA 91320

Loading...

Loading...