SX8652

Touch

Screen

Interface

SX8652

VDD

X+/BR

Y+/TR

X-/TL

Y-/BL

DIN

NIRQ

SCLK

DOUT

GND

Control

SPI

Digital

Filter

ref+

ref-

ADCin out

OSC

POR

Vref

NCS

AUX/WIPER

VDD

To the

Host

To the

touch

screen

NRST (DFN only)

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

-----4

GENERAL DESCRIPTION

The SX8652 is a very low power, high reliability controller

for 4-wire and 5-wire resistive touch screens used in PDAs,

portable instruments and point-of-sales terminal

applications. It features a wide input supply range from

1.65V to 3.7V and low power modes to preserve current

when the screen is unintentionally touched.

To compute touch screen X-Y coordinates and touch

pressure with precision, a low power 12-bit analog-digital

converter is activated with the possibility to enable on-chip

data averaging processing algorithms to reduce host activity

and suppress system noise.

The touch screen controller inputs have been specially

designed to provide robust on-chip ESD protection of up to

±15kV in both HBM and Contact Discharge, and eliminates

the need for external protection devices. The SX8652 is

controlled by a high speed SPI™ serial interface.

The SX8652 is available in a 4.0 mm x 3.0 mm 14-DFN

package and a 1.5 mm x 2.0 mm wafer level chip scale

package (WLCSP) for space conscience applications.

APPLICATIONS

DSC, DVR, Cell Phones

PDA, Pagers

Point-of-Sales Terminals

Touch-Screen Monitors

ORDERING INFORMATION

KEY PRODUCT FEATURES

Extremely Low Power Consumption: 23uA@1.8V 8kSPS

Superior On-chip ESD Protection

±15kV HBM (X+,X-,Y+,Y-)

±2kV CDM

±25kV Air Gap Discharge

±15kV Contact Discharge

±300V MM

Single 1.65V to 3.7V Supply/Reference

4-Wire or 5-Wire Resistive Touch Screen Interface

Integrated Preprocessing Block to Reduce Host Loading

and Bus Activity

Four User Programmable Operation Modes provides

Flexibility to address Different Application Needs

Manual, Automatic, Pen Detect, Pen Trigger

Low Noise Ratiometric Conversion

Precision, High Speed 12-bit SAR ADC Operating At 74k

SPS

Throughput: 5000 (X-Y) coordinates/second (c/s) with 7Sample Averaging

Low Power Shut-Down Mode < 1uA

SPI™ Serial Interface

Touch Pressure Measurement (4-Wire)

Auxiliary Input (4-Wire) For Alternate ADC Input or Start

of Conversion Trigger

Hardware & Software reset

-40°C to +85°C operation

DATASHEET

Part Number Package

SX8652ICSTRT

SX8652IWLTRT

1. 3000 Units / reel

Revision V1.7/October 2010

©2010 Semtech Corp.

1

1

(Dimension in mm)

12 - Ball WLCSP

14 - Lead DFN

(1.5x2.0)

(4.0x 3.0)

Marking

FG97

FG97

Page 1

Pb-Free, Halogen Free, RoHS/WEEE compliant product

Windows CE 6.0, Linux Driver Support Available

Packages: 14-LD (4.0 mm x 3.0 mm) DFN

12-Ball (1.5 mm x 2.0 mm) WLCSP

www.semtech.com

SX8652

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

Table of contents

Section Page

1. General Description................................................................................................................................................. 4

1.1. DFN Pinout Diagram and Marking Information (Top View).............................................................................. 4

1.2. WLCSP Pinout Diagram and Marking Information (Top View) ........................................................................ 4

1.3. Pin Description................................................................................................................................................. 5

1.4. Simplified Block Diagram................................................................................................................................. 5

2. Electrical Characteristics ......................................................................................................................................... 6

2.1. Absolute Maximum Ratings ............................................................................................................................. 6

2.2. Recommended Operating Conditions.............................................................................................................. 6

2.3. Thermal Characteristics................................................................................................................................... 6

2.4. Electrical Specifications ................................................................................................................................... 7

2.5. Host Interface Specifications ........................................................................................................................... 9

2.6. Host Interface Timing Waveforms.................................................................................................................... 9

3. Functional Description ........................................................................................................................................... 10

3.1. General Introduction ..................................................................................................................................... 10

3.2. Device Interface and ESD protection............................................................................................................. 11

3.2.1. Touchscreen interface............................................................................................................................. 11

3.2.2. Host Interface and Control Pins .............................................................................................................. 11

4. 4-wire Touch Screen Detailed Description ............................................................................................................ 12

4.1. Touch Screen Operation................................................................................................................................ 12

4.2. Coordinates Measurement............................................................................................................................. 12

4.3. Pressure Measurement.................................................................................................................................. 13

4.4. Pen Detection ................................................................................................................................................ 13

5. 5-wire Touch Screen Detailed Description ............................................................................................................ 14

5.1. Touch Screen Operation................................................................................................................................ 14

5.2. Coordinates Measurement............................................................................................................................. 14

5.3. Pen Detection ................................................................................................................................................ 14

6. Data Processing .................................................................................................................................................... 15

7. Power-Up, Reset ................................................................................................................................................... 15

8. Modes of Operation ............................................................................................................................................... 15

8.1. MANual Mode ................................................................................................................................................ 16

8.2. AUTOmatic mode .......................................................................................................................................... 16

8.3. PENDET Mode .............................................................................................................................................. 17

8.4. PENTRIG Mode............................................................................................................................................. 17

9. Host Interface ........................................................................................................................................................ 19

9.1. SPI Read/Write Registers.............................................................................................................................. 19

9.2. SPI Reading Channel Data............................................................................................................................ 19

9.3. SPI Host Commands ..................................................................................................................................... 20

9.4. SPI implementation and multiple Read/Write ................................................................................................ 20

9.5. Invalid Qualified Data..................................................................................................................................... 21

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 2

www.semtech.com

SX8652

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

Table of contents

Section Page

9.6. Register Map................................................................................................................................................. 22

9.7. SX8652 register ............................................................................................................................................ 23

10. Application Information ......................................................................................................................................... 24

10.1. Acquisition Setup ........................................................................................................................................... 24

10.2. Channel Selection.......................................................................................................................................... 24

10.3. Noise Reduction............................................................................................................................................. 24

10.3.1. POWDLY................................................................................................................................................. 24

10.3.2. SETDLY .................................................................................................................................................. 25

10.4. AUX Input - 4-wire touchscreen only ............................................................................................................. 25

10.5. Interrupt Generation....................................................................................................................................... 25

10.6. Coordinate Throughput Rate ......................................................................................................................... 25

10.6.1. SPI Communication Time ....................................................................................................................... 25

10.6.2. Conversion Time..................................................................................................................................... 26

10.7. ESD event...................................................................................................................................................... 26

11. Packaging Information........................................................................................................................................... 27

11.1. DFN Package................................................................................................................................................. 27

11.2. WLCSP Package ........................................................................................................................................... 28

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 3

www.semtech.com

SX8652

1

2

3

4

5

6

14

13

12

11

10

9

AUX/

WIPER

(NC)

VDD

X+/BR

Y+/TR

X-/TL

NRST

DIN

NCS

NIRQ

DOUT

Y-/BL

15

7

GND

8

SCLK

PIN

1

IDENTIFIER

FG97

YYWW

XXXXX

#

A

NIRQ SCLKDOUT

B C D

3

2

1

VDD NCS GNDDIN

X+/BR Y+/TR Y-/BLX-/TL

AUX/WIPER

FG97

YYWW

XXXXXX

BALL A1 IDENTIFIER

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

1. General Description

1.1. DFN Pinout Diagram and Marking Information (Top View)

DATASHEET

Figure 1. SX8652 DFN Top View, Pad on Bottom Side

YYWW: date code

XXXXX: Lot Number

1.2. WLCSP Pinout Diagram and Marking Information (Top View)

YYWW: date code

XXXXX: Lot Number

Figure 2. SX8652 WLCSP Top View, Solder Bumps on Bottom Side

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 4

www.semtech.com

SX8652

Touch

Screen

Interface

SX8652

VDD

X+/BR

Y+/TR

X-/TL

Y-/BL

DIN

NIRQ

SCLK

DOUT

GND

Control

SPI

Digital

Filter

ref+

ref-

ADCin out

OSC

POR

Vref

NCS

AUX/WIPER

VDD

To the

Host

To the

touch

screen

NRST (DFN only)

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

1.3. Pin Description

Pin Number #Name Type Description

DFN WLCSP

1 A1 AUX/WIPER Digital Input /

Analog Input

2 A2 VDD Power Input Input power supply, connect to a 0.1uF capacitor to GND

3 A3 X+/BR Analog IO X+ Right electrode (4-wire) / Bottom Right (5-wire) channel

4 B3 Y+/TR Analog IO Y+ Top electrode (4-wire) /Top Right (5-wire) channel

5 C3 X-/TL Analog IO X- Left electrode (4-wire) /Top Left (5-wire) channel

6 D3 Y-/BL Analog IO Y- Bottom electrode (4-wire) /Bottom Left (5-wire) channel

7 D2 GND Ground Ground

8 D1 SCLK Digital Input SPI Serial Clock Input

9 C2 DIN Digital Output SPI Serial Data Input

10 C1 DOUT Digital Output SPI Serial Data Output

11 B1 NIRQ Digital Output, open drain Interrupt Request Output, Active low, Need external pull-up

12 B2 NCS Digital Input SPI Chip Select Input, Active low

13 - NRST Digital Input DFN package only, Reset Input, Active low, Internal pull-up resistor

14 - (NC) Not Connected

15 - GND Power input Backside Ground

Conversion Synchronization (4-wire) or

Analog Auxiliary Input (4-wire) / Wiper Input (5-wire)

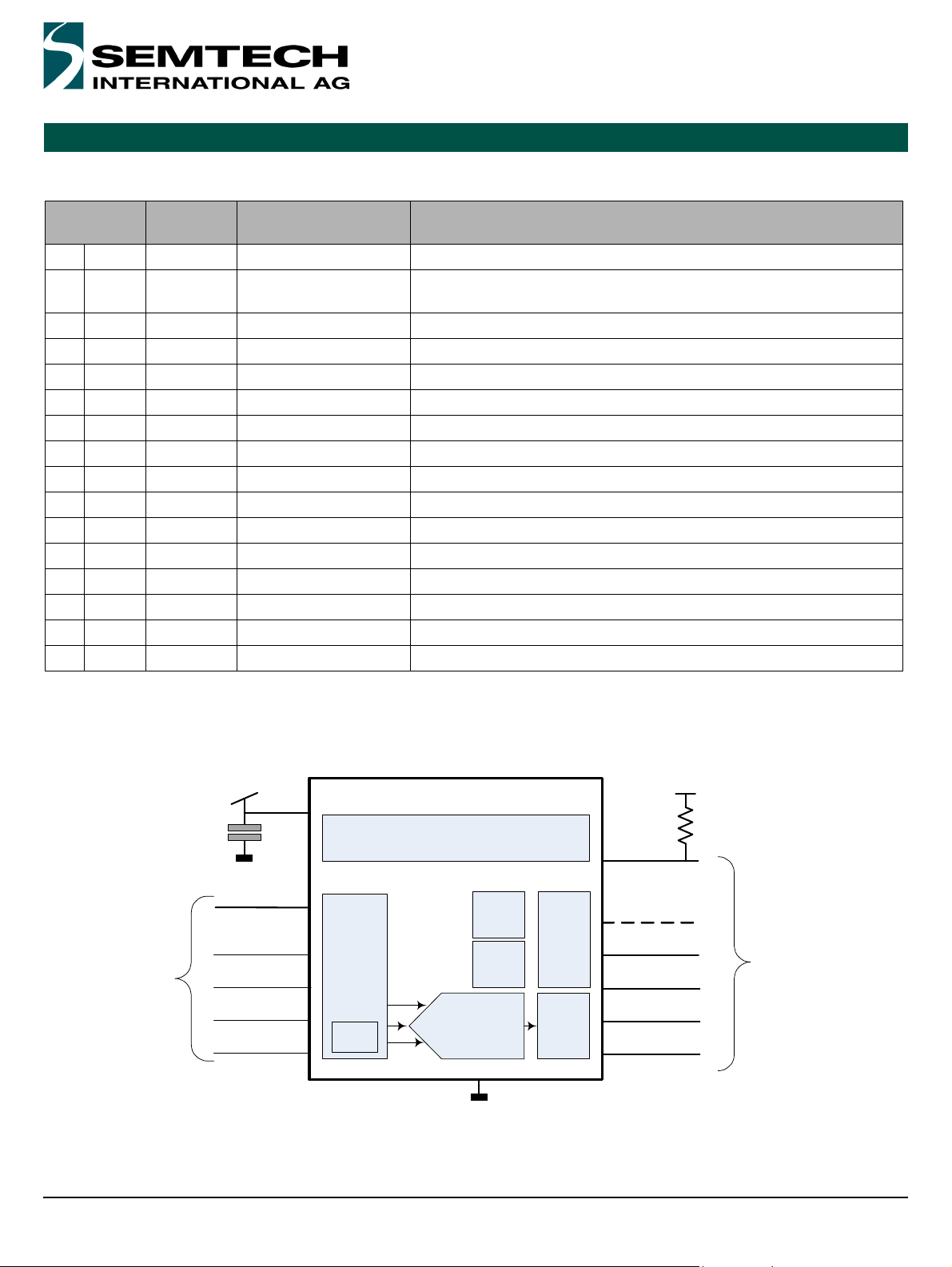

1.4. Simplified Block Diagram

The SX8652 simplified block diagram is shown in Figure 3.

Revision V1.7/October 2010

©2010 Semtech Corp.

Figure 3. Simplified block diagram of the SX8652

Table 1. Pin description

Page 5

www.semtech.com

SX8652

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

2. Electrical Characteristics

2.1. Absolute Maximum Ratings

Stresses above the values listed in “Absolute Maximum Ratings” may cause permanent damage to the device.

This is a stress rating only and functional operation of the device at these, or any other conditions beyond the “Recommended Operating

Conditions”, is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability

Parameter Symbol Min. Max. Unit

Supply Voltage V

Input voltage (non-supply pins) V

Input current (non-supply pins) I

Operating Junction Temperature T

Reflow temperature T

Storage temperature T

High ESD pins: X+/BR, X-/TL,

ESD HBM

(Human Body Model)

Y+/TR, Y-/BL, Aux/Wiper

All pins except high ESD pins ESD

DDABS

ESD

IN

IN

JCT

RE

STOR

HBM1

HBM2

-0.5 3.9 V

-0.5 3.9 V

10 mA

125 °C

260 °C

-50 150 °C

(i)

± 15

(ii)

± 8

± 2 kV

.

kV

kV

ESD (Contact Discharge) High ESD pins: X+/BR, X-/TL,

Y+/TR, Y-/BL, Aux/Wiper

Latchup

(iii)

ESD

Table 2. Absolute Maximum Ratings

(i) Tested to TLP (10A)

(ii) Tested to JEDEC standard JESD22-A114

(iii) Tested to JEDEC standard JESD78

2.2. Recommended Operating Conditions

Parameter

Supply Voltage V

Ambient Temperature Range T

Table 3. Recommended Operating Conditions

Symbol Min. Max Unit

2.3. Thermal Characteristics

Parameter

Thermal Resistance with DFN package - Junction to Ambient

Thermal Resistance with WLCSP package - Junction to Ambient

(iii)

(iii)

Symbol Min. Max Unit

CD

I

LU

DD

A

θ

JA

θ

JA

± 15 kV

± 100 mA

1.65V 3.7 V

-40 85 °C

39 °C/W

65 °C/W

Table 4. Thermal Characteristics

(

iii) θJA is calculated from a package in still air, mounted to 3" x 4.5", 4 layer FR4 PCB with thermal vias under exposed pad (if applicable)

per JESD51 standards.

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 6

www.semtech.com

SX8652

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

2.4. Electrical Specifications

All values are valid within the recommended operating conditions unless otherwise specified.

Parameter

Current consumption

Mode = MANUAL I

Mode = PENDET I

Mode =PENTRIG I

Mode=AUTO I

Symbol Conditions Min. Typ Max Unit

pwd

pndt

pntr

auto

Converter stopped, pen

detection off, SPI listening,

OSC stopped

Converter stopped, pen

detection activated, device

generates interrupt upon

detection, SPI listening, OSC

stopped

Converter stopped, pen

detection activated, device

starts conversion upon pen

detection. SPI listening, OSC

stopped

Converter stopped, pen

detection off, SPI listening,

OSC on, timer on

DATASHEET

0.4 1 uA

0.4 1 uA

0.4 1 uA

1.5 uA

Operation @8kSPS, VDD=1.8V I

Operation @42kSPS, VDD=3.3V I

Digital I/O

High-level input voltage V

Low-level input voltage V

Hysteresis

Output Logic High V

Output Logic Low V

Input leakage current L

High ESD Input - Output

capacitance

Input - Output capacitance C

opl

oph

IH

IL

V

HysLow

V

HysHigh

OH

OL

I

C

,C

X+/BR

,C

Y+/TR

C

AUX

NRST , CNIRQ

,C

NCS ,CDIN

C

DOUT, CSCLK

X-/TL

, C

Y-/BL,

,

23 50 uA

105 140 uA

0.8V

DD

VSS-0.3 0.2V

VDD > 2V 0.05 V

VDD < 2V 0.1 V

IOH>-2mA 0.8V

IOL<2mA 0 0.4 V

CMOS input ±1 uA

DD

50 pF

VDD+0.2 V

DD

DD

5 pF

DD

V

V

V

Revision V1.7/October 2010

©2010 Semtech Corp.

Table 5. Electrical Specifications

Page 7

www.semtech.com

SX8652

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

Parameter

Startup

Power-up time t

ADC

Resolution A

Offset A

Gain error A

Differential Non Linearity A

Integral Non Linearity A

Symbol Conditions Min. Typ Max Unit

por

res

off

ge

dnl

inl

Time between rising edge VDD

and rising NIRQ

At full scale 0.5 LSB

DATASHEET

1 ms

12 bits

±1 LSB

±1 LSB

±1.5 LSB

Resistors

X+, X-, Y+, Y- resistance R

Pen detect resistance R

chn

PNDT_00

R

PNDT_01

R

PNDT_10

R

PNDT_11

Touch Pad Biasing Resistance 5 Ohm

R

= 0 100 kOhm

PNDT

R

= 1 200 kOhm

PNDT

R

= 2 50 kOhm

PNDT

R

= 3 25 kOhm

PNDT

External components recommendations

Capacitor between VDD, GND C

vdd

Type 0402, tolerance +/-50% 0.1 uF

Table 5. Electrical Specifications

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 8

www.semtech.com

SX8652

tCKH

tDS

tDH

tCSS tCKL

tDCD

tDOD

tCSW

tCSI

tCCZ

CSN

SCLK

DIN

DOUT

D11

VOL

VOH

50%VDD

50%VDD

50%VDD

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

2.5. Host Interface Specifications

Parameter Symbol Condition Min Typ Max Unit

SPI TIMING SPECIFICATIONS

SCLK

Clock Frequency

Duty Cycle

NCS edge to first SCLK “↑” T

NCS edge to DOUT Low T

SCLK High Pulse Width T

SCLK Low Pulse Width T

Data Setup Time T

Data Valid to SCLK Hold Time T

Data Output Delay after SCLK “↓” T

NCS “↑” to SCLK Ignored T

(i)

f

SCLK

duty

CSS

DCD

CKH

CKL

DS

DH

DOD

CSI

40

50

80

80

40

70

50

5000

60

100

70

kHz

%

ns

NCS “↑” to DOUT Hi-Z state T

NCS Hold Time T

(i) All timing specifications refer to voltage levels (50% VDD, VOH, VOL) defined in Table 6 unless otherwise mentioned.

CCZ

CSW

150

Table 6. Host Interface Specifications

2.6. Host Interface Timing Waveforms

Figure 4. SPI Timing Waveform

90

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 9

www.semtech.com

SX8652

Touch

Screen

Interface

SX8652

VDD

X+/BR

Y+/TR

X-/TL

Y-/BL

DIN

NIRQ

SCLK

DOUT

GND

Control

SPI

Digital

Filter

ref+

ref-

ADCin out

OSC

POR

Vref

NCS

AUX/WIPER

VDD

NRST (DFN only)

HOST

INT

DIO

CS

SCLK

MISO

MOSI

SPI

Interface

4-wire touchscreen

Touch

Screen

Interface

SX8653

VDD

X+/BR

Y+/TR

X-/TL

Y-/BL

DIN

NIRQ

SCLK

DOUT

GND

Control

SPI

Digital

Filter

ref+

ref-

ADCin out

OSC

POR

Vref

NCS

AUX/WIPER

VDD

NRST (DFN only)

HOST

INT

DIO

CS

SCLK

MISO

MOSI

SPI

Interface

5-wire touchscreen

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

3. Functional Description

3.1. General Introduction

This section provides an overview of the SX8652 architecture, device pinout and a typical application.

The SX8652 is designed for 4-wire and 5-wire resistive touch screen applications. The touch screen or touch panel is the

resistive sensor and can be activated by either a finger or stylus. When the top layer is pressed, it makes contact with the

bottom sheet and the touch location can be measured.

As shown in Figure 5 with a 4-wire panel, the touch screen coordinates and touch pressure are converted into SPI format

by the SX8652 for transfer to the host. The auxiliary input can be used to convert with 12-bit resolution any analog input in

the supply range. It can also serves as an external synchronisation input to trig the touchscreen acquisition as described in

the Application Information section.

Figure 5. SX8652 with a 4-wire touch screen

A 5-wire touchscreen application is shown in Figure 6. The 5-wire top sheet acts as a voltage measuring probe. The

measurement accuracy is not affected by damage on this sheet and consequently the reliability is improved but the touch

pressure can not be calculated.

www.semtech.com

Revision V1.7/October 2010

©2010 Semtech Corp.

Figure 6. SX8652 with a 5-wire touch screen

Page 10

SX8652

T o uch

S c re e n

D riv e rs

In te rfac e

R

ch n

A

D

C

C o n trol

D a ta Pro cess in g

X + /B R

X -/TL

Y + /T R

Y -/B L

A U X /

W ip e r

M U X

R

ch n

R

ch n

R

ch n

P o w er

M an ag e m en t

V D D

G N D

N R S T

N IR Q

S P I

NCS

SCLK

DOUT

DIN

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

3.2. Device Interface and ESD protection

The touch screen controller inputs have been specially designed to provide robust on-chip ESD protection of up to ±15kV

in both HBM and Contact Discharge.

3.2.1. Touchscreen interface

The X+/BR, X-/TL, Y+/TR,Y-/BL, AUX/WIPER are the pins dedicated for the touchscreen interface. It provides the voltage

sequence in order to obtain the coordinates and pressure measurement.

The five pins are connected to BR, TL, TR, BL, WIPER on a 5-wire touchscreen. They are the electrodes on the 4 corners

of the bottom layer of the touchscreen plus the electrode on the top layer.

On a 4-wire touchscreen, only 4 electrodes are used: X+,X-,Y+,Y-. The AUX pin is not needed and therefore can be used

to convert an analog signal (range GND - VDD) into 12-bit digital value. The touchscreen interface pins are the most

exposed pins for an ESD event.

As shown in Figure 7, theses pins have internal ESD protection to GROUND and VDD.

3.2.2. Host Interface and Control Pins

The SX8652 is a slave device configured via the SPI interface.

NIRQ provides an interrupt to the host processor when a pen is detected or when channel data is available. The NIRQ pin

is an active low, open drain output to facilitate interfacing to different supply voltages and thus requires an external pull-up

resistor (1-10 kOhm).

The host can reset the chip via the SPI interface or with the dedicated pin NRST. The NRST pin is an active low input that

provides a hardware reset. An internal pull-up enables the interfacing with devices at different supply voltage.

NRST and NIRQ pins are protected to GROUND.

Revision V1.7/October 2010

©2010 Semtech Corp.

Figure 7. ESD protection

Page 11

www.semtech.com

SX8652

X-

Y+

Y-

X+

T

o

p

c

o

n

d

u

c

t

i

v

e

s

h

e

e

t

B

o

t

t

o

m

c

o

n

d

u

c

t

i

v

e

s

h

e

e

t

Y

e

l

e

c

t

r

o

d

e

s

X

e

l

e

c

t

r

o

d

e

s

Y

-

Y

+

R

y

t

o

t

Top conductive sheet before

the stylus contact

Y

-

Y

+

R

4

R

3

Top conductive sheet after

the stylus contact

Contact point

with the top

conductive

sheet

Rxtot R1 R2+=

Rytot R3 R4+=

X-

X+

R2

R1

+

-

R

T

Y-

Y+

R4

R3

Xpos

+

-

ADC

Vref

Xpos 4095

R2

R1 R2+

--------------------

⋅=

Ypos 4095

R4

R3 R4+

--------------------

⋅=

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

4. 4-wire Touch Screen Detailed Description

4.1. Touch Screen Operation

A 4-wire resistive touch screen consists of two resistive sheets separated by an insulator (Figure 4.2).

Figure 8. 4-wire Touch Screen

When a pressure is applied on the top sheet with a stylus for example, a connection with the lower sheet is made.

The contact point split the Rxtot bottom resistance in the vertical axis into two resistances

R1 and R2. In the same way, the Rytot resistance in the horizontal axis of the top sheet is

divided into two resistances R3 and R4.

The touchscreen controller imposes a voltage level on X or Y electrodes allowing the

detection of the contact position.

4.2. Coordinates Measurement

During the touch, the top and bottom touchscreen layers

are connected. The resistance between the two sheets

is RT. A current coming from the reference voltage goes

from X+ to X- to perform the X coordinate

measurement. Figure 9 shows the measurement

schematics.

Since the ADC had a high input impedance, no current

flows through RT and R3. The positive ADC input is

biased with a voltage created by the R1, R2 voltage

divider.

The conversion with the 12 bit ADC gives the X location.

Figure 9. Abscissa (X) coordinates measurement

The Y coordinate is measured in a similar fashion with the measurement setup given in Table 7.

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 12

www.semtech.com

SX8652

z1 4095

R4

R1 R4 R

T

+ +

---------------------------------

⋅= z2 4095

R4 Rt+

R1 R4 R

T

+ +

---------------------------------

⋅=

R

T

Rytot

Ypos

4095

------------

z2

z1

-----

1–⋅ ⋅=

R

T

Rytot Y⋅ pos

4095

-------------------------------

4095

z1

------------

1– Rxtot 1

Xpos

4095

-------------

–⋅–⋅=

X-

X+

R2

R1

Vref

+

-

R

T

Y-

Y+

R

4

R3

R

PNDT

Sb

Rb

IRQ

Q

Q

Internal

logic

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

4.3. Pressure Measurement

The 4-wire touchscreen allows pressure measurement. The contact resistance between the two sheets are a function of

the pressure applied on the top sheet. Indeed, the a low pressure applied with the finger will create a small contact area.

With a greater pressure, the contact area will be bigger and the RT resistance smaller.

The RT contact resistance is therefore an indication of the applied pressure. RT is deducted from Z1 and Z2 measurement.

The measurement setup given in Table 7 allows to find Z1 and Z2.

Arranging Z1 and Z2 with Rxtot and Rytot allows the

computation of RT.

An alternative calculation method is using Xpos and Ypos.

Measurement Vref + Vref- ADC +

X

Y

Z1

Z2

X+ X- Y+

Y+ Y- X+

X+ Y- Y+

X+ Y- X-

Table 7. Measurement setup

4.4. Pen Detection

The pen detection circuitry is used to detect a user action on the

touchscreen. The contact between the two layers generates an interrupt or

starts an acquisition sequence.

Doing a pen detection prior to conversion avoids feeding the host with

dummy data and saves power.

If the touchscreen is powered between X+ and Y- through a resistor R

no current will flow so long as pressure is not applied to the surface (see

Figure 10).

When a pressure is applied, a current path is created and brings X+ to the

level defined by the resistive divider determined by R

R1, RT and R4.

R

should be set to the greatest value of 200 kOhm for optimal detection (see Table 15). Increasing PowDly settings

PNDT

can also improve the detection on panel with high resistance.

The pen detection will set the PENIRQ bit of the RegStat register. The PENIRQ bit will be cleared and the NIRQ will be de-

asserted as soon as the host reads the status register.

In PENDET mode, the pen detection will set NIRQ low.

Revision V1.7/October 2010

©2010 Semtech Corp.

and the sum of

PNDT

Page 13

PNDT

,

Figure 10. 4-wire pen detection circuitry

www.semtech.com

SX8652

T

L

B

L

B

o

t

t

o

m

c

o

n

d

u

c

t

i

v

e

s

h

e

e

t

T

R

B

R

T

o

p

c

o

n

d

u

c

t

i

v

e

s

h

e

e

t

W

i

p

e

r

L

i

n

e

a

r

i

s

a

t

i

o

n

p

a

t

t

e

r

n

Xpos 4095

R2

R1 R2+

--------------------

⋅=

Ypos 4095

R4

R3 R4+

--------------------

⋅=

BR

R1

Vref

+

-

AUX/

WIPER

-

R

PNDT

Sb

Rb

Q

Q

Internal

logic

Bottom

layer

Top

layer

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

5. 5-wire Touch Screen Detailed Description

5.1. Touch Screen Operation

As the 4-wire, the 5-wire resistive touch screen consists of two resistive

sheets separated by an insulator (Figure 11). The main difference is that

the 4 wires are connected on the 4 corners of the bottom conductive

sheet. They are referred as Top Left, Top Right, Bottom Left, Bottom

Right.

The fifth wire is embedded in the top sheet and is used for sensing the

electrode voltage and is referred as the wiper.

Figure 11. 5-wire touchscreen

5.2. Coordinates Measurement

When the electrodes TL is connected with BL and TR with BR, they form with the linearization pattern 2 electrodes bars

which are very similar to the X electrodes in a 4-wire touchscreen. In the same way, the association of TL with TR and BL

with BR create Y electrodes.

The four corners are therefore able to produce voltage gradients in the horizontal and vertical axis. The wiper is connected

to the high input impedance of the ADC. When a pressure is applied on the top sheet, the contact point split the bottom

sheet resistance into R1 and R2 on the X axis and R3 and R4 on the Y axis.

The X and Y position converted by the 12-bit ADC

gives the following result.

5.3. Pen Detection

The BR pin is connected to the positive pin of the reference voltage through

R

. The wiper panel is grounded at the AUX/WIPER pin to provide the

PNDT

grounding path for a screen touch event.

The BR pin is monitored to detect voltage drop. When a pressure is applied on

the top surface, a current path is created between the two layers and the

PENIRQ bit of the RegStat register will be set. R

greatest value of 200 kOhm for optimal detection (see Table 15). Increasing

PowDly settings can also improve the detection on panel with high resistance.

In PENDET mode, the pen detection will set NIRQ low.

Revision V1.7/October 2010

©2010 Semtech Corp.

should be set to the

PNDT

Page 14

Figure 12. 5-wire pen detection circuitry

www.semtech.com

SX8652

s

n

cn=

s

n

1

3

---

K

cnc

n 1–

c

n 2–

+ +( )=

s

n

1

5

---

K

cnc

n 1–

c

n 2–

c

n 3–

c

n 4–

+ + + +( )=

c

max1cmax2cacbcccmin1cmin2

≥ ≥ ≥ ≥ ≥ ≥

s

n

1

3

---

K

cacbc

c

+ +( )=

voltage

time

voltage

time

VDD

NIRQ

t

POR

VDD/2

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

6. Data Processing

The SX8652 offers 4 types of data processing which allows the user to make trade-offs between data throughput, power

consumption and noise rejection. The parameter FILT is used to select the filter order N

The sn samples from the ADC can be averaged. The processed cn 12-bit value is then send through the SPI bus.

The noise rejection will be improved with a high order to the detriment of the power consumption.

The K coefficient in Table 8 is a filter constant. Its value is K=4079/4095.

FILT N

0 1 No average

1 3 3 ADC samples are averaged

2 5 5 ADC samples are averaged

3 7 7 ADC samples are sorted and

filt

Explanation Processing

the 3 center samples are

averaged

Table 8. Filter order

as seen in Table 8.

filt

7. Power-Up, Reset

During power-up, NIRQ pin is kept low, the POR reset all

registers and states of the SX8652. The SX8652 is not

accessible and SPI communications are ignored.

As soon as NIRQ rises, the SX8652 is in manual mode with

only the SPI peripheral enabled to minimize power

consumption.

The host can reset the SX8652 by setting the NRST pin low or

via the SPI bus. Writing the code 0xDE to the register

RegSoftReset reset the circuit.

When NRST is driven LOW by the host, NIRQ will be driven low

by the SX8652. After the reset NIRQ will be released by the

SX8652.

Figure 13. Power-up, NIRQ

8. Modes of Operation

The SX8652 has four operation modes that are configured using the SPI commands as defined in Table 13 and Table 15.

These 4 modes are:

manual (command ‘MANAUTO’ and RATE=0),

automatic (command ‘MANAUTO’ and RATE>0),

pen detect (command ‘PENDET’),

pen trigger mode (command ‘PENTRG’).

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 15

www.semtech.com

SX8652

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

In the PENDET mode the pen detection is activated. The SX8652 will generate an interrupt (NIRQ) upon pen detection and

set the PENIRQ bit in the SPI status register. To quit the PENDET mode the host needs to configure the manual mode.

In the PENTRG mode the pen detection is activated and a channel conversion will start after the detection of a pen. The

SX8652 will generate an interrupt (NIRQ) upon pen detection and set the CONVIRQ bit in the SPI status register. To quit

the PENTRIG mode the host needs to configure the manual mode. The PENTRG mode offers the best compromise

between power consumption and coordinate throughput.

DATASHEET

8.1. MANual Mode

In manual mode (RATE=0), the host sequences all the actions by the SPI commands described in Table 9.

When a command is received, the SX8652 executes the associated task and waits for the next command.

Command

CONVERT(CHAN)

SELECT(CHAN)

Select and bias a channel

Wait for the programmed settling time (POWDLY)

Start conversion

Select and bias a channel

Table 9. CONVERT and SELECT command

The channel can be biased for an arbitrary amount of time by first sending a SELECT command and then a CONVERT

command once the settling time requirement is met.

The SELECT command can be omitted if the large range of POWDLY settings cover the requirements. In the latter case,

the CONVERT command alone is enough to perform an acquisition.

With CHAN=SEQ, multiple channels are sampled. This requires programming the POWDLY field in register RegCTRL0.

The selected channel will be powered during POWDLY before a conversion is started. The channel bias is automatically

removed after the conversion has completed.

Action

8.2. AUTOmatic mode

In automatic mode (RATE > 0), SX8652 start the acquisition when a touch is detected. It converts all the channels selected

with RegChnMsk and set NIRQ low when it is finished.

After the host has read the channels, if CONDIRQ=1 and the touch is detected again, the SX8652 starts a new conversion

cycle.

To not loose data, the SX8652 does not begin conversion before the host read all the channels.

We can define the time ts between the start of the conversion and the end of the channels reading by the host.

The rate programmed is achieved if ts<1/RATE otherwise the new rate is 1/ts.

When the control CONDIRQ bit (see register RegStat Table 15) is set to ‘1’ then the interrupts will only be generated if the

pen detect occurred. This result in a regular interrupt stream, as long as the host performs the read channel commands,

and the screen is touched. When the screen is not touched, interrupts does not occur.

If the control CONDIRQ bit is cleared to ‘0’, the interrupts will be always generated. In case there is no pen detected on the

screen then the coordinate data will be qualified as invalid, see section [9.5]. This result in a regular interrupt stream as

long as the host performs the read channel commands,

This working is illustrated in Figure 16.

Figure 14 shows the SPI working in automatic mode with CONDIRQ=1. After the first sentence send through the SPI to

make the initialization, traffic is reduced as only reads are required.

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 16

www.semtech.com

SX8652

CS

DIN

DOUT

TOUCH

NIRQ

Read Channel Data CMD

Data from SX8652

Processing time

Time is 1/RATE

CS

DIN

DOUT

TOUCH

NIRQ

Read Channel Data CMD

Data from SX8652

Conversion time

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

The processing time is the

necessary time for the SX8652 to

makes the pen detection, the

settling time (POWDLY) and the

conversion of the selected

channels. This time increases with

the number of channel selected

and the filter used. NIRQ interrupt

signal notifies the host when the

conversions are done.

The host just need to read the

channels data to release the

interrupt.

DATASHEET

Figure 14. SPI working in AUTO mode

8.3. PENDET Mode

The PENDET mode can be used if the host only needs to know if the screen has been touched or not and take from that

information further actions. When pen detect circuitry is triggered the interrupt signal NIRQ will be generated and the status

register bit ‘PENIRQ’ will be set. The bit is cleared by reading the status register RegStat. The PENDET working is

illustrated in Figure 16.

8.4. PENTRIG Mode

The PENTRIG mode offers the best

compromise between power consumption

and coordinate throughput.

In this mode the SX8652 will wait until a pen

is detected on the screen and then starts the

coordinate conversions. The host will be

signaled only when the screen is touched and

coordinates are available. The flowchart is

describes in Figure 16.

The coordinate rate in pen trigger mode is

determined by the speed of the host reading

the channels and the conversion times of the

channels. The host performs the minimum

number of SPI commands in this mode.

The host has to wait for the NIRQ interrupt to

make the acquisition of the data.

The SPI working is illustrated in Figure 15.

Figure 15. SPI working in PENTRIG mode

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 17

www.semtech.com

SX8652

Touch Detected ?

Start channel conversion

Set interrupt

NIRQ=0

Release Interrupt

NIRQ=1

All channel

data read

All conversion

finished

yes

no

PENTRIG MODE

CONDIRQ=1 ?

Touch Detected ?

Set timer=RATE

Start timer

Start channel conversion

Set interrupt

NIRQ=0

Release Interrupt

NIRQ=1

yes

Timer expire

All channel

data read

All conversion

finished

yes

no

AUTO MODE

Touch Detected ?

Set interrupt

NIRQ=0

Release Interrupt

NIRQ=1

RegStat read

yes

no

PENDET MODE

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

Revision V1.7/October 2010

©2010 Semtech Corp.

Figure 16. AUTO, PENDET and PENTRIG Mode Flowchart

Page 18

www.semtech.com

SX8652

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

9. Host Interface

The host interfaced is composed of a SPI bus. It performs the read/ write operations on the registers and channels data.

9.1. SPI Read/Write Registers

The WRITE command allows the host to write a single or multiple registers in the SX8652. The host can read single or

multiple registers from the SX8652 by the READ command. This is defined in Table 10.

W/R command name CR(7:0) Function

7 6 5 4 3 2 1 0

WRITE(RA) 0 0 0 RA(4:0) Write register (see Table 14 for RA)

READ(RA) 0 1 0 RA(4:0) Read register (see Table 14 for RA)

Table 10. W/R commands

9.2. SPI Reading Channel Data

Five channels can be sampled by the SX8652: X, Y, Z1, Z2 and AUX. They are defined in Table 12. They can be converted

in sequence with the RegChanMsk register.

The READCHAN command allows the host to read the data obtained after the channels conversion and processing.

W/R command name CR(7:0) Function

7 6 5 4 3 2 1 0

READCHAN 0 0 1 x x x x x Read data from channel

Table 11. Read Channels Data

Channel CHAN(2:0) Function

2 1 0

X 0 0 0 X channel

Y 0 0 1 Y channel

Z1 0 1 0 First channel for pressure measurement

Z2 0 1 1 Second channel for pressure measurement

AUX 1 0 0 Auxiliary channel

reserved 1 0 1

reserved 1 1 0

SEQ 1 1 1 Channel sequentially selected from RegChanMsk register, (see Table 15)

Table 12. Channel definition

The channel data are 12-bit of unsigned format which corresponds to integers between 0 and 4095. This is send on two

bytes, MSB first then LSB. A mask with the value 0x0FFF (4095) must be done to filter the four first unknown bit.

When a channel data has been transmitted, the next one is sent in the successive order: X,Y, Z1, Z2 and AUX. If a channel

has not been converted, the data is not transmitted.

When the channel data buffer gets empty, the data will carry an invalid data as explained in the channel data format.

Remark: After a conversion sequence, it is possible to read only one time the same channel.

Example: the SX8652 is set to convert X and Y. The value 0xC0 is set in RegChanMsk. The first byte read after the

READCHAN command will be X(MSB), then X(LSB), Y(MSB) and at the end Y(LSB). If the host carry on the reading, it will

get invalid data.

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 19

www.semtech.com

SX8652

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

9.3. SPI Host Commands

.The host can issue commands to change the operation mode or perform manual actions as defined in Table 13.

command name CR(7:0) Function

7 6 5 4 3 2 1 0

SELECT(CHAN) 1 0 0 0 x CHAN(2:0) Bias channel (see Table 12 for CHAN)

CONVERT(CHAN) 1 0 0 1 x CHAN(2:0) Bias channel (see Table 12 for CHAN)

MANAUTO 1 0 1 1 x x x x Enter manual or automatic mode.

PENDET 1 1 0 0 x x x x Enter pen detect mode.

PENTRG 1 1 1 0 x x x x Enter pen trigger mode.

Table 13. Host Commands

9.4. SPI implementation and multiple Read/Write

The SPI implemented on the SX8652 is set to the common setting CPOL=0 and CPHA=0 which means data are sampled

on the rising edge of the clock, and shifted on the falling one.

The default state of the clock when NCS gets asserted is low. If a host send a command while the system is busy, the

command is discarded.

The SPI protocol is designed to be able to do multiple read/write during a transaction. During one single operation, as long

as NCS stay asserted, the register address is automatically increased to allow sequential read/write (or sequential retrieval

of data). Between each different operation though (READ/WRITE/READCHAN), the communication should be restarted.

This is described in Figure 17.

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 20

www.semtech.com

SX8652

NCS

SCLK

DIN

DOUT

1110 9 8 7 6 5 4 3 2 1 0

0 0 1

1110 9 8 7 6 5 4 3 2 1 0

Reading Channel Data

NCS

SCLK

DIN

DOUT

7 6 5 4 3 2 1 0

0 1 0

RA[4:0]

Reading Register

7 6 5 4 3 2 1 0

NCS

SCLK

DIN

DOUT

0 0 0

RA[4:0]

Writing Register

7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0

Multiple WriteSingle Write

Multiple ReadSingle Read

Multiple ReadSingle Read

NCS

SCLK

DIN

DOUT

Other command

CMD

Unknown bit

Multiple access

Single access

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

9.5. Invalid Qualified Data

The SX8652 returns 0xFFFF data in case of invalid qualified data.

This occurs:

When the SX8652 has read all the channel data in the FIFO

When a conversion is done without a pen being detected.

Figure 17. Data channel format

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 21

www.semtech.com

SX8652

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

9.6. Register Map

Register Address RA(4:0)

0 0000 RegCtrl0 Write, Read

0 0001 RegCtrl1 Write, Read

0 0010 RegCtrl2 Write, Read

0 0100 RegChanMsk Write, Read

0 0101 RegStat Read

1 1111 RegSoftReset Write

Table 14. Register address

The details of the registers are described in the next sections.

Register Description

DATASHEET

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 22

www.semtech.com

SX8652

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

9.7. SX8652 register

Register Bit Default Description

Set rate in coordinates per sec (cps) (± 20%)

If RATE =0: Manual mode. if RATE >0: Automatic mode

0000: Timer disabled -Manual mode

0001: 10 cps

7:4 0000 RATE

RegCtrl0

3:0 0000 POWDLY

0010: 20 cps

0011: 40 cps

0100: 60 cps

0101: 80 cps

0110: 100 cps

0111: 200 cps

Conversion (or first conversion when filtering is enabled) settling time (± 10%)

0000: Immediate (0.5 us)

0001: 1.1 us

0010: 2.2 us

0011: 4.4 us

0100: 8.9 us

0101: 17.8 us

0110: 35.5 us

0111: 71.0 us

DATASHEET

1000: 300 cps

1001: 400 cps

1010: 500 cps

1011: 1k cps

1100: 2k cps

1101: 3k cps

1110: 4k cps

1111: 5k cps

1000: 0.14 ms

1001: 0.28 ms

1010: 0.57 ms

1011: 1.14 ms

1100: 2.27 ms

1101: 4.55 ms

1110: 9.09 ms

1111: 18.19 ms

RegCtrl1

RegCtrl2

7:6 00 AUXAQC

5 1 CONDIRQ

4 0 SCREEN

3:2 00

1:0 00 FILT

7:4 0 reserved

3:0 0000 SETDLY

RPDNT

00: AUX is used as an analog input (4wire only)

01: On rising AUX edge, wait POWDLY

and start acquisition

The AUX trigger works only in manual mode with 4-wire touchscreen

Enable conditional interrupts

0: interrupt always generated at end of

conversion cycle. If no pen is detected

the data is set to ‘invalid qualified’.

Select the type of screen:

0: 4-wire 1: 5 -wire

Select the Pen Detect Resistor

00: 100 kOhm

01: 200 kOhm

Digital filter control

00: Disable

01: 3 sample averaging

Settling time while filtering (± 10%)

0000: Immediate (0.5 us)

0001: 1.1 us

0010: 2.2 us

0011: 4.4 us

0100: 8.9 us

0101: 17.8 us

0110: 35.5 us

0111: 71.0 us

10: On falling AUX edge, wait POWDLY

and start acquisition

11: On rising and falling AUX edges,

wait POWDLY and start acquisition

1: interrupt generated when pen detect

is successful

10: 50 kOhm

11: 25 kOhm

10: 5 sample averaging

11: 7 sample acquisition, sort, average 3

middle samples

1000: 0.14 ms

1001: 0.28 ms

1010: 0.57 ms

1011: 1.14 ms

1100: 2.27 ms

1101: 4.55 ms

1110: 9.09 ms

1111: 18.19 ms

Revision V1.7/October 2010

©2010 Semtech Corp.

Table 15. SX8652 Register

Page 23

www.semtech.com

SX8652

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

Register Bit Default Description

7 1 XCONV 0: no sample 1: Sample X channel

6 1 YCONV 0: no sample 1: Sample Y channel

5 0 Z1CONV 0: no sample 1: Sample Z1 channel

RegChanMsk

RegStat

4 0 Z2CONV 0: no sample 1: Sample Z2 channel

3 0 AUXCONV 0: no sample 1: Sample AUX channel

0 0 reserved

0 0 reserved

0 0 reserved

Host writing to this register is ignored.

7 0 CONVIRQ 0: no IRQ pending

1: Conversion sequence finished

IRQ is cleared by the channel data read command

6 0 PENIRQ Operational in pen detect mode

0: no IRQ pending

1: Pen detected IRQ pending

IRQ is cleared by the RegStat reading

5 1 RSTEVENT A reset event has occurred

4:0 00000 reserved

DATASHEET

RegSoftReset

7:0 0x00 Writing 0xDE to this register reset the SX8652

Any other data will not affect the SX8652

Table 15. SX8652 Register

10. Application Information

This section describes in more detail application oriented data.

10.1. Acquisition Setup

Prior to an acquisition, the SX8652 can be setup by writing the control registers. Registers are written by issuing the

register write command. They can be read by issuing the read command. Please refer to the section [9.7].

10.2. Channel Selection

The SX8652 can be setup to start a single channel conversion or to convert several channels in sequence. For a single

conversion, the channel to be converted is determined from the CHAN(2:0) field in the command word (defined in

Table 12).

Several channels defined in RegChanMsk can be acquired sequentially by setting the CHAN(2:0) field to SEQ. The

channels will be sampled in the order X, Y, Z1, Z2, AUX.

10.3. Noise Reduction

A noisy environment can decrease the performance of the controller. For example, an LCD display located just under the

touch screen can adds a lot of noise on the high impedance A/D converter inputs.

10.3.1. POWDLY

In order to perform correct coordinates acquisition properly, some time must be given for the touch screen to reach a

proper level. It is a function of the PCB trace resistance connecting the SX8652 to the touchscreen and also the

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 24

www.semtech.com

SX8652

CoordRate

1

T

comTconv

+

-------------------------------

=

T

com

8 16 N

chan

×+( ) T

SPI

×=

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

capacitance of the touchscreen. We can define tau as the RC time constant. POWDLY duration should be programmed to

10 tau to reach 12 bit accuracy.

Adding a capacitor from the touch screen drivers to ground is a solution to minimize external noise but it increases settling

time and consequently the power consumption.

10.3.2. SETDLY

A best method to filter noise is described in section [6] (Data processing). When filtering is enabled, the channel will be

biased initially during a time of POWDLY for the first conversion. The parameter SETDLY sets the settling time between the

subsequent conversions in a filter set. In most applications, SETDLY can be set to 0. In applications with a high tau and

where accuracy of 1LSB is required SETDLY should be increased.

DATASHEET

10.4. AUX Input - 4-wire touchscreen only

The AUX input can be used to sample an analog signal in the range 0-VDD. For system supply by battery, the battery

voltage can be monitored for example. The conversion is done in sequence with the touchscreen acquisition therefore the

sample rate is defined with RegCtrl0 in AUTO mode.

The AUX pin can also triggered conversions. A rising edge, a falling edge or both applied on the AUX pin can trigger the

conversion. This is defined by AUXACQ in RegCtrl1.

This method can be used to sample touchscreen when there is noise-free periods.

10.5. Interrupt Generation

An interrupt (NIRQ=0) will be generated:

During the power-up phase or after a reset

After completion of a conversion in MANUAL, PENTRIG or AUTO mode. CONVIRQ (bit [7] of RegStat) will be set at the

same time.

After a touch on the panel being detected in PENDET mode. PENIRQ (bit [6] of RegStat) will be set at the same time.

The NIRQ will be released and pulled high(NIRQ=1) by the external pull-up resistor:

When the power-up phase is finished

When the host read all channels data that were previously converted by the SX8652 in MANUAL, PENTRIG or AUTO

mode. CONVIRQ will be cleared at the same time.

When the host read the status register in PENDET mode. PENIRQ, will be cleared at the same time.

An active NIRQ (low) needs to be cleared before any new conversions will occur.

10.6. Coordinate Throughput Rate

The coordinate throughput rate depends on the following factors:

The SPI communication time: T

The conversion time: T

The coordinate rate is the frequency to get the X, Y, Z1 and Z2 coordinate:

10.6.1. SPI Communication Time

conv

com

The minimum time to read the channel data in PENTRIG mode is:

The highest throughput will be obtained with a SPI frequency of 5MHz when the host read the channel data as quickly as

possible after the NIRQ falling edge.

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 25

www.semtech.com

SX8652

T

conv

47 T

osc

⋅ N+

chan

POWDLY SETDLY N

filt

1–( ) T

osc

21N

filt

1+( )+ +[ ]=

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

10.6.2. Conversion Time

The maximum possible throughput can be estimated with the following equation

with:

N

N

= {1,3,5,7} based on the order defined for the filter FILT (see Figure 8).

filt

= {1,2,3,4,5} based on the number of channels defined in RegChanMsk

chan

POWDLY = 0.5us to 18.19ms, settling time as defined in RegCtrl0

SETDLY = 0.5us to 18.19ms, settling time when filtering as defined in RegCtrl2

Tosc is the oscillator period (555ns +/- 15%)

Table 16 gives some examples of Coordinate Rate and Sample Rate for various setting in PENTRIG mode.

Nch

[1..5 ]

2

2

Nfilt

[1 3 5 7]

1 0.5 3 71 0.5

PowDly

[uS]

SetDly

[uS]

Tconv

[uS]

Tcomm

[uS]

51 8 16.7

190 8 5.0

CoordRate

[kSPS]

4

3 140 0.5

740 14 1.3

Table 16. Coordinate throughput examples

10.7. ESD event

In case of ESD event, the chip may reset to protect its internal circuitry. The bit

occurs.

ESD event may trig the pen detection circuitry. In this case wrong data will be send to the host. To detect this false

coordinates on 4-wire touchscreen, Z1 and Z2 can be read. The conditions Z1<LowThreshold and Z2>HighThreshold

indicate an ESD event. The values LowThreshold and HighThreshold are given for indication only on the table below and

should be fine tune according to the system.

LowThreshold HighThreshold

10 4070

Table 17. Threshold to detect false coordinates

RSTEVENT

indicates that a reset event has

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 26

www.semtech.com

SX8652

MILLIMETERS

0.50 BSC

0.00A1

E1

aaa

bbb

N

e

L

A2

D1

D

E

b

1.55

0.30

3.90

2.90

3.05

-

0.18

DIM

A

DIMENSIONS

0.70

MIN

0.02

0.05

3.10

4.10

1.80

3.30

0.50

0.30

1.70

0.40

0.10

0.08

14

3.00

(0.20)

3.20

4.00

0.25

-

0.80

MAX

-

NOM

A

B

PIN1

INDICATOR

(LASER MARK)

aaa C

C

SEATING

PLANE

1 2

N

bbb C A B

COPLANARITY APPLIES TO THE EXPOSED PAD AS WELL AS THE TERMINALS.

CONTROLLING DIMENSIONS ARE IN MILLIMETERS (ANGLES IN DEGREES).

NOTES:

2.

1.

D

E

A1

e

bxN

D1

D/2

E/2

E1

LxN

A

A2

1.

CONTROLLING DIMENSIONS ARE IN MILLIMETERS (ANGLES IN DEGREES).

FAILURE TO DO SO MAY COMPROMISE THE THERMAL AND/OR

FUNCTIONAL PERFORMANCE OF THE DEVICE.

SHALL BE CONNECTED TO A SYSTEM GROUND PLANE.

THERMAL VIAS IN THE LAND PATTERN OF THE EXPOSED PAD

3.

THIS LAND PATTERN IS FOR REFERENCE PURPOSES ONLY.

CONSULT YOUR MANUFACTURING GROUP TO ENSURE YOUR

NOTES:

2.

DIM

X

Y

H

K

P

C

G

MILLIMETERS

(2.90)

0.30

0.70

1.70

0.50

3.30

2.20

DIMENSIONS

COMPANY'S MANUFACTURING GUIDELINES ARE MET.

3.60

Z

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

11. Packaging Information

11.1. DFN Package

DATASHEET

Revision V1.7/October 2010

©2010 Semtech Corp.

Figure 18. DFN Package Outline Drawing

Figure 19. DFN Package Land Pattern

Page 27

www.semtech.com

SX8652

0.10 C

0.08 C

0.05 C A B

CONTROLLING DIMENSIONS ARE IN MILLIMETERS

NOTES:

1.

A

B

C

A

B

C

INDEX AREA

A1 CORNER

0.25±0.02 SEATING

1 2 3

D

1.5±0.10

2.0±0.10

0.50

1.00

0.25

0.50

1.50

12X Ø0.315±0.03

PLANE

0.625 Max.

THIS LAND PATTERN IS FOR REFERENCE PURPOSES ONLY.

CONSULT YOUR MANUFACTURING GROUP TO ENSURE YOUR

NOTES:

2.

COMPANY'S MANUFACTURING GUIDELINES ARE MET.

1.

CONTROLLING DIMENSIONS ARE IN MILLIMETERS

0.50

0.25

1.50

0.50

1.00

12X Ø0.25

15kV ESD Low Power 4-Wire / 5-Wire Resistive

Touchscreen Controller with SPI Interface

ADVANCED COMMUNICATIONS & SENSING

11.2. WLCSP Package

DATASHEET

Revision V1.7/October 2010

©2010 Semtech Corp.

Figure 20. WLCSP Package Outline Drawing

Figure 21. WLCSP Land Pattern of WLCSP

Page 28

www.semtech.com

SX8652

ISO9001

CERTIFIED

© Se m tec h 2 010

All rig hts res erved. Re produc tio n in whole or in pa rt is prohibite d witho ut the prior writte n c ons ent of th e c opyrig ht o wne r. The

in form atio n p resente d in th is do cum ent does not form p art of a ny quo tatio n o r co ntra ct, is belie ved to be ac cu ra te and reliable

an d m a y be ch ang ed witho ut n otice. No liab ility will be ac ce pted b y th e publisher for an y co nse que nc e of its use. Pu blica tio n

th ereo f d oes n ot con ve y nor im ply any licen se un der pa te nt or othe r ind ustrial o r intelle ctu al pro perty righ ts. Sem te ch as sum es

no re sponsib ility or liability wha tso ever for any failu re or unexp ected op eration re sultin g from m is use, ne gle ct im proper

in sta lla tion, re pair or im proper h and lin g or un usual ph ysical or elec tric al stress inc lud ing , bu t no t lim ited to, expos ure to

pa rameters be yo nd the sp ecifie d m axim um ra tings o r op era tion outside th e spe cified ran ge.

SE M TECH P RO DUC TS ARE N OT D ES IG N ED , IN TEND ED , A UT HO RIZE D O R W A RR ANTE D T O B E S UITABLE F OR U SE IN

LIFE-SUP PO RT AP PL IC AT IO NS , DE VIC ES O R SYSTE MS O R O THER C RITIC AL APPLIC AT IO NS . IN C LUSION O F

SE M TECH P RO DUC TS IN SUC H A PP LICATIO NS IS U ND E RS TO OD TO BE U N DE RT AK EN S OL EL Y AT T HE C US TO M ER ’S

OW N RIS K. Sho uld a cu sto me r purc ha se or use Sem tec h p ro duc ts for any such una uthoriz ed application , the cus tom er sh all

in dem nify an d ho ld S em tech an d its o fficers , em ploye es, sub sid iarie s, affilia tes , and dis trib utors h arm les s a gains t all claim s,

costs d am age s a nd atto rn ey fe es w hic h c ould aris e.

All re feren ced bra nds, p ro du ct n am es, se rvice na m es an d tra dem arks are the pro pe rty o f t

he ir re spective ow ners.

Semtech Corporation Advanced Communications & Sensing Products

Contact information

TAIWAN TEL: 886-2-2748-3380

FAX: 886-2-2748-3390

SWITZERLAND TEL: 41-32-729-4000

FAX: 41-32-729-4001

KOREA TEL: 82-2-527-4377

FAX: 82-2-527-4376

UNITED KINGDOM TEL: 44-1794-527-600

FAX: 44-1794-527-601

SHANGHAI TEL: 86-21-6391-0830

FAX: 86-21-6391-0831

FRANCE TEL: 33-(0)169-28-22-00

FAX: 33-(0)169-28-12-98

JAPAN TEL: 81-3-6408-0950

FAX: 81-3-6408-0951

GERMANY TEL: 49-(0)8161-140-123

FAX: 49-(0)8161-140-124

ADVANCED COMMUNICATIONS & SENSING

DATASHEET

Revision V1.7/October 2010

©2010 Semtech Corp.

Page 29

www.semtech.com

Loading...

Loading...