查询SC4808B-1供应商

POWER MANAGEMENT

Description Features

The SC4808B-1 is a dual-ended, high frequency, integrated

PWM controller, optimized for isolated applications that

require minimum space. It can be configured for current

or voltage mode operation with required control circuitry

where secondary side error amplifier is used.

Some of the key features are high frequency operation of

1 MHz that allows the use of smaller components thus

saving cost and valuable board space. An internal ramp

on the Current Sense pin allows Internal Slope

Compensation programmed by an external resistor. Other

features include programmable frequency up to 1MHz,

Pulse by Pulse current and Line Monitoring Input with

Hysteresis to reduce stress on the power components.

A unique oscillator is used to synchronize two SC4808B1’s to work out of phase. This minimizes the input and

output ripple thus reducing noise on the output line and

reducing stress and size of input/output filter components.

The dual outputs can be configured in Push-Pull, Half Bridge

and Full Bridge format with programmable dead time

between two outputs depending on the size of the timing

components.

The SC4808B-1 also features a turn on threshold of 4.4V

and is available in MSOP-10 package.

120µA starting current

Pulse by pulse current limit

Programmable operation up to 1MHz

Internal soft start

Programmable line undervoltage lockout

Over current shutdown

Dual output drive stages on push-pull configuration

Programmable internal slope compensation

Programmable mode of operation (peak current mode

or voltage mode)

External frequency synchronization

Bi-phase mode of operation

-40 to 105 °C operating temperature

MSOP-10 lead free package. This product is fully WEEE

and RoHS compliant

Applications

Telecom equipment and power supplies

Networking power supplies

Industrial power supplies

Push-pull converter

Half bridge converter

Full bridge converter

Isolated VRM’s

SC4808B-1

High Performance Dual

Ended PWM Controller

Typical Application Circuit

Vin

Gnd_In

RSENSE

SYNC

OUTA

OUTB

CS

VCC

SYNC

LUVLO

SC4808

Vo

Gnd_Out

RC

REF

FB

GND

Revision: January 11, 2006

1 www.semtech.com

SC4808B-1

POWER MANAGEMENT

Absolute Maximum Ratings

Exceeding the specifications below may result in permanent damage to the device, or device malfunction. Operation outside of the parameters specified in

the Electrical Characteristics section is not implied.

retemaraPlobmySmumixaMstinU

egatloVylppuSV

tnerruCylppuSI

DNGotFER,OLVUL,SC,CR,CNYS 7ot5.0-V

DNGotBFV

tnerruCFERI

DNGotBTUO/ATUOV

)kaep(tnerruCecruoSBTUO/ATUOI

)kaep(tnerruCkniSBTUO/ATUOI

TtanoitapissiDrewoP

A

C°52=P

ecnatsiseRlamrehT

erutarepmeTnoitcnuJT

egnaRerutarepmeTegarotST

.ceS01)gniredloS(erutarepmeTdaeLT

)ledoMydoBnamuH(gnitaRDSEV

Electrical Characteristics

Unless specified: VCC = 12V; CL = 100pF; TA = -40°C to 105°C

CC

CC

BF

FER

B/ATUO

ecruos

knis

D

θ

AJ

J

GTS

DAEL

DSE

81ot5.0-V

02Am

V(ot5.0-

)5.0+V

FER

01Am

81ot5.0-V

052-Am

052Am

501.1W

1.311W/C°

051ot04-C°

051ot56-C°

003+C°

2Vk

retemaraPsnoitidnoCtseTniMpyTxaMtinU

MWP

elcyCytuDmumixaM,V5=BF,zHk05=csoF

849405%

BTUOroATUOtaderusaeM

elcyCytuDmuminiM,V5.1=BF,zHk05=csoF

BTUOroATUOtaderusaeM

esneStnerruC

niaG 3

langiStupnImumixaM 574525575Vm

yaleDtuptuOotSC 001sn

dlohserhTtnerruCrevO 058.059.1V

rotsiseRnoitasnepmoCepolSlanretnI

52kΩ

tesffOSCotBF 03.105.107.1V

tuptuO

leveLwoLTUO 005.07.V

leveLhgiHTUO 0.1152.1100.21V

emiTesiR 52sn

0%

emiTllaF 52sn

2 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Electrical Characteristics (Cont.)

Unless specified: VCC = 12V; CL = 100pF; TA = -40°C to 105°C

retemaraPsnoitidnoCtseTniMpyTxaMtinU

tuokcoLegatloVrednUCCV

dlohserhTtratS 0.404.45.4V

siseretsyH 001041081Vm

tuokcoLegatloVrednUeniL

dlohserhTtratSk41=32R Ω k01=33R, Ω )11egapees(%3-FERV%3+V

SC4808B-1

siseretsyHk41=32R Ω k01=33R, Ω )11egapees(

tratStfoS

pmaRtratStfoSlanretnI 002V/sµ

noitaruDtratStfoSk1=scR Ω

noitacilppaehtnialumrofeeS(

)81egapnonoitcesnoitamrofni

yaleDtratStfoS 041sµ

rotallicsO

ycneuqerFrotallicsOR

pmaRrotallicsO 2/FERV

ecnaticapacDNGotnipCR 22Fp

egnaRycneuqerFrotallicsO 050001zHK

KCOLC/cnyS

dlohserhTCNYSkcolC 0.1V

egnaRycneuqerFcnyS F

pagdnaB

k11= Ω C,

cso

cso

Fp002=054005055zHK

fo%6.5

FERV

21sµ

52.0+

cso

Vm

V

3.1*zHK

egatloVecnerefeR 079.2521.3082.3V

ecnerefeRtnerruC 5Am

llarevO

tnerruCputratSdlohserhttrats<CCV051Aµ

tnerruCylppuSgnitarepOV0=SC,V0=BF7Am

egatloVtnuhSreneZCCVAm01=DDI61V

3 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

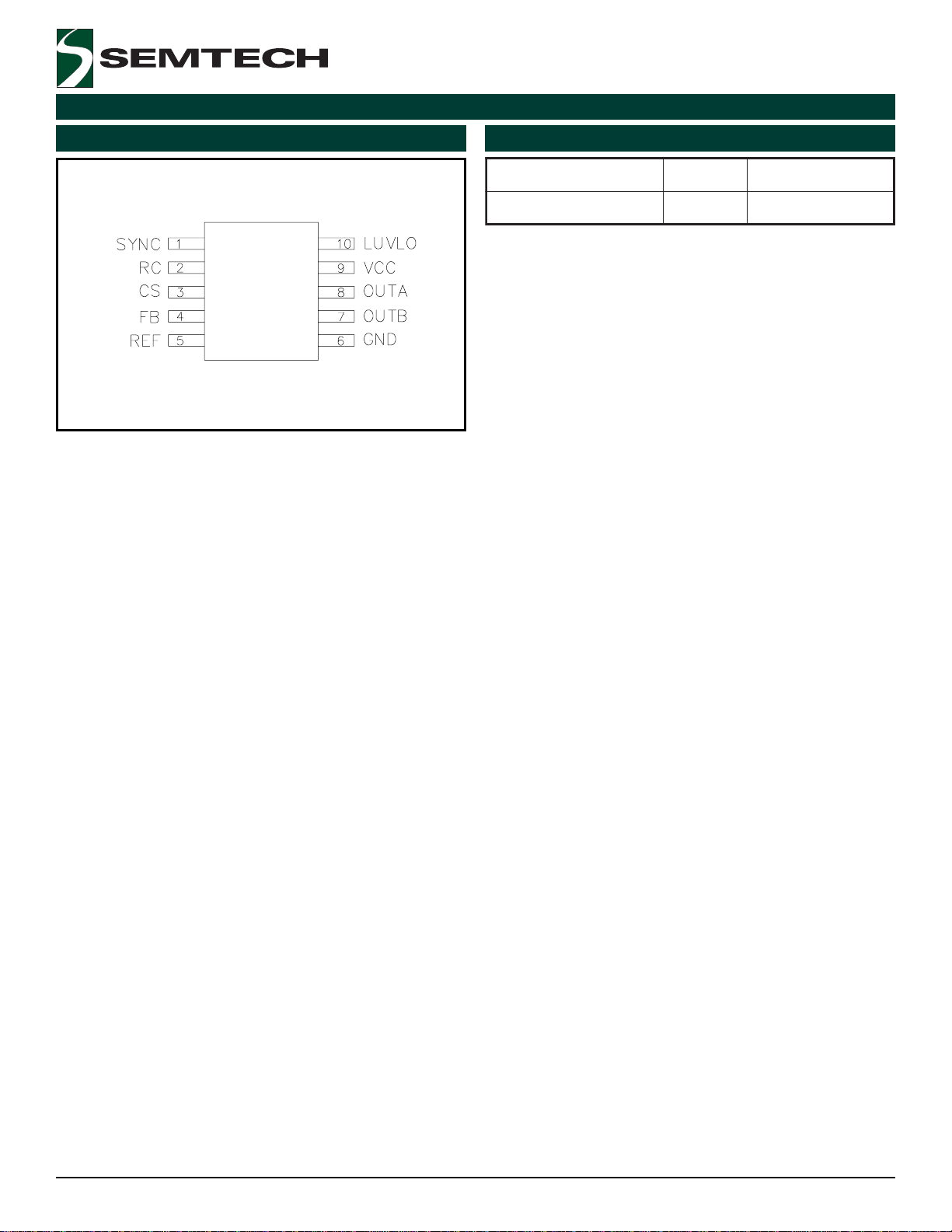

Pin Configuration Ordering Information

SC4808B-1

Top View

(MSOP-10)

rebmuNtraPegakcaPT(egnaR.pmeT

)2()1(

TRTSM1-B8084CS

01-POSMC°501otC°04-

A

Notes:

(1) Only available in tape and reel packaging. A reel

contains 2500 devices.

(2) Lead free product. This product is fully WEEE and

RoHS compliant.

)

4 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Pin Descriptions

SC4808B-1

FB: The inverting input to the PWM comparator. Stray inductances and parasitic capacitance should be minimized

by utilizing ground planes and correct layout guide lines

(see page 19).

REF: Bandgap reference output It should be by passed with

a 2.2uF low ESR capacitance, right at the IC pin.

CS: Current sense input and internal slope compensation

are both provided via the CS pin. The current sense input

from a sense resistor is used for the peak current and

overcurrent comparators. An internal 1 to 3 feed back voltage divider provides a 3X amplification of the CS signal.

This is used for comparison to the external error amplifier

signal. If an external resistor is connected from CS to the

current sense resistor, the internal current source will provide a programmable slope compensation. The value of

the resistor will determine the level of compensation. At

higher compensation levels, voltage mode of operation can

be achieved.

RC: The oscillator programming pin. The oscillator should

be referenced to a stable reference voltage for an accurate and stable frequency. Only two components are required to program the oscillator, a resistor (tied to Vref and

RC), and a capacitor (tied to the RC and GND). The following formula can be used for a close approximation of the

oscillator frequency.

F

≅

_

AOSC

1

CR

×

TOTOSC

F

≅

_

8.0

BOSC

1

CR

9.0

×

TOTOSC

where:

CCCC ++=

CircuitSCOSCTOT

4808

LUVLO: Line undervoltage lockout pin. An external resistive divider will program the undervoltage lockout level. The

external divider should be referenced to the quiet analog

ground (see page 19). During the LUVLO, the driver outputs are disabled and the softstart is reset. This pin can

also function as an Enable/Disable.

SYNC: SYNC is a positive edge triggered input with a threshold set to 1.0V. In a single controller operation, SYNC could

be grounded or connected to an external synchronization

clock within the SYNC frequency range (see page 3). In

the Bi-Phase operation mode SYNC pins could be connected to the Cosc (Timing Capacitors) of the other controller. This will force an out of phase operation (see page

12).

GND: Device power and analog ground. Careful attention

should be paid to the layout of the ground planes (see page

19).

OUTA and OUTB: Out of phase gate drive stages. The

driver’s peak source and sink current drive capability of

100mA, enables the use of an external MOSFET driver or

a NPN/PNP transistor buffer.

The oscillator RC network programs the oscillator frequency,

which is twice the OUTA/OUTB frequency. To insure that

the outputs do not overlap, a dead time can be generated

between the two outputs by sizing the oscillator timing

capacitor (see page 11).

VCC: The supply input for the device. Once VCC has exceeded the UVLO limit, the internal reference, oscillator,

drivers and logic are powered up. A low ESR capacitance,

should be used for decoupling right at the IC pin to minimize noise problems.

pFC

≅

SC224808

Where the frequency is in Hertz, resistance in ohms, and

capacitance in farads. The recommended range of timing

resistors is between 10 kohm and 200kohm and range of

timing capacitors is between 100pF and 1000pF. Timing

resistors less than 10 kohm should be avoided.

Refer to layout guide lines on (page 19) to achieve best

results.

5 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Block Diagram

SC4808B-1

VCC

REF

Bandgap

UVLO

LUVLO

Marking Information

LUVLO

SQ

R

OVER CURRENT

SOFT

START

500mv

Slope Comp.

Enable

R

2R

FB

Peak Current

OSC

RC

CS

OUTA

Disable

LUVLO

OUTB

GND

SYNC

SYNC

SQ

R

Q

T

Q

Top Mark

AB1B

yyww

Bottom Mark

xxxx

xxxx

yyww = Datecode (Example: 9912)

xxxx = Semtech Lot # (Example: E901

xxxx 01-1)

6 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

SC4808B-1 Typical Characteristics

(SC4808B-1A)

SC4808B-1

100.0

Start up Iq, Vcc = 4V

95.0

90.0

85.0

Iq(uA)

80.0

75.0

70.0

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ta (°C)

Iq (start up) vs. Temperature

3.90

3.85

3.80

3.75

Iq (mA)

3.70

3.65

Operating Iq, Vcc = 5V

Operating Iq, Vcc = 5.25V

1.69

1.68

1.67

1.66

1.65

1.64

1.63

FB to CS offset (V)

1.62

1.61

1.60

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ta (°C)

FB to CS Offset

FB to CS Offset vs. Temperature

1100

1000

Current Sense (mV)

900

800

700

600

500

Max Current Sense Signal

Over Current Signal

3.60

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ta (°C)

Iq (operating) vs. Temperature

3.22

Reference, Vcc = 5V

3.21

3.2

3.19

Reference (V)

3.18

3.17

3.16

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ta (°C)

Reference vs. Temperature

400

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ta (°C)

Current sense vs. Temperature

4.500

4.450

4.400

4.350

Vcc UVLO (V)

4.300

4.250

4.200

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ta (°C)

Vcc UVLO (Rising)

Vcc UVLO (Falling)

Vcc UVLO vs. Temperature

7 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

SC4808B-1 Typical Characteristics (Cont.)

SC4808B-1

100

98

96

94

92

90

88

Vcc UVLO Hysteresis (mV)

86

84

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ta (°C)

Vcc UVLO (Hysteresis)

Vcc UVLO Hysteresis vs. Temperature

3.170

3.165

3.160

3.155

3.150

3.145

3.140

LUVLO (V)

3.135

3.130

3.125

3.120

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ta (°C)

LUVLO (Rising)

Line UVLO vs. Temperature

1400

1200

1000

Oscillator Frequency (kHz)

800

600

400

200

Oscillator Frequency 1MHz

Oscillator Frequency 500kHz

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ta (°C)

Oscillator Frequency vs. Temperature

664

662

660

658

656

654

Synchronization Frequency (kHz)

652

650

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ta (°C)

Sync. Frequency @ Fosc = 500kHz

Synchronization Frequency vs. Temperature

140

135

130

125

120

115

110

LUVLO Hysteresis (mV)

105

100

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ta (°C)

LUVLO (Hysteresis)

Line UVLO Hysteresis vs. Temperature

49.5

Maximum Duty Cycle

49.5

49.5

49.4

49.4

49.4

Maximum Duty Cycle (%)

49.4

49.4

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ta (°C)

Maximum Duty Cycle vs. Temperature

8 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

SC4808B-1 Typical Characteristics (Cont.)

SC4808B-1

180

170

160

150

140

130

120

110

Soft Start Delay Time (us)

100

90

80

-40 -25 -10 5 20 35 50 65 80 95 110 125

Ta (°C)

Soft Start Delay Time

Soft Start Delay time vs. Temperature

9 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Application Information

THEORY OF OPERATION

SC4808B-1

The SC4808B-1 is a versatile double ended, high speed,

low power, pulse width modulator that is optimized for applications requiring minimum space.

The device contains all of the control and drive circuity required for isolated or non isolated power supplies where

an external error amplifier is used. A fixed oscillator frequency (up to 1MHz) can be programmed by an external

RC network.

The SC4808B-1 is a peak current or voltage mode

controller, depending on the amount of slope

compensation, programmable with only one external

resistor. The cycle by cycle peak current limit prevents core

saturation when a transformer is used for isolation while

the overcurrent circuitry initiates the softstart cycle.

The SC4808B-1 dual output drive stages are arranged in a

push-pull configuration. Both outputs switch at half the

oscillator frequency using a toggle flip flop. The dead time

between the two outputs is programmable depending on

the values of the timing capacitor and resistors, thus limiting

each output stage duty cycle to less than 50%.

The SC4808B-1 also provides flexibility with programmable

LUVLO thresholds, with built-in hysteresis.

SUPPLY

A single supply, VCC is used to provide the bias for the

internal reference, oscillator, drivers, and logic circuitry of

SC4808B-1. To ensure proper operation during start up,

VCC slew rate of less than 10V/mS is recommended.

PWM CONTROLLER

SC4808B-1 is a double ended PWM controller that can be

used in voltage or current mode applications. The

SC4808B-1 provides a 4.4V VCC UVLO, and a 3.125V reference. The oscillator frequency is programmed by a resistor and a capacitor network connected to an external reference provided by the SC4808B-1. The two outputs, OUTA

and OUTB, are 180 degrees out of phase and run at half of

the oscillator frequency.

An external error amplifier will provide the error signal to

the FB pin of the SC4808B-1.

The current sense input and internal slope compensation

are both provided via the CS pin. The current sense input

from a sense resistor is used for the peak current and

overcurrent comparators. An internal 1 to 3 feedback volt-

age divider provides a 3X amplification of the CS signal.

This is used for comparison to the external error amplifier

signal. If an external resistor is connected from CS to the

current sense resistor, the internal current source will provide a programmable slope compensation. The value of

the resistor will determine the level of compensation. At

higher compensation levels, voltage mode of operation can

be achieved. The error amplifier signal at the FB pin will be

used in conjunction with the CS signal to achieve regulation.

Two levels of undervoltage lockout are also available. The

LUVLO (line under voltage lockout) pin via an external resistive divider will program the undervoltage lockout level.

During the LUVLO, the driver outputs are disabled and the

softstart is reset.

Once VCC has exceeded the UVLO (VCC under voltage lockout) limit, the internal reference, oscillator, drivers and logic

are powered up.

SYNC is a positive edge triggered input with a threshold

set to 1.0V.

By connecting an external control signal to the SYNC pin,

the internal oscillator frequency will be synchronized to the

positive edge of the external control signal. In a single controller operation, SYNC should be grounded or connected

to an external synchronization clock within the SYNC frequency range (see page 3).

In the Bi-phase operation mode a very unique oscillator

is utilized to allow two SC4808B-1 to be synchronized

together and work out of phase. This feature is setup by

simple connection of the SYNC input to the RC pin of the

other part. The fastest oscillator automatically becomes

the master, forcing the two PWMs to operate out of

phase. This feature minimizes the input and output

ripples, and reduces stress on the capacitors.

10 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

0

0

Application Information (Cont.)

SC4808B-1

VCC UNDER VOLTAGE LOCK OUT

Depending on the application and the voltages available,

the SC4808B-1 (UVLO = 4.4V) can be used to provide the

VCC undervoltage lock out function to ensure the converters controlled start up.

Before the VCC UVLO has been reached, the internal reference, oscillator, OUTA/OUTB drivers, and logic are disabled.

LINE UNDER VOLTAGE LOCK OUT

The SC4808B-1 also provides a line undervoltage (LUVLO

= Vref) function. The LUVLO pin is programmed via an external resistor divider connected as shown below. The actual start-up voltage can be calculated by using the equation below:

33R23R

+

()

×=

33R

VCC

6

7

8

9

C33

101

0.1u,25V

10k

R33

R27

15k

C31

200p

REF

5

4

3

2

REF

FB

CS

RC

SYNC

Vin

2.2u,16V

U4

SC4808

C26

GND

OUTB

OUTA

VCC

LUVLOSYNC

56.2k

R23

R28

10

15

R26

2.2k

C29

82p

VV

R24 10k

R25 18

REFStartup

OSCILLATOR

The oscillator frequency is set by connecting a RC network

as shown below.

VCC

C33

0.1u,25V

10k

R33

R28

10

6

7

8

9

101

R27

15k

C31

200p

REF

5

4

3

2

REF

FB

CS

RC

SYNC

Vin

2.2u,16V

U4

SC4808

C26

GND

OUTB

OUTA

VCC

LUVLOSYNC

56.2k

R23

The oscillator has a ramp voltage of about Vref/2. The oscillator frequency is twice the frequency of the OUTA and

OUTB gate drive controls.

The oscillator capacitor C31 is charged by a current sourced

from the Vref through R27. Once the RC pin reaches about

Vref/2, the capacitor is discharged internally by the

SC4808B-1. It should be noted that larger capacitor values will result in a longer dead time during the down slope

of the ramp.

The following equation can be used as an approximation

of the oscillator frequency and the Dead time:

F

≅

_

AOSC

1

CR

×

TOTOSC

F

≅

_

8.0

BOSC

1

CR

9.0

×

TOTOSC

REFERENCE

A 3.125V(SC4808B-1) reference voltage is available that

can be used to source a typical current of 5mA to the external circuitry. The Vref can be used to provide the oscillator RC network with a regulated bias.

where:

CCCC ++=

CircuitSCOSCTOT

4808

pFC

≅

SC224808

T

deadtime

≅

VC

103

⋅

5.0

××

REFOSC

3

−

The recommended range of timing resistors is between 10

kohm and 200kohm, range of timing capacitors is between

100pF and 1000pF. Timing resistors less than 10 kohm

should be avoided.

11 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Application Information (Cont.)

SC4808B-1

SYNC/Bi-Phase operation

In noise sensitive applications where synchronization of

the oscillator frequency to a reference frequency is required,

the SYNC pin can accept the external clock. By connecting

an external control signal to the SYNC pin, the internal oscillator frequency will be synchronized to the positive edge

of the external control signal. SYNC is a positive edge triggered input with a threshold set to 1.0V (SC4808B-1).

In a single controller operation, SYNC should be grounded

or connected to an external synchronization clock within

the SYNC frequency range (see page 3).

OUTA (PWM1)

OUTB (PWM1)

OUTA (PWM2)

OUTB (PWM2)

Rosc1

Cosc1

REF

U1

5

REF

4

FB

3

CS

2

RC

LUVLOSYNC

GND

OUTB

OUTA

VCC

6

7

8

9

101

Rosc2

Cosc2

REF

U2

5

REF

4

FB

3

CS

2

RC

LUVLOSYNC

GND

OUTB

OUTA

VCC

6

7

8

9

101

FEED BACK

The error signal from the output of an external error amplifier such as SC431 or SC4431 is applied to the inverting

input of the PWM comparator at the FB pin either directly

or via an opto coupler for the isolated applications. For best

stability, keep the FB trace length as short as possible.

Vref

R37

2.2k

C40

22pF

6

5

MOCD207

FB

R34

3

4

C38

0.1u

5

C39

22n

C35

1

4

SC4431

Vref

2

VoutVout

R35C36

R32

R36

C37

R38

The signal at the FB pin is then compared to the 3X amplified signal from the current sense/ slope compensation

CS pin. Matched out of phase signals are generated to

control the OUTA and OUTB gate drives of the two phases.

A single ramp signal is used to generate the control signals for both phases, hence achieving a tightly matched

per phase operation.

Voltages below 1.5V at the FB pin, will produce a 0% duty

cycle at the OUTA/OUTB gate drives. This offset is to provide enough head room for the opto coupler used in isolated applications.

GATE DRIVERS

SC4808

SC4808

In the Bi-phase operation mode a very unique oscillator is

utilized to allow two SC4808B-1’s to be synchronized

together and work out of phase. This feature is set up by a

simple connection of the SYNC input to the RC pin of the

other part. The fastest oscillator automatically becomes

the master, forcing the two PWMs to operate out of phase.

This feature minimizes the input and output ripples, and

reduces stress on the capacitors.

OUTA and OUTB are out of phase bipolar gate drive output

stages, that are supplied from VCC and provide a peak

source/sink current of about 100mA. Both stages are capable of driving the logic input of external MOSFET drivers

or a NPN/PNP transistor buffer. The output stages switch

at half the oscillator frequency. When the voltage on the

RC pin is rising, one of the two outputs is high, but during

fall time, both outputs are off. This “dead time” between

the two outputs, along with a slower output rise and fall

time, insures that the two outputs can not be on at the

same time. The dead time is programmable and depends

upon the timing capacitor.

12 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

F

Application Information (Cont.)

It should be noted that if high speed/high current drivers

such as the SC1301 are used, careful layout guide lines

must be followed in order to minimize stray inductance,

which might cause negative voltages at the output of the

drivers. This negative voltage can be clamped to a reasonable level by placing a small Schottky diode directly at the

output of the driver as shown below.

VCC

EN

SC1301A

U3

C23

R28

10

0.1u

C34

0.1u

VCC

C26

2.2u,16V

U4

5

REF

4

FB

3

CS

2

RC

SC4808

SYNC

Vin

OUTB

OUTA

LUVLOSYNC

GND

VCC

56.2k

R23

6

7

8

9

C33

101

0.1u,25V

10k

R33

325

1 4

VCC

EN

SC1301A

U6

3

5

1 4

2

Gate_B

D_B

Gate_A

D_A

SC4808B-1

OVER CURRENT

Two levels of over current protection are provided by the

SC4808B-1. The current information is sensed at the CS

pin and compared to a peak current limit level of 525mV.

If the 525mV limit is exceeded, the OUTA and OUTB pulse

widths and duty cycle is reduced until the CS pin reaches a

second threshold of 950mV. At that point, the OUTA and

OUTB are disabled, and after a delay of 140µs, the internal softstart sequence is started. After the softstart duration (see page 18 for calculation of softstart time), normal

operation is achieved, unless the over current condition is

still present.

13 2006 Semtech Corp. www.semtech.com

SC4808B-1

POWER MANAGEMENT

Application Information (Cont.)

SLOPE COMPENSATION (Current or Voltage mode of operation)

In applications where a current mode control is used for regulation, the peak inductor current information is used to

produce the average output current. If a small perturbation due to changes in supply voltage or noise pick up is generated, instability may occur if the duty cycle is >50%.

This phenomenon is graphically shown below. The inductor current and disturbed inductor current are shown for three

different duty cycles conditions.

The top wave form shows the applications where the duty cycle D is less than 50%. As shown, even if an error is

introduced, after only a few cycles the error converges to zero.

The second wave form shows the case where D = 50%. Under this condition, even though the error does not completely

disappear, it stays constant and is not getting larger. This will be seen as jitter at the inductor voltage.

The bottom wave form shows D>50%. As shown, a very small error results in a much larger error only after a few cycles.

This will cause instability in the converter and the average output inductor current. The output load will not be able to be

kept in regulation.

i

: Small Inductor current perturbation

L

: Inductor current

I

L

D<50%

Error

Error

Time

D=50%

Time

I

I

i

L

L

L

i

L

Instability in current mode operation

due to Duty cycle >50%

Note: After a few c ycles the perturbation

disappear s and stable operation returns .

i

L

Note: After a few c ycles the perturbation

is still present, although this will cause

jitter, but there is no instability.

Error

D>50%

Time

I

i

L

L

Note: After a few c ycles the perturbation

becom es larger, and caus es instability.

14 2006 Semtech Corp. www.semtech.com

i

L

POWER MANAGEMENT

()

Application Information (Cont.)

SC4808B-1

The instability can be corrected by modification of the peak

current information slope. One of the methods to alter the

peak current information is to add a positive going ramp to

the output of the current sensing circuitry.

The SC4808B-1 achieves this by using an internal slope

compensation circuit. The oscillator ramp is internally buffered and an internal 25kOhms resistor in conjunction with

an external resistor at the CS pin will program the level of

slope compensation.

Current Transformer

N = 100

10k

R

D

Rsense

RSlope Comp

Cfilter

82p

RSlope Comp value will determine the Mode of operation (Voltage or Current)

Rosc

15k

Cosc

200p

REF

C

2.2u,16V

5

REF

4

FB

25k

3

CS

2

RC

1

SYNC

SC4808

GND

6

7

The Peak current information is sensed and the result is

realistically summed to the buffered oscillator ramp, as

shown above. The value of the external resistor R

slope comp

will determine the percentage of the slope compensation.

As the value for R

slope comp

is reduced, the current information becomes more dominant and the mode of operation

becomes more current mode. At the same time the slope

of the current information is modified to provide the slope

compensation.

If the R

slope comp

is increased, the internal ramp becomes the

dominant signal and more voltage mode of operation is

achieved. As it can be calculated from the second formula

below, a 100% voltage mode operation can be achieved by

choosing R

slope comp

100% current mode of operation is required, R

to be greater than 6.25K ohms. Also if a

slope comp

is

reduced to zero and the contribution from the internal ramp

is completely eliminated.

+

RR

×

V

Ramp

=

Comp_Slope%

()

V

CS

senseComp_slope

++

RRR

ernalintsenseComp_slope

or

RR

•≅

ernalintexternal

()

×

()

×−

Comp_slope%2.0

Comp_slope%2.01

Next page illustrates how the buffered oscillator ramp is

used to modify the sensed inductor current.

It should be noted that in order for the slope compensation to be effective, the current sensed signal slope should

be at least 50% less steeper than the oscillator positive

ramp slope. The slope will include the magnetizing current

of the transformer and the inductor output current in isolated applications. In non-isolated applications, the slope

will only include the inductor output current.

15 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Application Information (Cont.)

i

: Sm all Inductor current perturbation

L

: Inductor current

I

L

I

: Sensed Mosfet current

Sense

: Sum m ation of Isense and s lope compensation, at the C S pin of the SC4808.

I

CS

I

L

I

Sense

SC4808B-1

Slope Compensation generation from

Buffered Oscillator Ramp

D>50%

Note: Below wave form s are not to scale.

Buffered

Oscillator

Ramp

I

CS

16 2006 Semtech Corp. www.semtech.com

SC4808B-1

POWER MANAGEMENT

Application Information (Cont.)

Below the benefits from the slope compensation become apparent. The top wave form shows the stable operation

before the perturbation. The second wave form shows the perturbation and the instability caused from it if no slope

compensation is added to the current information. The last wave form shows the slope compensation and the effect of

it. The increase in the slope of the current information results in an early termination of the inductor current, hence a

reduction in the amount of error. As the cycle is repeated, the perturbation is reduced and finally eliminated.

δ

i

: Small Inductor current perturbation

L

∆

: Inductor current

I

L

: Sensed Mosfet current

I

Sense

: Summation of Isense and slope compensation, at the CS pin of the SC4808.

I

CS

Stable operation

( no perturbation)

∆

I

L

I

Sense

Instable operation

( with perturbation)

∆

I

L

δ

i

I

Sense

Stable operation

(Slope Compensation Added)

L

Stable current mode operation with Slope

Compensation

D>50%

Error Signal from Error amplifier

Note: After a few cycles the perturbation

becomes larger, and causes instability.

Error Signal from Error amplifier

Note: After a few cycles the perturbation

disappears and stable operation returns.

Error Signal from Error amplifier

∆

I

L

I

CS

δ

i

L

17 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Application Information (Cont.)

SC4808B-1

SOFT START

During start up of the converter, the discharged output capacitor and the load current have large supply current requirements. To avoid this a soft start scheme is usually

implemented where the duty cycle of the regulator is gradually increased from 0% until the soft start duration is

elapsed.

SC4808B-1 has an internal soft start circuit that limits the

duty cycle for a duration approximated by the formula below. Also the soft start circuitry is activated if an over current condition occurs. After an over current condition, OUTA

and OUTB are disabled and kept low for a duration of about

140µs. After the delay, the OUTA and OUTB are enabled

while the soft start limits the duty cycle. If the over current

condition persists, the soft start cycle repeats indefinitely.

Approximate internal soft start duration can be calculated

as below:

T

SoftStart

VREF

()

Ramp

SoftStart

≅

R

R

SlopeComp_Internal

×

GND_to_CS

2

1

+

START UP SEQUENCE

Initially during the power up, the SC4808B-1 is in under

voltage lock out condition. As the Vcc supply exceeds the

UVLO limit of the SC4808B-1, the internal reference, oscillator, and logic circuitry are powered up.

The OUTA and OUTB drivers are not enabled until the line

under voltage lock out limit is reached. At that point, once

the FB pin is above 1.5V, soft start circuitry starts the output drivers, and gradually increases the duty cycle from

0%. The soft start duration is internally set (see formula in

Soft Start section).

As the output voltage starts to increase, the error signal

from the error amplifier starts to decrease. If isolation is

required, the error amplifier output can drive the LED of

the opto isolator. The output of the opto is connected in a

common emitter configuration with a pull-up resistor to a

reference voltage connected to the FB pin of the SC4808B-

1. The voltage level at the FB pin provides the duty cycle

necessary to achieve regulation.

If an over current condition occurs, the outputs are disabled and after a soft start delay time of about 100µs, the

softstart sequence mentioned above is repeated.

If longer soft start durations are required, the simple external circuit shown below can be implemented.

VCC

C33

0.1u,25V

10k

R33

R28

10

6

7

8

9

101

MOCD207

R37

1k

6

C40

NA

5

Csoft start

REF

56.2K

R27

15k

C31

200p

REF

5

4

3

2

REF

FB

CS

RC

SYNC

SC4808

Vin

C26

2.2u,16V

U4

GND

OUTB

OUTA

VCC

LUVLOSYNC

56.2k

R23

Approximate soft start duration can be calculated as below:

37RCT

SoftStartSoftStart

×≅

18 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Application Information (Cont.)

LAYOUT GUIDELINES

SC4808B-1

Careful attention to layout requirements are necessary for

successful implementation of the SC4808B-1 PWM controller.

High current switching is present in the application and

their effect on ground plane voltage differentials must be

understood and minimized.

1). The high power parts of the circuit should be laid out

first. A ground plane should be used, the number and position of ground plane interruptions should be such as to

not unnecessarily compromise ground plane integrity. Isolated or semi-isolated areas of the ground plane may be

deliberately introduced to constrain ground currents to

particular areas, such as the input capacitor and FET

ground.

2). In the loop formed by the Input Capacitor(s) (Cin), the

FET must be kept as small as possible. This loop contains

all the high current, fast transition switching. Connections

should be as wide and as short as possible to minimize

loop inductance. Minimizing this loop area will a) reduce

EMI, b) lower ground injection currents, resulting in electrically “cleaner” grounds for the rest of the system and c)

minimize source ringing, resulting in more reliable gate

switching signals.

3). The connection between FETs and the Transformer

should be a wide trace or copper region. It should be as

short as practical. Since this connection has fast voltage

transitions, keeping this connection short will minimize EMI.

4) The Output Capacitor(s) (Cout) should be located as close

to the load as possible. Fast transient load currents are

supplied by Cout only, and connections between Cout and

the load must be short, wide copper areas to minimize inductance and resistance.

5) The SC4808B-1 is best placed over a quiet ground plane

area. Avoid pulse currents in the Cin FET loop flowing in

this area. GND should be returned to the ground plane close

to the package and close to the ground side of (one of) the

VCC supply capacitor(s). Under no circumstances should

GND be returned to a ground inside the Cin, Q1, Q2 loop.

Avoid making a star connection between the quiet GND

planes that the SC4808B-1 will be connected to and the

noisy high current GND planes connected to the FETs.

6) The feed back connection between the error amplifier

and the FB pin should be kept as short as possible The

GND connections should be connected to the quiet GND

used for the SC4808B-1.

7) If an Opto isolator is used for isolation, quiet primary

and secondary ground planes should be used. The same

precautions should be followed for the primary GND plane

as mentioned in item 5 mentioned above. For the secondary GND plane, the GND plane method mentioned in item

4 should be followed.

8) All the noise sensitive components such as LUVLO resistive divider, reference by pass capacitor, Vcc bypass capacitor, current sensing circuitry, feedback circuitry, and

the oscillator resistor/capacitor network should be connected as close as possible to the SC4808B-1. The GND

return should be connected to the quiet SC4808B-1 GND

plane.

9) The connection from the OUTA and OUTB of the

SC4808B-1 should be minimized to avoid any stray inductance. If the layout can not be optimized due to constraints,

a small Schottky diode may be connected from the OUTA/

B pins to the ground directly at the IC. This will clamp excessive negative voltages at the IC. If drivers are used, the

Schottky diodes should be connected directly at the IC from

the output of the driver to the driver ground (See page

13).

10) If the SYNC function is not used, the SYNC pin should

be grounded at the SC4808B-1 GND to avoid noise pick

up.

19 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Gain & Phase Margin

SC4808B-1

50

40

30

20

10

Gain (dB)

0

-10

-20

Phase

Gain

Gain

Phase (deg)

225

180

135

90

45

0

Phase (deg)

-45

-90

-135

-180

-30

10 100 1000 10000 100000

Freq (Hz)

-225

Typical SC4808B-1 Push Pull Converter Gain/Phase plot at Vin = 36V, Vout = 3.3V, Iout = 10A, Fosc = 650kHz

20 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Gain & Phase Margin (Cont.)

SC4808B-1

50

40

30

20

10

Gain (dB)

0

-10

-20

Phase

Gain

Gain

Phase (deg)

225

180

135

90

45

0

Phase (deg)

-45

-90

-135

-180

-30

10 100 1000 10000 100000

Freq (Hz)

-225

Typical SC4808B-1 Push Pull Converter Gain/Phase plot at Vin = 48V, Vout = 3.3V, Iout = 10A, Fosc = 650kHz

21 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Gain & Phase Margin (Cont.)

SC4808B-1

50

40

30

20

10

Gain (dB)

0

-10

-20

Phase

Gain

Gain

Phase (deg)

225

180

135

90

45

0

Phase (deg)

-45

-90

-135

-180

-30

10 100 1000 10000 100000

Freq (Hz)

-225

Typical SC4808B-1 Push Pull Converter Gain/Phase plot at Vin = 72V, Vout = 3.3V, Iout = 10A, Fosc = 650kHz

22 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Typical Step Load

SC4808B-1

Vout

500mV/Div

Iout

5A/Div

Cout = 6X22uF (132uF) Ceramic

Typical SC4808B-1 Push Pull Converter Step Load plot at Vin = 48V, Vout = 3.3V, Step = 37% to 75% Iout, Fosc = 650kHz

100us/Div

23 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

V

Evaluation Board Schematics

Size Document Number Rev

Date: Sheet of

SC4808EVB__non_sync 1.1

11Monday, October 07, 2002

For output power > 30W, adequate air flow should be provided to avoid over dissipation.

Title

SC4808 Push Pull 3.3V 50W non Synchronous

Note:

SEMTECH CORPORATION

SC4808B-1

Vin-

ON/OFF

4

2

2

R10

Vout-

D4

1N5819HW

M1

M2

1N5819HW

U7

CBRHD-02

5

0

D3

AC

EBC

VCC = 15V

1 3

1N5819HW

1

1

34

T1

0

2

1u,100V

1u,100V

R8

VCC

1u,100V

N = 100

SUD19N20-90

3

3

SUD19N20-90

R3116.2

4T

6

D2

0

R7

TBD

6

Sense-

C11

C12

Q1

C13

1

3

R6

in+

1

20k

FZT853

8

C32.2n

4

1

22u,6.3V

22u,6.3V

22u,6.3V

22u,6.3V

22u,6.3V

22u,6.3V

0.1u

0.1u

CON2

R3

R4

250

8 7

6T 1T

R510

MBRB2535CTL

0.9uH

C4

C5

C6

C7

C8

C9

C10

C2

7

Trim

GRM55DR72E105KW01

GRM55DR72E105KW01

P8208T

T2

6T 1T

253

4

PA0500

10

9

C12.2n

R210

4

MBRB2535CTL

D1

1

3

1 2

PG0006.102T

L1

Murata GRM32DR60J226KA01

R1

0

8

9

Sense+

Vout+

CON1

3input_half_brick

R12

56.2k

2.2uF 16V

56.2k

C35

R32

REF

ZM4743A

C14

LS4448

453

FB

OUTB

OUTA

VCC

G_A

3

4

1u,16V

C20

Sync Drive Supply

1k

15k

REFCSRC

GND

10

1

6

CMOSH-3

CMOSH-3

R16

R17

U1

R18

T3

D10

D11

2

CMOSH-3

0

D8

R13 10k

R14 15

J1

REF

2.2u,16V

C19

J2

VCC

C17

0.1u

1 4

VCC

3

5

SC1301A

U2

CMOSH-3

D7

D9

G_B

22nF

C18

R15

R2110k

2

CMOSH-3

C21

82p

C22

82p

JP1

2

J3

SYNC

SC4808

LUVLOSYNC

VCC

1016789

C23

0.1u,25V

C24

0.1u

1 4

3

5

SC1301A

U3

CMOSH-3

D14

D15

Q2

FMMT718

C2510nF

PE-68386

R19

0

0

CMOSH-3

D13

CMOSH-3

D12

R24

1k

REF

C28

NA

8

7

6

5

MOCD207

A

C

100

D16

1N5819HW

2

Vref

SC4431

R30

15k

4

R29

R26

2.2k

C32

0.1u

C33

22n

5

1

1nF

C30

4

U5

C29100pF

R27

15k

R28

25.5k

R25

11.5k

C31

470pF

3

Sync Drive Supply

2

U6

1

2

R20

2.2k

C26

0.1u

C27

22n

5

Sync Drive Supply

1

Vref

4

U4

SC4431

R23

18.2k

R22

37.4k

C34

.1uF

GRM32DR61C106KA01

G_B

G_A

VCC

GRM32DR61C106KA01

10u,16V

C16

1 2

LQH43MN102K011

R11

TBD

.1u,16V

C15

10u,16V

D5

2.2

R9

2.2

D6

L2

1 2

5output_half_brick

24 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Evaluation Board Bill of Materials

SC4808 Push Pull 3.3V 50W non Synchronous

SC4808EVB__non_sync Revision: 1.1

Bill Of Materials October 7,2002 13:35:18

1 1 CON1 5output_half_brick CON\5OUTPUT_HALF_BRICK

2 1 CON2 3input_half_brick CON\3INPUT_HALF_BRICK

3 2 C3,C1 2.2n SM/C_1206

4 6 C2,C10,C17,C24,C26,C32 0.1u SM/C_0805

5 6 C4,C5,C6,C7,C8,C9 22u,6.3V GRM32DR60J226KA01 SM/C_1210_GRM

6 3 C11,C12,C13 1u,100V GRM55DR72E105KW01 SM/C_2220

7 1 C14 .1u,16V SM/C_0805

8 2 C15,C16 10u,16V GRM32DR61C106KA01 SM/C_1210_GRM

9 1 C18 22nF SM/C_1206

10 1 C19 2.2u,16V SM/C_1206

11 1 C20 1u,16V GRM32RR71H105KA011 SM/C_1210_GRM

12 2 C22,C21 82p SM/C_0805

13 1 C23 0.1u,25V SM/C_1206

14 1 C25 10nF SM/C_0805

15 2 C27,C33 22n SM/C_0805

16 1 C28 NA SM/C_0805

17 1 C29 100pF SM/C_0805

18 1 C30 1nF SM/C_0805

19 1 C31 470pF SM/C_0805

20 1 C34 .1uF SM/C_0805

21 1 C35 2.2uF 16V SM/C_0805

22 2 D2,D1 MBRB2535CTL DIODE_D2PAK

23 4 D3,D5,D6,D16 1N5819HW SOD123

24 1 D4 ZM4743A SMB/DO214

25 8 D7,D9,D10,D11,D12,D13, CMOSH-3 CMOSH-3 (Central Semiconductor) SOD523

D14,D15

26 1 D8 LS4448 SM/DO213AC

27 1 JP1 short VIA\2P

28 1 J1 REF ED5052

29 1 J2 Vcc ED5052

30 1 J3 SYNC ED5052

31 1 L1 0.9uH PG0006

32 1 L2 LQH43MN102K011 LQH43MN102K01L SDIP0302

33 2 M1,M2 SUD19N20-90 SUD19N20-90 DPAKFET

34 1 Q1 FZT853 SM/SOT223_BCEC

35 1 Q2 FMMT718

36 4 R1,R7,R15,R19 0 SM/R_0805

37 2 R5,R2 10 SM/R_1206

38 1 R3 20k SM/R_1206

39 1 R4 250 SM/R_1210_MCR

40 2 R6,R11 TBD SM/R_0805

41 1 R8 0 SM/R_1206

42 2 R9,R10 2.2 SM/R_0805

43 1 R12 56.2k SM/R_1206

44 1 R13 10k SM/R_0805

45 1 R14 15 SM/R_0805

46 2 R16,R24 1k SM/R_0805

47 3 R17,R27,R30 15k SM/R_0805

48 1 R18 10 SM/R_0805

49 2 R26,R20 2.2k SM/R_0805

50 1 R21 10k SM/R_1206

51 1 R22 37.4k SM/R_0805

52 1 R23 18.2k SM/R_0805

53 1 R25 11.5k SM/R_0805

54 1 R28 25.5k SM/R_0805

55 1 R29 100 SM/R_0805

56 1 R31 16.2 SM/R_1206

57 1 R32 56.2k SM/R_0805

58 1 T1 PA0500 PA0500

59 1 T2 P8208T P8208T

60 1 T3 PE-68386 PE-68386

61 1 U1 SC4808 MSOP10

62 2 U2,U3 SC1301A SOT23_5PIN

63 2 U4,U5 SC4431 SOT23_5PIN

64 1 U6 MOCD207 SO-8

65 1 U7 CBRHD-02 CBRHD-02

SC4808B-1

Manufacturer # Foot PrintItem Quantity Reference Part

25 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Evaluation Board Gerber Plots

SC4808B-1

Board Layout Assembly Top

Board Layout Assembly Bottom

Board Layout Top

Board Layout Bottom

26 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Evaluation Board Gerber Plots

SC4808B-1

Board Layout INNER1 Board Layout INNER2

27 2006 Semtech Corp. www.semtech.com

POWER MANAGEMENT

Outline Drawing - MSOP-10

SC4808B-1

e

A

N

2X

E/2

PIN 1

INDICATOR

ccc

C

2X N/2 TIPS

aaa C

SEATING

PLANE

NOTES:

CONTROLLING DIMENSIONS ARE IN MILLIMETERS (ANGLES IN DEGREES).

1.

DATUMS AND TO BE DETERMINED AT DATUM PLANE

2. -A- -H-

DIMENSIONS "E1" AND "D" DO NOT INCLUDE MOLD FLASH, PROTRUSIONS

3.

OR GATE BURRS.

REFERENCE JEDEC STD MO-187, VARIATION BA.4.

12

B

D

C

bxN

bbb C A-B D

SIDE VIEW

-B-

A1

E1

A2

D

E

A

SEE DETAIL

DIM

aaa

bbb

GAGE

PLANE

0.25

A

DIMENSIONS

INCHES

MIN NOM MAX MIN MAX

--A1

A2

E1

L1

01

ccc

A

b

c

D

E

e

L

N

.000

.030

.007

.003

.114

.114

.016

0°

.118

.118

.193 BSC

.020 BSC

.024

(.037)

10

.004

.003

.010

H

-

-

-

-

.043

.006

.037 0.75

.011 0.17

.009

.122

.122

.032

8° 0°

DETAIL

MILLIMETERS

-

0.00

0.08

2.90

2.90

4.90 BSC

0.50 BSC

0.40

(L1)

A

NOM

3.00

3.00

0.60

(.95)

10

0.10

0.08

0.25

L

-

1.10

-

0.15

-

0.95

-

0.27

-

0.23

3.10

3.10

0.80

-

8°

c

01

Land Pattern - MSOP-10

NOTES:

Contact Information

X

DIMENSIONS

DIM INCHES

(C)

P

1.

THIS LAND PATTERN IS FOR REFERENCE PURPOSES ONLY.

CONSULT YOUR MANUFACTURING GROUP TO ENSURE YOUR

COMPANY'S MANUFACTURING GUIDELINES ARE MET.

G

Z

Y

C

G

P

X

Y

Z

(.161)

.098

.020

.011

.063

.224

Semtech Corporation

Power Management Products Division

200 Flynn Road, Camarillo, CA 93012

Phone: (805)498-2111 FAX (805)498-3804

MILLIMETERS

(4.10)

2.50

0.50

0.30

1.60

5.70

28 2006 Semtech Corp. www.semtech.com

Loading...

Loading...