Page 1

SERVICE

MANUAL

HD/HR RANGE

OF SERVOMOTORS

ISSUE 2

WARNING

Servomotors contain magnetic

material which will attract metal

particles. Care should be taken

when dismantling motors to

avoid this.

All D.C. servomotors

manufactured by SEM contain

magnets which are air stable

and can be dismantled without

demagnetisation

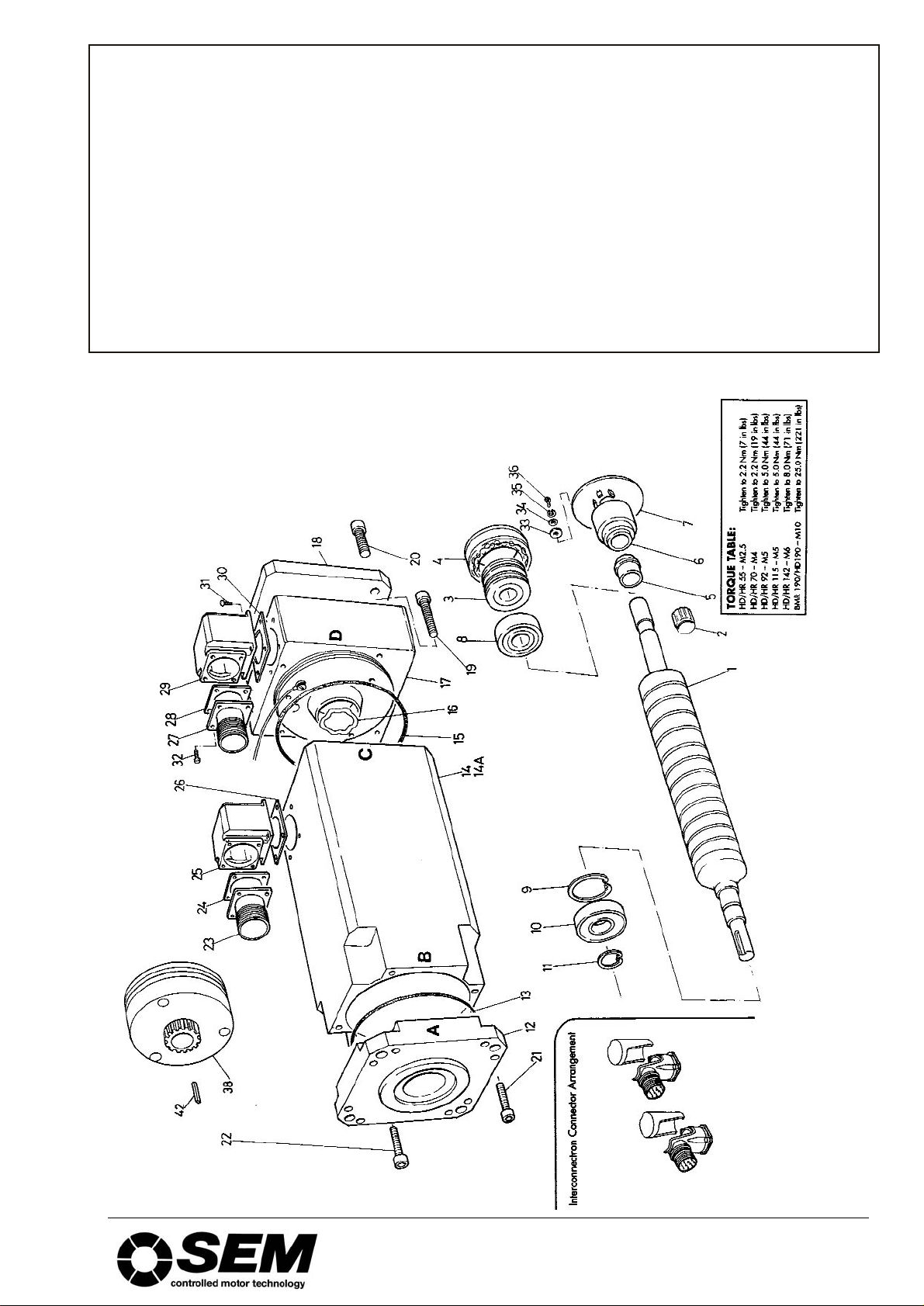

Page 2

HD/HR55

servicing instructions

1 GENERAL

1.1 Before starting work on the motor, these servicing instructions should

be read and fully understood.

1.2 Servicing of SEM motors must be done only by suitably trained and

qualified personnel, and only after such motors have been electrically

isolated and removed from their mechanical drives.

1.3 The jaws of any vice or clamp must be suitably protected when used to

grip any part of the motor.

1.4 When separating the motor end covers from the motor body, care must

be taken to avoid damage to their mating surfaces.

1.5 NOTE. There are strong magnetic forces between the stator and

the rotor of all SEM servomotors. Fingers should be kept clear of

the gaps between the stator and end covers during assembly and

disassembly of the rotor.

1.6 Dismantled components awaiting reassembly should be kept in a safe,

clean and dry location.

Various types of encoder are used, involving different procedures

for dismantling, reassembly, connection, setting up and testing.

Contact SEM with regard to relevant servicing procedures for the

particular type of encoder involved.

2 MARKING

2.1 The following relationships must be marked with a marker pen or other

suitable method before dismantling.

2.2 Drive end (DE) cover (A) to motor body (B).

2.3 Non-drive end cover (D) to motor body (C).

2.4 Enclosing Cover (18) to non-drive end (NDE) cover (17).

2.5 Prior to resolver dismantling, mark outside end faces of resolver stator

(4) and resolver rotor (3)

3 DISMANTLING THE MOTOR

3.1 Remove 4 M4 socket screws from N.D.E. enclosing cover (18), remove

the end cover and the gasket.

3.2 Remove 8 screws (21) from D.E. cover (12).

3.3 For Sagem resolver this must be removed prior to dismantling of the

motor, proceed as per instructions for tacho removal, for any other

manufacturer check with SEM for instructions.

3.4 Withdraw D.E. cover with complete attached assembly of rotor (1),

bearings (10 & 8), resolver rotor (3) and spacer (5). Remove circlip

(11) and press out rotor shaft to separate from D.E. housing. Remove

circlip (9) and remove bearing from D.E. housing. To remove resolver

rotor (3) use bearing extractor tool behind the shoulder on spacer (5);

the bearing can then be withdrawn. Handle the resolver assembly with

great care at all times.

3.5 Before removing N.D.E., go through the disconnection sequence:

3.6 Disconnection sequence. PIN REMOVAL TOOL REQUIRED –

available from SEM Ltd. Both connectors (23 & 27) must be removed

before N.D.E. cover can be removed. Take out 4 screws, pull the

socket forward to allow access to connector pins. Withdraw the

connector pins using the pin removal tool. Pull wires through from

feedback connector (23) to clear screw access; remove 4 screws (20)

from N.D.E. cover. Withdraw the cover carefully to avoid damage to

wiring.

3.7 Removal of resolver. Important: At all stages of removal and

reassembly, the resolver unit must be handled with care. Unscrew (36)

and release resolver body (4) complete. At this point the resolver rotor

(3) is free and will drop out of the resolver body unless held in place by

hand. Remove the resolver and store in a safe place until re-assembly.

3.8 Removal of D.E. cover – Brake Models. Remove 8 cover screws (21)

then 3 screws (19) holding brake assembly. This allows cover to be

removed, leaving the brake and bearing on the shaft and exposing the

leads to the brake. Disconnect these leads and remove complete rotor

assembly as Section 3.4. Pull the bearing off the shaft, leaving brake

free to be removed. When this sequence is complete, continue as

Section 3.4 above.

screws.

4.2 Fit the resolver to the N.D.E. cover with 3 screws and clamping

washers (metal shield outwards), feed both resolver and thermal

overload leads through the hole on the left of the N.D.E. cover.

4.3 Fit 2 connector elbows with cap screws and gaskets, bringing out the

leads at the same time. Press the pins firmly into the back of the

connectors until they click into place. Position the connectors and

gaskets and tighten down with screws and washers.

4.4 Fit O-ring, bearing and circlip to D.E. cover, slide rotor into

cover/bearing assembly. Slide bearing onto N.D.E. of shaft.

4.5 Supporting the inner race of the bearing, press both bearings into

place. Fit spacer and tolerance ring to N.D.E. Fit circlip at D.E.

4.6 Carefully stand motor upright (with N.D.E. down). Locate the wave

washer in the N.D.E. housing, lower the rotor/cover assembly very

carefully into the body and screw the D.E. cover to the body.

4.7 Support and press into position (resolver rotor). Fit a new tolerance

ring (2).

4.8 Fit brake, carefully press rotor into brake (ensuring that teeth line up

correctly). Fit rotor to body as above, but connect and isolate 2 brake

leads before pushing into place.

5 RESETTING THE RESOLVER.

5.1 This only applies to a standard resolver supplied by SEM with the

standard setting. For any other resolver, refer to the drive

manufacturer.

5.2 For these procedures it is necessary to make connections and links to

feedback connector pins. To avoid damage to these pins, it is

advisable to make such connections and links via a suitable separate

test socket which mates with the feedback connector multi-pin plug

(27) and which has short leads connected to its sockets. Alternatively

appropriate pins can be made available for connections and links by

withdrawing them from plug (27) as in Section 3.6 “Disconnection”.

5.3 If a brake is used, it must be temporarily held off during this operation

by applying a 24V dc supply across the brake terminals.

5.4 Undo 4 screws (20) and pull back the enclosing cover (18) to give

access to the resolver. With the above test plug connected to the

feedback connector, link pins R1 to S3 & pins R2 to S2. Connect a

signal generator (approx 5V 6kHz) between pins R1 and R2. Connect

an AC voltmeter between pins S1 and R2.

5.5 At the power connector, link motor phase pins V and W and then

connect a low voltage dc supply to motor phases at power connector

pins U (+ve) and V+W (-ve). Adjust this voltage to give between 25%

and 100% of motor rated current thereby causing the motor to turn to a

preferred position.

5.6 Slacken the 3 screws holding the resolver stator and then rotate it until

the voltmeter gives a maximum reading. Reconnect the AC voltmeter

to pins S4 and R2. Make a small final adjustment of the resolver stator

to get a minimum reading. Retighten the screws, disconnect the test

socket, the supplies, the voltmeter and links, let the brake (if used) be

re-applied.

5.7 Attach the protective shield (if fitted) to the resolver and fix the

enclosing cover (18) to the NDE cover in accordance with marks made

in operation 2.3.

6 ELECTRICAL TESTS NECESSARY BEFORE

CONNECTING MOTOR TO AMPLIFIER.

6.1 Measure motor stator winding resistances U-V, V-W, W-U. These

must be equal to within 3%.

6.2 Check dielectric strength by flash test at 1000 Vac from:

a Phase U (power connector pin) U to motor body.

b Phase U to thermal sensor (feedback connector pins Thermal

Sensor + and Thermal Sensor -).

c Phase U to brake connections (power connector pins B+ & B-).

If flash test is not possible then check that insulation resistance is

greater than 1megaohm.

6.3 Check dielectric strength by flash test at 500Vac or with a 500Vdc

supply from motor body to:

d Brake connections (power connector pins B+ and B-)

e Thermal sensor (feedback connector pins Thermal Sensor + and

Thermal Sensor -)

f Resolver (feedback connector pins R2 and S1.

If flash test is not possible then check that insulation resistance is

greater than 1megaohm.

4 RE-ASSEMBLY OF THE MOTOR

To fit N.D.E. cover to body. Note: new circlips, oil seals and

bearings must be fitted on the re-assembly as standard

procedure.

4.1 Feed the thermal overload leads through the hole in the N.D.E. cover,

feed the earth lead through the hole in the body and fit 4 cap head

SEM Limited, Faraday Way, Orpington, Kent BR5 3QT England

Telephone: +44 (0)1689 884700 ● Fax: +44 (0) 1689 884884

E-mail: info@sem.co.uk ● Internet http://www.sem.co.uk

Page 3

HD/HR55 parts list

ITEM NO. DESCRIPTION

1 Rotor Assembly

2 Tolerance Ring

3 Resolver Rotor

4 Resolver Body

5 Spacer (Non tacho motors only)

6 Tachogenerator Rotor Assembly

7 P.C.B. Assembly

8 N.D.E. Bearing

9 Bearing Retaining Circlip

10 D.E. Bearing

11 Bearing Retaining Circlip

12 D.E. Cover

13 D.E. ‘O’ Ring

14 Motor Body

14a Long Motor Body for Brake Motor

15 N.D.E. ‘O’ Ring

16 Wave Washer

17 Non Drive Encl Housing

18 N.D.E. Enclosing Cover

19 N.D.E. Housing Fixing Screw

20 N.D.E. Cover Fixing Screw

21 D.E. Cover Fixing Screw

22 Fixing Screw: Brake

23 M.S. Connector: Power

24 Gasket

25 Connector Housing

26 Gasket

27 MS Connector: Feedback

28 Gasket

29 Connector Housing

30 Gasket

31 Fixing Screw: Cap-head

32 Fixing Screw: Cheese-head

33 Plain Washer M4

34 Plain Washer M3

35 Single-turn Coil Spring Washer

36 Fixing Screw

37 Brake Key (Optional)

38 Brake (Optional)

SEM Limited, Faraday Way, Orpington, Kent BR5 3QT England

Telephone: +44 (0)1689 884700 ● Fax: +44 (0) 1689 884884

E-mail: info@sem.co.uk ● Internet http://www.sem.co.uk

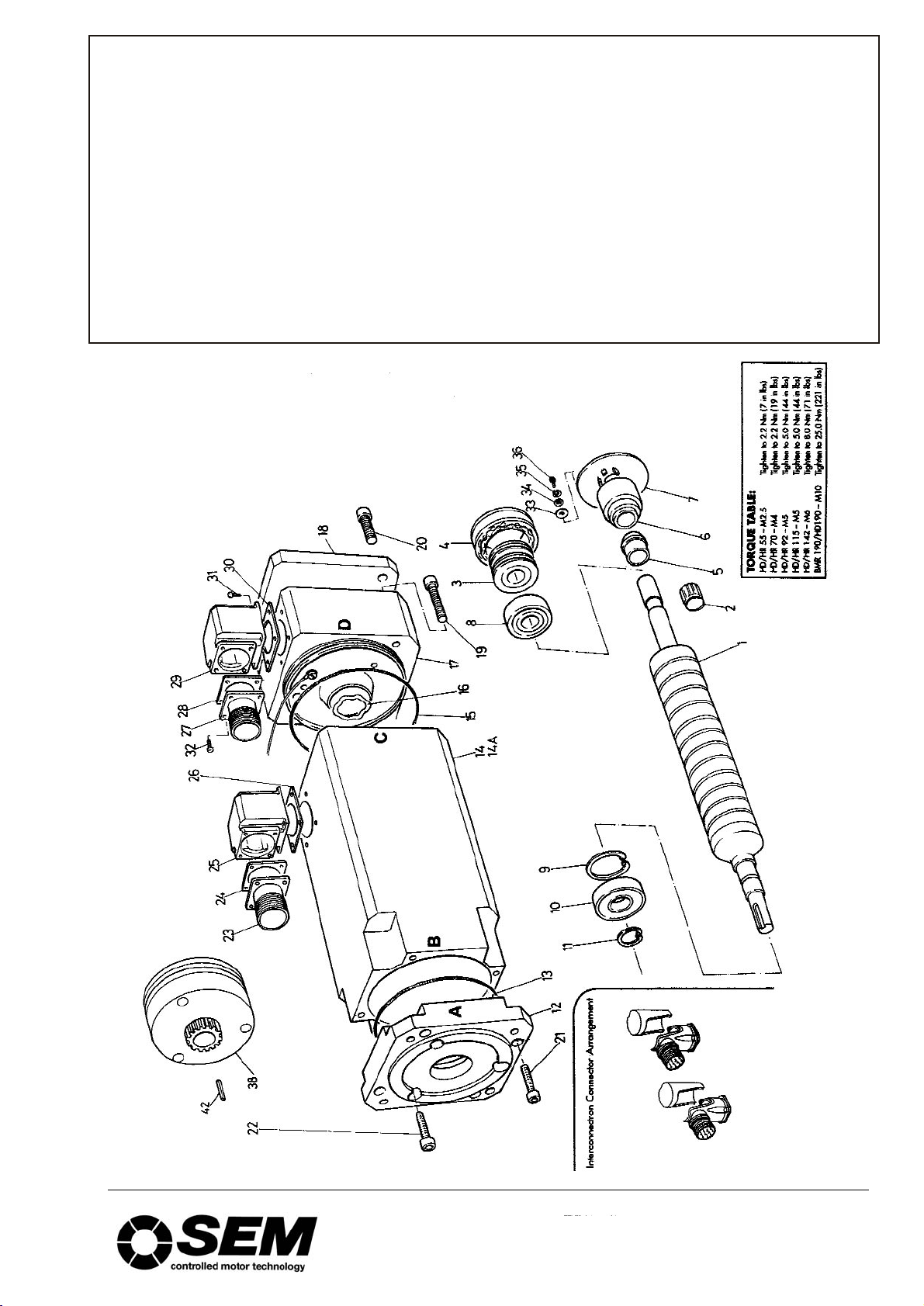

Page 4

HD/HR70

servicing instructions

1 GENERAL

1.1 Before starting work on the motor, these servicing instructions should

be read and fully understood.

1.2 Servicing of SEM motors must be done only by suitably trained and

qualified personnel, and only after such motors have been electrically

isolated and removed from their mechanical drives.

1.3 The jaws of any vice or clamp must be suitably protected when used to

grip any part of the motor.

1.4 When separating the motor end covers from the motor body, care must

be taken to avoid damage to their mating surfaces.

1.5 NOTE. There are strong magnetic forces between the stator and

the rotor of all SEM servomotors. Fingers should be kept clear of

the gaps between the stator and end covers during assembly and

disassembly of the rotor.

1.6 Dismantled components awaiting reassembly, should be kept in a safe,

clean and dry location.

Various types of encoder are used, involving different procedures

for dismantling, reassembly, connection, setting up and testing.

Contact SEM with regard to relevant servicing procedures for the

particular type of encoder involved.

2 MARKING

2.1 The following relationships must be marked with a marker pen or other

suitable method before dismantling.

2.2 Drive end (DE) cover (A) to motor body (B).

2.3 Non-drive end cover (D) to motor body (C).

2.4 Enclosing Cover (18) to non-drive end (NDE) cover (17).

2.5 Prior to resolver dismantling, mark outside end faces of resolver stator

(4) and resolver rotor (3)

3 DISMANTLING THE MOTOR

3.1 Remove 4 M4 socket screws from N.D.E. enclosing cover (18), remove

the end cover and the gasket.

3.2 Remove 8 screws (21) from D.E. cover (12).

3.3 For Sagem resolver this must be removed prior to dismantling of the

motor, proceed as per instructions for tacho removal, for any other

manufacturer check with SEM for instructions.

3.4 Withdraw D.E. cover with complete attached assembly of rotor (1),

bearings (10 & 8), resolver rotor (3) and spacer (5). Remove circlip

(11) and press out rotor shaft to separate from D.E. housing. Remove

circlip (9) and remove bearing from D.E. housing. To remove resolver

rotor (3) use bearing extractor tool behind the shoulder on spacer (5);

the bearing can then be withdrawn. Handle the resolver assembly with

great care at all times.

3.5 Before removing N.D.E., go through the disconnection sequence:

3.6 Disconnection sequence. PIN REMOVAL TOOL REQUIRED –

available from SEM Ltd. Both connectors (23 & 27) must be removed

before N.D.E. cover can be removed. Take out 4 screws, pull the

socket forward to allow access to connector pins. Withdraw the

connector pins using the pin removal tool. Pull wires through from

feedback connector (23) to clear screw access, remove 4 screws (20)

from N.D.E. cover. Withdraw the cover carefully to avoid damage to

wiring.

3.7 Removal of resolver. Important: At all stages of removal and

reassembly, the resolver unit must be handled with care. Unscrew (36)

and release resolver body (4) complete. At this point the resolver rotor

(3) is free and will drop out of the resolver body unless held in place by

hand. Remove the resolver and store in a safe place until re-assembly.

3.8 Removal of D.E. cover – Brake Models. Remove 8 cover screws (21)

then 3 screws (19) holding brake assembly. This allows cover to be

removed, leaving the brake and bearing on the shaft and exposing the

leads to the brake. Disconnect these leads and remove complete rotor

assembly as Section 3.4. Pull the bearing off the shaft, leaving brake

free to be removed. When this sequence is complete, continue as

Section 3.4 above.

feed the earth lead through the hole in the body and fit 4 cap head

screws.

4.2 Fit the resolver to the N.D.E. cover with 3 screws and clamping

washers (metal shield outwards), feed both resolver and thermal

overload leads through the hole on the left of the N.D.E. cover.

4.3 Fit 2 connector elbows with cap screws and gaskets, bringing out The

leads at the same time. Press the pins firmly into the back of the

connectors until they click into place. Position the connectors and

gaskets and tighten down with screws and washers.

4.4 Fit O-ring, bearing and circlip to D.E. cover, slide rotor into

cover/bearing assembly. Slide bearing onto N.D.E. of shaft.

4.5 Supporting the inner race of the bearing, press both bearings into

place. Fit spacer and tolerance ring to N.D.E. Fit circlip at D.E.

4.6 Carefully stand motor upright (with N.D.E. down). Locate the wave

washer in the N.D.E. housing, lower the rotor/cover assembly very

carefully into the body and screw the D.E. cover to the body.

4.7 Support and press into position (resolver rotor). Fit a new tolerance

ring (2). Fit brake, carefully press rotor into brake (ensuring that teeth

line up correctly). Fit rotor to body as above, but connect and isolate 2

brake leads before pushing into place.

5 RESETTING THE RESOLVER.

5.1 This only applies to a standard resolver supplied by SEM with the

standard setting. For any other resolver, refer to the drive

manufacturer.

5.2 For these procedures it is necessary to make connections and links to

feedback connector pins. To avoid damage to these pins, it is

advisable to make such connections and links via a suitable separate

test socket which mates with the feedback connector multi-pin plug

(27) and which has short leads connected to its sockets. Alternatively

appropriate pins can be made available for connections and links by

withdrawing them from plug (27) as in Section 3.6 “Disconnection”.

5.3 If a brake is used, it must be temporarily held off during this operation

by applying a 24V dc supply across the brake terminals.

5.4 Undo 4 screws (20) and pull back the enclosing cover (18) to give

access to the resolver. With the above test plug connected to the

feedback connector, link pins R1 to S3 & pins R2 to S2. Connect a

signal generator (approx 5V 6kHz) between pins R1 and R2. Connect

an AC voltmeter between pins S1 and R2.

5.5 At the power connector, link motor phase pins V and W and then

connect a low voltage dc supply to motor phases at power connector

pins U (+ve) and V+W (-ve). Adjust this voltage to give between 25%

and 100% of motor rated current thereby causing the motor to turn to a

preferred position.

5.6 Slacken the 3 screws holding the resolver stator and then rotate it until

the voltmeter gives a maximum reading. Reconnect the AC voltmeter

to pins S4 and R2. Make a small final adjustment of the resolver stator

to get a minimum reading. Retighten the screws, disconnect the test

socket, the supplies, the voltmeter and links, let the brake (if used) be

re-applied.

5.7 Attach the protective shield (if fitted) to the resolver and fix the

enclosing cover (18) to the NDE cover in accordance with marks made

in operation 2.2.

6 ELECTRICAL TESTS NECESSARY

BEFORE CONNECTING MOTOR TO

AMPLIFIER.

6.1 Measure motor stator winding resistances U-V, V-W, W-U. These

must be equal to within 3%.

6.2 Check dielectric strength by flash test at 1000 Vac from:

a Phase U (power connector pin) U to motor body.

b Phase U to thermal sensor (feedback connector pins Thermal

Sensor + and Thermal Sensor -).

c Phase U to brake connections (power connector pins B+ & B-).

If flash test is not possible then check that insulation resistance is

greater than 1megaohm.

6.3 Check dielectric strength by flash test at 500Vac or with a 500Vdc

supply from motor body to:

d Brake connections (power connector pins B+ and B-)

e Thermal sensor (feedback connector pins Thermal Sensor + and

Thermal Sensor -)

f Resolver (feedback connector pins R2 and S1.

6.4 If flash test is not possible then check that insulation resistance is

greater than 1megaohm.

4 RE-ASSEMBLY OF THE MOTOR

To fit N.D.E. cover to body. Note: new circlips, oil seals and

bearings must be fitted on the re-assembly as standard

procedure.

4.1 Feed the thermal overload leads through the hole in the N.D.E. cover,

SEM Limited, Faraday Way, Orpington, Kent BR5 3QT England

Telephone: +44 (0)1689 884700 ● Fax: +44 (0) 1689 884884

E-mail: info@sem.co.uk ● Internet http://www.sem.co.uk

Page 5

HD/HR70 parts list

ITEM NO. DESCRIPTION

1 Rotor Assembly

2 Tolerance Ring

3 Resolver Rotor

4 Resolver Body

5 Spacer (Non tacho motors only)

6 Tachogenerator Rotor Assembly

7 P.C. B. Assembly

8 N.D.E. Bearing

9 Bearing Retaining Circlip

10 D.E. Bearing

11 Bearing Retaining Circlip

12 D.E. Cover

13 D.E. ‘O’ Ring

14 Motor Body

14a Long Motor Body for Brake Motor

15 N.D.E. ‘O’ Ring

16 Wave Washer

17 Non Drive End Housing

18 N.D.E. Enclosing Cover

19 N.D.E. Housing Fixing Screw

20 N.D.E. Cover Fixing Screw

21 D.E. Cover Fixing Screw

22 Fixing Screw: Brake

23 M.S. Connector: Power

24 Gasket

25 Connector Housing

26 Gasket

27 MS Connector: Feedback

28 Gasket

29 Connector Housing

30 Gasket

31 Fixing Screw: Cap-head

32 Fixing Screw: Cheese-head

33 Plain Washer M4

34 Plain Washer M3

35 Single-turn Coil Spring Washer

36 Fixing Screw

37 Brake Key (Optional)

38 Brake (Optional)

SEM Limited, Faraday Way, Orpington, Kent BR5 3QT England

Telephone: +44 (0)1689 884700 ● Fax: +44 (0) 1689 884884

E-mail: info@sem.co.uk ● Internet http://www.sem.co.uk

Page 6

HD/HR92

servicing instructions

1 GENERAL

1.1 Before starting work on the motor, these servicing instructions should

be read and fully understood.

1.2 Servicing of SEM motors must be done only by suitably trained and

qualified personnel, and only after such motors have been electrically

isolated and removed from their mechanical drives.

1.3 The jaws of any vice or clamp must be suitably protected when used to

grip any part of the motor.

1.4 When separating the motor end covers from the motor body, care must

be taken to avoid damage to their mating surfaces.

1.5 NOTE. There are strong magnetic forces between the stator and

the rotor of all SEM servomotors. Fingers should be kept clear of

the gaps between the stator and end covers during assembly and

disassembly of the rotor.

1.6 Dismantled components awaiting reassembly, should be kept in a safe,

clean and dry location.

Various types of encoder are used, involving different procedures

for dismantling, reassembly, connection, setting up and testing.

Contact SEM with regard to relevant servicing procedures for the

particular type of encoder involved.

2 MARKING

2.1 The following relationships must be marked with a marker pen or other

suitable method before dismantling.

2.2 Drive end (DE) cover (A) to motor body (B).

2.3 Non-drive end cover (D) to motor body (C).

2.4 Enclosing Cover (17) to non-drive end (NDE) cover (11).

2.5 Prior to resolver dismantling, mark outside end faces of resolver stator

(4) and resolver rotor (3)

3 DISMANTLING THE MOTOR

3.1 Remove 4 M4 socket screws from NDE enclosing cover (17), remove

the end cover and the O Ring.

3.2 Grip the drive end of the rotor shaft (1) in a suitably protected vice and

loosen the nut (2). Leave this nut finger tight until the resolver is

required to be removed. (Note that a special tool is required, contact

SEM for details). Remove the unit from the vice at this point.

3.3 Disconnection sequence, (MS Connectors option). Remove 8 fixing

screws and pull M.S. plugs (29 & 30) clear of non drive end housing

sufficiently to allow access to wires for unsoldering of existing

connectors. When the wires are unsoldered the M.S. connectors can

be removed. (It is important to note all connections prior to

unsoldering).

3.4 Disconnection sequence, (Terminal Box assembly option).

Remove terminal box screws (27) lid, (21) and gasket (28). Unsolder

all connections from M.S. Connector (30) and release 3 motor leads

and 2 brake leads from terminal block (23). To remove the terminal box

(20) from the non drive end housing, remove screw and nut (25 & 26).

3.5 Removal of Resolver. Important. At all stages of removal and

reassembly, the resolver unit must be handled with care. (See Para

14). Unscrew (7 & 8) and release resolver body (4) complete. Remove

nut (2), noting that at this point the resolver rotor (3) is free, and will

drop out of the resolver body unless held in place by hand. Remove

the resolver and store in a safe place until re-assembly.

3.6 Removal of Drive End Cover, (Non Brake models). (do not lever

between body and end covers under any circumstance) Remove 4, M5

screws (36). Do not attempt to separate the N.D.E. housing from the

motor body at this stage. Remove 4 screws (35) and separate the drive

end cover from the motor body (10) and rotor shaft (1). Remove and

discard the oil seal (19) and the O-ring (13) (note that the oil seal must

be pressed out using a suitable tool. The rotor assembly is now free to

be removed, via the non-drive end, but it is still attached to the N.D.E.

cover by N.D.E. bearing (6).

3.7 Removal of N.D.E. Housing. TAKE CARE! The rotor itself is covered

by a protective tape, and before any attempt is made at further

withdrawal, the rotor must be properly supported and eased through

the motor body so that the tape is not damaged in any way. This is

most important. To remove rotor from N.D.E. cover, remove circlips

(14) from N.D.E. cover to release N.D.E. bearing (6). Support the

N.D.E. cover and rotor assembly in such a way as to allow the rotor to

be gently tapped or pushed out of the housing. (Only use a hide mallet

it tapping out is necessary).

3.8 Removal of D.E. Cover (Brake Models). Remove 3 screws which

hold brake assembly to D.E. housing, then follow instructions as for

non-brake model, (section 3.8). When drive end cover is removed, the

brake assembly (38) and bearing (15) are left on the rotor shaft (1).

After removing circlip (41) the bearing itself can only be removed by

use of a suitable tool. This will leave the brake assembly free to be

removed from the rotor shaft after disconnection of the relevant ‘spade’

connectors. Then follow instructions as applicable to nonbrake motor

(section 3.9).

4 RE-ASSEMBLY OF MOTOR

4.1 Note: New circlips, bearings oil seals and O-ring must be fitted on

reassembly as standard procedure. Also ensure that all marks made in

section 2 are in alignment as applicable. Fit bearing (6) into N.D.E.

housing. Fit D.E. Bearing (15) onto rotor (1). Supporting inner race of

N.D.E. bearing, press rotor assembly back into N.D.E. housing, fit

circlip (40). Fit new O-ring (13).

4.2 Carefully re-insert assembled rotor and N.D.E. housing through the

motor body at the same time feeding connection wires through the

crescent shape hole in the N.D.E. housing, taking care not to trap

wires or to damage the protective tape on the rotor when completing

this assembly. Tighten screws, using correct torque (see torque table).

Refit brake when fitted and fit bearing (15) (reconnect ‘spade’

connectors). Refit drive end housing (12) with wave washer 2, (16) and

O-ring (13) in position. Refit screws and tighten to correct torque (see

torque table). Fit oil seal (19).

4.3 Refit Resolver. Slide Resolver body into non drive end of rotor shaft

and screw into N.D. E. housing using screw (7) and clamps (8). Refit

resolver rotor (3), fit new nut (2) and tighten to correct torque (see

torque table), gripping drive end of rotor shah in a suitably protected

vice (as para 3). Re-assemble M.S. connectors or terminal box

assembly as applicable, in reverse sequence to paras 3.3 & 3.4.

5 RESETTING THE RESOLVER.

5.1 This only applies to a standard resolver supplied by SEM with the

standard setting. For any other resolver, refer to the drive

manufacturer.

5.2 For these procedures it is necessary to make connections and links to

feedback connector pins. To avoid damage to these pins, it is

advisable to make such connections and links via a suitable separate

test socket which mates with the feedback connector multi-pin plug

(30) and which has short leads connected to its sockets. Alternatively

appropriate pins can be made available for connections and links by

withdrawing them from plug (30) as in Section 3.3 and 3.4

“Disconnection”.

5.3 If a brake is used, it must be temporarily held off during this operation

by applying a 24V dc supply across the brake terminals.

5.4 Undo 4 screws (37) and pull back the enclosing cover (17) to give

access to the resolver. With the above test plug connected to the

feedback connector, link pins R1 to S3 & pins R2 to S2. Connect a

signal generator (approx 5V 6kHz) between pins R1 and R2. Connect

an AC voltmeter between pins S1 and R2.

5.5 At the power connector, link motor phase pins V and W and then

connect a low voltage dc supply to motor phases at power connector

pins U (+ve) and V+W (-ve). Adjust this voltage to give between 25%

and 100% of motor rated current thereby causing the motor to turn to a

preferred position.

5.6 Slacken the 3 screws (7) holding the resolver stator and then rotate it

until the voltmeter gives a maximum reading. Reconnect the AC

voltmeter to pins S4 and R2. Make a small final adjustment of the

resolver stator to get a minimum reading. Retighten the screws,

disconnect the test socket, the supplies, the voltmeter and links, let the

brake (if used) be re-applied.

5.7 Attach the protective shield (if fitted) to the resolver and fix the

enclosing cover (17) to the NDE cover in accordance with marks made

in operation 2.4.

6 ELECTRICAL TESTS NECESSARY

BEFORE CONNECTING MOTOR TO

AMPLIFIER.

6.1 Measure motor stator winding resistances U-V, V-W, W-U. These

must be equal to within 3%.

6.2 Check dielectric strength by flash test at 1000 Vac from:

a Phase U (power connector pin) U to motor body.

b Phase U to thermal sensor (feedback connector pins Thermal

Sensor + and Thermal Sensor -).

c Phase U to brake connections (power connector pins B+ & B-).

If flash test is not possible then check that insulation resistance is

greater than 1megaohm.

6.3 Check dielectric strength by flash test at 500Vac or with a 500Vdc

supply from motor body to:

d Brake connections (power connector pins B+ and B-)

e Thermal sensor (feedback connector pins Thermal Sensor + and

Thermal Sensor -)

f Resolver (feedback connector pins R2 and S1.

6.4 If flash test is not possible then check that insulation resistance is

greater than 1megaohm.

SEM Limited, Faraday Way, Orpington, Kent BR5 3QT England

Telephone: +44 (0)1689 884700 ● Fax: +44 (0) 1689 884884

E-mail: info@sem.co.uk ● Internet http://www.sem.co.uk

Page 7

HD/HR92 parts list

ITEM NO. DESCRIPTION

1 Rotor Assembly

2 Clamp Nut

3 Resolver Rotor

4 Resolver Body

5 Spacer (Resolver only)

6 Bearing Non Drive End

7 Resolver Body Fixing Screws

8 Resolver Body Synchro Clamp

10 Motor Body

11 Non Drive End Housing

12 Drive End Cover

13 ‘O’ Ring

14 Bearing Retaining Circlip

15 Bearing Drive End

16 Wave Washer

17 Non Drive End Enclosing Cover

18 ‘O’ Ring

19 Oilseal

20 Terminal Box

21 Terminal Box Lid

22 Key

23 Terminal Block Assembly

24 Blanking Plug

25 Conduit Nipple and ‘O’ Ring

26 Earth Lead Screw and Clamp

27 Terminal Box Lid Fixing Screws

28 Terminal Box Lid Gasket

29 Motor M.S. Connector 7 Pin (Optional)

30 M.S. Connector Feedback 17 Pin

31 ‘O’ Ring

32 ‘O’ Ring

34 Spacer Plate Gasket (Optional)

35 Fixing Screw Drive End Cover

36 Fixing Screw Non Drive End Housing

37 Fixing Screw Non D.E. Enclosing Cover

38 Brake (Optional)

39 Circlip (Brake) (Optional)

40 Circlip (Non Drive End)

41 Circlip (Drive End) (Optional)

42 Brake Key (Optional)

43 Tacho Stator and P.C.B. Assy (Optional)

44 Tacho Rotor Assy (Optional)

SEM Limited, Faraday Way, Orpington, Kent BR5 3QT England

Telephone: +44 (0)1689 884700 ● Fax: +44 (0) 1689 884884

E-mail: info@sem.co.uk ● Internet http://www.sem.co.uk

Page 8

HD/HR115

brake assembly (38) and bearing (15) are left on the rotor shaft (1).

3.9 After removing circlip (41) the bearing itself can only be removed by

use of a suitable tool. This will leave the brake assembly free to be

removed from the rotor shaft after disconnection of the relevant ‘spade’

connectors. Then follow instructions as applicable to nonbrake motor

(section 3.7).

servicing instructions

1 GENERAL

1.1 Before starting work on the motor, these servicing instructions should

be read and fully understood.

1.2 Servicing of SEM motors must be done only by suitably trained and

qualified personnel, and only after such motors have been electrically

isolated and removed from their mechanical drives.

1.3 The jaws of any vice or clamp must be suitably protected when used to

grip any part of the motor.

1.4 When separating the motor end covers from the motor body, care must

be taken to avoid damage to their mating surfaces.

1.5 NOTE. There are strong magnetic forces between the stator and

the rotor of all SEM servomotors. Fingers should be kept clear of

the gaps between the stator and end covers during assembly and

disassembly of the rotor.

1.6 Dismantled components awaiting reassembly, should be kept in a safe,

clean and dry location.

Various types of encoder are used, involving different procedures

for dismantling, reassembly, connection, setting up and testing.

Contact SEM with regard to relevant servicing procedures for the

particular type of encoder involved.

2 MARKING

2.1 The following relationships must be marked with a marker pen or other

suitable method before dismantling.

2.2 Drive end (DE) cover (A) to motor body (B).

2.3 Non-drive end cover (D) to motor body (C).

2.4 Enclosing Cover (17) to non-drive end (NDE) cover (11).

2.5 Prior to resolver dismantling, mark outside end faces of resolver stator

(4) and resolver rotor (3)

3 DISMANTLING THE MOTOR

3.1 Remove M5 socket screws from NDE enclosing cover (17), remove the

end cover and the O Ring.

3.2 Grip the drive end of the rotor shaft (11) in a suitably protected vice

and loosen the nut (12). Leave this nut finger tight until the resolver is

required to be removed. (Note that a special tool is required, available

from SEM). Remove the unit from the vice at this point.

3.3 Disconnection sequence, (MS Connectors option). Remove 8 fixing

screws and pull M.S. plugs (29 & 30) clear of non drive end housing

sufficiently to allow access to wires for unsoldering of existing

connectors. When the wires are unsoldered the M.S. connectors can

be removed. (It is important to note all connections prior to

unsoldering).

3.4 Disconnection sequence, (Terminal Box assembly option).

Remove terminal box screws (27) lid, (21) and gasket (28). Unsolder

all connections from M.S. Connector (30) and release 3 motor leads

and 2 brake leads from terminal block (23). To remove the terminal box

(20) from the non drive end housing, remove screw and nut (25 & 26).

3.5 Removal of Resolver. Important. At all stages of removal and reassembly, the resolver unit must be handled with care. (See Para 14).

Unscrew (7 & 8) and release resolver body (4) complete. Remove nut

(2), noting that at this point the resolver rotor (3) is free, and will drop

out of the resolver body unless held in place by hand. Remove the

resolver and store in a safe place until re-assembly.

3.6 Removal of Drive End Cover, (Non Brake models). (Do not lever

between body and end covers under any circumstance). Remove 4,

M5 socket screws (36). Do not attempt to separate the N.D.E. housing

from the motor body at this stage. Remove 4 screws (35) and separate

the drive end cover from the motor body (10) and rotor shaft (1).

Remove and discard the oil seal (19) and the O-ring (13) (note that the

oil seal must be pressed out using a suitable tool. The rotor assembly

is now free to be removed, via the non-drive end, but it is still attached

to the N.D.E. cover by N.D.E. bearing (6).

3.7 Removal of N.D.E. Housing. TAKE CARE! The rotor itself is covered

by a protective tape, and before any attempt is made at further

withdrawal, the rotor must be properly supported and eased through

the motor body so that the tape is not damaged in any way. This is

most important. To remove rotor from N.D.E. cover, remove circlips

(14) from N.D.E. cover to release N.D.E. bearing (6). Support the

N.D.E. cover and rotor assembly in such a way as to allow the rotor to

be gently tapped or pushed out of the housing. (Only use a hide mallet

if tapping out is necessary).

3.8 Removal of D.E. Cover (Brake Models). Remove 6 screws which

hold brake assembly to D.E. housing, then follow instructions as for

non-brake model, (section 3.7). When drive end cover is removed, the

4 RE-ASSEMBLY OF MOTOR

4.1 Note: New circlips, bearings, oil seals and O-ring must be fitted on

reassembly as standard procedure. Also ensure that all marks made in

section 2 are in alignment as applicable. Fit bearing (6) into N.D.E.

housing. Fit D.E. Bearing (15) onto rotor (1). Supporting inner race of

N.D.E. bearing, press rotor assembly back into N.D.E. housing, fit

circlip (40). Fit new O-ring (13).

4.2 Carefully re-insert assembled rotor and N.D.E. housing through the

motor body at the same time feeding connection wires through the

crescent shape hole in the N.D.E. housing, taking care not to trap

wires or to damage the protective tape on the rotor when completing

this assembly. Tighten screws, using correct torque (see torque table).

Refit brake when fitted and fit bearing (15) (reconnect ‘spade’

connectors). Refit drive end housing (12) with wave washer (16) and

O-ring (13) in position. Refit screws and tighten to correct torque (see

torque table). Fit oil seal (19).

4.3 Refit Resolver. Slide Resolver body into non drive end of rotor shah

and screw into N.D. E. housing using screw (7) and clamps (8).

4.4 Refit resolver rotor (3), refit nut (2) and tighten to correct torque (see

torque table), gripping drive end of rotor shaft in a suitably protected

vice (as section 3.2). Re-assemble M.S. connectors or terminal box

assembly as applicable, in reverse sequence to sections 3.3 & 3.4.

5 RESETTING THE RESOLVER.

5.1 This only applies to a standard resolver supplied by SEM with the

standard setting. For any other resolver, refer to the drive

manufacturer.

5.2 For these procedures it is necessary to make connections and links to

feedback connector pins. To avoid damage to these pins, it is

advisable to make such connections and links via a suitable separate

test socket which mates with the feedback connector multi-pin plug

(30) and which has short leads connected to its sockets. Alternatively

appropriate pins can be made available for connections and links by

withdrawing them from plug (30) as in Section 3.3 & 3.4

“Disconnection”.

5.3 If a brake is used, it must be temporarily held off during this operation

by applying a 24V dc supply across the brake terminals.

5.4 Undo 4 screws (37) and pull back the enclosing cover (17) to give

access to the resolver. With the above test plug connected to the

feedback connector, link pins R1 to S3 & pins R2 to S2. Connect a

signal generator (approx 5V 6kHz) between pins R1 and R2. Connect

an AC voltmeter between pins S1 and R2.

5.5 At the power connector, link motor phase pins V and W and then

connect a low voltage dc supply to motor phases at power connector

pins U (+ve) and V+W (-ve). Adjust this voltage to give between 25%

and 100% of motor rated current thereby causing the motor to turn to a

preferred position.

5.6 Slacken the 3 screws holding the resolver stator and then rotate it until

the voltmeter gives a maximum reading. Reconnect the AC voltmeter

to pins S4 and R2. Make a small final adjustment of the resolver stator

to get a minimum reading. Retighten the screws, disconnect the test

socket, the supplies, the voltmeter and links, let the brake (if used) be

re-applied.

5.7 Attach the protective shield (if fitted) to the resolver and fix the

enclosing cover (17) to the NDE cover in accordance with marks made

in operation 2.4.

6 ELECTRICAL TESTS NECESSARY

BEFORE CONNECTING MOTOR TO

AMPLIFIER.

6.1 Measure motor stator winding resistances U-V, V-W, W-U. These

must be equal to within 3%.

6.2 Check dielectric strength by flash test at 1000 Vac from:

a Phase U (power connector pin) U to motor body.

b Phase U to thermal sensor (feedback connector pins Thermal

Sensor + and Thermal Sensor -).

c Phase U to brake connections (power connector pins B+ & B-).

If flash test is not possible then check that insulation resistance is

greater than 1megaohm.

6.3 Check dielectric strength by flash test at 500Vac or with a 500Vdc

supply from motor body to:

d Brake connections (power connector pins B+ and B-)

e Thermal sensor (feedback connector pins Thermal Sensor + and

Thermal Sensor -)

f Resolver (feedback connector pins R2 and S1.

g If flash test is not possible then check that insulation resistance is

greater than 1megaohm.

SEM Limited, Faraday Way, Orpington, Kent BR5 3QT England

Telephone: +44 (0)1689 884700 ● Fax: +44 (0) 1689 884884

E-mail: info@sem.co.uk ● Internet http://www.sem.co.uk

Page 9

HD/HR115 parts list

ITEM NO. DESCRIPTION

1 Rotor Assembly

2 Clamp Nut

3 Resolver Rotor

4 Resolver Body

5 Spacer {Resolver only)

6 Bearing Non Drive End

7 Resolver Body Fixing Screws

8 Resolver Body Synchro Clamp

9 Spacer (Optional)

10 Motor Body

11 Non Drive End Housing

12 Drive End Cover

13 ‘O’ Ring

14 Circlip

15 Bearing Drive End

16 Wave Washer

17 Non Drive End Enclosing Cover

18 ‘O’ Ring

19 Oilseal

20 Terminal Box

21 Terminal Box Lid

22 Key

23 Terminal Block Assembly

24 Blanking Plug

25 Conduit Nipple and ‘O’ Ring

26 Earth Lead Screw and Clamp

27 Terminal Box Lid Fixing Screw

28 Terminal Box Lid Gasket

29 Motor M.S. Connector 7 Pin (Optional)

30 Feedback M.S. Connector 17 Pin

31 ‘O’Ring

32 ‘O’Ring

34 Spacer Plate Gasket (Optional)

35 Fixing Screw (Drive End)

36 Fixing Screw (Non Drive End Housing)

37 Fixing Screw (Non Drive End Enclosing

Cover)

38 Brake (Optional)

40 Circlip (Non Drive End)

41 Circlip (Drive End)

42 Brake Key (Optional)

43 Tacho Stator and P.C.B. Assembly

(Optional)

44 Tacho Rotor Assy (Optional)

45 Brake Circlip (Optional)

SEM Limited, Faraday Way, Orpington, Kent BR5 3QT England

Telephone: +44 (0)1689 884700 ● Fax: +44 (0) 1689 884884

E-mail: info@sem.co.uk ● Internet http://www.sem.co.uk

Page 10

HD/HR142

brake model, (section 3.6). When drive end cover is removed, the

brake assembly (38) and bearing (15) are left on the rotor shaft (l).

After removing circlip (41) the bearing itself can only be removed by

use of a suitable tool. This will leave the brake assembly free to be

removed from the rotor shaft after disconnection of the relevant ‘spade’

connectors. Then follow instructions as applicable to nonbrake motor

(section 3.7).

servicing instructions

1 GENERAL

1.1 Before starting work on the motor, these servicing instructions should

be read and fully understood.

1.2 Servicing of SEM motors must be done only by suitably trained and

qualified personnel, and only after such motors have been electrically

isolated and removed from their mechanical drives.

1.3 The jaws of any vice or clamp must be suitably protected when used to

grip any part of the motor.

1.4 When separating the motor end covers from the motor body, care must

be taken to avoid damage to their mating surfaces.

1.5 NOTE. There are strong magnetic forces between the stator and

the rotor of all SEM servomotors. Fingers should be kept clear of

the gaps between the stator and end covers during assembly and

disassembly of the rotor.

1.6 Dismantled components awaiting reassembly, should be kept in a safe,

clean and dry location.

Various types of encoder are used, involving different procedures

for dismantling, reassembly, connection, setting up and testing.

Contact SEM with regard to relevant servicing procedures for the

particular type of encoder involved.

2 MARKING

2.1 The following relationships must be marked with a marker pen or other

suitable method before dismantling.

2.2 Drive end (DE) cover (A) to motor body (B).

2.3 Non-drive end cover (D) to motor body (C).

2.4 Enclosing Cover to non-drive end (NDE) cover.

2.5 Prior to resolver dismantling, mark outside end faces of resolver stator

(4) and resolver rotor (3)

3 DISMANTLING THE MOTOR

3.1 Remove M5 socket screws from NDE enclosing cover (17), remove the

end cover and the O-ring.

3.2 Grip the drive end of the rotor shaft (1) in a suitably protected vice and

loosen the nut (2). Leave this nut finger tight until the resolver is

required to be removed. (Note that a special tool is required, available

from SEM). Remove the unit from the vice at this point.

3.3 Disconnection sequence, (MS Connectors option). Remove 8 fixing

screws and pull M.S. plugs (29 & 30) clear of non drive end housing

sufficiently to allow access to wires for unsoldering of existing

connectors. When the wires are unsoldered, the M.S. connectors can

be removed. (It is important to note all connections prior to

unsoldering).

3.4 Disconnection sequence, (Terminal Box assembly option).

Remove terminal box screws (27) lid, (21) and gasket (28). Unsolder

all connections from M.S. Connector (30) and release 3 motor leads

and 2 brake leads from terminal block (23). To remove the terminal box

(20) from the non drive end housing, remove screw and nut (25 & 26).

3.5 Removal of Resolver. Important. At all stages of removal and

reassembly, the resolver unit must be handled with care. (See Para

14). Unscrew (7 & 8) and release resolver body (4) complete. Remove

nut (2), noting that at this point the resolver rotor (3) is free, and will

drop out of the resolver body unless held in place by hand. Remove

the resolver and store in a safe place until re-assembly.

3.6 Removal of Drive End Cover, (Non Brake models). (do not lever

between body and end covers under any circumstance). Remove 4,

M8 socket screws (36). Do not attempt to separate the N.D.E. housing

from the motor body at this stage. Remove 4 screws (35) and separate

the drive end cover from the motor body (10) and rotor shaft (1).

Remove and discard the oil seal (19) and the O-ring (13) (note that the

oil seal must be pressed out using a suitable tool. The rotor assembly

is now free to be removed, via the non-drive end, but it is still attached

to the N.D.E. cover by N.D.E. bearing (6).

3.7 Removal of N.D.E. Housing. TAKE CARE! The rotor itself is covered

by a protective tape, and before any attempt is made at further

withdrawal, the rotor must be properly supported and eased through

the motor body so that the tape is not damaged in any way. This is

most important. To remove rotor from N.D.E. cover, remove circlips

(14) from N.D.E. cover to release N.D.E. bearing (6). Support the

N.D.E. cover and rotor assembly in such a way as to allow the rotor to

be gently tapped or pushed out of the housing. (Only use a hide mallet

if tapping out is necessary).

3.8 Removal of D.E. Cover (Brake Models). Remove 6 screws which

hold brake assembly to D.E. housing, then follow instructions as for nn-

4 RE-ASSEMBLY OF MOTOR

4.1 Note: New circlips, bearings, oil seals and O-ring must be fitted on

reassembly as standard procedure. Also ensure that all marks made

under Para. 1 (a,b,c,) are in alignment as applicable. Fit bearing 16)

into N.D.E. housing. Fit D.E. Bearing 115) onto rotor (1). Supporting

inner race of N.D.E. bearing, press rotor assembly back into N.D.E.

housing, fit circlip (40). Fit new O-ring l13). 11. Carefully re-insert

assembled rotor and N.D.E. housing through the motor body at the

same time feeding connection wires through the crescent shape hole

in the N.D.E. housing, taking care not to trap wires or to damage the

protective tape on the rotor when completing this assembly. Tighten

screws, using correct torque (see torque table). Refit brake when fitted

and fit bearing (15) (reconnect ‘spade’ connectors). Refit drive end

housing (12) with wave washer (16) and O-ring (13) in position. Refit

screws and tighten to correct torque (see torque table). Fit oil seal (19).

4.2 Refit Resolver. Slide Resolver body into non drive end of rotor shaft

and screw into N.D. E. housing using screw (7) and clamps (8). Refit

resolver rotor (3), refit nut (2) and tighten to correct torque (see torque

table), gripping drive end of rotor shaft in a suitably protected vice (as

para 3). Re-assemble M.S. connectors or terminal box assembly as

applicable, in reverse sequence to paras 4 & 5.

5 RESETTING THE RESOLVER.

5.1 This only applies to a standard resolver supplied by SEM with the

standard setting. For any other resolver, refer to the drive

manufacturer.

5.2 For these procedures it is necessary to make connections and links to

feedback connector pins. To avoid damage to these pins, it is

advisable to make such connections and links via a suitable separate

test socket which mates with the feedback connector multi-pin plug

(30) and which has short leads connected to its sockets. Alternatively

appropriate pins can be made available for connections and links by

withdrawing them from plug (30) as in Section 3.2 & 3.3

“Disconnection”.

5.3 If a brake is used, it must be temporarily held off during this operation

by applying a 24V dc supply across the brake terminals.

5.4 Undo 4 screws (37) and pull back the enclosing cover (17) to give

access to the resolver. With the above test plug connected to the

feedback connector, link pins R1 to S3 & pins R2 to S2. Connect a

signal generator (approx 5V 6kHz) between pins R1 and R2. Connect

an AC voltmeter between pins S1 and R2.

5.5 At the power connector, link motor phase pins V and W and then

connect a low voltage dc supply to motor phases at power connector

pins U (+ve) and V+W (-ve). Adjust this voltage to give between 25%

and 100% of motor rated current thereby causing the motor to turn to a

preferred position.

5.6 Slacken the 3 screws (7) holding the resolver stator and then rotate it

until the voltmeter gives a maximum reading. Reconnect the AC

voltmeter to pins S4 and R2. Make a small final adjustment of the

resolver stator to get a minimum reading. Retighten the screws,

disconnect the test socket, the supplies, the voltmeter and links, let the

brake (if used) be re-applied.

5.7 Attach the protective shield (if itted) to the resolver and fix the

enclosing cover (17) to the NDE cover in accordance with marks made

in operation 2.4.

6 ELECTRICAL TESTS NECESSARY

BEFORE CONNECTING MOTOR TO

AMPLIFIER.

6.1 Measure motor stator winding resistances U-V, V-W, W-U. These

must be equal to within 3%.

6.2 Check dielectric strength by flash test at 1000 Vac from:

a Phase U (power connector pin) U to motor body.

b Phase U to thermal sensor (feedback connector pins Thermal

Sensor + and Thermal Sensor -).

c Phase U to brake connections (power connector pins B+ & B-).

If flash test is not possible then check that insulation resistance is

greater than 1megaohm.

6.3 Check dielectric strength by flash test at 500Vac or with a 500Vdc

supply from motor body to:

d Brake connections (power connector pins B+ and B-)

e Thermal sensor (feedback connector pins Thermal Sensor + and

Thermal Sensor -)

f Resolver (feedback connector pins R2 and S1.

6.4 If flash test is not possible then check that insulation resistance is

greater than 1megaohm.

SEM Limited, Faraday Way, Orpington, Kent BR5 3QT England

Telephone: +44 (0)1689 884700 ● Fax: +44 (0) 1689 884884

E-mail: info@sem.co.uk ● Internet http://www.sem.co.uk

Page 11

HD/HR142 parts list

ITEM NO. DESCRIPTION

1 Rotor Assembly

2 Clamp Nut

3 Resolver Rotor

4 Resolver Body

5 Spacer 1Resolver only)

6 Bearing Non Drive End

7 Resolver Body Fixing Screws

8 Resolver Body Synchro Clamp

10 Motor Body

11 Non Drive End Housing

12 Drive End Cover

13 ‘O’ Ring

14 Circlip

15 Bearing Drive End

16 Wave Washer

17 Non Drive End Enclosing Cover

18 ‘O’ Ring

19 Oilseal

20 Terminal Box

21 Terminal Box Lid

22 Key

23 Terminal Block Assembly

24 Blanking Plug

25 Conduit Nipple and ‘O’ Ring

26 Earth Lead Screw and Clamp

27 Terminal Box Lid Fixing Screw

28 Terminal Box Lid Gasket

29 Motor M.S. Connector 7 Pin (Optional)

30 Feedback M.S. Connector 17 Pin

31 ‘O’ Ring

32 ‘O’ Ring

35 Fixing Screw (Drive End)

36 Fixing Screw (Non Drive End Housing)

37 Fixing Screw (Non Drive End Enclosing

Cover)

38 Brake (Optional)

40 Circlip (Non Drive End)

41 Circlip (Drive End)

42 Brake Key (Optional)

43 Tacho Stator and P.C.B. Assembly

(Optional)

44 Tacho Rotor Assy (Optional)

45 Tacho Fixing Adaptor

46 Brake Circlip (Optional)

SEM Limited, Faraday Way, Orpington, Kent BR5 3QT England

Telephone: +44 (0)1689 884700 ● Fax: +44 (0) 1689 884884

E-mail: info@sem.co.uk ● Internet http://www.sem.co.uk

Page 12

BMR/HD/HR190

the brake assembly free to be removed from the rotor shaft after

disconnection of the relevant ‘spade’ connectors. Then follow instructions as

applicable to nonbrake motor (section 3.7).

4 RE-ASSEMBLY OF MOTOR

servicing instructions

1 GENERAL

1.1 Before starting work on the motor, these servicing instructions should be

read and fully understood.

1.2 Servicing of SEM motors must be done only by suitably trained and qualified

personnel, and only after such motors have been electrically isolated and

removed from their mechanical drives.

1.3 The jaws of any vice or clamp must be suitably protected when used to grip

any part of the motor.

1.4 When separating th e motor end covers from the motor body, care must be

taken to avoid damage to their mating surfaces.

1.5 NOTE. There are strong magnetic forces between the stator and the

rotor of all SEM servomotors. Fingers should be kept clear of the gaps

between the stator and end covers during assembly and disassembly

of the rotor.

1.6 Dismantled components awaiting reassembly, should be kept in a safe, clean

and dry location.

Various types of encoder are used, involving different procedures for

dismantling, reassembly, connection, setting up and testing. Contact

SEM with regard to relevant servicing procedures for the particular type

of encoder involved.

2 MARKING

2.1 The following relationships must be marked with a marker pen or other

suitable method before dismantling.

2.2 Drive end (DE) cover (A) to motor body (B).

2.3 Non-drive end cover (D) to motor body (C).

2.4 Enclosing Cover (17) to non-drive end (NDE) cover (11).

2.5 Prior to resolver dismantling, mark outside end faces of resolver stator (4)

and resolver rotor (3)

3 DISMANTLING THE MOTOR

3.1 Remove M5 socket screws from NDE enclosing cover (17), remove the end

cover and the O Ring.

3.2 Grip the drive end of the rotor shaft (1) in a suitably protected vice and

loosen the nut (2). Leave this nut finger tight until the resolver is required to

be removed. (Note that a special tool is required, available from SEM).

Remove the unit from the vice at this point.

3.3 Disconnection sequence, (MS Connectors option). Remove 8 fixing

screws and pull M.S. plugs (29 & 30)

sufficiently to allow access

When the wires are unsolde red, the M.S. connectors ca n be removed. (It is

important to note all connections prior to unsoldering).

3.4 Disconnection sequence, (Terminal Box assembly option). Remove

terminal box screws (27)

from M.S. Connector (30) and release 3 motor leads and 2 brake leads from

terminal block (23). To remove the terminal box (20) from the non drive end

housing, remove screw and nut (25 & 26).

3.5 Removal of Resolver. Important. At all stages of removal and reassembly,

the resolver unit must be handled with care. (See Para 14). Unscrew (7 & 8)

and release resolver body (4) complete. Remove nut (2), noting that at this

point the resolver rotor (3) is free, and will drop out of the resolver body

unless held in place by hand. Remove the resolver and store in a safe place

until re-assembly.

3.6 Removal of Drive End Cover, (Non Brake models). (Do not lever between

body and end covers under any circumstance). Remove 4, M8 socket screws

(36). Do not attempt to separate the N.D.E. housing from the motor body at

this stage. Remove 4 screws (35) and separate the drive end cover from the

motor body (10) and rotor shaft (1). Remove and discard the oil seal (19) and

the O-ring (13) (note that the oil seal must be pressed out using a suitable

tool. The rotor assembly is now free to be removed, via the non-drive end,

but it is still attached to the N.D.E. cover by N.D.E. bearing (6).

3.7 Removal of N.D.E. Housing. TAKE CARE! The rotor itself is covered by a

protective tape, and before any attempt is made at further withdrawal, the

rotor must be properly supported and eased through the motor body so that

the tape is not damaged in any way. This is most important. To remove rotor

from N.D.E. cover, remove circlips (14) from N.D.E. cover to release N.D.E.

bearing (6). Support the N.D.E. cover and rotor assembly in such a way as to

allow the rotor to be gently tapped or pushed out of the housing. (Only use a

hide mallet if tapping out is necessary).

3.8 Removal of D.E. Cover (Brake Models) Remove 6 screws which hold

brake assembly to D.E. housing, then follow instructions as for non-brake

model, (Para.7). When drive end cover is removed, the brake assembly (38)

and bearing (15) are left on the rotor shaft (1). After removing circlip (41) the

bearing itself can only be removed by use of a suitable tool. This will leave

lid, (21) and gasket (28). Unsolder all connections

clear of non drive end housing

to wires for unsoldering of existing connectors.

4.1 Note: New circlips, bearings, oil seals and O-ring must be fitted on reassembly as standard procedure. Also ensure that all marks made under

section 2 are in alignment as applicable. Fit bearing (6) into N.D.E. housing.

Fit D.E. Bearing (15) onto rotor (1). Supporting inner race of N.D.E. bearing,

press rotor assembly back into N.D.E. housing, fit circlip (40). Fit new O-ring

(13).

4.2 Carefully re-insert assembled rotor and N.D.E. housing through the motor

body at the same time feeding connection wires through the crescent shape

hole in the N.D.E. housing, taking care not to trap wires or to damage the

protective tape on the rotor when completing this assembly. Tighten screws,

using correct torque (see torque table). Refit brake when fitted and fit bearing

(15) (reconnect ‘spade’ connectors). Refit drive end housing (12) with wave

washer (16) and O-ring (13) in position. Refit screws and tighten to correct

torque (see torque table). Fit oil seal (19).

4.3 Refit Resolver. Slide Resolver body into non drive end of rotor shaft and

screw into N.D. E. housing using screw (7) and clamps (8). Refit resolver

rotor (3), refit nut (2) and tighten to correct torque (see torque table), gripping

drive end of rotor shaft in a suitably protected vice (as section 3.2). Reassemble M.S. connectors or terminal box assembly as applicable, in

reverse sequence to sections 3.3 & 3.4.

5 RESETTING THE RESOLVER.

5.1 This only applies to a standard resolver supplied by SEM with the standard

setting. For any other resolver, refer to the drive manufacturer.

5.2 For these procedures it is necessary to make connections and links to

feedback connector pins. To avoid damage to these pins, it is advisable to

make such connections and links via a suitable separate test socket which

mates with the feedback connector multi-pin plug (30) and which has short

leads connected to its sockets. Alternatively appropriate pins can be made

available for connections and links by withdrawing them from plug (30) as in

Section 3.3 and 3.4 “Disconnection”.

5.3 If a brake is used, it must be temporarily held off during this operation by

applying a 24V dc supply across the brake terminals.

5.4 Undo 4 screws (37) and pull back the enclosing cover (17) to give access to

the resolver. With the above test plug connected to the feedback connector,

link pins R1 to S3 & pins R2 to S2. Connect a signal generator (approx 5V

6kHz) between pins R1 and R2. Connect an AC voltmeter between pins S1

and R2.

5.5 At the power connector, link motor phase pins V and W and then connect a

low voltage dc supply to motor phases at power connector pins U (+ve) and

V+W (-ve). Adjust this voltage to give between 25% and 100% of motor rated

current thereby causing the motor to turn to a preferred position.

5.6 Slacken the 3 screws (7) holding the resolver stator and then rotate it until

the voltmeter gives a maximum reading. Reconnect the AC voltmeter to pins

S4 and R2. Make a small final adjustment of the resolver stator to get a

minimum reading. Retighten the screws, disconnect the test socket, the

supplies, the voltmeter and links, let the brake (if used) be re-applied.

5.7 Attach the protective shield (if fitted) to the resolver and fix the enclosing

cover (17) to the NDE cover in accordance with marks made in operation

2.4.

6 ELECTRICAL TESTS NECESSARY

BEFORE CONNECTING MOTOR TO

AMPLIFIER.

6.1 Measure motor stator winding resistances U-V, V-W, W-U. These must be

equal to within 3%.

6.2 Check dielectric strength by flash test at 1000 Vac from:

a Phase U (power connector pin) U to motor body.

b Phase U to thermal sensor (feedback connector pins Thermal Sensor +

and Thermal Sensor -).

c Phase U to brake connections (power connector pins B+ & B-).

If flash test is not possible then check that insulation resistance is greater

than 1megaohm.

6.3 Check dielectric strength by flash test at 500Vac or with a 500Vdc supply

from motor body to:

d Brake connections (power connector pins B+ and B-)

e Thermal sensor (feedback connector pins Thermal Sensor + and

Thermal Sensor -)

6.4 Resolver (feedback connector pins R2 and S1.f flash test is not possible then

check that insulation resistance is greater than 1megaohm.

SEM Limited, Faraday Way, Orpington, Kent BR5 3QT England

Telephone: +44 (0)1689 884700 ● Fax: +44 (0) 1689 884884

E-mail: info@sem.co.uk ● Internet http://www.sem.co.uk

Page 13

BMR/HD/HR190

parts list

ITEM NO. DESCRIPTION

1 Rotor Assembly

2 Clamp Nut

3 Resolver Rotor

4 Resolver Body

5 Spacer (Resolver only)

6 Bearing Non Drive End

7 Resolver Body Fixing Screws

8 Resolver Body Synchro Clamp

10 Motor Body

11 Non Drive End Housing

12 Drive End Cover

13 ‘O’ Ring

14 Circlip

15 Bearing Drive End

16 Wave Washer

17 Non Drive End Enclosing Cover

18 ‘O’ Ring

19 Oilseal

20 Terminal Box

21 Terminal Box Lid

22 Key

23 Terminal Block Assembly

24 Blanking Plug

25 Conduit Nipple and ‘O’ Ring

26 Earth Lead Screw and Clamp

27 Terminal Box Lid Fixing Screw

28 Terminal Box Lid Gasket

29 Motor M.S. Connector 7 Pin (Optional)

30 Feedback M.S. Connector 17 Pin

31 ‘O’ Ring

32 ‘O’Ring

35 Fixing Screw (Drive End)

36 Fixing Screw {Non Drive End Housing)

37 Fixing Screw (Non Drive End Enclosing

Cover)

38 Brake (Optional)

40 Circlip (Non Drive End)

41 Circlip (Drive End)

42 Brake Key (Optional)

43 Tacho Stator and P.C.B. Assembly

(Optional)

44 Tacho Rotor Assy (Optional)

45 Tacho Fixing Adaptor

46 Brake Circlip (Optional)

SEM Limited, Faraday Way, Orpington, Kent BR5 3QT England

Telephone: +44 (0)1689 884700 ● Fax: +44 (0) 1689 884884

E-mail: info@sem.co.uk ● Internet http://www.sem.co.uk

Page 14

REMOVAL OF

AC TACHO

Instructions common to

HD 55, HD 70, HD 92, HR 92

Extreme care to be taken during the removal and reassembly of the Tacho. When stripping Tacho Motor, Tacho

parts must be removed first.

1. Disconnect leads at feedback connector

2. Undo screws holding PCB board and lift off

3. Undo screws holding Tacho stator in N.D.E. cover and lift out.

4. With suitable extractor, pull out the Tacho rotor, taking care not to

damage these components.

5. Continue with dismantling of the motor.

Re-assembly

6. Replace the stator, fit tacho rotor and PCB in the correct position.

The screws that clamp the stator to PCB must not be

over tightened – this causes the PCB to distort. Use a suitable

Loctite or similar screw lock adhesive, to prevent screws from

loosening.

7. Refit rotor noting original position and using a power supply to

position motor rotor as during removal. Lock rotor with clamp nut

and tighten using correct torque. (See torque tables).

8. Refit stator, rotor and PCB Assembly. Refit screw aligning position

of PCB relative to the end housing. Reset tacho using appropriate

electrical device.

REMOVAL OF DC TACHO

(1) Remove cable from processing PCB

(2) Remove processing PCB by pulling it off the 3 connectors which

support it. Then proceed as AC tacho.

REMOVAL OF

AC TACHO

Instructions common to

HD 92, HR 92, HD 115, HR 115 HD 142,

HR 142, BMR 190/HD 190

Extreme care to be taken during the removal and reassembly of the Tacho.

1. Mark the relationship of PCB to the end housing (11). Insert a strip

or tube of non-magnetic material (e.g. card or plastic) in the air gap

between stator and rotor to prevent demagnetising the rotor and

damaging the windings. (ROTOR MUST BE PROTECTED FROM

CONTACT WITH ANY FERROUS METALTO PREVENT

DEMAGNETISATION).

2. Unplug cables from the PCB and remove the 3 screws holding the

PCD to the end housing. Carefully remove the PCB and stator

assembly.

3. To mark the position of rotor, connect a D.C. power supply to motor

terminals U(+ve) and V(-ve), adjust the voltage to give a current

between 25% and 100% of the motor rated current. The rotor will

move to a preferred position. If motor has a brake, it must be

released to allow this to happen. Then mark position of tacho rotor

relative to the end housing.

4. WE STRONGLY RECOMMEND THAT CUSTOMERS DO NOT

REMOVE THE STATOR FROM THE PCB. However, if the Stator

has to be removed, proceed as follows: To remove the stator from

the PCB – mark position of stator relative to PCB, unscrew the

screws holding the PCB to stator and separate.

NOTE: IT IS RECOMMENDED THAT IF ANY PARTS OF THE

TACHO ARE TO BE REPLACED, THE COMPLETE MOTOR BE

RETURNED TO SEM FOR IN-HOUSE REPAIR.

Re-assembly

5. Replace the stator on PCB (if it was removed) in the correct

position. The screws that clamp the stator to PCB must not be over

tightened – this causes the PCB to distort. Use a suitable Loctite or

similar screw lock adhesive, to prevent screws from loosening.

6. Refit rotor noting original position and using a power supply (as

para. 3) to position motor rotor as during removal. Lock rotor with

clamp nut and tighten using correct torque. (See torque tables).

7. Refit stator and PCB assembly protecting rotor from contact with

stator as during removal. Refit screw aligning position of PCB

relative to the end housing.

REMOVAL OF DC TACHO

(1 ) Remove cable from processing PCB

(2) Remove processing PCB by pulling it off the 3 connectors which

support it. Then proceed as AC tacho.

SEM Limited, Faraday Way,

Orpington, Kent BR5 3QT England

Telephone: +44 (0) 1689 884700

Fax: +44 (0) 1689 884884

E-mail: info@sem.co.uk

Internet: http://www.sem.co.uk

UL VERSIONS

AVAILABLE

WARNING

Servomotors contain magnetic material which will attract metal particles. Care should be

taken when dismantling motors to avoid this.

All D.C. servomotors manufactured by SEM contain magnets which are air stable and can

be dismantled without demagnetisation

Loading...

Loading...