1.INSTALLATION, INTEGR ATION AND CHECKOUT

1.1 Introduction

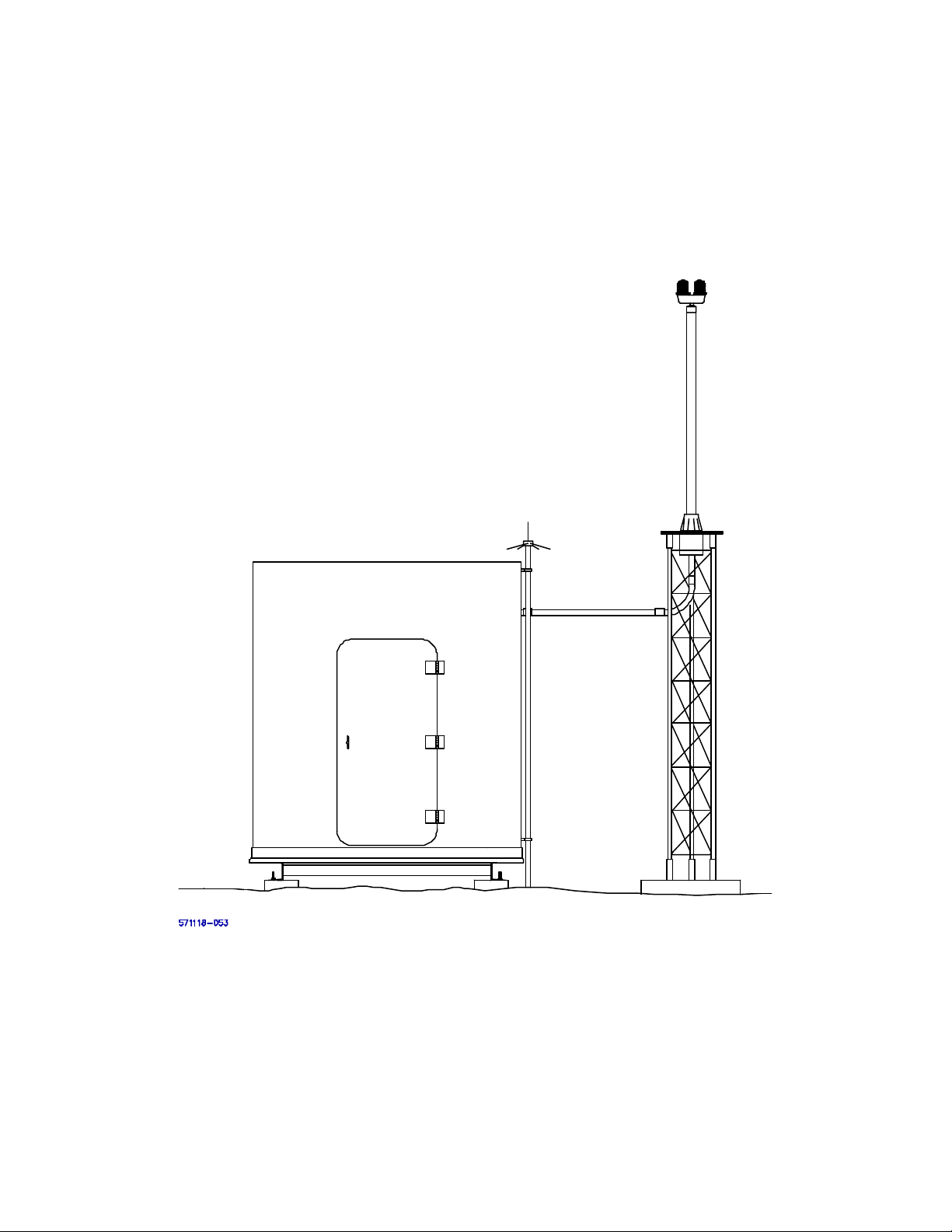

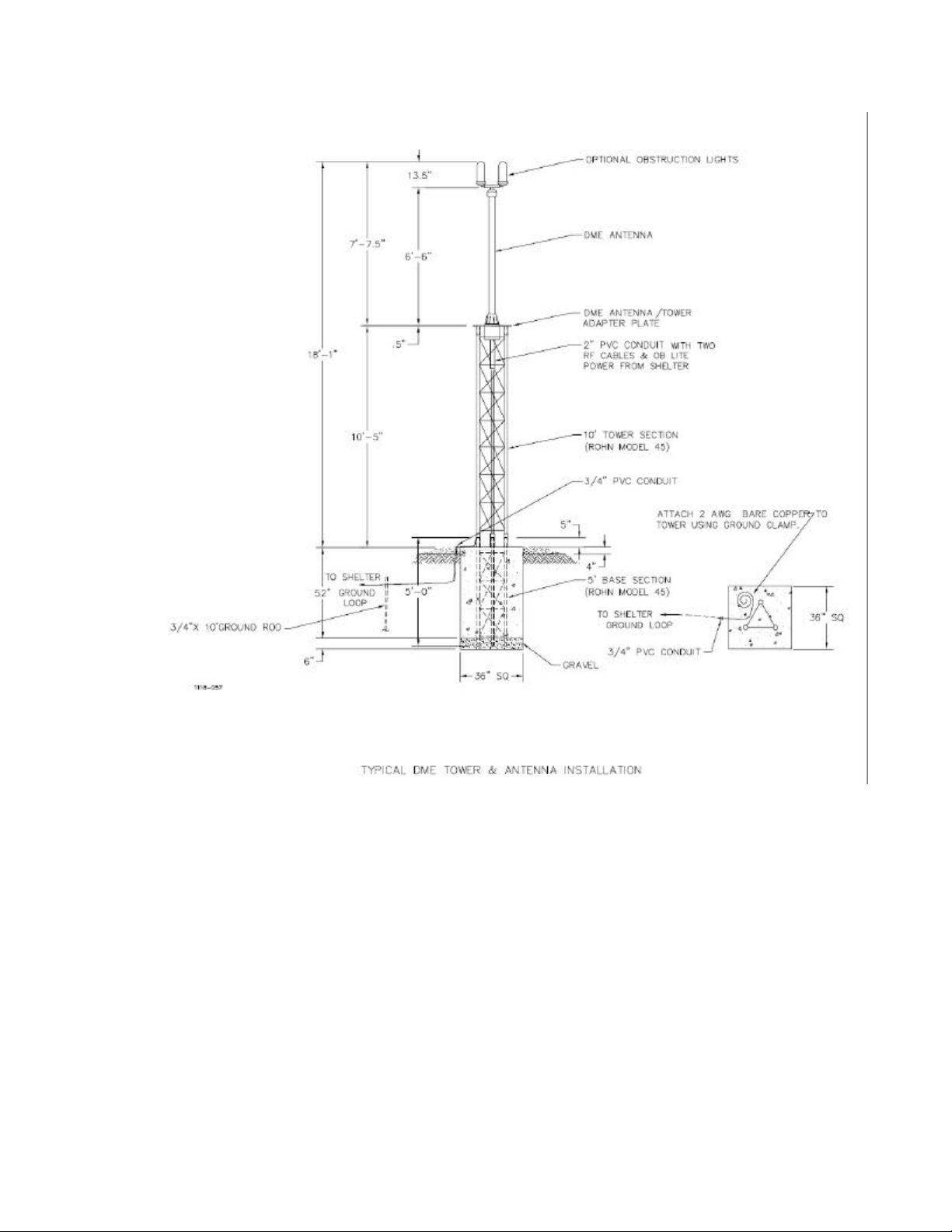

This section contains installation information for the independently located DME. If the DME is to be

collocated with VOR or ILS refer to the basic instructions in this section and to the installation instructions

for the VOR or ILS equipment. With respect to general requirements, a good VOR or ILS site will satisfy

the DME requirements as well. System performance must be verified by flight inspection. Figure 1-1

shows a typical DME site.

NOTE

After flight inspections and prior to use by pilots, it is mandatory that

the monitor be left in control of the facility and not in bypass.

1.2 Site Information

1.2.1 Site Selection

The signal radiated from the DME is affected by obstructions and terrain in the immediate vicinity of the

antenna and by obstructions and terrain within the service range of the station. An ideal site would be the

highest ground in the vicinity with level terrain, cleared of all objects for a radius of at least 3000 feet (915

meters), and with no obstructions extending above the horizontal plane of the antenna within the service

range of the station. In most localities, it is not possible to satisfy the ideal site requirements. Every effort

must be made to obtain the best site available. Although no absolute minimum requirements can be stated,

a site is normally acceptable if it meets the recommendations contained in the following paragraphs.

1.2.1.1 Terrain Features

The terrain should be level within a radius of 200 feet (61 meters). In a radius between 200 and 1000 feet

(61 and 305 meters), a downward slope is acceptable if (1) the rate of descent is not more than 4 feet in 100

feet (1.22 meters in 30.5 meters) and (2) contour lines are generally circular around the site. Beyond a

radius of 1000 feet (305 meters), terrain should be below the horizontal plane of the antenna.

1.2.1.2 Obstructions

There should be no structures within 750 feet (229 meters) of the antenna. Metallic structures should not

subtend vertical angles greater than 1.2 degrees as measured from the antenna. Wooden structures with

negligible metal content should not subtend vertical angles greater than 2.5 degrees as measured from the

antenna. Structures having considerable length (such as aircraft hangers or administration buildings)

should be situated lengthwise on a radial from the antenna. Single trees less than 35 feet (11 meters) high

may be tolerated beyond 750 feet. No group of trees or groves may be within 1000 feet. No overh ead

power or control lines are permissible within 750 feet of the antenna.

Figure 1-1 Typical DME Site

1.2.2 Shelter Requirements

The shelter location depends primarily on the maximum cable run allowed and on the desired location for

the DME antenna. An RF transmission line of 2" foamflex cable (with Type N connectors at each end),

one cable for the monitor antenna made up of 1/4" foamflex (with a Type N connector at one end and a

TNC male connector at the opposite end), and one AC cable for the OB Lite may be supplied with the

DME equipment. These cables are 35 feet long. When the requirements exceed 35 feet, company

engineering personnel can provide the necessary planning to determine the requirements.

The DME ground equipment is designed to operate continuously and unattended, but space must be

allocated for maintenance personnel and their equipment.

1.3 Unpacking and Repacking

The DME electronic subsystem is shipped unassembled. Only general precautions can be given because

the crating and unpacking depends upon destination and what optional equipment is included. Most items

are packed separately in individual containers; these are then grouped for crating. Each crate contains a

packing list which details what equipment is enclosed in the crate. Unpack the equipment and visually

inspect each item for accuracy and damage, but DO NOT REMOVE any ESD protective wrapping.

Report any damage immediately. After inspection, repack each item to prevent damage. During

installation, unpack items as they are needed.

1.3.1 Environmental Considerations

The environmental conditions must not exceed those listed in the Specifications of Table 1-1 Error!

Reference source not found..

1.4 Input Power Requirement Summary

The requirements for input power must not exceed those listed in the Specification of Table 1-1 Error!

Reference source not found..

1.5 Installation Procedures

1.5.1 Installation Tools and Test Equipment

Refer to Error! Reference source not found.for a list of test equipment and Table 1-1 for a list of special

tools required for installation.

Table 1-1 Special Tools Required for Installation

Description

Tube Cutter

File

Knife

2-1/4" Hole Saw

Assorted Screw Drivers and Wrenches

Thread Tape

1.5.2 Installation Kits

Refer to Table 1-2 for all component or modification kits required to install the DME station. Some kits

listed are optional equipment. Kits ending with “X” have many different varieties and will vary depending

on the site specific requirements. In all necessary cases installation drawings for each kit are provided with

the kit hardware.

Table 1-2 Component or Modification Kits Required to Install the DME

Part Number Description

470085-000X DME Tower Antenna Kit

470561-0001 DME Unidirectio nal GS Tower Mount Antenna Kit

470628-000X DME Battery Backup Kit, 35AHr

470622-0001 DME Accessory Kit

470627-0001 DME AC Power/Installation Kit

470291-000X DME OB Light Kit

470623-0001 Environmental Sensors Kit

470360-000X PMDT Kit

Table 1-3 Additional kits required to Install Shelter and Tower Grounding Systems

Part Number Description

470252-0002 Civil Install Kit, 45G Rohn Tower

470225-0001 Civil Install Kit, Shelter

470557-0001 Shelter Internal Grounding Kit

1.5.3 Shelter Foundation Installation

For shelters not supplied by SELEX Sistemi Integrati Inc., the manufacturer of the shelter will supply

drawings for the site engineer.

1.5.4 Shelter Installation

a. Use a crane and four nylon slings (20 feet long) to position the equipment shelter on the four concrete

piers.

b. Attach the shelter to the pier anchor bolts using appropriate hardware.

1.5.5 Tower Foundation and Tower Installation

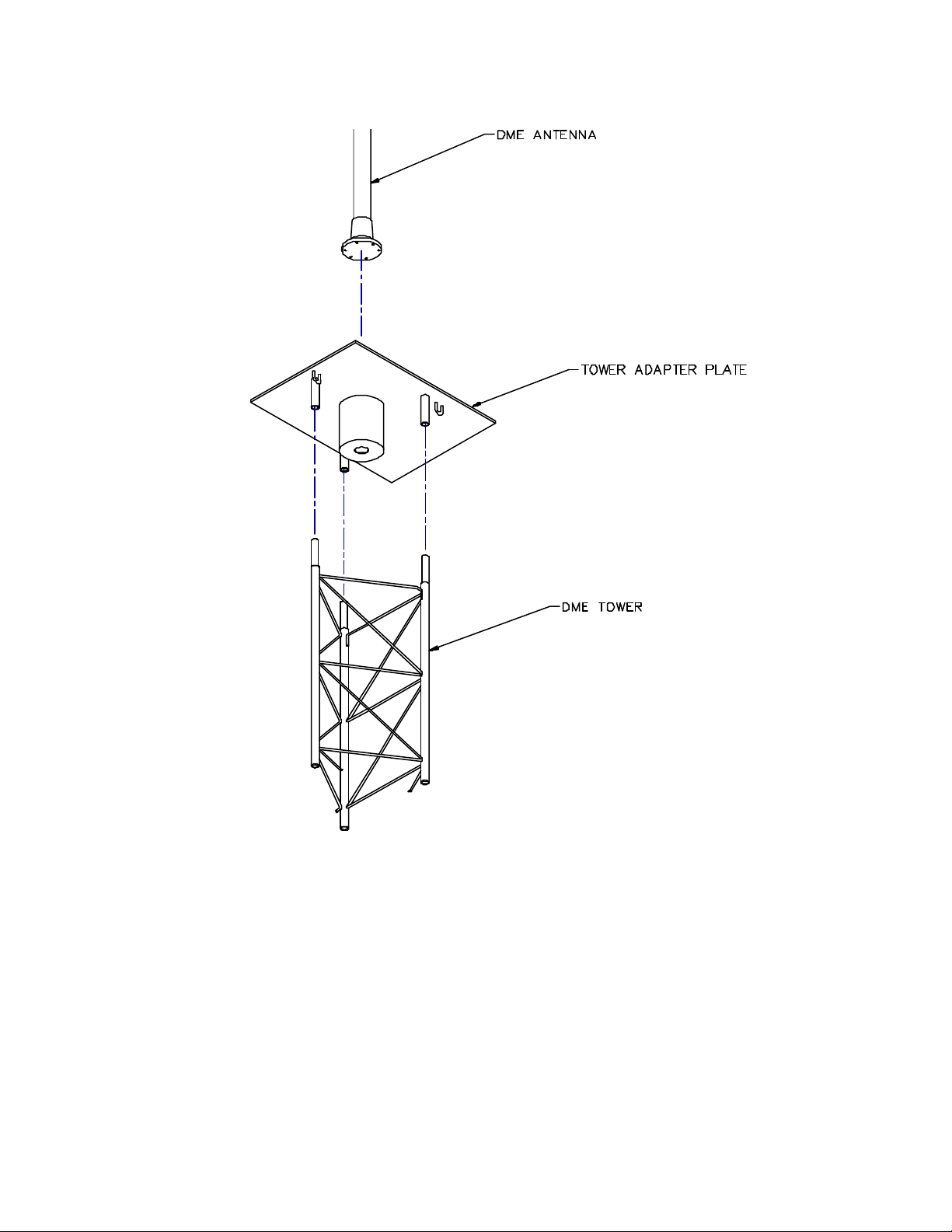

A triangular steel tower is available for use as a support for the DM E antenna. Figure 1-2 shows the

installation details for this tower. Figure 1-3 illustrates the triangular tower adapter plate required to mount

the antenna to the DME tower.

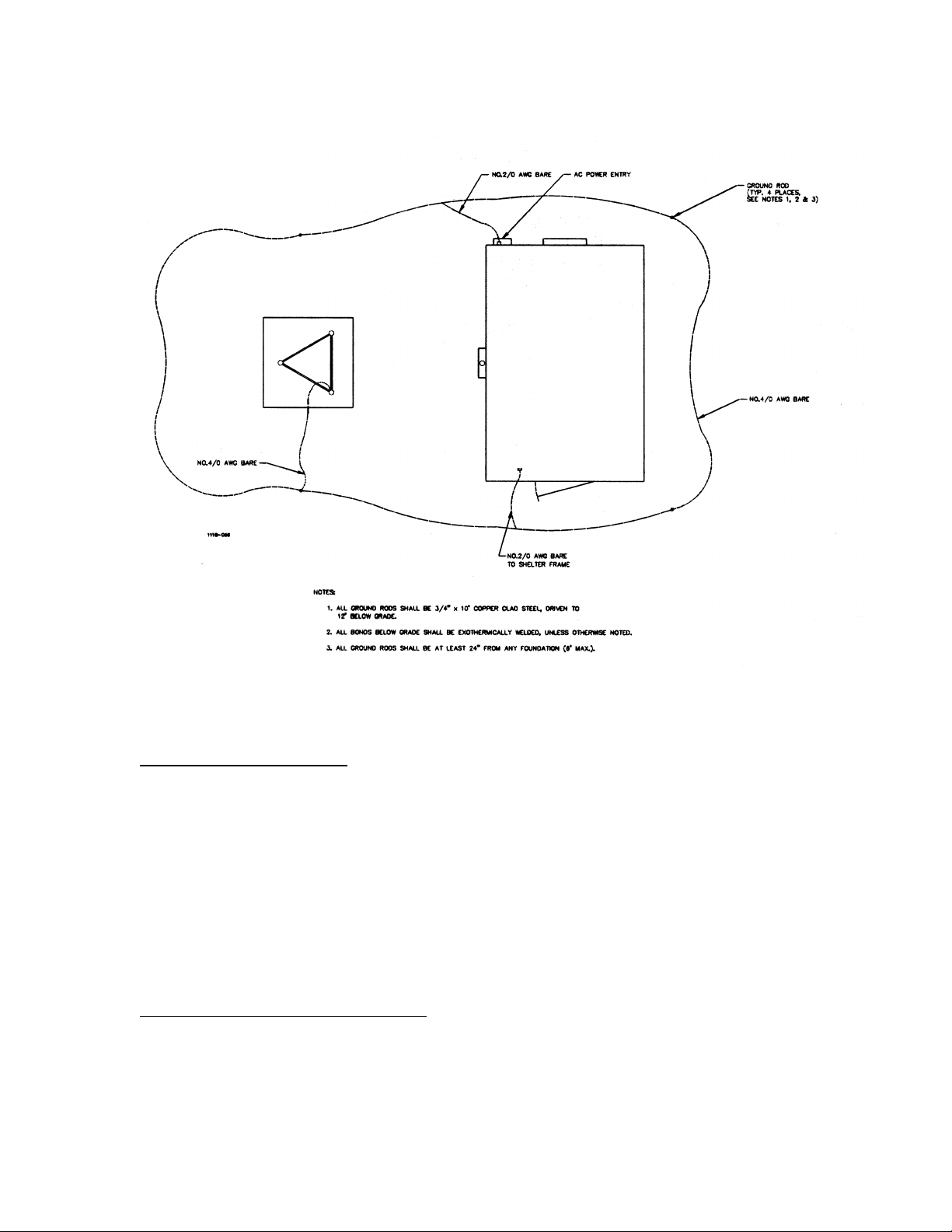

1.5.6 Shelter and Tower Installation Grounding

a. Install ground rods and ground wire as detailed in Figure 1-2 and Figure 1-4.

b. Install the 470557 Shelter Internal Grounding Kit per the drawing provided with the kit.

c. Verify the shelter grounding plate, AC wiring, lightning protection, RF tower, and telephone

equipment all share a common grounding potential. The impedance between any of these items should

be below 10O.

1.5.7 Air Conditioner Installation

If a wall mounted air conditioner is supplied, install the air conditioner in the wall opening and secure it in

place using bracket su pplied. Apply silicon seal around air conditioner and wall opening to maintain a

weather tight seal.

Figure 1-2 Typical DME Tower Installation Diagram

Figure 1-3 Triangular Tower Adapter Plate

Figure 1-4 Typical DME Shelter and Tower Grounding Diagram

1.5.8 DME Cabinet Installation

a. Unpack the DME 19” rack system and stand upright inside the equipment shelter.

b. The rack can be located on an outside wall or in the center of the room; however the ventilation

louvers located on the left side of the cabinet must not be obstructed.

c. To level the rack use the adjustable feet then lock the feet positions using the jam nuts.

d. If desired the front and rear doors can easily be removed by sliding up the three hinge pins on the left

inside edge of each door. If the doors are removed be sure to replace them after installation.

e. Use #6 grounding wire provided in the AC Power/Installation Kit (Figure Error! Reference source

not found.) to connect from the DME grounding bus bar to the shelter grounding plate using the

shortest path possible.

NOTE: Do not install any modules in the rack until it is properly grounded.

1.5.9 Battery Backup Assembly Installation

a. Insure DME system AC and DC circuit breakers are in the OFF position.

b. Construct battery backup unit as detailed in Figure Error! Reference source not found. or per the

drawing provided with supplied battery backup kit.

c. Install the four twelve-volt batteries and connect batteries in series.

d. Install battery backup wiring between the DME transmitter cabinet and the battery backup assembly.

The battery ground lead should connect to the grounding bus bar and the battery hot wire (+48V)

should connect to TX1 DC breaker located on the 1A26 Status Panel Assembly.

e. When supplied with two battery kits then connect the hot wire (+48V) from the second battery set to

the TX2 DC breaker; otherwise install the jumper wire between TX2 DC breaker and TX1 DC breaker

as provided in the battery kit.

f. Install safety cover(s) over batteries or lid(s) on battery backup box.

CAUTION: Shorting the battery leads can cause a fire or explosion.

1.5.10 Primary AC Power Installation

AC wiring for the DME will require a separate circuit breaker for the DME system and DME obstruction

lights. The convenience outlet located on the front of the 1A26 Status Panel is powered from the

obstruction light breaker.

a. Insure DME system AC and DC circuit breakers are in the OFF position

b. Insure that shelter DME system circuit breaker is in the OFF position.

c. Connect primary AC power to DME as detailed in Figure Error! Reference source not found..

1.5.11 Shelter to Tower Conduit Connections

a. Using a 2-1/4" hole saw, cut a hole in the wall between the DME transmitters and the antenna tower at

a height above the top of the DME transmitter cabinet.

b. Refer to Figure Error! Reference source not found.. Slide 2" x 5" threaded conduit into hole. Install

reducing washer and 2" locknut on each end of threaded conduit. Tighten locknut.

c. Install protective bushing on exposed threaded conduit threads of interior shelter wall. Install 2" PVC

female adapter on threaded conduit of outer shelter wall.

d. Refer to Figure 1-7. Cut 2" PVC appropriate length to center of tower directly under antenna.

e. Install 2" PVC hole adapter in bottom of triangular tower adapter plate. Install reducing washer and 2"

locknut onto hole adapter. Install protective bushing over exposed threads.

f. Cut 2" PVC appropriate length to extend from triangular tower adapter plate to 2" PVC from shelter.

Insure that 2" PVC from triangular tower adapter plate is cut so that PVC from shelter slopes slightly

downward as it runs to tower.

g. Install 2", 90 degree PVC connector and 2" conduit adapters between the two pieces of 2" PVC and

insure that all pieces fit. Drill a 1/8" hole in the bottom of 2" 90 degree PVC connector. This will

allow any water seepage to drain. Pre-fit all pieces to insure proper mating.

1.5.12 Obstruction Light Installation and Wiring

The obstruction light assembly is shipped separately from the DME antenna and it is necessary to attach the

obstruction light to the top of the DME antenna; and the wiring that extends from the antenna must be

connected to the bul b sockets. Figure 1-8 shows the assembly details.

NOTE

The mounting hole on the top of the DME antenna is threaded for a

3/4" pipe thread. There are two versions of obstruction light assemblies

available: one is threaded for a 3/4" pipe thread; the other is threaded

for a 1" pipe thread. For the 3/4" pipe version, a 1" to 3/4" reducer and

a 3/4" by 1-1/2" nipple stainless steel combination should be used.

a. Remove lens and bulbs.

b. Remove the hole cap at the top of the DME antenna and fish out the AC wires using stiff wire bent into

a hook.

c. Route the three wire AC cable from the DME antenna through the required pipe adapters and into the

bulb sockets.

d. Thread the obstruction light assembly into the antenna. Use thread tape on all pipe threads to insure a

water tight fit.

e. Connect the three AC wires from the antenna to the bulb sockets, as shown in Figure 1-5 or Figure 1-6.

f. Install the lighting rod to the obstruction light nipple as detailed in Figure Error! Reference source

not found..

g. Verify the obstruction light bulbs match the site AC voltage rating then install the bulbs and lens.

h. After installing antenna to tower, connect remaining obstruction light power wires to DME cabinet and

shelter circuit breaker box as shown in Figure 1-5 or Figure 1-6. Note that the 070219-0001 cable is

located in the Antenna Kit (Figure Error! Reference source not found.).

Figure 1-5 DME Obstruction Light Interconnect Diagram with Photo Sensor

Figure 1-6 DME Obstruction Light Interconnect Diagram without Photo Sensor

1.5.13 DME Antenna Installation

a. Use a crane and nylon slings to lift the DME antenna to the top of tower.

b. Install DME antenna on triangular tower adapter plate as shown in Figure Error! Reference source

not found.. Orientation of the obstruction bulbs and lightning rod is not important.

c. Secure antenna with appropriate hardware provided in the DME antenna kit.

Figure 1-7 Typical Shelter to Tower Conduit Installation

Figure 1-8 Obstruction Light Installation Diagram

1.5.14 DME Transmitter to Antenna Interconnect

a. Refer to Figure 1-7. Route ½” Heliax RF feedcable through conduit and connect to antenna connector

J1 (RF INPUT).

b. Route ¼” Heliax antenna monitor cable through conduit and connect to antenna connector J2 (RF

MONITOR OUTPUT). Note that in most installations the J3 RF MONITO R OUTPUT port can be

used instead of J2 however J2 is preferred.

c. Route obstruction light power cable through conduit and to antenna connector J4 (OBSTN LT

INPUT).

d. Connect ½” Heliax RF feedcable to DME transmitter connector 1J1 (RF OUT) .

e. Connect ¼” Heliax antenna monitor cable to DME transmitter connector 1J2 (ANT MON1).

f. Place obstruction light circuit breaker to the ON position. Verify obstruction lights illuminate.

g. Using PVC cement, glue 2" PVC conduit connections previously installed.

1.5.15 Connecting VOR or ILS Keyer Wiring

a. Verify that the primary AC power (located in the shelter main circuit breaker box) , VOR equipment

and DME equipment circuit breakers are in the OFF position.

b. Using the two-conductor electrical cable and forked terminal lugs provided in the AC

Power/Installation kit (Figure Error! Reference source not found.), connect KEY_OUT+ and

KEY_OUT- signals from the 1A19 Interface CCA located in rear of the DME cabinet to the

appropriate location as identified in Table 1-4.

Note after equipment startup refer to section Error! Reference source not found. Error! Reference

source not found. to configure external keying.

Table 1-4 External Keying Connection Locations

KEY_OUT+ (1A19TB2-14)

SELEX Navaid

1150 VOR TB10-5 TB10-6

2100 Localizer 1A18TB4-1 1A18TB4-2

2110 Glideslope 1A18TB4-1 1A18TB4-2

1.5.16 RC SU and RMM Connections

a. If the DME is provided with a 2238 RCSU then connect the copper wires from the RCSU to the

1A19TB2-1 and 1A19TB2-2 locations on the Interface CCA for a Dedicated Modem connection type.

For a RF Modem/Fiber connection type, the RS23 2 connection should be made to the 1A19J5 DB9

connector. DIP switch S2 -1 located on the 1A8A1 Low Power Backplane CCA should be set to match

the Connection Type as well.

b. If a telephone line is available for remote maintenance monitoring (RMM), connect the tip and ring

wires from the telephone interface box to the 1A19 Interface CCA locations TB2-3 and TB2-4.

Polarity is not important. DIP switch S2-2 located on the 1A8A1 Low Power Backplane CCA should

be set to “DIAL-UP” when using this internal dial-up modem. Use the two -conductor electrical cable

provided in the AC Power/Installation kit (Figure Error! Reference source not found.) for this

connection.

c. If the DME’s internal dial-up modem is unable to comply with local telephone requirements then

connect the telephone line to an external modem and connect the external modem serial port to the

1A19 Interface CCA J6 connector. DIP switch S2 -2 located on the 1A8A1 Low Power Backplane

CCA should be set to “~EXTERNAL” when using an external dial-up modem. Reset the DME station

after changing the S2-2 switch.

d. DIP switch S1-6 located on the 1A8A1 Low Power Backplane CCA controls whether the DME station

will allow remote configuration of transmitter and monitor parameters. When set to “RMT

Destination

KEY_OUT- (1A19TB2-15)

Destination

ALLOWED” a remote user logged into Security Level 3 can put the DME station in Local Mode from

the PMDT and change all parameters as if connected directly to the cabinet in the shelter. When set to

“~NOT ALLOWED” the system can not be put in Local Mode from the PM DT and remote parameter

changes are blocked throughout the software.

1.6 Inspection

Prior to energizing the equipment, a visual inspection is made to eliminate circumstances that could cause

power-up failures.

a. Visually inspect wire, RF coaxial cables and connectors for corrosion, loose connectors and

improperly assembled connectors.

b. Insure all terminal boards are free of foreign objects such as pieces of wire or other objects that could

cause electrical shorts within the equipment. Remove foreign objects as necessary.

c. Inspect the battery backup units to ensure that all terminals and connectors are tight and that there are

no metal shavings or other objects that could cause damage to the equipment.

1.7 Initial Start-up and Preliminary Testing

The following para graphs detail the step-by-step procedures for initial start -up and preliminary testing of

the DME.

1.7.1 Input Voltage Checks

After the AC and DC power has been connected to the DME transmitter. It is necessary to check the input

power to insure the proper voltage is applied to the system.

a. Assure that the DME AC and DC circuit breakers to the OFF position.

b. Set the shelter primary AC power circuit breakers to the ON position.

c. Using an AC voltmeter check voltage across the AC Monitor 1A22TB3-1 (LINE) to 1A22TB3-2

(NEUTRAL) terminals. Insure the voltage meets the range specified in section Table 1-1 Error!

Reference source not found..

d. Turn on the DME DC circuit breaker while leaving the AC circuit breakers OFF.

e. Using a DC voltmeter check voltage across 1A20 BCPS1 E7 (BATT_POS) to E9 (GND). Insure the

voltage is 42 to 50Vdc.

f. For dual equipment check voltage across 1A21 BCPS2 E7 (BATT_POS) to E9 (GND). Insure the

voltage is 42 to 50Vdc.

g. Turn DC circuit breakers to the OFF position.

1.7.2 Installing Modules in Transmitter Cabinet

Since the DME transmitter cabinet is shipped separately from its electronic modules, it will be necessary to

install them into the transmitter equipment cabinet. Insure AC and DC circuit breakers are set to the OFF

position.

CAUTION

Many of the modules used in the DME transmitter contain

Electrostatic Discharge (ESD) sensitive components. ALWAYS

wear protective wrist strap when installing modules or CCAs.

Before modules are installed into transmitter cabinet, check

modules or CCAs for cracked or broken connectors, bent pins, and

loose hardware. Report any damage immediately.

1.7.3 Turn on Procedure

a. Verify all assemblies are properly installed and are fully seated.

b. Turn AC and DC circuit breakers to the ON position.

c. Verify the PWR_OK LEDs are lit on all card cage modules.

d. Verify the CPU_OK LEDs are lit on the RTC, Monitor, and RMS assemblies.

1.7.4 PMDT Hookup and Setup

a. Unpack the PMDT laptop computer and follow the manufacturer’s installation instructions to power-

up the computer, create a user account, and logon to Windows™ as an administrator.

b. Insert the 978178-XXXX PMDT CD-ROM into the laptop computer.

c. Select Start >> Run then type D:\Setup.exe to start the PMDT installation. Note if installation

does not start then use the correct drive letter associated with the CD-ROM drive.

d. Follow the default prompts for PMDT installation.

e. In order for the PMDT controls to be properly displayed change the DPI Setting to “Normal (96 DPI)”

in Windows on the Display Properties >> Settings >> Advanced >> General tab. Note that Display

Properties can be accessed by right-clicking on the Windows background then selecting Properties.

f. At the DME assure the AC and DC breakers are in the ON position.

g. Plug the USB cord between the laptop computer and 1A13J1 (PMDT USB) located on the RMS CCA.

h. Windows should detect the USB device and start installing a driver. If prompted for the USB driver

files they are installed in the PMDT directory at C:\Program Files\SELEX-SI\PMDT\FTDI USB

Driver.

i. Start the PMDT application by double-clicking on the desktop icon named PMDT.

j. Select System >> PMDT Setup.

k. In the Navaid Direct COM Port control pick the COM port that contains “USB Serial Port” in the

description.

l. On the PMDT configuration screen, setup other options such as Language and Print Screen mode then

select OK to save the changes.

m. Refer to section Error! Reference source not found. Error! Reference source not found. to connect

to the DME equipment at Security Level 3.

1.7.5 Site Adjustments and Configurations

a. Press the LOCAL CONTROL button on the 1A1 LCU to put the DME into Local Mode.

b. At the LCU bypass the Integral monitor and put Transmitter 1 on antenna.

c. If the VSWR reading on the Monitors >> Data >> Integral screen is in alarm then shut down the DME

and troubleshoot the RF feedcable to antenna connection before continuing. VSWR alerts detected by

each power amplifier can also be found on the Transmitters >> Data >> Transmitter Data screen that

indicate a faulty RF load.

d. On the Monitors >> Data >> Integral screen note the ERP (Effective Radiated Power) value for each

monitor.

e. On the Monitors >> Configuration >> Integral screen change the Monitor 1 Replay Attenuation setting

until the Monitor 1 EPR is 0 ± 1dB.

f. For dual monitor equipment change the Monitor 2 Replay Attenuation setting until the Monitor 2 EPR

is 0 ± 1dB.

g. On the RMS >> Configuration >> Station screen verify the channel number and type (X or Y) match

the site requirements and frequency paring requirements as identified in Table 1-5. If corrections are

needed then refer to section Error! Reference source not found. Error! Reference source not

found..

h. While on the RMS >> Configuration >> Station screen type a Station Identifier message that will be

used to uniquely identify the station when performing local or remote maintenance. It is suggested that

the site name and runway identifier be included.

i. If the DME is provided with a 2238 RCSU then on the RMS >> Configuration >> General screen

check the RCSU Present box and configure the Connection Type and Interlock Control to match the

installation requirements.

j. Set the Primary Ident Code to the assigned station identifier as detailed in section Error! Reference

source not found. Error! Reference source not found.. Also select the keying source and other

keying options while on that screen.

k. Select RMS >> Config Backup to save changes to the DME configuration.

l. If using a wattmeter with removable elements for site maintenance then perform the procedure in

section Error! Reference source not found. Error! Reference source not found..

Table 1-5 DME Channel Frequency Allocation

ILS/VOR Frequency Monitor Interrogator Transmitter Reply Receiver LO

DME

Channel

1X - - - 1025 12 962 12 900

1Y - - - 1025 36 1088 30 900

2X - - - 1026 12 963 12 901

2Y - - - 1026 36 1089 30 901

3X - - - 1027 12 964 12 902

3Y - - - 1027 36 1090 30 902

4X - - - 1028 12 965 12 903

4Y - - - 1028 36 1091 30 903

5X - - - 1029 12 966 12 904

5Y - - - 1029 36 1092 30 904

6X - - - 1030 12 967 12 905

6Y - - - 1030 36 1093 30 905

7X - - - 1031 12 968 12 906

7Y - - - 1031 36 1094 30 906

8X - - - 1032 12 969 12 907

8Y - - - 1032 36 1095 30 907

9X - - - 1033 12 970 12 908

9Y - - - 1033 36 1096 30 908

10X - - - 1034 12 971 12 909

10Y - - - 1034 36 1097 30 909

11X - - - 1035 12 972 12 910

11Y - - - 1035 36 1098 30 910

12X - - - 1036 12 973 12 911

12Y - - - 1036 36 1099 30 911

13X - - - 1037 12 974 12 912

13Y - - - 1037 36 1100 30 912

14X - - - 1038 12 975 12 913

14Y - - - 1038 36 1101 30 913

15X - - - 1039 12 976 12 914

15Y - - - 1039 36 1102 30 914

16X - - - 1040 12 977 12 915

16Y - - - 1040 36 1103 30 915

17X - - 108.0 1041 12 978 12 916

17Y - - 108.05 1041 36 1104 30 916

LOC

(MHz)

GS

(MHz)

VOR

(MHz)

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Table 1-5 DME Channel Frequency Allocation

ILS/VOR Frequency Monitor Interrogator Transmitter Reply Receiver LO

DME

Channel

18X 108.1 334.7 - 1042 12 979 12 917

18Y 108.15 334.55 - 1042 36 1105 30 917

19X - - 108.2 1043 12 980 12 918

19Y - - 108.25 1043 36 1106 30 918

20X 108.3 334.1 - 1044 12 981 12 919

20Y 108.35 333.95 - 1044 36 1107 30 919

21X - - 108.4 1045 12 982 12 920

21Y - - 108.45 1045 36 1108 30 920

22X 108.5 329.9 - 1046 12 983 12 921

22Y 108.55 329.75 - 1046 36 1109 30 921

23X - - 108.6 1047 12 984 12 922

23Y - - 108.65 1047 36 1110 30 922

24X 108.7 330.5 - 1048 12 985 12 923

24Y 108.75 330.35 - 1048 36 1111 30 923

25X - - 108.8 1049 12 986 12 924

25Y - - 108.85 1049 36 1112 30 924

26X 108.9 329.3 - 1050 12 987 12 925

26Y 108.95 329.15 - 1050 36 1113 30 925

27X - - 109.0 1051 12 988 12 926

27Y - - 109.05 1051 36 1114 30 926

28X 109.1 331.4 - 1052 12 989 12 927

28Y 109.15 331.25 - 1052 36 1115 30 927

29X - - 109.2 1053 12 990 12 928

29Y - - 109.25 1053 36 1116 30 928

30X 109.3 332 - 1054 12 991 12 929

30Y 109.35 331.85 - 1054 36 1117 30 929

31X - - 109.4 1055 12 992 12 930

31Y - - 109.45 1055 36 1118 30 930

32X 109.5 332.6 - 1056 12 993 12 931

32Y 109.55 332.45 - 1056 36 1119 30 931

33X - - 109.6 1057 12 994 12 932

33Y - - 109.65 1057 36 1120 30 932

34X 109.7 333.2 - 1058 12 995 12 933

34Y 109.75 333.05 - 1058 36 1121 30 933

35X - - 109.8 1059 12 996 12 934

35Y - - 109.85 1059 36 1122 30 934

LOC

(MHz)

GS

(MHz)

VOR

(MHz)

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Table 1-5 DME Channel Frequency Allocation

ILS/VOR Frequency Monitor Interrogator Transmitter Reply Receiver LO

DME

Channel

36X 109.9 333.8 - 1060 12 997 12 935

36Y 109.95 333.65 - 1060 36 1123 30 935

37X - - 110.0 1061 12 998 12 936

37Y - - 110.05 1061 36 1124 30 936

38X 110.1 334.4 - 1062 12 999 12 937

38Y 110.15 334.25 -

39X - - 110.2 1063 12 1000 12 938

39Y - - 110.25 1063 36 1126 30 938

40X 110.3 335 - 1064 12 1001 12 939

40Y 110.35 334.85 - 1064 36 1127 30 939

41X - - 110.4 1065 12 1002 12 940

41Y - - 110.45 1065 36 1128 30 940

42X 110.5 329.6 - 1066 12 1003 12 941

42Y 110.55 329.45 - 1066 36 1129 30 941

43X - - 110.6 1067 12 1004 12 942

43Y - - 110.65 1067 36 1130 30 942

44X 110.7 330.2 - 1068 12 1005 12 943

44Y 110.75 330.05 - 1068 36 1131 30 943

45X - - 110.8 1069 12 1006 12 944

45Y - - 110.85 1069 36 1132 30 944

46X 110.9 330.8 - 1070 12 1007 12 945

46Y 110.95 330.65 - 1070 36 1133 30 945

47X - - 111.0 1071 12 1008 12 946

47Y - - 111.05 1071 36 1134 30 946

48X 111.1 331.7 - 1072 12 1009 12 947

48Y 111.15 331.55 - 1072 36 1135 30 947

49X - - 111.2 1073 12 1010 12 948

49Y - - 111.25 1073 36 1136 30 948

50X 111.3 332.3 - 1074 12 1011 12 949

50Y 111.35 332.15 - 1074 36 1137 30 949

51X - - 111.4 1075 12 1012 12 950

51Y - - 111.45 1075 36 1136 30 950

52X 111.5 332.9 - 1076 12 1013 12 951

52Y 111.55 332.75 - 1076 36 1139 30 951

53X - - 111.6 1077 12 1014 12 952

53Y - - 111.65 1077 36 1140 30 952

LOC

(MHz)

GS

(MHz)

VOR

(MHz)

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Table 1-5 DME Channel Frequency Allocation

ILS/VOR Frequency Monitor Interrogator Transmitter Reply Receiver LO

DME

Channel

54X 111.7 333.5 - 1078 12 1015 12 953

54Y 111.75 333.35 - 1078 36 1141 30 953

55X - - 111.8 1079 12 1016 12 954

55Y - - 111.85 1079 36 1142 30 954

56X 111.9 331.1 - 1080 12 1017 12 955

56Y 111.95 330.95 - 1080 36 1143 30 955

57X - - 112.0 1081 12 1018 12 956

57Y - - 112.05 1081 36 1144 30 956

58X - - 112.1 1082 12 1019 12 957

58Y - - 112.15 1082 36 1145 30 957

59X - - 112.2 1083 12 1020 12 958

59Y - - 112.25 1083 36 1146 30 958

60X - - - 1084 12 1021 12 959

60Y - - - 1084 36 1147 30 959

61X - - - 1085 12 1022 12 960

61Y - - - 1085 36 1148 30 960

62X - - - 1086 12 1023 12 961

62Y - - - 1086 36 1149 30 961

63X - - - 1087 12 1024 12 962

63Y - - - 1087 36 1150 30 962

64X - - - 1088 12 1151 12 963

64Y - - - 1088 36 1025 30 963

65X - - - 1089 12 1152 12 964

65Y - - - 1089 36 1026 30 964

66X - - - 1090 12 1153 12 965

66Y - - - 1090 36 1027 30 965

67X - - - 1091 12 1154 12 966

67Y - - - 1091 36 1028 30 966

68X - - - 1092 12 1155 12 967

68Y - - - 1092 36 1029 30 967

69X - - - 1093 12 1156 12 968

69Y - - - 1093 36 1030 30 968

70X - - 112.3 1094 12 1157 12 969

70Y - - 112.35 1094 36 1031 30 969

71X - - 112.4 1095 12 1158 12 970

71Y - - 112.45 1095 36 1032 30 970

LOC

(MHz)

GS

(MHz)

VOR

(MHz)

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Table 1-5 DME Channel Frequency Allocation

ILS/VOR Frequency Monitor Interrogator Transmitter Reply Receiver LO

DME

Channel

72X - - 112.5 1096 12 1159 12 971

72Y - - 112.55 1096 36 1033 30 971

73X - - 112.6 1097 12 1160 12 972

73Y - - 112.65 1097 36 1034 30 972

74X - - 112.7 1098 12 1161 12 973

74Y - - 112.75 1098 36 1035 30 973

75X - - 112.8 1099 12 1162 12 974

75Y - - 112.85 1099 36 1036 30 974

76X - - 112.9 1100 12 1163 12 975

76Y - - 112.95 1100 36 1037 30 975

77X - - 113.0 1101 12 1164 12 976

77Y - - 113.05 1101 36 1038 30 976

78X - - 113.1 1102 12 1165 12 977

78Y - - 113.15 1102 36 1039 30 977

79X - - 113.2 1103 12 1166 12 978

79Y - - 113.25 1103 36 1040 30 978

80X - - 113.3 1104 12 1167 12 979

80Y - - 113.35 1104 36 1041 30 979

81X - - 113.4 1105 12 1168 12 980

81Y - - 113.45 1105 36 1042 30 980

82X - - 113.5 1106 12 1169 12 981

82Y - - 113.55 1106 36 1043 30 981

83X - - 113.6 1107 12 1170 12 982

83Y - - 113.65 1107 36 1044 30 982

84X - - 113.7 1108 12 1171 12 983

84Y - - 113.75 1108 36 1045 30 983

85X - - 113.8 1109 12 1172 12 984

85Y - - 113.85 1109 36 1046 30 984

86X - - 113.9 1110 12 1173 12 985

86Y - - 113.95 1110 36 1047 30 985

87X - - 114.0 1111 12 1174 12 986

87Y - - 114.05 1111 36 1048 30 986

88X - - 114.1 1112 12 1175 12 987

88Y - - 114.15 1112 36 1049 30 987

89X - - 114.2 1113 12 1176 12 988

89Y - - 114.25 1113 36 1050 30 988

LOC

(MHz)

GS

(MHz)

VOR

(MHz)

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Table 1-5 DME Channel Frequency Allocation

ILS/VOR Frequency Monitor Interrogator Transmitter Reply Receiver LO

DME

Channel

90X - - 114.3 1114 12 1177 12 989

90Y - - 114.35 1114 36 1051 30 989

91X - - 114.4 1115 12 1178 12 990

91Y - - 114.45 1115 36 1052 30 990

92X - - 114.5 1116 12 1179 12 991

92Y - - 114.55 1116 36 1053 30 991

93X - - 114.6 1117 12 1180 12 992

93Y - - 114.65 1117 36 1054 30 992

94X - - 114.7 1118 12 1181 12 993

94Y - - 114.75 1118 36 1055 30 993

95X - - 114.8 1119 12 1182 12 994

95Y - - 114.85 1119 36 1056 30 994

96X - - 114.9 1120 12 1183 12 995

96Y - - 114.95 1120 36 1057 30 995

97X - - 115.0 1121 12 1184 12 996

97Y - - 115.05 1121 36 1058 30 996

98X - - 115.1 1122 12 1185 12 997

98Y - - 115.15 1122 36 1059 30 997

99X - - 115.2 1123 12 1186 12 998

99Y - - 115.25 1123 36 1060 30 998

100X - - 115.3 1124 12 1187 12 999

100Y - - 115.35 1124 36 1061 30 999

101X - - 115.4 1125 12 1188 12 1000

101Y - - 115.45 1125 36 1062 30 1000

102X - - 115.5 1126 12 1189 12 1001

102Y - - 115.55 1126 36 1063 30 1001

103X - - 115.6 1127 12 1190 12 1002

103Y - - 115.65 1127 36 1064 30 1002

104X - - 115.7 1128 12 1191 12 1003

104Y - - 115.75 1128 36 1065 30 1003

105X - - 115.8 1129 12 1192 12 1004

105Y - - 115.85 1129 36 1066 30 1004

106X - - 115.9 1130 12 1193 12 1005

106Y - - 115.95 1130 36 1067 30 1005

107X - - 116.0 1131 12 1194 12 1006

107Y - - 116.05 1131 36 1068 30 1006

LOC

(MHz)

GS

(MHz)

VOR

(MHz)

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Table 1-5 DME Channel Frequency Allocation

ILS/VOR Frequency Monitor Interrogator Transmitter Reply Receiver LO

DME

Channel

108X - - 116.1 1132 12 1195 12 1007

108Y - - 116.15 1132 36 1069 30 1007

109X - - 116.2 1133 12 1196 12 1008

109Y - - 116.25 1133 36 1070 30 1008

110X - - 116.3 1134 12 1197 12 1009

110Y - - 116.35 1134 36 1071 30 1009

111X - - 116.4 1135 12 1198 12 1010

111Y - - 116.45 1135 36 1072 30 1010

112X - - 116.5 1136 12 1199 12 1011

112Y - - 116.55 1136 36 1073 30 1011

113X - - 116.6 1137 12 1200 12 1012

113Y - - 116.65 1137 36 1074 30 1012

114X - - 116.7 1138 12 1201 12 1013

114Y - - 116.75 1138 36 1075 30 1013

115X - - 116.8 1139 12 1202 12 1014

115Y - - 116.85 1139 36 1076 30 1014

116X - - 116.9 1140 12 1203 12 1015

116Y - - 116.95 1140 36 1077 30 1015

117X - - 117.0 1141 12 1204 12 1016

117Y - - 117.05 1141 36 1078 30 1016

118X - - 117.1 1142 12 1205 12 1017

118Y - - 117.15 1142 36 1079 30 1017

119X - - 117.2 1143 12 1206 12 1018

119Y - - 117.25 1143 36 1080 30 1018

120X - - 117.3 1144 12 1207 12 1019

120Y - - 117.35 1144 36 1081 30 1019

121X - - 117.4 1145 12 1208 12 1020

121Y - - 117.45 1145 36 1082 30 1020

122X - - 117.5 1146 12 1209 12 1021

122Y - - 117.55 1146 36 1083 30 1021

123X - - 117.6 1147 12 1210 12 1022

123Y - - 117.65 1147 36 1084 30 1022

124X - - 117.7 1148 12 1211 12 1023

124Y - - 117.75 1148 36 1085 30 1023

125X - - 117.8 1149 12 1212 12 1024

125Y - - 117.85 1149 36 1086 30 1024

LOC

(MHz)

GS

(MHz)

VOR

(MHz)

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Table 1-5 DME Channel Frequency Allocation

ILS/VOR Frequency Monitor Interrogator Transmitter Reply Receiver LO

DME

Channel

126X - - 117.9 1150 12 1213 12 1025

126Y - - 117.95 1150 36 1087 30 1025

1.7.6 System Checkout

a. Bypass the Integral monitor and select Tx1 Main.

b. For dual equipment bypass the Standby monitor and select Tx2 Load.

c. If the DME station has an alarm condition, then refer to section Error! Reference source not found.

to perform fault isolation and corrective maintenance.

d. Perform section Error! Reference source not found. Error! Reference source not found.

procedure.

e. Perform section Error! Reference source not found. Error! Reference source not found.

procedure.

f. Perform section Error! Re ference source not found. Error! Reference source not found.

procedure.

g. Perform the SELEX-SI Site Acceptance Test (SAT) Procedure for the 2160/2170 DME system. Note

if this procedure is not available then perform all remaining performance checks in section Error!

Reference source not found. of this manual.

h. Save the final DME configuration to disk using the System >> Configuration Save command from the

PMDT. It is recommended that a backup copy of the station configuration also be maintained off site.

1.7.7Performance Tuning During Flight Inspection

a. If the DME is not able to achieve usable distance then refer to section Error! Reference source not

found. Error! Reference source not found. to adjust the receiver threshold.

b. If flight inspection reports an unlock condition or a range error while on a radial approach then refer to

section Error! Reference source not found. Error! Reference source not found. to configure echo

suppression.

c. If changes to the station are made during flight inspection then create a new station configuration file

using the System >> Configuration Save command from the PMDT.

LOC

(MHz)

GS

(MHz)

VOR

(MHz)

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Pulse Code

µs

Freq

(MHz)

Loading...

Loading...