Page 1

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 1

M2500 Engine Controller

Installation Manual

Page 2

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 2

Contents

1 Preface ......................................................................................................................................... 4

2 Installation ................................................................................................................................... 5

3 Terminal Connections .................................................................................................................. 6

4 Inputs ........................................................................................................................................... 7

4.1 Power Supply ........................................................................................................................... 7

4.2 Mode/ Control Inputs ............................................................................................................... 7

4.2.1 Connection of Mode Selector Switch .................................................................................. 8

4.2.2 Remote Start (terminal 8) ..................................................................................................... 9

4.2.3 Remote Stop (terminal 9) ..................................................................................................... 9

4.2.4 Override (terminal 10) ....................................................................................................... 10

4.2.5 Crank Disconnect (terminal 11) ......................................................................................... 10

4.2.6 Reset (terminal 12) ............................................................................................................. 10

4.2.7 COM (terminal 13) ............................................................................................................ 11

4.3 Speed detection ...................................................................................................................... 11

4.3.1 Connection of magnetic pick-up ........................................................................................ 11

4.3.2 Connection of PNP pick-up ............................................................................................... 12

4.3.3 Connection of NPN pick-up ............................................................................................... 12

4.4 Digital sensor inputs .............................................................................................................. 13

4.4.1 Connection of a normally open sensor without cable monitoring ..................................... 13

4.4.2 Connection of a normally closed sensor without cable monitoring ................................... 14

4.4.3 Connection of a normally open sensor with cable monitoring .......................................... 14

4.4.4 Connection of a normally closed sensor with cable monitoring ........................................ 15

4.4.5 COM (terminal 13) ............................................................................................................ 15

4.5 Analogue sensor inputs .......................................................................................................... 15

4.5.1 Analogue inputs (terminals 27 to 34) ................................................................................. 16

4.5.2 COM (terminal 13) ............................................................................................................ 16

5 Outputs ....................................................................................................................................... 17

5.1 Engine Status Outputs ............................................................................................................ 17

5.1.1 Connection of Engine Status Outputs ................................................................................ 17

5.1.2 Ready (terminal 36) ........................................................................................................... 18

5.1.3 Start warning (terminal 37) ................................................................................................ 18

5.1.4 Engine running (terminal 38) ............................................................................................. 18

5.1.5 Cool Down (terminal 39) ................................................................................................... 18

5.1.6 REF 1 (terminal 40) ........................................................................................................... 18

5.2 Engine Control Outputs ......................................................................................................... 19

5.2.1 Connection of Engine Control Outputs .............................................................................. 19

5.2.2 Auxiliary Lubrication Pump (terminal 41) ........................................................................ 19

5.2.3 Crank (terminal 42) ............................................................................................................ 20

5.2.4 C/B trip (terminal 43) ......................................................................................................... 20

5.2.5 Air Intake Valve (terminal 44) ........................................................................................... 20

5.2.6 REF 2 (terminal 45) ........................................................................................................... 20

Page 3

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 3

5.3 Alarm Outputs ........................................................................................................................ 20

5.3.1 Connection of alarm outputs .............................................................................................. 21

5.3.2 Common Alarm (terminal 46) ........................................................................................... 21

5.3.3 Shutdown (terminal 47) ..................................................................................................... 21

5.3.4 Cable break (terminal 48) .................................................................................................. 21

5.3.5 CAN (terminal 49) ............................................................................................................. 21

5.3.6 REF3 (terminal 50) ............................................................................................................ 21

5.4 Digital Outputs ....................................................................................................................... 22

5.4.1 Connection of digital outputs ............................................................................................. 22

5.4.2 Digital Outputs Out 1 to Out 12 (terminals 51 to 62) ........................................................ 23

5.4.3 REF 4 (terminal 50) ........................................................................................................... 23

5.5 Control Relays ....................................................................................................................... 23

5.5.1 Engine Stop Output (terminal 64 and 65) .......................................................................... 23

5.5.2 Run/ Stop Solenoid (terminal 66 and 67) .......................................................................... 24

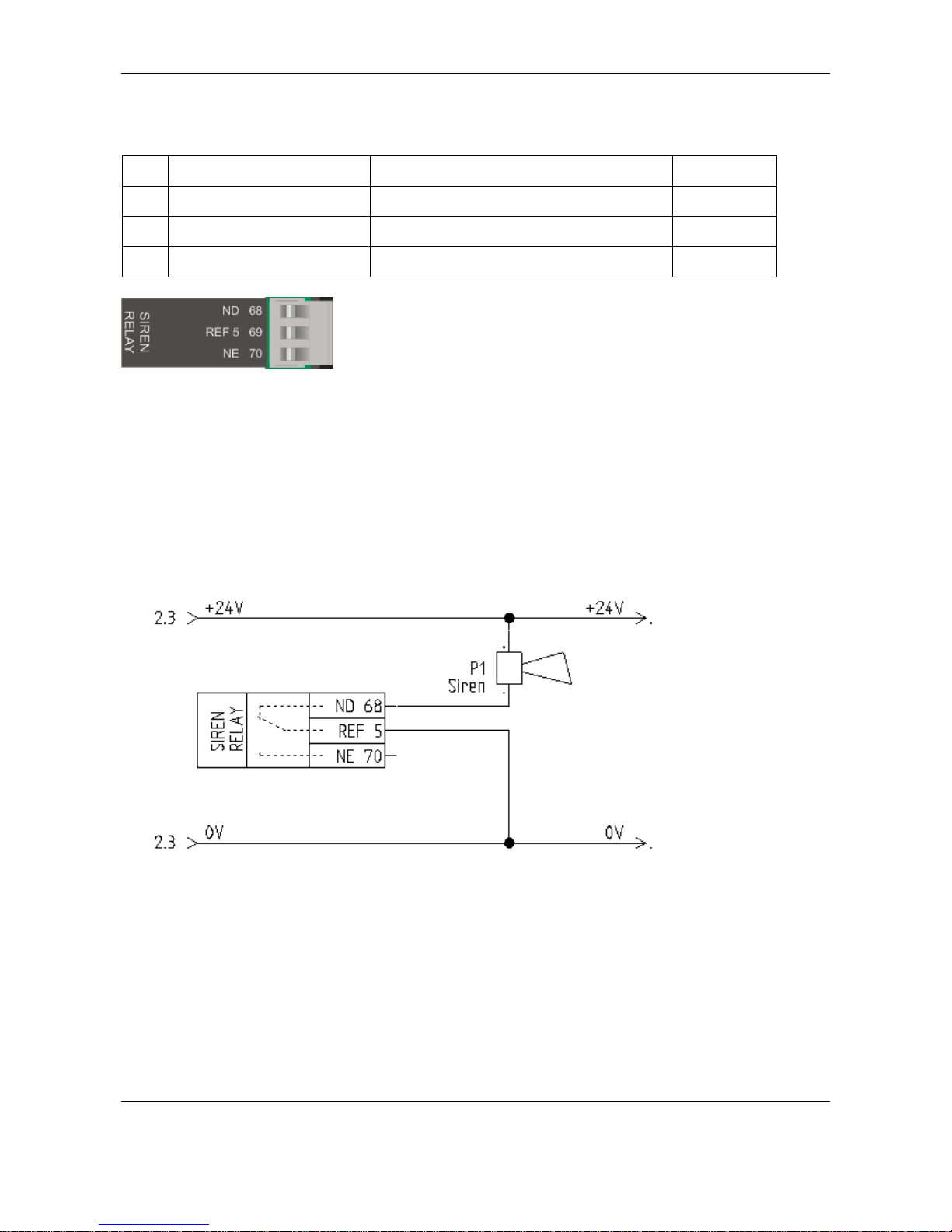

5.6 Siren Relay ............................................................................................................................. 26

5.6.1 Connection of the Siren Relay ........................................................................................... 26

6 Communication .......................................................................................................................... 27

6.1 CAN J1939 Bus ..................................................................................................................... 27

6.1.1 CAN J1939 Connector: ...................................................................................................... 27

6.1.2 CAN cable .......................................................................................................................... 27

6.1.3 RS485 MODBUS ............................................................................................................... 28

6.1.4 RS485 cable ....................................................................................................................... 28

7 Functional Description ............................................................................................................... 29

7.1 Remote Mode ......................................................................................................................... 29

7.2 Alarm Monitoring .................................................................................................................. 31

7.2.1 Alarm flowchart: ................................................................................................................ 32

7.3 Shutdown Monitoring ............................................................................................................ 33

7.3.1 Shutdown flowchart: .......................................................................................................... 34

7.4 Specification .......................................................................................................................... 35

Page 4

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 4

1 Preface

The M2500 - Engine Controller is designed for control and monitoring of marine engines.

Together with the optional M2600 - Shutdown Unit the M2500 - Engine Controller forms a

complete alarm, control and protective safety system for marine engines.

Typical applications are marine generator engines such as auxiliary generators, emergency

generators, harbour generators and propulsion engines.

The M2500 is designed for assembly in the main switchboard or at the engine.

This manual describes the installation of the M2500 - Engine Controller.

Page 5

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 5

2 Installation

The M2500 is designed for flush mounting to the front panel of the switchboard. It is secured by 6

mounting brackets which are supplied with the M2500.

The panel cut out dimension is 138mm x 210mm

Page 6

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 6

3 Terminal Connections

Primary and

back-up

power supply

Inputs for

activation of

operation

modes,

Inputs for

remote start and

stop

Input for

magnetic, NPN

or PNP pickup for speed

detection

Digital sensor

inputs for

alarms and

shutdowns

Analogue

sensor inputs

for alarms and

shutdowns

Outputs for

indication of

engine state

(e.g. to PMS)

Control

outputs

Common

alarm outputs

Programmable

outputs for

indication of

alarms and

shutdowns

Engine stop

relay

Programmable

output for stop

or run

solenoid with

cable

monitoring

Siren relay

RS485 Modbus

Adjustment of

display contrast

Interface for

CANJ1939

Slot for SD card for read out

of log and configuration

USB interface for

configuration and

read out of alarm log

Future use

Page 7

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 7

4 Inputs

4.1 Power Supply

Redundant Power Supply (2x 24V DC, -30 % / +30 %)

Alarm in case any power supply fails (common alarm + display text).

Primary supply will not be monitored during cranking, as the battery voltage will drop during this

process.

Nr.

Description

01

Primary Supply +

02

Primary Supply -

03

Primary Supply +

04

Primary Supply -

4.2 Mode/ Control Inputs

Nr.

Description

Logic (NO/NC)

05

Remote Mode

NO

06

Local Mode

NO

07

Off Mode

NO

08

Remote Start

NO

09

Remote Stop

NO

10

Override

NO

11

Crank disconnect

NO

12

Reset

NO

13

COM

Common

reference for

control inputs

Page 8

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 8

4.2.1 Connection of Mode Selector Switch

The external mode selector switch is used for switching the M2500 into OFF, REMOTE or LOCAL

mode.

4.2.1.1 Local Mode (terminal 5)

The local mode input is considered active when connected to COM, inactive when open.

When active the M2500 will be in local mode. This means start and stop are only available from the

push buttons on the front panel. The remote start and stop terminals are disabled. The LOCAL LED

on the front panel will be lit. Not ready LED on the front panel will be lit and READY output

terminal 36 will be deactivated indication that the engine is not available for remote start.

4.2.1.2 Remote Mode (terminal 6)

The remote mode input is considered active when connected to COM, inactive when open.

When active the M2500 will be in remote mode. This means start and stop are only available from

the REMOTE START and REMOTE STOP terminals. The Local start and stop push buttons are

disabled.

Provided no alarm, shutdown or Off command is active, the green REMOTE LED on the front

panel will be lit and the engine is ready for remote start.

4.2.1.3 Off (terminal 7)

The off input is considered active when connected to COM, inactive when open.

When activated, the M2500 will initiate a stop procedure. Engine start will be blocked as long as

this input is active.

Not ready LED on the front panel will be lit indicating that the engine is not available for remote

start.

Page 9

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 9

4.2.2 Remote Start (terminal 8)

The Remote Start input is considered active when connected to COM, inactive when open. It can be

a pulse or continuous signal.

The input is only enabled in remote

mode.

When activated, the M2500 will

generate a start signal to the engine.

The pre-configured number of start

attempts is available. During the start

attempt the green Engine Running

LED on the front panel will be fast

flashing. During the rest periods

between start attempts this LED will

be slow flashing. When the engine is

running, the LED will be lit continuously.

If the engine does not start the M2500 will initiate a stop procedure and a Start Fail Alarm. The red

ALARM LED on the front panel will be lit. The alarm text “START FAILURE” will be shown on

the display.

4.2.3 Remote Stop (terminal 9)

The Remote Stop input is considered active when connected to COM, inactive when open. It can be

a pulse or a continuous signal.

The input is only enabled in remote

mode.

When activated, the M2500 will

initiate a stop procedure. During the

stop procedure the green Running

LED will be slow flashing. The

Stopping LED will be lit. If the

engine does not stop the M2500 will

generate a Stop Fail Alarm. The red

ALARM LED on the front panel will

be lit. The alarm text “STOP

FAILURE” will be shown on the

display.

The engine will be blocked for start as long as the stop input is active. When activated

simultaneously, Stop overrides Start.

Page 10

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 10

4.2.4 Override (terminal 10)

The Override input is considered active

when connected to COM, inactive

when open.

When activated all shutdowns that are

marked override will be disabled,

meaning the engine will continue

running despite of a shutdown. If the

override is deactivated while a

shutdown is present, shutdown will be

executed immediately.

4.2.5 Crank Disconnect (terminal 11)

The Cranck Disconnect input is

considered active when connected

to COM, inactive when open.

This input is only used in case

there is no pick-up for speed

detection. The input is a contact

from a tacho-relay that signals

that the speed of the engine is

above ignition speed. When

receiving the Crank Disconnect

signal the M2500 will deactivate

the crank output after a start

attempt. If the M2500 looses this

signal without a stop procedure, the ALARM LED will be lit and a Tacho Fail Alarm will be

displayed.

4.2.6 Reset (terminal 12)

This Reset is considered active when

connected to COM, inactive when open.

When activated, this input will reset the siren

and the alarm/ shutdown.

Page 11

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 11

4.2.7 COM (terminal 13)

The COM is the common reference for all digital inputs.COM and power supply minus are

internally connected.

4.3 Speed detection

Speed detection

Remark

14

Pick-up

Supply voltage for PNP or NPN pick-up

15

Pick-Up signal input

16

Reference for pick-up signal

4.3.1 Connection of magnetic pick-up

The magnetic pick-up is connected as follows:

For use of magnetic pick-up the DIP switches 3 and 4 on the rear side of M2500 must be in OFF

position. The DIP switches are placed between the RS485 and CAN connectors on the rear side of

M2500.

DIP Switch Position

1 OFF

2 OFF

Page 12

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 12

4.3.2 Connection of PNP pick-up

The NPN pick-up is connected as follows:

For use of PNP pick-up the DIP switch 3 on the rear side of M2500 must be in ON position, DIP

switch 4 must be in OFF position. The DIP switches are placed between the RS485 and CAN

connectors on the rear side of M2500.

DIP Switch Position

1 ON

2 OFF

4.3.3 Connection of NPN pick-up

The NPN pick-up is connected as follows:

For use of NPN pick-up the DIP switch 3 on the rear side of M2500 must be in OFF position, DIP

switch 4 must be in ON position. The DIP switches are placed between the RS485 and CAN

connectors on the rear side of M2500.

DIP Switch Position

1 OFF

2 ON

Page 13

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 13

4.4 Digital sensor inputs

Nr.

Description

Remark

17

Digital input 1

Sensor input for digital sensor 1

18

Digital input 2

Sensor input for digital sensor 2

19

Digital input 3

Sensor input for digital sensor 3

20

Digital input 4

Sensor input for digital sensor 4

21

Digital input 5

Sensor input for digital sensor 5

22

Digital input 6

Sensor input for digital sensor 6

23

Digital input 7

Sensor input for digital sensor 7

24

Digital input 8

Sensor input for digital sensor 8

25

Digital input 9

Sensor input for digital sensor 9

26

COM

Common reference for digital

sensor inputs

The Digital sensor inputs are used for the connection of the digital sensors. Digital sensors can be

Normally Open (NO) or Normally Closed (NC) logic. Cable break and short circuit monitoring is

available.

4.4.1 Connection of a normally open sensor without cable monitoring

The following example shows the Connection of a normally open sensor without cable monitoring.

The sensor is considered active when

connected to COM, inactive when open.

When activated, the input generates an

alarm or shutdowns or a control signal,

depending on the configuration.

Page 14

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 14

4.4.2 Connection of a normally closed sensor without cable monitoring

The following example shows the Connection of a normally closed sensor without cable

monitoring.

The sensor is considered active when open,

inactive when connected to COM.

When activated, the input generates an

alarm or shutdowns or a control signal,

depending on the configuration.

4.4.3 Connection of a normally open sensor with cable monitoring

The following example shows the Connection of a normally open sensor with cable monitoring.

The sensor is considered

active when connected to

COM, inactive when open.

Resistor R1 is used for

cable break monitoring.

Resistor R2 is used for short

circuit monitoring.

It is very important that

both resistors are mounted

close to the sensor.

Page 15

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 15

4.4.4 Connection of a normally closed sensor with cable monitoring

The following example shows the connection of a normally closed sensor with cable monitoring.

The sensor is considered

active when open, inactive

when connected to COM.

Resistor R1 is used for short

circuit monitoring.

Resistor R2 is used for cable

break monitoring.

It is very important that both

resistors are mounted close

to the sensor.

4.4.5 COM (terminal 13)

The COM is the common reference for all digital inputs.COM and power supply minus are

internally connected.

4.5 Analogue sensor inputs

Analogue sensor inputs are used for temperature and pressure measurements.

All analogue sensors use 4-20mA signals.

Analogue Sensor Inputs

Remark

27

4mA -20mA

Analogue input 1

28

4mA -20mA

Analogue input 2

29

4mA -20mA

Analogue input 3

30

4mA -20mA

Analogue input 4

31

4mA -20mA

Analogue input 5

32

4mA -20mA

Analogue input 6

33

4mA -20mA

Analogue input 7

34

4mA -20mA

Analogue input 8

35

COM

Common reference for

analogue sensor inputs

Page 16

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 16

4.5.1 Analogue inputs (terminals 27 to 34)

The analogue sensor inputs are for

generating alarms and shutdowns. In

case the input signal is below 3mA or

above 25mA the M2500 will generate a

sensor fail alarm. Cable Error LED will

be lit.

Delay times can be programmed for

alarms and shutdowns.

4.5.2 COM (terminal 13)

The COM is the common reference for all digital inputs.COM and power supply minus are

internally connected.

Page 17

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 17

5 Outputs

All outputs are relay contacts.

5.1 Engine Status Outputs

Nr.

Description

Type

Rating

36

Ready/ Not Ready

NO Relay

1A

37

Start warning

NO Relay

1A

38

Engine Running

NO Relay

1A

39

Cool down

NO Relay

1A

40

REF1

Common reference for engine status outputs

5.1.1 Connection of Engine Status Outputs

Following example shows the connection of an external relay for the engine running signal:

Page 18

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 18

5.1.2 Ready (terminal 36)

Normally Open Relay output. The Ready output indicates the availability of the engine for remote

start e.g. for a power management system. The output can be configured as “Engine Ready” or

“Engine Not Ready”. The output is activated when closed to COM (terminal) 40.

Note: Configuration as Ready Output:

The output is activated when the engine is available for remote start. The output is de-activated in all

other conditions (e.g. M2500 in Local mode shutdown error or start blocking) (normally de-energized

output).

Note: Configuration as Not Ready output:

The output is activated when the engine is not available for remote start (e.g. M2500 in Local mode

shutdown error or start blocking).

The output is de-activated when the output is ready for remote start (normally energized output).

5.1.3 Start warning (terminal 37)

Normally Open Relay output. This output is activated for a preconfigured time before each start

attempt. The output is activated when closed to COM (terminal) 40. The relay is normally deenergized.

5.1.4 Engine running (terminal 38)

Normally Open Relay output. This output indicates that the engine is running. The output is

activated when closed to COM (terminal) 40. The relay is normally de-energized.

5.1.5 Cool Down (terminal 39)

Normally Open Relay output. This output indicates that the engine is in cool down mode. After

receiving the engine stop command, the M2500 will trip the C/B. The engine will continue running

for the duration of the cool down time. After expiration of the cool down time the M2500 will stop

the engine. The cool down time can be configured. Cool Down only applies to remote mode and

only for normal stops. Shutdowns will be executed immediately.

Note:

Purpose of this output is to give a signal to a synchronizer in order to avoid re-synchronization.

The output is activated when closed to COM (terminal) 40. The relay is normally de-energized.

5.1.6 REF 1 (terminal 40)

Common reference for all output relays terminals 36 to 39.

Page 19

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 19

5.2 Engine Control Outputs

Nr.

Description

Type

Rating

41

Auxiliary lubrication pump

NO Relay

1A

42

Crank

NO Relay

1A

43

Circuit breaker trip

NO Relay

1A

44

Air intake valve

NO Relay

1A

45

REF 2

Common reference for the control

outputs

5.2.1 Connection of Engine Control Outputs

Following example shows the connection of an external relay for the C/B trip signal:

5.2.2 Auxiliary Lubrication Pump (terminal 41)

Normally Open Relay output. When the engine is stopped the output becomes active every 30 min

for 2 min. Immediately after stop the first lubrication period is after 20 min. The interval and

duration times can be configured.

The relay is normally de-energized.

Page 20

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 20

5.2.3 Crank (terminal 42)

Normally Open Relay output. This is the start output of the M2500. It activates for each start

attempt and remains active until either the engine has fired or the crank time has expired or a stop

command has been activated at the M2500.

The relay is normally de-energized.

5.2.4 C/B trip (terminal 43)

Normally Open Relay output. This output trips the circuit breaker before the engine stops. It is

always activated after a stop command has been received or a shutdown has been activated.

The relay is normally de-energized.

5.2.5 Air Intake Valve (terminal 44)

Normally Open Relay output. This is an alternative stop output. The output is activated immediately

when a stop procedure is activated, regardless if this is a normal stop or a shutdown.

The relay is normally de-energized.

5.2.6 REF 2 (terminal 45)

Common reference for all output relays terminals 41 to 44.

5.3 Alarm Outputs

Nr.

Description

Type

Rating

46

Common Alarm

NO Relay

1A

47

Shutdown

NO Relay

1A

48

Cable Break

NO Relay

1A

49

Communication Error

NO Relay

1A

50

REF 3

Common reference for the alarm outputs

Page 21

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 21

5.3.1 Connection of alarm outputs

Following example shows the connection of an external relay for signaling a shutdown to an

external alarm system:

5.3.2 Common Alarm (terminal 46)

Normally Open Relay output. This output becomes energized for each alarm and shutdown.

The relay is normally de-energized. In case a new alarm/ shutdown appear while the relay is already

energized, the alarm will de-energize for two seconds and then energize again.

5.3.3 Shutdown (terminal 47)

Normally Open Relay output. This output becomes active for each shutdown.

The relay is normally de-energized.

5.3.4 Cable break (terminal 48)

Normally Open Relay output. This output becomes active for each cable break at the digital inputs

or sensor fails at the analogue inputs.

The relay is normally de-energized.

5.3.5 CAN (terminal 49)

Normally Open Relay output. This output becomes active in case a communication error on the

CAN J1939 is detected.

The relay is normally de-energized.

5.3.6 REF3 (terminal 50)

Common reference for all output relays terminals 46 to 49.

Page 22

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 22

5.4 Digital Outputs

Nr.

Description

Type

Rating

51

Digital Output 1

(start fail in default config)

NO Relay

1A

52

Digital Output 2

(stop fail in default config)

NO Relay

1A

53

Digital Output 3

NO Relay

1A

54

Digital Output 4

NO Relay

1A

55

Digital Output 5

NO Relay

1A

56

Digital Output 6

NO Relay

1A

57

Digital Output 7

NO Relay

1A

58

Digital Output 8

NO Relay

1A

59

Digital Output 9

NO Relay

1A

60

Digital Output 10

NO Relay

1A

61

Digital Output 11

NO Relay

1A

62

Digital Output 12

NO Relay

1A

63

REF 4

Common reference for

the digital outputs

5.4.1 Connection of digital outputs

Following example shows

the connection of an

external relay to digital

output 2:

Page 23

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 23

5.4.2 Digital Outputs Out 1 to Out 12 (terminals 51 to 62)

Normally Open Relay output. These are programmable alarm and shutdown outputs. It is also

possible to program these outputs to activate with any of the alarms generated from the analogue

measurements.

Note:

In factory default configuration Digital Output 1 (terminal 51) is the START FAILURE OUTPUT.

In factory default configuration Digital Output 2 (terminal 52) is the STOP FAILURE OUTPUT.

5.4.3 REF 4 (terminal 50)

Common reference for all output relays terminals 51 to 62.

5.5 Control Relays

Nr.

Description

Type

Rating

Remark

1

Engine Stop

Energized to stop

1A

2

Engine Stop

3

Run/ Stop Solenoid

Energized to run or

energized to stop

24V DC / 6A

Cable monitoring

4

Run/ Stop Solenoid

Note: Cable break monitoring:

Cable break monitoring is required for the stop solenoid output. The nominal voltage for this output is

24V DC, 6A current when activated.

5.5.1 Engine Stop Output (terminal 64 and 65)

Terminals 64 and 65 are a normally open contact. This output will

be activated for the stop procedure until the stop time has expired

(energized to stop). The output is activated both for normal stops

and shutdowns. It is active in parallel with the stop solenoid relay.

Purpose of this output

is to give a potential

free signal to the

shut.

The relay is normally

de-energized

Page 24

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 24

5.5.2 Run/ Stop Solenoid (terminal 66 and 67)

This output can be configured for control of the fuel valve (run solenoid) or stop solenoid.

Output configured for control of stop solenoid

In this case terminals 66 and 67 are the output for control of the stop solenoid. This output will be

activated for the stop procedure until the stop time has expired (energized to stop) or (in case

magnetic pick up is used for speed detection) until the engine speed is down to 10rpm (value

depending on what is practical), both for normal stops and shutdowns.

The relay is normally de-energized. This output includes cable monitoring for the stop solenoid.

Note:

The RUN/STOP solenoid can only be used with 24V DC. This can be either the same supply as for the

controller or a separate power supply.

Please observe correct polarity when connecting the fuel valve.

When deactivated there will be a current of 5mA on this output due to the cable monitoring circuit

inside the M2500.

Note:

The coil connected to this output must require a current > 5mA for activating. Otherwise the stop

solenoid could be activated by the cable monitoring circuit.

This is especially important in case the stop solenoid is not activated directly by the M2500 output

but by an intermediate relay, that typically requires a much lower current to activate than the stop

solenoid.

The cable monitoring on this output can be disabled in the configuration, however the 5mA limit

still applies.

In case the connection to the stop solenoid is lost and cable monitoring is enabled an alarm will be

activated.

Page 25

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 25

Output configured for control of run solenoid (fuel valve)

In this case terminals 66 and 67 are a normally open contact for control of the fuel valve. This

output will be activated during start and operation of the engine (energized to run). For engine stop

the output will be de-activated. The relay is normally de-energized. This output includes cable

monitoring for the run solenoid.

Note:

Please note that this output can only be used with 24V DC. This can be either the same supply as for the

controller or a separate power supply.

Please observe correct polarity when connecting the fuel valve.

When deactivated there will be a current of 5mA on this output due to the cable monitoring circuit

inside the M2500.

Note:

The coil connected to this output must require a current > 5mA for activating. Otherwise the fuel valve

could be activated by the cable monitoring circuit.

This is especially important in case the fuel valve is not activated directly by the M2500 output but

by an intermediate relay, that typically requires a much lower current to activate than the fuel valve.

The cable monitoring on this output can be disabled in the configuration, however even then the

5mA limit still applies.

In case the connection to the fuel valve is lost and cable monitoring is enabled an alarm will be

activated.

Page 26

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 26

5.6 Siren Relay

Nr.

Description

Type

Rating

68

ND

Relay contact in de-energized position

1A

69

REF 5

Reference contact of alarm relay

1A

70

NE

Relay contact in energized position

1A

The siren relay is typically used for connection of a siren. It is normally energized.

It will de-energize with any new alarm or shut-down. After pressing RESET the alarm relay will

energize again.

5.6.1 Connection of the Siren Relay

In below example the siren will activate with any new incoming alarm or shutdown.

Page 27

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 27

6 Communication

6.1 CAN J1939 Bus

The M2500 can communicate directly with the engine ECU by CAN bus, SAE J1939 for a

maximum distance 250m.

6.1.1 CAN J1939 Connector:

Pin 1: CAN H

Pin 2: CAN L

Pin 3: CAN COM

The CAN J1939 is to be terminated on both ends with a 120Ω resistor.

6.1.2 CAN cable

Unshielded twisted pair 2 x 2 x 0,22... 2 x 2 x 0,5 (e.g. Lapp Kabel UNITRONIC®, BUS CAN

UL/CSA (CMX), part number 2170267).

One pair is to be used for CAN H and CAN L, one wire of the remaining pair is to be used for CAN

com.

Page 28

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 28

6.1.3 RS485 MODBUS

M2500 includes an RS485 interface MODBUS RTU communication.

RS485 Connector:

Pin 1: RS485 A

Pin 2: RS485 B

Pin 3: RS485 COM

The RS485 Modbus is to be terminated on both ends with a 120Ω resistor.

6.1.4 RS485 cable

Unshielded twisted pair 2 x 2 x 0,22... 2 x 2 x 0,5 (e.g. Lapp Kabel UNITRONIC®, BUS CAN

UL/CSA (CMX), part number 2170267).

One pair is to be used for RS485 A and RS485 B, one wire of the remaining pair is to be used for

RS485 com.

Page 29

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 29

7 Functional Description

7.1 Remote Mode

In remote mode (terminal 5 connected to com) Start and stop is only available from the REMOTE

START (terminal 08) and REMOTE STOP (terminal 09) terminals.

Provided the engine is ready for remote start (Not Ready LED on the front panel of M2500 is off)

the start procedure works as follows:

Remote Start flowchart:

Start Warning

Fuel Valve on

Engine

running?

Cranking

All start

attempts

completed?

YES

NO

Start Fail

Not ready

Lube Pump

C/B Trip

Air Intake

Common Alarm

Engine Stop

Stop Solenoid

Alarm Relay

Engine ready for

REMOTE START

NO

Start Delay

Survey Delay

Run

Fuel Vanve

Cranking

Fuel Valve on

Rest Time

NO

YES

Engine Running

Run

Fuel Vanve

YES

Remote Start

Command

YES

NO

Lube pump

according config

Ready for remote

start

Page 30

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 30

Remote Stop flowchart:

Run

Fuel Vanve

C/B Trip

Cool Down

YES

Stop Fail

Not ready

Run

Fuel Valve

Engine Running

NO

Cool Down Run

Remote Stop

Command

YES

NO

Run

Fuel Vanve

Cool Down

Time expired?

Stop Procedure

Engine Stop

Stop Solenoid

Stop Time

expired?

NO

Engine

stopped?

Ready

Lube Pump

according config

YES

NO

Engine stopped

and ready for start

Page 31

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 31

7.2 Alarm Monitoring

The alarm monitoring is always active regardless of Local or remote mode.

Note:

Alarms are abnormal conditions that will be indicated and logged by the M2500, but they will not stop

the engine.

Alarms can be set to continuous monitoring (regardless if the engine is running or not) or

conditional monitoring (only monitored if the engine is running).

An individual programmable time delay is available for each alarm.

A new incoming alarm will always shift the M2500 display to the Current Alarm display. At the

same time the Alarm LED on the front panel will be fast flashing, the common alarm output

(terminal 46) will activate and the Siren Relay (terminals 68, 69 and 70) will de-energize.

Depending on the configuration it is possible to activate one or more of the digital outputs.

The common alarm output will de-activate for 2s and re-activate when a new alarm appear.

The siren relay (terminals 68, 69 and 70) will de-activate for 2s and re-activate when a new alarm

appear.

After accepting an alarm (by pressing the Reset button or external reset terminal 12) the common

alarm LED will change to steady light, the common alarm output and the optional digital output

will remain active, provided the alarm is still present on the input. The siren relay will energize

again after pressing Siren Reset or Reset button or external reset terminal 12.

When the all alarms disappear from the inputs and alarms have been acknowledged, the common

alarm LED will switch off, the common alarm output and the optional digital outputs will

deactivate.

Page 32

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 32

7.2.1 Alarm flowchart:

Engine Running

Alarm Procedure

Alarm input

activated?

YES

NO

Run

Fuel Vanve

Override

activated AND

Alarm marked

for override?

Alarm marked

for blocking?

NO

Monitoring

delay expired?

NO

YES

Running

Fuel Valve

Not Ready

Common Alarm

Alarm Relay de-

energized until

Reset

YES

Page 33

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 33

7.3 Shutdown Monitoring

The shutdown monitoring is always active regardless of Local or remote mode.

Note:

Shutdowns are abnormal conditions that will be indicated and logged by the M2500 and they will stop

the engine.

Shutdowns can be set to continuous monitoring (regardless if the engine is running or not) or

conditional monitoring (only monitored if the engine is running).

An individual programmable time delay is available for each shutdown.

A new incoming shutdown will always shift the M2500 display to the Current Alarm display. At

the same time the shutdown LED on the front panel will be fast flashing, the common shutdown

output (terminal 46) will activate and the Siren Relay (terminals 68, 69 and 70) will de-energize.

Depending on the configuration it is possible to activate one or more of the digital outputs.

Note:

A shutdown will block the engine for start until it has been reset and the shutdown signal has

disappeared.

After accepting a shutdown (by pressing the ACK button or external reset terminal 12) the

Common shutdown LED will change to steady light. The shutdown output and the optional digital

output will remain active provided the shutdown is still active on the input. The siren relay will

energize again.

Page 34

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 34

7.3.1 Shutdown flowchart:

YES

Stop Fail

Not ready

Engine Running

Shut Down

Procedure

Shut Down

input

activated?

YES

NO

Run

Fuel Vanve

Stop Time

expired?

NO

Engine

stopped?

Not Ready

Lube Pump

according config

Common Alarm

Shut Down

YES

NO

Engine stopped

and blocked for

start

Override

activated AND

Shutdown

marked for

override?

Shutdown

marked for

blocking?

NO

Monitoring

delay expired?

NO

YES

Not Ready

C/B trip

Air Intake

Common Alarm

Shut Down

Engine Stop

Stop Solenoid

Alarm Relay de-

energized until

Reset

YES

Reset?

Shutdown still

active and marked

for continuous

monitoring?

NO

YES

Engine ready for

AUTO START

Page 35

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 35

7.4 Specification

Environmental conditions:

Operating temperature: -15°C to +70°C

Humidity: 95%

Vibration: DNV vibrations class B

EMC: IEC 60945

Enclosure: IP44 (panel front only)

Supply:

Primary Supply: +24 V DC (-30 % / +30 %) Isolated, 500mA

Backup Supply: +24 V DC (-30 % / +30 %) Isolated, 500mA

Pick Up Input:

Connection: Screw terminals

Type: Magnetic (2-wire), NPN and PNP (3-wire), configurable via DIP

switch.

Rated frequency 40.0 to 10000 Hz

Sensor inputs:

9 Digital inputs: Normally open contacts to COM (default) or normally closed

contacts to COM. Optional cable monitoring (short circuit and

cable break).

8 Analogue inputs: 4-20mA -, with optional cable monitoring.

Mode / Control inputs:

Connection: Screw terminals (2,5mm2)

Activation: Connect to COM

All relays (except where otherwise specified):

Relay response time: 20 ms (worst case)

Contact set(s) 1 normally open

Contact rating: AC: 1 A, 250 V AC, DC: 1 A, 35 V DC

Function: Normally de-energized.

Run/ Stop Solenoid relay:

Relay response time: 20 ms (worst case)

Contact set(s) 1 normally open

Contact rating: AC: 8 A, 250 V AC, DC: 8 A, 35 V DC

Function: Normally de-energized (Default) or normally energized

Cable monitoring (cable break and short circuit).

System fault output relay (Siren):

Relay response time: 20 ms (worst case)

Contact set(s) 1 change over

Contact rating: AC: 1 A, 250 V AC, DC: 1 A, 35 V DC

Function: Normally energized.

Page 36

SELCO A/S M2500 Installation Manual

Revision: 23-04-2012 Page 36

SAE J1939, CAN Bus:

Connection: Screw terminal connector, 3-wire with COM (Isolated)

Distance: Max. 40m

Protocol: SAE J1939

Speed: 250Kbit/s

Termination: 120 ohm termination

RS485, Modbus:

Connection: Screw terminal connector, 3-wire with COM (Isolated)

Distance: Max. 500m

Protocol: Modbus RTU

Speed: 19200 bit/s

Termination: 120 ohm termination

USB:

Connection: USB type B socket (Female connector), USB 2.0 Full speed

Device,

Mass storage device for configuration, inspection of log files and

other diagnostics information.

Loading...

Loading...