S4E16400/S4E16401

Technical Manual

Read this manual carefully and use the product correctly.

Rev.1.1

NOTICE

No part of this material may be reproduced or duplicated in any form or by any means without the written

permission of Seiko Epson. Seiko Epson reserves the right to make changes to this material without notice.

Seiko Epson does not assume any liability of any kind arising out of any inaccuracies contained in this material

or due to its application or use in any product or circuit and, further, there is no representation that this material

is applicable to products requiring high level reliability, such as, medical products. Moreover, no license to

any intellectual property rights is granted by implication or otherwise, and there is no representation or warranty

that anything made in accordance with this material will be free from any patent or copyright infringement of a

third party. This material or portions thereof may contain technology or the subject relating to strategic

products under the control of the Foreign Exchange and Foreign Trade Law of Japan and may require an export

license from the Ministry of Economy, Trade and Industry or other approval from another government agency.

All other product names mentioned herein are trademarks and/or registered trademarks of their respective

companies.

©SEIKO EPSON CORPORATION 2008, All rights reserved.

Table of Contents

1. OVERVIEW .....................................................................................................................1

1.1 Overview........................................................................................................................................1

1.2 Features.........................................................................................................................................1

1.3 Product Codes and Packaging ....................................................................................................2

2. SPECIFICATIONS ........................................................................................................... 3

2.1 System Configuration...................................................................................................................3

2.1.1 System Configuration ...............................................................................................................3

2.2 Specifications of Secondary Module ..........................................................................................5

2.2.1 Overview of Specifications........................................................................................................5

2.2.2 Block Diagram ..........................................................................................................................5

2.2.3 Pin Description .........................................................................................................................7

2.2.4 Absolute Maximum Ratings ......................................................................................................8

2.2.5 Electrical Characteristics ..........................................................................................................8

2.2.6 Functional Description ..............................................................................................................9

2.2.7 Embedding Conditions ...........................................................................................................10

2.3 Specifications of Secondary Module ........................................................................................11

2.3.1 Overview of Specifications......................................................................................................11

2.3.2 Block Diagram ........................................................................................................................ 11

2.3.3 Pin Description .......................................................................................................................13

2.3.4 Absolute Maximum Ratings ....................................................................................................14

2.3.5 Electrical Characteristics ........................................................................................................14

2.3.6 Functional Description ............................................................................................................15

2.3.7 External Connection Examples (Reference)...........................................................................16

2.3.8 Embedding Conditions ...........................................................................................................16

2.4 Overall Specifications ................................................................................................................20

2.4.1 Overview of Specifications......................................................................................................20

2.4.2 Functional Description ............................................................................................................20

2.4.3 Transmission monitoring.........................................................................................................20

2.4.4 Sequence ...............................................................................................................................22

2.4.5 Safety against Foreign Metal Objects.....................................................................................25

2.4.6 Embedding Conditions ...........................................................................................................26

3. EXTERNAL DIMENSIONS............................................................................................28

4. PRECAUTIONS............................................................................................................. 30

4.1 General precautions ...................................................................................................................30

4.2 Precautions on Handling............................................................................................................30

4.3 Precautions on radio laws and regulations..............................................................................31

5. SATISFIED LAWS AND REGULATIONS...................................................................... 32

5.1 Japan ...........................................................................................................................................32

5.2 The United States of America ....................................................................................................32

5.3 Europe (R&TTE member nations)..............................................................................................32

5.4 Taiwan..........................................................................................................................................33

6. EXPORTING.................................................................................................................. 33

6.1 Notes on Exporting to US ..........................................................................................................33

6.2 Notes on exporting to R&TTE member nations .......................................................................34

6.3 Notes concerning export to Taiwan ..........................................................................................35

REVISION HISTORY.........................................................................................................37

S4E16400/S4E16401 Technical Manual EPSON i

(Rev.1.1)

1. OVERVIEW

1. OVERVIEW

1.1 Overview

This product is a wireless power transmission system used for charging lithium-ion battery or other secondary

batteries, consisting of the primary module (a module on the primary side) used for power transmission and the

secondary module (a module on the secondary side) used for power reception.

Prior to staring power transmission, the primary module and the secondary module exchange ID to ensure

that they are the predefined combination permitted to transmit/receive power.

Note that assurance of quality and safety is ensured only for combined use of the S4E16400 and S4E16401,

i.e., as the primary module used for power transmission and as the secondary module used for power reception

respectively. Total quality assurance including safety will not be applied to environments other than this

combination. If any of the modules is modified, the assurance will also not be applied. For precautions when

using this product, read Chapter 4 carefully to use this product correctly.

1.2 Features

This product uses following functions to provide a reliable safety wireless power supply system that allows

for reducing charge pins, improving waterproof feature, and preventing an accident due to unpermitted power

supply process.

Transmission current: 500 mA typical *1 Standby power: 50 mW or less

Transmission efficiency: 70% maximum. *1 Recharge function

After ID authentication Detection of removal of secondary

Oscillation frequency: 121.21kHz Detection of foreign object

Detection of landing Detection of abnormal temperature

Power save after fully charged Detection of AC adapter

*1 Specification depends on operating conditions. For details, see Section 2.3.5 describing electrical

conditions.

S4E16400/S4E16401 Technical Manual EPSON 1

(Rev.1.1)

1. OVERVIEW

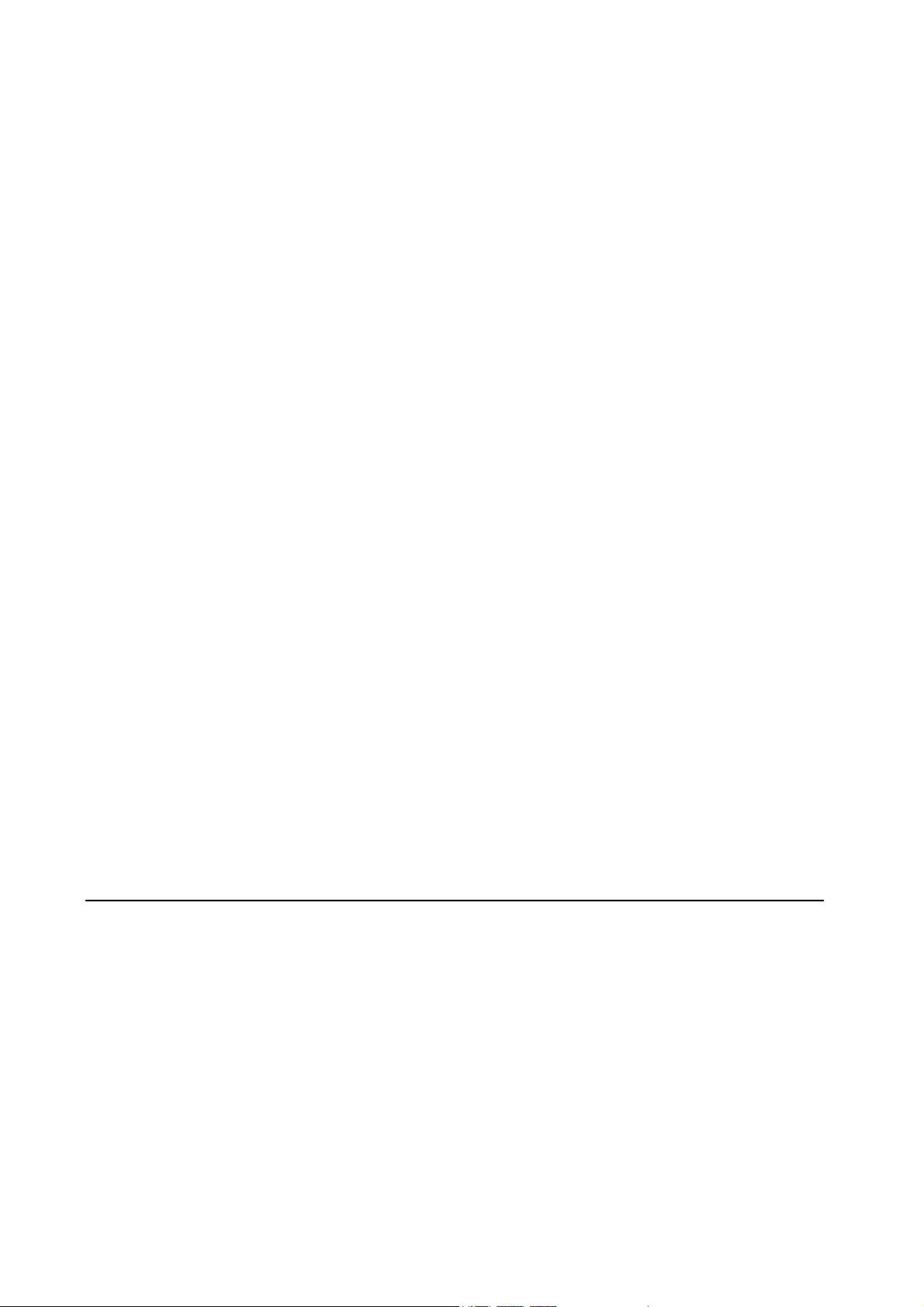

1.3 Product Codes and Packaging

Primary module

S4E164000010000

Secondary module

S4E164010010000

Sales code

Primary circuit module

S4E964000110000

Primary coil unit

S4E964000120000

Secondary circuit module

S4E964010110000

Secondary coil unit

S4E964010120000

Packaging

Tray package

Tray package

Tray package

Tray package

2 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

2. SPECIFICATIONS

y

2. SPECIFICATIONS

2.1 System Configuration

System Configuration

2.1.1

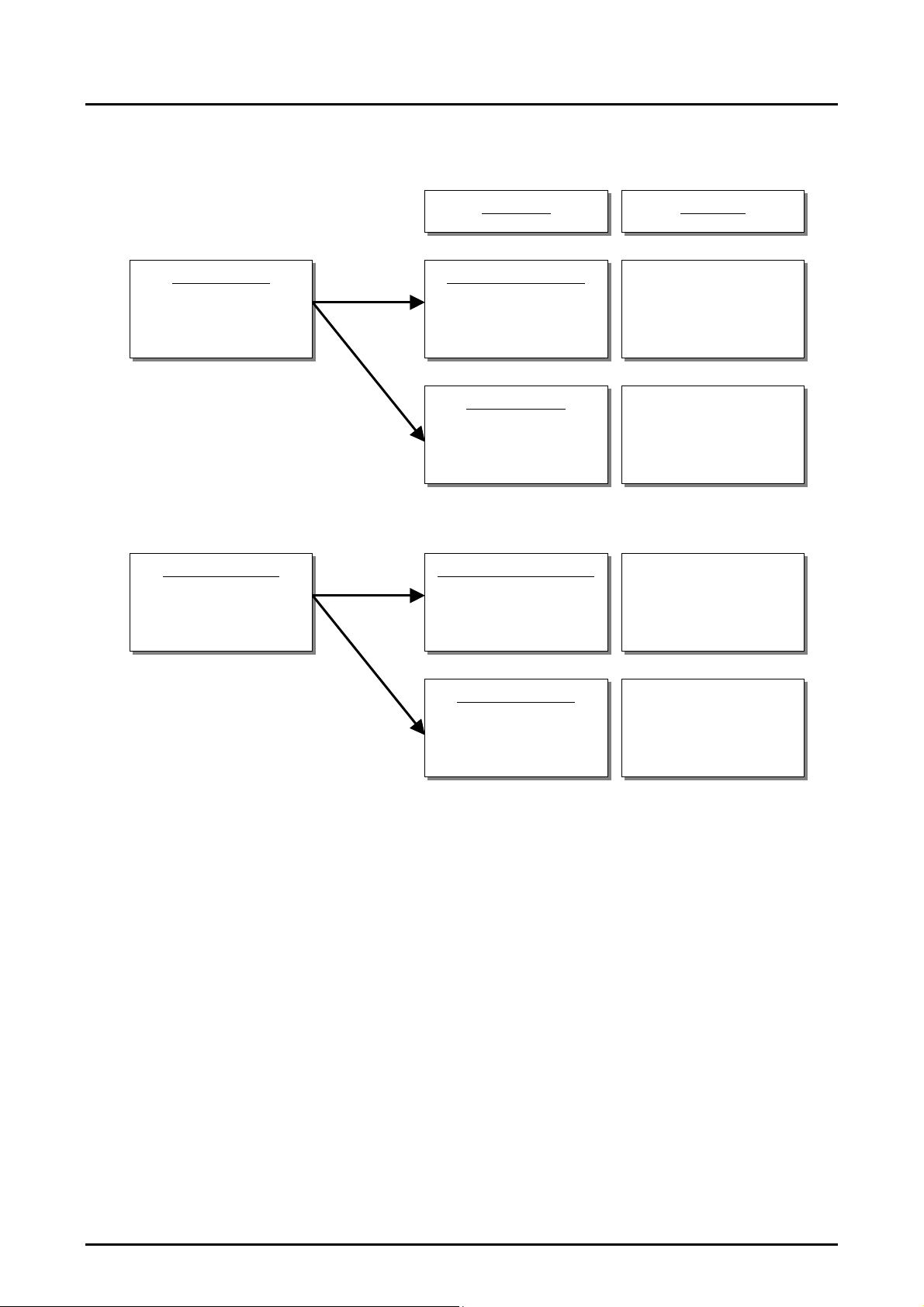

The following diagram shows an example of system configuration for the noncontact power transmission

modules.

Connector

for external

power supply

Secondary circuit module

Rectification circuit

Control circuit

Voltage control

Secondar

Primary coil unit

Charge

control

circuit

coil unit

Flux

Secondary

battery

Primary circuit module

Control circuit

Driving circuit

Fig.1 Example of System Configuration

AC Adapter

S4E16400/S4E16401 Technical Manual EPSON 3

(Rev.1.1)

2. SPECIFICATIONS

A

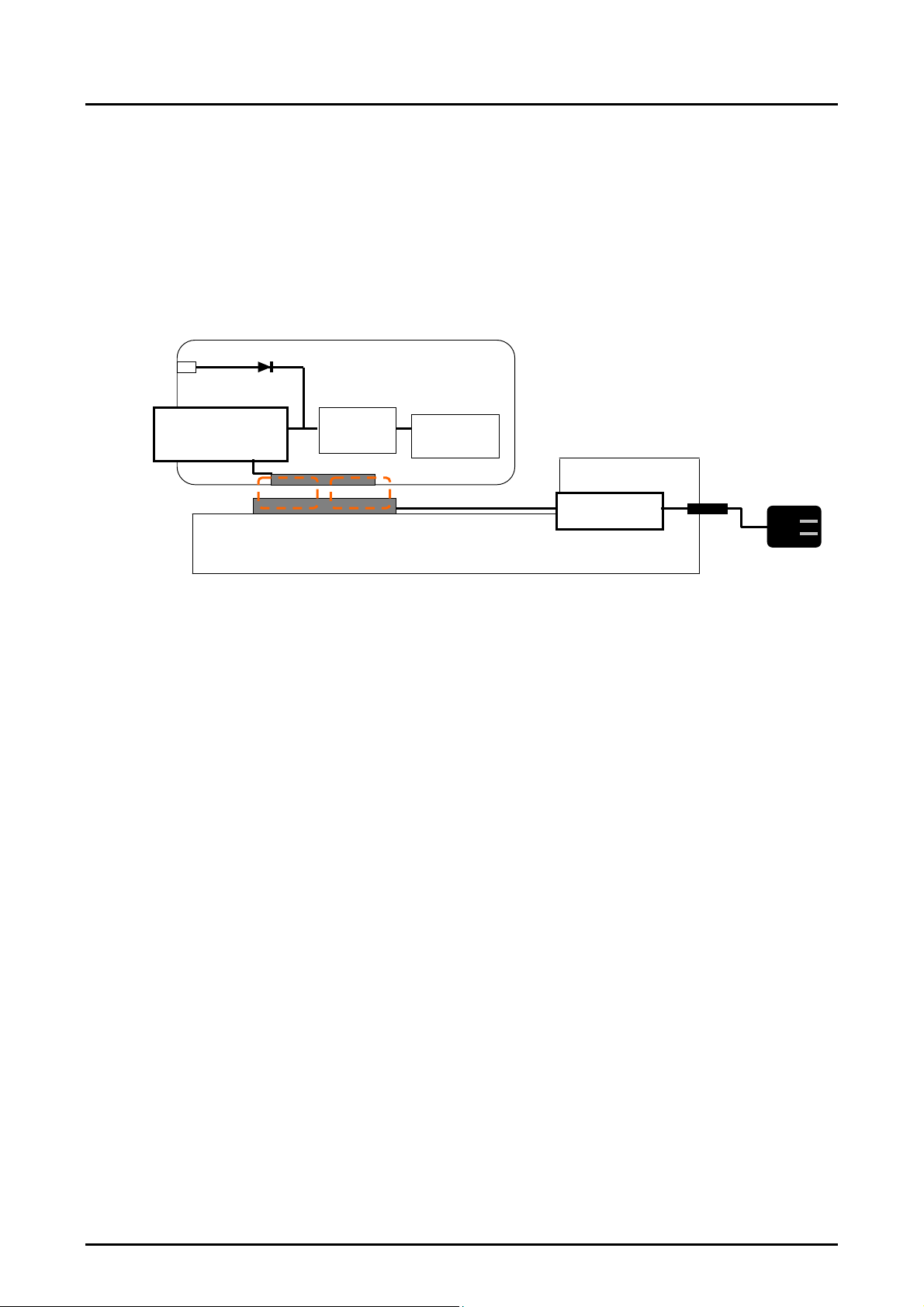

The operation of modules on the primary side and the secondary side must satisfy overall specifications

described in Section 2.4. Operations sequence is specified in the same section, whereas the system operation

sequence of Start - Charge - Finish is as outlined in the following:

(1)Standby

E:Battery voltage < Recharge

voltage (Battery has dropped)

(4)Save mode

E:Battery voltage ≥ Recharge voltage

A:Initialization

Starts intermittent output 1

E:Landing detection

(The secondary module has been placed on the top of the

primary module)

(2)ID exchange

E : ID exchange fail

E : Fully charged (Charging has been completed)

A : Starts intermittent output 2

Any state

E: Removal (The secondary module has been

removed from the primary module)

A: Stops transmission

Any state

E: Foreign object detection (Foreign metal object has

been detected)

: Stops transmission

(3)Charging

Fig.2 Sequence (Outline)

(1) To standby

(1) To standby

E:Event

A:Action

E:ID exchange succeeds

A:Starts serial output

Starts charging (Charging process begins)

Intermittent output 1:

interval = 300 mS approx.

(Standby)

Intermittent output 2:

Interval = 5 S approx.

(Save mode)

4 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

2. SPECIFICATIONS

2.2 Specifications of Secondary Module

Overview of Specifications

2.2.1

This chapter describes the specifications of the primary module (module on the primary side) that belongs to

the noncontact power transmission modules.

The main function of the primary module is to convert power supplied by AC adapter into magnetic energy

and transmit it to the secondary module (module on the secondary side).

The module has the following functions allowing for safety charging process.

♦ Detection of foreign metal objects

♦ Detection of abnormal temperature

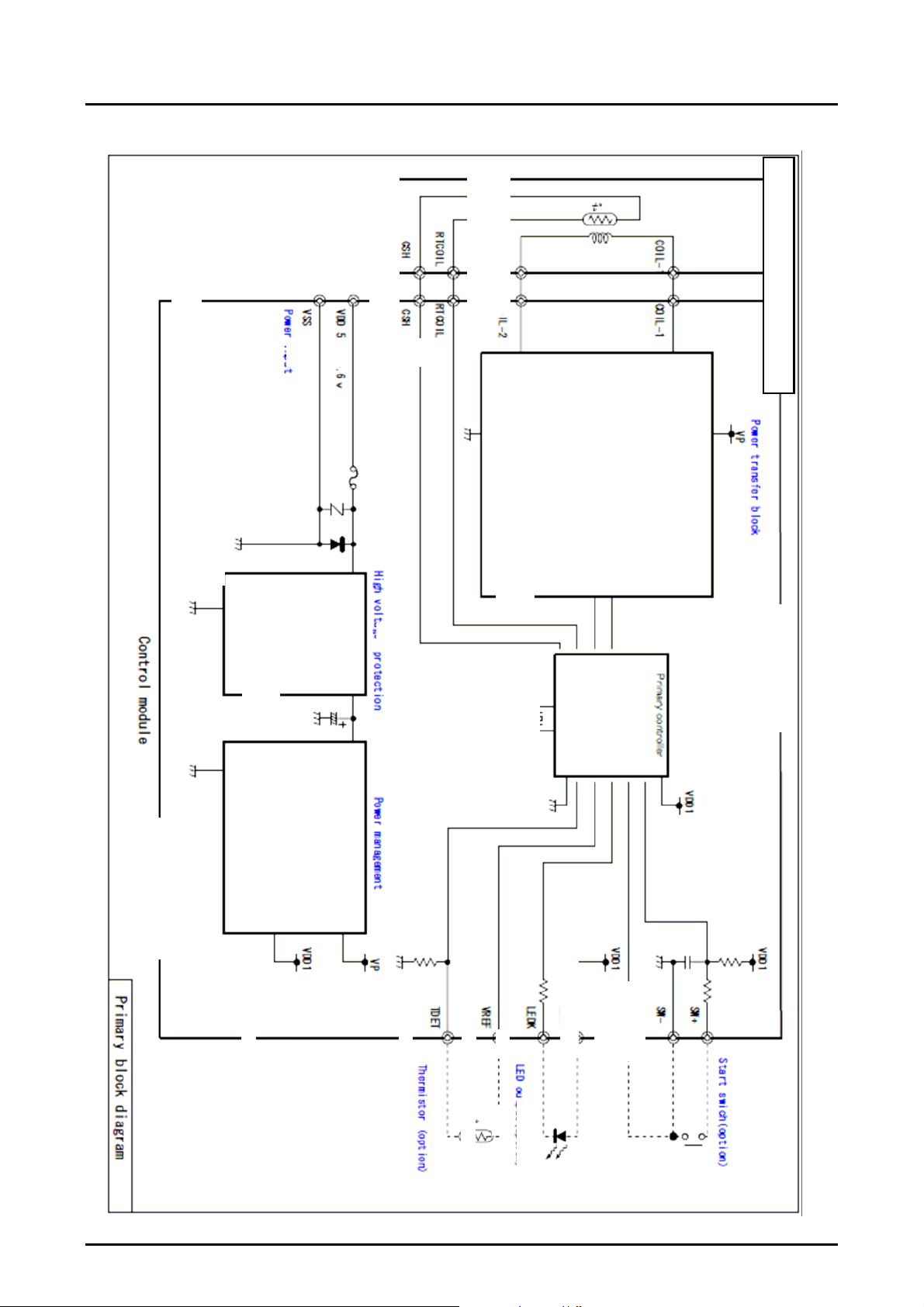

Block Diagram

2.2.2

The block diagram of the primary module is shown in the next page. The primary module consists of (1) Coil

unit and (2) Circuit module, and the following explains each of the functional blocks.

(1) Primary coil unit

♦ Coil and magnet sheet for inducing electromagnetic field

♦ Thermistor for detecting abnormal temperature

(2) Primary circuit module

♦ Control IC IC specifically for the module (S1F8811) manufactured by Seiko Epson

♦ Driving block Switcing driver consisting of power MOSFET family.

♦ Overvoltage protection block Overvoltage protection circuit for input voltage using a

voltage monitoring circuit and transistor

♦ Power management block Generates VDD1 power supply for control IC and VP power

supply for driver.

S4E16400/S4E16401 Technical Manual EPSON 5

(Rev.1.1)

2. SPECIFICATIONS

P

i

y

bl

k

di

g

p

(

p

)

(

p

)

r

g

p

A

A

VDD1

tion

o

Start switch

SW+

VDD1

tion

o

ut

ram

a

LED out

UTO

SW-

VDD1

LED

LEDK

VREF

Thermistor (option)

oc

TDET

VP

VDD1

ement

Power mana

mar

r

8M

Primary controle

Control module

High voltage protection

VP

Power transfer block

ut

CSH

COIL-1

COIL-2 COIL-2

RTCOIL

VDD 5.2 to 5.6V

VSS

Power in

COIL-1

6 EPSON S4E16400/S4E16401 Technical Manual

CSH

RTCOIL

Coil unit

(Rev.1.1)

2. SPECIFICATIONS

2.2.3 Pin Description

Pin Description Table for Primary Coil Unit (4 pins Connector)

No. Pin Name Description

* RTC

1

2 SH A thermistor pin. Connect this with the CSH pin on the circuit module connector -2.

3 COIL-2 A coil connection pin. Connect this with the COIL-2 pin on the circuit module connector -2.

4 COIL-1 A coil connection pin. Connect this with the COIL-1 pin on the circuit module connector -1.

Pin Description Table for Primary Circuit Module

Connector - 1

No. Pin Name In/Out Description

1 VDD I Power pin

2 VSS I GND pin

Connector - 2

No. Pin Name Description

1 COIL-1 A coil connection pin. Connect this with the COIL-1 pin on the coil unit.

2 COIL-2 A coil connection pin. Connect this with the COIL-2 pin on the coil unit.

3 SH A thermistor pin. Connect this with the CSH pin on the coil unit.

* RTC

4

Pins for Soldering -1

No. Pin Name In/Out Description

1 VDD

2 VSS

3 SW+ I

4 SW- O

5 AUTO I When selecting SW mode, short between this pin and SW-.Leave this pin open for

6 LEDA

7 LEDK

8 VREF

9 TDET

A thermistor pin. Connect this with the RTCOIL pin on the circuit module connector -2.

A thermistor pin. Connect this with the RTCOIL pin on the coil unit.

-

-

-

-

-

-

Power pin

GND pin

When SW mode is selected, install a momentary switch between SW+ and

SW-.When auto-start mode is selected, leave these pins open.

auto-start mode.

For driving the LED used for displaying primary module status.

External thermistor can be added. Leave these pins open when no external

thermistor is used.

S4E16400/S4E16401 Technical Manual EPSON 7

(Rev.1.1)

2. SPECIFICATIONS

Pins for Soldering -2

No. Pin Name In/Out Description

1 TEST1

2 TEST2

3 TEST3

4 TEST4

5 TEST5

6 TEST6

Absolute Maximum Ratings

2.2.4

Item Symbol Standard Unit Remarks

Supply voltage VDD -0.3 to +7.0 V

Input current Iin Max. 800 mA

Input pin voltage Vin -0.3 to +7.0 V

Performance assurance

temperature

Operating humidity Hop Max. 90 %RH

Storage temperature Tst -20 to +60

Storage humidity Hst Max. 90 %RH

[Caution] Using with a condition exceeding the above absolute maximum rating may result in malfunction or

unrecoverable damage. Moreover, normal function may be achieved temporarily but its reliability

may be significantly low.

Electrical Characteristics

2.2.5

The following describes the electrical characteristics of the primary circuit module.

Item Symbol Conditions Min. Typ. Max. Unit

Supply voltage VDD 5.2 5.4 5.6 V

Input current Iin 700 mA

Standby power Pstb Excluding AC adapter 50 mW

Low input voltage

detection

Transmission frequency F1 During power transmission 121.21 kHz

Transmission frequency

Transmission frequency

[Caution] Do not use the product over the range of the power voltage or input current. The authentication

function and various detection functions may not properly operate and cause a functional failure.

[Caution] Only the coil unit specified by Epson must be connected for use. When using a coil unit or circuit

module other than specified, or using a modified coil unit or circuit module, safety and other

functions may not operate normally. Using such items results nonconformity of technical standards

related to the radio law.

-

-

-

-

-

-

Test pin. Leave this pin open.

Test pin. Leave this pin open.

Test pin. Leave this pin open.

Test pin. Leave this pin open.

Test pin. Leave this pin open.

Test pin. Leave this pin open.

Top -10 to +45

Vlow

F2

F3

For continuous 5 sec.

During authentication

(Approx. 500 msec)

During detection of a foreign

material (including a metal)

(Approx. 1 msec)

°C

°C

3.8 4.0 4.2 V

129.03 kHz

114 kHz

8 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

2. SPECIFICATIONS

Electrical Characteristics of Primary Coil Unit

Item Symbol Condition Min. Typ. Max. Unit

Inductance L1c 19.6 uH

Resistance R2c 203

Functional Description

2.2.6

The following describes the functions of the primary module.

Item Description

Detection of landing Monitors intermittently to check whether the secondary module is placed on the top

of the primary module.

Fig. 3 shows the timing of the landing detection.

Detection removal Detects removal of the secondary module from the primary module, and enters

standby status.

Authentication Reciprocal process of authentication between the primary module and secondary

module. The process ensures that the power transmission is permitted only between

the predefined combination. The authentication procedure will be defined

separately.

Detection of foreign metal

objects

Detection of foreign metal

objects

Monitors constantly to check whether any foreign metal object is inserted. If

detected, the module stops power transmission. However some metals objects may

not be detected depending on the method of embedding the module into chassis or

characteristics of the object. Therefore, this function is not assured to detect every

bit of the foreign objects. After the foreign metal object is removed, the module

resumes the initial state.

Detects the temperature of the center of coil, and when it becomes 70 °C or higher,

stops the power transmission. Power-on reset is required to resume the

transmission.

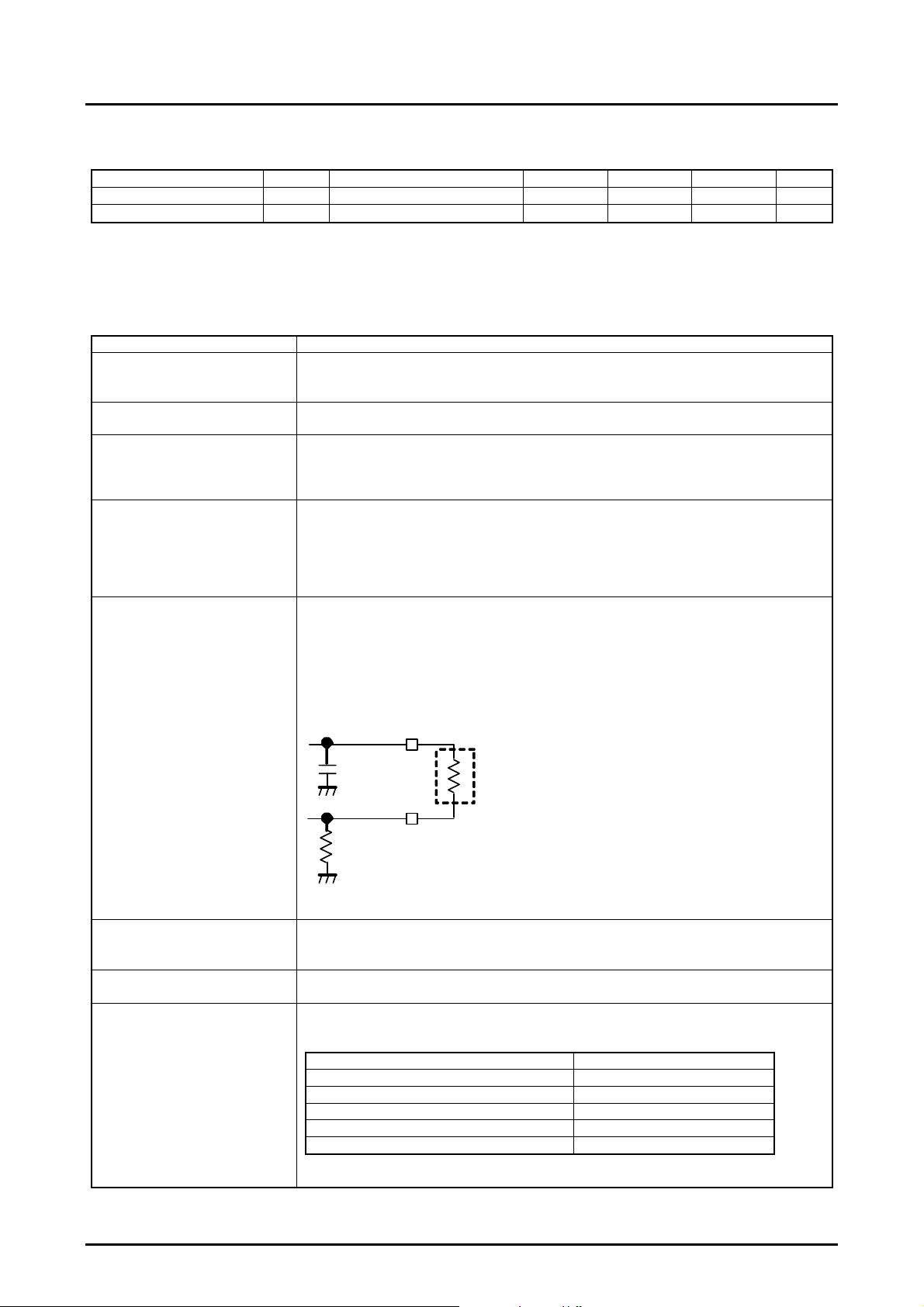

Installing thermistor between VREF and TDET as shown in the following diagram

enables you to detect temperature at any position.

Detected temperature: 60°C (absolute temperature, recommended component is

used)

VREF

mΩ

1000pF

TDET

RT

External

100KΩ

Recommended component

Murata Manufacturing NCP15WF104F03RC (100KΩ ±1%/4250K±1%)

Overvoltage protection Stops power supply to the subsequent overvoltage protection blocks immediately

when input voltage exceeds 6.2 ± 0.2V.When the input voltage returns to normal

level, the module resumes the initial state.

Detection of low voltage Stops power transmission when input voltage drops below 4.0 V during the

transmission. Power-on reset is required to resume the transmission.

Detection of low voltage Can display the state of primary module by connecting LED with the LEDA and

LEDK pins.

State LED

Standby Off

During power transmission On

Standby after fully charged Off

When detecting abnormal temperature Blinking

When detecting low voltage Blinking

S4E16400/S4E16401 Technical Manual EPSON 9

(Rev.1.1)

2. SPECIFICATIONS

線

2.2.7 Embedding Conditions

This section describes conditions required to embed the primary module.

To connect the primary coil unit and the primary circuit module, be sure to use the cable with specifications

shown in the following (1) or (2).

[Caution] If cables having different specifications are used, they may violate the technical standards related to

Transmission circuit drives

Transmission circuit stops

Driving time for detecting

landing 5ms

(1)

(2)

the radio law.

(Time)

Interval time

325ms

Fig.3 Landing Detection Timing

コネクタ:JST 社製 型番 SHR-04V-S

Connector: Model number SHR-04V-S manufactured by JST

:AWG#28

Line: AWG#28

50 ± 3mm

110 ± 3mm

Fig.4 Specification of Cable

10 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

2. SPECIFICATIONS

y

f

The following shows an example of embedding the primary coil unit.

2.8 ± 0.2mm (*1)

Primar

coil - Surface of cradle

(*1) Reference value. Will be

defined separately in view o

probable generalization and

compatibility.

Temperature

detection element

Magnet sheet

25 mm or more for metal

chassis

Primary coil

Fig.5 Section of Primary Module (Coil Unit)

x Material

Resin must be used for the material of chassis.

[Caution] In order to prevent the temperature detection element from being damaged by shock, consider

installing “escape” on a chassis or other solution when designing the chassis.

2.3 Specifications of Secondary Module

Overview of Specifications

2.3.1

This chapter describes the specifications of circuit on the secondary side that belongs to the noncontact power

transmission modules.

The main function of the circuit on the secondary side is to convert flux supplied from the primary module

into direct-current power and supply it to the charge control circuit.

The circuit also has the function of detecting fully charged state for the purpose of power saving, as well as

the recharging function.

Block Diagram

2.3.2

The block diagram of the circuit on the secondary side is shown in the next page. The secondary module

consists of (1) Coil unit and (2) Circuit module. The following explains each of the functional blocks.

(1) Primary coil unit

♦ Coil and magnet sheet for inducing electromagnetic field

(2) Secondary circuit module

♦ Control IC IC specifically for the module (S1F8820B) manufactured by Seiko Epson

♦ Rectification unit Rectification circuit

♦ Load modulation unit For transmit information to the primary side.

♦ Voltage control unit For regulating output voltage.

♦ Output control unit Output gate using power MOSFET.

S4E16400/S4E16401 Technical Manual EPSON 11

(Rev.1.1)

2. SPECIFICATIONS

AC adaptor input

Output Control

VDD

Charger circuit

VOUT+

Battery

Charger circuit

Secondary block diagram

VOUT-

ACIN(input)

Power output

LEDRI(input)

Full charge detector

AC adapter detect

VDD

Load reduce signal

ICUT (output)

VBAT (input)

Battery voltage detect

LED Indicator (N-ch Open drain)

LEDRI(output)

Rectifier Load modulation Voltage regulation

Secondary controller

Control module

COIL-1

COIL-2

COIL-1

COIL-2

Coil unit

12 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

2. SPECIFICATIONS

2.3.3 Pin Description

Pin Description Table for Secondary Coil Unit (Pins for Soldering)

No. Pin Name Description

1 COIL-2 A coil connection pin. Connect this with the COIL pin on the circuit module.

2 COIL-1 A coil connection pin. Connect this with the COIL pin on the circuit module.

Pin Description Table for Secondary Circuit Module (20 Pins Connector)

No. Pin Name In/Out Description

1,3 COIL1 I

2,4 COIL2 I

5,6,7,8 NC

9,10 VOUT+ O DC output (+)

11,12 VOUT- O DC output (-)

13 ACIN I

14 VBAT I

15 ICUT O A load reduction signal used for periodical authentication.

16 LEDRI I A full charge detection pin. Charging process is determined to be completed

17 TEST1 - Test pin. Connect this with VOUT-.

18 TEST2 - Test pin. Connect this with VOUT-.

19 LEDG O For outputting the state of the secondary module.

20 NC - A NC pin. Leave this pin open.

-

(*) For the coil connection pin, the coil connection land (2 positions) that supports soldering can be used in

addition to the 20 pins connector.

A coil connection pin. Connect this with the COIL pin on the coil unit.(*)

A coil connection pin. Connect this with the COIL pin on the coil unit.(*)

A NC pin. Leave this pin open.

An AC adapter detecting pin. Output from VOUT ± is stopped when AC adapter

is detected. Leave these pins open if the function of detecting AC adapter is not

used.

A battery voltage monitoring pin. Leave this pin open if the recharging function is

not used.

when H level state continues for 5 seconds, and the module enters full charge

standby state. Connect this pin with VOUT- if the function of detecting full

charge state is not used.

State Output

During power output L level (-10 mA max.)

During stop of power output Open

S4E16400/S4E16401 Technical Manual EPSON 13

(Rev.1.1)

2. SPECIFICATIONS

2.3.4 Absolute Maximum Ratings

Item Symbol Standard Unit Remarks

Input pin voltage Vin Vout - -0.3 to Vout + +0.3 V VBAT, LEDRI, ACIN

Performance assurance

temperature

Operating humidity Hop Max. 90 %RH

Storage temperature

Storage humidity Hst Max. 90 %RH

Top

Tst

[Caution] Using with a condition exceeding the above absolute maximum rating may result in malfunction or

unrecoverable damage. Moreover, normal function may be achieved temporarily but its reliability

may be significantly low.

Electrical Characteristics

2.3.5

The following describes the electrical characteristics of the secondary circuit module.

Item Symbol Conditions Min. Typ. Max. Unit

Output voltage Vout unloaded 4.9 5.2 5.5 V

Output voltage ripple Loaded with 100 mA 100 mV

Voltage detected by LEDRI VLEDRI 2.2 2.5 2.8 V

ICUT output current

Detected voltage by ACIN VACIN 4.0 4.1 4.2 V

Detected voltage by VBAT VVBAT 3.8 3.9 4.0 V

LEDG current ILEDG -6 mA

I

ICUTH

I

ICUTL

[Caution] Only the coil unit specified by Epson must be connected for use.

[Caution] Do not connect a load that drops Vout to 3V or less. Doing so may cause secondary circuit

module to reset.

Electrical Characteristics of Secondary Coil Unit

Item Symbol Conditions Min. Typ. Max. Unit

Inductance L2c 11.68 uH

Resistance R2c 196

-10 to 45

-40 to 80

With maximum load

ICUT=Vout-0.1V

High, V

ICUT=0.1V

Low, V

°C

°C

150 mV

0.2 mA

0.3 mA

mΩ

14 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

2. SPECIFICATIONS

Output Voltage - Current Characteristics

The following shows the characteristics of output voltage to output current. The characteristics vary greatly

depending on positional relation between coils on the primary side and the secondary side. If you consider a

design with large deviation, therefore, be sure to check whether the design can supply necessary power.

When you determine the location where the power greater than the 4.5V voltage and 400mA current can be

output, refer to Section 2.4.6 "Embedding Conditions".

Output V-I curve

6

5.5

5

4.5

4

3.5

3

2.5

2

Output voltage Vout(V)

1.5

1

0.5

0

0 100 200 300 400 500 600

(*)

upper

lower

Output current Iout(mA)

[Conditions] Input power : Vin=5.4V Iin≤680mA, Positional deviation: z=3.3 to 4.3mm / x=0.0 - 5.0mm

(*) Do not use in a Vout < 3.0V condition. Doing so may cause the control circuit on the secondary side to

reset.

Fig.6 Output Voltage and Current Characteristics

Functional Description

2.3.6

This section describes functions of circuit on the secondary side.

Item Description

Stops power supply to the charge control circuit by turning the LEDRI pin L ≥ H

Detection of fully charged state

Recharge function

Detection of AC adapter

Authentication

when fully charged state stops the charging process, and transmits the power save

mode command to the primary module. Connect the LEDRI pin with VOUT- if this

function is not used.

Starts recharging process if the battery voltage becomes recharge voltage (3.9 ±

0.1V) or less when the module enters power save mode due to fully charged state.

If this function is not used, leave the VBAT pin open.

Prioritizes AC adapter to supply power to the charge control circuit if the power is

currently supplied direct from the AC adapter. If this function is not used, leave the

VBAT pin open.

Reciprocal process of authentication between the primary module and secondary

module. The process ensures that the power transmission is permitted only

between the predefined combination. The authentication procedure will be defined

separately.

S4E16400/S4E16401 Technical Manual EPSON 15

(Rev.1.1)

2. SPECIFICATIONS

2.3.7 External Connection Examples (Reference)

Example of Application to Charging Circuit

[Caution] Circuit examples described above show connection examples for peripheral circuits of this product

and do not guarantee charging operation. Make a full evaluation on the actual application to select

parts. When you charge the battery, secure the service range and conditions recommended by the

battery manufacturer by detecting the battery condition (voltage, current, temperature) outside the

battery and build in protective circuits and control devices that operate when they detect a problem

to assure safety.

Embedding Conditions

2.3.8

This section describes examples of embedding the secondary module.

This product is designed on the premise of a metal shield being placed on the top of the secondary coil

unit.Place an aluminum, copper or another metal sheet with the size of approx. 35 × 35 mm on a position 0 to 5

mm away from the surface of the secondary coil unit. If the metal shield and the battery pack are not mounted,

the accuracy of the foreign metal detection function drops. Also, if a metallic housing or another metallic or

magnetic part is placed in the non-metal area of Figure 8, the leaked flux is absorbed by those metals and the

authentication range may become smaller. If the leaked flux is absorbed by the metal, the input current to the

primary module increases. Therefore, you can determine whether the leaked flux is absorbed by the metal or not

by simply measuring an increase of input current to the primary module without connecting the secondary

module to a load. The following shows the permissible value of increased input current to the primary module

that does not affect on the authentication range.

You can also check the authentication range using the special jig.

Permissible value of increased input current to the primary module caused by shield and other metal (*): 5 15mA

(Vertical distance from the primary coil: 4.0 mm)

(Vertical distance from the primary coil: 0.0mm)

16 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

2. SPECIFICATIONS

A

The following describes checking procedure when the top of the secondary coil unit is in situation (1) - (4) as

shown below.

(1) No metal, (2) Battery pack, (3) Circuit board, (4) Metal or magnetic component

(1) When no metal is placed on the secondary coil unit

OK

(2) When a battery pack is placed on the secondary coil unit.

OK

Measure input current I1 to the primary module at

the (X, Z) = (0, 4) position and without any load

Measure input current I2 after affixing a 35 × 35

(mm) aluminum sheet to the secondary coil unit.

Yes

Adjust the aluminum sheet, and affix it to the

secondary coil unit then measure input current I2.

Measure input current I1 to the primary module at

the (X, Z) = (0, 4) position and without any load.

Place the battery pack at the same distance of an actual

equipment from the secondary coil unit, and measure

input current I2.

Yes

djust the position of the battery pack, and

measure input current: I2.

5≤I2-I1≤15mA?

No

5≤I2-I1≤15mA?

No

S4E16400/S4E16401 Technical Manual EPSON 17

(Rev.1.1)

2. SPECIFICATIONS

A

A

A

c

t

(3) When a circuit board is placed on the secondary coil unit.

OK

(4) When metal or magnetic component is placed on the secondary coil unit.

Measure input current I1 to the primary module at the (X,

Z) = (0, 4) position and without any load

ffix an A x A (mm) aluminum sheet to the secondary coil unit, and place

the circuit board at the same distance of an actual equipment from the

secondary coil unit, and then measure input current I2.

Yes

djust the aluminum sheet, and affix it to the secondary

coil unit then measure input current I2.

(Measure input current I1 to the primary module at

the (X, Z) = (0, 4) position and without any load.

Place the metal or magnetic component at the same distance of an

actual equipment from the secondary coil unit, and measure inpu

current I2.

OK

Yes

component, and measure input current: I2.

5≤I2-I1≤15mA?

No

5≤I2-I1≤15mA?

No

djust the position and size of the metal or magneti

18 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

2. SPECIFICATIONS

The secondary coil unit and the secondary circuit module must be connected using a 50 to 200-mm long wire

lead or conductive pattern.

0 - 5mm

Secondary coil - Surface of cradle

Satisfies requirements in overall

specifications described in section 2.4.5

Fig.7 Section of Secondary Module (Coil Unit)

x Material

Resin must be used for the material of chassis.

Secondary coil unit

Metal shield

25mm

Primary coil unit

68mm

Metal-free area

Fig.8 Metal-Free Area

[Caution] The description in Section 2.3.8 may be subject to change.(The specification is not final.)

Metal shield

Magnet sheet

Secondary coil

S4E16400/S4E16401 Technical Manual EPSON 19

(Rev.1.1)

2. SPECIFICATIONS

2.4 Overall Specifications

Overview of Specifications

2.4.1

This chapter describes the overall specifications of the primary module (a module on the primary side) and

the secondary module (a module on the secondary side), consisting of the noncontact power transmission

modules.

The primary module drives intermittently while in standby state to keep detecting the landing of the

secondary module. If the primary module detects the secondary module, they execute reciprocal authentication

to ensure that they are the predefined combination permitted for the power transmission. If they pass the

authentication process, then the transmission can begin.

When the secondary module detects the fully charges state, it communicates with the primary module to enter

save mode, and shifts itself to save mode. If the secondary module maintains the landing state, the secondary

module detects that the battery voltage drops below the voltage defined to start recharging, and transmits the

information to the primary module to start recharging. If the recharging function is not used, the secondary

module continues to wait for the detection of removal.

During charging process, the secondary module reduces load periodically, and the primary module checks

whether the eddy-current loss occurs on the secondary side, caused by foreign metal objects. If any foreign

metal object is detected, the primary module stops power transmission.

Functional Description

2.4.2

The following describes the functions available when the primary module and the secondary module are

combined.

Item Description

Authentication Reciprocal process of authentication between the primary module and secondary

module. The process ensures that the power transmission is permitted only between

the predefined combination. The authentication procedure will be defined separately.

Transmission monitoring Monitors constantly to check whether any foreign metal object is inserted. If detected,

the power transmission is stopped. For this purpose, the secondary module reduces

load periodically, and the primary module checks whether the eddy-current loss occurs

on the secondary side, caused by foreign metal objects. However some metals objects

may not be detected depending on the method of embedding the module into chassis or

characteristics of the object. Therefore, this function is not assured to detect every bit of

the foreign objects.

Transmission monitoring

2.4.3

The noncontact power transmission module uses the following detection method assuming that metal objects

may erroneously be inserted into transmitter area during transmission. The secondary module enters unloaded

state at the timing shown in the following diagram, and flows load modulation current for a certain period of

time. The primary module monitors that load is changed between low and high state periodically. For example,

the primary module determines the eddy-current caused by foreign metal objects by detecting in low state the

higher load than standard value. When the primary module detects a foreign object, it stops transmission and

enters standby state.

The output current from the secondary module must be synchronized with the output from the ICUT pin of

secondary control IC (see the secondary circuit block diagram), and it must be above 5mA (inclusive) but below

40 mA (inclusive) in the low load state.

20 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

2. SPECIFICATIONS

Load reduction

signal

(ICUT)

Load reduction

signal

(ICUT)

Load current

Load modulation

H

L

Low load time

416clk(3.43mS)

H

L

Normal load

5mA to 40mA

ON

OFF

Normal load time

151512clk(1250mS)

16clk(132µS)

200clk(1.65mS)

Fig.9 Transmission Monitoring Timing

(Time)

Normal load time

151512clk(1250mS)

Transmission frequency:121.21KHz

S4E16400/S4E16401 Technical Manual EPSON 21

(Rev.1.1)

2. SPECIFICATIONS

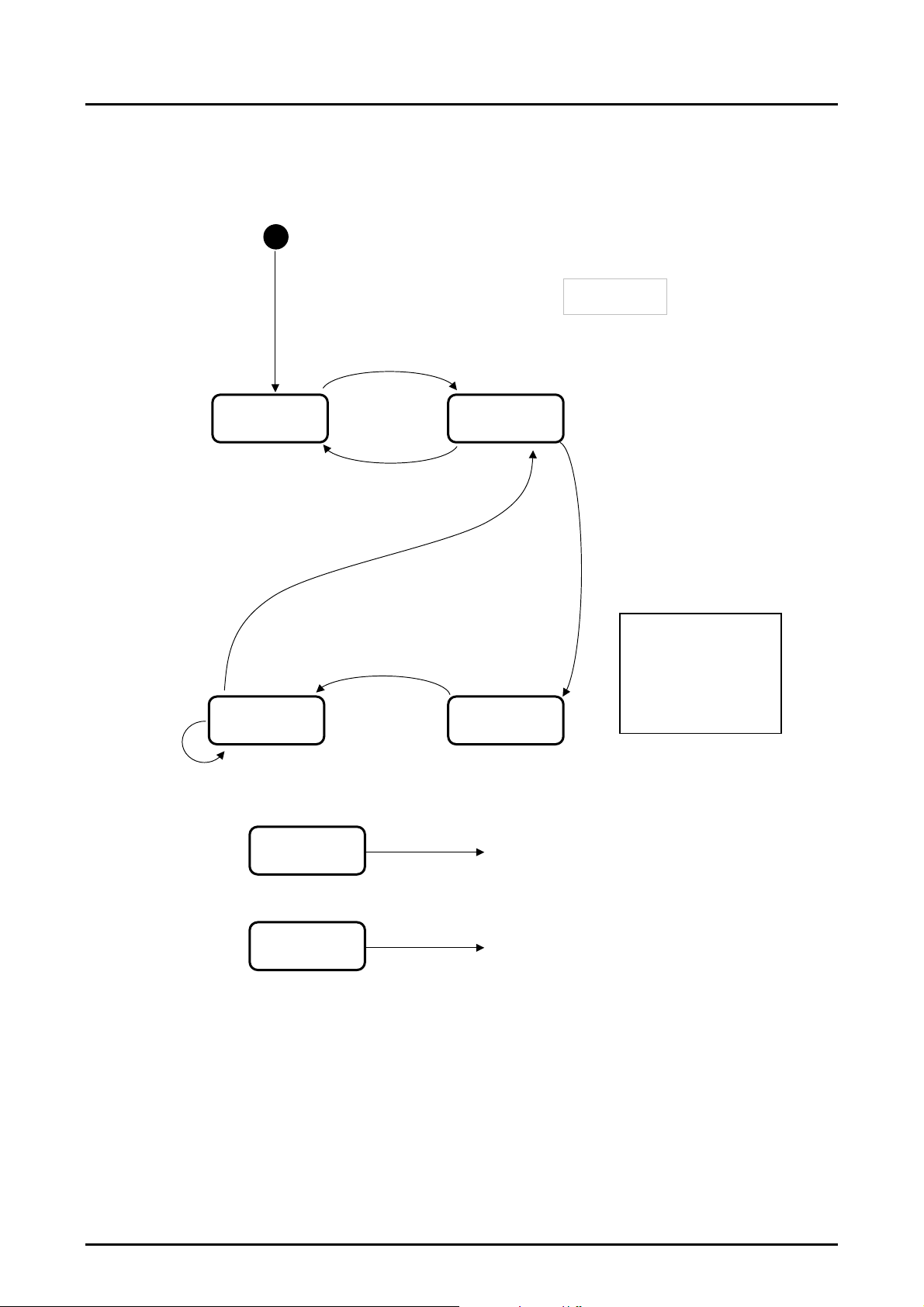

2.4.4 Sequence

This section describes the operations sequence of the noncontact power transmission modules.

However, ID code system will be defined separately because it will include items that should be handled as

confidential.

The following state transition diagrams show the sequence of the primary module and of the secondary

module.

22 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

2. SPECIFICATIONS

A

A

E:Timer 300 mS approx.

A:Transmits power 5 mS (detects landing)

E:ID code NG

Detects foreign object

:Stops transmission

E:Timeout

A:Stops transmission

E:Receives VBAT response command

(Vbat =< recharge voltage)

A:Stops transmission

Clears SAVE_f

E:Receives VBAT response

command

(Vbat > recharge voltage)

A:Stops transmission

E:No removal x 64

E:Timer 5 s

A:Transmits power 40 mS

(detects removal)

(1)p Standby state

(2)p Negotiation

state

(3) p Setup state

E:Receives start command (SAVE_f=1)

A:Sends VBAT command

(6)p Fully charged

standby

state

Any state error

(4) p "Determine

command" state

E:Receives save command

A:(LED is OFF)

Stops transmission monitoring

Stops removal detection

Stops transmission

Sets SAVE_f

E:Abnormal temperature/A:Stops transmission

Fig.10 Primary Module

E:Power-ON

A:System reset

Clears all flags

E:Detects landing

A:Starts serial transmission

E:Receives secondary ID code

A:Sends primary ID code

E:Receives setup command

A:Sends setup command (result)

(5)p Power

transmission state

End

E:Event

A:Action

E:Receives start command (SAVE_f=0)

A:Sends start charging command

E:Receives response to start charging command

A:(LED is ON)

Starts transmission monitoring

Starts removal detection

Starts charging transmission

E:Detects foreign object

:(LED is OFF)

Stops start transmission

Stops removal detection

Stops transmission

S4E16400/S4E16401 Technical Manual EPSON 23

(Rev.1.1)

2. SPECIFICATIONS

E: Timeout

A:

E: Timer 1 s

A: Sends save command

E: Timeout

A:

(5) s “Determine

recharge” state

(7) s Fully charged

state

Any state

Fig.11 Secondary Module

Initialization

Clears all flags

(1) s Standby state

(2) s ID exchange

state

(3)s Setup state

E: Receives VBAT command

A: Measures VBAT

Sends VBAT response command

E: Fully charged (LEDRI)

A: Stops transmission monitoring

Closes output gate

Sends save command

E: Detects AC adapter

A: Closes output gate

Sets AC_f

E: Voltage level OK

A: Sends secondary ID code

E: Receives primary ID code

A: Sends setup command

E: Receives setup command

(result)

A: Sends start command

(4) s “Determine

command” state

(6) s Power

transmission state

(1)To: s Standby state

E: Timer 30 mS

A: Opens output gate

Starts detecting full

charge

E: Receives start charging command

A: Sends response to start charging

command

Starts transmission monitoring

24 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

2. SPECIFICATIONS

Safety against Foreign Metal Objects

2.4.5

As this system uses electromagnetic induction for power transmission, metal placed on the primary coil may

generate heat due to induction heating. The following design is incorporated into the modules against heat

generation of metal.

<Before ID authentication>

If a foreign metal object placed before authentication is detected, the system does not execute authentication

process and does not start power transmission.

<After ID authentication>

If a foreign metal object inserted after the authentication and during power transmission is detected by the

primary side, the system stops transmission and execute authentication process again. A metal object with

material and size that cannot be detected before and after the authentication must not rise its temperature higher

than 55 deg C under room temperature (25°C).

[Caution] The detecting ability may vary depending on the condition that the module is built on the product.

Make a full evaluation on it and check that there is nothing inconvenient before using. If it doesn’t

properly detect foreign matters, they may generate heat due to induction heating and reach

dangerous temperature.

[Caution] The detecting ability is not assured to detect all heat generating metals. Add safety circuits if

necessary and secure safety before using.

S4E16400/S4E16401 Technical Manual EPSON 25

(Rev.1.1)

2. SPECIFICATIONS

2.4.6 Embedding Conditions

Output voltage on the secondary side depends on the position of primary coil unit and secondary coil unit.

Therefore the following defines the horizontal distance (X) and the vertical distance (Z) of the center of each

coil. Consider the following positional relation when you design a chassis for your product into which the coil

unit is embedded.

Item Recommended Value Allowable value

Transmission distance (vertical distance) 4.0mm See Figure 12.

Deviation of the center of coil (to horizontal) 0.0mm See Figure 12.

Distance between coils:Z(mm)

6.0

(X,Z)

5.0

(5.0,4.3)

4.0

(5.0,4.3)

(5.0,3.3)

7.0 1.0 2.0 3.0

6.0 0.0

5.0

4.0

3.0

2.0

1.0

1.02.03.0

Allowable range for authentication

and 4.5 V/400 mA output

4.0

(5.0,3.3)

5.0 6.0 7.0

Deviation of Center of Coil: Z (mm)

Fig.12 Allowable Range for Authentication and 4.5 V/400 mA Output

(Deviation of position between the primary coil unit and secondary coil unit.)

[Caution] The value shown above may vary depending on the condition that the module is built on the

product. Make a full evaluation on it and check that there is nothing inconvenient before using

26 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

2. SPECIFICATIONS

f

t

Secondary coil uni

3.3 – 4.3mm

2.8mm is

recommended

Primary coil unit

Fig.13 Section of Primary Coil Unit and Secondary Coil Unit

[Caution] The description in Section 2.4.5 may be subject to change.(The specification is not final.)

5mm max.

Deviation of the center o

coil

S4E16400/S4E16401 Technical Manual EPSON 27

(Rev.1.1)

3. EXTERNAL DIMENSIONS

3. EXTERNAL DIMENSIONS

The following diagrams are attached to this document.

♦ Module on the primary side S4E164000010000 Product diagram

28 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

3. EXTERNAL DIMENSIONS

♦ Module on the secondary side S4E164010010000 Product diagram

S4E16400/S4E16401 Technical Manual EPSON 29

(Rev.1.1)

4. PRECAUTIONS

4. PRECAUTIONS

4.1 General precautions

♦ This product is designed and manufactured for general consumer use and is not designed for an

application for any life-support or other devices that require a very high degree of reliability. We are

not responsible for any results caused by the use of this product or those devices for such application.

♦ The content of this document is subject to change without prior notice.

♦ Neither a part or the whole of this document may be transferred, reproduced, or used for any other

purpose without our permission

♦ Application circuits, programs and usage contained in this document are reference information. We do

not provide any guarantee on the right (including intellectual property right and know-how, hereafter

intellectual property) of a third party infringement or generation of damage. This document may not

be construed as granting anyone a license of the intellectual property right of us or any other third

parties.

♦ Characteristics, large and small, indicate magnitude relationships on the number line.

♦ Of the products referred to in this document, the export of those falling under the strategic material

category stipulated in the Foreign Exchange and Foreign Trade Control Law shall require the granting

of an export license according to said law.

♦ The warranty period of this product is one year after shipment of the product. Though we shall be

responsible for replacing the product due to a trouble within the scope of this specification, we shall

not be liable for other damages. We do not guarantee products for which 1 year has passed since the

shipment.

4.2 Precautions on Handling

♦ Provide full safety measures to the system and devices using this product.

♦ Metal placed on the primary coil may generate heat due to induction heating. We recommend that you

describe the following points in the instruction manual and the finished product case.

( Do not place other products than the specified secondary products on the primary side. They

♦ Do not allow input exceeding the maximum rating and DC characteristics. It can cause troubles of

♦ Some adapters may generate a noise. In this case, install a ferrite core to prevent it.

♦ As transmission characteristics of a noncontact power transmission module changes due to the usage

♦ If you find a trouble such as smoke, abnormal smell and overheating during operation (charging) and

♦ Be careful of the following when you install a module.

may cause heat and a trouble.

( Do not place metal such as coins and clips on the primary product (charger) when they are

live and on standby as they are in danger of generating heat.

various detecting functions including generation of overheat and detection of foreign matters,

authentication function and permanent damage. We recommend that you describe the following points

in the instruction manual and the finished product case.

( Manufacturer providing built-in finished products) Use the specified AC adapter.

( Using other ones than is specified can cause heat, smoke and a trouble.

Example of taking measures: Ferrite core Kitagawa Kogyo RFC-8 3 turns Mounting location: Near the

module

environment (size of the housing, material, phase position of the primary and secondary coils,

environment with metal parts) of this module, we cannot guarantee operation in all usage environments.

Check the operating condition and safety in the actual usage environment. Add protective circuits and

redundant circuits in necessary and secure safety before using.

standby, stop using it immediately.

¾ Install a module properly to the case device, jigs and tools in order not to add stress such as

30 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

4. PRECAUTIONS

warpage and distortion. Generation of deformation, flaking and damage may cause a functional

trouble and imperfect condition.

¾ Be careful not to rub the coil with a sharp edge and damage it by rubbing it. Damage on the

insulating coating may cause a functional trouble and imperfect condition.

¾ Make a full evaluation on physical stress including deformation and shock with your product

before using.

¾ Design the layout so that the product may not be exposed to liquid leakage when you install this

module.

¾ Each module has a part where wiring is exposed such as a coil terminal. So take full care against

short-circuit to other parts or leak when you handle the unit.

¾ Be careful so that conductive material such as metal fragments may not enter and interfere with

the circuit area of this product. They may cause malfunction and damage.

¾ Water entered into this product can cause malfunction of instruments and damage. We do not

guarantee operation if condensation is caused.

¾ As this module may cause flaking, floating and lysis due to organic solvent, be careful enough to

wipe it using organic solvent.

¾ Use the material that desn’t generate high-voltage leak for the equipment, tools and workers and

make a ground when you assemble this module.

¾ We recommend that you assemble the module in the environment that is not directly exposed to

dust, corrosive gas, direct sunlight and strong ultraviolet where the temperature and humidity is

apprpriate.

♦ Do not use the product under the following environment.

¾ The place where corrosive gas is generated

¾ The place where strong eadio wave and magnetic force are generatedOutput characteristic, ID

authentication and various sensor functions may not properly operate

¾ The environment where strong shock and vibration are produced

¾ Do not put this product in a microwave and on an electromagnetic cooking device. It may cause

heat, smoke and a fire.

♦ Be careful of the following as this product emits radio wave.

¾ If you find this product causing radio wave interference with other wireless devices, use it apart

from them or turn off the power on the primary side to prevent radio wave interference.

¾ Do not place a magnetic cared near the product and have it caught by it. Magnetic data may be

lost.

¾ Turn off the power on the primary side near a electronic device that handles high control and faint

signals. Electronic devices amy malfunction. Check the effect by the radio wave interference

when you use the product for those device or use it near them.

Example ・・・Heart pacemaker, audiophone, fire alarm, automatic door and other

electro-medical apparatus

¾ Do not use the product in a medical institution and a aircraft. Turn off the power on the primary

side and abstain from the use of the product in a place where use of wireless devices is generally

restricted.

4.3 Precautions on radio laws and regulations

This product (module) is scheduled to support the following standards related to the radio law. If you

disassemble and modify this product, you may receive punishment based on nonconformity of standard of each

country. Never modify the product. Contact our sales division for the latest standard support status.

¾ Japan: Radio law enforcement regulations Article 100 paragraph one number one and Article 44

paragraph two (1)

¾ United States:.FCC Part 15 Subpart C

¾ Europe: (R&TTE member nations): EN300330-1V1.3.1 and –2 V1.3.1(Receiver class 3, Product

class 1, Duty class 4)

¾ Taiwan: Administrative Regulations on Low Power Radio Waves Radiated Devices

♦ Please handle this product or bult-in products according to regulations of the country to which you

export or put them on sale.

♦ Take note that you may need to take various procedures due to regulations for exporting and sales to

other countries than is specified.

S4E16400/S4E16401 Technical Manual EPSON 31

(Rev.1.1)

5. SATISFIED LAWS AND REGULATIONS

t

d

5. SATISFIED LAWS AND REGULATIONS

5.1 Japan

This product is compliant with the Radio law enforcement regulations article 100 paragraph one number one

and article 44 paragraph two (1). We recommend that you clearly specify describe notes on the following points

in the instruction manual of built-in products.

x This product is compliant with the Radio law enforcement regulations article 100 paragraph one

number one and article 44 paragraph two (1).

As this product is designed based on domestic regulations, use it only in Japan.

x

x

If you disassemble and modify this product, you may receive punishment based on

nonconformity of the Radio law enforcement regulations. Never modify the product.

( If you find this product causing radio wave interference with other wireless devices, use i

apart from them or turn off the power on the primary side to prevent radio wave

interference.

( Make an inquiry on the use of the product to the contact described below.

Carrier wave frequency 121.2kHz

Contact: To the company name providing the finishe

5.2 The United States of America

This product is compliant with the following standard.

Intentional radiation device standard FCCpart15 Subpart C

FCC ID: BKMDGE001

Attach the label showing the following contents to the built-in product.

“Contains Transmitter Module FCC ID: BKMDGE001” or “Contains FCC ID: BKMDGE001”

Precautions

FCC WARNING

Changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

This transmitter must not be co-located or operated in conjunction with any other antenna or transmitter.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

5.3 Europe (R&TTE member nations)

This product is compliant with the following standard.

Wireless device technical standard: EN300330-1 V1.3.1 and EN300330-2 V1.3.1

Receiver class 3

Product class 1

Duty class 4

R&TTE member nations (As of February, 2008)

Austria, Belgiumj, Bulgaria, Cyprus, Czech, Denmark, Estonia, Finland, France, Germany, Greece, Hungary,

Iceland, Italy, Lichtenstein, Lithuania, Latvia, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,

Slovakia, Slovenia, Spain, England, Rumania

32 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

6. EXPORTING

科學及醫療用電波輻射性電機設備之干

5.4 Taiwan

This product (or module) is compliant with the “Administrative Regulations on Low Power Radio Waves

Radiated Devices” and “Low-power Radio-frequency Devices Technical Regulations (LP0002)”.

The following device handling instructions shall be followed.

Article 12. Without permission granted by the DGT, any company, enterprise, or user is not allowed to

change frequency, enhance transmitting power or alter original characteristic as well as performance to a

approved low power radio-frequency devices.

Article 14. The low power radio-frequency devices shall not influence aircraft security and interfere legal

communications; if found, the user shall cease operating immediately until no interference is achieved. The said

legal communications means radio communications is operated in compliance with the Telecommunications Act.

The low power radio-frequency devices must be susceptivle with the interference from legal communications or

ISM radio wave radiated devices.

We recommend that you clearly specify describe notes on the following points in the instruction manual of

built-in products.

Permission No.

低功率電波輻射性電機管理辦法

第十二條

第十四條

經型式認證合格之低功率射頻電機、非經許可、公司、商號或使用者均不得擅自

變更頻率、加大功率或變更原設計之特性及功能。

低功率射頻電機之使用不得影響飛航安全及干擾合法通信;經發現有干擾現象

時、應立即停用,並改善至無干擾時方得繼續使用。

前項合法通信、指依電信法規定作業之無線電通信。

低功率射頻電機須忍受合法通信或工業、

擾。

Example of the sentense:

CCAB08LPxxxOTY

6. EXPORTING

6.1 Notes on Exporting to US

The primary and built-in products of this product (module) fall under the category of intentional and

unintentional radiation devices regulated in US.Check that the product is compliant with the following

standards before exporting it for the sale in US.

♦ Required approval As of February, 2008

Finished devices embedded with this product require approval from FCC authorities concerned as

intentional and unintentional radiation devices. You need to have an official authentication authority

certify that the product conforms to the following standard to get a license.

(1) Intentional radiation device standard FCCpart15 Subpart C

(2) Unintentional radiation device standard FCCpart15 Subpart B

(3) Product Safety Standard UL standard (varies depending on the device)

Since this product has already acquired the certificate of conformance of (1), you do not need to aquire a new

certificate of conformance of (1) for finished goods containing this product (except for the case where a

technology to which the Intentional radiation device standard applies). You need to clearly describe notes on (1)

in the specified method on the finished goods or in the instruction manual.

S4E16400/S4E16401 Technical Manual EPSON 33

(Rev.1.1)

6. EXPORTING

r

FCC WARNING

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

This transmitter must not be co-located or operated in conjunction with any other antenna o

transmitter.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

Also, attach the label showing the following contents to the finished goods.

“Contains Transmitter Module FCC ID: BKMDGE001” or

“Contains FCC ID: BKMDGE001”

If you use a module for which certificate of conformance of (1) has been acquired by us, and you need the

certificate conformance, please contact with us accordingly.

Customers who sell finished goods need to acquire certificate of conformance as finished built-in goods for

(2) to (3). The information to be provided on the finished goods or in the instruction manual must follow the

applicable standards and regulations.

♦ (Unauthorized export) Regulations as of February, 2008

You can export up to 200pcs per model with the Form740 document (have it prepared by a US

importer and present it according to a request by an inspecter to pass customs) to export the product

for evaluation and exhibition. You need to acquire FCC ID to prepare Form740.

Post a notice to show that this product is not in conformity to the standard (example shown below) to

introduce and evaluate the product in public places such as an exhibition. You may need to make a

special application by the guidance of the regulating authority. Observe the guidance of the authority

in that case.

You may not export the product for the purpose of putting it on sale in US.

This device has not been authorized as required by the rules of the Federal Communications

Commission. This device is not, and may not be, offered for sale or lease, or sold or leased,

until authorization is obtained.

6.2 Notes on exporting to R&TTE member nations

The primary and built-in products of this product fall under the category of wireless devices regulated in

R&TTE member nations. Check that the product is compliamt with the following standards before exporting it.

♦ Required approval As of February, 2008

You can sell finished devices embedding this product as electric equipment with a wireless function

provided that you have acquired a CE mark.

You need to have an official authentication authority certify that the finished devices conform to the

following standard to get a CE mark.

(1) Wireless device technical standard EN300330-1 V1.3.1 and EN300330-2 V1.3.1

(2) Wireless device EMC standard EN301489-1 V1.6.1 and EN301489-3 V1.4.1

(3) Product safety standard (Example) EN60950-1 (appropriate standard selection by

application)

(4) Electric product leakage magnetic field standard EN50366 : 2003 version

(5) Home electric equipment EMC standard EN55014

(1) to (5) are standards required to acquire a CE mark as wireless devices or electric equipment with a

wireless function.

(1) The certificate of conformance of (1) is scheduled to be acquired by this product (module).

Customers who sell finished goods need to acquire certificate of conformance as finished built-in

goods for (2) to (5)

34 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

6. EXPORTING

You do not need to aquire a new certificate of conformance of (1) for finished goods embedded with a

module for which certificate of conformance of (1) has been acquired. As the certificate of conformance of (1)

(such as the test report, technical documents, and other documents required to acquire the certificate of

conformance of customer's products) is required for application of CR markings, consult us for details.

You can use products compliant with all standards described above outside a car. Do not use it in a car. You

need to acquire an additional standard (ISO7637-1 and ISO7637-2) if you are supposed to use it in a car.

♦ Export before acquiring a CE mark As of February, 2008

You may not use the product to put it on the market in R&TTE member countries. Include

precautionary notes describing the following points and give users a guidance in advance before

exporting the product. Post a notice to show that this product is not in conformity to the standard in an

exhibition. You may need to make a provisional application by the guidance of the regulating

authority. Observe the guidance of the authority in that case.

This equipment falls under the category of wireless equipment. You may import the equipment for

experiment, research or display in an exhibition and may not use it for sales.

Example of the sentense:

This device has not been authorized as required by the rules of the Federal Communications

Commission. This device is not, and may not be, offered for sale or lease, or sold or leased,

until authorization is obtained.

♦ Export after acquiring a CE mark As of February, 2008

The following markings are required on the equipment.

Manufacturer Manufacturer name of the equipment for which a CE mark has been acquired

Trademark Trademark of the equipment for which a CE mark has been acquired

Equipment name Name of the equipment for which a CE mark has been acquired

Clear indication of the receiver class It is class 3.

For subassemble shipment, markings described above on the package can be alternative.

You can export the product to put in on the market in R&TTE member countries. The product need to be

compliant with the regulation in the final demand country (the country in which the product is sold) if you

export the product to a third country via the member country.

As other UE nations than R&TTE member nations have their own regulations, you need to check if the

product conforms to the regulation per country.

6.3 Notes concerning export to Taiwan

This product (or module) is controlled by the “Administrative Regulations on Low Power Radio Waves

Radiated Devices” and “Low-power Radio-frequency Devices Technical Regulations (LP0002)”. Check that the

product is compliant with these standards before exporting it for the sale in Taiwan. For details, consult with the

Taiwan authority.

The following device handling instructions shall be followed.

Article 12. Without permission granted by the DGT, any company, enterprise, or user is not allowed to

change frequency, enhance transmitting power or alter original characteristic as well as performance to a

approved low power radio-frequency devices.

Article 14. The low power radio-frequency devices shall not influence aircraft security and interfere legal

communications; if found, the user shall cease operating immediately until no interference is achieved. The said

legal communications means radio communications is operated in compliance with the Telecommunications

Act. The low power radio-frequency devices must be susceptivle with the interference from legal

communications or ISM radio wave radiated devices.

We recommend that you clearly specify describe notes on the following points in the instruction manual of

built-in products.

S4E16400/S4E16401 Technical Manual EPSON 35

(Rev.1.1)

6. EXPORTING

科學及醫療用電波輻射性電機設備之干

低功率電波輻射性電機管理辦法

第十二條

第十四條

經型式認證合格之低功率射頻電機、非經許可、公司、商號或使用者均不得擅自

變更頻率、加大功率或變更原設計之特性及功能。

低功率射頻電機之使用不得影響飛航安全及干擾合法通信;經發現有干擾現象

時、應立即停用,並改善至無干擾時方得繼續使用。

前項合法通信、指依電信法規定作業之無線電通信。

低功率射頻電機須忍受合法通信或工業、

擾。

Example of the sentense:

36 EPSON S4E16400/S4E16401 Technical Manual

(Rev.1.1)

REVISION HISTORY

Date Page Esstab./Rev. Description

2008/05/27 Full page New

2008/08/05 All Revised Major modification

REVISION HISTORY

S4E16400/S4E16401 Technical Manual EPSON 37

(Rev.1.1)

International Sales Operations

AMERICA

EPSON ELECTRONICS AMERICA, INC.

HEADQUARTERS

2580 Orchard Parkway

San Jose , CA 95131,USA

Phone: +1-800-228-3964 FAX: +1-408-922-0238

SALES OFFICES

Northeast

301 Edgewater Place, Suite 210

Wakefield, MA 01880, U.S.A.

Phone: +1-800-922-7667 FAX: +1-781-246-5443

EUROPE

EPSON EUROPE ELECTRONICS GmbH

HEADQUARTERS

Riesstrasse 15 Muenchen Bayern,

80992 GERMANY

Phone: +49-89-14005-0 FAX: +49-89-14005-110

ASIA

EPSON (CHINA) CO., LTD.

7F, Jinbao Bldg.,No.89 Jinbao St.,

Dongcheng District,

Beijing 100005, China

Phone: +86-10-6410-6655 FAX: +86-10-6410-7320

SHANGHAI BRANCH

7F, Block B, Hi-Tech Bldg., 900, Yishan Road,

Shanghai 200233, CHINA

Phone: +86-21-5423-5522 FAX: +86-21-5423-5512

EPSON HONG KONG LTD.

20/F., Harbour Centre, 25 Harbour Road

Wanchai, Hong Kong

Phone: +852-2585-4600 FAX: +852-2827-4346

Telex: 65542 EPSCO HX

EPSON (CHINA) CO., LTD.

SHENZHEN BRANCH

12/F, Dawning Mansion, Keji South 12th Road,

Hi- Tech Park, Shenzhen

Phone: +86-755-2699-3828 FAX: +86-755-2699-3838

EPSON TAIWAN TECHNOLOGY & TRADING LTD.

14F, No. 7, Song Ren Road,

Taipei 110

Phone: +886-2-8786-6688 FAX: +886-2-8786-6660

EPSON SINGAPORE PTE., LTD.

1 HarbourFront Place,

#03-02 HarbourFront Tower One, Singapore 098633

Phone: +65-6586-5500 FAX: +65-6271-3182

SEIKO EPSON CORPORATION

KOREA OFFICE

50F, KLI 63 Bldg., 60 Yoido-dong

Youngdeungpo-Ku, Seoul, 150-763, KOREA

Phone: +82-2-784-6027 FAX: +82-2-767-3677

GUMI OFFICE

2F, Grand B/D, 457-4 Songjeong-dong,

Gumi-City, KOREA

Phone: +82-54-454-6027 FAX: +82-54-454-6093

SEIKO EPSON CORPORATION

SEMICONDUCTOR OPERATIONS DIVISION

IC Sales Dept.

IC International Sales Group

421-8, Hino, Hino-shi, Tokyo 191-8501, JAPAN

Phone: +81-42-587-5814 FAX: +81-42-587-5117

Document Code: 411529401

Revised August 2008 in JAPAN

First Issue June 2008

Loading...

Loading...