Page 1

Operating

Instructiona

*

*********

* T H - 2 B

* *

* T H - 6 B *

* • *

* T H - 7 B *

* *

* T H - 8 B *

*************

• *

SEIKO

SEWING.

MACHINE

CO.

Page 2

1

Lubrication

2

Setting

3

Thre

ad 2

4

Removal

Contents

the

and

needle

insertion

2.

2

of bobbin ' 3

5 Winding

6 Needle

7 Tension

the

threading

of

8 Pressure of

9 Adjustment of

10

Determination

forward

11

Timing

12 Removal

13

Adjusting

(A)

and backward amount 7

of

shuttle

Adjusting

of

feed

(B) Adjusting the

(C) Adjustment

(D)

Adjusting the forward and backward

needle

(E) Timing of

®

Positioning

®

Adjusting

® Adjusting the

® Adjusting the clearance

01

hook

®

Determination

rock

® Each

foot

bobbin

bobbin

presser

stitch

of

thread

on

the

needle

dog. (7B &

for

bar

frame

needle

the

frame

timing

(2B &

thread

thread

and

needle

thread

foot

length

positioning

tension

hook 9

each

points

position

8B

height

timing

and hook

between the

height

position

of

the

for

7B & 8B

for

up/down moving amount

8B

only)

for

stitch

releasing

mechanism

against

Types) 9

length

needle

at

..i.......

hole

of feed dog 10

of

feed

of

of the

position

dog-rise

upper

needle

between

position

side

bar

tip

needle

of

needle

of

of

needle

hook

and

bar

of

of

eye. 11

the

presser

10

10

11

11

tip

12

12

I3

4

5

5

7

7

8

g

Page 3

Specification

for

Model

TH

Types

Max.

Needle:

Feed

Presser

Needle

Bed

Working

Use:

Sewing

mechanism:

lift:

bar

size:

space:

speed:

stroke:

800

Sewing

models

DDX1,

(8B)

(7B)

(6B)

(2B)

20mm

(s.p.m.)

speed

and

BY X 1

Alternating

Flat

presser;

Roller

Alternating

(10mm

56™"

253inmx656mm

180mm

Suitable

materials

sproting

X

400mm

for

such

goods

may

be

applications.

(forTH-2B)

pressers

or

flat

pressers

by

lever)

sewing

as

shoeSf

and

changed

presser

of

thick

extra

bagSt

fabrics*

,

by

heavy

the

leathert

Page 4

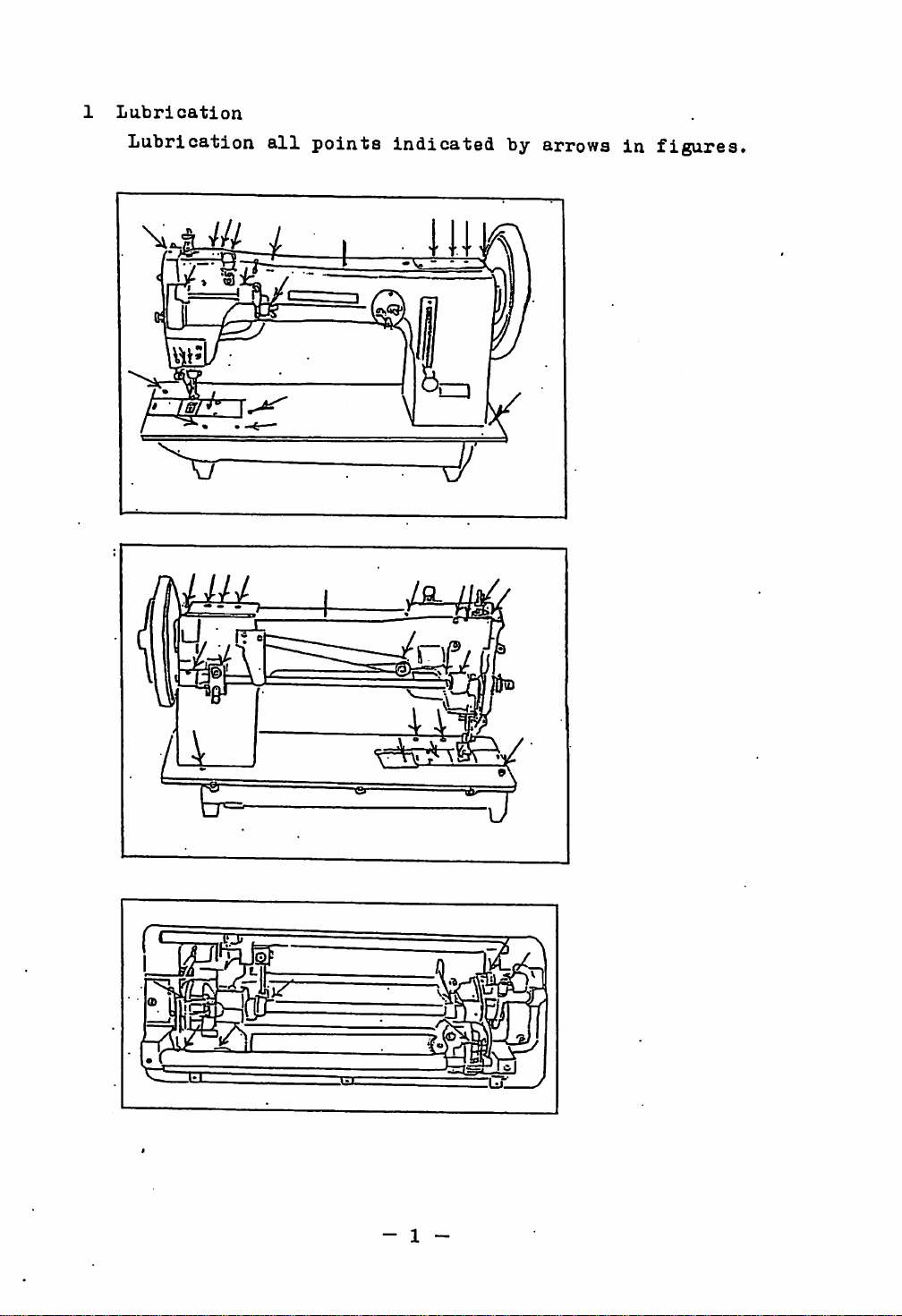

1

Lubrication

Lubrication

all

points

indicated

by

arrows

in

figures.

- 1 -

Page 5

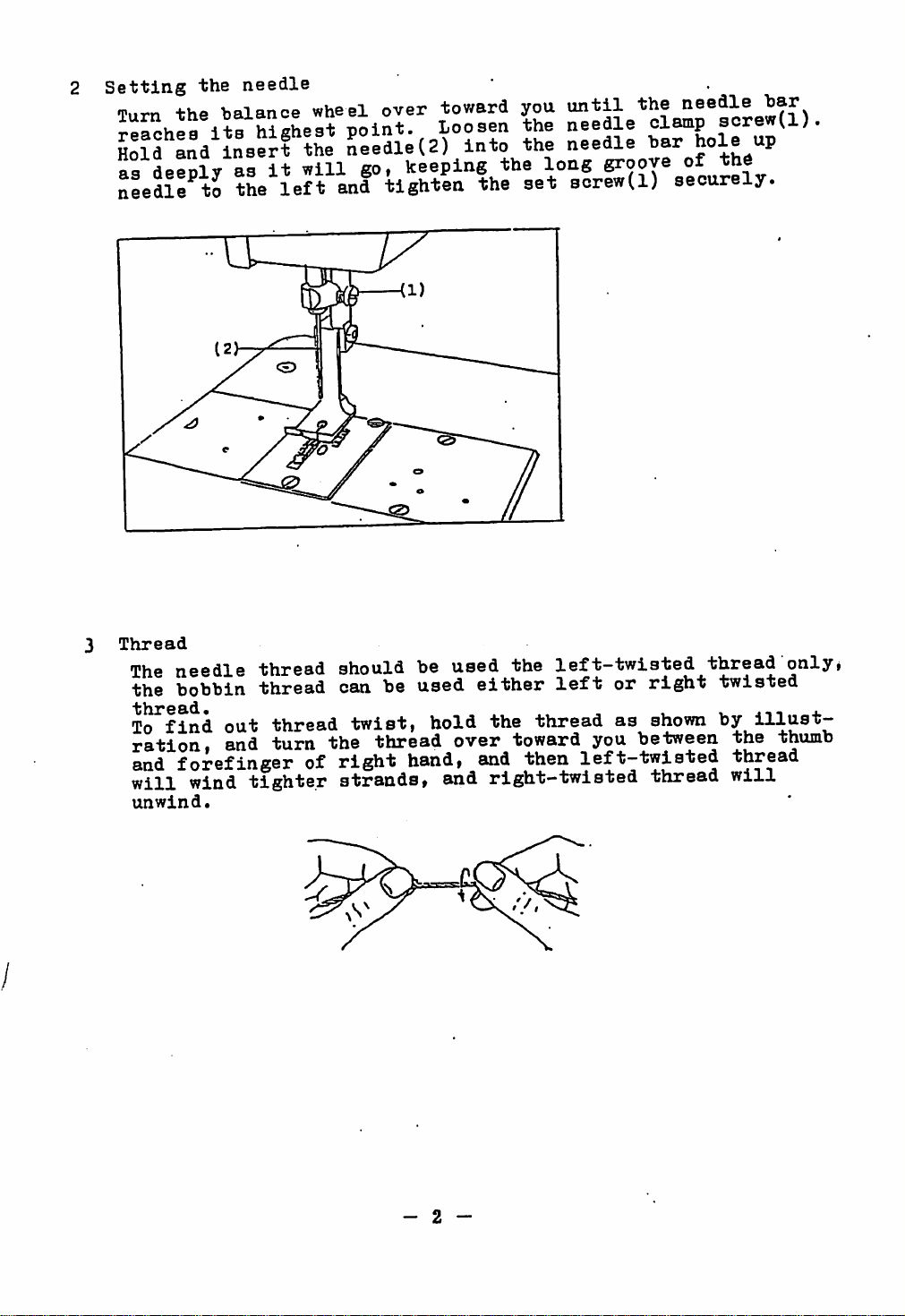

Setting

Tii-rn

Sold

as

deeply

needle

the

needle

+hP

balance wheel over tov/ard you

ita

Ind

to

hisLst

insert

as

it

the

left

Mint.

the

Ledle(2)

will

and

go,

tighten

Loosen

keeping

into

the

the

the

the

long

set

until

the needle

needle

needle

groove

sorew(l)

clamp

bar

hoi®

of the

securely.

"bar

sorew(l).

"P

3

Thread

The

the

To

find

ration,

and

will

unwind.

needle

bobbin

forefinger

wind

thread

thread

out

thread

and turn the thread over toward

tighter

should be

can be

twist,

of

right

strands,

used

used

hold the

hand,

and

the

left—twisted

either

and

right-twisted

left

thread

then

left-twisted

or

right

as

you

shown

between the

thread

thread

twisted

by

illust

thread

will

only»

thumb

- 2 -

Page 6

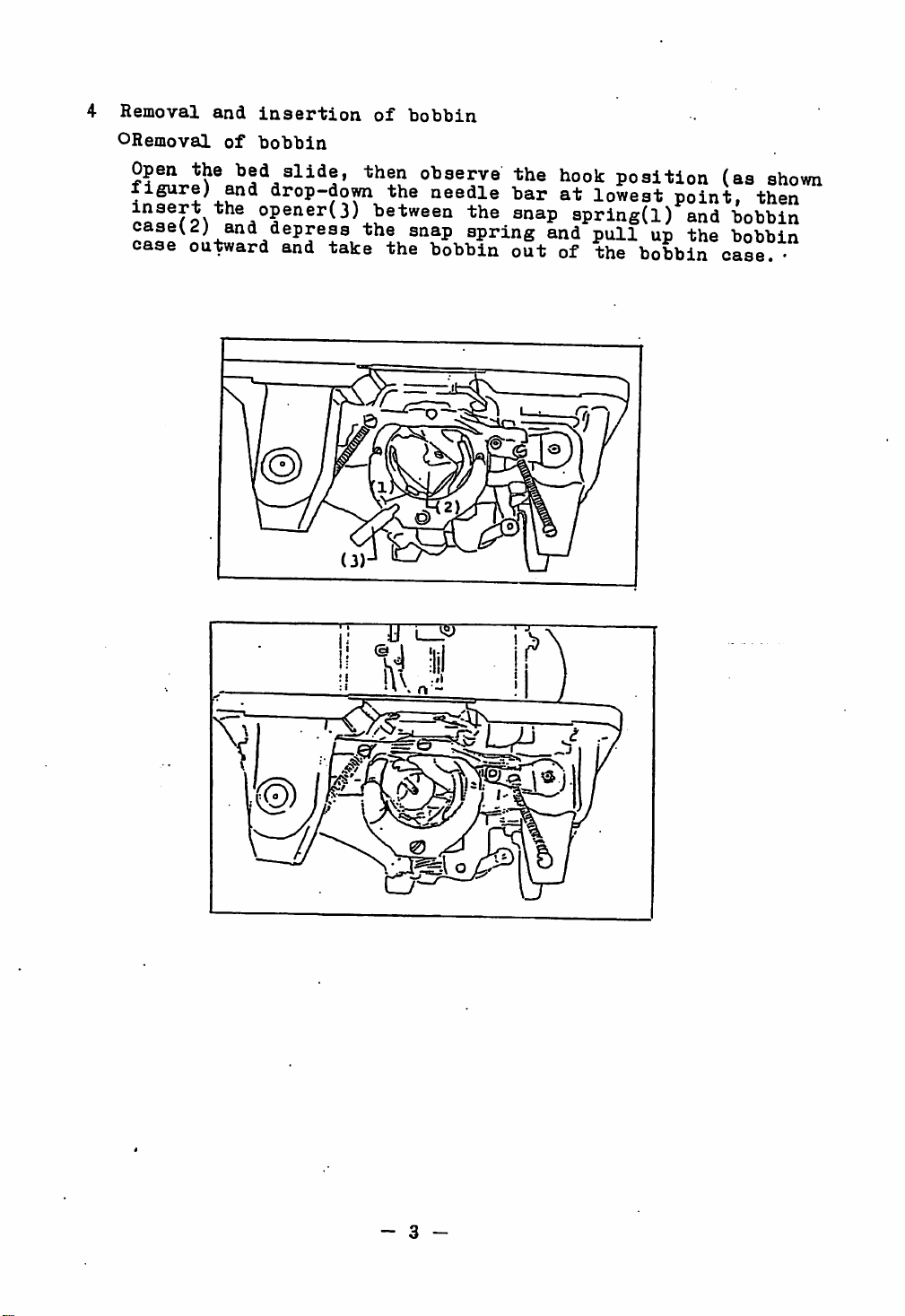

4

Removal

ORemoval

Open

the

figure)

caseu)

case

outward and

and

of

and

and

insertion

bobbin

bed

slide,

drop-do^

depress

of

bobbin

then observe the

the needle

the

take

the

snap

bobbin

bar

spring

out

hook

at

and

position (as

lowest

apring(l)

pull

up

of the bobbin

point,

and

the

case.

shown

then

bobbin

bobbin

•

b

- 3 -

Page 7

OInsertion

Put

down

bobbin

slit(7).

the

the

of

bobbin

bobbin(4)

thread

case

spring!6;

and

into

pass

to

the

bobbin

the

lead

thread

it

easel5)

through

out

from

while

underneath

the

bobbin

holding

the

case

5 Winding

the

bobbin

thread

Pass the thread in the order numerically

in

figures.

(1)

Spool

teneion thread guide

tension discs

guide—?-(5)

(6)

Move

pin—^(2)

»-(4)

Bobbin

the

bobbin winding

Thread

»-the

Meedle

guide

clearance between

thread tension

(winding several timesj ^

lever#

un-\U

instructed

(am)-^(3)

Needle

two

thr^d

Winding

left

length

&

rightward

shouldbeadjusted^by

the

positioning of the lever(6).

- 4 -

screw(7)

and

Page 8

6

Needle

threading

Pass

in

(3) Clearance between two

the

the

Spool

thread

figures.

pin—^(2)

in

the

Thread

order

tension

numerically

guide

of

discs

guide of thread tension ^(5) Thread

-I

®

^7^

Tension

Tension

(9) Thread guide on

(11)

Needle

single

sprffig_~^'(g)

spring

turn

^(q)

face

el

>-(6) Thread guide

Thread

plate

take

-^(10)

instructed

thread

tension

^(4)

controller

up

levIT^^

Needle clamp

Thread

discs

5^

Tension of bobbin

(A)

When

stitch tension is

IS enpged with the needle thread

material

(B)

Pig.

(B)

loose

thread

thickness,

shows

bobbin

and

as

unbalanced

thread.

- 5 _

needle

well

shown

(B)

thread

Balanced

balanced,

by

Tight

bobbin

tension, tight

(C)

Loose

bobbin

tension

at

fig.

the center of

(A)

needle

thread

needle or

thread

the

bobbin

of

loose

tension

needle

tension

thread

given

thread or

tight

Page 9

Adjusting

By

turning

nut

clockwiseneedle

tension

By

turning

nut

counter-clockwise^^^

thread

needle

increases.

tension

thread

the

tension

the

tensionregulating

decreases.

tension

regulating

thread

needle

S

Adjusting

By

loosening

screw(1).

The

set

the

bobbin

By

turning the tension

thread

regulating

decreases.

hoBbin

screw(l)

thread

tension

screw

set

thread

screw(l)

should

tension

tension

regulating

increases

counter—clockwise

and

exactly

was

and

tension

be

adjusted.

by

turning

regulating

tightened

screw

thread

after

clockwise/^

the

tension

tension

- 6 -

Page 10

8

Pressure

Loosen

of

the

clockwise^^pressre

thumb screw

^ter

in

adjustment,

accordance

presser

nut,

counter-clockwise^^>.pressure

with

lU

(ill

foot

then

tighten

the

turn

the

increases

the

materials

pressure

turn the pressure

nut.

Adjustment

to

regulating

be

sewn.

decreases,

should

thumb

screw

regulating

be made

Adjustment

perfSLld!

deoreasea,

ias

determined

of

Md

stitch

length

regulating

lever(l),

lever{l),

reverse

stitch

forward

knurling nut(2) 4 (3) clockwise/'"^ feed

by

turning the knurling nut(2) & (3) oounte?-

}^:

increases.

®^

ikO/.- A

The

knurling

®^^®^

(Note)

When

of

desired

upward

the

loosened,

feed

& downward movemei

regulating

the

screw(4) should be

is

atitlh

nut(2)

stitch

feed

performed,

is

length

&

length

lever

adjusting

tightened,

;

10

Determination

forward

Equivalent

obtained

feed

ing

and

by

regulating

collar

of

positioning

backward

stitch

adjustment

B)

should be placed

amount

length

set

plate(A)-, and

for

stitch

at

forward

of t upward &

back-lever(feed

on

feed regulating

- 7 -

length

and

backward

downward

at

can be

position

regulat

set

of

plate

(A)

Page 11

11

Timingofthread

(a)

When

(b)

moving

thread

Adjustment

Pull-up

clearance

of

disc(5)

releasing

the

should

tension

the

and

tension

the

be

—

presser

should

tighten

plate.

releasing

meohanism

lifting lever(l),

adjusted

"bar

be made

releasing

the

so

as

lifter(3),

over

plate(4)

screws(2)

to

3mm

upper

Sdo.

the

between

and

tension

on

the

tip

tension

ii

Page 12

12 Removal

Pull-down the opening &

lever(A) instructed in

tnd

then

and

remove

(B)

at

feed dog

Pig-3

shuttle

pull-down

-t—the

the

raised

instructed

shows

hook

removal

closing

the

fig-li

It

rlghtward

outer

position

in

hook

oi

the

of the shuttle

ring

Setting the shuttle

made

the

in

above

13 Adjusting

(A)Adjusting

Ledle^hoildhepositioned

feed

the

contrary

description.

hook

order

can

he

of

ri

rig-

2

on

the each points , *

dog

needle

and

position

moved

against

needle

together , the

Fig-

x.

holeoffeed

1

f7-B

dog.(

amount

out) of feed shaft

screw(3)

(Needle

is

to

of

needle

dog.)

be

•

dorpping

set

at

hole

point

the

of

("PP®r\acrew(3)

center

the

feed

- 9 -

(Note)

Peed

should

without

connector(A)(4).

shaf

t(upper)

be

moving

fixed

^ .

connector(

by the

feed

shaft(upper)

and

needle

..

AU4;

screw(3)

.

Page 13

(B)

Adjusting

the

height

of

feed

dog

(C)Adjuatment

I —

for

L^LIS

timingoffeed

and

position.

lipper&lowerf^d

aorews(l)

sh^t

ah^t

aMit(2)

8hlft?pf

„\^®

feed^do/shouid

at

the

dog-rise

vihfating

AdjustSenI

showf"^

o ^

oonneotor

la

"PP®''^lower

eod

-®^ace

PLUS^lwus+nK

of'^e^'e'^

set

adjusted

downwird!

materialstoSe

'r

foot

hf'

««

^®®'^

''®

116-5^(85"'

lower

screw

at

®^J*i3ted

fe,^.

'^og

®«°a

"^wo

Ot

a

^^^hoiltiin®

position

of

ri'T^s

16—17m*

0

Adjustment of the clearance between

presser

made

by

L.

forward

needle

»•

bar

and

the

acrew(l).

ZISlr

bar

needle

and

backward

frame

bar

rHis

is

to

be

e:?c:

O

imlQ

2

-10-

Page 14

(E)Timing

®

Positioning

When

from

hook

of

needle

the

its

should

of

needle

lowest

meet

and

needle

bar

positioni

the

hook

and

has

center

the

risen

the

tip

of

hook

4.5nutt - 5.5mm

tip

of

the

line

of

the

needle

Distance

and

the

©Adjusting

Loosen

between

tip

the

by wrench which

4^

V *4-

of

the

height

screw

the

the

inserts

2.3niiii'—3iaa

4.5iDni'-~5>

hook

of

adjust the needle bar{3) ^

©Adjusting

Loosen

spanner,

backward

of

hook.

adjustment.

the

the

then

(high

Tighten

position

screw(4)

determine

or

low

the

upper

should

of

needle

needle

to

of

of

the

the

speed)

screw(4)

5iiun

side

bar

the

upward

the

shaft

forward

of

the

be 2.5mm —

bar

connecting

hole(l)

and

tip

of

hook

crank

the

or

tip

of

after

needle-eye

3mm.

3tud(2)

of

arm and

downward.

by

£

m n

-

11

-

Page 15

©Adjusting the .clearance.between

needle

and

the tip of

hook

Loosen

rock

should

ward

set

frame,

be

or

leftward.

screw(l)for

then

mo-ved"4—^

Ij

needle

Pig--

©determination

lieedle

fdt

(4) positioned lower part of needle bar rock frame(2),

bar

ooai

rock

of

the

frame

position

for

7B & 8B

the

fi

of

needle

needle

bar

bar

rock

rock

frame

frame

outer

(Fig.

aP

/ - tip

—

tip

—0.05—0.3mn

hinge

hinge

hook

hook

right-

6)

hook

of

hook

stud,

stud(small)

and

also the

of

of

of

thT

feed

2^

® ^

dog

needle

°

moving

the balance

position,

bar rock

the

needle

needle

wheel,

r

Inn^

rock

wh«i f ^ frame(2),

wheel and

stitoh^skipplng

^

frame

tighten

looseness

hin^

position

needle

stud(small)(4) to slightly

bracket(8).

bar

rook frame hinge

the

of

each

the

screw

leftward

exactly.

&

rightward

resulted

frame

^Se

and

tighten

and

in

the

hinge

bar

determines

center

stud(large)

then

stud(large) (6).

stud(large)(6)

rock

frame

smooth

of

the

needle

the

set

screw(l)of

-fclie

needle

the

needle

bar bar

(6)

turn the balance

^ of the needle

leftward

to

breakingofneedle,

@

to

&

position

hole

bar

the

aide

12

-

Page 16

@Eaoh

a

timiag

Timingofinside

before

of

needle—eye

nrlsaei-

AdjS^ln?

for

up/down

bar

lifter,

irmade

moving

preeser

reaches

by

turning

two

amountofpresaer

to

feed

set

torews(2)ofupward&downward

the

dogi

after

balance

foot

Snwnina

downing

wheel

toward

(2B&8B

the^lever°®

only)

you.

By^up"!

needle

As

for

set

to

b For the

foot e(iuivalently, the

pinch

Ajustment should be

c

Up/down

presser foot

Upthe

Down

doTO^lifting

is

touch with feed dog

2B

Type,

at

same

setting

acrew(3)

moving

3crew(4)i

the

adjusting feed

point

of

io

amount

can

screw(4)

eooentriot-1'inside

either

dog

on

the upper face of the needle

inside

"to

made

be

obtained

the

,

be

presser

lifting

adjusted.

by the

of inside presser foot

amount

the

amount

eccentric connection crank

materials

by

loosing the screwt4;.

increases.

decreases.

J

Presser

speedily or slowly.

and

outer presser foot

foot

and outside

being

foot

and

against

plate.

presser

sewn.

outside

— 1 3 —

Page 17

1.

POSITION

Turn

its

the

( or

And

*

top dead

groove

-l^urn

on the

at

its

tighten

Needle

its

OF

the

h^Andwheel

the

cam

highest

lowers

highest

CAM(i^^28102)

until

center.

on

the

cam

cam,

and the

/'/28102,

center

point

the

screw(a)

//28102

by

0.4

point

FOR

the needle

At

this

faces

to

shown

securely.

mm

from

CONNECTING

bar

point,

the

make

of

the upper

as

the

center

upper

shaft

top.

set

i^mm

following

of

* Needle

ROD

lowers by

the

distance

shaft

I

Groove.

O.ifmm

cam(;^f28l02)

between

when

figure.)

the

1

1^

at

the

highest

from

with

the

groove

needle

• 1

i

is

1\

point

2.

POSITION OF FEEDING CAM(//28063)

STANDARD:

HOW

TO

(7B

Turn

screw

hole

(6B,

Turn

screw

groove

When

up

Imin

should

ADJUST:

and

8B

the

feed

in

rotating

A on

2B

and

the feed

in

rotating

on

swaying

and

down

this

type)

side

be

still.

cam(/ff28063)

direction

the

cara(#28102) and

2/RF

type)

cam(J/28063)

direction

the

cam

and

the

at

stitch

the

of

the

until

until

tighten

point

needle,

aligns

aligns

length

where

the

with

tighten

the lower

with

the

screw(B).

regulating

the

the

lower

the

the

the

point

feed

edge

dog

of

upper

screw(B).

edge

7p,oB

of the second

upper

(Fig.

lever(//28l6i|)

of

hook

and

the

edge

(Fig.

edge

4 )

^^ype

reaches

the

needle

second

of

the

3 )

of

the

center

qhaf

of

uppei

t

F;,.

3

Page 18

3.

HEIGHT OF

STANDARD;When

To

make

NEE;DLE

the

from

the

needle

surface

edge of the needle eye

f

30

pk'fe I

sure;

The

part

at

S

upper edge of the needle eye should

A of the needle guard

the

needle

is

of

is

its

the

its

highest

needle

is

30•

lowest

e

point,

plate

5^0.5>nra,

on

the

point.

the

to

height

the

shuttle

lower

reach

driver)

.

POSITION OF

Turn

extreme

the

hook with B

should

be

SHUTTLE

handwheel

left

side.

part

at

1mm

of

from

HOOK

until

At

the

the

this

driver,

the

shuttle

point,

edge

driver(#28/h51)

when

the

point

of

the

For adjustment, loosen the screw(^2810it

for

Flat

bed

type)

, , x

contacting

of the

shuttle

for

Cylinder type,

reaches

C

shuttle

race(E).

part

at

of

the

hooktD)

#28805

PL/IT

TTft-

_paPtf^

.

Page 19

;7^

"t

4-

V

6B.

Zb.CH^RF

i • Ji

w—^

Loading...

Loading...