Page 1

TE

TF-B.BB

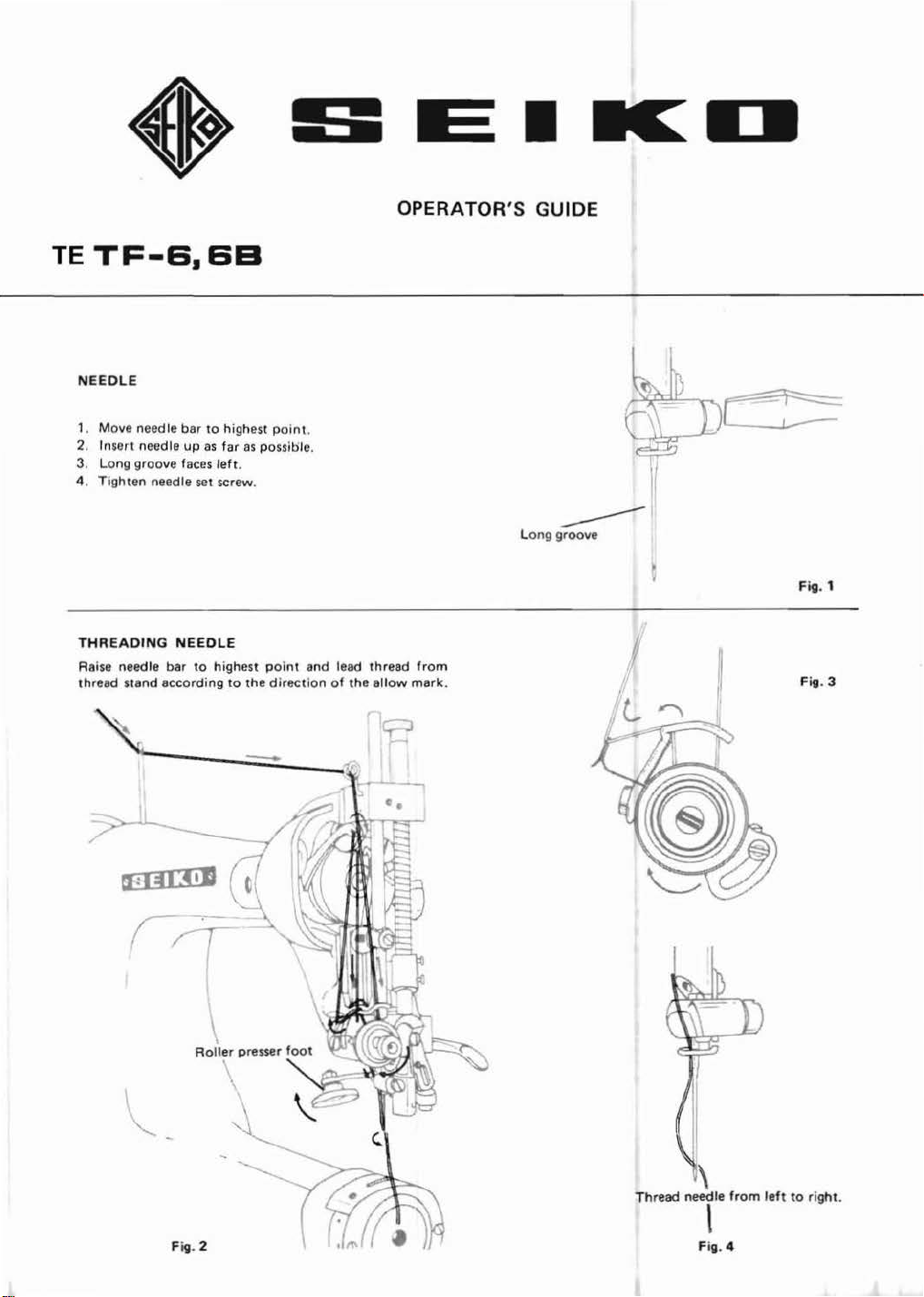

NEEDLE

OPERATOR

'S GUIDE

1. Move needle bar to highest poi

2. Insert needle

3. Long groove faces

4. Tighten needle set screw.

THREADING

Raise needle bar

thread stand according

up

as

left

NEEDLE

to

highest

far

to

as

possitile.

.

the

point

direction

~

:----

.....:

-=--

nt.

and lead thread

of

the

allow

from

mark

Long g

roov

e

----

Fig. 1

.

Fig. 3

Thread needle

F

ig.

2

\

\

Fig. 4

from

left

to right

.

Page 2

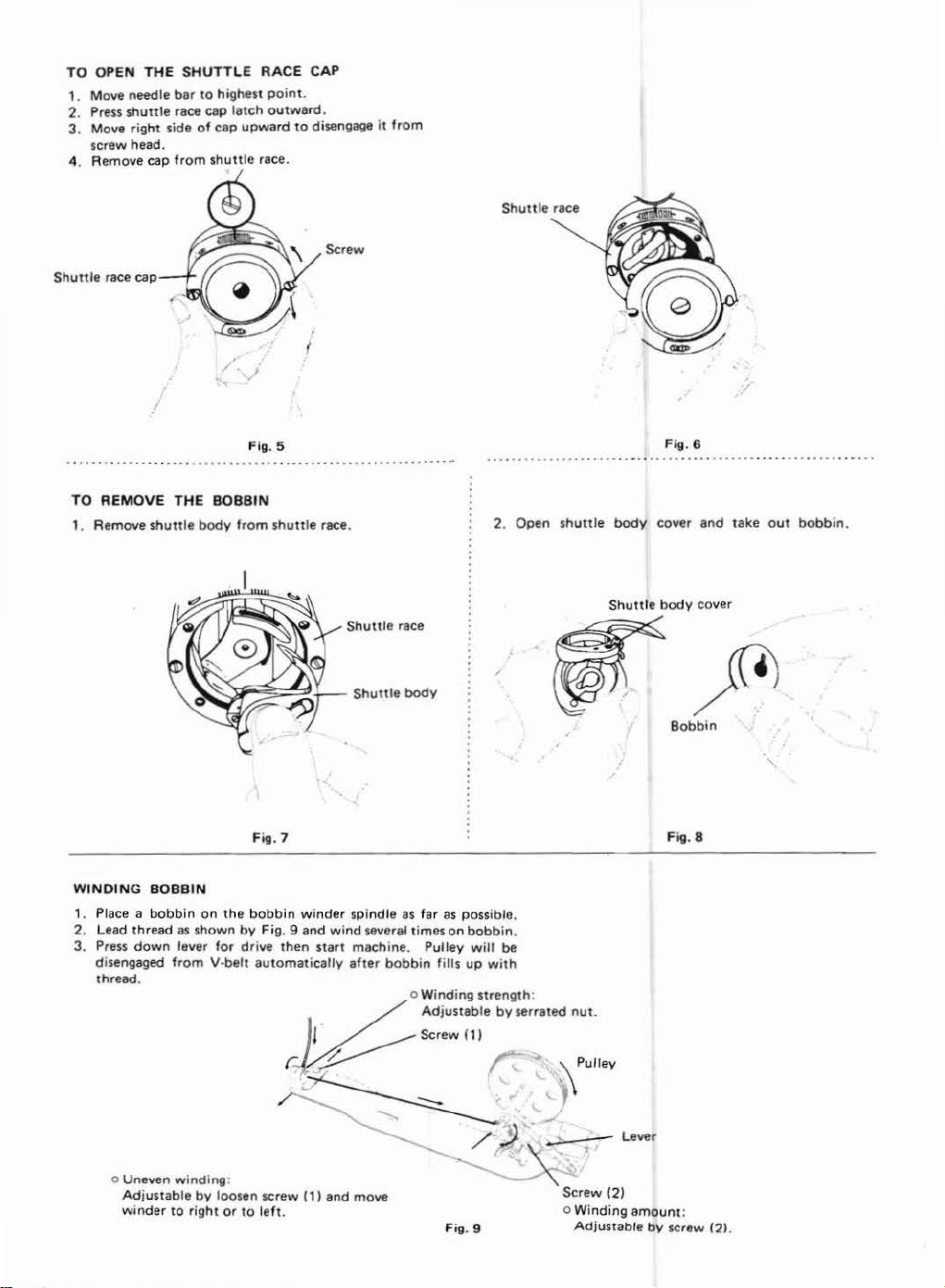

TO OPEN

1.

Move

2.

Press

3.

Move

screw head.

4.

Remo

Shuttle

THE

needle

shuttle

right

ve

cap

race cap

SHUTT

bar

to

race cap

side

of

from

LE

RACE

highest point.

latch

outward.

cap

upward

shuttle

race.

/

CAP

to

disengage it

Screw

from

TO

REMOVE

1. Remove

WINDING

1. Place a

2. Lead thread

3.

shuttle

BOBBIN

bobbin

Press

down

disengaged

thread.

THE

BOBBIN

body

on

the

as

shown

lever

for

from V·belt

Fig. 5

from

shutt

le race.

Shuttle

Fi

g.

7

bobbin winder spind le

by

Fig. 9

and

then

wind

start

mach

after

drive

automatically

race

as far

several times

ine.

Pulley

bobb

in f

as

possible.

on

bobbin

will

ills up

2. Open

.

be

with

Fig. 6

shuttle body

~~

Shuttle

cover

body

Bobbin

and

cover

take

out

bobbin.

'

Fig. 8

~Lever

Un

o

Ad

winder

even windi

justable

ng:

by

loosen screw (1)

to

right

or

to

left

Screw

and

.

move

Fig. 9

o Win

ding

Adjustable

(2)

amount

by

screw

:

121

.

Page 3

THREADING

1.

Hold

shuttle

shown

and

3.

Close

shuttle

THE SHUTTLE

in l

eft

bobb

cover

hand

in

place

body

(~

with

into

.

the

it.

open

side

Fig.

up

as

10

2.

Pass

THREAD

thread

TENSION

into

slot

as

shown

.

Fig.

11

BOBBIN

To

ADJUSTING

1.

2.

adjust,

To

shorten

feed

regulator

To

lengthen

Thumb

THREAD

turn

.. ,

adjusting

\ I

STITCH

the

sti t

downward

the

stitch, move feed

scre_w

Tension spring

screw

;(S$

·-

~.Q{J

\.~

LENGTH (Tf -6)

ch,

loosen

thumb

.

Tension

screw

screw and

regulator

Fig.

regulating

14

Fig.

move

upward

Fig.

16

12

.

~

~

~

NEEDLE

To

(TF·

6B)

Loosen

between

stitch

length

setting

Serrated

Fig.

13

THREAD

adjust,

turn

the

serrated

F and 0

in

setting

to 0 positiflo.

c . . t

nut

Lever

Perfect

Tight

Loo

se

serrated

nut

marks o n the

nut

and

adjust

to F position

<:1

....

----0

~

stitching

tension of needle thread

tension

of

needle thread

Serrated

stitch

plate. To

F

P

late

and

nut

length

increase

to

decrease

Fig.

by

Fig.

15

lever

the

17

in

REVERSE STITCHIN

(

only

Tf ·6B)

Press

down lever

Lever

/

as

far

T

G

as

ot will

..

go.

-----0

1

Fig. 18

TO

REGULATE

The

pressure

hile still

w

on

the met

sufficie.nt

PRESSER

More

~

erial

to

insure

FOOT

~

}

should

correct

PRESSURE

Less

be

as

light

feeding.

Fig.

as

possible,

19

Page 4

LUBRI

CATION

Use

white

sufficiently

-

...

~

-

t

,

...

r/

~

~-

·-

F

ig.

INSTALLATI

1.

Set

up

machine

2.

Attach

under

3. Install

bobbin

spindle oil. When

to

respective necessary

I

\

........

\ L

/•

20

ON OF THE

the

table

clut

table.

machine

and

ch

etc.,

moto

head

to

head.

the

the

the

winder,

starting

parts

.J

1-

MAC

HIN

stand before

r, knee lifter,

and

table

fix

.

the

the

before

E

the

the

machine

starting

I t

\

'~

'

'

·.

~-

.. ' •7-'\..

Fig. 21

installment

switch,

thread

initially

operation

~

~-

"'

~

y

-.

.

.~

• ·

#v·

~

~,,

'~

~

.

~;

~

of

etc.,

to

stand,

and

.

-

after

kept

and

pre-running. (l

2

away

for

a lo ng

....

/

Fig.

oiling

.. :

22

time

without

point)

-lb-

using

at

Fig.

all, oil

23

Fig.

24

1

0

.

'"

...

y

0

0

3

V-belt

Thread

stand

t 1 .

·'·

·--

h

l }

Fgi.

25

SEIKO

11

-3, lma

Tel

: (03)

Cabl

e Address:

SEWING

do

1-<:home,

872·6171-7,

"SEIKOSEWMCO"

MACHINE CO.,LTD

Telto-ku,

7288

Tokvo.

Telex: 26571

TOKYO

48

1 1 1

SEIKO

-\

Pedal

Jepen

Fig.

26

.

.

J

Loading...

Loading...