Page 1

DOCUMENT NUMBER 39NPI-53E1-03

OFL-12 SERIES

OFL-126001

OFL-127001

MASS PRODUCTION POLISHER

INSTRUCTION MANUAL

Seiko Instruments Inc.

Components Sales Dept.

1-8, Nakase, Mihama-ku

Chiba-shi, Chiba-ken, 261, Japan

Telephone: 043-211-1211

Facsimile: 043-211-8030

Page 2

DOCUMENT NUMBER 39NPI-53E1-03

OFL-12 SERIES

OFL-126001

OFL-127001

MASS PRODUCTION POLISHER

INSTRUCTION MANUAL

Seiko Instruments Inc.

Components Sales Dept.

1-8, Nakase, Mihama-ku

Chiba-shi, Chiba-ken, 261, Japan

Telephone: 043-211-1211

Facsimile: 043-211-8030

Page 3

OFL-12 SERIES OFL-126001 OFL-127001 MASS PRODUCTION POLISHER

INSTRUCTION MANUAL

Document Number 39NPI-53E1-03

First Edition March 1995

Second EditionNovember 1995

Third Edition March 1996

Copyright 1995, 1996 by Seiko Instruments Inc.

All rights reserved.

Seiko Instruments Inc. (SII) has prepared this manual for use by SII personnel,

licensees, and customers. The information contained herein is the property of SII

and shall not be reproduced in whole or in part without the prior written approval of

SII.

SII reserves the right to make changes without notice to the specifications and

materials contained herein and shall not be responsible for any damages (including

consequential) caused by reliance on the materials presented, including but not

limited to typographical, arithmetic, or listing errors.

is a trademark of Seiko Instruments Inc.

SII

Please address any questions, comments, and suggestions to:

Seiko Instruments USA Inc. Seiko Instruments GmbH

Electronic Components Div. OFC Div.

2990 West Lomita Boulevard, Siemensstra e 9,

Torrance, CA 90505, U.S.A. 63263 Neu-Isenburg, Germany

Telephone: 310-517-8113 Telephone: 6102-2970

Facsimile: 310-517-7792 Facsimile: 6102-297222

Seiko Instruments (H.K.) Ltd. Seiko Instruments Taiwan Inc.

Sales Dept. Sales Dept.

45th Floor, Wyler Center 2, 200 5f-1, No.99, Sec.2, Chung shan.Rd.,

Tai Lin Pai Road Kwai chung, N.T., Taipei 104, Taiwan, R.O.C

Kowloon, Hong Kong. Telephone: 886-2-5635001, 5235111

Telephone: 852-421-8611 Facsimile: 886-2-5219519

Facsimile: 852-480-5479

- ii -

Page 4

PREFACE

This manual has been prepared to provide the information necessary to allow the

user to operate the OFL-12 Mass Production Polisher (hereafter referred to as OFL-

12) correctly and fully utilize its functions. Before using the OFL-12, be sure to read

this instruction manual thoroughly. Store the manual in a safe place for future

reference.

NOTE

The OFL-12 can only polish ferrules which meet the following conditions:

Ferrule material Zirconia (ZrO

)

2

Ferrule diameter 2.5 mm (0.0984 inch)

The OFL-12 can polish ferrules after assembly only with ST-type

connectors. Please contact SII for options if you wish to polish almina

ceramic capillary ferrules, f e rrules with dif f e ren t ou ter d iam ete r, f e rrule s that

require flat, angled PC, or another style of polishing.

NOTE

The polishing film and polishing fluid used on the OFL-12 are selected

especially for the processes performed on the OFL-12. If you use any other

polishing film or fluid, we cannot guarantee that the polishing specifications

will be met.

- iii -

Page 5

Before using the OFL-12, please make sure that all of the following items (shown in

figure 0-1) are present.

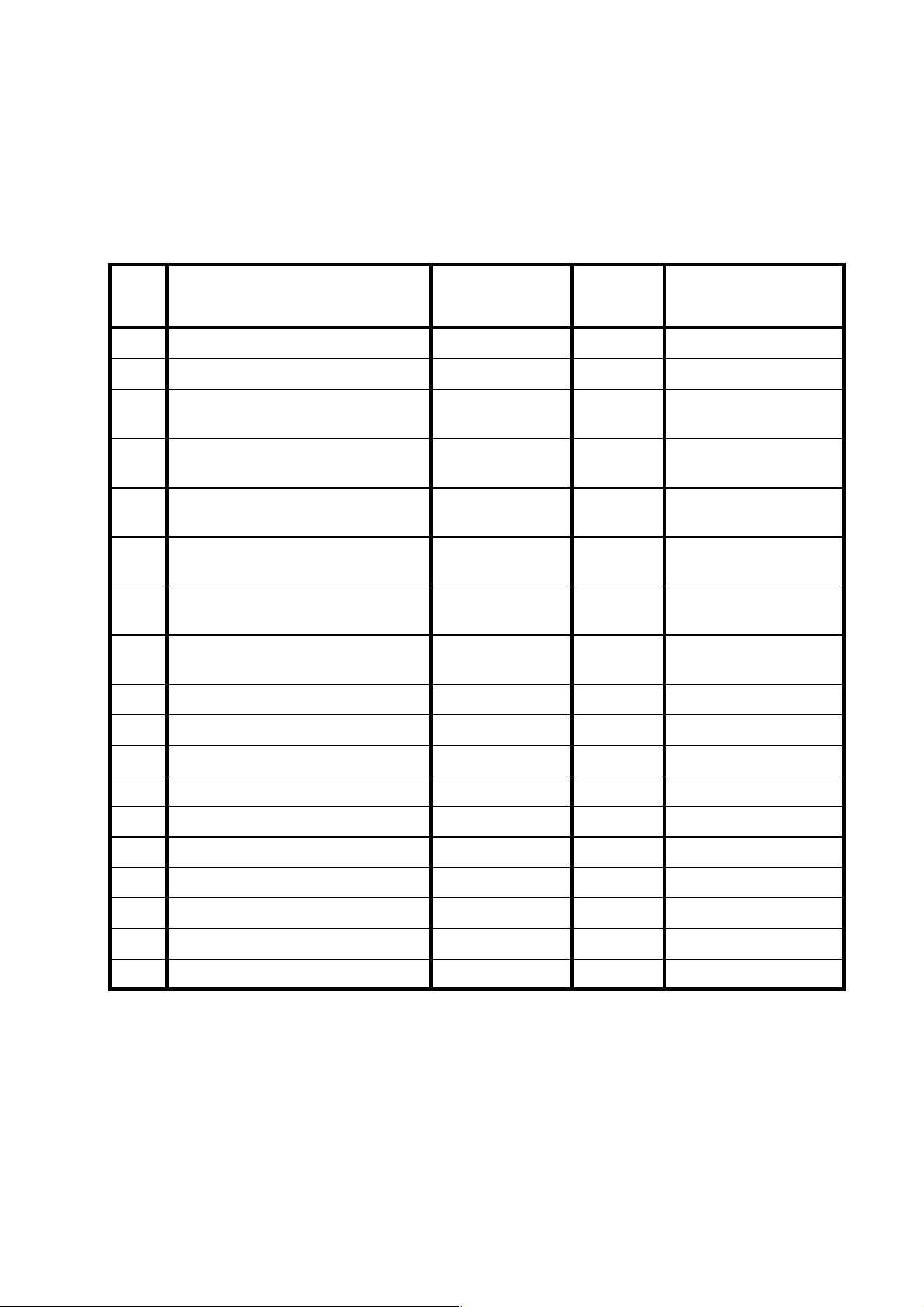

Table 0-1. Standard Parts

No

Part Part code Qty. Remarks

.

1 Basic machine OFL-12 1

2 Holding jig KJJ100101 1 for 2.5 mm dia.

3 Polishing disk KJD100100 1 synthetic rubber

disk

4 Adhesive removal pad KJO100101 1 with synthetic

rubber sheet

5 Polishing film (adhesive

removal)

6 Polishing film (grinding) (KJW100200

7 Polishing film (polishing) (KJW100300

8 Polishing film (finishing) (KJW100400

(KJW100100

)

)

)

)

10*

Sheets

1*

Sheet

1*

Sheet

1*

Sheet

abrasive paper

green label

yellow label

white label

9 Polishing fluid (KJA100100) 1* 100 ml

10 Squeezable dropper bottle KJO100200 2 50 ml2

11 Power cord KKO100420 1

12 Fuse KKO100320 2 250 V, 1 A

13 Ball-end hex wrench KJO100500 1

14 Instruction manual KKO100220 1

15 Soft brush KJO101000 1

16 Setup Stand KJO100600 1

17 Grease KJO101200 1

18 Maintenance Manual KKO100520 1

* The quantity listed is the quantity included in the standard OFL-12 package. See

Table 0-2 for the quantities included in additional orders of individual items.

- iv -

Page 6

Basic machine

➀

Polishing film (adhesi ve removal) (10)

Maintenance Manual

Instruction Manual

Adhesive removal pad

Polishing disk (1)

Holding jig (1)

Polishing fil m (gri nding) (1)

Polishing film (polishing ) (1)

Polishing film (finishing) (1)

16) Soft brush17) Ball-end hex wrench

15) Fuse (2)

14) Setup stand

18) Power cord

Figure 0-1 Standard Parts

11) Grease

13) Squeezable dropper bottle (2)

12) Polishing fluid (1 bottl es)

- v -

Page 7

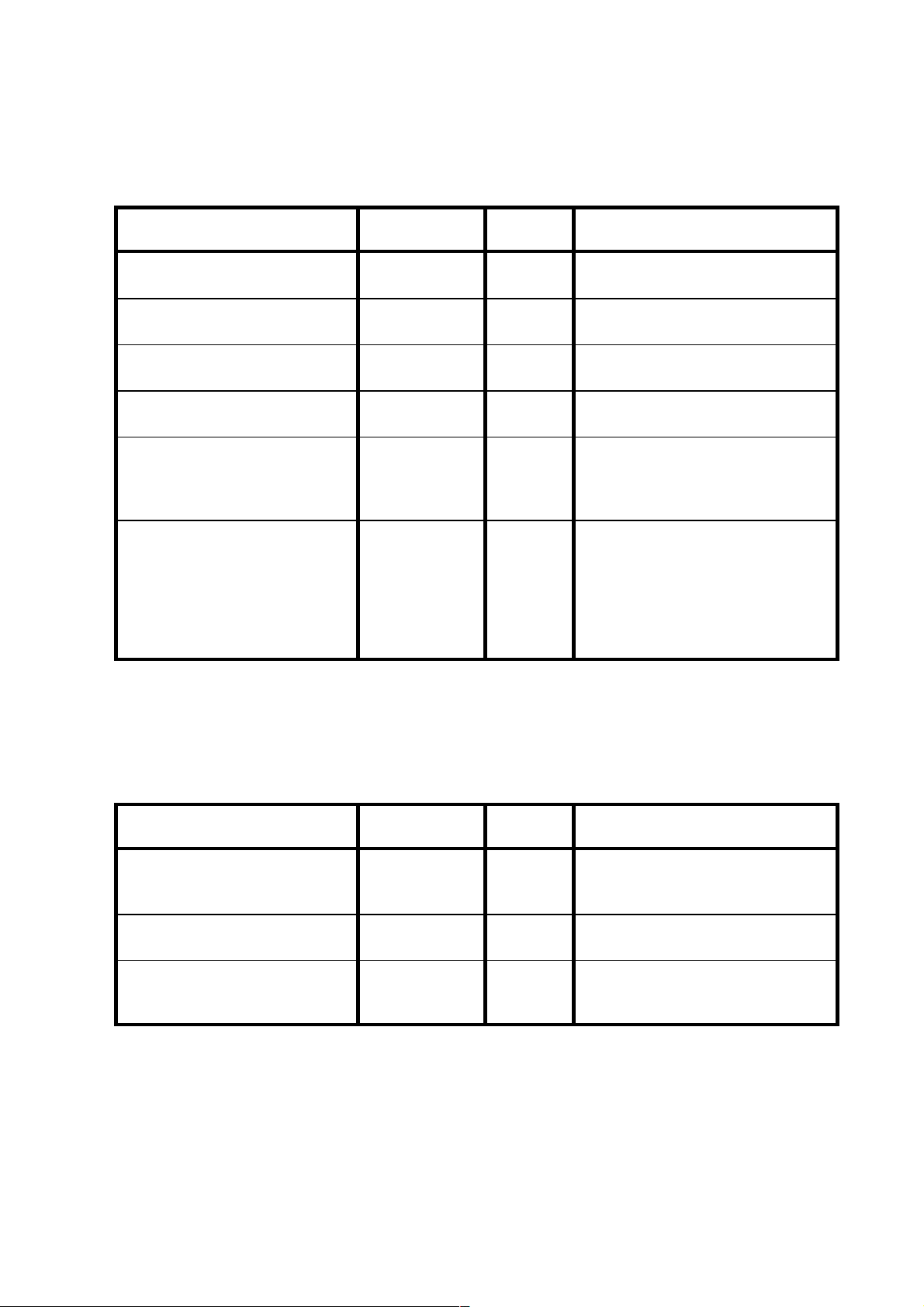

The available consumable items are listed in Table 0-2.

Table 0-2Consumable Items

Part Part code Qty. Remarks

Polishing film (adhesive

removal)

Polishing film (grinding) KJW10020

Polishing film (polishing) KJW10030

Polishing film (finishing) KJW10040

Polishing fluid KJA100100 2

Standard consumable

supplies kit

KJW10010

0

0

0

0

100

sheets

10

sheets

10

sheets

10

sheets

change after 1 use

change after 10 use

change after 10 use

change after 10 use

can polish approximately

(100

ml

2)

600 ferrules per container

(12 ferrules at one time, 50

uses)

KJS100100 1 set contents:

Polishing film

adhesive removal 100

grinding 10

polishing 10

finishing 10

Polishing fluid 2

The Standard Consumable Supplies Kit (part code 110-S-001) is sufficient to polish

about 1200 ferrules.

The available optional items are listed in Table 0-3.

Table 0-3Options

Part Part code Qty. Remarks

Holding jig for D4 KJJ200100 1 for zirconia capillary ferrule

(diameter:2.0mm (0.0787

inch))

Angled PC polishing set

KJS100500 1 set for angled PC polishing

(minimum set)

OFL-12 consumer

supplies kit for alumina

KJS100200 1 set for alumina ceramic

capillary ferrule

ceramic capillary ferru le

- vi -

Page 8

TABLE OF CONTENTS

Section Page

CHAPTER 1 USER NOTES

1.1 PRECAUTIONS FOR USING THE OFL-12................................................. 1-1

1.2 PREPARATION........................................................................................... 1-1

1.3 PRECAUTIONS FOR USING POLISHING FLUID ......................................1-2

CHAPTER 2 OVERVIEW

2.1 PARTS NOMENCLATURE..........................................................................2-2

2.2 OPERATIONAL PROCEDURE....................................................................2-6

CHAPTER 3 POLISHING PREPARATION

3.1 POLISHING DISK PREPARATION .............................................................3-1

3.2 POLISHING FILM PREPARATION..............................................................3-2

3.3 THRUST (POLISHING PRESSURE) SETTING ..........................................3-3

3.4 SETTING UP POLISHING TIME .................................................................3-4

CHAPTER 4 POLISHING PROCEDURE

4.1 MOUNTING THE FERRULES..................................................................... 4-1

4.2 REMOVING ADHESIVE (HAND POLISHING) ............................................4-4

4.3 ADJUSTING FIBER HOLDER..................................................................... 4-5

4.4 GRINDING (1ST POLISHING) AND POLISHING (2ND POLISHING).........4-6

4.5 FINISHING (3RD POLISHING)....................................................................4-10

4.6 POLISHING CONDITION CHECK...............................................................4-13

CHAPTER 5 MAINTENANCE

5.1 CLEANING AFTER POLISHING .................................................................5-1

5.2 CHANGING POLISHING FILM....................................................................5-1

- vii -

Page 9

Section Page

CHAPTER 6 TROUBLESHOOTING

APPENDIX

STANDARD POLISHING EFFICIENCY AND SPECIFICATIONS............... A-1

- viii -

Page 10

CHAPTER 1

USER NOTES

In this chapter, important notes for users are given. Please read them carefully

before using the OFL-12.

1.1 PRECAUTIONS FOR USING THE OFL-12

To protect the OFL-12 and use it correctly, please pay attention to the following

notes:

Do not leave the OFL-12 outdoors, or where water might damage it.

Do not subject the OFL-12 to undue vibrations or reckless drops.

Do not touch the operation panel or the switches with wet hands.

The OFL-12 is heavy (about 25 kg (55 lbs)), so place it on a sturdy table.

Be sure to supply electric power at the voltage and frequency specified.

Be sure to connect the grounding pin of the power cord plug to ground to

prevent electric shock.

Do not touch the rotating parts during use.

Be sure to disconnect the OFL-12 from the power source before changing the

polishing disks or other parts.

1.2 PREPARATION

In addition to the main Mass Production Polisher and its accessories, please

prepare the following items:

Cleaning paper lint-free synthetic cleaning tissue

Ethyl alcohol

Water Tap water

Washing container 3 (one for each polishing unit), approximately 3 (0.75

gal) each.(for washing the ferrules and holding jig)

1 - 1

Page 11

1.3 PRECAUTIONS FOR USING POLISHING FLUID

Please pay attention to the following when using the polishing fluid:

If you get the polishing fluid on your skin or into your eyes, rinse with water

quickly and thoroughly.

Make sure the area where the polishing fluid is being used is well ventilated.

If the polishing fluid gets on your clothes, they should be washed thoroughly.

After using, seal the container and store in a place that is between 0 and

50C (32 and 122F).

1 - 2

Page 12

CHAPTER 2

OVERVIEW

In this chapter, the parts of the OFL-12 basic machine and operational procedure

are explained.

In section 2.1, the names of the parts of the OFL-12 basic machine and their

function are explained.

In section 2.2, the standard operating procedure for polishing the ferrules is

explained.

2 - 1

Page 13

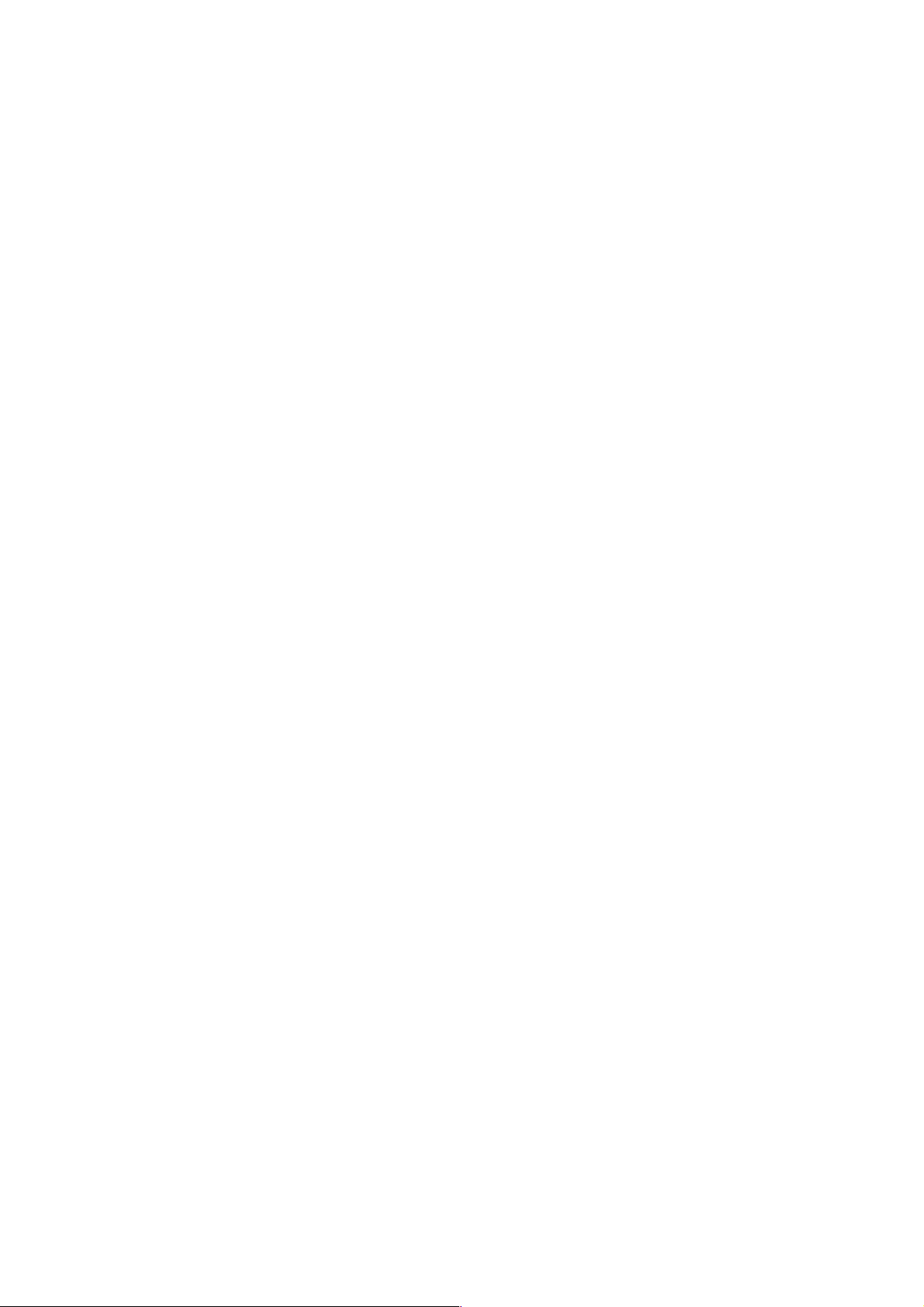

2.1 PARTS NOMENCLATURE

The parts of the OFL-12 basic machine are explained in this section. Figure 2-1

shows the OFL-12 after the polishing disks have been installed on the machine.

Fiber holder

Weight arm

Fuse holder (2 places

on the back side)

Protection cover

Timer

Polishing disk

POWER lamp

OFF button

Reset button (Counter)

Counter

ON button

Power switch

Figure 2-1 External View of OFL-12 and Operating Panel

2 - 2

Page 14

Power switch

Switches the power ON/OFF.

ON button (green)

When this button is pressed, the polishing disk begins to rotate. When the time

limit expires as set by the timer, the polishing disk stops rotating.

OFF button (red)

When this button is pressed, the polishing disk stops rotating and the polishing

operation stops immediately.

POWER la mp

Lights when power is input.

Timer

Specifies polishing time. The remaining time is displayed during polishing

operation.

Counter

The number of polishing operations can be checked on this counter. The

counter increments each time the ON button is pressed. To reset the counter,

press the reset button underneath the counter.

Fuse holder (2 places)

Holds a 250 V, 1 A fuse.

Fiber holder

The fibers are hung on this pole during polishing. The height is adjustable

according to the length of the fiber by loosening the black clamping knob,

slidingthe pole to the appropriate height, then tightening the knob.

Protection cover

When the cover is open, the polishing machine does not work if the switch is

turned on.

Polishing disk

Has a rubber disk on top onto which the polishing film is placed. The softness

ofthe rubber means that the tip of the ferrule will have a convex surface

polishedonto it.

2 - 3

Page 15

11) Weight arm

Provides the correct polishing pressure to the ferrule tips. There are three

setting positions for the weight on each arm.

12) Thrust pin

Applies the polishing pressure to the center of the holding jig so that a high

level of polishing can be obtained.

13) Rotation stop pin

Keeps the holding jig from rotating while the polishing disk is rotating.

2 - 4

Page 16

Protection Cover

Protection covers are provided with this machine to prevent operator from

touching the moving parts.

Open the covers with the knobs. Each covers are fixed with magnets when

they are closed.

When the cover is open, the machine does not operate if the switch is turned

on.

Do not pinch your fingers when you open or close the covers.

Do not force the cover open.

If the cover is damaged, stop using the machine and contact your dealer.

Take care not to cut your hand on the damaged cover.

When the machine operates abnormally, for example, the machine operates

with the covers open, stop using the machine and contact your dealer.

2 - 5

Page 17

2.2 OPERATIONAL PROCEDURE

The standard operating procedure for polishing the ferrules is shown below.

The numbers on the right hand side of the diagram correspond to the

explanations on the next page.

Check the condition of the ferrule

Polishin g prepa rat io n Sec t io n 3

Prepare the pol ishing disk

Prepare the polishing film

Setting the thrust

Polishin g procedure Section 4

Mount ferrules

Remove adhesive (hand polish)

Sectio n 3. 1

Sectio n 3. 2

Sectio n 3. 3

Sectio n 4. 1

Sectio n 4. 2

(1)

(2)

(3)

Grinding

Polishing

Finishing

Check polishing

Polishing complete

Maintenance Section 5

Sectio n 4. 4

Sectio n 4. 4

Repolish

Sectio n 4. 5

Sectio n 4. 6

NG

2 - 6

Page 18

(1) It is best to use only a small amount of adhesive on the tip of the ferrule. If

too much is used, sometimes it cannot be removed within the standard 30

seconds of hand polishing used to remove the adhesive.

(2) The polishing film, polishing fluid, and polishing conditions used in each of

the polishing steps are listed in Table 2-1. Refer to the details for each of

the polishing steps in the corresponding sections.

Polishing Step

Table 2-1 Polishing Media and Conditions

Polishing

Film

Polishing

Fluid

Thrust

(Std.)

1

Polishin

g Time

(Std.)

Polishing

Film Life

Adhesive removal

(hand polishing)

Grinding

(1st polishing)

abrasive

paper

(KJW100100)

green label

(KJW100200)

none approx.

30 sec. dispose of

1 to 2 kg

(2.2 to

4.4 lbs)

water Point 1 1 min.

30 sec.

every time

(max. 12

ferrules)

10 times

(max. 120

ferrules)

Polishing

(2nd polishing)

yellow label

(KJW100300)

water Point 2 1 min.

30 sec.

10 times

(max. 120

ferrules)

Finishing

(3rd polishing)

1 The polishing thrust (pressure) varies according to the number of ferrules mounted in the holding

jig. Refer to section 3.3 for setting the thrust.

white label

(KJW100400)

Polishing

fluid

(KJA100100)

Point 2 1 min. 10 times

(max. 120

ferrules)

(3) Mount the ferrules in the holding jig evenly according to the explanation

given in section 4.1. When the ferrules are mounted incorrectly, the

ferrules can slip and the tips of the ferrules may not be polished correctly.

When mounting less than 12 ferrules in the holding jig, make sure they are

arranged in a balanced pattern, according to the explanation given in

section 4.1. An unbalanced arrangement of ferrules in the holding jig may

not be polished evenly.

2 - 7

Page 19

2 - 8

Page 20

CHAPTER 3

POLISHING PREPARATION

In this chapter, all the preparations prior to starting polishing are explained.

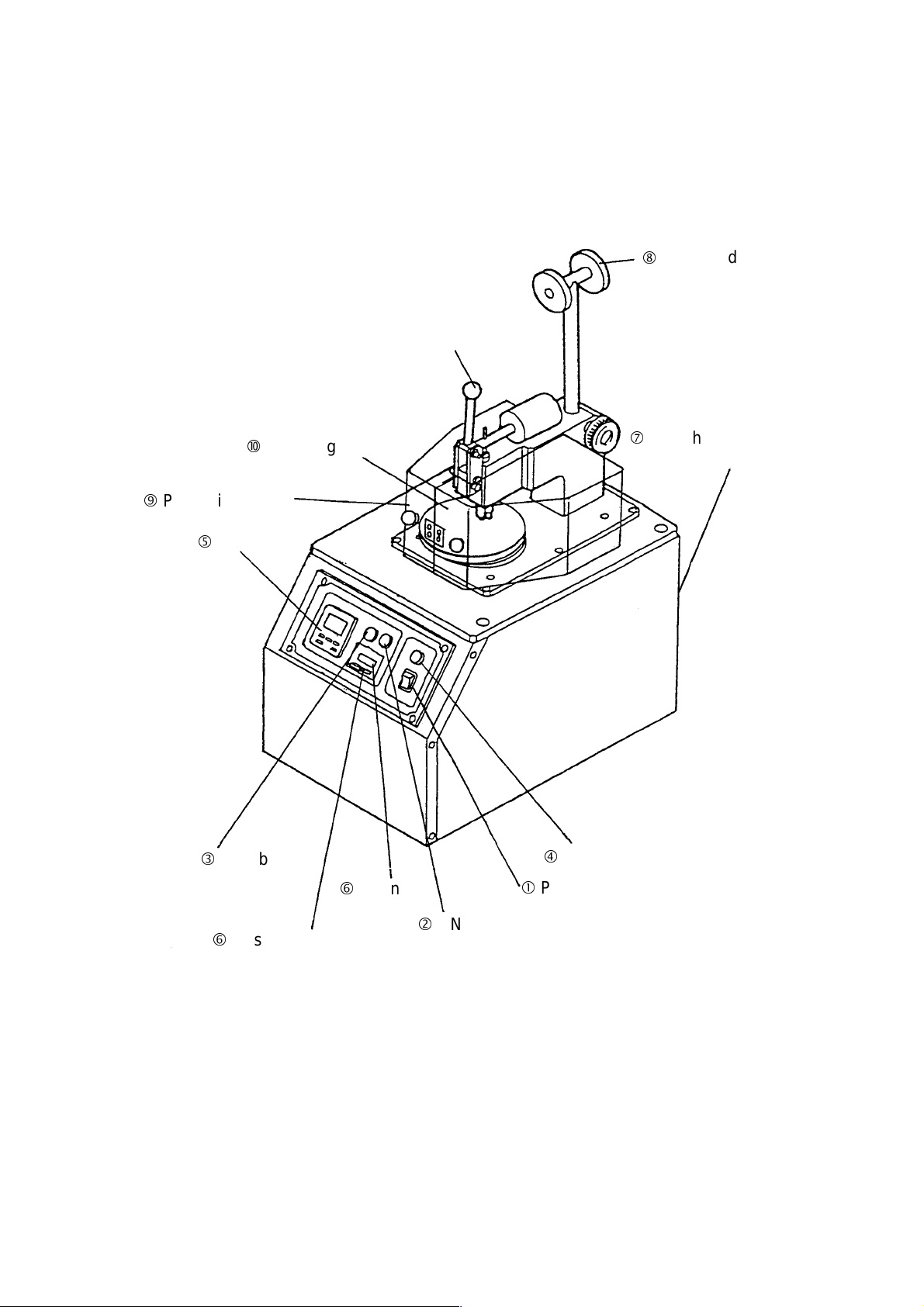

3.1 POLISHING DISK PREPARATION

Polishing disk

Polishing disk (underside)

Grease here

Guide pin

Step 1 Disconnect the power cord

from the outlet.

Step 2 Apply grease included in the

product to the underside of the

polishing disk. Also apply

grease to the center hole of

the underside.

Step 3 Attach the polishing disk to the

drive coupling, fitting the guide

pins on the drive coupling into

the holes on the underside of

the polishing disk.

NOTE

Make sure the pins on the drive

coupling go into the holes on the

underside of the polishing disk.

Drive coupling

NOTE

Do not use the polishing disk

without applying grease to prevent

the machine from being worn out.

Apply grease to the disk before it

dissipates. It is recommended that

you should apply grease once a

month.

3 - 1

Page 21

3.2 POLISHING FILM PREPARATION

Air

Colored label

Polishing film

Step 1 Clean the rubber surface of the

Step 2 Place the polishing film on the

Rubber disk

Polishing disk

polishing disk using cleaning

paper and ethyl alcohol. Be

sure to remove all dirt and

other foreign matter.

polishing disk so it is centered.

With your hand, spread the

polishing film from the center

outward to squeeze out the air.

Air

NOTE

Polishing film for Grinding: Green label

Polishing film for Polishing: Yellow label

Polishing film for Finishing: White label

3 - 2

Page 22

3.3 THRUST (POLISHING PRESSURE) SETTING

The polishing pressure (thrust) is set according to the polishing step and the number

of ferrules mounted in the holding jig. The polishing pressure is set by moving the

weight on the weight arm.

Step 1 Set the weight at one of the

three set positions for the

weight on the weight arm.

When you move the weight

along the weight arm, you can

feel the weight click at the set

Weight arm

positions. Do not set the

weight inbetween the set

positions.

Point 3

Weight

Point 2

Point 1

Step 2 The weight set position to be

used depends on the polishing

set up and number of ferrules

mounted in the holding jig.

Refer to Table 3-1.

No. of

Mounted

Ferrules

12

10

8

6

NOTE

If you have less than six ferrules

to polish, use dummy and/or

unusable ferrules so there are at

least six ferrules mounted in the

holding fixture. This is so that

the ferrules will get polished at

an equal quality level. Refer to

section 4.1.

Table 3-1 Weight Set Points

Weight Set Point

Grinding Polishing Finishing

1

1

2

3

2

2

3

3

2

2

3

3

3 - 3

Page 23

3.4 SETTING UP POLISHING TIME

Procedure of setting up polishint time

Press the polishing time setup keys to specify the polishing time. The

polishing time setup keys 1 through 4 correspond to each digit of the

setup time display.

SETUP PANEL

Remaining time display

Displays remaining polishing time

during polishing operation.

Setup time display

Displays the setup polishing time.

Polishing time setup keys

Sets up the polishing time.

Setup Time Display

Polishing time setup keys

key 4

m S

key 3 key 2 key 1

Each time you press either of the polishing time setup keys, the

number of the corresponding digit increases by 1.

If you press “Reset”, “MODE”, or “DISPLAY” key, they do not function.

3 - 4

Page 24

CHAPTER 4

POLISHING PROCEDURE

When all of the polishing preparations have been made, ferrule polishing can begin.

4.1 MOUNTING THE FERRULES

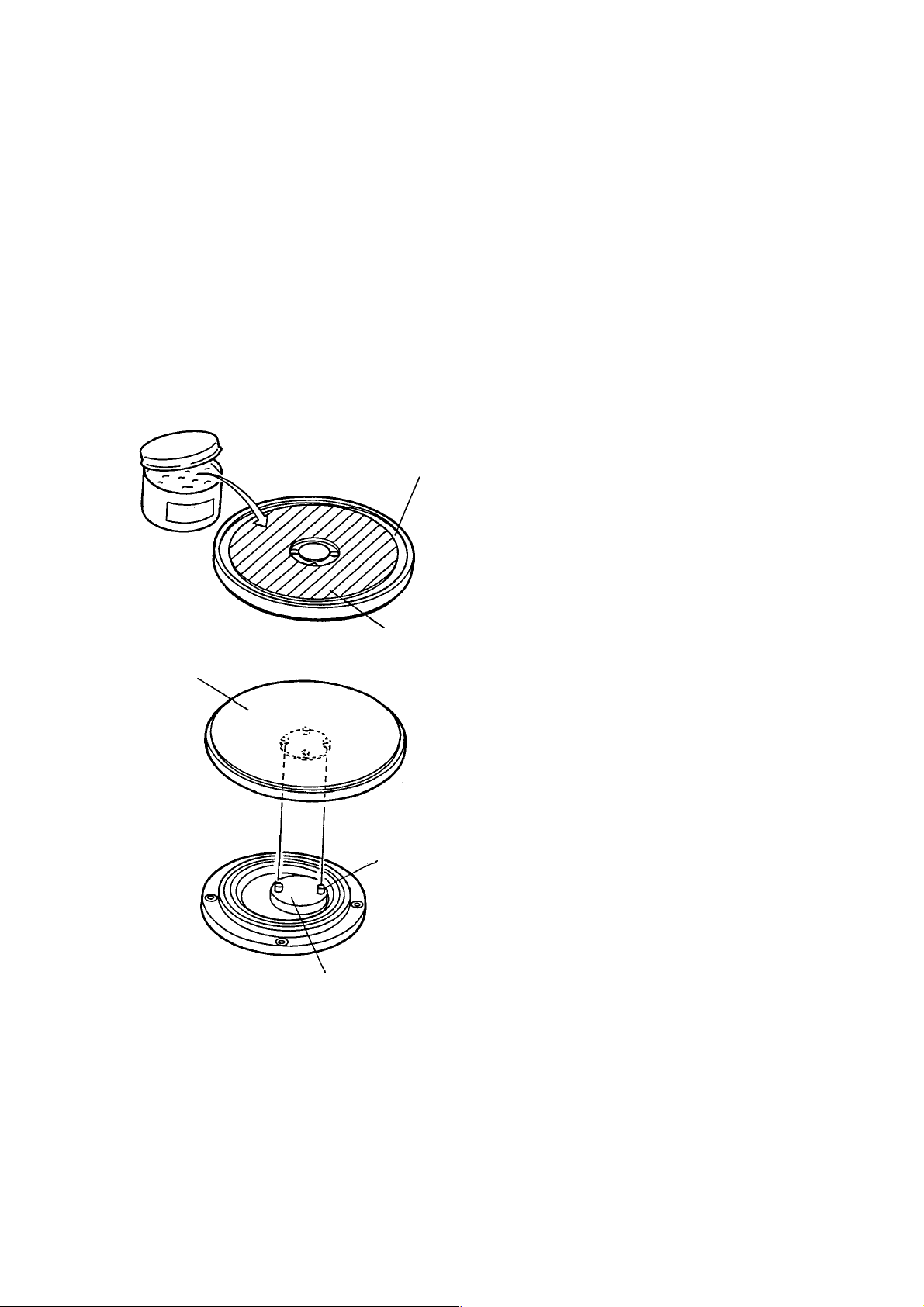

Step 1 Place the setup stand on a

desk or table and put the

holding jig onto the setup

stand, fitting the hole in the

V-grove

holding jig onto the pin on the

setup stand.

Ferrule

Step 2 Loosen the clamping screws

on the holding jig, turning

Ferrule flange

about 3 turns using the ballend hex wrench.

Holding jig

Clamping screw

Ball-end hex wrench

Step 3 Place the ferrules into the V-

grooves in the holding jig. See

Figure 4-1 for where to place

the ferrules to have a balanced

pattern.

Step 4 On each side of the holding jig,

tighten the clamping screw with

the ball-end hex wrench while

lightly pushing the flange on

the ferrules against the holding

jig.

NOTE

To tighten the clamping screws

with the appropriate tightness,

tighten finger tight, then use the

ball-end hex wrench to tighten

one quarter turn more.

4 - 1

Page 25

Dividing plane

CAUTION

Make sure that the ferrules do

not move after clamping them in

the holding jig.

Setup stand

Wire tie

Fiber

Ferrule

Holding jig

Step 5 Separate the fibers into two

bundles, one on each half of

the holding jig, and tie each

bundle with a wire tie.

NOTE

If you have less than six ferrules

to polish, use dummy or

unusable ferrules so there are at

least six ferrules mounted in the

holding fixture. This is so that

the ferrules will get polished at

an equal quality level.

4 - 2

Page 26

12

1

1

10

9

11

8

7

2

3

(12) (10)

76

8

4

5

1

2

10

9

8

7

6

6

5

2

3

4

5

1

6

5

(8) (6)

4

Figure 4-1 Balanced Ferrule Arrangements

Ferrule mounting is complete.

3

2

4

: Ferrule

3

4 - 3

Page 27

4.2 REMOVING ADHESIVE (HAND POLISHING)

Step 1 Clean the surface of the

Step 2 Place a new piece of abrasive

Step 3 Take the holding jig with the

Figure-8 motion

Adhesive removal pad

Holding jig

synthetic rubber sheet with

ethyl alcohol. Make sure all

dirt and other foreign matter is

removed.

paper onto the rubber pad.

ferrules mounted in it and rub

the tips of the ferrules against

the abrasive paper using a

figure-8 motion. Rub for about

10 seconds using only the

weight of the holding jig, then

for about 20 seconds with

about 1 to 2 kg (2.2 to 4.4 lbs)

of hand pressure.

Abrasive paper (for adhesive removal)

Step 4 Clean the tips of the ferrules

with cleaning paper. Make

sure that there is no adhesive

remaining on the tips of the

ferrules. Use a new piece of

abrasive paper every time this

polishing step is done.

NOTE

If the ferrules are mounted

incorrectly, the ferrule can slip

and the tip of the ferrule may not

be polished correctly.

4 - 4

Page 28

4.3 ADJUSTING FIBER HOLDER

This section describes how to adjust the height of the fiber holder. This adjustment

is done when mounting the holding jig onto the polishing unit. Refer to sections 4.4

and 4.5.

Step 1 Hang the looped fibers (which

have been tied into two

bundles) on the spool at the

end of the fiber holder (at the

lowest position).

Step 2 Mount the holding jig onto the

polishing unit as described in

steps 4 and 5 of sections 4.4

and 4.5.

Weight

Fiber holder

Fibers

Clamping knob

Polishing unit

Step 3 Loosen the clamping knob for

the fiber holder and slide the

fiber holder up so that the

fibers will not interfere with the

polishing.

Step 4 Tighten the clamping knob to

clamp the fiber holder in place.

NOTE

Always hang the fibers on the

fiber holder so that they do not

affect the weight. In this case

polishing may not be done

correctly because the adaquate

polishing pressure is not applied

to the holding jig.

4 - 5

Page 29

4.4 GRINDING (1ST POLISHING) AND POLISHING (2ND POLISHING)

Weight

Weight arm lever

Rotation stop pin

Holding jig

Notch in holding jig

Step 1 Open the protection covers.

Step 2 Place the polishing film for

grinding (green label) on the

polishing disk, then set the

weight position for grinding.

Step 3 Pull the weight arm lever

toward you.

NOTE

Set the weight arm lever to the

sown position with the protection

covers open.

Step 4 Clean the polishing film using

cleaning paper and water.

Using the squeezable dropper

bottle, wet the polishing film

with about 2 ml of water.

Rotation stop pin

Thrust pin

Notch in holding jig

NOTE

When you supply water, use the

squeezable dropper bottle to

avoid spilling water on the

operation panel.

Step 5 Put the holding jig (after

completing the previous

polishing step) onto the

polishing film with the rotation

stop pin in the notch in the

holding jig.

Step 6 Lift the weight arm lever up,

setting the thrust pin into the

hole in the center of the

holding jig.

4 - 6

Page 30

NOTE

Make sure that the weight arm

lever goes to the full up position.

If it does not, the correct

polishing pressure will not be

applied to the holding jig and

polishing will not be performed

correctly.

NOTE

Take care not to pinch your hand

with the weight when you attach

or detach the holding jig to or

from the machine.

Step 7 Close the protection covers.

Step 8 Set the timer to 1 min. 30 sec.

(standard).

Preparation for polishing is

complete.

Step 9 Press the ON button. The

polishing disk begins to rotate

and polishing begins.

NOTE

Press the OFF button if there is

any problem. The polishing disk

will stop rotating and polishing

will stop.

4 - 7

Page 31

Step 10 Th e polishing will automat ically

stop when the time set on the

timer is up. After the polishing

is completed, pull the weight

arm lever toward you and

remove the holding jig from the

polishing disk.

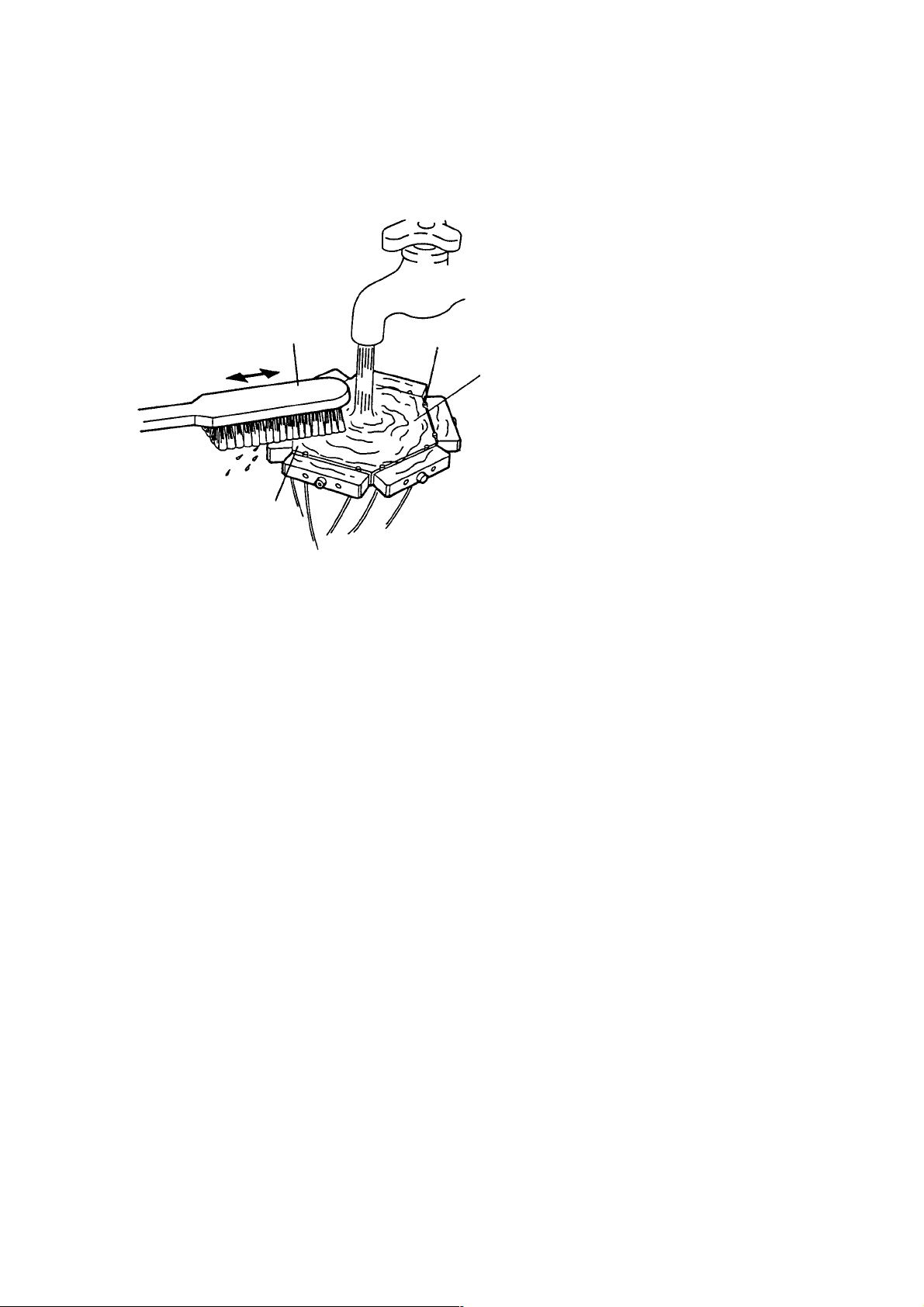

Soft brush

Ferrule tip

When removing the holding jig

NOTE

Water

from the polishing unit, lift the

holding jig up so the ferrules do

not touch the polishing film.

Step 11 Clean the holding jig and the

tips of the ferrules under

Holding jig

running water using the brush.

After cleaning, clean the brush,

removing all polishing grit or

other matter.

This illustration shows running water being used for washing. (There is no problem

if washing is done in the washing container, but using running water is preferred.)

NOTE

After cleaning, remove

waterdrops completely from the

holding jig.

4 - 8

NOTE

Do not touch the operation panel

with wet hands.

Page 32

Step 12 Clean the tips of the ferrules

with cleaning paper.

Fluorescent lights

Polished surface

Ferrule

Straight lines

Step 13 (Only after grinding.) Make

sure that the polished surface

is clean.

NOTE

Don’t take the ferrules out of the

holding jig yet.

Check the ferrule tip surface.

If the reflection of two parallel

fluorescent light tubes is

parallel, the polishing is

satisfactory. If the reflection

is not parallel, redo the

grinding step.

Step 14 Clean the surface of the

polishing film with cleaning

paper and water.

Distorted lines

Step 15 Replace the polishing film for

grinding with the polishing film

for polishing (yellow label),

then set the weight position for

polishing. Repeat procedures 2

through 12 (except for step 11)

using the polishing film for

polishing.

4 - 9

Page 33

4.5 FINISHING (3RD POLISHING)

Weight

Weight arm le ver

Rotation stop pin

Step 1 Replace the polishing film for

polishing with the polishing film

for finishing (white label), then

set the weight position for

finishing.

Step 2 Pull the weight arm lever

toward you.

Step 3 Using the squeezable dropper

bottle, apply polishing fluid to

the entire surface of the

polishing film.

NOTE

Holding jig

Notch in holding jig

Rotation stop pin

Thrust pin

Notch in holding jig

Apply 2 ml or more polishing fluid

Step 4 Put the holding jig (after

completing the polishing step)

onto the polishing film with the

rotation stop pin in the notch in

the holding jig.

Step 5 Lift the weight arm lever up,

setting the thrust pin into the

hole in the center of the

holding jig.

4 - 10

Page 34

NOTE

Make sure that the weight arm

lever goes to the full up position.

If it does not, the correct

polishing pressure will not be

applied to the holding jig and

polishing will not be performed

correctly.

Step 6 Set the timer to 1 min.

(standard).

Preparation for polishing is

complete.

NOTE

The first time a sheet of finishing

polishing film is used, the

polishing fluid will not completely

soak into the polishing film.

Therefore, when using a sheet of

finishing polishing film for the

first time, polish twice (1 minute

each).

Step 7 Press the ON button. The

polishing disk begins to rotate

and polishing begins.

NOTE

Press the OFF button if there is

any problem. The polishing disk

will stop rotating and polishing

will stop.

Step 8 The polishing will automatica lly

stop when the time set on the

timer is up. After the polishing

is completed, pull the weight

arm lever toward you and

remove the holding jig from the

polishing disk.

4 - 11

Page 35

Soft brush

Holding jig

Ferrule tip

Water

NOTE

When removing the holding jig

from the polishing unit, lift the

holding jig up so the ferrules do

not touch the polishing film.

Step 9 Clean the holding jig and the

tips of the ferrules under

running water using the brush.

After cleaning, clean the brush,

removing all polishing grit or

other matter.

NOTE

There is no problem if washing is

done in the washing container,

but using running water is

preferred.

Step 10 Take the ferrules out of the

holding jig, undo the wire ties,

wash the ferrule tips with water

and dry the tips of the ferrules

with cleaning paper.

Step 11 Clean the ferrules with

cleaning paper and ethyl

alcohol. Clean the surface of

the polishing film with cleaning

paper and water.

NOTE

Do not leave any polishing fluid

on the polishing film because the

polishing fluid can dry on the

polishing film, scratching the

ferrules if the film is used again.

If polishing will not be done for a

period of time, keep the polishing

film immersed in water so that

any polishing fluid on it will not

dry.

4 - 12

Page 36

4.6 POLISHING CONDITION CHECK

g

g

g

g

g

g

Check the condition of the ferrule tips after polishing. If there was a deep scratch

caused in the fiber during the adhesive removal step, satisfactory polishing cannot

be obtained. In this case, repolish.

NOTE

When repolishing ferrules that have an unsatisfactory polished condition,

polish from the grinding step to the finishing step to obtain consistent

polished quality.

(1) Speckles (2) Slight Scratch

Speckles

Repolish, doin

the polishing and

finishing steps.

Occurs near the end of the life of

the polishing film.

Occurs when the ferrule

mountin

in the holding jig is poor.

Slight scratch

Repolish, doing the polishing and

finishing steps.

Occurs when there is insufficient

cleaning between polishin

steps.

Occurs when you rub the tips of

the ferrules against the polishin

film when mounting the holdin

ji

to and removing it from the

polishing unit.

4 - 13

Page 37

(3) Fiber Scratch or Large

g

Scratch

Large scratch

(4) Polishing Fluid Remaining

Fiber scratch

Repolish, doin

the grinding,

polishing, and finishing steps.

Scratch was made during the

adhesive removal step.

Make sure you correctly follow

the

procedure for adhesive removal

(10 seconds with only the weight

of the jig, 20 seconds with 1 to 2

kg hand pressure).

Polishing fluid

Clean the tip of the ferrule. If you

cannot remove the polishing fluid,

do the finishing step again.

Clean the ferrules carefully after

every polishing step.

4 - 14

Page 38

CHAPTER 5

MAINTENANCE

In order that the machine functions correctly, the following maintenance operations

must be carried out after completion of polishing operations.

5.1 CLEANING AFTER POLISHING

After finishing polishing, or when stopping polishing for a period of time, clean

the OFL-12 as well as all of the polishing films carefully with water. If no

cleaning is done, the remaining polishing fluid will harden. Also make sure

that no waterdrops remain on the operation panel.

When the OFL-12 won’t be used for a long time, ultrasonically clean the

holding jig in ethyl alcohol, then oil the holding jig and keep it in a vinyl

envelope.

5.2 CHANGING THE POLISHING FILM

The standard lifetime of a sheet of polishing film is 10 uses (120 ferrules

maximum) (for the abrasive paper for adhesive removal the lifetime is only

one use).

5 - 1

Page 39

5 - 2

Page 40

CHAPTER 6

TROUBLESHOOTING

Figure 6-1 is a list of anticipated problems during machine operation along with

items to check. If a problem develops, refer to the appropriate section in Figure 6-1

to find what is out of the ordinary, and solve the problem. If the problem cannot be

solved, please contact SII.

6 - 1

Page 41

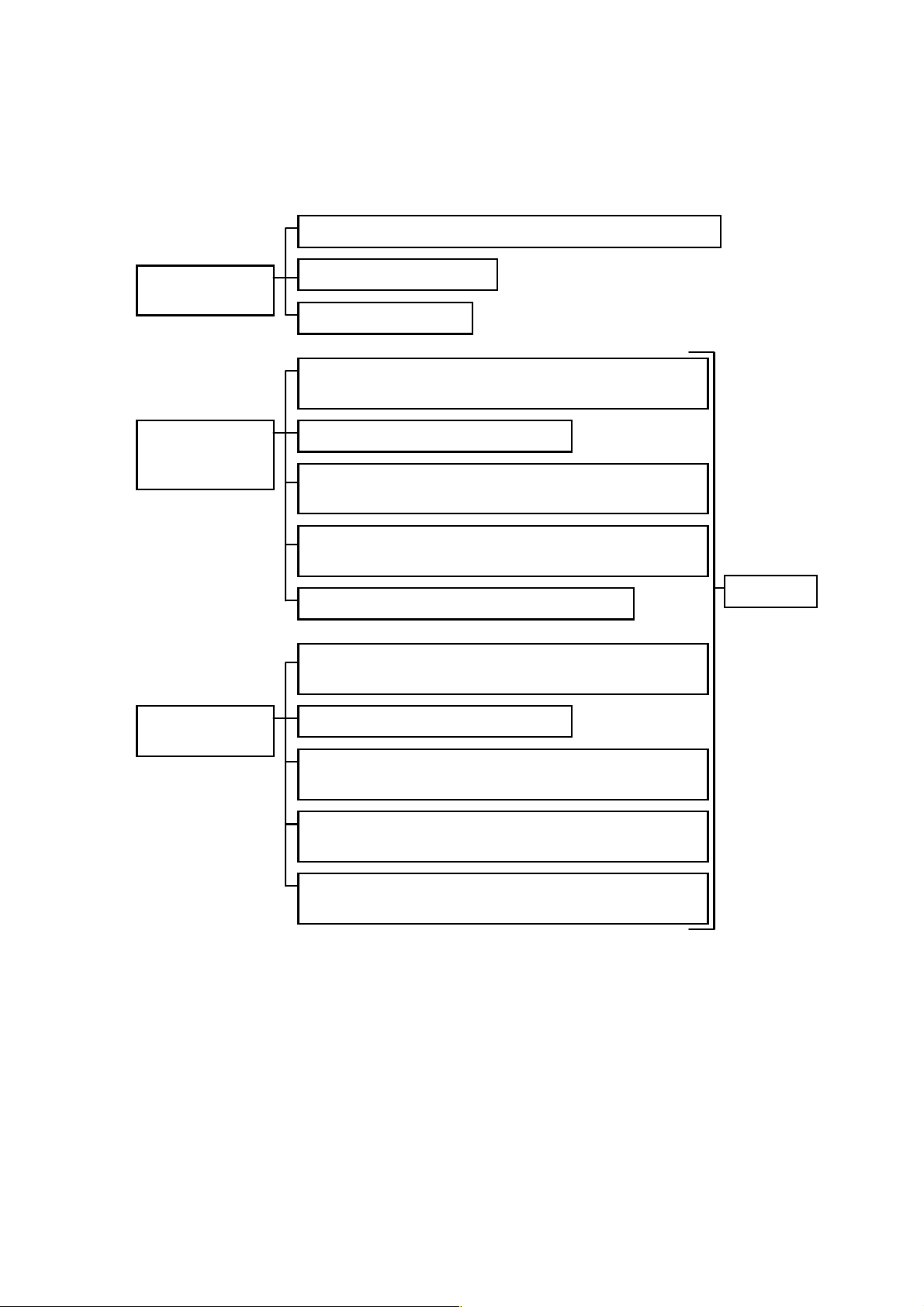

Is the power cord plugged i nt o a power outlet?

j

Doesn’t

operate

Can’t obta in

predome

shape

Speckles

Large scratch

End curve

radius out of

tolerance

Bad surface

condition

Many

scratches

Return loss

below 40 dB

Is the timer set to 0?

Is the fuse blown?

Has the polishing film been used more than 10

times?

Is water being used?

Is the surface of the polishing film being cleaned

with water between polishing steps?

Is the mounting correct: ferrules in the holding

ig and the holding jig on the unit?

Is the weight at the correct position?

Has the polishing film been used more than 10

times?

Is poli shing fluid being use d?

Is the surface of the polishing film being cleaned

with water between polishing steps?

Are the ferrules being c le an ed wit h water

between polishing steps?

Repolish

Refer to

section

4.6

Was the tip of the ferrule rubbed on the film

when being removed from the unit?

Figure 6-1 Troubleshooting Chart

6 - 2

Page 42

APPENDIX

STANDARD POLISHING EFFICIENCY AND SPECIFICATIONS

Applicable EC Directives & Standards

Directives Title

89/392/EEC Machinery

89/336/EEC Electromagnetic Compatibility

Standards

Machinery: EN292-1 (1991)

EN292-2 (1991)

EN294 (1992)

EN418 (1992)

EN60204-1 (1992)

EMC: EN55022 (1987 and 1994) / Class B

EN50082-1 (1992)

IEC801-2 (1984)

IEC801-3 (1984)

IEC801-4 (1988)

Standard polishing efficiency (R20 convex surface polishing) :

Standard polishing time (excluding adhesive removal)

Grinding 1.5 minutes

Polishing 1.5 minutes

Finishing 1.0 minutes

Polishing process 3 steps (excluding adhesive removal)

Return loss 40 dB or more

End curve radius 10 to 25 mm (0.394 to 0.984 inch)

End curve offset 50 m (0.00197 inch) or less

Fiber under-cut 0.1 m or less

Noise 60 dB (A) or less

General specifications:

Power supply 220/230 VAC, 50/60 Hz (OFL-126001)

230/240 VAC, 50/60 Hz (OFL-127001)

Power consumption 55 W

Operating temperature 10 to 40C (50 to 104F) (noncondensing)

Physical dimensions 240 (W)390 (D)530 (H) mm

(9.4515.420.5 inches)

(with fiber holder at the lowest position)

Weight approximately 25 kg (55 lbs)

Timer 0 through 99 min. 59 sec. (Unit: second)

A - 1

Page 43

Operating environmental specifications :

Operating temperature 10 to 40C (50 to 104F) (noncondensing)

Relative humidity 15% to 85%

Vibration operating: 0.25 G 5 to 100 Hz 10min.

powered-off: 0.50 G 5 to 100 Hz 20min.

Acceptable impact 50 mm (1.97 inch) drop (one side)

Storing environmental specifications :

Storing temperature -25 to 65C (8 to 149F) (noncondensing)

Relative humidity 15% to 85%

A - 2

Loading...

Loading...