Page 1

User's Guide

Océ CS 6060

Solvent Ink

Color Inkjet Printer

IP-6600

U00086051201

Read this User's Guide to use the printer safely and

properly. Keep this manual in a place where you

can quickly access it at any time.

Seiko I Infotech Inc.

Page 2

IP-6600 Solvent Ink Color Inkjet Printer User's Guide

Documents Number U00086051201

First Edition, December 2003

Second Edition, February 2004

Copyright © 2003, 2004 by Seiko I Infotech Inc.

All rights reserved

Seiko I Infotech Inc. reserves the right to make changes without notice to the specifications and

materials contained herein and shall not be responsible for any damages (including

consequential) caused by reliance on the materials presented, including but not limited to typographical, arithmetic, or listing errors.

Please address any questions, comments, and suggestions to:

Seiko I Infotech Inc.

Blue Sphere Nihonbashi Bldg.

11-1, Nihonbashi Tomizawa-cho,

Chuo-ku, Tokyo 103-0006, Japan

This manual acknowledges the following trademarks:

SII is a trademark of Seiko I Infotech Inc.

All other trademarks are the properties of their respective companies.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

Durch die Kennzeichnung dieses Produktes mit dem CE-Zeichen erklärt Seiko den folgenden

Direktiven der Europäischen Union zu entsprechen (mit Wirkung vom siehe Datum):

Januar 1996:- EG-Direktive 73/23/EEC ergänzt durch EG-Direktive 93/68/EEC, Angleichung der

Gesetze der einzelnen Mitgliedsstaaten bezüglich Geräten mit niedriger Betriebsspannung.

Januar 1996:- EG-Direktive 89/336/EEC, Angleichung der Gesetze der einzelnen Mitgliedsstaaten

bezüglich elektromagnetischer Kompatibilität.

Den vollständigen Text dieser Erklärung einschließlich der Definition der entsprechenden

Direktiven sowie der jeweiligen Standards erhalten Sie von Ihrem Seiko Colorgrafx Systems

Kundendienst oder Ihrem Seiko Engineering Systems Kundendienst.

Page 3

Introduction

Thank you very much for purchasing the IP-6600 Color Inkjet

Printer (simply called the printer below).

This printer is a color inkjet printer that adopts solvent ink, supports

64 inch media width, and builts-in SCSI interface.

This manual, the IP-6600 User's Guide, describes the features of

the printer, names of components, information to be known before

use, and basic operations, such as how to turn the power on and off

and set media and ink.

The following items should be read before reading Section 1.

- Deliverables

- Safety precautions

- Handling precautions

- Manual legend (notation rules)

Read these items to use the printer safely and properly. Keep this

manual in a place where you can quickly access it at any time.

Page 4

Page 5

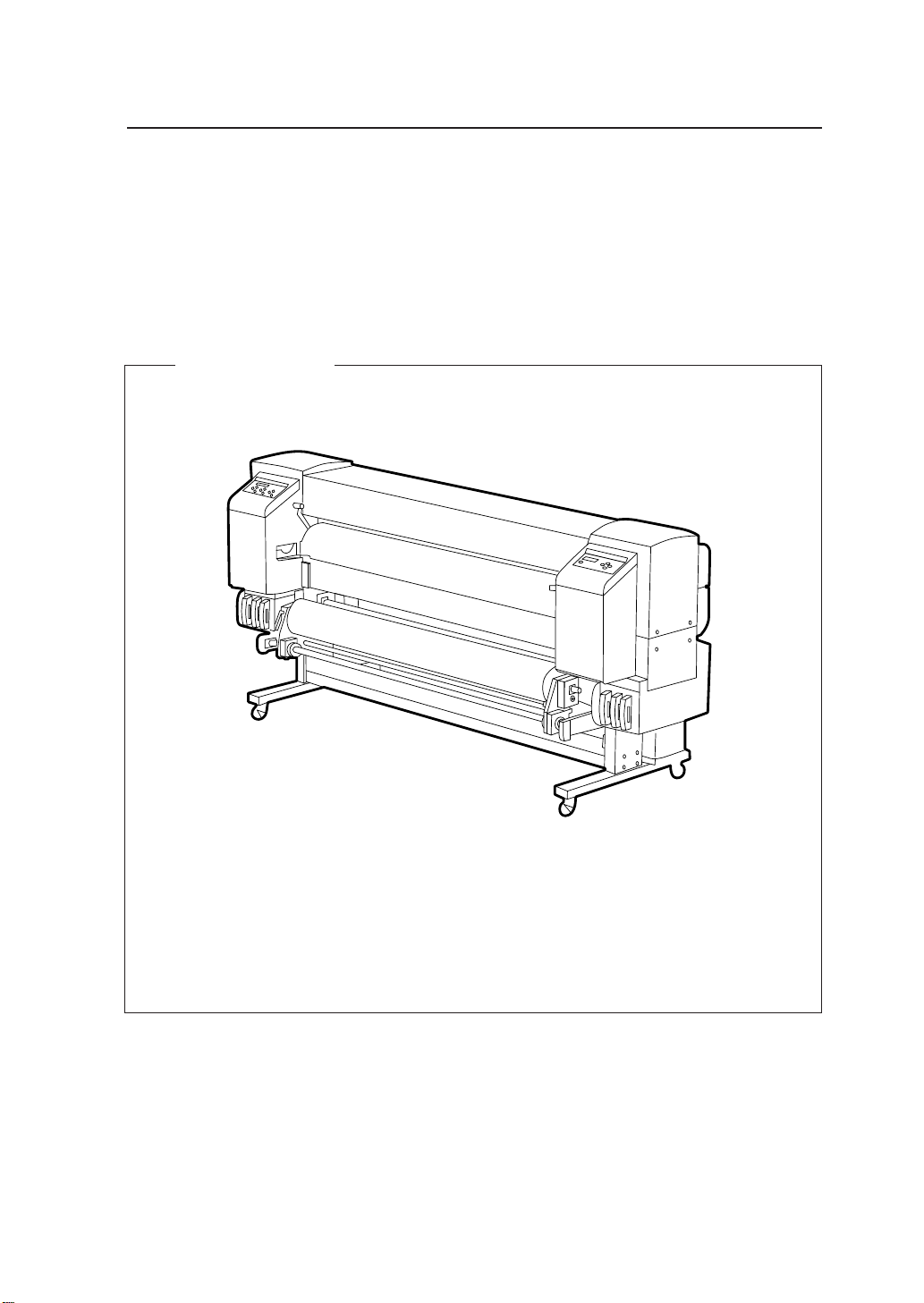

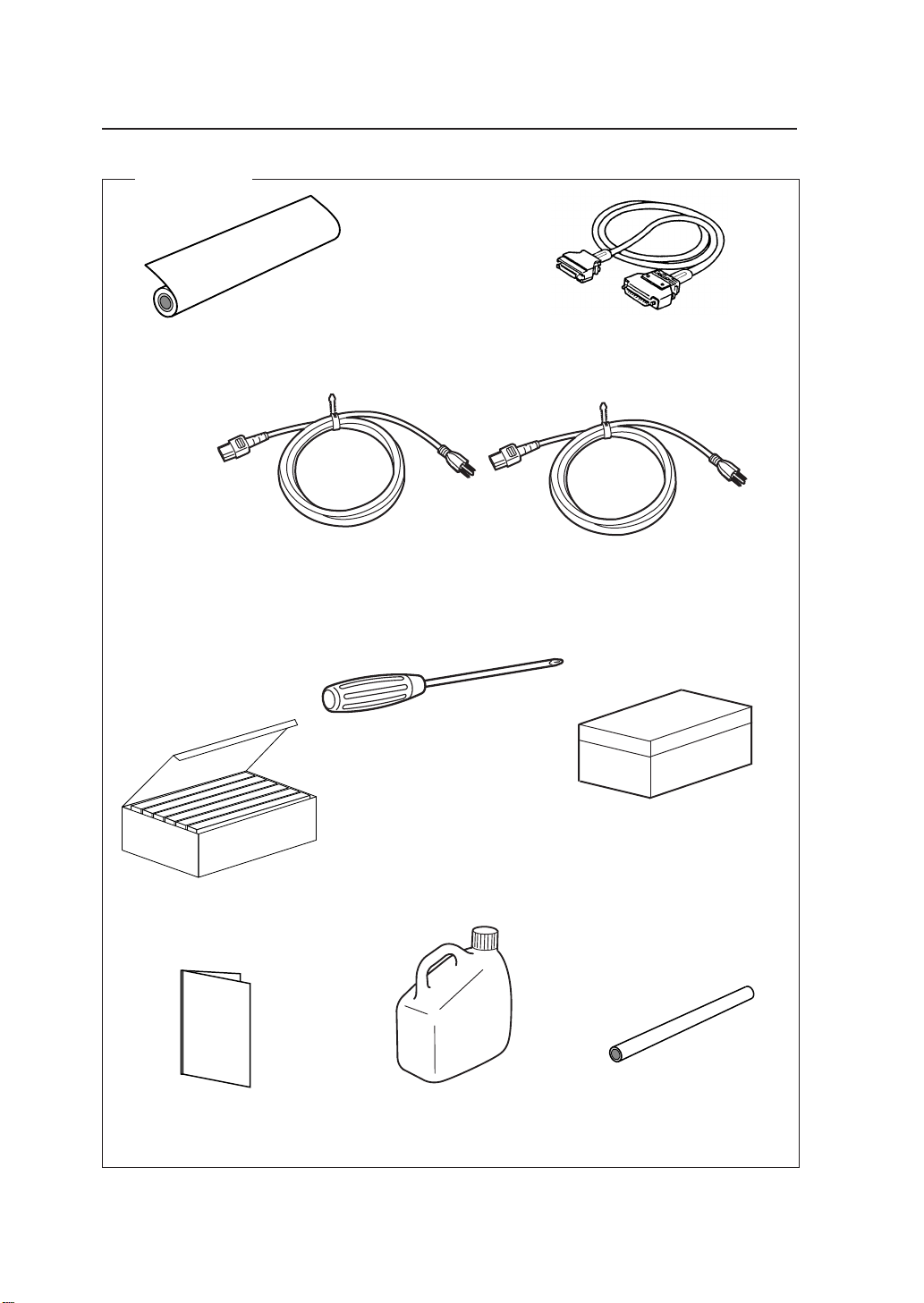

Deliverables

The printer components, including options, are installed on the main

unit on delivery. Make sure that the following items are present.

If any parts are missing or damaged, contact the shop where you

purchased the product or the nearest service dealer.

Basic components

Printer main unit <1>

• Built-in SCSI interface.

• Including a winding unit.

i

Page 6

Accessories

Roll paper(for installations)

<1>

Ink kit 6 colors IP6-100

(Y, M, C, Bk, Lc, Lm)

<1>

SCSI cable

<1>

Power cord

<2>

• Power cord for printer

• Power cord for heater

+ screw driver

(for head up/down adjustment)

Maintenance kit IP6-108

<1 set>

• Cap cleaning liquid: 100 ml

• Wiper cleaning liquid: 100 ml

• Cleaning swab: 50 pieces

• Syringe: 10 pieces

User's Guide

<1 copy>

*: Ink capacity of each ink cartridge for ink kit 6 colors IP6-100 is 500 ml.

Approximately 100 ml ink for each color is consumed at initial ink charge. Therefore, this 100 ml ink for each

color cannot be used for print.

Waste ink bottle IP6-109

<1>

Paper tube 64"

<1>

ii

Page 7

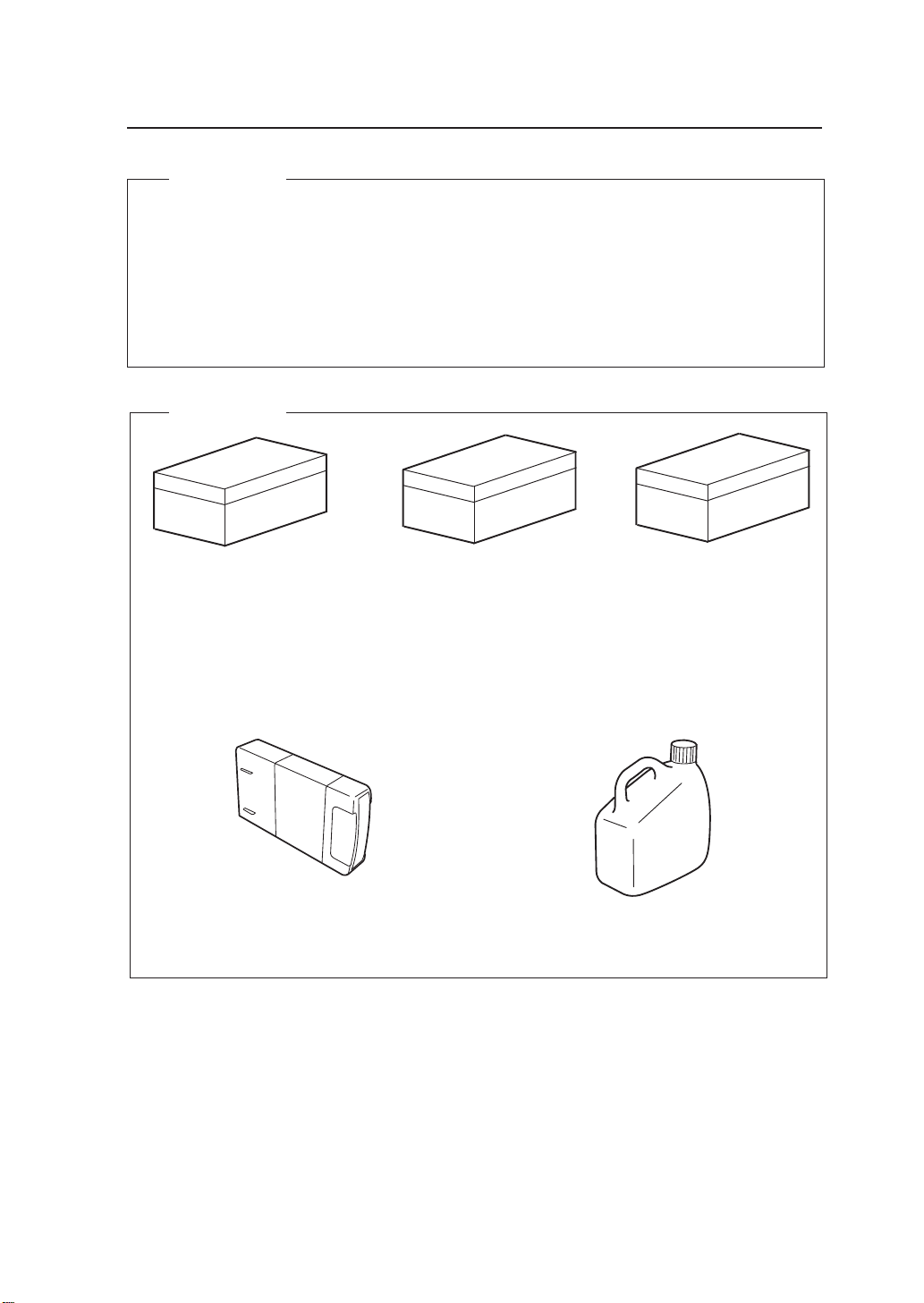

Options

• Dryer 64 (IP-260) : 1

• Dryer 64 for North America (IP-263) : 1

• Roll Cover 64 (IP-261) : 1

• Exhaust Attachment (IP-262) : 1

• PS RIP (Photo Print 4 Dx) (IP-540) : 1

• PS RIP (Photo Print 4 Server) (IP-541) : 1

Consumables

Maintenance Kit IP6-108

<1 set>

• Cap cleaning liquid: 100 ml

• Wiper cleaning liquid: 100 ml

• Cleaning swab: 50 pieces

• Syringe: 10 pieces

Ink cartridges IP6-XXX

(Y, M, C, Bk, Lc, Lm)

See page 1-8 for the item number.

* : Options and consumables can be ordered separately.

Cleaning Kit IP6-117

<1 set>

• Cleaning liquid cartridge: 6

• Dummy cartridge: 6

Storage Kit IP6-137

<1 set>

• Maintenance liquid cartridge: 6

• Dummy cartridge: 6

Waste ink bottle IP6-109

<1>

iii

Page 8

Safety Precautions

The following symbols are used in this manual to ensure the proper

use of the printer and to prevent the printer from being damaged.

Follow the instructions marked with these symbols.

Serious personal injury or death:

Failure to follow the guidelines marked with

WARNING

this symbol could result in serious personal

injury or death.

Minor personal injury or product and/or

peripheral damage:

CAUTION

Example of symbols:

Failure to follow the guidelines marked with

this symbol could result in minor personal

injury or product and/or peripheral damage.

This symbol ( ) denotes items that require special care

while executing a certain procedure or operation.

This symbol (

This symbol (

prevent accidents or injury.

) denotes items that are forbidden.

) denotes items you should follow to

iv

Page 9

WARNING

Use the power supply voltage specified on the nameplate. DO NOT

plug several devices into one electrical outlet as this might result in fire

or electric shock.

Make sure the printer is well grounded. If not, a short circuit may cause

fire or electrical shock.

DO NOT disassemble or remodel the printer. DO NOT repair the printer

by yourself. Doing so may cause fire, electric shock or other accidents.

DO NOT damage, break, process, or heat the power cable. If it is

damaged, replace it with a new one. Using a damaged power cable may

cause fire or electric shock.

NEVER use the printer in a place of extreme humidity or any place

where it can possibly be splashed by any liquids. If any liquids get into

the printer, it could lead to fire, electric shock, or other serious accidents.

DO NOT remove the covers attached to the printer because they contain

high-voltage and extremely hot parts. Careless removal might result in

an electric shock or burn.

DO NOT allow metal or liquids to touch the internal parts of the printer.

Doing so may cause fire, electric shock, or other accidents.

DO NOT disconnect or connect the power cable with wet hands. Doing

so may lead to electric shock.

Turn the printer off and unplug the power cable immediately after it

thundered.

v

Page 10

WARNING

Power OFF the printer and unplug the power cable from the power outlet

in any of the following cases:

• When putting your hands inside the printer.

• Smoke, strange noise or smells generate from the printer.

•A piece of metal or any liquid touches the internal parts or slot of

the printer.

• An error requiring service by a service center occurs.

DO NOT put your hand into the paper delivery slot as it may lead to

injury by the cutting device.

Do not leave the printer stained with ink.

The coating of the printer may be damaged.

The ink used for the device contains organic solvent

(Ethylenglycolmonbutyleteracetat).

Therefore, observe the local rules strictly related to organic solvent stuff.

The ink used for the device contains organic solvent

(Ethylenglycolmonobutyletheracetat), Since the ink is flammable, never

use fire when using the device.

Do not swallow ink or avoid its splashes on the eye. If it gets into the

eye, wash it off with a clean running water and consult a doctor as

required. If it is swallowed, do not try to vomit it forcefully, but cunsult

a doctor.

Keep ink cartridges out of reach of children.

vi

Page 11

CAUTION

Handle the paper rolls with care because they are very heavy. If you

drop them, it could lead to personal injury.

Hold the electric cable by the plug when connecting or disconnecting it.

Failing to do so may cause the cable to fray or break which could lead to

electric shock and/or fire.

DO NOT get ink on your skin or clothes. Wash off any ink immediately

with soapy water.

DO NOT put any paper rolls on an unstable table or a tilted surface as

they could fall leading to an injury.

The heater will be hot.

Pay attention not to touch and not to be burned.

In order to ensure the safe operation of the printer heed all of the cautions

and warnings contained throughout this manual.

vii

Page 12

Handling Precautions

Power Supply

1. Install the printer near an easily accessible electrical outlet.

2. Do not provide power to the printer through the same power

line as for noise-generating devices, such as a motor.

3. Use the power supply matched with the specification of the

printer.

4. Connect the power cable to an electrical outlet. Do not plug

several devices into one electrical outlet.

Printer

1. Do not place anything on top of the printer. Do not rest your

elbows on the printer.

2. Open and close the top cover gently from the front of the printer

with both hands.

3. Before connecting or disconnecting the interface connector, turn

the printer off.

4. Do not clean the surface of the cover with benzene or paint

thinner. The coating may come off or deteriorate.

Wipe the cover clean with a soft cloth. If the cover is very dirty,

use a cloth moistened with a neutral detergent.

5. Do not touch the ink-jet head surface.

Regular Inspection and Maintenance

The following regular inspection and maintenance must be

performed in terms of characteristics of solvent ink.

1. Clean the capping unit every day.

2. Check moisture of wipper sponge every day.

3. Perform the head cleaning every one month.

4. Perform the service cleaning when leaving the printer for long

time (2 weeks or more at power off state.)

5. Perform the head wash and the ink charge before printing when

leaving the priner for long time.

See pages 2-48 and 2-59 for regular inspection and maintenance.

viii

Page 13

Consumables

1. Always use the recommended consumables (media, ink, etc.).

2. Do not use ink past the date of expiration as this may cause a

3. Put a used ink cartridge into a plastic bag and dispose of it as an

4. Do not get ink on your skin or clothes. Wash off any ink

5. Check waste ink bottle regularly so as not to leak the waste ink.

6. When the waste ink bottle is installed or removed, spread the

7. Store ink in a dark and cool place.

8. Do not attempt to disassemble ink cantridges.

9. Media for solvent ink on the market can be used for this printer.

Failure to follow this instruction may cause poor print quality

or a breakdown.

breakdown.

industrial waste. Observe any regulations for disposal of waste

ink bottles.

immediately with soapy water.

stain preventing sheet so as not to stain the floor with spilt ink.

NEVER store ink in a high temperature or direct sunshining

place.

Doing so, ink may cause characteristic changes.

ix

Page 14

Manual Legend (Notational rules)

This manual uses the notational rules for marks, keys, LCDs, and

LEDs:

Marks

WARNING

Boxes marked with a "WARNING" describe points of caution for

avoiding serious personal injury.

CAUTION

Boxes marked with a "CAUTION" describe points of caution for

avoiding injury to yourself or damage to the printer.

NOTE

Boxes marked with a note describe precautions while handling the

printer.

HINT: Hint mark

The hint symbol describes operations that make using or

HINT

handling the printer easier.

Reference mark

This mark is followed by a reference section or page number.

x

Page 15

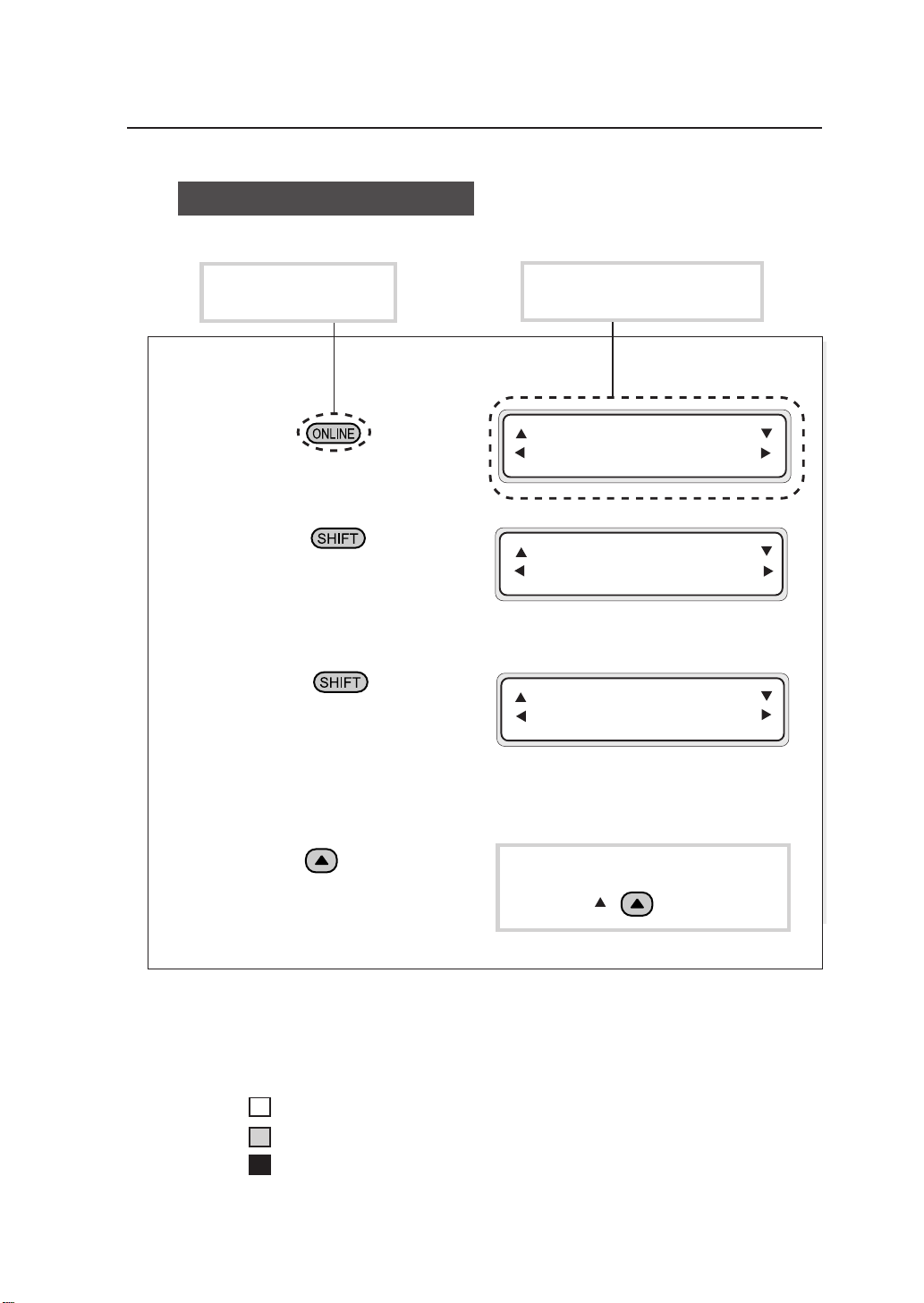

Notation of Keys/LCDs/LEDs

Example 1: Keys and messages shown on the LCDs in the text

This represents a key

on the operation panel.

1

Press to put the

printer offline.

2

Press to select

the first menu in the

local operation mode.

3

Press again to

select the second menu

in the local operation

mode.

This represents the LC display

on the operation panel.

INK ENTRY

PAPER F•ADJ

SERVICE FEED

CLEANING

FUNC SYSTEM

ADJUST RESET

4

Press to enter the

function menu.

Example 2: LED's states in the text

LED's states of "On", "flashing", and "Off" are characterized by the following

symbols:

On

Flashing

Off

This represents a key to seledt the

menu. (Ex. :

key)

xi

Page 16

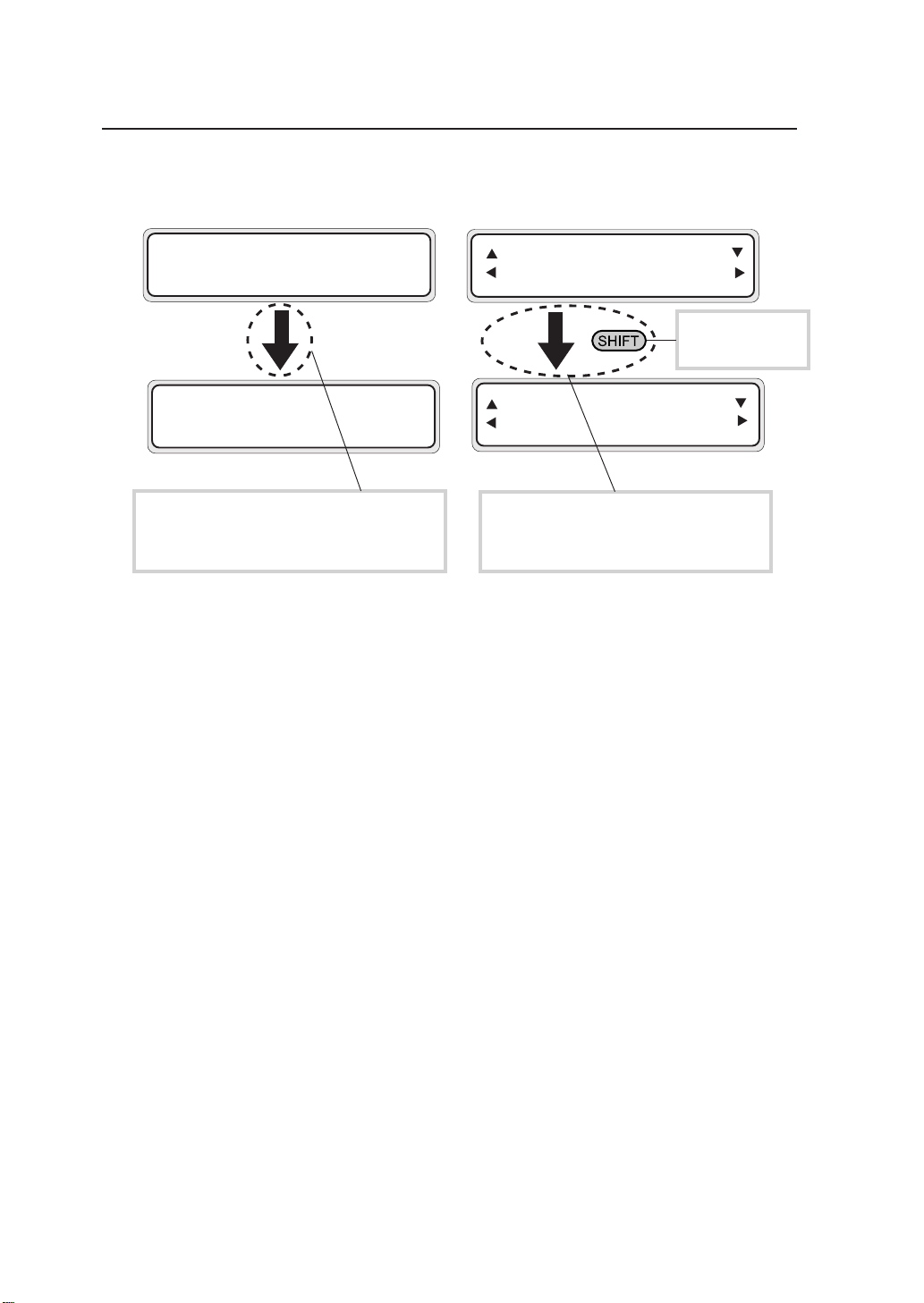

Example 3: LCD's state transitions and key operations in the text

INITIALIZING

WAIT A MOMENT

INK ENTRY

PAPER F. ADJ

A key on the

operation panel.

PRINT READY

ROLL : 64" (COATED)

This indicates that the LCD screen

changes to another automatically without

pressing a key.

SERVICE FEED

CLEANING

This shows that the LCD screen

changes to another when the operator

presses a key.

xii

Page 17

TABLE OF CONTENTS

Introduction

Deliverables ......................................................................................... i

Safety Precautions..............................................................................iv

Handling Precautions........................................................................ viii

Manual Legend (Notational rules)....................................................... x

Section 1 Getting Started (Basic knowledge) 1-1

Operating Conditions ....................................................................... 1-2

Installation Space ................................................................ 1-2

Environmental Conditions ................................................... 1-3

Consumables ................................................................................... 1-5

Paper ................................................................................... 1-5

Ink .................................................................................... 1-8

Waste Ink Bottle ................................................................ 1-10

Maintenance Kit ................................................................. 1-11

Storage Kit ......................................................................... 1-12

Cleaning Kit ....................................................................... 1-12

External Views, Part Names, and Functions ................................. 1-13

Front .................................................................................. 1-13

Rear .................................................................................. 1-14

Rear .................................................................................. 1-14

Heater ................................................................................ 1-15

Operation Panel ................................................................ 1-16

Heater Control Panel ......................................................... 1-18

Drying Device 64 (Option) ................................................. 1-19

Roll Cover 64 (Option) ....................................................... 1-19

Exhaust Attachment (Option) ............................................ 1-19

PS RIP (PhotoPrint 4 DX) (Option) ................................. 1-19

PS RIP (PhotoPrint 4 Server) (Option) ............................ 1-19

LCD Messages and Printer State .................................................. 1-20

Messages on the LCD ....................................................... 1-20

CONTENTS-1

Page 18

Section 2 Basic Operations

Connecting with Computer .............................................................. 2-2

System configuration (connection example) ....................... 2-2

Connection procedure ......................................................... 2-2

Turning the Power On/Off ................................................................ 2-5

Turning the Power On ......................................................... 2-6

Turning the Power Off ......................................................... 2-9

Replacing the Paper Roll ............................................................... 2-11

Installing Paper Roll in the Printer ..................................... 2-11

Removing the Paper Roll from the Printer......................... 2-17

Replacing Paper Roll with Another .................................... 2-18

Replacing Empty Paper Roll ............................................. 2-18

Replacing Jammed Paper Roll .......................................... 2-18

Installing/Removing Cut Sheet in/from the Printer ............ 2-19

Replacing Ink Cartridges ............................................................... 2-20

Ink Cartridge Replacement Procedure .............................. 2-20

Replacing Empty Ink Cartridge .......................................... 2-22

If an Ink Cartridge Is Not Installed ..................................... 2-23

If an Ink Cartridge Is Not Detected .................................... 2-24

Replacing the Waste Ink Bottle...................................................... 2-25

Waste Ink Bottle Replacement Procedure ........................ 2-25

If the Waste Ink Bottle Is Full ............................................. 2-27

If the Waste Ink Bottle Is Not Installed .............................. 2-28

Head Cleaning "CLEANING" ......................................................... 2-29

Paper Feed "FEED" ....................................................................... 2-31

Using the Origin Point Setting Function ............................ 2-32

Installing Paper on Winder............................................................. 2-35

Changing Heater Control Setting Temperature ............................. 2-40

Using the Media Pressure Alternation Lever ................................. 2-42

Using the Head Up/Down Lever .................................................... 2-43

Using the Media Edge Guard ........................................................ 2-45

CONTENTS-2

Page 19

Using the FAN Guard Positioning Bar ........................................... 2-46

Using the Print Pause/Restart and Cancel Keys ........................... 2-47

Inspection & Maintenance ............................................................. 2-48

Section 3 Operation Panel Menu Operations

Basic Menu Operation ..................................................................... 3-2

Menu Hierarchical Structure ................................................ 3-2

Menu Tree ........................................................................... 3-3

Basic Operations and Keys ................................................. 3-8

Operation Procedure for Choice Input, Value Input,

Execution, and Character Input ........................................... 3-9

Menu Operations ........................................................................... 3-15

INK Menu .......................................................................... 3-15

PAPER Menu .................................................................... 3-16

ENTRY Menu .................................................................... 3-17

F.ADJ Menu....................................................................... 3-32

SERVICE Menu ................................................................. 3-35

CLEANING Menu .............................................................. 3-38

FEED Menu ....................................................................... 3-39

FUNC Menu....................................................................... 3-40

ADJUST Menu .................................................................. 3-41

SYSTEM Menu .................................................................. 3-44

RESET Menu .................................................................... 3-48

Section 4 Heater Controller Operation

Temperature Control........................................................................ 4-2

LDC Display ..................................................................................... 4-4

Parameter Setup Mode.................................................................... 4-6

Error Messages ............................................................................... 4-9

CONTENTS-3

Page 20

Section 5 Troubleshooting

Troubleshooting ............................................................................... 5-2

Clearing Paper Jam ......................................................................... 5-3

When an Error Message Appears ................................................... 5-4

Service Call Errors .............................................................. 5-4

Communication Errors ......................................................... 5-6

Operator Call Errors ............................................................ 5-7

When the Printer Fails to Work Correctly ...................................... 5-11

When a Print Error Occurs............................................................. 5-12

When There Is an Abnormal Sound .............................................. 5-13

Appendix

Basic Specifications ......................................................................... A-2

Printer Specifications ........................................................... A-2

Options/Consumables ..................................................................... A-3

Options ................................................................................A-3

Consumables.......................................................................A-4

Celsius and Fahrenheit Conversion List ..........................................A-5

CONTENTS-4

Page 21

Section 1 Getting Started

(Basic knowledge)

This section provides necessary information to operate the

printer. Familiarize yourself with the basics of the printer

before reading Section 2 and later.

Contents of this section

Operating Conditions

Installation Space

Environmental Conditions

Consumables

Media/Paper

Ink

Waste Ink Bottle

Maintenance Kit

Storage Kit

Cleaning Kit

Maintenance Liquid Cartridge

External Views, Names of Parts, and Functions

Front

Rear

Heater

Operation Panel

Heater Control Panel

Drying Device 64

Roll Cover 64

Exhaust Attachment

PS RIP (PhotoPrint 4 DX)

PS RIP (PhotoPrint 4 Server)

LCD Messages and Printer State

Messages on the LCD

Section 1 Getting Started (Basic knowledge)

1-1

Page 22

Operating Conditions

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

This section describes the operating conditions for the printer.

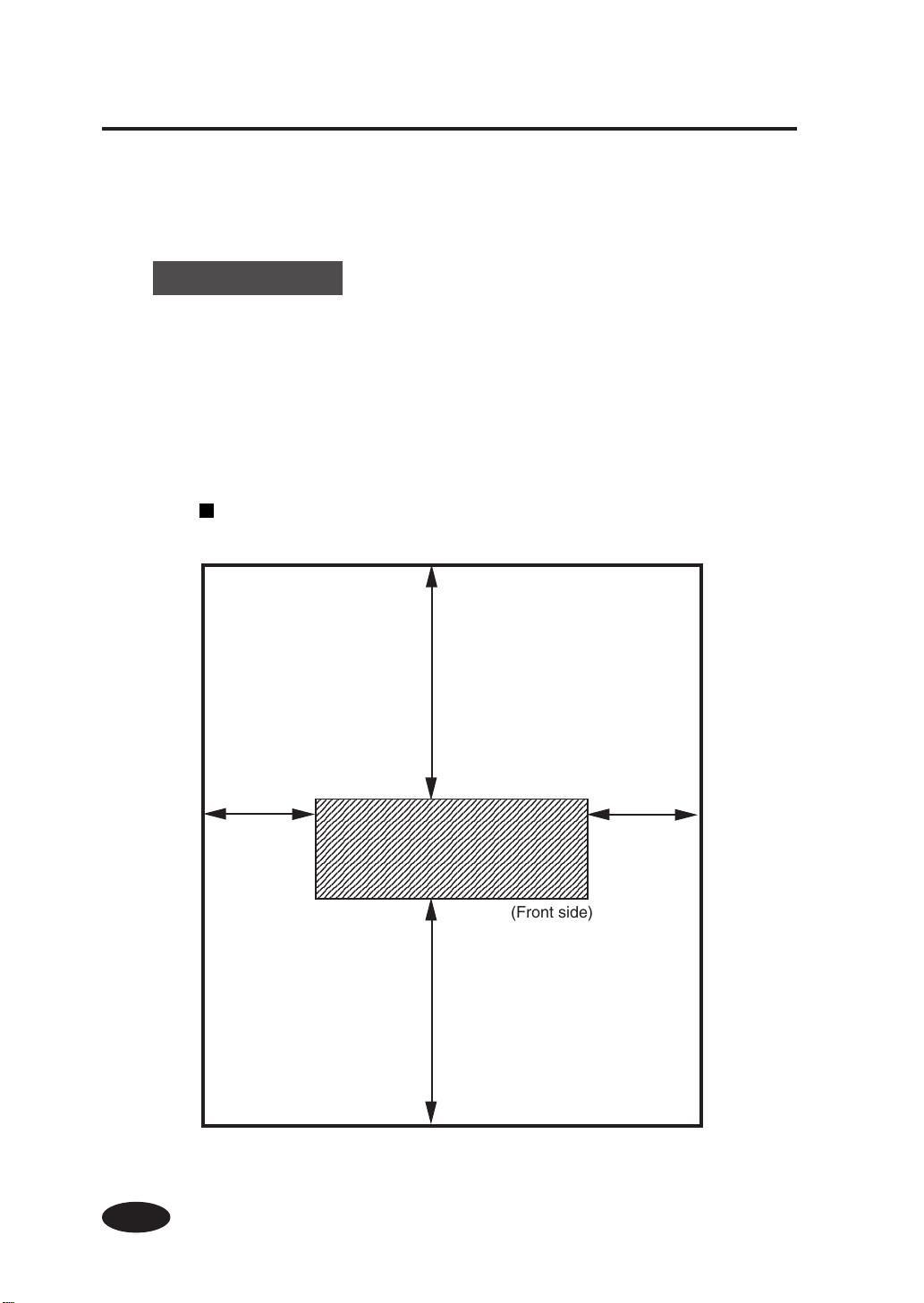

Installation Space

There must be a sufficient space around the printer for the

replacement of frequently used parts, for the output of drawings,

and for ventilation. In addition, the maintenance space, shown

below, is required to repair the printer or replace components.

The installation/maintenance space is shown in the following figure.

Installation and maintenance space

1-2

400

1000

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

23456789012345678901234567890121234567890123

1000

400

(Front side)

Height direction: 1700

(Unit : mm)

Page 23

Environmental Conditions

Operating temperature and humidity levels

The printer should be used within the temperature and humidity

levels shown below.

Temperature: 15 °C to 30 °C

Humidity: 30% to 70%

-To obtain better print quality, use the printer within

HINT

temperatures of 20 to 25 °C.

- When operating temperature is lower than 20 °C, the print

speed goes down two-third of normal print speed to keep

a good print quality.

- When the head temperature goes high, the print time is

delayed.

Operating Conditions

Section 1 Getting Started (Basic knowledge)

NOTE

- When the printer is used out of range of the operating

temperature and humidity, the print may be stopped and

the print quality may be degraded.

1-3

Page 24

Places where the printer must not be installed

Do not install the printer in the following places:

- Places exposed to direct sunlight

- Places subject to vibration

- Places with excessive dust

- Places subject to extreme changes in temperature or humidity

- Places near an air conditioner or a heater

- Places where the printer may get wet

- Places subject to direct air circulation from vents

- Places near a diazo copier that may generate ammonia gas

- Places with poor ventilation

- Unstable places

1-4

Page 25

Consumables

Media/Paper

Available media types

We prepared the following types of media:

• Glossy vinyle chrolide

• Matted vinyle chrolide

• Banner

Contact our service center for details.

Section 1 Getting Started (Basic knowledge)

1-5

Page 26

Precautions for storing media

-Avoid direct sunlight and water regardless of before and after

opening the package. Put paper in envelope to prevent dust and

store media in a dry, cool and dark place.

-Avoid rapid change of temperature and humidity and store media

with no condensing.

- Do not store media in standing condition to prevent disorder of

media and damage of roll edge.

- Do not pile up paper rolls.

Precautions for disposing of paper

- Dispose of media in rule matched to the actual situation.

If there is a limitation for disposal regulations, follow the

regulations.

Precautions for use

-Avoid a change of temperature and humidity after opening

package.

Set media after leaving media in the operation environment for

3 hours or more. Use care for a change of humidity by turning

ON/OFF the air conditioner.

- In terms of media characteristics, curl of paper in low humidity

and wrinkle of media in high humidity may occur easily.

Use paper in normal temperature and humidity environment

(around 23 °C and 50%RH).

- Do not use scratched, wrinkled, curled, or stained with dust

media.

Especially, roll edge (both edges of roll) affects media feeding.

Also, do not drop or wet the media. If doing so, it may cause

bad effect to print quality and causes a malfunction.

- Hold margins of the media so as not to touch the print surface.

Adhesion of sebaceous matter or sweat may cause bad effect to

print quality.

- Amend mis-roll of the media before setting.

1-6

Page 27

Precautions for handling prints.

- Do not touch the print surface before drying up the ink.

Hold margins of the media for handling.

Especially use care before 24 hours after printing.

- Rubbing print surface causes color fading or color transfer.

Do not pile print surface to prevent color transfer.

- Do not pile together with copy prints or laser prints to prevent

sticking due to ink or toner.

- Do not rub, scratch, or hold the media to prevent pealing.

- Do not rub or leave the paper in wet condition to prevent blurring.

Other precautions

- Media causes color fading and a change in quality in getting

old.

Check paper condition and use well-conditioned paper.

- Paper dust due to cutting may cause float of coating.

- When using vinyl (with glue), adhesive matter (with glue) may

be sticked to the platen.

In this case, wipe up the adhesive matter referring to "Section 2,

Inspection & Maintenance".

Sticking of adhesive matter may cause paper jamming.

Consumables

Section 1 Getting Started (Basic knowledge)

1-7

Page 28

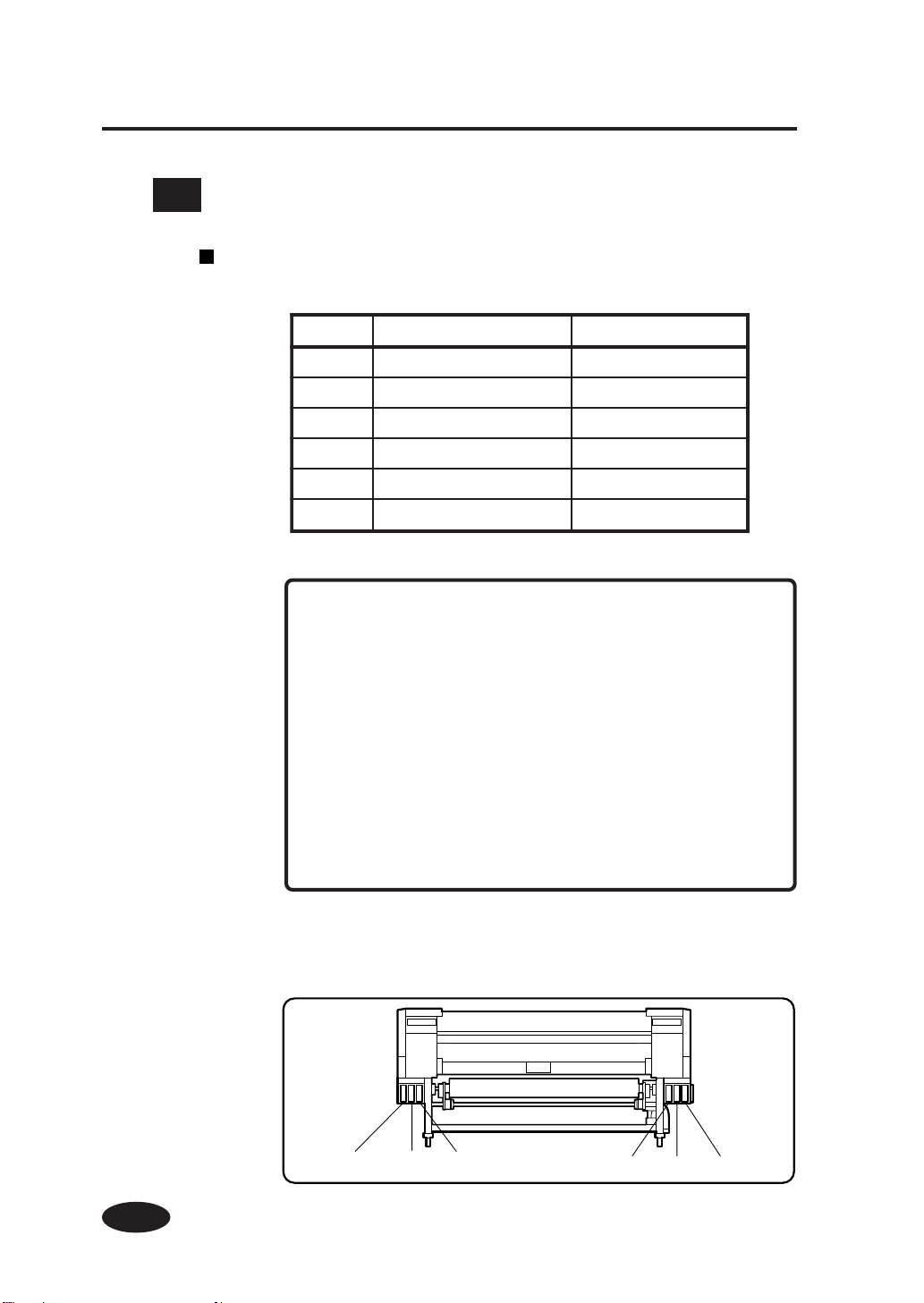

Ink

Ink types

Use our recommended ink cartridges listed below.

.oNmetIrolocknIyticapacknI

101-6PI)wolleY(Ylm0001

201-6PI)atnegaM(Mlm0001

301-6PI)nayC(Clm0001

401-6PI)kcalB(kBlm0001

501-6PI)nayCthgiL(cLlm0001

601-6PI)atnegaMthgiL(mLlm0001

NOTE

- Failure to use the recommended ink cartridge may lead to a

deterioration of the print quality or a printer malfunction.

- The valid period of the ink is 12 months after the manufacture

date.

- Do not shake ink cartridges before use.

- All six color cartridges must be installed.

If any of the cartridges is removed, a new one must be

installed.

1-8

Ink cartridges must be installed in all six slots. The positions of ink

cartridges are specified by color. (See the figure below.)

Black Light Magenta Light Cyan Yellow Magenta Cyan

Page 29

Consumables

WARNING

- Never bring the ink close to fire. Failure to follow this warning

might result in fire.

CAUTION

- Do not swallow ink or avoid its splashes on the eye. If it gets

into the eye, wash it off with a clean running water and consult

a doctor as required. If it is swallowed, do not try to vomit it

forcefully, but see a doctor.

- Do not attempt to disassemble ink cartridges.

Precautions for ink storage and processing

CAUTION

- Securely put a used ink cartridge into a plastic bag and

dispose of it as an industrial waste. Observe any regulations

for disposal of ink cartridges.

NOTE

- Ink has an expiration date. When it expires, the printer quality

may deteriorate or the printer may malfunction.

- Store ink cartridges in a dry, cool and dark place.

- Always use the recommended consumables (paper, ink, etc.).

Failure to follow this instruction may cause poor print quality

or a breakdown.

Section 1 Getting Started (Basic knowledge)

1-9

Page 30

Waste Ink Bottle

Use our recommended waste ink bottle listed below.

- Never put the waste ink bottle near open flames. Failure to

- Do not swallow ink or avoid its splashes on the eye. If it gets

.oNmetIskrameR

901-6PI)lm000,5(eceip1

WARNING

follow this warning might result in fire.

CAUTION

into the eye, wash it off with a clean running water and consult

a doctor as required. If it is swallowed, do not try to vomit it

forcefully, but see a doctor.

1-10

NOTE

- Install the waste ink bottle securely.

- A waste ink bottle must always be installed. If it is removed

for replacement, a new one must be installed.

Page 31

Precautions for handling the waste ink bottle

CAUTION

- After use, securely fasten the attached cap and dispose of

this product as industrial waste.

If you have any questions, please contact your nearest sales

office.

NOTE

- When the waste ink bottle is installed or removed, hold it

with both hands with its mouth facing up. If not, waste ink

may spill from the bottle.

Consumables

Maintenance Kit

Use our specified cleaning liquid.

Section 1 Getting Started (Basic knowledge)

.oNmetIskrameRytitnauQ

diuqilgninaelcpaClm001

diuqilgninaelcrepiWlm001

801-6PI

bawsgninaelCseceip05

egnirySseceip01

CAUTION

- Do not swallow ink or avoid its splashes on the eye. If it gets

into the eye, wash it off with a clean running water and consult

a doctor as required. If it is swallowed, do not try to vomit it

forcefully, but see a doctor.

1-11

Page 32

Storage Kit

Cleaning Kit

.oNmetIskrameRytitnauQ

egdirtracdiuqilecnanetniaM6

731-6PI

egdirtracymmuD6

.oNmetIskrameRytitnauQ

egdirtracdiuqilgninaelC6

711-6PI

egdirtracymmuD6

1-12

Page 33

External Views, Part Names, and Functions

This section shows the external views of the printer, the names of

parts of the printer and describes their functions.

Front

(4)

(2)

(6)

(3)

Ink cartridge

(4)

Roll paper

(5)

Lock

(1) Operation panel The lamps and LCD, which indicate the printer status, and keys for

(2) Heater control panel The keys for setting heater temperature are located on the heater

(3) Ink holder Holds the ink cartridge.

(4) Flange Sets paper roll.

(5) Caster Unlocks the caster to move the printer, and lock it to secure the

(6) Paper pressure alternation lever

(7) Pressure roller up/down lever

(8) Paper-out release lever (ME lever)

Unlock

setting functions are located on the operation panel.

control panel.

printer.

Alternates paper pressure depending on the paper thickness.

Presses down the paper after inserting the paper into the paper

supplying part and releases the pressing down of the paper.

Releases paper-out detection sensor.

(7)

(1)

(3)

(4)

(8)

Section 1 Getting Started (Basic knowledge)

1-13

Page 34

(20)

(15)

(16)

RearRear

(24)

(20)

(11)

(23)

(21)

(22)

(9)

(10)

(9) Power receptacle

(10) Printer switch

(11) Rear cover

(12) SCSI connector

(13) ID switch SCSI controller

(14) Terminator switch

(15) Paper outlet

(16) Waste ink bottle

(17) Power receptacle

(18) Heater switch

(19) 100 V/200 V alternation switch

(20) Cap cover

(21) Wiper cover

(22) Print stop/restart, cancel keys

(23) FAN guard potitioning slide bar

(24) Head up/down lever

(13)

(14)

(12)

SCSI controller

Printer power supply

Heater power supply

(19)

(18)

(17)

Network controller

1-14

Page 35

Heater Å

(Front)

External Views, Part Names, and Functions

The printer builts in three heaters for fixing and stabilizing print

image on the print media.

Rear cover

(Rear)

Paper roll

Paper inlet

(25) Front heater (Front) Preheats the media.

(26) Print heater (Rear) Infiltrates ink into the media and fixes ink.

(27) Rear heater (Finish) Drys ink and stabilizes print image.

* Three heaters are controlled separately.

(25)

(26)

paper feed direction

(27)

Paper outlet

WARNING

- Heaters become hot.

NEVER touch the heaters. If doing so, it could lead to

burn.

Section 1 Getting Started (Basic knowledge)

1-15

Page 36

Operation Panel

(4) LCD

Shows the printer status

and menus.

A

(3) Power switch

Turns the printer ON

or OFF.

Keys, LEDs, and the LCD are laid out on the operation panel as

follows. It has a buzzer to alert errors or invalid key operations.

E

B

C D

(2) Keys

Used to set printer functions.

1-16

(1) LED

The LEDs light, flash, or turn off to

the status of the printer.

Page 37

External Views, Part Names, and Functions

Functions of LCD, LEDs and keys

rebmuNemaNnoitcnuF

DELataD)A(

)neerg(

DELrorrE)B(

)egnaro(

)1(

DEL

)2(

yeK

)3(

hctiwsrewoP

)4(

DCL

DELknI)C(

)neerg(

)neerg(

)neerg(

yekENILNO.setatsenilffodnaenilnoneewtebsehctiwS

yeKTFIHS

yeKLECNAC.retemaraptupninaslecnaC

yeKRETNE.retemarapasretnerounemastceleS

yeK

yeK

yeK

yeK

DCL

DELrepaP)D(

DELenilnO)E(

hctiwSrewoP.FFOroNOretnirpehtnrutotdesU

enilnO:nO-

enilffO:ffO-

.)yalpsidlevel

.yek

.etatsnoitpeceratadehtswohS

retupmocehtmorfdeviecergniebsiataD:gnihsalF-

deviecergniebsiatadoN:ffO-

.derruccosahrorrenarehtehwsetacidnI

derruccosahrorrenA:nO-

etatsgninraW:gnihsalF-

).derruccosahrorreoN(lamroN:ffO-

.gninrawasetacidniroegirtrackniehtsierehtrehtehwswohS

.tneserperasegdirtracknillA:nO-

).tuonursahsknirolocfoenO(.tuogninnursiknI:gnihsalF-

).tuonursahsknirolocfoenO(knioN:ffO-

.tessirepaprehtehwswohS

).tessiteehstucrorepaplloR(.tessirepaP:nO-

).tessiteehstucronrepapllorrehtieN(repapoN:ffO-

.enilfforoenilnosiretnirpehtrehtehwswohS

edomesuapenilnO:gnihsalF-

Section 1 Getting Started (Basic knowledge)

unemehtsehctiws(tupniretemaraprofyekyrailixuanasadesU

unemahctiwsropuorgunemastceleS

.)nwod/purebmun,noitceles(

,sretcarahcciremunahplahtiwsutatsrosegassemretnirpswohS

aevahsuneM.)senilowt,stigid61(slobmysro,anakatak

ro,,,htiwunemhcaesseccA.erutcurtslacihcrareih

1-17

Page 38

Heater Control Panel Å

LCD

Front Heater ON/OFF key

Front Heater UP/DOWN key

Functions of LCD, LEDs and keys

rebmuNemaNnoitpircseddnanoitcnuF

TNORF

DCL

yek

TNIRP

RAER

Print Heater ON/OFF key

FFO/NOTNORFyek.retaehtnorfehtffo/nosnruT

PUTNORFyek.retaehtnorfehtrofeulavgnittesehtsesaercnI

NWODTNORFyek.retaehtnorfehtrofeulavgnittesehtsesaerceD

FFO/NOTNIRPyek.retaehtnirpehtffo/nosnruT

PUTNIRPyek.retaehtnirpehtrofeulavgnittesehtsesaercnI

NWODTNIRPyek.retaehtnirpehtrofeulavgnittesehtsesaerceD

FFO/NORAERyek.retaehraerehtffo/nosnruT

PURAERyek.retaehraerehtrofeulavgnittesehtsesaercnI

NWODRAERyek.retaehraerehtrofeulavgnittesehtsesaerceD

Rear Heater ON/OFF key

Print Heater UP/DOWN key

.detacidnisi"FFO"

.hctiwsniamehtnonrutotdegru

.hctiwsniamehtnonrut

Rear Heater UP/DOWN key

ehtfoerutarepmettnerrucehtdnaerutarepmetgnittesehtsetacidnI

siti,ffodenrutsiretaehehtfohctiwsniamehtnehW.retaehtnorf

,ffodenrutsiretaehtnorfehtnehW.hctiwsniamehtnonrutotdegru

ehtfoerutarepmettnerrucehtdnaerutarepmetgnittesehtsetacidnI

sitiffodenrutsiretaehehtfohctiwsniamehtnehW.retaehtnirp

.detacidnisi"FFO",ffodenrutsiretaehtnirpehtnehW

raerehtfoerutarepmettnerrucehtdnaerutarepmetgnittesehtsetacidnI

otdegrusiti,ffodenrutsiretaehehtfohctiwsniamehtnehW.retaeh

.detacidnisi"FFO",ffodenrutsiretaehraerehtnehW

1-18

Page 39

Dryer 64 (Option)

The dryer 64 dries the output media.

Roll Cover 64 (Option)

Protects paper roll from dust.

Exhaust Attachment (Option)

External Views, Part Names, and Functions

Mounts an exhaust gas pipe to the printer or the drying device.

PS RIP (PhotoPrint 4 DX) (Option)

RIP software for the IP-6600.

PS RIP (PhotoPrint 4 Server) (Option)

RIP software for the IP-6600.

Section 1 Getting Started (Basic knowledge)

1-19

Page 40

LCD Messages and Printer State

This section explains the messages shown on the LCD and outlines

menu operations.

Messages on the LCD

(1) Initialization display

The printer is being initialized.

Booting

INITIALIZING

WAIT A MOMENT

*: When the system starts normally, both controllers go

online and enter idle mode automatically.

(2) Online state (idle mode) display

The printer can receive data from the computer.

PRINT READY

ROLL : 64” (PAPER)

Status display

Paper information

*: When the key is pressed in the menu mode,

"CLEANING" menu appears.

1-20

Page 41

(3) Online state (print mode) display

The printer is printing.

PRINTING

ROLL : 64” (PAPER)

Status display

Paper information

(4) Online state (drying mode) display

The printer is drying the media.

DRYING

ROLL : 64” (PAPER)

LCD Messages and Printer State

*Only when the print drying time is preset, the drying state will be displayed

after print. (See Section 3, Operation Panel Menu Operations.)

(5) Online state (print pause mode) display

The printer is paused.

- Print stop and resume

PRINTING

ROLL : 64” (PAPER)

PRINT READY

ROLL : 64” (PAPER)

The ONLINE LED flashes.

Press the

key in the print pause mode to start the head cleaning.

Section 1 Getting Started (Basic knowledge)

1-21

Page 42

- Print cancel (end)

PRINT READY

ROLL : 64” (PAPER)

The ONLINE LED flashes.

PRINT READY

ROLL : 64” (PAPER)

(6) Online state (print information mode) display

Paper total count and ink removing amount are displayed.

PRINT READY

ROLL : 64” (COATED)

1-22

TOTAL CT XXXX

Bk INK REST: XXX%

Lm INK REST: XXX%

Three-second

intervals or

Lc INK REST: XXX%

Y INK REST: XXX%

Three-second

intervals or

M INK REST: XXX%

C INK REST: XXX%

Then, the printer returns to online idle mode.

Page 43

(7) Offline (menu mode) display

Menus can be operated in offline mode.

INK ENTRY

PAPER F•ADJ

SERVICE FEED

CLEANING

FUNC SYSTEM

ADJUST RESET

*: , , , and are access keys to menus.

*: When the

menu appears.

LCD Messages and Printer State

key is pressed in the menu mode, "CLEANING"

Section 1 Getting Started (Basic knowledge)

(8) Shutdown state display

The printer is shutting down.

SHUTDOWN

WAIT A MOMENT

1-23

Page 44

1-24

Page 45

Section 2 Basic Operations

Contents of this section

Connecting with Computer

System configuration (connection example)

Connection procedure

Turning the Power On/Off

Turning the Power On

Turning the Power Off

Replacing the Paper Roll

Installing Paper Roll in the Printer

Removing the Paper Roll from the Printer

Replacing Paper Roll with Another

Replacing Empty Paper Roll

Replacing Jammed Paper Roll

Installing/Removing Cut Sheet in/from the Printer

Replacing Ink Cartridges

Ink Cartridge Replacement Procedure

Replacing Empty Ink Cartridge

If an Ink Cartridge Is Not Installed

If an Ink Cartridge Is Not Detected

Replacing the Waste Ink Bottle

Waste Ink Bottle Replacement Procedure

If the Waste Ink Bottle Is Full

If the Waste Ink Bottle Is Not Installed

Head Cleaning "CLEANING"

Paper Feed "FEED"

Using the Origin Point Setting Function

Installing Paper on Winder

Changing Heater Control Setting Temperature

Using the Media Pressure Alternation Lever

Using the Head Up/Down Lever

Using the Media Edge Guard

Using the FAN Guard Positioning Bar

Using the Print Pause/Restart and Cancel Keys

Inspection & Maintenance

2-1

Section 2 Basic Operations

Page 46

Connecting with Computer

This section only shows system configurations and cable connection

procedure.

System configuration (connection example)

The following connection is possible.

Printer

Connection procedure

Connect a cable as follows:

1

Turn the printer and the computer OFF.

NOTE

- When the printer is connected with the computer, turn the

printer ON, and then turn the computer ON. To turn the

system OFF, turn the computer OFF, and then turn the printer

OFF.

(Printer server PostScript RIP)

SCSI interface

2-2

Page 47

Connecting with Computer

2

3

Connect a SCSI cable to a SCSI connector on the rear of

the printer.

(It can be connected to any one of two SCSI connectors.)

NOTE

- Use a dedicated SCSI cable (68-68-pin, 6 m).

If using a cable except the specified one, the printer can

not satisfy FCC and CE regulations.

Section 2 Basic Operations

SCSI connector

Set the ID switch on the rear of the printer.

Set the ID number with a small normal

driver, etc. (Initial ID value: 4)

ID switch

NOTE

- The ID number must not be unique in the SCSI chain. (Initial

setting: 4)

2-3

Page 48

4

Set the terminator on the rear of the printer to ON or OFF.

Terminator switch

The printer has the SCSI terminator ON/OFF function. If the external

terminator is not used and the printer is a terminating device in the SCSI

chain (only one SCSI connector is connected), set the terminator switch to

ON. If the printer is not a terminating device, set it to OFF.

2-4

Page 49

Turning the Power On/Off

The power of the printer and the power of the heater are separated.

<Printer>

The printer has two power switches as follows.

(1) Printer switch

(2) Power ON/OFF switch

(1)

(2)

Power receptacle

Printer rear (Left side)

Printer front (Operation panel)

The printer is turned ON by turning the printer switch ON.

Afterward, turn the printer ON/OFF by the ON/OFF switch on the

operation panel.

NOTE

- When the printer is connected with the computer, turn the

printer ON, and then turn the computer ON. To turn the

system OFF, turn the computer OFF, and then turn the

printer OFF.

-Turn the computer ON after the printer becomes to the

online state.

<Heater>

The heater has two power switches as follows.

(1) Heater switch

(2) 100/200 V alternation switch

(1)

(2)

Section 2 Basic Operations

Printer rear (Right side)

For Heater

100-120V 12A 50/60Hz

Power receptacle

2-5

Page 50

Turning the Power On

<Printer>

1

Printer switch

OFF (0)

2

Printer switch

ON (1)

Turn OFF (0) the printer switch on the left rear of the

printer, and plug one end of the supplied power cable into

the socket of the printer. Insert the other power plug of

the cable into an electrical outlet.

Socket

Turn ON (1) the printer switch on the left rear of the

printer.

Power ON/OFF

switch

2-6

3

Socket

Turn ON the power ON/OFF switch on the operation panel.

Page 51

Tur ning the Power On/Off

When the switch is turned ON, a power-on self-diagnostic test is performed

and the following message appears on the LCD on the operation panel.

Booting

INITIALIZING

WAIT A MOMENT

PRINT READY

ROLL : 64” (PAPER)

If a 64" paper roll is used

The heater control panel is displayed by turning the printer power ON.

However, turn the heater power ON to use the heater.

When the heater power is turned OFF, the following message is displayed

on the heater control panel.

Section 2 Basic Operations

TURN ON

THE HEATER

NOTE

- Turn OFF the printer while “PRINT READY” is displayed on

the LCD panel except emergency.

Do not turn OFF the printer while “INITIALIZING” or

“CLEANING” is displayed on the LCD panel to avoid drop of

the ink and damage of the head.

- If the fan does not run or the operation panel lamp does not

HINT

light when the printer switch and power ON/OFF switch on

the operational panel are turned ON, the power supply may

be faulty.

- If an error is detected during the self-diagnostic test at

powering on, an error message appears on the LCD. See

the Section 5, Troubleshooting and take an appropriate

measure.

2-7

Page 52

<Heater>

1

Power cable

Turn OFF the heater switch on the right rear of the

printer, and plug one end of the supplied power cable into

the socket of the printer. Insert the other power plug of

the cable into an electrical outlet.

Heater switch OFF (0)

100/200 V alternation switch

Power socket

NOTE

- Do not use the other power cable than specified in this printer.

- Verify that the supplied power cable meets the local AC power

supply specifications.

- Verify that the 100 / 200 V alternation switch settings meets

the local AC power supply specifications.

2-8

2

Turn ON the heater switch on the right rear of the printer

to turn the heater ON.

Heater switch ON (1)

100/200 V alternation switch

Page 53

Turning the Power Off

Necessary for Power Supply protection

Fill cap done:

After Printer switched on

and in standby:

- First time after 20 hours

- Then every 3 days

After Printer switched off:

- 1 Time during switch

down procedure

<Printer>

Tur ning the Power On/Off

1

Turn OFF the power ON/OFF switch on the operation

panel for a couple of seconds.

SHUTDOWN

WAIT A MOMENT

The above message is displayed on the LCD to indicate that a

shutdown process is in progress. After the process ends, the power

is turned OFF.

The fill cap (filling ink into the cap unit) is performed automatically

to maintain good head condition at turning off the printer.

Press the

off the printer.

Performing the fill cap operation is recommended.

CAUTION

- The printer switch on the rear of the printer should be used

only when the printer is turned OFF completely in order to

move it, connect it with a computer, install or maintain its

parts.

-Turn the power ON/OFF switch OFF, wait for at least ten

seconds, then turn it ON again.

- The printer performs fill cap operation to keep the good

head condition at first 20 hours after print wait state and

every 3 days.

It is recommended to keep the printer ON.

and the ON/OFF keys to skip the fill cap at turning

Section 2 Basic Operations

2-9

Page 54

<Heater>

1

Heater switch

OFF (0)

The heater power is also turned OFF by turning OFF the

ON / OFF switch on the operation panel. Therefore, the

heater switch turning OFF operation is not necessary in

the normal use.

NOTE

- Use the heater switch on the right rear of the printer only

when turning the printer OFF completely for transferring,

installing, and maintenance service of the printer.

2-10

Page 55

Replacing the Paper Roll

This section describes how to install a paper roll in the printer, and

remove it from the printer.

A paper roll is replaced in the following three cases:

- If a paper roll is replaced with another

- If it is replaced when it runs out

- If it is replaced when it jams

A paper replacement procedure in each case is explained below:

Installing Paper Roll in the Printer

1

2

Open the rear cover and slide the media edge guards to

the both edge of the platen.

Section 2 Basic Operations

NOTE

- Set the media edge guard after completion of the paper roll

replacing. (See page 2-45)

Insert the paper roll in the paper roll right flange (fix side).

Right flange (fixed)

Paper roll

NOTE

- Be sure not to damage the edge of

the paper roll when inserting the

paper roll in the flange.

2-11

Page 56

3

Slide the left flange (movable side) and put it into the

paper roll.

4

Left flange (movable)

Paper roll

CAUTION

Be sure not to catch

your finger in the rail of

the flange.

Tighten the left flange knob securely.

Pull the winder sensor lever to front side.

Left flange knob

2-12

5

Winder sensor lever

Lift the pressure roller up/down lever.

Head up/down lever

Page 57

Replacing the Paper Roll

6

Feed the paper until a buzzer sounds from the paper feeder.

Feed the paper until an edge of the paper goes out 200 mm or more from the

paper outlet.

(Paper setting direction)

<Outside rolling>

Flange

Paper

<Inside rolling>

Flange

Paper

Section 2 Basic Operations

NOTE

- Paper may stick to the paper feeder and is hard to set due to

operational condition especially low humidity. In such a case,

float paper from the paper feeder and set paper to the paper

feeder by holding both edges of the paper.

- Be sure not to hit the edge of the paper roll by the rear cover.

- Be sure that the media edge guard is not set under the paper.

(See page 2-45 Using the Media Edge Guard.)

2-13

Page 58

7

When feeding a paper roll, hold it at the center and

rewind the flange to take up the slack in the paper.

The guide line on the printer is no more than a guide

line. Install paper roll on the printer in a straight line

against the paper roll.

The paper roll should not be inserted in the right of the perforated line.

If the paper roll is inserted in the right of the perforated line, adjust the

flange position.

8

9

Push down the pressure roller up/down lever.

Pressure up/down lever

Perform operations according to the guidance message shown on the LCD.

Confirm the media edge guard setting again.

Confirm whether the media edge guard does not goes down of the

paper.

CHECK EDGE GUARD

*OK?

Confirm the position of the media edge guard and press the

key.

2-14

Page 59

Replacing the Paper Roll

10

11

Select either paper roll or cut sheet.

SELECT PAPER

ROLL/SHEET : ROLL

Select ROLL PAPER, CUT SHEET , or BASE with or key.

(See Page 2-23 "Using the Origin Point Setting Function" about "BASE")

Press the key to change setting.

Press the key to leave the setting as it is.

Select a paper type.

○○○

SELECT PAPERTYPE

PAPER : PAPER

Select paper type with or key.

Press the key to change setting.

Press the key to leave the setting as it is.

SELECT PAPER

ROLL/SHEET : SHEET

SELECT PAPERTYPE

PAPER : XXX

SELECT PAPER

ROLL/SHEET : BASE

○○○

Section 2 Basic Operations

(When registering a new paper type)

SELECT PAPERTYPE

PAPER : PAPER

Select a paper type with and keys.

SELECT PAPERTYPE

PAPER : TYPE01

SELECT PAPERTYPE

NEW PAPER ENTRY

• Press key to enter to NEW PAPER ENTRY menu.

• Operation of the new paper entry is the same as operation for paper

entry from ENTRY menu.

• Press key to return to SELECT PAPERTYPE menu.

(only registered paper types can be

selected.)

2-15

Page 60

12

The paper will be set automatically.

PREPARING PAPER

WAIT A MOMENT

- If it is ended normally, return to offline or online state.

- If abnormal end occurs, an error message will be displayed.

Go back to 1.

13

Determine positions of the media edge guard and the

slide bar of the vacuum fan.

Slide bar of the vacuum fan

2-16

Page 61

Removing the Paper Roll from the Printer

Replacing the Paper Roll

1

2

Lift the pressure roller up/down lever.

Pressure roller up/down lever

Loose the left flange knob, pull out the paper roll from the

flange, and remove the paper roll from the printer.

Left flange

(2)

Flange knob

Paper roll Right flange

(3)

(1)

(4)

Section 2 Basic Operations

2-17

Page 62

Replacing Paper Roll with Another

1

2

3

Replacing Empty Paper Roll

1

Put the printer offline. (Press the key.)

ZNK ENTRY

PAPER F•FDJ

Press the key and press the key.

LIFT LEVER

Replace the paper according to the “Installing Paper Roll

in the Printer” and “Removing it from The Printer.”

A message appears on the LCD.

LIFT LEVER

SET PAPER

2

Replacing Jammed Paper Roll

2-18

Replace the paper according to the “Installing Paper Roll

in the Printer” and “Removing it from the Printer.”

See the Cleaning Paper Jam in Section 5, Troubleshooting.

Page 63

Installing/Removing Cut Sheet in/from the Printer

Install/Remove the cut sheet in/from the printer refering to the

procedures for the paper roll.

Replacing the Paper Roll

Cut sheet

Cut sheet

Installing Removing

Guide line

NOTE

- When installing the cut sheet in the printer, set the cut sheet

using the guide line.

Section 2 Basic Operations

2-19

Page 64

Replacing Ink Cartridges

This section describes how to replace an ink cartridge.

Ink cartridges should be replaced in the following two cases:

- If ink has run out

- If an ink cartridge is not installed

The ink cartridge replacement procedure in the following each case

is explained below.

NOTE

- Do not remove the ink cartridge from the printer until ink

cartridge becomes empty.

- Make sure the upside and downside of the ink cartridge before

installing.

Ink Cartridge Replacement Procedure

1

2

Open the ink cover.

Ink cartridge

Push here to open/close the ink cover.

Remove an ink cartridge from the printer.

2-20

Ink cover

Page 65

Replacing Ink Cartridges

3

4

Insert a new ink cartridge into the printer.

New ink cartridge

Ink cover

Close the ink cover.

Section 2 Basic Operations

Ink cover

5

End of ink cartridge replacement.

- If it is ended normally, return to offline or online state.

- If abnormal end occurs, an error message will be displayed.

Go back to 1.

- The printer continues to print when the ink remains in the sub-tank

during replacing ink cartridge.

2-21

Page 66

Replacing Empty Ink Cartridge

1

2

A guidance message appears.

OPEN L INKCOVER

CHANGE XX INK

XX: Ink name

Bk: BLACK

Lm: LIGHT MAGENTA

Lc: LIGHT CYAN

OPEN R INKCOVER

CHANGE XX INK

XX: Ink name

C: CYAN

M: MAGENTA

Y: YELLOW

Replace the ink cartridge according to the “Ink Cartridge

Replacement Procedure.”

2-22

Page 67

If an Ink Cartridge Is Not Installed

Replacing Ink Cartridges

1

2

The guidance message appears.

OPEN L INKCOVER

SET XX INK

XX: Ink name

Bk: BLACK

Lm: LIGHT MAGENTA

Lc: LIGHT CYAN

OPEN R INKCOVER

SET XX INK

XX: Ink name

C: CYAN

M: MAGENTA

Y: YELLOW

Replace the ink cartridge according to the “Ink Cartridge

Replacement Procedure.”

Section 2 Basic Operations

2-23

Page 68

If an Ink Cartridge Is Not Detected

1

2

The guidance message appears.

OPEN L INK COVER

CHECK XX INK

XX: Ink name

Bk: BLACK

Lm: LIGHT MAGENTA

Lc: LIGHT CYAN

OPEN R INKCOVER

CHECK XX INK

XX: Ink name

C: CYAN

M: MAGENTA

Y: YELLOW

Replace the ink cartridge according to the “Ink Cartridge

Replacement Procedure.”

2-24

Page 69

Replacing the Waste Ink Bottle

This section describes how to replace a waste ink bottle.

The waste ink bottle should be replaced in the following two cases:

- If the waste ink bottle is full

- If the waste ink bottle is not installed

The waste ink bottle replacement procedures for these cases are

explained below.

NOTE

-Do not replace the waste ink bottle during printing.

Waste Ink Bottle Replacement Procedure

1

Loosen the knob and lift up the lever from the waste ink

bottle.

Section 2 Basic Operations

Tube

2

3

(1)

(2)

Lever

Waste ink bottle

Wait for a while to drop the remaining ink into the ink tub.

Take out the filled waste ink bottle from the printer, and

securely cap the waste ink bottle to replace with a new

one.

Knob

(3)

2-25

Page 70

4

Wipe up the spilt ink into the waste ink bottle unit.

5

6

Lift the lever and mount a new waste ink bottle.

Drop the lever and insert the ink tube securely and

tighten the knob.

(2)

(1)

2-26

7

8

The selection message of the waste ink counter setting

(reset (clear)) will be displayed.

#INK COUNT RESET

*NO

Select “YES” and press the key.

#INK COUNT RESET

*YES

Page 71

If the Waste Ink Bottle Is Full

Replacing the Waste Ink Bottle

1

Replace the waste ink bottle according to the “Waste Ink

Bottle Replacement Procedure.”

2

The selection message of the waste ink counter setting

(reset (clear)) will be displayed.

#INK COUNT RESET

*NO

NOTE

- Make sure visually whether or not the waste ink bottle is

not full before using the printer.

Section 2 Basic Operations

#INK COUNT RESET

*YES

NOTE

- The waste ink counter is prepared for urging waste ink

disposal with the error message when the waste ink is more

than the specified amount by counting the used (waste)

ink amount.

The waste ink counter can detect full of the waste

simultaneously but cannot detect actual full state of the

waste ink.

The counter counts up from the empty of the waste ink

bottle. Always select “*YES” for the “INK COUTN RESET”

menu when replacing the waste ink bottle with a new one.

If not, the waste ink full counter cannot be only used

effectively, but also the waste ink becomes full before

generating warning and the waste ink may be spilt over.

3

Select “*YES’ and press the key.

2-27

Page 72

If the Waste Ink Bottle Is Not Installed

1

2

3

A guidance message appears on the LCD.

BOTTLE ISN’T SET

SET BOTTLE

Insert a new waste ink bottle into the printer and install

the waste ink bottle cover.

⇒ See the step 3 of the Waste Ink Bottle Replacement

Procedure.

The selection message of the waste ink counter setting

(rest (clear)) will be displayed.

#INK COUNT RESET

*NO

#INK COUNT RESET

*YES

2-28

4

Select “*YES’ and press the key.

Page 73

Head Cleaning "CLEANING"

1

2

3

Put the printer offline. (Press the key.)

INK ENTRY

PAPER F•ADJ

Press the key to display the CLEANING menu.

INK ENTRY

PAPER F•ADJ

SERVICE FEED

CLEANING

Press the key to enter the head cleaning menu.

Section 2 Basic Operations

#CLEANING

*NORMAL

4

5

# CLEANING

>NORMAL

Press the key.

# CLEANING

* OK?

Press the key and key to select a cleaning

option.

#CLEANING

*SOFT

#CLEANING

*HARD

2-29

Page 74

6

Press the key.

#CLEANING

*BOTTLE OK?

7

8

9

Press the key again.

CLEANING

WAIT A MOMENT XXX

NOTE

- The cleaning takes several minutes.

When the cleaning is completed, the screen is retured to

step 3 automatically.

# CLEANING

>NORMAL

Press the key to return to the original offline mode.

XXX : Figure will be increased

in about 10 seconds.

2-30

Page 75

Paper Feed "FEED"

This section describes how to manually feed paper after printing.

1

2

3

Put the printer offline. (Press the key.)

INK ENTRY

PAPER F•ADJ

Press the key to display the FEED menu.

SERVICE FEED

CLEANING

Hold down the key.

PAPER FEEDING

While the key is kept pressed, the currently selected roll paper is fed.

If a cut sheet is used, it is discharged.

Section 2 Basic Operations

4

When the key is released, paper feeding stops and

the top screen returns to offline mode.

SERVICE FEED

CLEANING

2-31

Page 76

Using the Origin Point Setting Function

<Origin Point Setting>

When printing a small size image such as a A4 size image on the

64-inch width paper, the large blank will be generated as the figure

shows below.

In this case, rewind the print paper and set the print origin point to

print an image on the blank area.

The print origin point setting at paper rewinding is called as “Origin

Point Setting Function.”

(1st time printing) (Paper rewinding) (2nd time printing)

Blank area

<How to Use the Origin Point Setting Function>

Origin point

Base point

2-32

1

Lift the pressure roller up/down lever and rewind the

paper.

SET PAPER

PUSH DOWN LEVER

Pressure roller up/down lever

NOTE

- Rewind the paper after the paper is enoughly dried.

If not, the 1st time printing image may be damaged.

Page 77

Paper Feed "FEED"

2

Pressure roller up/down lever

3

4

Push down the pressure roller up/down lever.

Select “BASE” in the “SELECT PAPER” menu and press

the key.

SELECT PAPER

ROLL/SHEET: BASE

Input the paper width and press the key.

PAPER WIDTH

*1372 mm

Section 2 Basic Operations

The paper width detected at

previous time is displayed.

(Paper width input range: 290

to 1635 mm)

5

Input the base point (print offset value for paper width

direction: origin point).

BASE POINT

*0000 mm

The previous setting value will be displayed.

The base point set at previous

time is displayed.

2-33

Page 78

6

Select “*Yes” or “No” of back feed operation.

PAPER FEED BACK

*NO

The area from the paper output

sensor position to the print start

position (the grid roller) becomes

print dead area.

NOTE

- Cut the edge of the paper so that it will be parallel to the

guide line before installing the paper.

If the edge of the paper is not parallel to the guide line, the

front side of the print is cut, the platen is stained with ink,

and the paper jam may be caused.

7

Select a paper type again.

PAPER FEED BACK

*YES

The print dead area can be

decreased by rewinding the paper

for length between the paper output

sensor and grid roller.

(20 to 30 mm from the front edge

cannot be printed.)

2-34

SELECT PAPER TYPE

PAPER: TYPE01

PREPARING PAPER

WAIT A MOMENT

NOTE

- When using the origin point setting function, keep front,

right, and left margins sufficiently because the paper is

rewinded manually.

- The paper width and base point settings cannot be saved.

- The origin point setting function can be used only for paper

roll. This function cannot be used for the cut sheet.

Page 79

Installing Paper on Winder

A paper winder unit is built in the printer. It winds roll paper for

storage without cutting it.

Use the paper winder unit as follows:

1

Prepare the paper tube and 1 m-lead paper of which

paper width is the same as the paper’s youwilluse.

Attachthelead paperonthepapertube.

Tape

Approx.1m

Lead paper

Paper tube

NOTE

- Pay attention to the direction of attaching tape on the

winding side according to the winding direction setting

(outer side rewind/inner side rewind).

- Attach the paper to the take out roller straightly to protect

slanting feed.

Section 2 Basic Operations

2

Insert the paper tube with the lead paper to the left

flange.

Left flange

Left flange

Tension roller

Paper tube

Paper tube

2-35

Page 80

Left flange

3

Paper tube

Slide the right flange (movable side) and insert it into the

paper tube.

Paper tube Right flange

Right flange

4

5

Tighten the right flange knob securely.

Paper tube

Right flange

Knob

Lift the pressure roller up/down lever, insert paper from

the paper feed side through the paper feeder, push down

the pressure roller up/down lever, and feed paper from

the Feed menu on the operation panel (see Section 3,

Operation Panel Menu Operations (Feed Menu)) until

paper is wound.

Paper feeder

Paper delivery unit (rear)

Pressure roller up/down lever

2-36

(1)

(2)

(3)

Pressure roller up/down lever

Page 81

Installing Paper on Winder

9 Check the position of the winder switch:

Switch position Winding

Outside Outside

Centre Off

Inside Inside

6

Lead paper

7

Tape the edge of the paper on the lead paper at three

positions: both sides and center.

Paper

Tape

Tape

Paper tube

Tension roller

Manually turn the scroller flange in the direction of

winding to wind the paper slightly.

Tension roller

Section 2 Basic Operations

8

Check the positions of the paper and winding sensor,

and install it.

Winder switch

Winder switch

2-37

Page 82

The winding unit supports two winding methods; tension winding and

slack winding.

Generally, use the slack winding. If the slack winding does not work

correctly, use the tension winding.

Also, inner winding and outer winding are available.

Tension roller setting.

•

• Slack winding: Set the tension roller to the upper side.

Tension roller

•Tension winding: Set the tension roller to the lower side.

2-38

Tension roller

Page 83

Installing Paper on Winder

Winding unit switch setting

•

Either internal winding or external winding can be selected.

When the winding unit is not used, turn the winding unit switch

off.

Inner winding

Outer winding

Winding unit OFF

NOTE

- Slacken the paper so that it passes inside the winding

sensor.

- If the winding unit is not used, turn the winding unit switch

off.

- When the paper roll for the winding unit nears the diameter

of the winding unit’s flange, remove the winding side paper

roll and replace the paper tube with a new one.

If not so, a winding error may occur.

In case that the paper roll for the winding

unit exceeds the diameter of the winding

unit’s flange.

-When printing without using a winding unit, edge of paper

or printing surface may be damaged or be folded due to

contact with the winding sensor caused by winds.

Section 2 Basic Operations

2-39

Page 84

Changing Heater Control Setting Temperature

Front Heater ON/OFF key

Front Heater UP/DOWN key

LCD

Rear Heater ON/OFF key

Print Heater ON/OFF key

Print Heater UP/DOWN key

Preset temperature

Current temperature

Rear Heater UP/DOWN key

In normal use, temperatures of all heaters for the every selected

media are preset automatically.

Therefore, ON/OFF setting and temperature setting for all heaters

are not necessary.

Use the heater control panel only when the fine adjustment for the

heater temperature is desired.

Set on/off and setup temperature of three heaters on the heater

control panel.

2-40

• ON/OFF setting: Use ON/OFF key for each heater.

•Temperature setting: Use the up key or down key for each heater.

• LCD screen: (When the heater is turned ON)

• Upper line: Preset temperature for each heater

• Lower line: Current temperature for each heater

(When the heater is turned OFF)

• Upper line: “OFF” for each heater

• Lower line: Current temperature for each heater

The preset temperature range is fixed to 15 °C to 55 °C.

Precautions for setting the heater temperature

The heater temperature is preset automatically, but the ON/OFF

setting for all heaters are not preset automatically.

Therefore, in normal use, keep the heaters to the ON state (state

that temperatures are displayed).

Page 85

Changing Heater Control Setting Temperature

Heater preset temperature by medium

The heater preset temperature for medium is listed in the table.

Preset the heater temperature according to the media you use.

muideMepyTaideM

TNORFTNIRPRAER

elynivyssolG

edilorhc

edilorhcelynivtaMettaMC°54C°04C°54

rennaBrennaBC°54C°04C°54

yssolGC°54C°04C°54

NOTE

- When the rear heater temperature is set to high, fixibility of

the ink is improved, but media wrinkle or mat print may be

caused.

Adjust heater temperature according to the media type and

environmental temperature.

- Set the front/rear heater temperature higher 5 °C than the

print heater’s.

Bad temperature balance between the front/rear heater

and print heater may cause media wrinkle.

teserpdednemmoceR

erutarepmet

edomtnirP

htap4

noitcerid-ib

htap4

noitcerid-ib

htap4

noitcerid-ib

Section 2 Basic Operations

2-41

Page 86

Using the Media Pressure Alternation Lever

Alternate the media gripping pressure of the paper transmission

roller according to the media.

Use the media pressure alternation lever to alternate the media

gripping pressure (See the figure below) .

Generally, set the media pressure alternation lever to “normal

pressure.” When media cannot be fed correctly due to skew, set

the media alternation lever to “high pressure”.

Normal pressure (for thinner (normal) media)

2-42

High pressure (for thick media)

Paper pressure alternation lever

NOTE

- The shape of the lever groove is shown below.