OPERATING

LSW-27BLK

INSTRUCTIONS

MODELS

LTW-27B,

•27BK,

-27BM

SEIKO

SEWING

TOKYO•JAPAN

MACHINE

CO.,

LTD.

SPECIFICATIONS

SPEED:

Maximum 3,500 r.p.m. (LSW-27BLK 2,400 r.p.m.)

NEEDLE: DPX7,

HOOK:

FEED:

STITCH

LIFT

OILING:

SIZE

MOTOR:

DIAMETER

OF

OF

Rotating hook

Drop

LENGTH:

PRESSER

Semi-self oiling system

BED:

177

250W, 2P clutch motor

OF

MOTOR

(LTW-27BK•27BM•LSW-27BLK50cycle

NEEDLE

GAUGE:

(LTW-27BK . 27BM 2,800 r.p.m.)

#9to#20

feed

and

5mm

FOOT:

mmX518

1/16"

(LSW-27BLK DPX7, #11 to #22)

needle feed

(LSW-27BLK 6.5mm)

7 mm (by a lever)

mm

PULLEY:

to

1-1/2"

50 cycle

(LTW-27BK.LSW-27BLK,

(LTW-27BM,

5/16"

80^6,

standard)

60 cycle

6656,60cycle

1/8" to 1/2")

65,6

55?^)

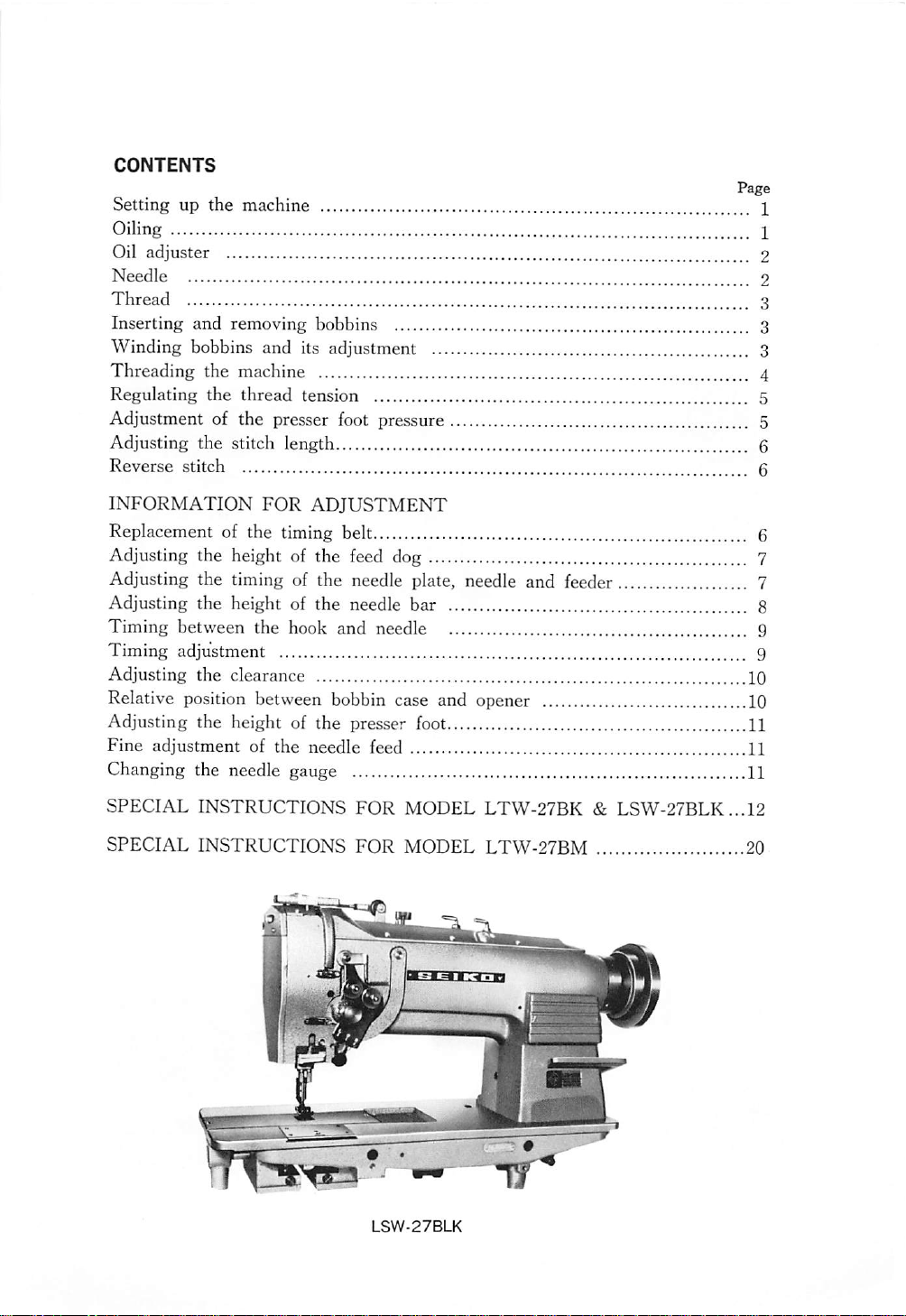

CONTENTS

Page

Setting up the machine 1

Oiling I

Oil adjuster 2

Needle 2

Thread

Inserting

Winding

Threading

Regulating

and

removing bobbins 3

bobbins

the

the

and

its adjustment 3

machine 4

thread

tension 5

Adjustment of the presser foot pressure 5

Adjusting the stitch length 6

Reverse stitch 6

3

INFORMATION

FOR

ADJUSTMENT

Replacement of the timing belt 6

Adjusting the height of the feed dog 7

Adjusting the timing of the needle plate, needle and feeder 7

Adjusting

Timing

Timing

Adjusting

the

heightofthe

between

adjustment 9

the

the hook

clearance 10

needle

and

bar

needle 9

Relative position between bobbin case and opener 10

Adjusting the height of the presser foot 11

Fine

adjustment of the needle feed 11

Changing the needle gauge 11

SPECIAL

SPECIAL

INSTRUCTIONS

INSTRUCTIONS

FOR

FOR

MODEL

MODEL

LTW-27BK

LTW-27BM

&

LSW-27BLK...12

20

8

LSW-27BLK

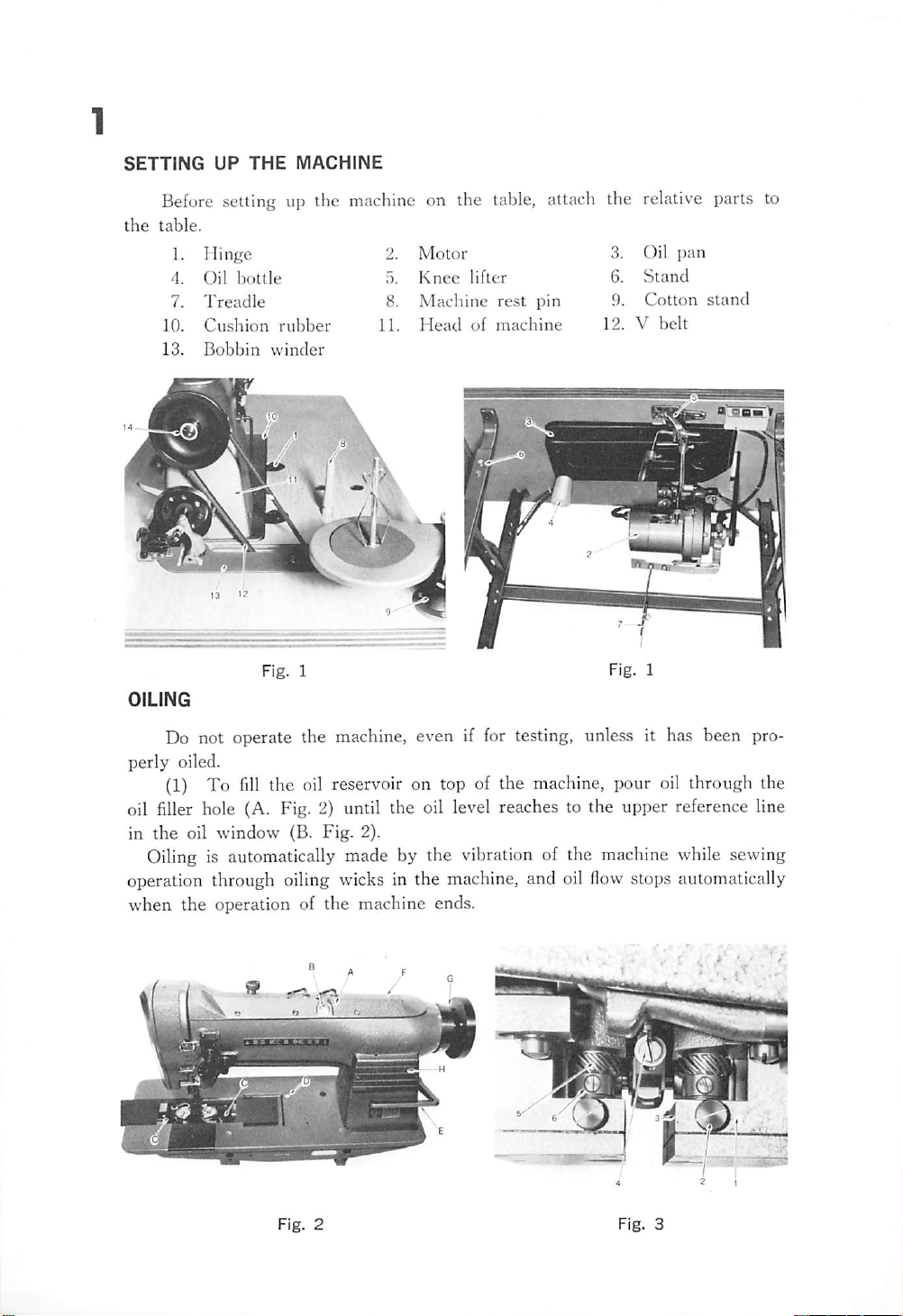

SETTING

UP

THE

MACHINE

Before setting up the machine on the table, attach the relative parts to

the

table.

1. Hinge 2. Motor 3. Oil pan

4.

Oil

7.

10.

13.

OILING

bottle

Treadle

Cushion

Bobbin

rubber

winder

Fig.

1

5.

Knee

lifter

6.

Stand

8. Machine rest pin 9. Cotton stand

11.

Head

of

machine

12. V

Fig.

belt

1

Do not operate the machine, even if for testing, unless it has been pro

perly oiled.

(1)

To

fill

oil

in

the oil reservoir on top of the

filler

hole (A. Fig. 2) until the oil level reaches to the upper reference line

the

oil

window

(B.

Fig.

2).

machine,

pour oil through the

Oiling is automatically made by the vibration of the machine while sewing

operation through oiling wicks in the machine, and oil

when the operation of the machine ends.

Fig.

2

flow

stops automatically

Fig.

3

(2)

The

hook

mechanism

the

machine.

Push open the slide-plates in the bed and pull out the oil

Fig.

2).

should

receive

careful

attention whenlubricating

gauges

(C.

Fill oil in the reservoirs for the rotating hook mechanism up to the level

marked on each oil gauge.

Care

must

be

taken

that

oil flow stops

when

oil level falls to

the

bottom.

(3) Oiling adjustment to the hook mechanism.

The maximum oil

flow

is made when the reference line on the oil adjusting

knob (2) is in a line with the point (1), and it stops when the reference line

is

upright.

To adjust this, loosen the pinch screw (3) and turn the oil adjusting knob,

tighten

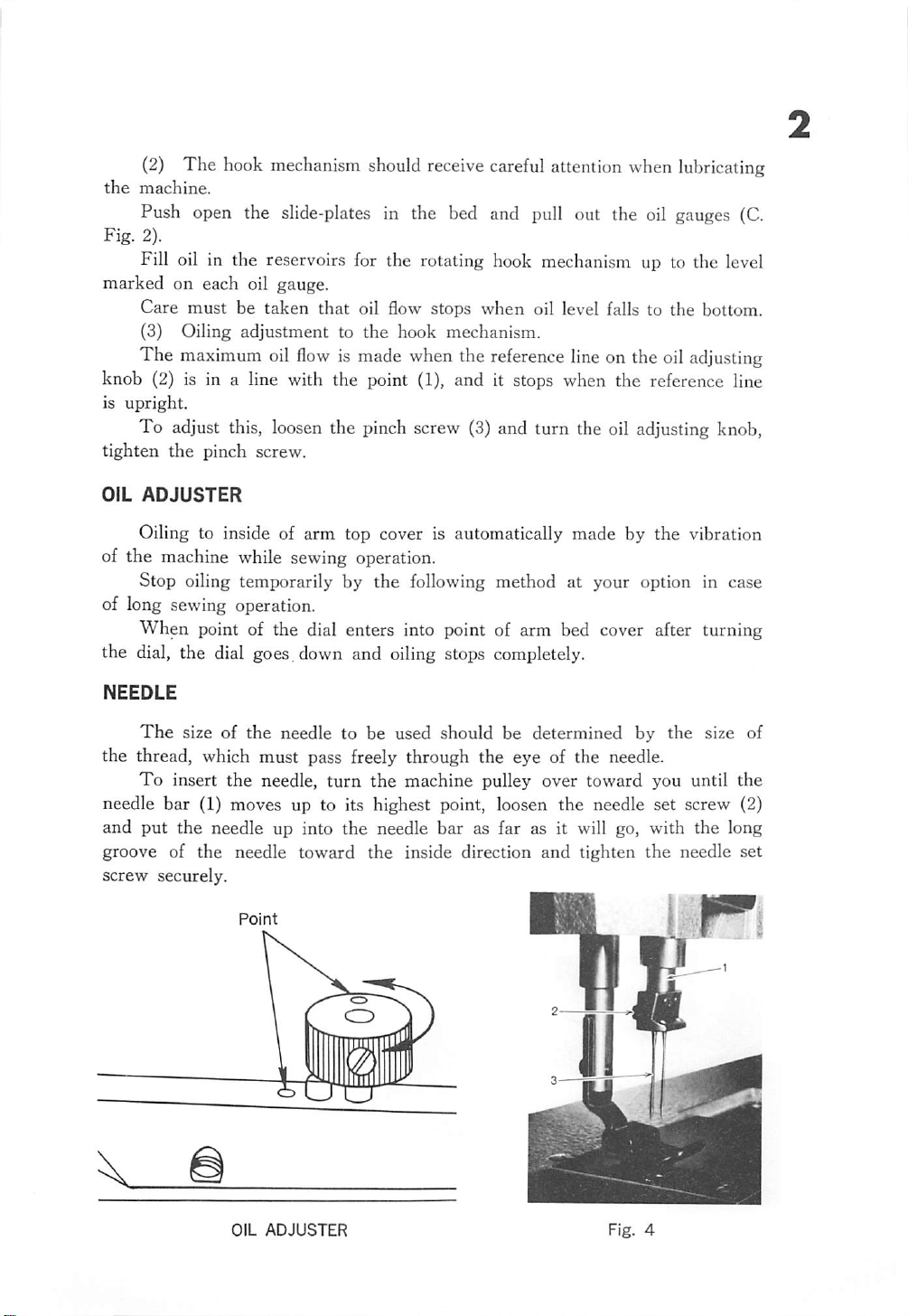

OIL

the

pinch screw.

ADJUSTER

Oiling to inside of arm top cover is automatically made by the vibration

of the machine while sewing operation.

Stop oiling temporarily by the following method at your option in case

of long sewing operation.

When point of the dial enters into point of arm bed cover after turning

the dial, the dial goes, down and oiling stops completely.

NEEDLE

The

size of the needle to be used should be determined by the size of

the thread, which must pass freely through the eye of the needle.

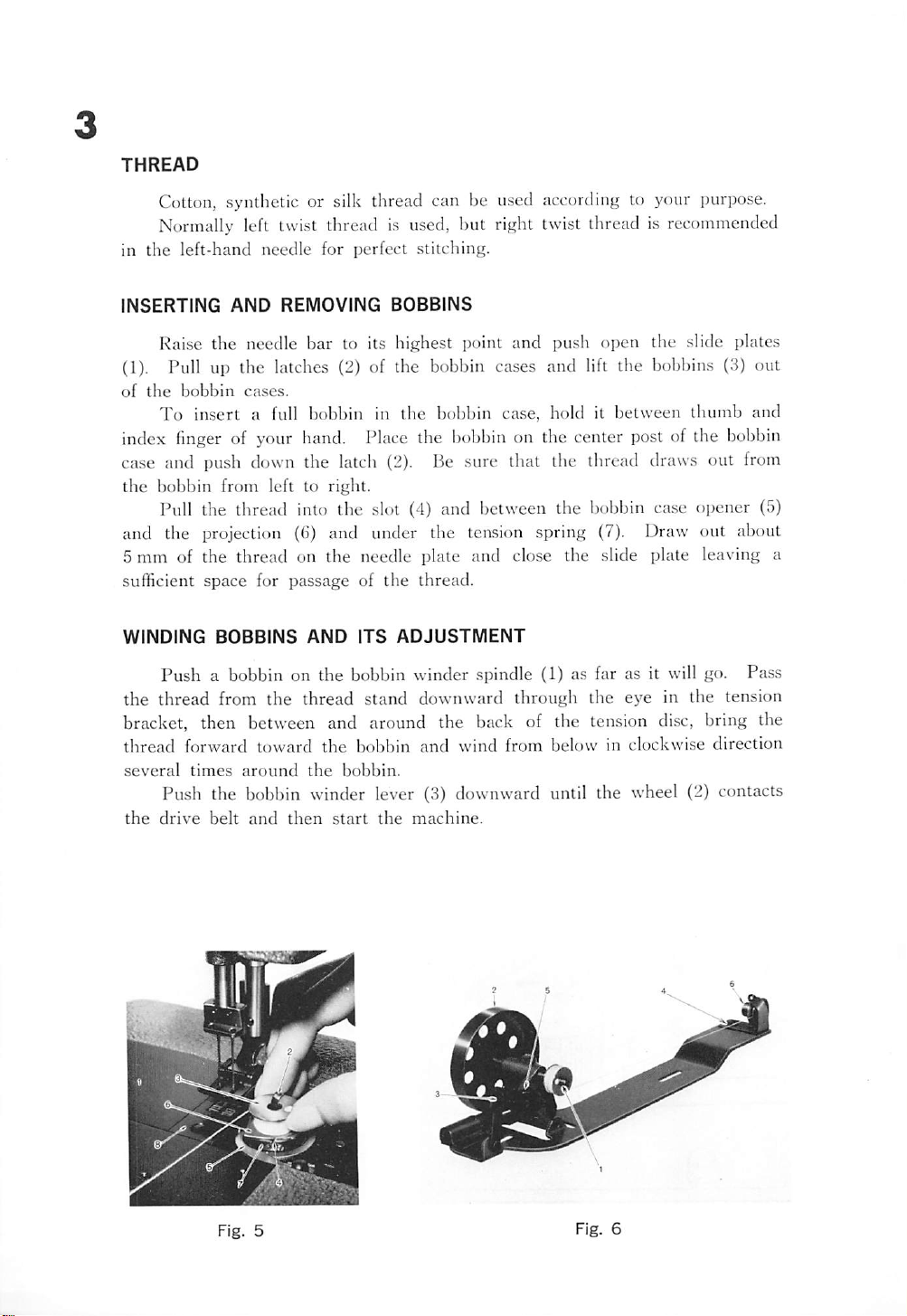

To

insert the needle,

turn

the

machine pulley over toward you until the

needle bar (1) moves up to its highest point, loosen the needle set screw (2)

and

put

the needle up into the needle bar as far as it will go, with the long

groove of the needle toward the inside direction and tighten the needle set

screw

securely.

OIL

ADJUSTER

Fig.

4

THREAD

CoUon,

synthetic or silk tliread can be used according to your purpose.

Normally left twist thread is used, but right twist thread is recommended

in the left-hand needle for perfect stitching.

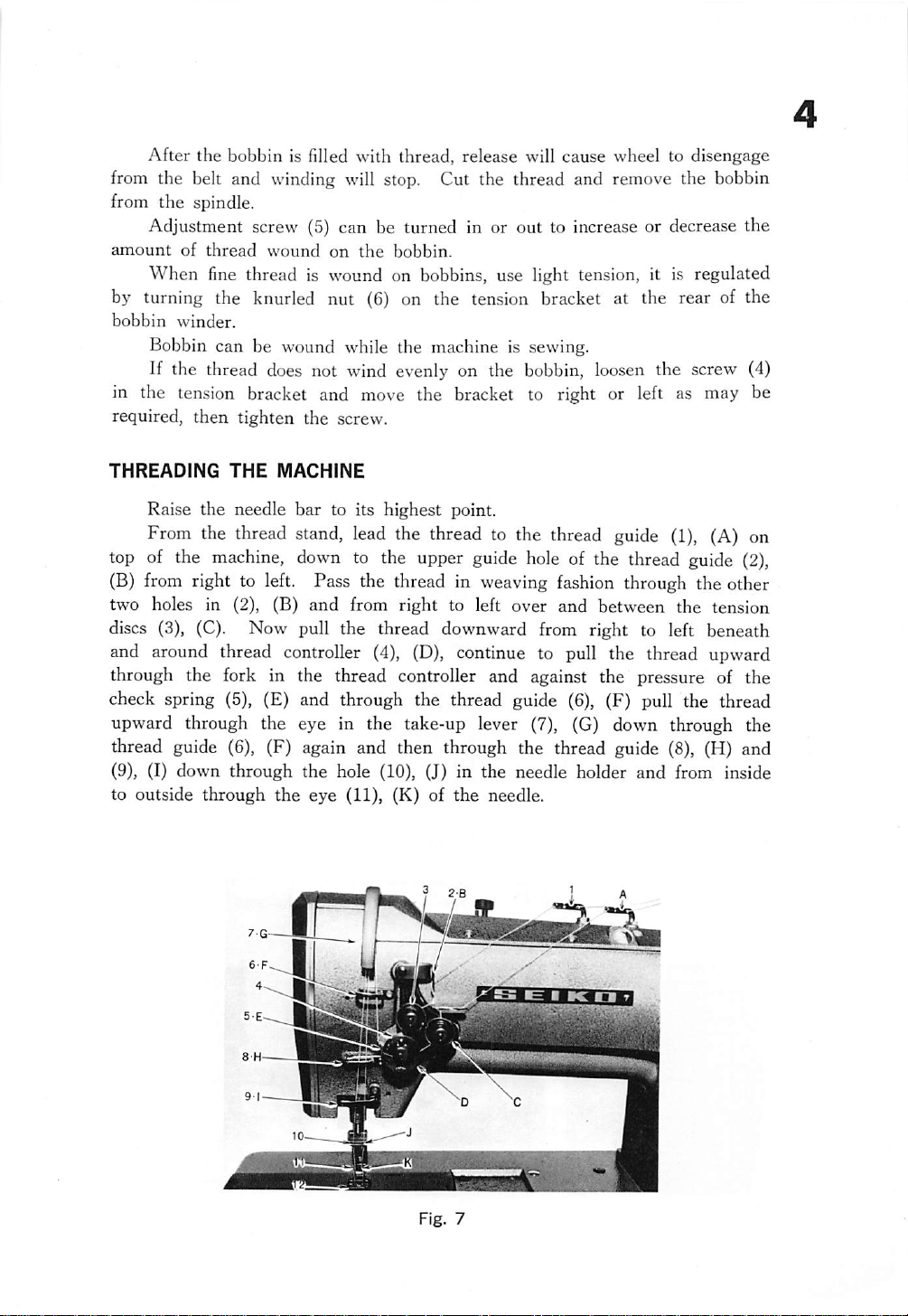

INSERTING

Raise the neetlle bar to its highest

AND

REMOVING

BOBBINS

iK)int

and push open the slide plates

(1). Pull up the latches (2) of the bobbin cases and lift the bobbins (3) out

of

the

index

bobbin

To

finger

cases.

insert

a full bobbin in

the

bobbin case, hold it between

thumb

of your hand. Place the bobbin on the center post of the bobbin

and

case and push down the latch (2). Be sure that the thread draws out from

the

bobbin

Pull the thread into the slot (4) and between the bobbin

from left to right.

ca.se

ojjener (5)

and the projection (6) and under the tension spring (7). Draw out about

5 mm of the thread on the needle plate and close the slide plate leaving a

sufficient

WINDING

space

BOBBINS

for passage of

AND

the

ITS

ADJUSTMENT

thread.

Push a bobbin on the bobbin winder spindle (1) as far as it will go. Pass

the thread from the thread stand downward through the eye in the tension

bracket, then between and around the back of the tension

thread

several

forward

times

toward

around

the

the

bobbin

bobbin.

and

wind

from

belowinclockwise

disc,

bring the

direction

Push the bobbin winder lever (3) downward until the wheel (2) contacts

the

drive

belt

and

then

start

the

machine.

Fig.

Fig.

5

6

After

the

bobbin

from the belt and winding will stop. Cut the thread and remove the bobbin

from

the

spindle.

is filled

with

thread,

release

will

cause

wheeltodisengage

Adjustment screw (5) can be turned in or out to increase or decrease the

amount

of

thread

wound

on

the

bobbin.

When fine thread is wound on bobbins, use light tension, it is regulated

by turning the knurled nut (6) on the tension bracket at the rear of the

bobbin

winder.

Bobbin can be wound while the machine is sewing.

If the thread does not wind evenly on the bobbin, loosen the screw (4)

in the tension bracket and move the bracket to right or left as may be

required, then tighten the screw.

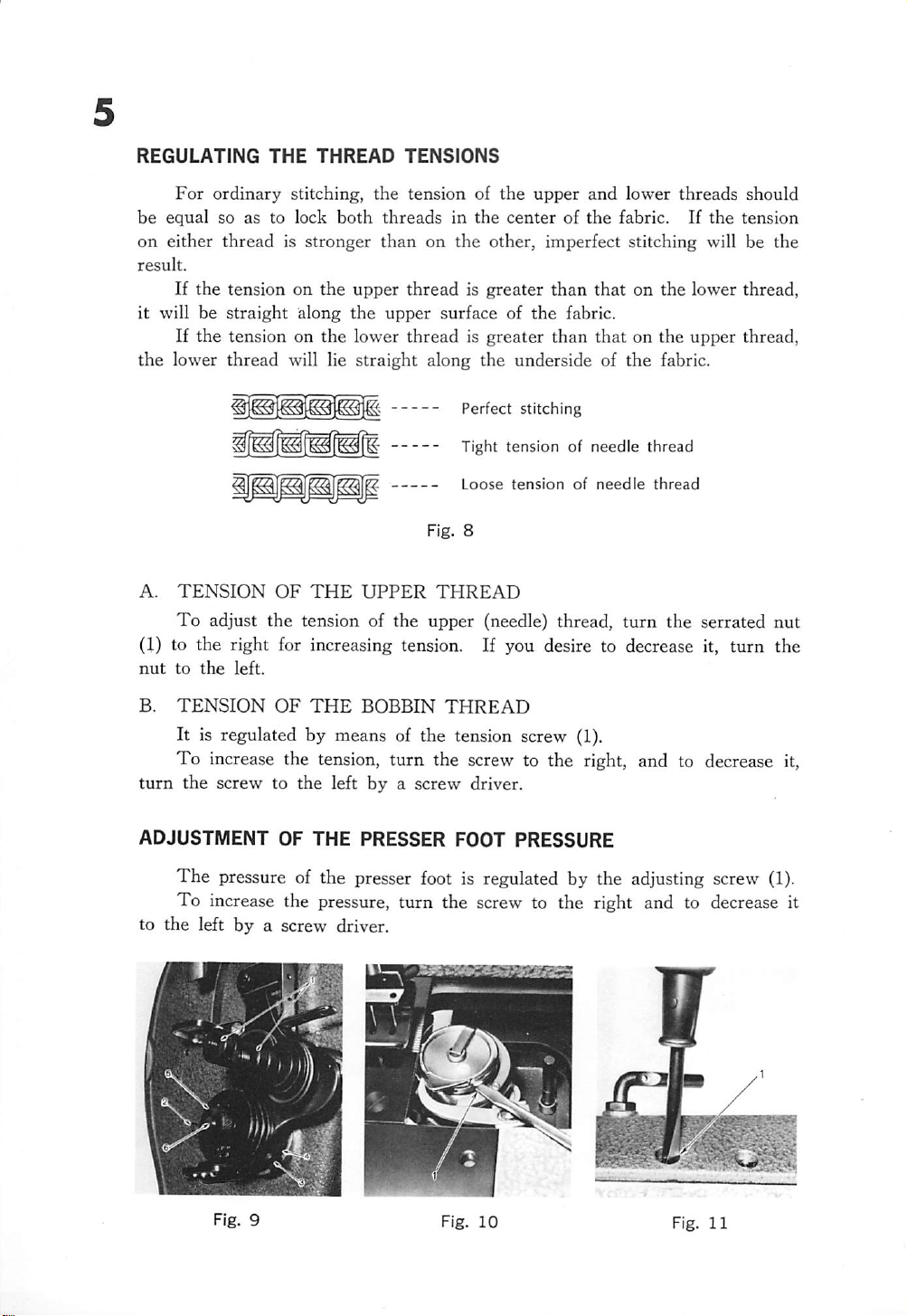

THREADING

Raise the needle bar to its highest point.

From the thread stand, lead the thread to the thread guide

top of the

(B)

from right to left. Pass the thread in weaving

two holes in (2), (B) and from right to left over and between the tension

THE

machine,

MACHINE

down

to the upper

guide

hole

of the thread

fashion

(1),

(A) on

guide

(2),

through the other

discs (3), (C). Now pull the thread downward from right to left beneath

and around thread controller (4), (D), continue to pull the thread upward

through the fork in the thread controller and against the pressure of the

check spring (5), (E) and through the thread guide (6), (F) pull the thread

upward through the eye in the take-up lever (7), (G) down through the

thread guide (6), (F) again and then through the thread guide (8), (H) and

(9), (I) down through the hole (10), (J) in the needle holder and from inside

to outside through the eye (11), (K) of the needle.

?

28

ltj

Fig.

7

REGULATING

For

ordinary stitching,

be

equal

on either thread is stronger

result.

If the tension on the upper thread is greater than

it

will be straight along

the

If

THE

so as to

tension on

THREAD

lock

the

TENSIONS

the

tension of

both

threads

than

the

upper surface of

lower

threadisgreater

the

upper

and

in

the

centerofthe

on the other, imperfect stitching will be the

that

the

fabric.

than

thatonthe

the lower thread will lie straight along the underside of

Perfect stitching

lower threads should

fabric.

If

the

tension

on the lower thread,

upper thread,

the

fabric.

A.

Tight tension of needle

Loose

tension

Fig. 8

TENSION

To

adjust the tension of the upper (needle) thread, turn the serrated

OF

THE

UPPER

THREAD

of

needle

thread

thread

(1) to the right for increasing tension. If you desire to decrease it,

nut

to

the

left.

B.

TENSION

OF

THE

BOBBIN

THREAD

It is regulated by means of the tension screw (1).

To increase the tension, turn the screw to the right, and to decrease it,

turn

the screw to the left by a screw driver.

ADJUSTMENT

OF

THE

PRESSER

FOOT

PRESSURE

The pressure of the presser foot is regulated by the adjusting screw

To increase the pressure, turn the screw to the right and to decrease it

to

the

left

by

a screw driver.

turn

nut

the

(1).

Fig.

10

Fig.

11

ADJUSTING

The

the

down

of

the

machine

the

handwheel

In

due

a notch in

plunger

wheel,

down

either

marking

on

the

handwheel

ence

mark

plunger.

THE

STITCH

LENGTH

stitch length is changed by pressing

button

the

with

(D, Fig. 2) in the bed plate

andbysimultaneously

slowly

course,

the

toward

plunger

you.

will

feeding mechanism. Hold

and

continuetoturn

forward

the

on

the

or

desired

coincides

arm.

rearward,

number

with

Then

enter

the

until

of

the

release

turning

into

the

hand-

the

stitches

refer

the

Numerals on pulley

show

stitch

number

per

of

inch

Stitch length

(m/m)

REVERSE

To

depress

When

as required.

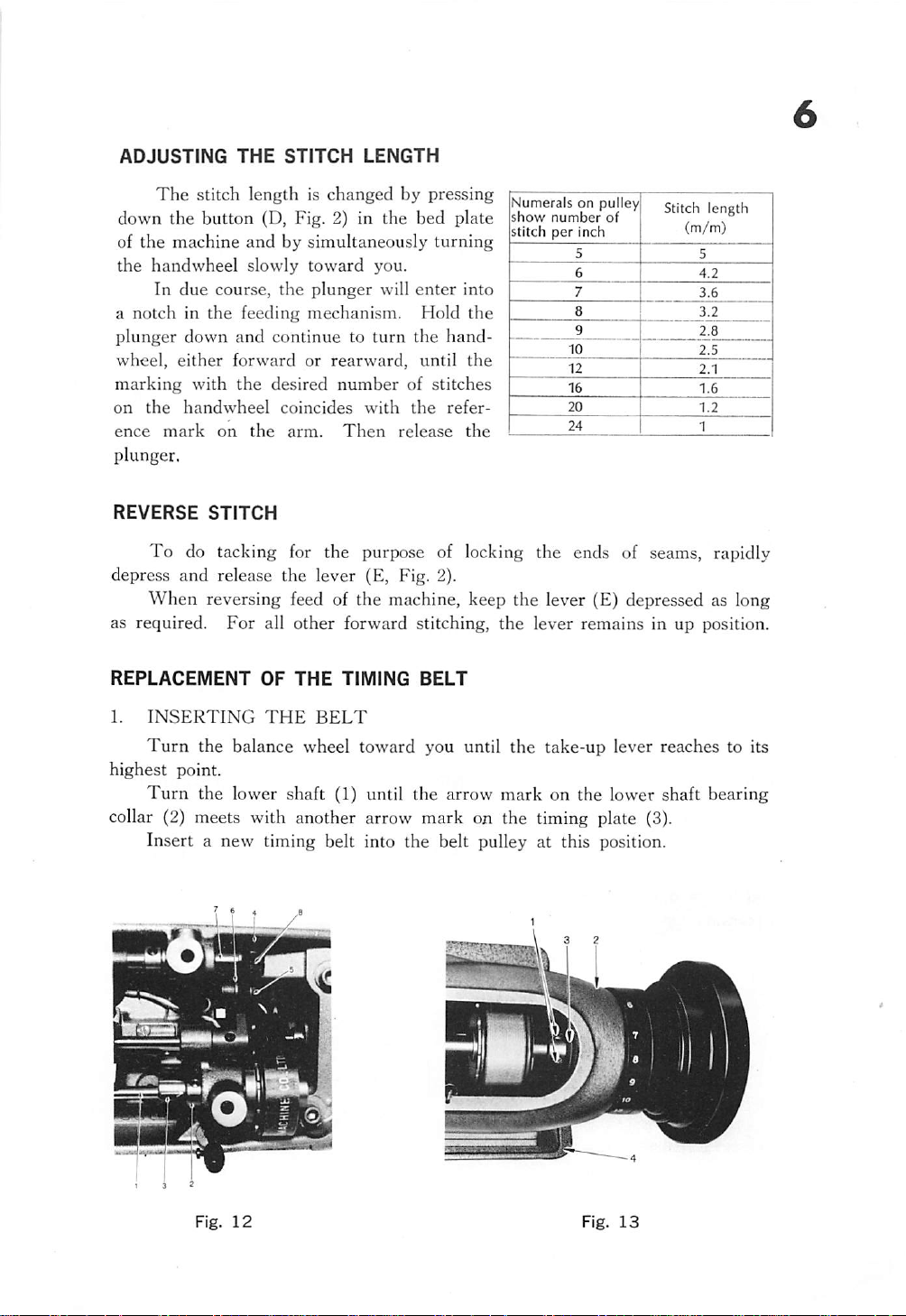

REPLACEMENT

1.

INSERTING

Turn

highest

Turn

STITCH

do tacking for the purpose of locking the ends of seams, rapidly

and

release the lever (E, Fig. 2).

reversing feed of the machine, keep the lever (E) depressed as long

For

all other forward stitching, the lever remains in up position.

OF

THE

THE

the

balance wheel

TIMING

BELT

toward

BELT

you until

the

take-up

lever reaches to its

point.

the lower shaft (1) until the arrow mark on the lower shaft bearing

collar (2) meets with another arrow mark on the timing plate (3).

Insert a new timing belt into the belt pulley at this position.

I

2.

REMOVING

THE

TIMING

BELT

Remove the arm top cover (F, Fig. 2) and remove the timing belt from

the

belt pulley, loosen

Loosen

the two set screws (G, Fig. 2) for the handwheel and remove the

the

collar

set

screws (1, Fig. 13).

handwheel adjusting screw (14, Fig. 1), draw out the handwheel from the

arm

shaft.

Loosen

rear bushing (3, Fig. 13) from the arm hole.

In case of the machine with reverse stitch mechanism,

lever (E, Fig. 2) with its shaft.

the arm shaft rear bushing set screw (2, Fig.

draw

13),

pull out the

out the reverse

Removing or inserting the timing belt is made through the hole drawn out

the rear bushing.

After inserting the belt correctly, replace the rear bushing, screws, the arm

top

cover,

mentioned

etc. to their

in

the

item

original

No.

places.

1.

Finally,

adjust

the

timing

marks

ADJUSTING

The

plate

(2) is normally 1 mm.

To

the

feed dog to its highest point.

THE

HEIGHT

maximum height of the feed dog (1) from the surface of the needle

adjust this height, tilt

OF

THE

the

FEED

machine,

DOG

turn

the

handwheel

so as to raise

Loosen the set screw (4, Fig. 3) and raise or lower the feed dog as may

be

required.

Securely tighten the set screw.

ADJUSTING THE

1.

THE

POSITION

Adjust

Set the

equal

the

screw.

position

before

the

starting

feed

of the

TIMING

OF

motion

feeder

feed

motion

OF THE

THE

FEEDER

to the

so that both

NEEDLE

maximum

and

after

PLATE,

AGAINST

and

loosen

clearances

finishing

NEEDLE&FEEDER

THE

NEEDLE

the

screw

A and B

the

feed.

(Fig.

Securely

(4,

PLATE

Fig.

12).

15)

are

tighten

r

Fig.

14

1

mm

Fig.

15

2.

THE

POSITION

FEEDER

To adjust this, turn the handwheel to raise the needle

point

and

put

correct

OF

THE

needles.

NEEDLE

AND

NEEDLE

HOLE

bar

to its highest

OF

THE

Turning the hand wheel to lower slowly the needle bar, check whether

the

needle

If

plate (H, Fig. 2) and loosen

the

arm.

the

descends

needle

does

to

the

not

center

enter

of

the

needle

into

the

the

screw (1, Fig. 16) through the window of

hole

centerofthe

of

the

hole,

feeder

remove

or

not.

the

side

Holding the bottom of the needle bar rock frame (I, Fig. 17), move it as

may be required to get the correct position to the center of the needle hole

of

the

feeder.

Then,

tighten

the

screw

and

replace

the

side plate.

ADJUSTING

1.

When

between

eyeis22.2

To

of the needle

correct position.

THE

HEIGHT

the

the

mm.

needle

surface of

bar

adjust this, loosen

bar

and the needle

After

this, tighten

OF

THE

NEEDLE

BAR

is at its highest point, normally

the

needle plate

the

screw (2, Fig. 17)

bar

the

and

the

upper

and

move

connecting stud (3, Fig. 17) to get the

set screw.

the

measurement

end

of

the

the

setting position

2. There, is another method for this adjustment by setting the needle

to its

lowest

point.

The normal position, in this case, is 4.1 mm approximately from the hook

pointtothe

NOTE:

upper

These measurements are approximate standard, accordingly, following final adjustments

are

recommended.

endofthe

needle

eye.

needle

bar

Bb

Fig.

Fig.

16

17

TIMING

Set the stitch length to 0, turn the balance wheel to lower the needle bar to

its lowest point turn the wheel toward you, and when the needle raises 2.1 mm

from the lowest point of its travel, normally the hook point is at the center

of the

end of the needle eye should be 2 mm, further the clearance between the

hook

BETWEEN

After setting the needle bar height as stated 1. or 2., confirm as under.

needle,

point

and

If they are not measured as above, adjustments are made as follows:

and

the

THE

the

measurement

needle

2.1mm

HOOK

hollow

AND

should

Fig.

NEEDLE

between

be

0.05

18

the

hook

to 0.2

point

mm.

and

the

upper

TIMING

Loosen

gear

(2,

two

set

Loosen

the

proper

For

model

Loosen

to

rightorleft

ADJUSTMENT

the

two

set

Fig,

screws

19A)

securely.

to the

screws

center

{1,

Fig.

of the

19A),

small

set

gear

the

(5,

the screw (6, Fig. 3) on the small gear, move the

timing.

LSW-27BLK

the

two

and

Then,

set

set

the

tighten

screws

proper

the

screws

(1)—Fig.

timing.

securely.

19A—,

Then,

move

tighten

positionofthe

Fig.3)and

hook

the

large

drive

the

screws

tighten

and set

gear

securely.

large

the

(2)

Fig.

19A

For

model

Loosen the three set screws (1)—Fig.

proper timing. Then, tighten the screws securely.

LTW-27BK

Fig.

19B—,

19B

10

move the hook and set the

ADJUSTING

Loosen

the

rightorleft

to use perfect needles.

RELATIVE POSITION BETWEEN

Loosen

THE

CLEARANCE

the set screw (3, Fig. 3) and

to get the

the

screw

(1),

correct

turn the

clearance

BOBBIN

balance

(4),

move

and

CASE AND OPENER

wheel

the hook

tighten

until the

the

saddle

screw.

opener

located at the extreme right hand position of its travel.

In

this

position,

adjust

it so that the

clearance

between

the

inside

the opener and the tab on the bobbin case holder is about 0.2mm.

After the adjustment, tighten the screw securely.

(5) to

Be

edge

sure

(2)

is

of

Fig.

20

11

ADJUSTING THE HEIGHT OF THE PRESSER FOOT

Loosen

lifter and loosen the screw (4, Fig. 17).

Move

screws securely.

FINE ADJUSTMENT OF THE NEEDLE FEED

Ordinarily,

the

needle

If,

of

the

ments

Loosen

rock

shaft

momentum. Tighten the nut

CHANGING

Remove

in this order.

pair

of pliers.

Put the desired needle clamp in place by screwing it tight into the needle

bar.

Loosen the needle bar connecting stud screw (2, Fig. 17) and turn the

needle bar to correct the direction of the needle clamp.

Set the correct timing between the hook and the needle.

Put the feeder, needle plate and presser foot in this order securely.

sufficiently the adjusting screw (1, Fig.

the

when

needle

are

offered.

(7,

presser

the

feed.

the

feed

the nut

Fig.

THE

the

The

foot

up or

feed

motion

motion

does

accordingtothe

(5,

Fig,

12)

12)

for

more

NEEDLE

needle,

needle clamp is a screwed type that is removed with a

GAUGE

presser

down

of the

not

synchronize,orincreasingordecreasing

sewing

and

bring

feed

momentumorkeep

firmly.

foot,

needle

as may be

lower

feed

conditions,

(6,

Fig.

clamp,

11),

raise the presser bar

required,

and

synchronizes

the

following

12)

close

to the

away

needle

plate and feed dog

tighten

with

feed

from

the

that of

that

adjust

driving

for

less

12

SPECIAL

INSTRRCTIONS

FOR

MODEL

LTW-27BK

AND

LSW-27BLK

Models LTW-27BK and LSW-27BLK are specially designed as two-needle

angular seam sewing machines. Model LTW-27BK employs standard size

bobbins, while model LSWr27BLK uses large-capacity bobbins. Both models

are equipped with devices to prevent the presence of lower thread loops when

sewing seams with acute (less

NEEDLE BAR

Pushing the

"L"

or

oneofthe

"R"

two

STOP

needle

will

selectively

individual

MECHANISM

bar

change

needle

than

90°) andles.

over

suspend

bars.

lever

the

reciprocating

(1)—Fig.

21—to

movement

either

position

of either

Basically, there are two functions to this mechanism, one which causes the

needle bars to operate and stop, and the other which switches from one needle

bar

to

the

other.

Fig,

21

13

A) NEEDLE BAR STOPPING AND OPERATING MECHANISM

The

two needle bars individually and jointly, with the components as

sembled to their

22) to accomplish the stopping and the operation.

The

positioning

needle

inserted

the

bar

into

set screws of

insides,

connecting

grooves

the

cooperate with the needle bar connecting stud (Fig.

of the

(1)

needle

needle

stud is

done

bar at their

by

meansofsplit

near the top ends of the

bar

position guides.

upper

needle

ends

stop

bars, as

rings

relative

(2)

wellaswith

At their opposite ends the needle bars are locked to the needle bar con

necting

a

sequently, when

needle

what

stud by

mechanism

means

inside

positioned

of three

the

needle

as

bars move up and down with the

may

best be described as

special

bars

described

"operational".

high-strength

beyond

above

steel

balls

expanded

the diameters of the bars. Con

and as pictured on Fig.

needle

bar connecting stud and are,

Needle

to the

which

22,

are

by

the

0.

Needle

bar

connecting

stud

Fig.

Needle

22

bar

Fig.

23A

Operating mode Non-operating mode

Fig.

23B

The

mechanism

disposed

within

the

needle

bar is

detailedonFig.

23A

which shows a needle bar in the operational state, while Fig. 23B shows a

needle

adjusting

bar in

nut

stopped

(3)

against

position.

cone

The

forceofspring

(4)

which

in turn

(1)

forces

pushes

three

plunger

steel

(2)

balls

and

(5)

outwardly beyond the diameter of the needle bar and against the countersink

at the bottom end of the needle bar connecting stud (6). At the same time

triangular prism (18) is allowing three steel balls (7) to recede below the dia

meter

connecting

21) into

selector block

rod end of the reciprocating

of

When

the

needle bar. Consequently,

stud

will cause

the

stoppinganeedle

either

the

"L"

(8)—Fig.

or

23B—directly above the respective rod end (9). This

bar by

"R"

needle

the

movement

needle

bar

moving

positions,

to reciprocate.

the

change

the

mechanism

bar nowcontacts the selector

of

the

needle

over lever (1)

locates

needle

block

causing

bar

(Fig.

bar

the rod to move downward inside the needle bar causing cams (10 and 11) to

likewise move downward. This allows upper balls (19A) to recede below the

diameter of the needle bar while at the same time forcing lower balls (19B)

outwardly beyond the diameter of the needle bars. Lower balls (19B) are now

forced against the tapered mouth (14) of the needle bar bushing (13) and will

stop the downward movement of the needle bar. While needle bar position

guide (15) contacts the bottom of the upper end of the needle bar rock frame,

thereby locking the needle

upper balls

(1*9A)

do no longer lock the needle

bar

tightly into place.

At

the same time the retracted

bar

against the underside of

the needle bar connecting stud (6) and so allow the latter to glide along the

needle

bar.

14

PREVENTION

Needle bar position guide (1) in conjunction with

position bracket (3), attached to needle bar connecting stud (2)—Fig. 24—in

conjunction with needle bar position guide plate (4) keep the needle

rotating. In the operating mode, bracket (3) serves this purpose, while

a needle

rotation.

OF

NEEDLE

bar

is stopped the channels embossed into the guide plate (4) prevent

BAR

ROTATION

the

bifurcated needle

bar

bar

from

when

n

Fig.

24

15

VERTICAL ADJUSTMENT OF NEEDLE BAR POSITION

The

trouble-free

are

fixed

making

bushing

the

(5)—Fig.

exact

within the needle bar rock frame

vertical

engagement

required

fine

24—is

position

and

adjustment

of the

disengagement,

of the

providedinneedle

needle

respectively,

(20)—Fig.

needle

bar

bars is

23.

bar

position,

connecting

important

since

their

for

their

positions

For the purpose of

and

eccentric

link

(6).

B) NEEDLE BAR RELEASE MECHANISM

When

or

"R"

its highest position, will contact the underside of selector block (8) causing

said needle

the

needle

position, the rod

bar

bar

to become disengaged from its driving mechanism.

change over lever (1)—Fig. 21—is set to either

end

(9) of

the

selected needle bar, when

same

"L"

is in

OPERATION

Shifting

the needle

The

and

was disengaged, is fixed to their normal position as Fig. 25B.

same

time, the needle

When

the

21—,

connection

stop separates from

position.

Then,

its highest position

OF

THE

NEEDLE

the

needle

bar

change over frame to move in direction of the arrow (Fig. 25).

needle

bar

disengaing

needle

bar

returntotheir

the

needle

bar

change over frame connection, when

bar

stops when same reached in its

the

needle

change over frame and

first position.

the

needle

bar

connecting

and

becomes normal

BAR

change

bar

bar

CHANGE

over

lever—Fig. 21—to

stop pushing the lever release (4)—Fig.

Thereby,

stopping

stud

incorporates with the needle

twin

OVER

the

needle

stud

needle operation.

FRAME

the

next

bar

the

slide block for needle

and returns to

"R"

will cause

needle

change over frame

bar

lowers

At

the

highest position.

their

first

bar

in

W

Fig.

25

SPECIALLY-DESIGNED ROTATING HOOKS FOR ANGULAR

SEAM

developed

ances

Furthermore, the

for

when

thread

The horn-like extension (4) of the

taking up the slack, while it courses around the hook.

SEWING

The

rotating hooks for models LTW-27BK and LSW-27BLK have been

specifically

(1)—Fig.

much

increased

Also,

should

the

upper

guard

(2)

The cap-type

26—to

hook

thread

the

(needle)

will

design

for these

allow

for

machine

the

model

volume.

machines

most

LSW-27BLK

and are

effective

be stopped at that point of its stitching cycle

thread is about to

allow

unhampered

passage

of the bobbin case assures

hook

gib retains the upper thread temporarily

provided

transit of the

with

its

pass

over the

of the

larger

thread.

smooth

with

sewing

bobbin

hook,

thread handling.

specific

thread.

provides

the shape of

Thus looping is prevented, particularly when heavy threads or those lacking

smoothness are employed.

Automatic lubrication of the moving parts of the hooks

allows

the main

tenance of adequate sewing speeds without sacrificing their useful service

16

clear

life.

Fig.

26

METHOD

OF

PREVENTING

LOOPINGOFTHE

LOWER

(BOBBIN)

THREAD

When sewing angular seams—particularly acute angles—with machines

fitted

with

conventional

Bobbin

types

of rotary

Fig.

hooks,

20

mm

27

the

appearanceoflarge

KIO-H

mm

T,

B

• ^

loops

of

17

the lower thread

by the transport of the

needle

with

by means of springs any

bar

The

devices

Fig.

rotary

27A

LSW-27BLK.

to

pick

up any

the dotted outline of the thread take-up spring

rest

position

figure,

guide hole in retainer (2).

out

of spring (1) is such

(25/32'')

THREAD

each of the two upper (needle) threads—installed in the machines.

spring

When

from

of

There

under

CONTROLLER

can

be noticed at

material

is

at

rest.

hooksofmodels

which

shows

Fig.

prevent the

excess

the

methodofthreading

27B

shows

excessofthread

prior to

(1)

in this position,

thread

are

pulling

travelsadistancetowhere

bobbin case tension spring (3).

that

can

be absorbed.

SPRINGS

two separate

around

looping

of thread.

the

back

further

slack

and

LTW-27BK

for

individual

the

underside of the work.

the

sewn

corner,

and

of the

lower

of the

position

the

excess

of thread take-up

preventionofloops.

(lA)

thread.

its eye

demand

thread

for bobbin

The

loop containing as

thread

This

while

the one

LSW-27BLK

thread by withdrawing

bobbin

caseofmodel

spring

Also

which shows same in a

As can be seen

coincides

function

controller springs—one for

with

threadisthen

and

much

is caused

raised

are

equipped

(1)

ready

note

froni

the

thread

pulled

effectiveness

as 20 mm

that

this

Rg.

28

When sewing angular seams with either one of the two needle bars

stopped, upper thread is not drawn out at an equal rate for both needle bars.

Consequently,

condition.

A)

Adjusting

Loosen

for

more

(2).

two

thread

controller

springs

are

These springs can be adjusted individually.

the rear thread controller

set

screw

action;for

(2),

less

turn

action

thread

turn

spring

controller

stop

(3)

to the

required

spring

left

stop

and

to

(3)

tighten

cope

to the

with

set

right

screw

this

B) Adjusting the front thread controller spring

Loosen set screw (11) and turn spring stop (10) to the left to increase

the

action

of this

of thread take-up spring (7) and to the right to reduce the

spring.

After the

desired

setting of the spring has been

established,

tighten set screw (11).

C) Adjusting

I. Slightly

II. To adjust the

driver into the slot of the take-up spring slot

take-up

loosen

spring

tension

nut (4) and also set screw

tension

of the rear thread take-up spring (1)

(5).

placeascrew

(6)

and turn to the left

to tighten the spring tension and to the right to loosen same. After

the

desired

III. To adjust the

tension

tension

has been

determined,

tighten set

of the front thread take-up spring

screw

(7),

(5).

set screws (9) in collar (8) turning same to the left to tighten and to the

right to loosen it. Upon determining the desired tension of this spring,

tighten set screws (9) and also nut (4).

loosen

18

action

two

ADJUSTING

I.

Set

II.

Turn

its

travel.

4.1mm

4.4

in

LTW-27B

mminLSW-27BLK

THE

HEIGTH

stitch

lengthtoshortest

OF

THE

stitch.

NEEDLE

CLAMPS

handwheel until needle bar has descended to the lowest point of

2

mm

Fig.

29

Fig.

30

19

III.

Turn

hook

IV.

onlysothat

To

correctly adjust the position of

hook

point

the

comestothe

needle

as (7)—Fig. 29.

needles (1) relative to hook points

(2), remove the needle clamps (3) from their respective needle bars by

removing needle clamp

needle clamp adjusting screw (5) become accessible.

set

screw

(4).

Upon

removing

the

needle clamps,

Turn

screw (5) either in or out to obtain the 4.4 mm (11/64") in LSW-27BLK

(4.1mm (5/32") in LTW-27BK) distance between the eye of the needle

when at its lowest position and

clamps with needles have been replaced on

V.

Be sure

of needle

Turn

hand

that

needle clamp adjusting screw (5) contacts

bar

plug (6) and tighten needle clamp set screws (4).

wheel toward you allowing needles to rise.

hook point crosses the centerline of the rising needle, it should be 2 mm

(5/64")

above the upper end of

necessary. (Fig. 30)

the

hook point (Fig. 29) after the needle

the

needle bars.

When

the

eye of

the

needle. Adjust if

adjusting

the

the

rotating

bottom

TIMING

ADJUSTMENT

Turning

the

OF

THE

hand

wheel, confirm whether

LOWER

STEEL

the

BALL

needle

bar

motion is not

smooth due to projection of the lower steel ball (2)—Fig. 31—out of the out

bar

side diameter of the needle

(3).

Normally, when the lever is changed over and the needle stop stud (1)

is pushed, those parts in the needle

bar

begin to operate at the same time

and the needle bar stops at its highest point.

Confirm in this position whether there is not a excess play on the needle

bar

in

vertical

direction.

This adjustment is made by the steel ball guide (4) and its nut (5), and

the

standard

dimention

is

30.5

mm

30.5mm

Fig.

31

20

SPECIAL

ASSEMBLING

INSTRUCTIONS

THE

KNIFE

FOR

CHANGE

MODEL

OVER

LTW-27BM

PEDAL

1. Connect the knife chantre over lever {1, Fig. 32), the pedal (1, Fig.

33)

and

the

chain

(2, Fig. 33).

The

proper position of the pedal is about at an angle of 20°.

2.

of

the

Attach

table

the

knife

releasing

.so

that the hole (3, Fig. 32) of the lever (2, Fig. 32)

rod

bracket

(3, Fig. 33) on

the

and

underside

the

hole

{5, Fig. 33) of the releasing rod (4, I'ig. 33) assembled to the releasing rod

bracket

(3, Fig. 33) are on a vertical line.

A.ssemble the releasing rod to be j)arallel with the knee lifter connecting

rod

(0, Fig. 33).

At

the

same time, adjust the length of the chain so that

the

releasing rod

is parallel with the underside surface of the table.

3.

Set

the

pedal

extension

rod (9, Fig. 33)

with

the

screw (8, Fig. 33) to

the pedal and attach the pedal extension rod (10, Fig. 33) to the releasing rod

atalittle

to

the

left

fr{)m

the

center

of

it.

Care

must

be

taken

.so

that

the

pedal extension rod can move slightly.

4. Adjust so that there is no slack on the chain attached to the front of

the

pedal, and connect the two pedal extension rods with

(11, Fig. 33).

the

adjusting screw

Fig.

Fig.

32

33

21

KNIFE

to

REPLACEMENT

1. To

(2) to

2. To replace a new knife,

lowest

that the

of the

CHANGE

The

operation and stopping of the knife

To

operate the knife, pedal the treadle toward A direction (Fig. 34), and

stopittoward

remove

remove

position.

clearance

knife

Securely tighten the two screws.

OVER

B direction.

OF

the

knife,

it.

Then, put the

between

(2)

is 1

mm

OPERATION

THE

loosen

as the illustration on the

KNIFE

the two

turn

the handwheel until the knife lowers to its

knife

the

surfaceofthe

Fig.

like

34

screws

the

are

made by pedaling.

\

(1) and pull

figure

needle

35,

plate

figure.

but

(3)

down

adjust

and

the

them

the

knife

so

edge

J

1mm

Fig.

35

ADJUSTING THE KNIFE POSITION {right and left directions)

22

Loosen

the

right

needle

ADJUSTING

(up or down direction)

1. When fitting the knife oscillating crank, adjust the oscillating shaft (2,

Fig. 36) so that the right end of the shaft comes out about 1mm

oscillating crank (1, Fig. 36),

an equal distance starting from the horizontal line (A, Fig. 37).

Then

2. When fitting the stop collar, adjust the clearance between tlie end of the

pin (1, Fig. 37) and the groove on the part (2, Fig. 37) is 0.5mm, and in this

position, set the stop collar (4, Fig. 36) closely to the oscillating shaft (2, Fig.

36), then tighten the collar set screw (5, Fig. 36).

or

plate.

the two

left

THE

tighten

screws

(4, Fig. 35), adjust the knife holder (5,

so that the

KNIFE

the

CHANGE

screw (3, Fig. 36)-

knife

lowers

also,

adjust the crank to actuate up or down at

OVER

to the

POSITION

center

of

the

Fig.

groove

from

35) to

of the

the

mm

Fig.

36

Fig.

37

23

TIMMING

Normally, when the needle is at its lowest point, liie knife should be at

its highest point or vice versa.

This is due to the

is

fed,

To

of the

Then, tighten the cam set screws.

BETWEEN

anditcuts

time

this,

cam

(2)

THE

NEEDLE AND KNIFE

reason

the

material

loosen

the

fasterorslower

; f

rv

that the

after

two

set

as may be

knife

the

screws

does

feeding

(1),

required.

not

operate

motion.

adjust

the

while

rotating

the

material

position

Fig.

38

Loading...

Loading...