Seiko LSC-8BV-1.8BLV-1, LSC-8B-I.8BL-1, LSC-8BH-I.8BLH-I Operating Instructions Manual

LSC-8BV-1

OPERATING

INSTRUCTIONS

FOR

LSC-8BV-1.8BLV-1

LSC-8B-I.8BL-1

LSC-8BH-I.8BLH-I

as

E ( K

II

LSC-8B-1

SEIKO

SEWING

MACHINE

CO.,

LTD.

TOKYO•JAPAN

INSTRUCTIONS

FOR

SEIKO

MODEL

LSC

TYPE

INDUSTRIAL

SEWING

MACHINES

This

is a

guidetouseofSEIKO

model

LSC

type

industrial

sewing

machines

under

the

best

condition.

SEIKO

LSC series are a single needle, lock-stitching, needle,

upper&lower

feed, reverse feed, semi-automatic lubrication

system,

cylinder

bed sewing

machine.

Please read

this

guide

thoroughlysothat

you

may

expect

good

performance.

Specifications

Model

LSC-8BV-1

LSC-8BLV-1

LSC-8B-1

LSC-8BL-1

LSC-8BH-1

LSC-8BLH-1

Speed

(s.p.m.)

2,500

2,200

2,300

2,200

2,500

2,200

Needle

DPx

17

Standard

^16

Standard

#16

Standard

#18

Standard

#18

Standard

#16

Standard

#16

Hook

Rotary

Standard

Large

Standard

Large

Standard

Large

Stitch

Length (Max.) 6

mm

7

mm

6

mm

7

mm

6

mm

7

mm

Presser

Foot

Alternating

pressers

Presser Lift

Up/Down

Moving

Amount

3 — 6

mm

Presser

Lift

8mm(by

lever)

Needle

Bar

Stroke

33.2

mm

Thread

Take

Up

Slide

motion

type

Thread

TakeUpStroke

57.5

mm

67

mm

57.5

mm

67

mm

57.5

mm

67

mm

Diameter of Cylinder Bed

46

mm

50

mm

46

mm

50

mm

46

mm

50

mm

Working

Space

258mmx

110

mm

Weight

29kg(with

base)

Motor

250

W •2PClutch

Motor

Thread

Synthetic

Use: All kinds of work In the clothing, footwear, upholstery, leather industry such as shoes, canvas

products, dress shields, sleeve, sandals, gloves, sports goods, especially. Model LSC-8BV-1 &

LSC-8BLV-1

are suitable for various kinds of tape stitching with a edge binder which is interchange

able

without

having any

alternationtoany

other

parts.

1

—

INDEX

CONTENTS

Page

Setting up

the

machine 2

Oiling 2 —3

Oil

adjustment

3

Needle

4

Thread

4

Winding

bobbin

5

Adjustment

of

the

bobbin

winder

5

Inserting and removing

the

bobbin

6

Threading

the

machine

7

Regulating

the

thread

tension 7

Regulating

the

pressureongoods 8

Adjusting the stitch length and reverse stitch 9

Adjusting the liftofthe alternating presser feet 9

Instructions

for

LSC-8BV-1

and

8BLV-1

10

INFORMATION

FOR

ADJUSTMENT

Adjusting

the

heightofthe

feed dog 11

Adjusting

the

timingofthe

needle plate, needle and feeder 11 —12

Adjusting

the

heightofthe

needle

bar

12

Timing between

the

needle and the hook 13

Timing between the needle and the feeder 14

Adjusting the heightofthe

presser feet

14—15

Timingofthe vibrating presser foot 15

Adjusting

the

thread controller spring 16

SETTING UP THE MACHINE (Fig. 1)

»

Before

setting

up

the

machine

on

the

table,

attach

the

relative

parts

to

the

table.

(1) Stand (2) Motor

(4) Cotton stand (5) Tape stand (only

LSC-8BV-1,

(7) Knee lifter

8BLV-1)

and Machine base

(9) V shape belt (10) Bobbin winder

if

(3) Treadle

(6) Machine head

(8) Chain

Fig. 1

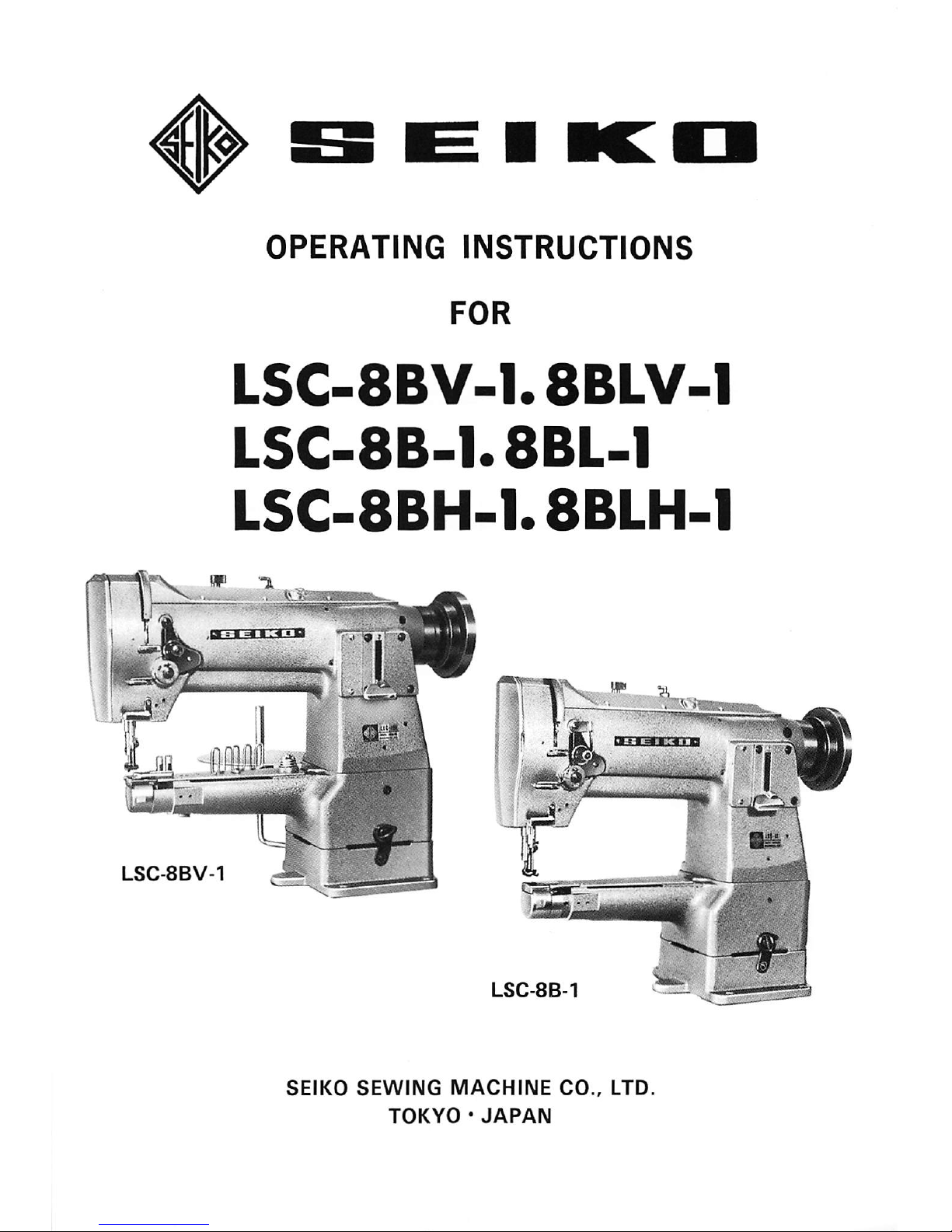

OILING AND ITS

ADJUSTMENT

(Fig.

2)

* Do

not

operate

the

machine,

eveniffor

testing,

unlessithas

been

pro

perly

oiled.

To

fill

the

oil

reservoir

on

the

topofthe

machine,

pour

oil

through

the

oil filler hole (A), until oil level

reaches

to

the

upper

reference

line (B).

♦

Oilingisautomatically

made

by

the

vibrationofthe

machine

while

sew

ing

operation

through

the

oiling

wicks

in

the

machine,

and

oil flow

stops

automatically

when

the

operation

of

the

machine

ends.

» When

starting

the machine initially and

after

kept

away for a long time

without using

at

all,

make

sure the oil volume through oil level indicator

(B),

and oil sufficiently to respective necessary

parts

before

starting

operat

ion

and

try

pre-running.

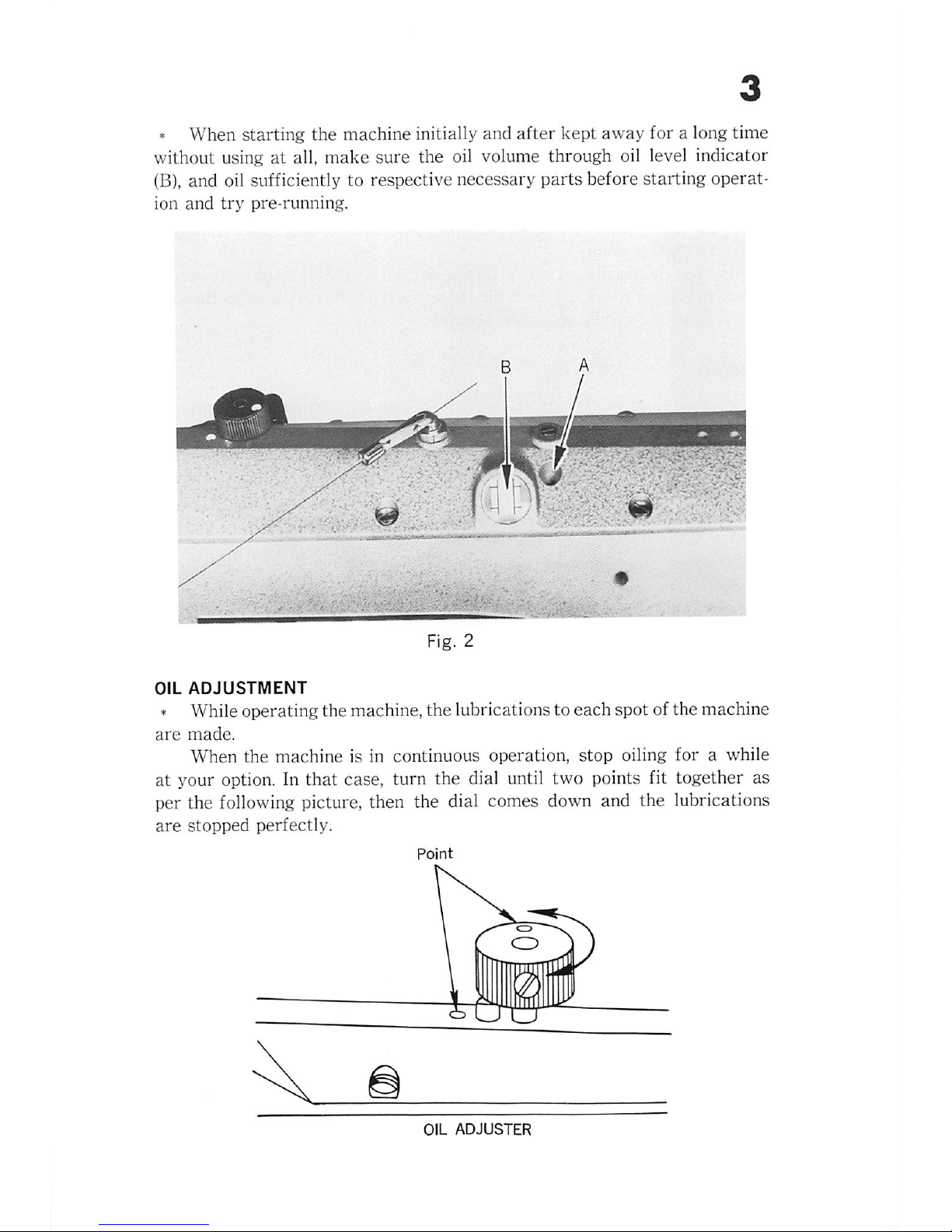

OIL

ADJUSTMENT

><•

While operating the machine, the lubrications to each spot ofthe machine

are

made.

When

the

machine

is in

continuous

operation,

stop

oiling

forawhile

at your option. In

that

case, turn the dial until two points fit together as

per the following picture, then the dial comes down and the lubrications

are

stopped

perfectly.

OIL

ADJUSTER

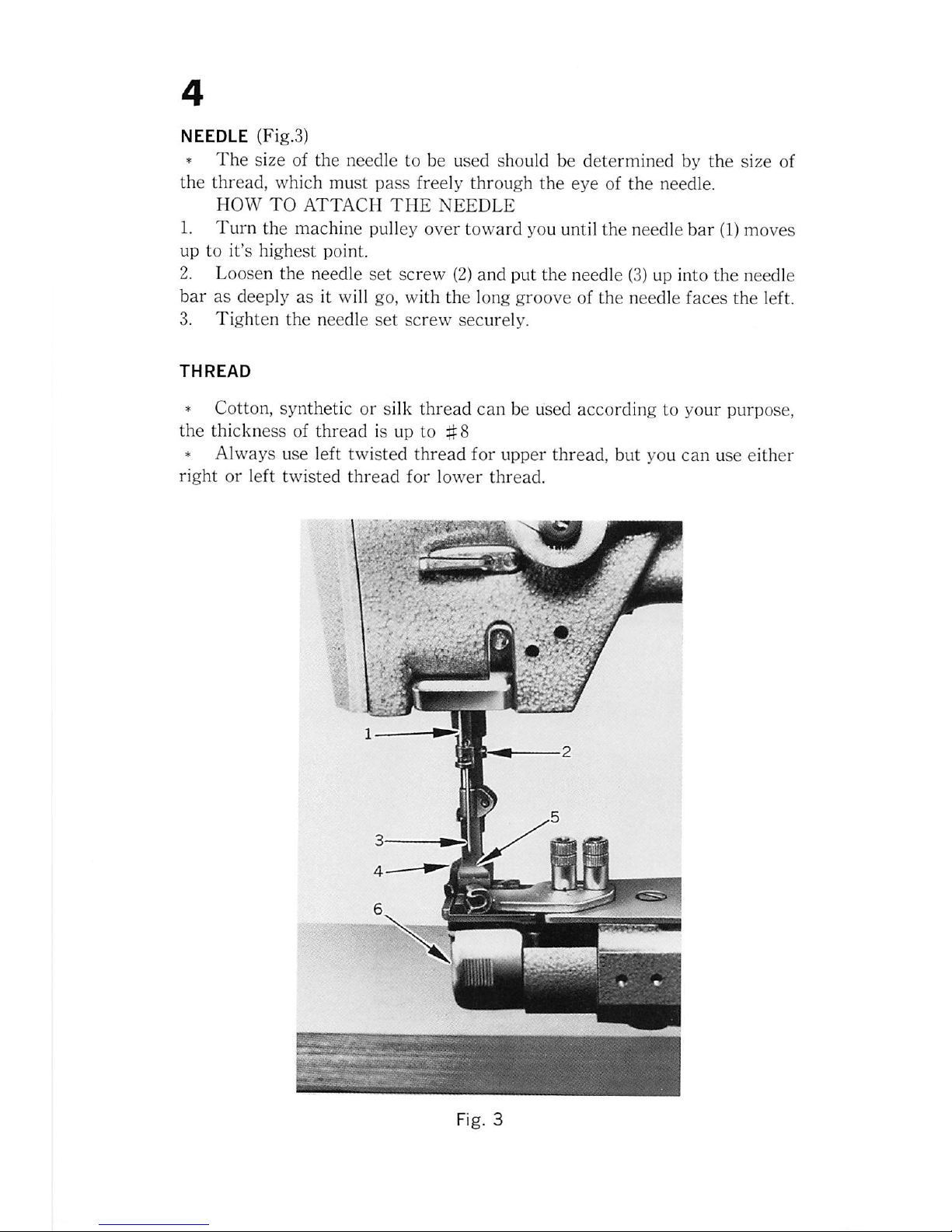

NEEDLE {Fig.3)

*

The

size of the needle to be used should be

determined

by

the

size of

the

thread,

which

must

pass

freely

through

the

eyeofthe

needle.

HOW

TO

ATTACH

THE

NEEDLE

1.

Turn

the

machine

pulley

over

toward

you

until

the

needle

bar

(1)

moves

uptoit's

highest

point.

2. Loosen the needle

set

screw

(2)

and

put

the

needle (3) up into

the

needle

bar

as deeply as it will go,

with

the

long groove of

the

needle faces

the

left.

3.

Tighten

the

needle

set

screw

securely.

THREAD

* Cotton, synthetic or silk

thread

can

be used according to your purpose,

the

thickness

of

thread

is

up

to

#8

* Always use left

twisted

thread

for upper thread, but you

can

use

either

right

or

left

twisted

thread

for

lower

thread.

Loading...

Loading...