Page 1

OPERATING

INSTRUCTIONS

FOR

LSC-8BV-1.8BLV-1

LSC-8B-I.8BL-1

LSC-8BH-I.8BLH-I

as

E ( K

II

LSC-8BV-1

LSC-8B-1

SEIKO

SEWING

TOKYO•JAPAN

MACHINE

CO.,

LTD.

Page 2

INSTRUCTIONS

This

is a

under

FOR

SEIKO

guidetouseofSEIKO

the

best

condition.

MODEL

LSC

model

TYPE

LSC

INDUSTRIAL

type

industrial

SEWING

sewing

MACHINES

machines

SEIKO

LSC series are a single needle, lock-stitching, needle,

feed, reverse feed, semi-automatic lubrication

machine.

Please read

this

guide

thoroughlysothat

Specifications

Model

Speed

(s.p.m.)

Needle

Hook

Stitch

Length (Max.) 6

Presser

Foot

Presser Lift

Moving

Presser

Up/Down

Amount

Lift

LSC-8BV-1

2,500

DPx

17

Standard

Rotary

Standard

mm

^16

LSC-8BLV-1

2,200

Standard

Large

7

mm

#16

you

LSC-8B-1

2,300

Standard

Standard

6

system,

may

#18

mm

Alternating

3 — 6

8mm(by

expect

LSC-8BL-1

Standard

pressers

mm

lever)

cylinder

2,200

#18

Large

7

mm

upper&lower

bed sewing

good

performance.

LSC-8BH-1

2,500

Standard

#16

Standard

6

mm

LSC-8BLH-1

2,200

Standard

Large

7

mm

#16

Needle

Bar

Stroke

Thread

Take

Up

Thread

TakeUpStroke

Diameter of Cylinder Bed

Working

Space

Weight

Motor

Thread

57.5

46

mm

mm

67

mm

50

mm

Slide

57.5

mm

46

mm

258mmx

29kg(with

250

W •2PClutch

33.2

mm

motion

110

Synthetic

type

base)

67

50

mm

Motor

mm

mm

57.5

46

mm

mm

Use: All kinds of work In the clothing, footwear, upholstery, leather industry such as shoes, canvas

products, dress shields, sleeve, sandals, gloves, sports goods, especially. Model LSC-8BV-1 &

LSC-8BLV-1

able

without

are suitable for various kinds of tape stitching with a edge binder which is interchange

having any

alternationtoany

other

parts.

67

mm

50

mm

Page 3

—

INDEX

CONTENTS

Page

Setting up

Oiling 2 —3

Oil

adjustment

Needle

Thread

Winding

Adjustment

Inserting and removing

Threading

Regulating

Regulating

the

machine 2

bobbin

of

the

bobbin

the

machine

the

thread

the

pressureongoods 8

winder

the

bobbin

tension 7

Adjusting the stitch length and reverse stitch 9

Adjusting the liftofthe alternating presser feet 9

Instructions

for

LSC-8BV-1

and

8BLV-1

1

3

4

4

5

5

6

7

10

INFORMATION

Adjusting

Adjusting

Adjusting

the

the

the

Timing between

FOR

ADJUSTMENT

heightofthe

timingofthe

heightofthe

the

needle and the hook 13

feed dog 11

needle plate, needle and feeder 11 —12

needle

bar

12

Timing between the needle and the feeder 14

Adjusting the heightofthe

presser feet

14—15

Timingofthe vibrating presser foot 15

the

Adjusting

thread controller spring 16

Page 4

SETTING UP THE MACHINE (Fig. 1)

»

to

Before

the

table.

setting

up

the

machine

on

(1) Stand (2) Motor

(4) Cotton stand (5) Tape stand (only

(7) Knee lifter

8BLV-1)

and Machine base

(9) V shape belt (10) Bobbin winder

the

table,

LSC-8BV-1,

attach

the

relative

parts

(3) Treadle

(6) Machinehead

(8) Chain

if

Fig. 1

OILING AND ITS

* Do

perly

oil filler hole (A), until oil level

♦

ing

automatically

not

oiled.

To

fill

Oilingisautomatically

operation

ADJUSTMENT

operate

the

oil

through

when

the

machine,

reservoir

the

the

operation

(Fig.

eveniffor

on

the

reachestothe

madebythe

oiling

wicksinthe

of

2)

topofthe

vibrationofthe

the

machine

testing,

machine,

upper

machine,

ends.

unlessithas

pour

oil

reference

machine

and

oil flow

been

through

line (B).

while

pro

the

sew

stops

Page 5

» When

without using

(B),

and oil sufficiently to respective necessary

ion

and

starting

try

pre-running.

the machine initially and

at

all,

make

sure the oil volume through oil level indicator

after

parts

kept

away for a long time

before

starting

operat

OIL

ADJUSTMENT

><•

While operatingthe machine, the lubrications to each spot of the machine

are

made.

When

at your option. In

the

machine

that

is in

continuous

operation,

stop

oiling

forawhile

case, turn the dial until two points fit together as

per the following picture, then the dial comes down and the lubrications

are

stopped

perfectly.

OIL

ADJUSTER

Page 6

NEEDLE {Fig.3)

*

The

size of the needle to be used should be

the

thread,

HOW

1.

Turn

uptoit's

which

TO

the

machine

highest

must

ATTACH

point.

2. Loosen the needle

bar

as deeply as it will go,

3.

Tighten

THREAD

the

needle

pass

THE

pulley

set

screw

with

set

screw

freely

NEEDLE

over

the

through

toward

(2)

and

you

put

long groove of

securely.

determined

the

eyeofthe

until

the

needle

the

needle (3) up into

the

needle faces

by

needle.

bar

the

the

(1)

the

size of

moves

needle

left.

* Cotton, synthetic or silk

the

thicknessofthreadisupto#8

* Always use left

right

or

left

twisted

twisted

thread

thread

thread

for

can

be used according to your purpose,

for upper thread, but you

lower

thread.

can

use

either

Page 7

WINDING

THE

LOWER THREAD ON

THE

BOBBIN

(Fig.

4)

Pushabobbin

1.

Pass

2.

in

the

tension

disc.

3.

Bring

clock-wise

4.

Push

belt

(9, Fig. 1) will

5.

The

after

the

THE

ABOVE

ADJUSTMENT

*

IN

CASE

If

the

in

the

tension

required,

*

WINDING

Adjustment

the

amount

*

WINDING

Strengthofthe

on

the

thread

from

bracket,

the

thread

direction

the

lever

several

(3)

engage

pulley (2) will

bobbin

thread

is

filled

OPERATION

OF

UNEVEN

does

bracket

then

tighten

AMOUNT

screw

of

thread

STRENGTH

winding

the

bobbin

the

thread

then

between

forward

times

toward

and

automatically

with

thread.

CAN

OF

THE

WINDING

not

wind

and

move

the

screw.

OF

(5)

can

be

wound

on

can

winder

stand

and

toward

around

the

other

then

start

BE

DONE

BOBBIN

evenly

the

bracket

THREAD

turned

the

bobbin.

be adjusted

spindle

around

the

bobbin

the

side

the

be

free

WHILE

WINDER

on

in

(1)asfar

downward

the

and

bobbin.

so

that

machine.

from

SEWING.

(Fig.

the

bobbin,

to

the

or

outtoincrease

with

nut

as

it will go.

through

back

wind from

the

the

belt

4)

loosen

of

pulley

the

the

the

and

eye

tension

below

(2)

and

stopped

screw

rightorleftasmay

or

decrease

(6).

(7)

in

V

(4)

be

Fig. 4

Page 8

INSERTING AND REMOVING BOBBIN (Fig. 5

Raise

the

1.

Fig.

3)

Pullupthe

2.

3.

To

insert

about5cm,

4.

Lead

and

under

*

THREAD

bobbin

5.

keeping

into

6.

case.

Draw

the

the

hookasdeeply

Close

needle

a full

and

the

endofthread

the

tension

WINDING

Check

out

about5cmofthe

slotofthe

the

end

latch

insert

cover,

bartoits

(1,

Fig.5)and

bobbin

the

spring

the

thread

bobbin

as

but

highest

draw

(Fig. 6),

bobbin

pulled

(1,

holditpulling

into

out

Fig.6)and

DIRECTION

winding

endofthread,

case

faces

it'will

leave

go,

sufficient

point.

out

the

bobbin

through

when

directionasshown

upper

and

push

and

Draw

the

then

space

6)

bobbin

out

case.

the

slotofthe

the

fitting

pull

side.

down

for

out

the

end

from

the

endofthread

bobbin

thread

the

guide.

bobbin

Fig.

up

the

latch

And

fit

the

the

latch

passageofthe

cover

the

bobbin

into

No.

6.

(1, Fig. 5)

bobbin

securely.

thread.

(6,

by

case,

the

case

4'5

Page 9

THREADING

THE

MACHINE (Fig. 7)

1. Raise the needle

thread

top of the machine arm, down to the upper guide hole of the thread guide

(2)

two

(3).

thread

the

guide

down through the

(8),

stand

From

from right to left.

holes in (2)

Now pull the thread downward from right to left beneath and around

thread

(6),

(9) and

the

the

thread

controller

controller

pull the thread upward through the eye in the take-up lever

(10),

I t

7—4—^1

• '.0-1%

® ed up by

®rii

1

iJ-JB**/

9—12

bartoits

following

stand,

Pass

and

from

(4),

continue to pull the thread upward through the fork in

and

thread

and from left to right through the eye of the needle.

DETQcrmii

El=•=1

^

highest point

order:

lead

the

the

thread

righttoleft

against

guide

the

(6)

again and then through the

i ^

i--

ifri'i

and

lead

the

thread

thread

in weaving fashion through the

check

to

the

over

and

between

spring

2.

After

hold

the

your

pulley

that

bobbin

put their ends of

other

the

presser

operation.

thread

(5)and

the

endofthread

left

hand,

with

your

thread

needle

side

bed

foot

guide (1) on

the

tension discs

through

above

thread

and

the

threading,

turn

right

maybepick-

thread.

thread

through

for

starting

from

other

thread

guide

with

the

hand

And

on the

under

the

the

(7)

so

Fig. 7

REGULATING

* For ordinary stitching, the tension of the upper and lower threads should

THE

THREAD

TENSIONS

be equal so as to lock both threads in the center of the fabric. If the tension

on either

the

* If the tension on the upper

thread, it will be

* If

thread, the lower

result.

the

thread

tensiononthe

is stronger

straight

thread

than

on

the

other, imperfect stitching will be

thread

along the upper surface of

lower

will lie

threadisstronger

straight

Fig. 8

is stronger

along the underside of

Perfect

Tight tension of needle thread

Loose

stitching

tension

of

than

the

than

needle

that

on the lower

fabric.

that

on

thread

the

the

upper

fabric.

Page 10

HOW

TO

REGULATE

THE THREAD TENSION (Fig. 9)

1.

TENSION

To

the

upper

turn

the

the

right

ion. If

it,

turn

2.

TENSION

To

turn

the

the

right,

turn

the

a

screw

OF

UPPER

adjust

the

(needle)

serrated

for

increasing

you

desiretodecrease

the

nuttothe

OF

BOBBIN

increase

screw

the

(2,

andtodecrease

screwtothe

driver.

THE

THREAD

tension

thread,

nut

(1)

tens

left.

THE

THREAD

tension,

Fig.6)to

left

of

to

it,

by

ADJUSTMENT

The

pressure

To

To

increase

decrease

*

*

OF

Fig. 9

THE

of

the

it.

PRESSURE

the

presser

pressure,

turn

the

» / # \ i "S

ON GOODS (Fig. 10)

feetisregulated

turn

the

screw

to

the

1

by

screwtothe

left.

the

right.

adjusting

screw

(1).

Page 11

ADJUSTING THE STITCH LENGTH (Fig. 11)

Stitch length is adjusted by turning the

ference

stitch

♦

right.

mark

length on

If you

on

the

collar

the

plate

(2).

desiretodecrease

(3)

comes

the

stitch

serrated

in line

length,

» When you desire reverse stitch, push the lever

•'

''j

Fig. 11

ALTERNATING

high

enough

for

feet lift to equal height.

the

wing nut

the

(1),

lift.

move up

presser

presser

THE

foot

HEIGHT

(5,

Fig. 3) or vice versa,

OF

ADJUSTING THE

The

thickness of the material sewn should control the height of the lift

of

the

alternating

It

should

With

normal

* To adjust

lift,

and

*

When

against

instructions

normallybejust

adjustment

the

push

down

altering

thatofthe

"ADJUSTING

^ -11

LIFT

OF THE

presser

feet.

both

lift, loosen

this

nuttolower

the lift of the lifting

vibrating

nut

with

turn

(11)sothat

the

desire

the

serrated

(4)

up as far as it will go.

the re

number

nut to

PRESSER FEET (Fig. 12)

clearance

of

the

nuttoraise

the

material.

foot (4, Fig. 3) unequally

see

THE

PRESSER

FEET".

of

the

the

the

Fig.

12

Page 12

TO

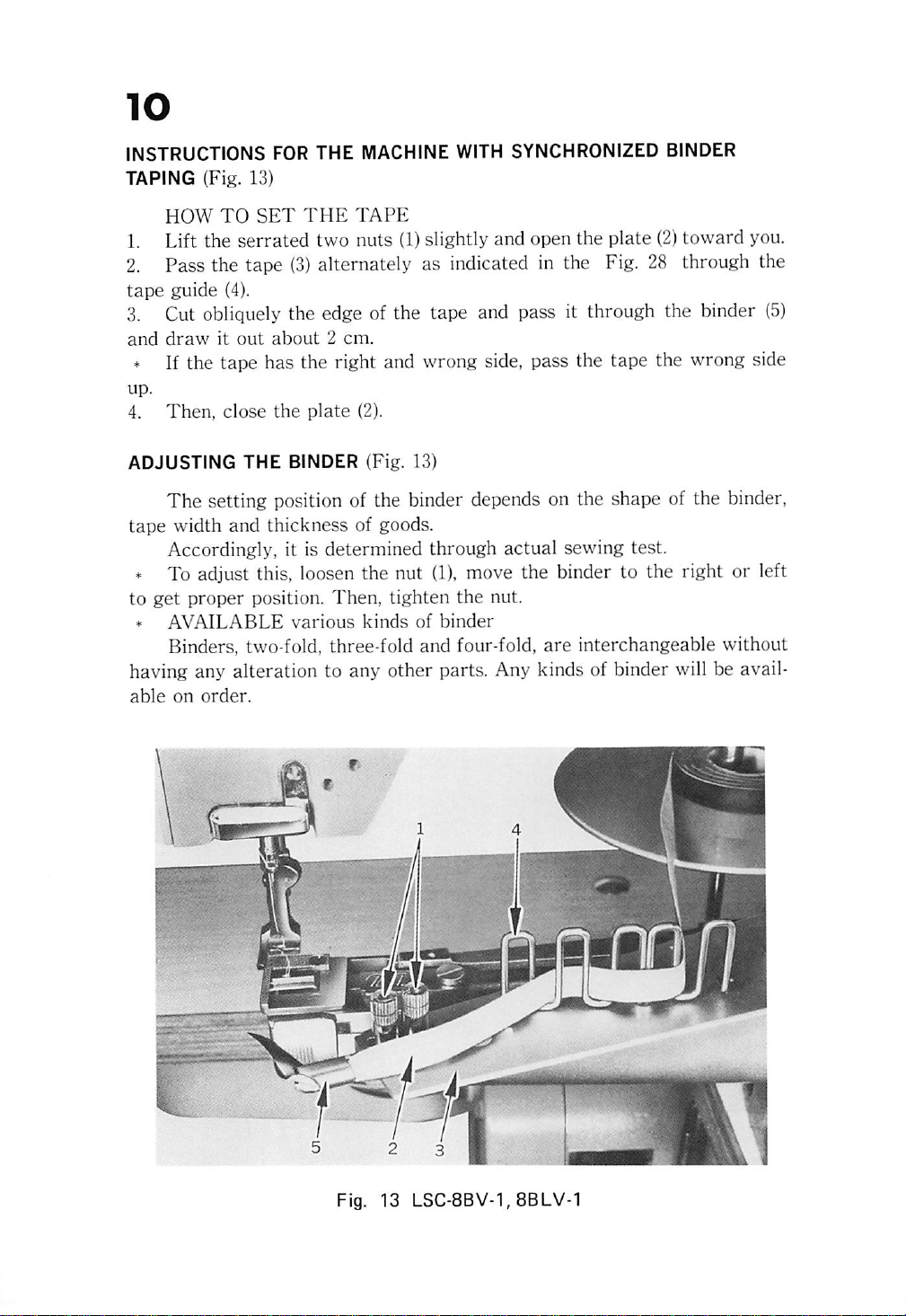

INSTRUCTIONS FOR THE MACHINE WITH SYNCHRONIZED BINDER

TAPING {Fig. 13)

HOW

TO

SET

THE

TAPE

1. Lift the

2. Pass the tape

tape

guide

3. Cut obliquely the edge of the tape and pass it through the binder

and

drawitout

* If the tape has the right and wrong side, pass the tape the wrong side

up.

4.

Then,

serrated

(4).

close

two

nuts

(1)slightly

(3)

alternately as indicated in the Fig. 28 through the

about2cm.

the

plate

(2).

and

open the

plate

(2)

toward

you.

(5)

ADJUSTING

THE

BINDER (Fig. 13)

The setting position of the binder depends on the shape of the binder,

tape

width

and

thickness

of goods.

Accordingly, it is determined through actual sewing test.

* To adjust this, loosen the nut

to

get

*

AVAILABLE

proper

position.

various

Then,

kinds

Binders, two-fold, three-fold and four-fold,

(1),

tighten

of

move the binder to the right or left

the

nut.

binder

are

interchangeable without

having any alteration to any other parts. Any kinds of binder will be avail

able

on

order.

Page 13

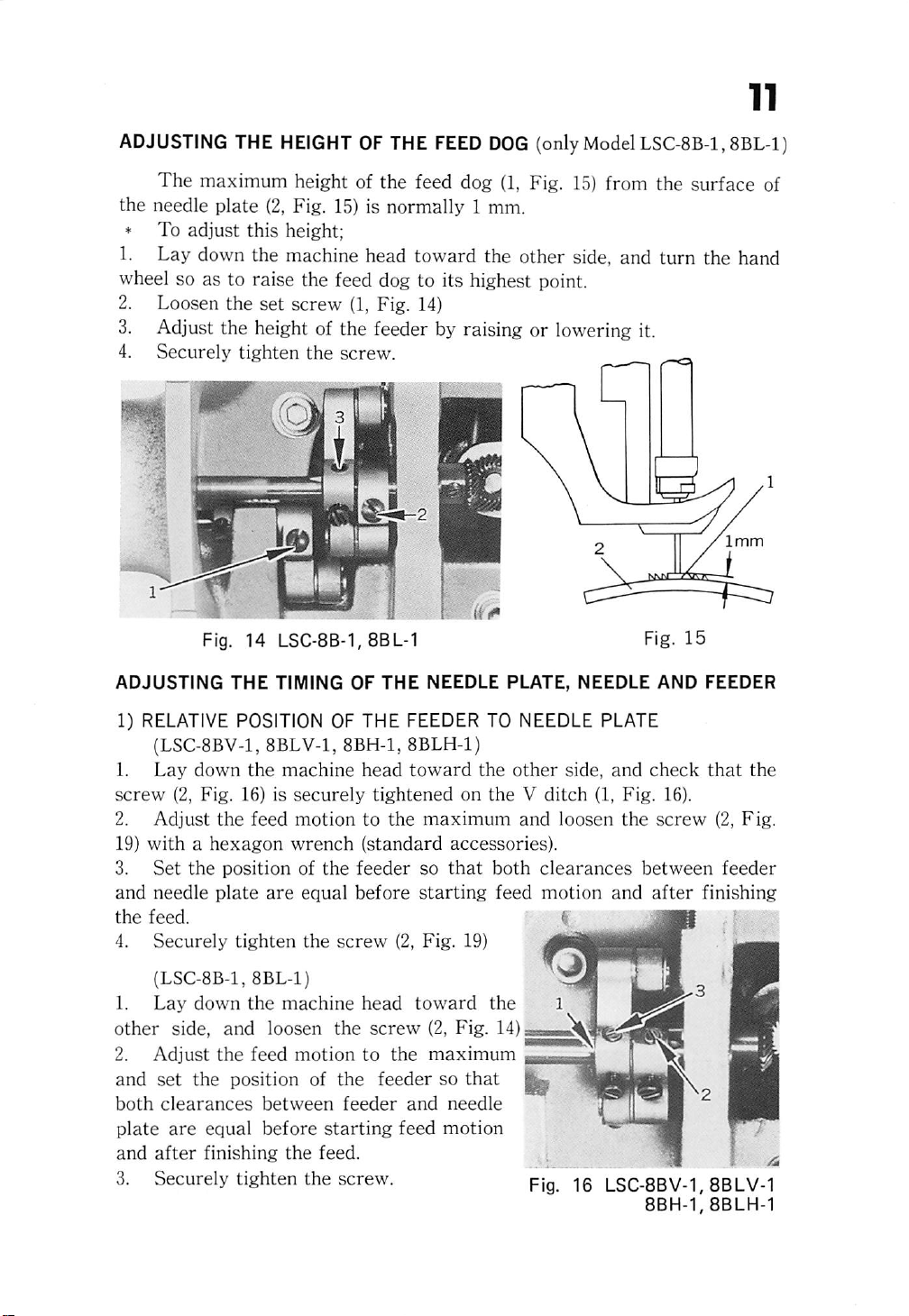

ADJUSTING

The

the needle

» To

1. Lay down the machine head toward the other side, and turn the hand

wheel so as to raise the feed dog to its highest point.

2. Loosen

3.

Adjust the height of the feeder by raising or lowering it.

4. Securely tighten

THE

HEIGHTOFTHE

maximum height of the feed dog

plate

(2, Fig. 15) is

adjust

the

this

set

height;

screw

the

(1, Fig. 14)

screw.

FEED

normally

DOG

(1,

1 mm.

(only

Fig.

Model

15)

LSC-8B4,

from the surface of

8BL-1)

m

Fig.

Fig.

14

LSC-8B-1,8BL-1

15

ADJUSTING

1) RELATIVE POSITION OF

(LSC-8BV-1, 8BLV-1, 8BH-1, 8BLH-1)

1.

Lay

screw

2.

19)

3.

and

4.

1.

other

2.

and

both

plate

and

3.

(2, Fig. 16) is

Adjust

withahexagon

Set

needle

Securely

Lay

side,

Adjust

set

clearances

are

after

Securely

THE

down

the

down

the

the

feed

positionofthe

plate

tighten

the

and

the

feed

the

position

between

equal

finishing

before

tighten

TIMING OF

machine

securely

motion

wrench

are

equal

the

screw

machine

loosen

the

motiontothe

of

the

feeder

starting

the

feed.

the

screw.

THE

THE

head

tightened

to

the

(standard

feeder

before

head

screw

feedersothat

NEEDLE PLATE, NEEDLE AND FEEDER

FEEDER TO NEEDLE PLATE

toward

maximum

so

starting

(2,

Fig.

toward

and

feed

the

other

on

theVditch

and

accessories).

that

both

feed

19)

the 1 J

(2,

Fig.

14)

maximum

needle

motion

side,

(1,

loosen

clearances

motion

and

Fig.

the

and

[ Vj

check

16).

screw

between

after

finishing

^

^ J ^

Fig.

16

LSC-8BV-1,

8BH-1,8BLH-1

that

the

(2,

Fig.

feeder

H|r

BQ

HI

/"

8BLV-1

Page 14

2) THE

POSITION

OF THE

NEEDLE

AND

NEEDLE

HOLE

OF THE

FEEDER

• To adjust this,

est

point

and

•

the

• If

1.

Turning

needle

the

Lay

the

descends

needle

down

turn

the

putaperfect

hand

wheel to

to

the

does

not

the

machine

hand

needle.

center

enter

head

wheel to

lower

of

into

toward

slowly the needle

the

needle

the

center

the

(3, Fig. 14, Fig. 16) is securely tightened on

2.

Remove

3.

Loosen

4.

Holding

as

mayberequiredtoget

5.

Tighten

the

cover

the

screw

the

bottomofthe

the

screw

(5,

(1,

and

Fig.

Fig.

the

close

11)

17)

needle

correct

the

bar

positiontothe

cover.

raise

the

needle

holeofthe

of

the

hole,

other

side,

and

the

V ditch (1, Fig. 16).

rock

frame

(1, Fig. 18),

feeder.

bar,

feeder

check

bartoits

check

whether

or

the

move

high

not.

screw

it

Fig.

normally

upper

18

the

endofthe

measurement

needle

eye

ADJUSTING

*

When

between

the

Fig.

THE

HEIGHT

the

needle

surfaceofthe

17

barisat

OF

THE

needle

its

NEEDLE

lowest

plate

and

BAR

point,

the

12.6 mm (LSC-BBV-l), 12.8 mm (LSC-8B-1), 13.1 mm (LSC-8BLV-1) and

13.3

mm (LSC-8BL-1)

*

To

adjust

1.

Loosen

2. Move

stud

(3,

Fig.

3.

Tighten

NOTE:

this,

the

the

18)toget

the

These

screw

setting

measurements

(2,

Fig.

18)

position of the needle

the

correct

screw.

position.

are

approximate

lowing final adjustments, TIMING

THE

NEEDLE,

are

recommended.

bar

and

needle

standard,

BETWEEN

bar

connecting

accordingly, fol

THE

HOOK AND

is

Page 15

TIMING

BETWEEN

THE

HOOK

AND

THE

NEEDLE

* After settingthe

needle

bar height,confirm as

follows:

Set the stitch length to 0, turn the hand wheel to lower the needle bar to

its lowest point, turn the hand wheel toward you.

raises

When the needle

2 mm (2.5 mm for LSC-8BLV-1, 8BLH-1,

fromthelowestpoint of its travel,normally the hook point

comes

8BL-1)

at the center

line of the needleand the measurement betweenthe hook point andthe upper

endof the

needle

eyeshould be 2mm, further the

clearance

between the hook

point and the needle hollow should be about 0.05 to 0.1 mm.

•

TIMING

1.

Loosen

2.

Adjust

of

its

revolution.

3.

Also

rightorto

4.

After

AND THE CLEARANCE ADJUSTMENT (Fig.

the

two

the

timing. If

adjust

the

the

leftasmay

adjustment,

screws

clearance

(1).

require

require.

securely

earlier,

by

means

tighten

turn

of

the

the

movement

screws.

hook

19)

toward

of

the

the

hook

direction

to

the

m

Page 16

TIMING

BETWEEN

NEEDLE

AND

FEEDER

* During the feeder feeds the material, the needle also moves together

with

the

feeder

*

To

adjust

1.

Remove

2. Loosen

HOW

TO

ADJUST

1.

Turn

pointofhook

2. Pushing the stitch length regulating lever

turn the cam

feeder

rest.

the

this,

the

the

hand

crossed.

(2,

and

feeds

top

screws

wheel

Fig.

the

material.

cover

(2, Fig. 10)

(1, Fig. 21)

toward

21)

and set at the point both the needle and the

and

you to

move

the

the

cam

point of

(4,

Fig.

(2, Fig. 21)

the

11)

needle

and

the

up and down,

3. Tighten the screws securely and close the top cover.

Fig. 21 LSC-8BV-1,8BLV-1

8BH-1,8BLH-1

ADJUSTING

*

ADJUSTMENT

1.

Loosen

THE

the

HEIGHT

BY

screw

2. Raise the presser

OF

THE

PRESSER

THE

PRESSER

(1,

Fig.

10)

sufficiently.

bar

lifter and loosen the

Fig. 21 LSC-8B-1,8BL-1

FEET

BAR

LIFTER

set

screw

{1,

Fig. 22).

3. Move the lifting presser foot (4, Fig. 3) up or down as may be required

soasto

4.

get

Tighten

the

the

correct

screws

height.

securely.

Page 17

* ADJUSTING THE LIFT OF ALTERNATING

PRESSER

FEET

If the height of the lifting presser foot changes, the momentums of the

lifting and vibrating presser footvary,thusthe

er

foot

must

be adjusted.

HOW

TO

ADJUST:

1.

Lower the presser bar lifter, holding the vibrating presser foot

3)

2.

Loosen

downasmay

After

3.

the hexagon screw

be required.

setting

the

position, tighten the screw.

(2,

Fig.

22)

height

ofthe vibratingpress

and movethe presser foot up or

(5,

Fig

TIMING

*

lowering the

feeder

OF

THE

VIBRATING

This

is the normal timing when,

earlier

presser

than

the

bar

needle

PRESSER

turn

FOOT

the

lifter, the vibrating

eye

comes

to,

vibrating presser foot should leave the feeder

the

feeder.

This

hold

the

goods while

stitches.

*

To

adjust

1.

Set

the

2. Loosen

the

cam

(4, Fig. 22)

3.

Tighten

is due to the reason

the

this,

lift of

the

the

the

two

screws

faster

screws.

alternating

that

the vibrating presser foot must tightly

needle is passing

presser

the

feettoequal.

(3, Fig. 22) and adjust the

or

slower

as

maybedesired.

hand

presser

and

when

after

wheel

toward

foot should

the

needle

the needle eye has left

goods for avoiding

rotating

you,

after

reach

raises,

the

the

irregular

position of

Fig.

22

Page 18

16

ADJUSTING

»

Normally,

the

upper

while

bin

1.

2.

left)

3.

1.

2.

3.

tension

4.

raisingofthe

case.

*

For

Loosen

Move

Tighten

*

HOW

Loosen

Loosen

Turn

Tighten

more

(to

THE

thread

the

the

the

TO

ADJUST

the

the

the

tension

lighten

the

THREAD

the

thread

until

needle

controller

stop

stop

(4,

screw.

serrated

screw

the

screw

the

screw

Fig.

THE

(4,

stud

tension,

and

CONTROLLER

controller

needle

and

passingofthe

action

nut

Fig.

on

(3,

Fig.

9) to

the

TENSION

(5,

Fig.9)slightly.

18) slightly.

(6,

Fig.9)slightly

turntothe

the

nut.

spring

reaches

the

9)

right.

OF

to

thread

THE

SPRING

(2,

Fig.9)should

the

goods,

upper

(For

less

SPRING

to

the

right)

withascrew

anditshould

thread

through

action,

left

to

hold

slack

the

moveitto

strengthen

driver.

of

pause

bob

the

the

Page 19

i

©

SEIKO

11-3, Imado 1-chome, Taito-ku, Tokyo 111-8534,

TEL: +81-3-3872-6173,4

FAX:

E-Mail: seikOOOl

www.tctv.ne.jp/selk0001/

SEWING

+81-3-3873-6596

©tctv.ne.jp

MACHINE

(Overseas

group)

CO.,

LTD.

Japan

00093000-(E)

Loading...

Loading...