Page 1

User's Guide

Black-and-White Raster Plotter

LP-1020

LP-1020L

Read this User's Guide to use the plotter safely and

properly. Keep this manual in a place where you

can quickly access it at any time.

Seiko I Infotech Inc.

Page 2

Page 3

U00107742300 November 2007

U00107742301 December 2007

©Seiko I Infotech 2007

Reprinting of this manual without permission is prohibited.

The content of this manual may be changed without notice.

D-SCAN is a registered trademark of Seiko Instruments, Inc.

Ethernet is a registered trademark of Xerox, Inc.

HP is a registered trademark of Hewlett-Packard (U.S.A.)

MICRO CADAM is a trademark of CADAM, Inc. (U.S.A.)

Athlon is a trademark of Advanced Micro Device, Inc.

Intel, Pentium and Core are registered trademarks or a trademark of Intel Corporation.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

Durch die Kennzeichnung dieses Produktes mit dem CE-Zeichen erklärt Seiko den folgenden

Direktiven der Europäischen Union zu entsprechen (mit Wirkung vom siehe Datum):

Januar 1996:- EG-Direktive 73/23/EEC ergänzt durch EG-Direktive 93/68/EEC, Angleichung der

Gesetze der einzelnen Mitgliedsstaaten bezüglich Geräten mit niedriger Betriebsspannung.

Januar 1996:- EG-Direktive 89/336/EEC, Angleichung der Gesetze der einzelnen Mitgliedsstaaten

bezüglich elektromagnetischer Kompatibilität.

Den vollständigen Text dieser Erklärung einschließlich der Definition der entsprechenden

Direktiven sowie der jeweiligen Standards erhalten Sie von Ihrem Seiko Colorgrafx Systems

Kundendienst oder Ihrem Seiko Engineering Systems Kundendienst.

This Perchlorate warnig applies ONLY in California USA

“Perchlorate Material - special handling may apply,

See www.dtsc.ca.gov/hazardouswaste/perchlorate”

Page 4

CE Marking

It is legally mandatory for products distributed or sold in the EU to bear a CE Mark that

indicates compliance with requirements set forth in EC directives for the particular

product. These directives set the scope of machinery subjected to the specific directive.

Our LP-1020 complies with the EMC Directive (2004/108/EC) and Low Voltage Directive

(2006/95/EC).

For inquiries concerning CE Marks:

Seiko Instruments Europe S.A

European Head Office

Avenue de Messidor 198, 1180, Brussels, Belgium

TEL: +32 (0) 2 346 62 74

FAX: +32 (0) 2 347 52 68

Page 5

Introduction

Thank you for purchasing our LP-1020/1020L Black-and-White Raster

Plotter (hereafter referred to as “this device”).

This manual explains the overall device operations, functions and

operation method under the premise that installation of the device has

been completed.

Before using this device, please read the “Safety Precautions” so that you

may operate this device safely and correctly. Keep this manual in a place

where you can quickly access it at any time.

This device employs either one of the following feeders: 1-roll paper

feeder for standard sheet drawings with output up to 2.5 m, or 2-rolls

paper feeder for long sheet drawings with output up to 10 m.

This manual explains how to use the 2-rolls paper feeder devices, but also

accomodates the 1-roll paper feeder devices.

i

Page 6

Safety Precautions

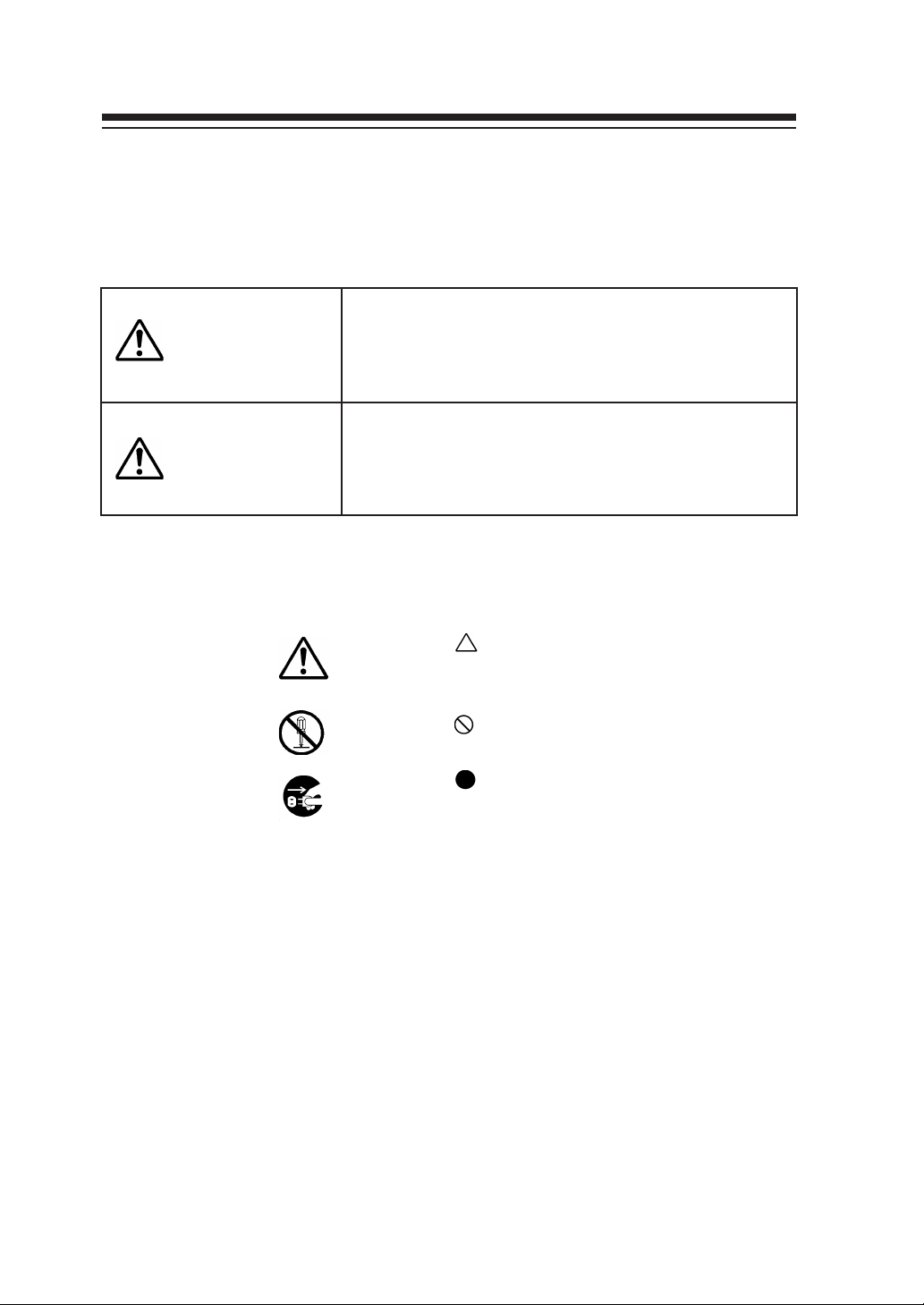

The following symbols are used in this manual to ensure the proper use of

the plotter and to prevent the plotter from being damaged.

Please follow these guidelines:

WARNING

CAUTION

Example of symbols:

Warnings must be followed carefully to avoid serious

bodily injury or death.

Cautions must be observed to avoid damage to your

equipment and bodily injury.

This symbol ( ) denotes items that require special care while

executing a certain procedure or operation.

This symbol ( ) denotes items that are forbidden.

This symbol ( ) denotes items you should follow to prevent

accidents or injury.

ii

Page 7

Warning

DO NOT touch any of the parts inside the plotter with a "HIGH

VOLTAGE" label attached as it may result in electric shock.

DO NOT touch any of the parts inside the plotter with a "HIGH

TEMPERATURE" label attached as it may result in severe burns.

DO NOT disassemble or modify the plotter. DO NOT repair the plotter

by yourself. Doing so may cause fire, electric shock or other accidents.

DO NOT throw the toner cartridge or waste toner bottle into fire or

place them near heat as they could explode or catch fire leading to

serious accidents and/or bodily injury.

NEVER use the plotter in a place of extreme humidity or any place

where it can possibly be splashed by any liquids. If any liquids get into

the plotter, it could lead to fire, electric shock, or other serious

accidents.

DO NOT allow metal to touch the internal parts of the plotter. Doing so

may cause fire, electric shock, or other accidents.

DO NOT disconnect or connect the power cable with wet hands. Doing

so may lead to electric shock.

Power OFF the plotter and unplug the power cable from the power

outlet in any of the following cases:

◆ When putting your hands inside the plotter.

◆ Smoke, strange noise or smells erupt from the plotter.

◆ A piece of metal or any liquid touches the internal parts or slots of

the plotter.

◆ An error requiring service from a service center occurs.

Using the plotter in any manner other than for which it was designed may

cause accidents or fire.

iii

Page 8

Caution

DO NOT disassemble, modify the toner cartridge. If toner gets on your

skin or clothes, wash off the affected area immediately with soap and

water.

Handle the toner cartridge with extreme care. Should any toner get into

your eyes, do not rub them, flush them immediately with water, and see

a physician immediately.

Handle the paper rolls with care because they are very heavy. Dropping

them may lead to personal injury.

Use care when cutting the paper rolls with a scissors or knife during

installation.

DO NOT unplug the electric cable by pulling on the cable. Doing so

may cause the cable to fray or break which could lead to electric shock

and/or fire.

In order to ensure the safe operation of the plotter heed all of the cautions

and warnings contained throughout this manual.

iv

Page 9

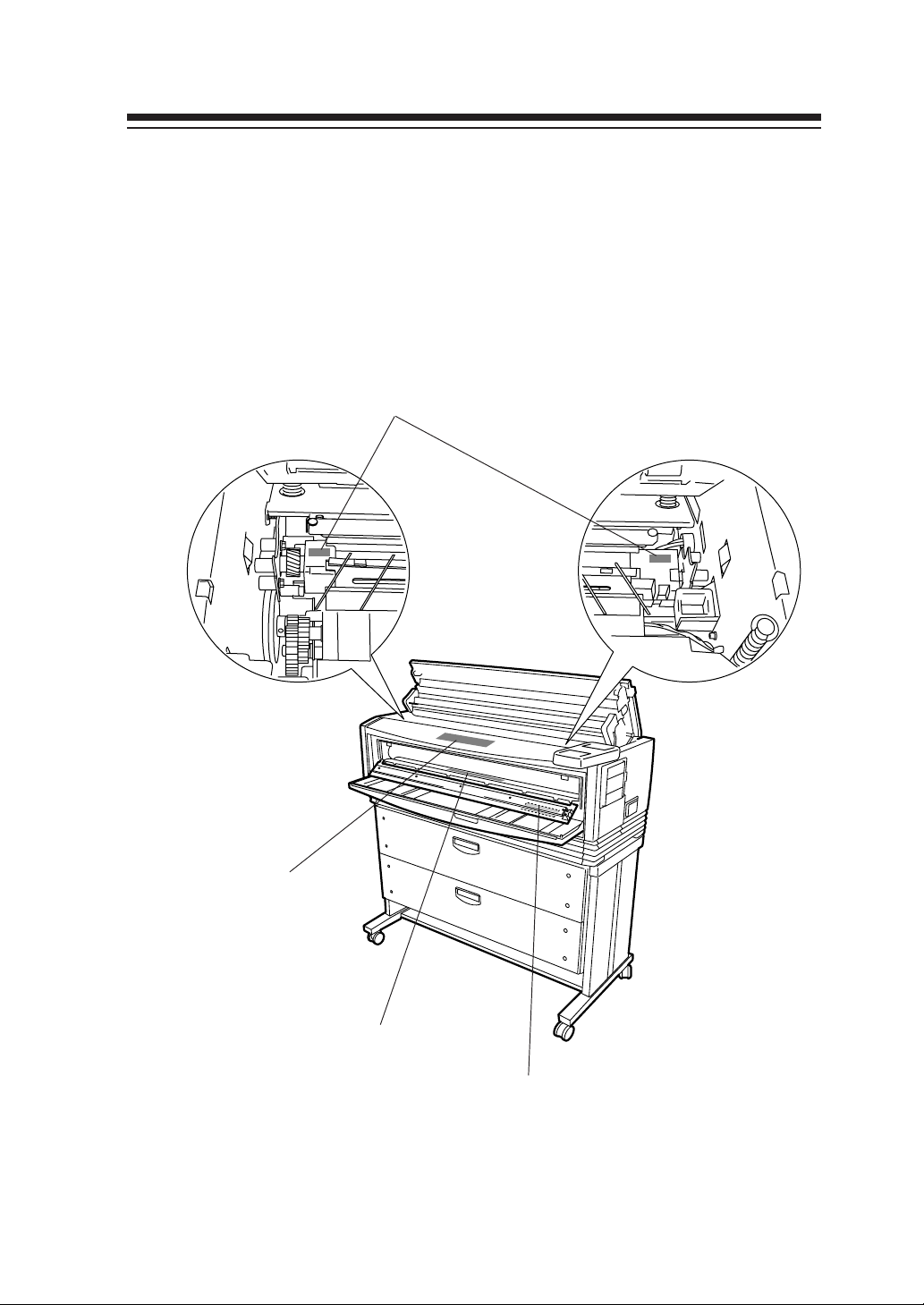

Warning labels

Warning labels are affixed to this device at the locations indicated in the

diagram below. You should understand the meanings of these warning

labels and handling instructions.

3 “WARNING: HIGH VOLTAGE” label

2a “Caution when dealing with

paper jam” label

1 “Caution: high temperature” label

2b “Caution when dealing with

paper jam” label

v

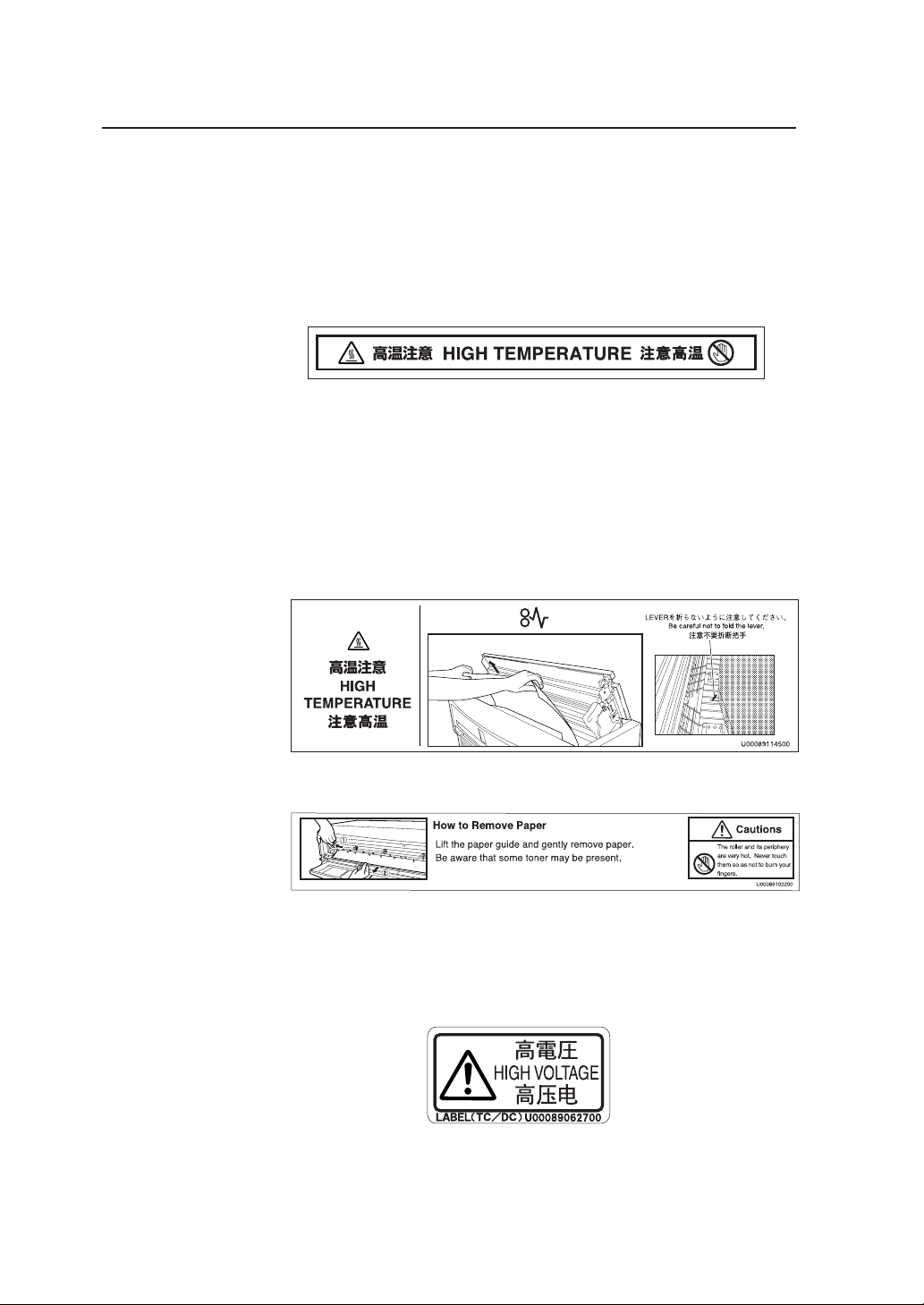

Page 10

1 “Caution: high temperature” label (It is affixed to the inside of

the fixation door.)

This label cautions you not touch this area due to high temperature.

The fixation device will become hot. Take care to avoid contact when

dealing with paper jams.

2 “Caution when dealing with paper jams” label

This label indicates the direction that jammed paper should be pulled

out when paper is jammed in the fixation device. Follow the

directions on the label to remove the paper.

a

b

3 “WARNING: HIGH VOLTAGE” label

This label cautions against contact due to high voltage application. As

it is dangerous, never contact this area.

vi

Page 11

How to read this manual

Manual make-up

This manual is composed of 13 chapters and an appendix.

Chapter 1 provides information that you should know before using this

device, such as device features and part names. First read chapter 1 for an

understanding of basic matters pertaining to this device.

Chapter 2 provides information on matters you will need to know to

operate this device, such as turning the power on and off, and how to put

paper in the device. Refer to this chapter for basic information on

operating this device.

Chapters 3 to 13 provide information on device functions, operation and

how to manage the settings. First read chapters 3 and 4 for an overview

of functions and operations. Then proceed to the chapter you want to

refer to.

Chapter 5: Refer to this chapter when setting the data format you

will use.

Chapter 6: Refer to this chapter when setting the operating

conditions for the engine of this device.

Chapter 7: Refer to this chapter when you have loaded a different

type of paper in the device and you must change the

settings accordingly.

Chapter 8: Refer to this chapter to confirm Setup contents or to set

the date and time.

Chapter 9: Refer to this chapter when setting the communication

protocol.

Chapter 10: Refer to this chapter when conducting initialization.

Chapter 11, 12: Refer to these chapters when setting the communication

conditions for Ethernet and parallel connection or when

returning to the default settings.

Chapter 13: Refer to this chapter when using "Teioplot".

Chapter 14 provides information on troubleshooting if a problem occurs

with this device. Appropriate countermeasures should be conducted in

accordance with the explanations in this chapter.

The basic specifications and command list for this device can be found in

the appendix. The menu structure is explained in great detail here. Refer

to this menu to perform settings for menus which are not fully explained

by the setting operations for chapters 5 to 13.

vii

Page 12

Notation method

Markings

◆ Contain important information.

Warning

◆ This mark indicates warnings that must be followed

carefully to avoid serious bodily injury or death.

Caution

◆ This mark indicates cautions that must be observed to

avoid damage to the equipment and bodily injury.

Note

This is a “Tip” mark.

Contain additional hints for better use.

DSCAN format

Please remember:

The DSCAN format described in this manual as well as DSCAN that

appears on the operation display are for only customers in Japan.

⇒ This is a “See” mark.

A reference section and page is indicated after this mark.

viii

Page 13

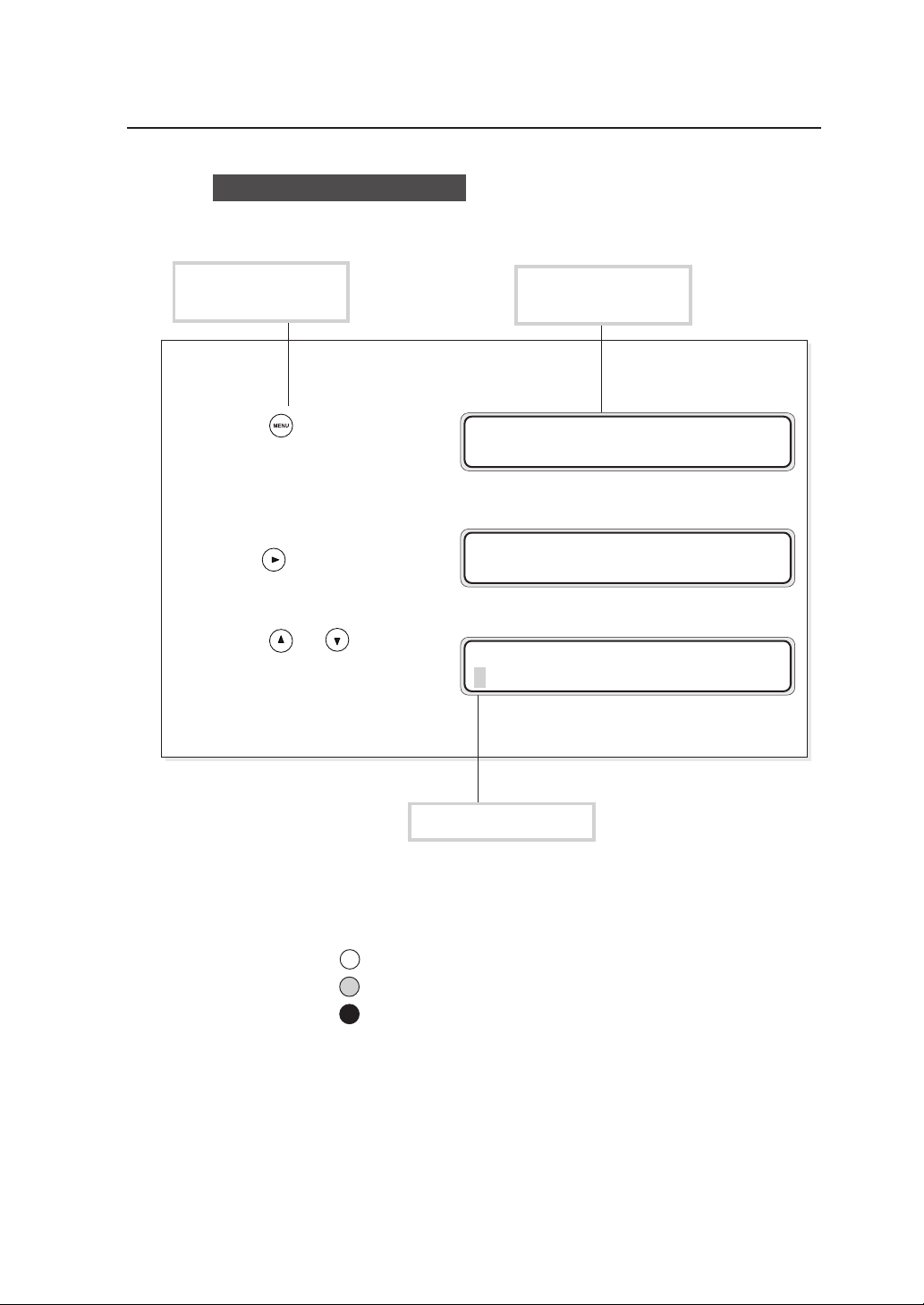

Key/LCD/LED notations

Indicates a control

panel key.

1 Press to proceed to the

menu screen where settings

are managed.

2 Press and select “SETUP.”

3 Press or and select

“PORT2_HPGL.”

Indicates the control

panel LCD.

MENU

#SETUP

SETUP

#PORT1_HPGL

SETUP

#PORT2_HPGL

Indicates flashing light

LED on, flashing, and off states are indicated as follows:

On

Flashing

Off

ix

Page 14

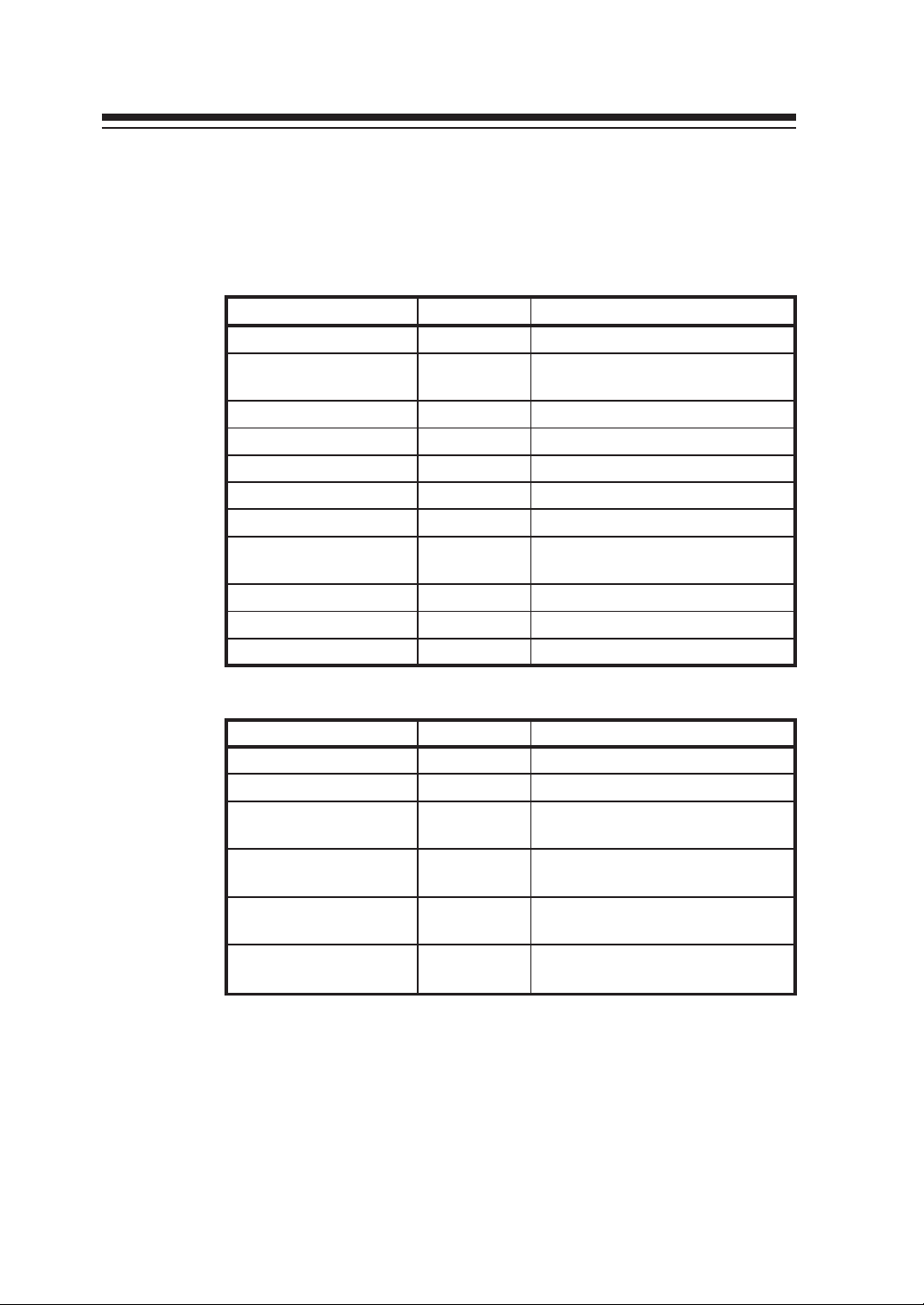

Supplied components

Components and options listed below are included.

If any components are missing or broken, contact your retailer or your

nearest service center.

Item Quantity Remarks

Plotter unit 1 unit

Toner cartridge 3 units

Waste bottle 1 unit Pre-installed

Quick Reference Guide 1 or 2 copies 200V: English and Chinese

CD-ROM 1 set

Paper flange 2 units/drawer

Process cartridge 1 unit With 2 ozone filters

Roll paper 1 box

Scanner exit guide 3 pieces MF model only

Panel sheet 2 sheets 200V only: English and Chinese

Power cable 2 units 200V only: 2 types

For checking at the time of

installation

A0, A1, A3 x 1 unit each, for

checking at the time of installation

Options

Item Quantity Remarks

LP-817 (bucket) 1 unit

LP-819 (carrier sheet set) 1 unit MF model only

LP-840

(color upgrade kit-S)

LP-841

(color upgrade kit-L)

LP-842

(color upgrade kit-S)

LP-843

(color upgrade kit-L)

1 unit

1 unit

1 unit MF-S model (Asia and Oceania)

1 unit MF-L model (Asia and Oceania)

MF-S model

(North/South America and Europe)

MF-L model

(North/South America and Europe)

x

Page 15

TABLE OF CONTENTS

Introduction .......................................................................................... i

Safety Precautions.............................................................................. ii

Warning labels .................................................................................... v

How to read this manual ................................................................... vii

Manual make-up ................................................................... vii

Notation method ...................................................................viii

Markings ............................................................................... viii

DSCAN format ...................................................................... viii

Key/LCD/LED notations ........................................................ ix

Supplied components ......................................................................... x

Chapter 1 Getting started 1-1

Features...........................................................................................1-2

Operating conditions ........................................................................ 1-4

Environmental conditions .................................................... 1-4

Installation space ................................................................. 1-6

Usable paper .......................................................................1-7

Spool memory configuration .............................................. 1-10

The names and functions of each part .......................................... 1-11

Front .................................................................................. 1-11

Right side/rear side ........................................................... 1-12

Interior ............................................................................... 1-13

Control panel .....................................................................1-14

How to read the status displays for this device.............................. 1-17

CONTENTS-1

Page 16

Chapter 2 Basic operations 2-1

Plotting procedures overview...........................................................2-3

Turning the power on and off ........................................................... 2-3

Power on ............................................................................. 2-4

Power off ............................................................................. 2-6

Installation operations ...................................................................... 2-7

Online and offline ........................................................................... 2-10

Online ................................................................................2-10

Offline ................................................................................2-10

Replacing paper rolls ..................................................................... 2-11

Precautions during replacement ........................................ 2-13

How to detach the paper rolls ............................................ 2-14

How to attach the paper roll .............................................. 2-16

Replacing the toner........................................................................ 2-19

Precautions on handling ....................................................2-20

Toner replacement procedures .......................................... 2-21

Replacing the waste toner bottle ................................................... 2-24

Replacing the process cartridge ....................................................2-28

CONTENTS-2

Precautions during replacement ........................................ 2-24

Waste toner bottle replacement procedures......................2-25

Precautions during replacement ........................................ 2-28

Process cartridge replacement procedures ....................... 2-29

Page 17

Manual paper feeding (cut paper).................................................. 2-34

Manual feeding procedures ...............................................2-34

Manual paper feeding procedure ...................................... 2-35

Pause, continue, cancel (and additional printing) ..........................2-39

Print stop ........................................................................... 2-39

Continue printing ............................................................... 2-39

Cancel printing...................................................................2-40

Additional printing ..............................................................2-40

Web function .................................................................................. 2-41

Functions ...........................................................................2-41

Web function startup method.............................................2-42

Cleaning the exterior...................................................................... 2-43

Using paper of new standard series ..............................................2-44

Using paper of Chinese standard series........................................ 2-46

Limiting rolls to be used .................................................................2-48

Chapter 3 Menu overview 3-1

Channels and ports..........................................................................3-3

Data formats ....................................................................................3-3

Data formats which can be used .........................................3-3

Data format auto-judging .....................................................3-3

CONTENTS-3

Page 18

Jobs .................................................................................................3-4

Reprinting ............................................................................3-4

Settings menu .................................................................................. 3-5

PDL menu ........................................................................................3-8

When using our company’s printer driver ............................3-8

Items which you can set .................................................................. 3-9

Idle status ............................................................................3-9

Printing status .................................................................... 3-11

Menu screen .................................................................................. 3-11

Setup menu “SETUP” ........................................................ 3-11

Device menu “DEVICE” ..................................................... 3-12

Paper menu “PAPER” ........................................................ 3-13

Function menu “FUNCTION” ............................................. 3-14

Protocol menu “PROTOCOL” ............................................ 3-15

Reset menu “RESET” ........................................................ 3-16

System menu “SYSTEM” .................................................. 3-17

Chapter 4 Basic Menu Operation 4-1

Summary of basic menu operation .................................................. 4-2

Offline menu operation .................................................................... 4-3

Switching the menu on the same hierarchy ........................ 4-3

Moving the menu hierarchy ................................................. 4-4

Setting or changing the parameters .................................... 4-5

Exiting the setting .............................................................. 4-10

CONTENTS-4

Page 19

Chapter 5 "SETUP" Menu 5-1

Setting parameter items................................................................... 5-2

Setup menu setting parameter table ................................... 5-3

Setup parameter priority mode .......................................... 5-10

PARAMETER MODE (DSCAN only) ................................. 5-11

MEDIA SERIES (HP-GL, TIFF, CALS only) ...................... 5-11

AUTO SUPPLY ................................................................. 5-12

FIXING MODE ................................................................... 5-13

COPY COUNT................................................................... 5-14

SUPPLY PARAM............................................................... 5-15

DRAWING PARAM. .......................................................... 5-17

SCALING PARAM. ............................................................ 5-21

FORMAT PARAM. (HP-GL DSCAN only) ......................... 5-24

PEN PARAMETER (HP-GL DSCAN only) ........................ 5-29

RASTER PARAM .............................................................. 5-34

Chapter 6 "DEVICE" menu 6-1

Setting items .................................................................................... 6-2

POWER SAVE .................................................................... 6-3

EDGE CUT TIMER .............................................................. 6-4

DOOR OPEN CUT .............................................................. 6-5

DENSITY ............................................................................. 6-5

TRACING PAP. MODE ....................................................... 6-5

BOTTLE MODE ................................................................... 6-6

CONTENTS-5

Page 20

Chapter 7 "PAPER" menu 7-1

Setting items .................................................................................... 7-2

MEDIA TYPE ....................................................................... 7-2

MEDIA SERIES ................................................................... 7-3

Chapter 8 "FUNCTION" menu 8-1

Setting items .................................................................................... 8-2

MENU PRINT ...................................................................... 8-3

HPGL SELF PLOT .............................................................. 8-5

DSCAN SELF PLOT ........................................................... 8-6

ERROR LOG ....................................................................... 8-7

JOB LOG ............................................................................. 8-8

ENGINE LOG .................................................................... 8-10

SYSTEM DATE ................................................................. 8-11

SYSTEM TIME .................................................................. 8-11

INIT CHARG. INF .............................................................. 8-11

PRINT CHARG. INF .......................................................... 8-11

MAINTE INFO ................................................................... 8-12

DATA DUMP ..................................................................... 8-12

Chapter 9 "PROTOCOL" menu 9-1

Setting items .................................................................................... 9-2

PDL SELECT....................................................................... 9-3

XPT PORT .......................................................................... 9-4

PRINTER NAME ................................................................. 9-4

USER NAME ....................................................................... 9-5

CONTENTS-6

Page 21

Chapter 10 "RESET" menu 10-1

Reset functions .............................................................................. 10-2

SYSTEM RESET ............................................................... 10-2

PORT RESET ................................................................... 10-3

Chapter 11 "SYSTEM" menu 11-1

Setting items .................................................................................. 11-2

Communication parameter "COMM. PARAM" .................. 11-3

WEB LOCK ....................................................................... 11-5

ENABLE SERIES .............................................................. 11-6

APPLY ROLL .................................................................... 11-8

CHINA SIZE .................................................................... 11-10

INITIAL SET .................................................................... 11-11

LANGUAGE..................................................................... 11-12

LENGTH UNITS .............................................................. 11-12

ADMIN PASSWORD ....................................................... 11-12

Chapter 12 Ethernet parameter "ETHERNET" 12-1

Setting items .................................................................................. 12-2

PORT SELECT ................................................................. 12-4

DHCP ................................................................................ 12-4

IP ADDRESS ..................................................................... 12-5

SUBNET MASK ................................................................. 12-5

ROUTING TABLE.............................................................. 12-6

SETUP DETAILS .............................................................. 12-7

CONTENTS-7

Page 22

Chapter 13 Terioplot 13-1

About Terioplot .............................................................................. 13-2

Terioplot Hardware Requirements ................................................. 13-3

Settings .......................................................................................... 13-4

Restrictions .................................................................................... 13-5

Chapter 14 Troubleshooting 14-1

Troubleshooting ............................................................................. 14-2

When an error message appears .................................................. 14-3

Paper Jam ......................................................................... 14-3

Door Open ....................................................................... 14-14

Operator Call ................................................................... 14-16

Warning ........................................................................... 14-17

Service Call Errors .......................................................... 14-25

Error log ....................................................................................... 14-29

Troubleshooting for ethernet........................................................ 14-34

If "BOTTLE MAINT. STARTS" appears ....................................... 14-36

CONTENTS-8

Classification of Error/Warning ........................................ 14-29

Format of Message ......................................................... 14-29

Log Registration Format .................................................. 14-30

Type of Error Log ............................................................ 14-31

Error Log Classification Table ......................................... 14-33

Page 23

When a print error occurs ............................................................ 14-37

When there is an abnormal sound ............................................... 14-38

Appendix Appendix-1

Basic specifications ............................................................ Appendix-2

Plotter Specification ................................................ Appendix-2

Menu structure .................................................................... Appendix-4

[SETUP] MENU ...................................................... Appendix-4

[DEVICE] MENU .................................................. Appendix-10

[PAPER] MENU .................................................... Appendix-11

[FUNCTION] MENU ............................................. Appendix-12

[PROTOCOL] MENU ............................................ Appendix-13

[RESET] MENU .................................................... Appendix-14

[SYSTEM] MENU ................................................. Appendix-15

Command list .................................................................... Appendix-21

HP-GL,HP-GL/2 Device Control Command List ... Appendix-21

HP-GL,HP-GL/2 Device Plotting Command List .. Appendix-22

HP RTL Plotting Command List ........................... Appendix-25

D-SCAN Format Command List ........................... Appendix-27

TIFF Tag ............................................................... Appendix-33

CALS Format Records ......................................... Appendix-34

ftp Tag .................................................................. Appendix-34

lpd Support Commands ........................................ Appendix-36

xpt(socket I/F) ....................................................... Appendix-36

CONTENTS-9

Page 24

Page 25

Chapter 1

Getting started

Chapter 1 provides necessary information to operate this device. Read

this chapter to understand the basics of this device before proceeding to

the following chapters.

Contents of this chapter

Features

Operating conditions

The names and functions of each part

How to read the status displays for this device

Chapter 1 Before using this device

1-1

Page 26

Features

This device is an electrophotographic black-and-white raster plotter

which produces plots by receiving graphic data created by a work station

or PC (hereafter referred to as a computer.)

This device is equipped with the following features:

High speed plotting

output, high resolution

2-roll paper feeding

mechanism, long drawing

compatible

This device has 80 mm (3.15 inches)/sec recording speed and

can output A0 size drawings at 3.4 sheets per minute. It can also

output high accuracy drawings at 600 dpi resolution.

This device employs a 2-roll paper feeding mechanism that sets

2 sizes from a choice of 4 sizes: A0 size (or 36 inch size), A1 (or

24 inch size), A2 (or 18 inch size), and A3 (or 12 inch size). By

employing paper rolls compatible with drawing sizes ranging

from A0 to A4, a low running cost is achieved by reducing paper

consumption.

This device can also output 2.5 m / 98.4 inch size (10 m / 393.7

inch for the LP-1020L) long sheet drawings. The maximum

plotting range of this device is as follows:

(Note)

Picture quality and printing accuracy can only be assured for plain paper

and recycled paper. (Only up to twice the length of the standard-size

paper can be assured for tracing paper and film.)

LP-1020

• A0 size paper roll : 841 × 2500 mm (33.1 × 98.4 inches)

• A1 size paper roll : 594 × 1830 mm (23.4 × 72 inches)

• A2 size paper roll : 420 × 1200 mm (16.5 × 47.2 inches)

• A3 size paper roll : 297 × 920 mm (11.7 × 36.2 inches)

LP-1020L

• A0 size paper roll : 841 × 10,000 mm (33.1 × 393.7 inches)

• A1 size paper roll : 594 × 10,000 mm (23.4 × 393.7 inches)

• A2 size paper roll : 420 × 1220 mm (16.5 × 47.2 inches)

• A3 size paper roll : 297 × 920 mm (11.7 × 36.2 inches)

1-2

Page 27

▼Features

Manual feeding

mechanism

Multiport interface

Supports a variety of

paper types

Front paper feeding/

finished drawing outlet

This device is equipped with a manual feeding print function.

(Note)

The picture quality and printing accuracy for manually fed printing cannot

be assured.

The device is equipped with an Ethernet interface and allows for

network connection to network. It can also be equipped with

both parallel interface and USB interface. In addition, 10 logical

ports can be used for the Ethernet interface, which then allows

up to 12 computers, including parallel interface and USB

interface, to be simultaneously connected.

4 types of rolls—paper, recycled paper, tracing paper, and

film—are supported.

The device has a front paper feeding and finished drawing outlet

structure. This allows for paper to be loaded and output drawings

to be processed only at the front of the device. This means that

the device requires only a small installation space.

The device was designed for simple, front operation, allowing

paper to be loaded and toner cartridges to be replaced with ease.

Chapter 1 Before using this device

1-3

Page 28

Operating conditions

This section covers operating conditions of this device including

environmental conditions, installation space, supported papers and spool

memory configuration.

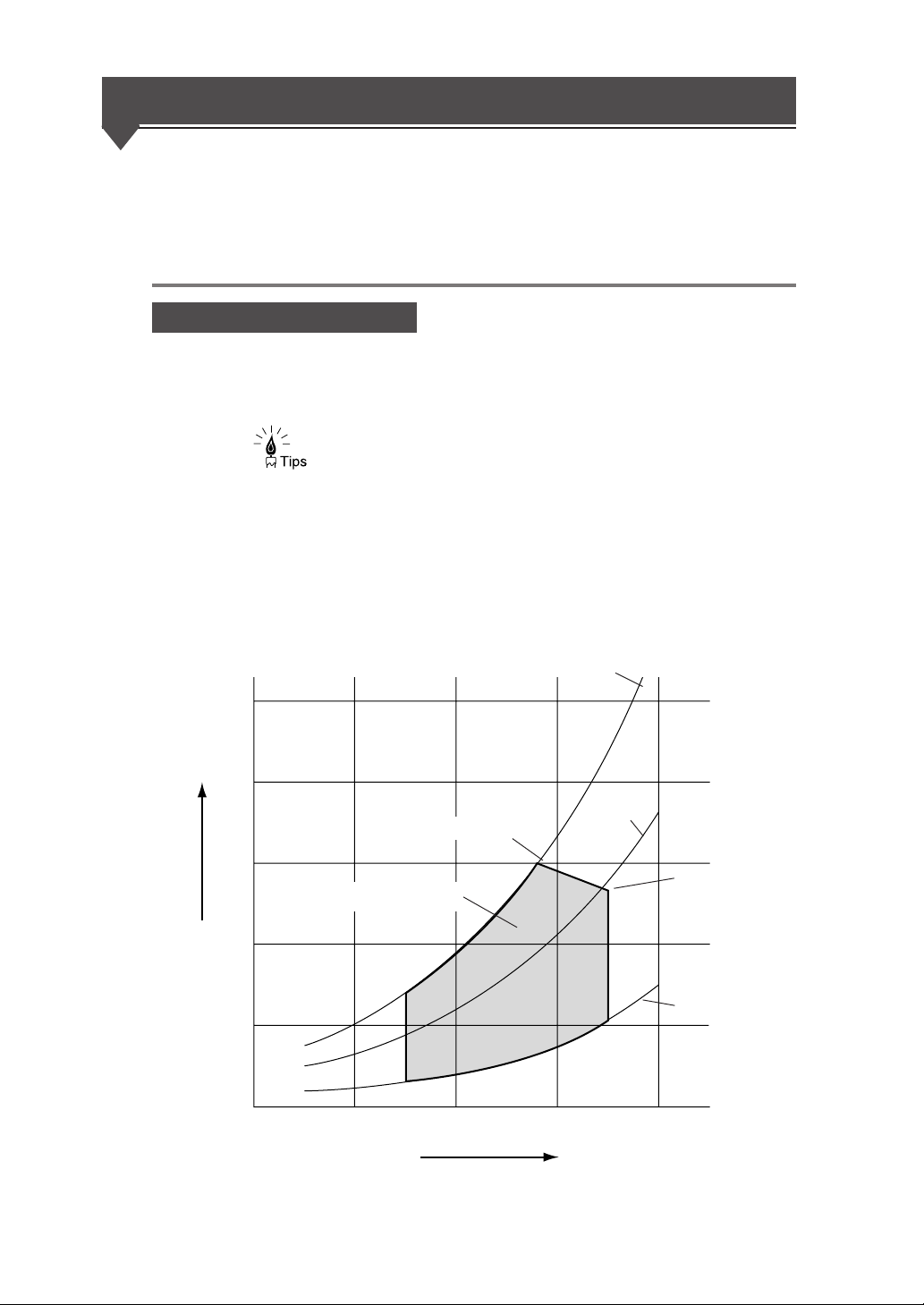

Environmental conditions

This device should be used within the temperature and humidity ranges

indicated in the graph below.

◆ To obtain the best picture quality, use the device within a

temperature and humidity range of 20 to 30°C, 45 to 60%RH.

(relative humidity)

■Operating temperature and humidity range

Vapor

pressure

(×103Pa)

80%RH

5

4

28°C, 80%RH

3

Operating temperature and

humidity range

2

1

15°C

0

10

20 30

Temperature

(50%RH)

35°C

35°C, 48%RH

20%RH

(°C)

40

1-4

Page 29

▼Operating conditions

Do not install the plotter in the following places:

◆ Places exposed to direct sunlight

◆ Places subject to vibration

◆ Places with excessive dust

◆ Places subject to extreme changes in temperature or humidity

◆ Places near an air conditioner or a heater

◆ Places where the plotter may get wet

◆ Places subject to direct air flow from a vent

◆ Places near a diazo copier that may generate ammonia gas

◆ Places with poor ventilation

Chapter 1 Before using this device

1-5

Page 30

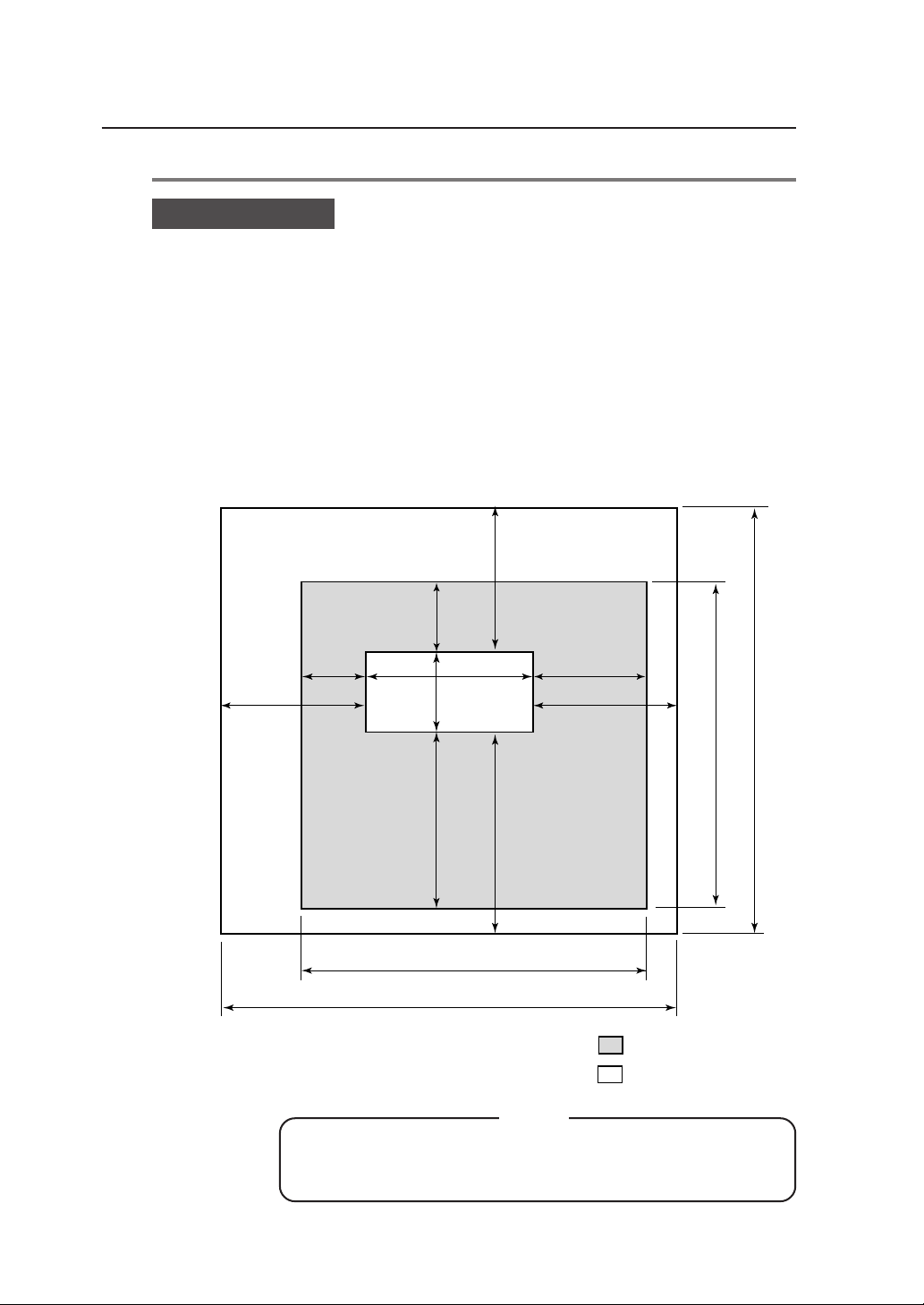

Installation space

When installing this device, space to the front, rear, left and right sides of

the device should be accommodated for the replacement of consumables,

the processing of output drawings, and the ventilation. The minimum

installation space indicated in the diagram below should be ensured. The

maintenance space indicated in the diagram below is needed to perform

parts replacement, etc.

■Installation/maintenance space

300

700

(27.6)

(11.8)

300

552

(11.8)

1154

(45.4)

(21.7)

600

(23.6)

600 (23.6)

700 (27.6)

1-6

(Height is 2000 mm / 78.7 inches)

◆When moving this device from its current location to a

different location, contact our company’s service center.

800 (31.5)

2554 (100.6)

900 (35.5)

2054 (80.9)

Note

1652 (65)

2052 (80.8)

Installation space

Maintenance space

units: mm (inch)

Page 31

Supported

▼Operating conditions

Use roll paper specified by our company as indicated below:

Note

◆If paper not specified by our company is used, picture quality

cannot be assured. Moreover, the device may malfunction.

■Roll paper specified by our company

Part No. Paper type & size

LP-733

LP-780 A1 size width (594 mm / 23.4 inches)

LP-788 A2 size width (420 mm / 16.5 inches)

Plain paper

(67g / m

LP-781 A3 size width (297 mm / 11.7 inches)

LP-735

LP-782 A1 size width (594 mm / 23.4 inches)

LP-740 A2 size width (420 mm / 16.5 inches)

Tracing paper

(75g/m

2

LP-783 A3 size width (297 mm / 11.7 inches)

LP-744

LP-786 A1 size width (594 mm / 23.4 inches)

LP-743 A2 size width (420 mm / 16.5 inches)

Mat film

(#300)

LP-787 A3 size width (297 mm / 11.7 inches)

LP-734

LP-947 A1 size width (594 mm / 23.4 inches)

LP-948 A2 size width (420 mm / 16.5 inches)

Recycled paper

(66g / m

LP-949 A3 size width (297 mm / 11.7 inches)

Chapter 1 Before using this device

A0 size width (841 mm / 33.1 inches)

2

)

A0 size width (841 mm / 33.1 inches)

)

A0 size width (841 mm / 33.1 inches)

A0 size width (841 mm / 33.1 inches)

2

)

1-7

Page 32

■9×12 inch series

The following roll paper of the widths can be also used.

Roll width Name of fixed form Lengthwise Widthwise

36 inches

(914.4 mm)

24 inches

(609.6 mm)

18 inches

(457.2 mm)

12 inches

(304.8 mm)

E-form size

D-form size

D-form size

C-form size

C-form size

B-form size

B-form size

A-form size

1219.2 mm

(48 inches)

914.4 mm

(36 inches)

914.4 mm

(36 inches)

609.6 mm

(24 inches)

609.6 mm

(24 inches)

457.2 mm

(18 inches)

457.2 mm

(18 inches)

304.8 mm

(12 inches)

914.4 mm

(36 inches)

609.6 mm

(24 inches)

609.6 mm

(24 inches)

457.2 mm

(18 inches)

457.2 mm

(18 inches)

304.8 mm

(12 inches)

304.8 mm

(12 inches)

228.6 mm

(9 inches)

■8.5×11 inch series

Roll width Name of fixed form Lengthwise Widthwise

34 inches

(863.6 mm)

22 inches

(558.8 mm)

17 inches

(431.8 mm)

11 inches

(279.4 mm)

1-8

E-form size

D-form size

D-form size

C-form size

C-form size

B-form size

B-form size

A-form size

1117.6 mm

(44 inches)

863.6 mm

(34 inches)

863.6 mm

(34 inches)

558.8 mm

(22 inches)

558.8 mm

(22 inches)

431.8 mm

(17 inches)

431.8 mm

(17 inches)

279.4 mm

(11 inches)

863.6 mm

(34 inches)

558.8 mm

(22 inches)

558.8 mm

(22 inches)

431.8 mm

(17 inches)

431.8 mm

(17 inches)

279.4 mm

(11 inches)

279.4 mm

(11 inches)

215.9 mm

(8.5 inches)

Page 33

■30×42 inch series

Roll width Name of fixed form Lengthwise Widthwise

(762.0 mm)

■Map series

Roll width Name of fixed form Lengthwise Widthwise

700.0 mm

(27.6 inches)

500.0 mm

(19.7 inches)

■DIN series

Roll width Name of fixed form Lengthwise Widthwise

707.0 mm

(27.8 inches)

500.0 mm

(19.7 inches)

30 inches

30× 42 size form size

B1 form size

B2 form size

B2 form size

B1 form size

B2 form size

B2 form size

B3 form size

1066.8 mm

(42 inches)

1000.0 mm

(39.4 inches)

700.0 mm

(27.6 inches)

700.0 mm

(27.6 inches)

1000.0 mm

(39.4 inches)

707.0 mm

(27.8 inches)

707.0 mm

(27.8 inches)

500.0 mm

(19.7 inches)

▼Operating conditions

762.0 mm

(30 inches)

700.0 mm

(27.6 inches)

500.0 mm

(19.7 inches)

500.0 mm

(19.7 inches)

707.0 mm

(27.8 inches)

500.0 mm

(19.7 inches)

500.0 mm

(19.7 inches)

353.0 mm

(13.9 inches)

Chapter 1 Before using this device

■China series

The China series roll cannot be used for plotting with cut sheet feeding. It

can be used for real size plotting only.

Chinese series

A0 roll width

914 mm

(36 inches)

910 mm

(35.8 inches)

900 mm

(35.4 inches)

880 mm

(34.6 inches)

Chinese series

A1 roll width

620 mm

(24.4 inches)

610 mm

(24 inches)

---

---

Chinese series

A2 roll width

450 mm

(17.7 inches)

440 mm

(17.3 inches)

Chinese series

A3 roll width

310 mm

(12.2 inches)

297 mm

(11.7 inches)

1-9

Page 34

Paper storing precautions are as follows:

◆Store the paper in a cool dark place with in the specified

humidity ranges.

◆Store the paper in it’s packaging material so that dust will not

accumulate on the paper.

Spool memory configuration

Spool memory configurations are available for this device as specified

below.

Notes

Expansion kit

LP-815

Extends spool memory.

Spool memory is the memory needed to receive plotting data.

If plots cannot be produced normally due to spool memory

shortage, installing the following options allows plots to be

produced normally.

■Spool memory configuration when LP-815 is installed

Note

◆The maximum capacity to be actually spooled is slightly

different from the values indicated in the above table.

Confirm the capacity by executing “MENU PRINT.”

1-10

Page 35

The names and functions of each part

This section explains the names, usage information, and functions of each

part of this device.

Front

Chapter 1 Before using this device

1 Roll 1 drawer (door 1) Install paper roll. (⇒ page 2-11)

2 Roll 2 drawer (door 2) Install paper roll. (⇒ page 2-11)

3 Manual feed drawer (door 4)

Open this drawer when a paper jam occurs during

manual feeding. (⇒ page 14-3)

4 Finished drawing outlet Drawings exit from here.

5 Top cover (door 6) Open this cover when a paper jam occurs near the top door.

(⇒ page 14-3)

6 Fixation door (door 7) Open this door when a paper jam occurs in the vicinity of the finished

drawing outlet. (⇒ page 14-3)

7 Manual paper feeding guide (door 8)

Open this door when feeding the paper manually. (⇒ page 2-34)

8 Manual feed inlet Insert paper from this inlet during manual feeding. (⇒ page 2-34)

9 Toner cover Open this cover when replacing toner. (⇒ page 2-19)

0 Control panel The LEDs and LCD which indicate device status and the keys to set

various functions are laid out here. (⇒ page 1-14)

A Waste toner door Open this door to replace a waste toner bottle. (⇒ page 2-24)

1-11

Page 36

Right side/rear side

1 Main power switch Turns the device power on and off. (⇒ page 2-3)

2 Power cord Plug this cord into a power cord socket.

3 Parallel interface connector

This is an interface connector conforming to the standards of the

Parallel interface connector of Centronix.

4 Ethernet interface connector

This is an interface connector for a 100 BASE-TX and 10 BASE-T

Ethernet interface connector.

5

USB interface connector

6 Cutter door (door 5) Open this door to deal with paper jams at the cutter area.

7 Cutter door inside (door 9)

8 Cutter door lower small door (door 10)

This is an interface connector for a USB 2.0 interface connector.

(⇒ page 14-3)

Open this door to deal with paper jams at the cutter area.

(⇒ page 14-3)

Open this door to deal with paper jams at the cutter area.

1-12

Page 37

Interior

▼The names and functions of each part

Chapter 1 Before using this device

1 Paper feed knob Feeds the end of the roll to the paper feed inlet. (⇒ page 2-11)

2 Paper flange This flange is attached to the roll paper. (⇒ page 2-11)

1-13

Page 38

Control panel

1 LEDs

The device status is

indicated by LED’s on,

flashing, and off.

The keys, LEDs and LCD are laid out on the control panel as illustrated in

the following diagram.

2 LCD

The status of this device, as well as a

menu to set the device functions appears

on a 20-digit, 2-line display.

4 Power key

Use this key to turn

ON/OFF this device.

1-14

3 Keys

Use these keys to set device functions.

Page 39

▼The names and functions of each part

LCD, LEDs, and key functions

Number Name Function

Error lamp (red)

Toner lamp (green)

Waste toner lamp

LED’s

Display LCD

(green)

Process lamp

(green)

Menu lamp

(green)

MENU key

Indicates the presence or absence of errors.

On: Error present

Off: No error present

Indicates the amount of remaining toner.

On: There is sufficient toner.

Flashing: Toner is running low.

Off: There is no toner (plots cannot be produced

without replenishment.)

Indicates the toner waste bottle replacement time.

On: Normal

Flashing: Replacement timing is approaching

Off: Plots cannot be produced without replacement

Indicates the process cartridge replacement time.

On: Normal

Flashing: Replacement time is approaching

Off: Process cartridge is not installed.

Indicates that this device is ready for setting,

receiving data, or printing.

On: Setting operations can be performed

Off: Ready to receive data and print.

Displays a variety of messages in a 20-figure and 2line display to inform you of the device status.

Switches the status of the device from setting ready

status to data receive and print ready status.

Chapter 1 Before using this device

Keys

Power

ENTER key

CANCEL key

Key

Key

Key

Key

Power key

Inputs the parameters.

Cancels parameter input.

Switches menu items and changes parameters.

Switches menu items and changes parameters.

Switches menu items/hierarchy and changes.

Switches menu items/hierarchy and changes.

Turns the device power on and off.

1-15

Page 40

How to read the status displays for this device

This section explains the control panel LEDs and LCD which inform you

of the status of the device.

The following are the main displays.

Data standby display

Standard configuration

PR I NT READY

This is a print ready status.

Data processing display

PROCESS I NG ✽ S001

F01 HPGL J009

Communication channel name

F : FTP protocol

L : LPD protocol

X : XPT protocol

PR : Parallel

USB : USB

Error lamp

Menu lamp

Indicates that data is being processed.

(flashing)

Sxxx: The job number standing

by for processing

PDL name

HPGL

DSCAN

TIFF

CALS

Port number (this number is not displayed when using

parallel or USB interface.)

Jxxx: The job number being processed

Error lamp

Menu lamp

1-16

Data is being processed.

The various information for the data currently being processed is displayed.

Note

◆Parallel and USB are only displayed when each interface is

installed.

Page 41

Printing in progress display

▼How to read the status displays for this device

PR I NT 0 2 / 9 9✽ S001

F01 HPGL J009

Data is being printed.

The various information for the data currently being printed is displayed.

Print information display

T O T A L CO U N T mmmmmm

T O T A L RUN ( m ) mmmmmm

This display appears when is pressed in data standby or print ready status.

The total number of prints and the length of media printed appear.

Error lamp

Menu lamp

Scheduled number of prints

Number of prints executed

Error lamp

Menu lamp

◆ Many of our customers who have signed a maintenance

agreement regularly telephone our service center for

assistance. When contacting our service center, please make

a note of this information for your reference.

◆ This display appears for approximately three seconds, after

which the display will automatically return to the original data

standby display condition.

Chapter 1 Before using this device

Setting ready display

MENU

#SETUP

The functions for this device can be set. ⇒ chapter 3

Error display

CLOSE DOOR1

An error has occurred.

Errors are classified according to those which can be dealt with by the operator, or

errors which can only be dealt with by your dealer or our service center, etc. ⇒

Chapter 14

Error lamp

Menu lamp

Error lamp

Menu lamp

1-17

Page 42

Warming up display

WA RM I NG U P n n n

Displays the warming-up status and the time remaining until the device is ready.

Power saving display

POWER SA V I NG

This display appears when the device enters the power saving mode after the data

standby status has continued for a certain period of time.

Error lamp

Menu lamp

Counts down

1-18

Page 43

Chapter 2

Basic operations

Chapter 2 describes basic operating procedures for this device such as

turning the power on and off, replacing paper, and replacing toner will be

explained.

Contents of this chapter

Plotting procedures overview

Turning the power on and off

Installation operations

Online and offline

Replacing paper rolls

Replacing the toner

Replacing the waste toner bottle

Replacing the process cartridge

Manual paper feeding (cut paper)

Pause, continue, cancel, and additional printing

Web function

Cleaning the exterior

Using paper of new standard series

Using paper of Chinese standard series

Limiting rolls to be used

Chapter 2 Basic operations

2-1

Page 44

Plotting procedures overview

Plotting is usually conducted in accordance with the following

procedures.

For information on computer operations, refer to your computer manual.

1 Turn on the power for the computer and this device.

For information on turning on the device power, refer to “Turning the

power on/off” (⇒ page 2-3)

2 Confirm the status of the device on the control panel.

Confirm that the LEDs are not indicating abnormalities and that the LCD

indicates Data standby status.

Press when the Menu lamp is on.

When the Toner lamp is flashing or off, replace the toner. (⇒ page 2-19)

When the Toner waste bottle lamp is flashing or off, replace the waste

bottle. (⇒ page 2-24)

When the Process lamp is flashing or on, replace the process cartridge.

(⇒ page 2-28)

When the Error lamp is on, refer to chapter 14 for information on

troubleshooting.

3 Open your application software on your computer and

create a drawing.

If the device settings do not conform to the application software you are

using, reset the settings for this device (⇒ Chapters 5 to 12).

4 Send the data from the computer to this device.

2-2

Page 45

Turning the power on and off

This device has two power switches: the main power switch located at

the lower-left as seen from the rear of the device; and the power key on

the control panel.

The device power is turned on by first turning on the main power switch, and

then pressing the device’s control panel power key.

Notes

◆While data is being processed, do not turn off the main

power switch. Doing so may damage the system.

◆When the power is on and the Main power switch is turned

off, or when the power goes out due to blackout etc.,

restoring the power (turning the Main power switch back on

or resetting from a blackout) is the first step, but will not turn

the plotter on. You must also turn ON the power key on the

control panel.

Chapter 2 Basic operations

Main power switch

Control panel

Power key

2-3

Page 46

Power on

1 Turn on the Main power switch located at the lower-left

2 Press the power key located on the control panel of this

as seen from the rear of the device.

Main power switch

Press the power switch toward the ⎪

symbol (upwards).

2-4

device (when the main power switch is on).

INITIAL IZING

WA I T A MOME N T

When you first turn on the power after purchasing this device, a guidance

display prompts you to set the panel's display language. If this setting has

already been completed, this message is omitted.

LANGUAGE?

✽ ENGL I SH

Page 47

▼Turning the power on and off

When a job is saved, the following message appears and the device stands

by for selection.

When a job is not saved, this message is omitted.

DELETE JOB?

Y=ENTER N=CANCEL

If a key input is not made,

this message will time-out

after about 10 seconds

and the device starts up

with the job in saved

condition.

Under normal conditions, the display reads “INITIALIZING STANDBY”

and is changed to the following message.

SYSTEM VERS I ON

01A

The message is changed to the “WARMING UP".

WARM I NG U P n n n

Warm up will take about 4

minutes. (about 8 minutes

with LP-1020L)

nnn: a count down for the

warm up is displayed.

The message indicates that the device is now online (“PRINT READY”).

Chapter 2 Basic operations

PRINT READY

A “PRINT READY” message indicates that the device is functioning

normally.

2-5

Page 48

Power off

1 Press the Power key on the device panel for about 1

When turning the power off, confirm that the device is in the data receive

standby mode.

second.

Release the key when the display reads "SHUTTING

DOWN."

When a job is present, it is automatically saved and will be printable the

next time you turn the power on.

(Only when HDD is installed)

Note:

Even when “SHUTTING DOWN” appears, the

power will not turn off until you release the

power key.

2-6

SHUTDOWN

WA I T A MOME N T

When the shut down process has been completed, the power will turn off.

This indicates that the

device is executing a shut

down.

2 Turn the main power off when you are not using this

device for an extended period of time.

Main power switch

Press the power switch toward the symbol

(downwards).

Page 49

Installation operations

When you first turn on the power after purchasing this device, it will start

up differently from how it will regularly start up thereafter. A guidance

display will prompt panel display language selection, initializing of

parameters appropriate for your region, and the setting of an IP address.

By setting this IP address when the plotter is installed, you will be able to

utilize the browser of a host computer on the same network as the plotter

to make various settings.

Moreover, when using the network to operate the device, you must also

initialize the following plotter settings from the browser or the device

panel. If you neglect to set these settings, connection with the router will

not be possible.

1 Subnet mask settings

2 Routing table settings

Once you set the panel display language selection, initialized optimal

setup parameters according to your region, and set IP address settings,

this guidance display will not appear the next time the power is turned on.

When “INITIALIZE” is executed in the System menu (explained later),

the IP address will return to an unset condition, and the IP address setting

guidance display will appear once again when the power is turned on.

Notes

◆The panel display language selection allows you to select

the language which will appear on the device control panel,

and can also be set from “LANGUAGE” in the System menu.

◆Initializing of the optimal parameters for your region for such

items as media series can also be set from “INITIALIZE” in

the System menu.

◆The IP address is a communication parameter during

Ethernet connection which is assigned specifically to each

device.

Chapter 2 Basic operations

2-7

Page 50

■Turning on the power

INITIAL IZING

WA I T A MOME N T

LANGUAGE?

✽ ENGL I SH

Select the language to be displayed on the panel using the

, keys.

LANGUAGE?

✽ ENGL I SH

Press the key to go to the confirmation screen.

LANGUAGE?

✽ ENGL I SH OK?

Press the

key to choose this setting.

INITIAL SET

✽ STANDARD

Select the optimal setup parameters according to your region

using the

, keys.

When a language has already been selected.

2-8

INITIAL SET

✽ CH I NA

Press the

key to go to the confirmation screen.

INITIAL SET

✽ CH I NA OK?

Press the

Proceed to the next page

key to determine this setting.

Page 51

Continued from the preceding page

US I NG NETWORK?

Y=ENTER N=CANCEL

Press the key.

▼Installation operations

IP ADDRESS?

✽ 000. 000 . 000 . 000

Input the values using the , , , ,

keys.

IP ADDRESS?

✽ 192.168.123.123

Press the

screen.

key to go to the confirmation

IP ADDRESS?

✽ 192.168.123.123 OK?

Press the key to determine the selection.

The device will be automatically

rebooted.

DISPLAYING NEXT?

Y= ENTER N=CANCEL

Chapter 2 Basic operations

SYSTEM VERS I ON

01A

PR I NT READY

2-9

Page 52

Online and offline

The device is “ONLINE” when it can receive and print data from the host

computer and is “OFFLINE” when settings are being input on the control

panel. You must set the device to “offline” to operate the menu from the

control panel.

Online

To print from the host computer, the device must be online. Always make

sure that the device is online to print from the host computer. If the device

is not online, follow the procedures below to set the device online. The

device will automatically go online when the device power is turned on.

1 Press the key to turn the Menu lamp off.

Offline

PR I NT READY

To select menu operations and paper feed method etc. using the device

control panel, the device must be offline. Before using the control panel

keys, set the device offline according to the following procedures.

1 Press the key to turn the Menu lamp on.

MENU

#SETUP

2-10

Page 53

Replacing paper rolls

How to detach and reattach the paper rolls will be explained here.

Detach and replace a paper roll when the device has run out of paper or

when you change the paper roll size on type. When the paper is used up

during printing, the Error lamp will turn on and the LCD will display the

following message:

Example: The screen requesting the A3 tracing paper to be loaded in the

roll 1 drawer.

SET PAPER

A0

or

SET PAPER

ROL L 1 A 0

or

SET PAPER

A0 ( TRACE )

Chapter 2 Basic operations

or

SET PAPER

ROL L 1 A 0 ( TRACE )

◆ When a paper replacement message appears on the LCD, it is

possible to cancel the drawing that you sent to print. Use this

function when you don’t have the required paper.

Example)

SET PAPER

A1

Press the key.

CANCEL PR I NT ?

Press the

*Printing will be cancelled.

key.

PR I NT READY

2-11

Page 54

If an error message about paper supply appears on LCD, paper of larger

size than required (or, if a type of paper is specified, paper of different

type) can be chosen for printing.

e.g.

SET PAPER

A1

Press the key.

FORCE PR I NT?

Press the

key.

PR I NT 0 1 / 0 1✽ S001

F01 HPGL J009

*Prints only when paper of larger size than required is available or if

paper of a different type is available.

*Alternative print is disabled, if printing on the manually fed paper.

Notes

◆"A1" in the above example indicates the paper roll width and

its indication changes as follows:

Example:

A series: "A0", "A1", "A2", "A3"

9" series: "36"", "24"", "18"", "12""

8.5" series: "34"", "22"", "17"", "11""

30x42 series: "30""

MAP series: "707 mm", "500 mm"

DIN series: "707 mm", "500 mm"

Chinese series: "914 mm", "620 mm", "450 mm"

"310 mm","297 mm"

◆When a paper type is specified as "SET PAPER A0

(TRACE)" and the paper roll is loaded, the display may be

automatically switched to the paper menu. In such a case,

set the type of the paper roll.

◆If the media series is different (that is, appropriate media series

was not loaded into the tray), the display may be automatically

switched to the paper menu when the paper roll is reloaded. In

such a case, set the media series of the paper roll.

2-12

Page 55

Precautions during replacement

◆The rolls are heavy so be careful not to hurt yourself by

dropping them while you are replacing the rolls.

◆When attaching the rolls, use a cutter to cut the end of the

paper roll. While doing this, take care not to cut yourself or

damage the device.

◆When opening and closing the paper roll drawers, take care

not to get your hands caught in the drawer.

Do not open other paper roll drawers while one paper roll

drawer is open. Doing so will increase your chances of

getting your hands caught in the drawers.

▼Replacing paper rolls

Caution

Chapter 2 Basic operations

Notes

◆If you change the paper type, you must also change the

device settings accordingly. ⇒ chapter 7

◆Use media types specified by our company.

If you use media types which are not specified by our

company, we cannot assure printing quality.

◆Store the paper in a cool, dark location with low humidity.

2-13

Page 56

How to detach the paper rolls

1 Pull out the Roll 1 or Roll 2 drawer.

Use your fingers to grasp the handle in the

center of the drawer and pull the drawer out

gently.

(The diagram indicates a case where the Roll 2

drawer is opened.)

2-14

2 Rewind the paper roll and then remove it.

Turn the paper flange in the direction indicated

in the diagram and continue to rewind the roll

until you see the end of roll. Lift up the paper

flange and remove the paper roll.

Paper flange

Page 57

▼Replacing paper rolls

3 Remove the paper flange and take out the paper roll.

Loosen the paper flange by turning the knobs in

the “OPEN” direction and remove both ends of

the paper flange.

L

O

C

S

E

O

P

N

E

Note

Knob

◆Take care not to use excessive force

when you turn the paper flange knobs.

The flange ends may come off.

Chapter 2 Basic operations

2-15

Page 58

How to attach the paper roll

◆ The paper flange ends do not have a designated right or left

side. You can attach them to either side.

1 Attach the paper flange to a paper roll.

L

O

C

S

E

O

P

N

E

Knob

2 Move the flange guide.

Push in the paper flange ends until they contact the

paper roll tube, then secure the flange ends by

turning the knob in the “CLOSE” direction.

Note

◆If the paper flange knobs are loosely

fitted, the paper roll will move adversely

to the right and left and negatively affect

the drawing. Make sure that the knobs

are tightened securely.

Label

the label which is affixed to the inside of the drawer

indicates the flange positions for the application of

different roll widths. Move the flange guide to

match the paper roll size you are using.

C

N

Flange guide

3 Load the paper roll into the drawer.

Hold the paper roll so that the end of the paper is

positioned at the bottom facing the back of the

device. Then align the paper flange to the

depressions in the flange guide and gently insert the

flange in place.

◆Take care not to drop the paper roll

while performing these activities.

L

O

S

E

O

P

E

Note

2-16

Page 59

▼Replacing paper rolls

4 Insert the end of the paper roll into the paper feed inlet of

the device.

Turn the paper flange and insert the end of the

paper roll so that it is straight. Turn the paper

feed knob so that the end of the paper roll

projects about 10 cm.

Paper feed knob

5 Cut the end of the paper.

While holding the end of the paper roll, cut it off

with the cutter.

Chapter 2 Basic operations

The “Paper cutter position” label is affixed to

both ends of the space where the cutter blade

should be inserted. Insert the cutter blade into

the space where the label arrow is pointing.

Slide the cutter blade along the space and cut the

paper.

◆ The paper can be cut cleanly when the

cutter is inserted in a perfectly sideways

direction.

Caution

◆Take care not to hurt yourself and damage the device when

handling the cutter.

◆Handle the cutter blade with care so that you do not break it.

◆When sliding the cutter along the space, take care not to cut

the back of your hand on the sides of the paper tray.

2-17

Page 60

6 Close the paper roll drawer.

Gently push in the Roll 1 or Roll 2 drawer.

When the paper roll drawer is closed, the following

message appears.

WA I T A MOME N T

(It will take about 30 seconds until paper feeding is ready.)

◆After closing the paper roll drawer, wait until the “WAIT A

MOMENT” message disappears before opening the paper

roll drawer again. As the device initiates a paper detection

just after the paper roll drawer is closed, so opening the

paper roll drawer during this operation may cause a paper

jam.

After the replacement, the device will return to the

status before the paper roll was replaced.

Note

2-18

Note

◆If you change the type of paper roll, you must change the

corresponding settings, referring to “Paper settings” (⇒

page 7-2).

Page 61

Replacing the toner

When the toner level runs low, the Toner lamp will flash. Although plots

can still be produced under this condition, obtain a new toner cartridge as

soon as possible and replace the toner.

When there is no more toner availabe, the Toner lamp will go out, the

Error lamp will come on, and printing will no longer be possible. The

following message appears on the LCD.

SET TONER CARTR I DGE

OPEN LEVER

If the Toner lamp starts flashing or the ERROR message appears, replace

the toner according to the procedures indicated below.

◆ When you open the toner door, you will find a “Toner

replacement” label affixed to the inside surface. Refer to this

when replacing toner.

◆ After the Toner lamp starts flashing, approximately 50 m of

plots can be produce at normal size and density.

Chapter 2 Basic operations

Note

◆If plots with a high printing rate—such as drawings

containing many solid print areas and inversed (black and

white inverted) drawings—are printed just before the toner

runs out, the toner may be used up and the device may be

damaged.

To avoid such a case, refill toner as soon as possible when

the toner lamp is flashing.

2-19

Page 62

Precautions on handling

Do not throw empty toner cartridges into fire. Doing so

may cause accident and fire.

Put the waste cartridge into the wrapping contained in the

toner cartridge package and dispose of it as non-burnable

garbage.

◆Do not drop and tap the toner cartridge with force. Doing so

may cause the toner to leak from the cartridge.

◆Do not directly touch the toner. If the toner gets on your skin

or clothing, quickly wash it off with water.

◆Take care not to get toner in your eyes or breathe it in. If the

toner gets in your eyes, wash your eyes out with lots of water

and consult your physician.

Warning

Caution

2-20

Notes

◆If you move the toner cartridge from a cold to a warm

location, leave it in room temperature for over three hours

before using it.

◆After replacing the toner, try to use it up within a six month

period. A toner cartridge installed for an extended period of

time will degrade the drawing quality.

◆Keep toner cartridges in a cool, dark place.

◆Use only genuine toner cartridges.

Page 63

Toner replacement procedures

◆Toner should be replaced only when the device power is On.

If the toner is replaced while the power is Off, the device will

not be able to detect the amount of toner and an error status

will not be cancelled even when toner has been replaced

correctly.

◆Replace toner after plotting finishes. Replacing the toner

during plotting may cause the operation to stop and the

plotting data to be lost.

1 Open the toner cover.

▼Replacing the toner

Notes

Chapter 2 Basic operations

2 Take out the new toner cartridge from the package.

3 Mix the toner by shaking the new toner cartridge.

Shake it strongly up, down, left and right, five or

six times.

2-21

Page 64

4 Set the toner cartridge into the main unit.

5 Pull the lever to the right end.

2-22

At this time, the following message appears on

the LCD. After performing the procedure 6

operation, return the lever and remove the toner

cartridge.

CLOSE LEVER

REMOVE CARTR I DGE

If the above message does not appear, check to

see that the lever has been pulled up to the right

end.

Page 65

▼Replacing the toner

6 Tap the cartridge to allow toner to drop down.

7 Return the lever to the left.

Chapter 2 Basic operations

8 Remove the toner cartridge and close the cover.

At this time, the following message appears on

the LCD.

WA I T A MOME N T

2-23

Page 66

Replacing the waste toner bottle

When the waste bottle is nearly full with waste toner, the Waste toner

lamp will flash. Although plots can continue to be produced for a little

while longer, replace the waste bottle soon.

When the waste bottle becomes full with waste toner, the Waste toner

lamp will go out. The Error lamp will turn on and plotting will not be

possible. The following message appears on the LCD.

CHANGE

WA S T E BOT T L E

If the Waste toner lamp starts flashing or the message appears on the

control panel, replace the waste bottle in accordance with the procedures

outlined below.

◆ A “Waste bottle replacement” label is affixed to the side of the

waste toner bottle. Refer to this when replacing the waste

bottle.

◆ Even after the Waste toner lamp starts flashing, you should be

able to produce about 120 m of plots.

2-24

Precautions during replacement

Warning

Do not throw waste bottles containing waste toner into

fire.

Doing so may cause an accident and fire.

Dispose of waste bottles as non-burnable garbage.

Page 67

▼Replacing the waste toner bottle

Caution

◆Do not drop and hit waste bottles containing waste toner.

Doing so may cause toner to leak.

◆Take care not to directly contact the waste toner. If the toner

gets on your skin or clothing, quickly wash it out with water.

◆Take care not to get the waste toner into your eyes or

breathe it in.

If waste toner gets into your eyes, wash your eyes out with

plenty of water and consult a physician.

Notes

◆Replace the waste bottle after plotting has been completed.

If replacement is attempted during plotting, the plotting data

may be lost.

◆The toner inside the waste bottle cannot be re-used.

Chapter 2 Basic operations

Waste toner bottle replacement procedures

1 Take out a new waste toner bottle from its package and

remove the cap.

◆ This cap should be used to cover the waste toner bottle which

you are removing, so keep it at hand. ⇒ procedure 4.

2 Open the waste toner bottle door.

The waste bottle door is located at the right side of the device.

2-25

Page 68

3 Remove the waste toner bottle from the main unit.

1 Lift up the waste bottle,

2 Remove it by pulling it out from the bottom

end toward you.

When you have removed the waste toner bottle,

the LCD will display the following message.

SET

WA S T E BO T T L E

4 Attach the cap to the waste toner bottle.

New bottle

Cap

Bottle containing

waste toner

Attach the cap which you have removed in

procedure 1 to the waste bottle containing waste

toner.

Dispose of the waste bottle containing waste

toner as non-burnable garbage.

Note

◆Attach the cap securely as it may

come off.

2-26

Page 69

▼Replacing the waste toner bottle

5 Attach a new waste toner bottle.

1 Insert the mouth of the waste toner bottle

onto the waste toner discharge port of the

main unit by slightly lifting it.

2 Set it onto the bottom surface and position it

so that it is stable.

After the following message appears, the device

status will return to the status before the waste

bottle was replaced.

WA I T A MOME N T

Chapter 2 Basic operations

6 Close the waste door.

2-27

Page 70

Replacing the process cartridge

When the Process cartridge approaches the end of its life, the Process

lamp flashes and the following message appears. It is still possible to

continue to produce plots in this condition, but you must replace the

cartridge soon.

PR I NT READY

REPLACE PROCESS

Note

◆Above message may not appear in certain cases.

If a new process cartridge is not installed soon, the Process lamp goes out,

Error lamp comes on and plotting becomes impossible. The following

error message appears on LCD.

SET

PROCESS CARTR I DGE

When the Process lamp flashes or goes out, follow the procedures

indicated below to replace the Process cartridge.

Precautions during replacement

Do not throw the process cartridge into fire. Doing so may

cause accident and fire.

Dispose of process cartridge as non-burnable garbage.

Warning

2-28

Page 71

▼Replacing the process cartridge

Notes

◆Until you are ready to install the Process cartridge, do not

unpack it and store it in its cardboard container.

◆Firmly hold the handles on both sides with both hands when

handling the Process cartridge.

◆Take care not to scratch the surface of the photoconductor

drum during handling.

◆With the exception of the handle area, take care to avoid

contacting the surface of the photoconductor drum as much

as possible.

◆Except when you install the Process cartridge into the device