Page 1

SEIKO

{(

im

(B

JP

M t O ^

mid®

X)

jMT

2n>

^

IO

JES JLi

^ ^ ^ ^ ^ ^

SSlSiD

STSRM

SlUMRSS

1?®

Page 2

•

•/tf

•

Page 3

SPECIFICATIONS

Maximum

Number

Needle:

Thread:

Feed

:

Stitch:

Presser

Presser

Lubrication:

Oil

volume:

Working

Motor:

Diameter

speed:

of

needle

:

foot:

bar

lift:

space:

of motor puiley

3.000-Max.4,000

and

needle

gauge)

One, two, three and four

DV

X59 ft18to

Synthetic

Upper,

upto#2

drop

and

r.p.m.

#25

needle

(Speed

(#22

feed

changesbynumberofneedle

standard)

(LD-8,

28,

Needle and drop feed (LD-7, 27, 37, 47):

3 to 12

Alternating

Flat presser

8mm by lever

13mm by knee lifter

Full-automatic

550

270mmx135mm

250Wor400W

50 cycle 80mm, 60 cycle

cc

stitches

pressers

foot

per inch

oiling

2P

(LD-8,

(LD-7,

clutch

28.

38,

27, 37, 47)

motor

65mm

48)

38,

48)

Page 4

CONTENTS

Page

Setting

Oiling 3

Inserting needle thread, threading loopers 4

Threading

Regulating tensions, regulating pressure on material 6

Adjusting

Adjusting feed dog & To

Feed dog

forward

Adjusting loopers position in relation to needles 10

Height of needle bar 11

Loop deflector,

up machine 1 & 2

needles

stitch

forward

and

length and lift of

& backward position.

backward

spreader

position

set

pressers

feed dog in relation to needles 8

Timing

of feed dog eccentric. Needle bar

12

Adjusting thread guide, looper thread take up, needle thread tension releaser 13

Replacing arm

Timing of vibrating presser foot 15

Gauge 16

shaft

connecting belt 14

5

7

9

Page 5

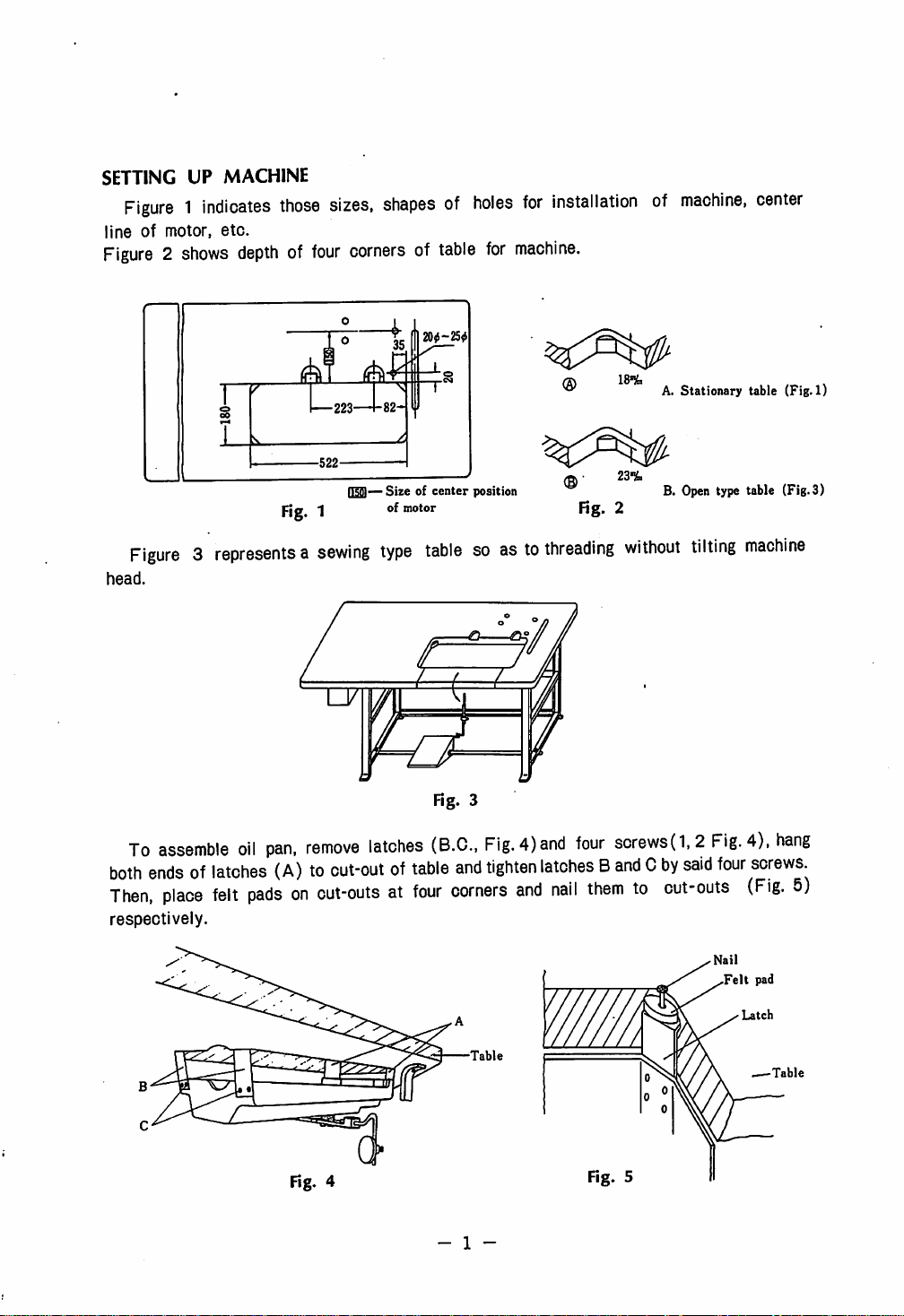

SETTING UP MACHINE

Figure1indicates

lineofmotor,

Figure2shows

etc.

those

depthoffour

sizes,

shapesofholes

cornersoftable

20<-25<J

for

machine.

for

installationofmachine,

18%

A. Stationary table (Fig. 1)

center

Fig. 1

Figure3representsasewing

head.

To

assemble

both

endsoflatches

Then,

place

respectively.

oil

pan,

remove

(A)toout-outoftable

felt

padsonout-outsatfour

]—

Sizeofcenter

of

motor

type

latches

position

23%

Fig. 2

tablesoastothreading

Fig. 3

(B.C.,

Fig.

and

tighten

corners

4)and

and

four

sorews(1,2

latches8and0by

nail

themtoout-outs

B. Open type table (Fig. 3}

without

tilting

Fig.

said

four

Felt

machine

4),

hang

screws

(Fig.

5)

pad

Table

Fig. 4

- 1 -

Fig. 5

Table

Page 6

Attach two L shape hinges(A, Fig.6) to

(B),

then,

push

the

the

machine

on

the

support

table.

plate

(a,

bed

side and

hook

Fig.7)downwardasfar

themtosemi-oiroie

as it

will

go

hinges

and

set

Caution:

When

putting

the

machineonother places

(a, Fig. 7) so as to keep the balance of the machine.

Fig. 6

Pass

order

the rope

1

to

3.

from

A to 8

and

Table

D

Oil

through

tank

the V

/

than

table,

shaped

pullupthe

Fig. 7

groove

0

support

and

plate

in the

(D

Fig. 8

- 2 -

(D

Page 7

OILING

Machine

has an automatic oiling mechanism, but, oiling points (Arrows, Fig. 9) are

provided for hand oiling for parts in movable contact which are not lubricated

reservior.

— .

Fig. 9

from

oil

Automatic

lubrication

system

(A) Automatic oiling system is composed of an oil reservior, holicw arm shaft and

hollow bed shaft through which necessary amount of oil is delivered to all of parts in

movable

contact, except these parts described in the

column

(B),

while

machine

is in

operation. Oil is distributed by centrifugal force through small jets.

The amount of oil flow, which should be slow, can be seen in the oil window (B,

Fig. 12), It can be adjusted with oil

When running in,

keep

speed

at

1,800

pump

(C Fig. 11) by opening or closing it.

to

2,500

R.P.M.

(B) Keep clean oil reservoir and pour oil in the reservoir (oil pan) up to the center

line (A, Fig. 10).

When

oil has been soiled for several months use, release it through the hole (B, Fig.

10) and pour new oil in the oil reservoir.

Page 8

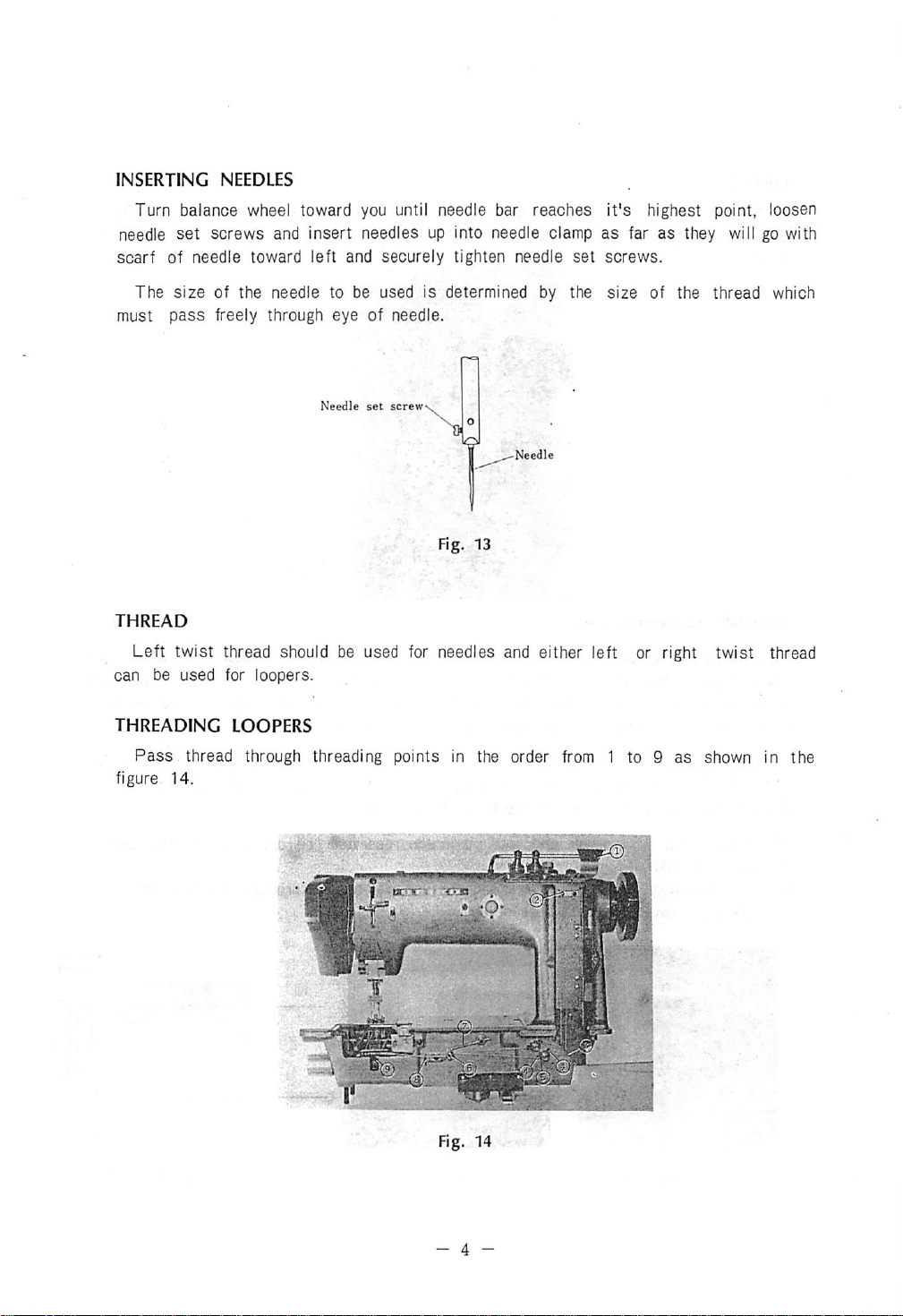

INSERTING

Turn

balance

needle

scarf

must

THREAD

can be

set

of needle toward left and

The

size

pass

Left

twist

used

NEEDLES

wheel toward you until needle bar

screws

and insert needles up into needle clamp

securely

tighten needle

of the needle to be used is determined by the

reaches

set

it's

highest point, loosen

as

far

as

they will go with

screws.

size

of the

thread

which

freely through eye of needle.

Needle

set

screw

Fig. 13

thread should be used for needles and either left or right twist thread

for loopers.

THREADING

Pass

thread through threading points in the order from 1 to 9

figure

14.

LOOPERS

Fig. 14

as

shown in

the

- 4 -

Page 9

Before threading further, turn balance wheel toward you soasto bring

wheel to the arm point as shown (B, Fig. 15),

the arrow and slightly turn it toward right, then loopers can move toward you.

will

make

threading

easier.

hold

the dial {Fig. 16)

letter

pull

it toward

M on the

This

Then,

pass

threads in the order from 10 to 12 and draw threads 50mm and

loopers, and return the dial to

threads.

THREADING

Pass

NEEDLES

threads through threading points in the order shown in the figure 18 from 1 to

Fig. 15

it's

original position. Be sure not to make

in

'"'g-

Fig. 16

pass

cross

10 and draw threads about 50mm. (Refer to Fig. 21 for threading tension-discs).

them

of

Hg.

18

- 5 -

Page 10

REGULATING

Tension

regulated

according to the material.

Looper

TENSIONS

should

..Needle

thread

be just

thread

pjg

enough

Perfect

to set the stitch in the material, and it

stitching

Imperfect

stitching

\

Fig. 20

Tight

of

tension

looper

should

''U

B ^

thread

Loose

of

needle

be

tension

thread

For more tension, turn the nuts (E, Fig. 21 and F, Fig.

and for

less

tension,

turn

them

toward

arrow

direction.

22)

toward'^arrow

direction,

m

f'g-

21

REGULATING

Always use the lightest pressure possible to allow higher working speed. It can be

adjusted

screw driver for

(B, Fig. 23). Before adjusting pressure, open the face plate (A, Fig.24) and

the distance between

it by the screw on the (B).

by

PRESSURE

turning

ON

MATERIAL

the regulating screw (A. Fig. 23)

more,

pressure, and for less pressure turn it toward^ arrow direction.

(B)

and

(C)

Fig. 24 is about 20mm. If it is not 20mm, adjust

toward

arrow

Fig.

direction

22

confirm

with

a

Fig. 23

- 6 -

Fig. 24

Page 11

ADJUSTING STITCH LENGTH

Numeral

length of stitch, turning parts (G, Fig. 25) toward right, at the same time turn balance

wheel over toward you until plunger enters a notch in adjustable eccentric on arm shaft.

Then, turn the

Now, press the button (11, Fig. 26) and at the same time turn balance wheel over to

ward you to increase length of stitch cr over

length

until it springs outwardly. Then, the machine is ready for operation.

numbersonthe stitch

(G)

1/4

turn.

on the stitch indicator.

indicator

Then,

show

the

number

from

you to shorten stitch, until desired

release the button (H) and turn the

of stitch per

inch.To

plunger

change

(G)

CAUTION:

After determination of the stitch length, adjustment for loopers (page

spreader (page 12) must be made.

ADJUSTING

The lift of vibrating and lifting presser foot is controlled by the wing nut(1, Fig. 27).

Loosen wing nut and raise it for higher lift or lower it for less lift, then securely tighten

the

nut.

Be sure to operate the

fM

Fig.

LIFT

OF

PRESSERS

machine

25

after the

plunger

(G) has

v.;

Fig. 26

-•

yes

sprung

10)

•" •"

outwardly.

and for

Fig. 27

- 7 -

Page 12

ADJUSTING

FEED

DOG

Itisthe

needle

is

The

at

the

parallel

plate

lowest

Adjustment

adjusting

After

30).

screw

the

correct

positionoffeeder

and

teeth

protrude

point.

1.5mm

adjustmentismadebythe

for

feed

height,

(B,

dog

loosen

Fig.

29)torighttoraise

has

correctly

the

nut

been

where

from

screw

(A,

set,

teethoffeeder

surfaceofneedle

(J,

Fig.

28)

Fig.

29)

and

the

the

feeder

securely

and

tighten

are

.parallel

plate,

tilting

machine

screw(H,

turnitto

the

nut

Rg. 28

with

when

head.

Fig.

30),

lefttolower

and

screw

surface

needle

turn

(H,

of

bar

the

it.

Fig.

NEEDLES

screws(A.

dog,

I||J^

Rg. 30

set

feeder

Fig.

32,C,Fig.

parallel

with

Rg.

29

TO

SET

FEED

DOG

Remove

adjust

of needle plate for feeder, then tighten feeder.

For more

is

necessary,

(J.

Fig.

Fig.31),

Fig.

position of feed bar. Then securely tight-

en

screws.

the

needle

so

that

needles

sideways

after

28),

remove

and

loosen

32)

and screw (C, Fig.32), and set

SIDEWISE

plate

enter

adjustment of feeder b

tightening

the

cover

position

{A,

Fig.

into

needle

the

plate

screw (B,

IN

RELATION

31),

screw

(B,

loosen

holeoffeed

TO

two

set

-|j|•J ^

m

^.

1

Fig. 31

27).

slots

.".jj

Page 13

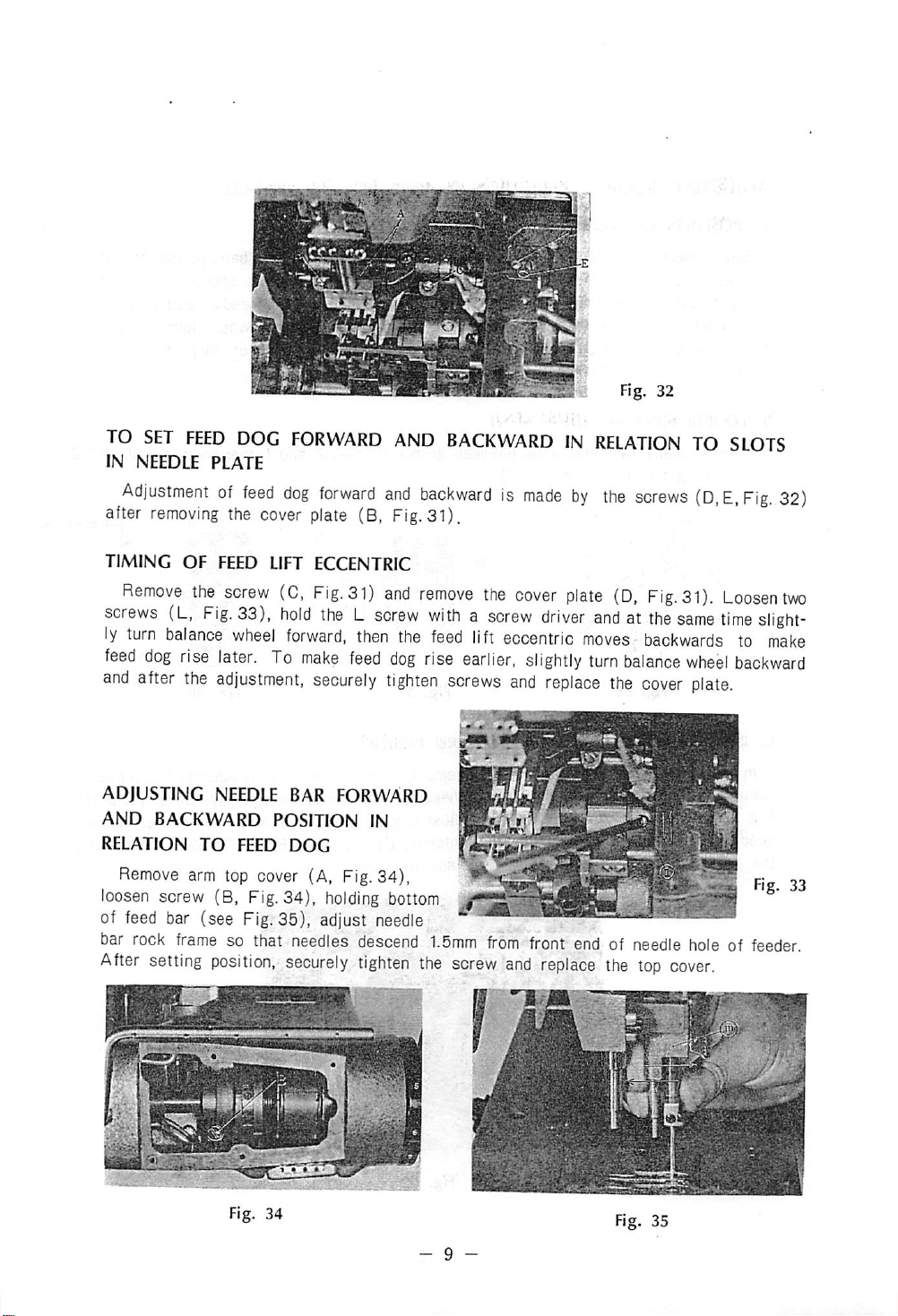

TO

SET

FEED

DOG

IN NEEDLE PLATE

Adjustmentoffeed

after

removing

the cover plate (B, Fig.31).

FORWARD

dog

forward

AND

BACKWARDINRELATIONTOSLOTS

and

backwardismadebythe

Fig. 32

screws

(D.E.Fig.

32)

TIMING

Remove

screws

ly

turn

feed

dog

and

after

of

feed

bar

rock

After

OF

FEED LIFT ECCENTRIC

the

screw

{L.

Fig.

balance

rise

later.

the

adjustment,

bar

(see'Fig.

frame

so that

setting

position,

(C,

33).

wheel

hold

forward,

To

make

Fig.31)

securely

theLscrew

then

feed

and

remove

withascrew

the

feed

dog

rise

tighten

lift

earlier,

screws

35),'adjust'needle

needles

securely

descend

tighten

1.5mm

the

screw

the

cover

eccentric

and

from

and

plate

driver

slightly

replace

front

replace

(D,

Fig.31).

andatthe

moves

turn

endofneedle

balance

the

the

backwards

cover

top

Loosen

same

time

to

wheel

backward

plate.

holeoffeeder.

cover.

two

slight

make

•

:;'Vv•

Mft

Page 14

ADJUSTING

A.

POSmON

LOOPERS

OF

LOOPERS

POSITION

IN RELATION

TO

NEEDLES

Set loopers to

this case, clearance between looper holder and

as figure 36 (only for

should be 0. Tighten

front position, clearance between right side surface of back of loopers and

deflector (M, Fig. 37) should also be

B. LOOPER SIDEWAY ADJUSTMENT

It is so

mm

C.

LOOPERS

In

made

and tighten screw (N, Fig.

loopers

shouldbesame

Fig.

31),

loosen

needlesbystrengthorweaknessoftightening

the

position,

looper

that clearance between

Fig. 36

FORWARD

forward

holder

compound

looper

AND

and

backward

(B. Fig. 36) slightly tilting their back

and

walking

set screws (C, Fig. 36). Further,

38).

BACKWARD

movement,

positioningroovesofneedles.

screw

tighten

the

(A,

screw

Fig.

39),

and

adjust

replace

bottom"

foot machine). For needle feed

1.5mm.

groove

Fig. 37 Fig. 38

of needle and

POSITION

crossing

To

loopers

two

the

cover

of loopers should be 0~1.5mm

when

looper

point

Feed

dog

^

pointofneedles

adjust

movement

screws

this,

remove

fasterorslower

(8.C,Fig.

plate.

portion

to left.

machine,

loopers are in

is 0.05 to 0.2

and

looper

cover

39).

After

points

plate

against

setting

In

it

loop

(D,

Fig. 39

-10

-

Page 15

Turn

balance

ance

wheel,

(Fig.41).

D.

NEEDLE

Turn

balance

center of needle, adjust so that right side of needle guard touches to side of

(Fig.

44)

loosen

GUARD

but

wheel

wheel

looper

toward

the

Fig. 40

toward

does

you.

screw

(D,

you,

not

touchtoneedle,

and

Fig.

when

align

39)

looper

the

and

point

set

points"

and

tighten

Needle

(B,

looper

are

guard

Fig.

40)

point

to the center of

Centerofneedle

Fig. 41

2.5mm

screws

and

arrow

(Fig.

42)

(A,8,Fig.

on

needles

from

43).

bal

the

needle

Fig. 42 Fig. 43

HEIGHT

OF

NEEDLE

Adjustmentismade

Fig.

46),

adjust

of

needle

eye is 2 to

needle

Fig. 45

BAR

after

locper

positionsothat

3mm

(Fig. 45)

position

has

been

the

measurement

by

two screws (B, Fig. 46).

-

11

-

determined,

from

looper

Fig. 44

open

face

pointtoupper

plate

Fig. 46

(A,

end

Page 16

LOOP

Tilt

47)

from

DEFLECTOR

machine

and

adjust

0.5mm

Looper

and

clearance

to

1mm.

turn

balance

between

wheel,

left

Driver

when

looperisin

sideofloop

front;

deflector

Loop

deflector \

and

Iccsen

right

screw

side

1%

(0,

of

Fig.

needle

Fig. 47

Adjust

SPREADER

Adjusting

of needle reaches to circumference of

sideofneedle

When

and

50)

by the screw"

loop

deflectorsothatitcomes

spreader

spreader

left

sideoflooperto0.2to0.5mmbythe

through

which

(0,

and

holder

point,

spreader

spreader

Fig.

48)

turn

balance

pointto1.5mmbyscrew

Spreader holder

Spreader sideway

is at

extreem

point

pass

from

0.5 to 2mm.

cut0to

wheel

looper

opreader

left

upper

Fig. 47-1

1mm

from

the

needle

toward

(A, Fig. 48), adjust measurement between

end,

adjust

portionofthe

®

screw

youtolower

(B,

Fig.

48).

Fig, 48

clearance

(0,

Fig.

between

48).

looper

needle,

Clearance

(Fig.

50) is

(Fig.

47-1).

when

spreader

adjusted

point

point

(Fig.

—

I—0.2-0.

Fig. 49

0.5-214,

Looper

Fig. 50

-

12

-

Spreader

Page 17

Tilt

machine,

(A,B.Fig.

right

for

smaller

curely tighten

To

decrease

adjustmentbyeither

loosen

51),

move

them

spreader

screws.

the'arnoum,'

lowering

spreader

driving

toward

stroke.

reverse

thread

eccentric

left

for

After

positionofspreader

the

take-uporraising

bigger

screw

spreader

the

and

thread

its

counter

stroke,

has

and

been

guide.

balance

move

them

determined,'

screws

toward

se

LOOPER

To

take-up

amountofthread,

ADJUSTING

Remove

lever

54)

right to open tension more, move the collar

toward left to open tension less.

Normally, opening of tension is 1.5mm

when

sition,

THREAD

increase

rod

arm

(A,

Fig.

on

collar

lifter lever

tighten

TAKE-UP

amountofthread,

(B,

Fig.

53) to left or

reverse

NEEDLE

54),

and

the

THREAD TENSION

top

cover,

loosen

move

the

works.

After setting

screw.

the

adjustment.

lower

screw

collar

move

move

Fig. 52

lifting

(C,

Fi'g.

toward

po-

looper

looper

After

thread

thread

the

RELEASER

-/SSSSSm

fi

//

guide

(A,

guide

downward.

adjustment,

Fig.

53)

securely

and

looper

To decrease

tighten

screws.

Fig. 53

thread

Fig. 54

-

13

-

Page 18

REPLACING

Turn

to

its

highest

adjustsothat

lower

shaft

with bed rim (D, Fig. 55) and is toward

arm shaft (see Fig. 55), in this position,

assemble

shaft

pulley.

balance

pulley

a

new

ARM

wheel to

point,

arrow

belt

SHAFT CONNECTING

raise

turn

mark

(A,

needle

lower

(B,

Fig.

Fig.

55)isparallel

to

arm

and

shaft

55)

bar

and

on

lower

BELT

9

9

^

^

Fig. 55

Fig. 56

ADJUSTMENT OF

Raise presser bar lifter (A, Fig.57). adjust

needle

after

adjust

12.5mm by guide lever screw,

plate

(B,

Adjustmentismade

removing

distance

Fig.

rubber

between

PRESSER

57)

and

through

stopper

the

HEIGHT

bottomoflifting

the

hole

(D, Fig.57)

from

hole.

position

guide

when

bottom of lifting presser reaches to needle plate.

SIDEWAY

FEET

Insert vibrating and lifting presser feet

into respective presser bar

will go, adjust so that they are parallel

and vertical against

and

feed

In

56).

measurement

presser

Lower

(A,

the

Fig.

ADJUSTMENT OF

as

farasthey

slots

of needle plate

dog.

this position, set screws (C,D, Fig.

foot

by

presser

58)

between

(C,

presser

bar

and

guide

Fig.

bar

lifter

upper

57) to

lifting

lever

surface of

bracket

(A,

(B,

8mm.

Fig.

PRESSER

screw,

Fig.

57),

58) to

km

Fig. 57

-

14

-

Fig. 58

Page 19

TIMING OF VIBRATING

To

set

positionoflifting

balance

to

cover

60)toleft,

movestoright,itbecomes

feed

wheel

dog,

plate

toward

after

(A,

then

youtolower

needle

Fig.

59),

vibrating

PRESSER

ecoentrio,

eye

has

loosen

presser

slower.

FOOT

lower

the

needle,

reachedtofeed

screw

foot

and

(A,

Fig.

reachestoneedle

presser

adjust

dog.

60),

bar

so

To

move

lifter

that

adjust

lifting

plate

(A.

vibrating

this,

eccentric

faster

Fig.

presser

remove

than

57).

reaches

(B,

needle,

turn

side

Fig.

if

Amountofliftofvibrating

equal

height. Adjustment is

presser

made

foot

and

by screw (B, Fig. 59).

Fig. 59

lifting

presser

foot

should

normally

be

Fig. 60

Page 20

GAUGE

3/16-

1/4"

1/4'-1/4"

1/4- 1/2-

3/4"

(3/16'to2")

(1/2"to2")

1/4' - 1/4' - 1/4'

5/16' - 5/16' -

3/8"-3/8"

1/2' -

1/4"-.1"

1/2"

- 3/8'

- 1/2'

- 1/4'

5/8-

5/16"

3/4-

MM"

(3/16"to2-)

L B X

l.

•

.l.•-t-

(A

=3/4'to2')

{B=3/16'.•Mimmum)

°-l

P-

A..•"•

1.

When

exchanging

A.toG

2.

When

mustbereplace

u

rohine'or

•

-^•r!:e:s=t[:rh::e

!a:Nnrne"dl"'harrusf'b:

4.

When

exchanging

bed

plate

-;Vr.;v••:,

Fig. 61

gauge

size.

accordingtothe

tranap

narts

vioeversa,

needle

needle

and

bed

plate

c ^^

for

instance

0,

four

thread

re"aoe"

guage

slide

mustbereplaced.

iradditrrthrs/Tarts'lnTionrd

to

size.

from

needle

tension

A.

Needle

B. Needle clamp

C.

Vibrating

D.

Lifting

e.

Needle

p.

Feed

bar

presser

presser

plate

dog

^

thread

foot

guard

foot

in

the

-16-

Loading...

Loading...