Page 1

OPERATING

INSTRUCTIONS

FOR

JW-8BL-20

JW-8BL-30

JW-28BL-20

JW-28BL-30

SEIKO

SEWING MACHINE CO., LTD.

TOKYO

JAPAN

Page 2

OPERATING

This

is a

guidetouseofSEIKO

duty

materials sewing machine

mechanism,

Please read

under

this

INSTRUCTIONS

the

guide

Specifications

MAX. SPEED (s.p.m.)

MAX.

STITCH

MAX.

LIFTOFFOOT

NEEDLE

BOBBIN

WORKING

BED

DIMENSION

POWER

MOTOR

(mm)

SIZE

(mm)

SPACE

REQUIRED

PULLEY

(mm)

(mm)

(W)

DIA.(mm)

NET/GROSS WEIGHTSM^

MAX.

SPEED

MAX.

STITCH

MAX.

LIFTOFFOOT

NEEDLE

BOBBIN

WORKING

BED

DIMENSION

POWER

MOTOR

NET/GROSS

NEEDLE

(s.p.m.)

(mm)

SIZE

(mm)

SPACE

REQUIRED

PULLEY

WEIGHTS

SPACING

(mm)

(mm)

(W)

DIA.(mm)

JW series

with

compound

best

condition.

thoroughlysothat

JW-8BL-20 JW-8BL-30

(mm)

DY X3 (sandard No. 24) •

508X153

846X230

JW-28BL-20 JW-28BL-30

(mm)

DY X 3

508X153

846X230

M^

3/16"

(4.7

mm),

SEIKO

model

JW

SERIES

long-arm high

speed

feed and walking

you

may

expect

SINGLE

1,600

NEEDLE

10

20

good

performance.

SY5213.794

37?>x 13

762X153

1,100x230

400W,2P

7Oi'^/

6O0 (50/60HZ)

109/kgs. 151/kgs. 0.377/M3

TWIN

NEEDLE

1,500

10

20

(sandard

60^/509*

112/kgs.

2-3/8"

No.

24)•SY5213•794

37^.x

13

400W,

2P

(50/60HZ)

154/kgs.

(60

mm).

Standard

762X153

1,100x230

0.377/M3

1/4"(6.4mm)

MODEL

for

foot

feeding

heavy-

CODE

EXPLANATION

J :

Jumbo

W :

B :

L :

USE

Tent,

Plate,

Horizontal

Reverse

Large

Hook&Bobbin

FOR

Sail

Clodi,

Leather,

(Super

Hook

Stitch

etc.

Long

Arm)

Rubberized

8 : Single-Needle

20:

508

mm

28:

Twin-Needle

30:

762

mm

Fabrics, Heavy

with

(20

inch)

with

(30

inch) Working

Synthetic,

Compound

Working

Compound

Heavy

Upholstery

Space

Space

Feed

Feed

& Walking

& Walking

Materials,

Foot

Foot

Fiber

Page 3

—

INDEX

CONTENTS

Page

Setting up

Caution before starting

the

machine 2

the

operation

Oiling 2 —3

Needle

Thread

Winding

Removing

Threading

Regulating

Adjustmentofthe

Adjustmentofthe

Reverse stitching 6

the

lower

threadonthe

and

inserting

the

needle 5

the

thread

the

tensions 5

stitch

pressure 6

bobbin

bobbin

1

2

3

4

4

4

6

INSTRUCTIONS

Relative

and

positionofvibrating

the

needle

Adjustmentofthe

Timing between

Adjustment

the

of bobbin case

Adjustmentofthe

Timingofthe

Adjustmentofthe

Adjustmentofthe

Replacementofthe

To

re-engage

vibrating

the

Adjustmentofthe

Adjustmentofthe

Treadle

assembly

FOR

ADJUSTMENT

holeofthe

heightofthe

hook

heightofthe

and

clearance

thread

safety

controller

connection

clutch

built-in

oiling

for

complete

and

lifting presser bar, also,ofthe

feeder

needle

feed dog 7

and

the

needle 8

opener

presser

lifting presser

for

the

belt

bobbin

the

hook

set

feet

feet

vibrating

spring

and

lifting presser

feet

winder

saddle 14

11-

7

9

9

10

10

11

12

13

14

15

Page 4

SETTINGUPTHE

Setting

bolts

(A)

up

under

the

MACHINE

machine on

the

bed.

(Fig.1)

the

table

after

removed

two

pieces of

supporting

CAUTION

1. Do

not

has

been

During

2.

The

machine

(The

auxiliary

3. Do

OILING

not

operation.

ting

speed

casebycase.

(Figs.2,3,4&5)

1. Oil

shouldbeappliedateachofthe

4&5.

BEFORE

operate

properly

practice

opearate

To

aretobe

STARTING

the

oiledatevery

period

pulley

hand

turns

wheel

the

take

THE

OPERATION

machine,

the

even if

spot

new

machine

towardtothe

only

and

turnstoclockwise.)

machineatmaximum

practice

changedtoproper

operation

condition

place

for

testing

reservoir

shouldbeoiled

operator.

andoridling, unless it

required

speedof1,500

at

speed

of

1,000

suitable

designatedbyarrows

lubrication.

more

s.p.m.,

s.p.m.,

for

the

frequency.

for

starting

but

materials

in Fig. 2,

opera

in

3,

Page 5

2.

To

fill

the

oil

oil gauge (Fig. 6 A)

reference

Whenincontinuous

3.

lineofthe

/ ;ji« H

I.--

for

reservoir

and

of

pour

oil gauge (Fig. 6-1 B).

use, it

shouldbeoiledatleast

hook

the

I,.

Ilf

saddle

oil until

Ik/

from

the

hole

after

taken

out

the

the

oil level reachedtothe

upper

twiceaday.

NEEDLE

1.

2. To insert

(Figs.7 & 8)

SEIKO

(standard

The

type

needle

JW

series

machines

No.

24)•SY5213•794.

size of needle to be used should be

and

thicknessofthe

the

needle,

bar

movesupto

barasdeeplyasit will go,

(28BL).

Tighten

the

needle

set

IT'

S

"I

'J.

are

sewing

turn

the

its highest

with

screw

setupto

use

determinedbythe

materials.

machine pulley over

point,

the

securely.

put

long

grooveofthe

standard

the

Fig.

6-1

needleofDY x 3

sizeofthread,

toward

needle up

needle

you until

into

faced

the

the

needle

outside

Page 6

THREAD

Normally, left twisted

(Fig.9)

thread

side needleoftwin-needle

right

twisted

thread.)

Left

Twist

Is used

for

upper

(needle) thread. (But, for left

288Lmachine.Itcanbefinished

Right

Twist

in fine results

with

WINDING

1. Pass

which

2. Press

matically,

The

thread.

REMOVING

1. Draw

latch

2. Insert

THE

LOWER

the

thread

setupto

the

lever

In engage

bobbin

X 3

AND

back

the

(2)toa vertical

the

bobbin

hinged latch (2) and

3.

When

closing

through.

THREADONTHE

through

the

shaftofbobbin

(6)toarrow

with

will

automatically

^ o .

INSERTING

side

plate

position,

and

draw

the

side

plate

(1) - (4),

direction,

the

operationofthe

-i

Fig.

10

THE

BOBBIN

(1)onthe

then

pull

thread

the

thread

(1), leave

BOBBIN

and

winder.

be

stopped

bedofthe

remove

out

end

just

wind

then

(Figs.

about

(Figs.

several

(5)

the

machine.

after

12 &13)

and

4—5cm(3),

under

enough

10 &11)

times

bobbin

the

machine,

insert

the

tension

space

winds

bobbin

-

3^-

the

for

arround

the

X A

and

raise

bobbin.

then

push

spring (4).

the

threadtopass

the

thread

is filled

the

down

bobbin

auto

with

hinged

the

Page 7

THREADING

1. Pass

the

THE

thread

NEEDLE

from

thread

guide (1) -

eyeiet

(2) - tension disc (3) - tension

thread guide (4) - guide (5) - thread take-up spring (6) - guide (7) - take-up

lever (8) - guide (7) - lowerguide (9) - self threading needle bar thread guide

(10) -

through

(Remark) Wind

2. With

the

the

eyeofthe

the

thread a single timetotension thread guide (4).

needle (11),

left hand hold the end of

the

needle thread leaving it slack from the

hand to the needle. Turn the machine pulley over toward you until the

needle moves down and up again to itshighest point,

thus

catching

the

bobbin

thread, draw up the needle thread, and the bobbin thread will come up with

it through

feet

and

the

close

hole in

the

slide.

the

feed dog. Lay the threads back under

the

presser

St

REGULATING

THE

1. The tension on

2. The tension on

spring on

To increase

the

tension,

the

outsideofthe

the

turn

THREAD

the

the

tension,

over

TENSIONS

(Figs.

needle thread is regulated by

bobbin thread Is regulated by

bobbin case (Fig. 17 A).

turn

over

nutorscrew to

nutorscrewtothe

Fig.

16

16 &17)

left.

the

w

7

thumb

the

the

nut

(Fig. 16 A).

screwofthe

right, and to decrease

tension

Page 8

ADJUSTMENT

The

lengthofstitch

while

turning

setting

To

decrease

When

confirmed

the

increase

the

the

topofbutton

desired

releasing

OF THE

STITCH

LENGTH

is regulated by pressing

the

machine

pulley

(1)tothe

the

lengthofstitch,

lengthofstitch,

lengthofstitchisobtained,

the

button

turn

(1)tothe

(2)

turn

the

(Fig.18)

slowly

feed

the

machine

down

with

eccentric.

machine

pulleytoopposite

operate

original

the

button

right

handinthe

pulley

the

position.

(1)

over

toward

machine

Fig.

19

with

left

condition

you.

direction.

after

hand,

of

To

fully

ADJUSTMENT

The

pressureofthe

To

increase

screwtocounter-clockwise.

REVERSE

The

chain

lever

(A)

To

feed

anddonot

OF THE

the

pressure,

STITCHING

for

the

underneath

the

work

stoptopress

PRESSURE

presser

(Fig. 20)

feed reversing pedal is

of

toward

feet

turn

the

bedofthe

you,

down

(Fig.19)

is regulated by

the

screw to clockwise, and decrease it,

machine.

press

down

on

the

way.

the

adjusting

connectedtothe

firmly

on

the

screw.

hookoffeed

feed

reversing

reversing

turn

the

pedal,

Fig.

20

Page 9

INSTRUCTIONS

FOR

ADJUSTMENT

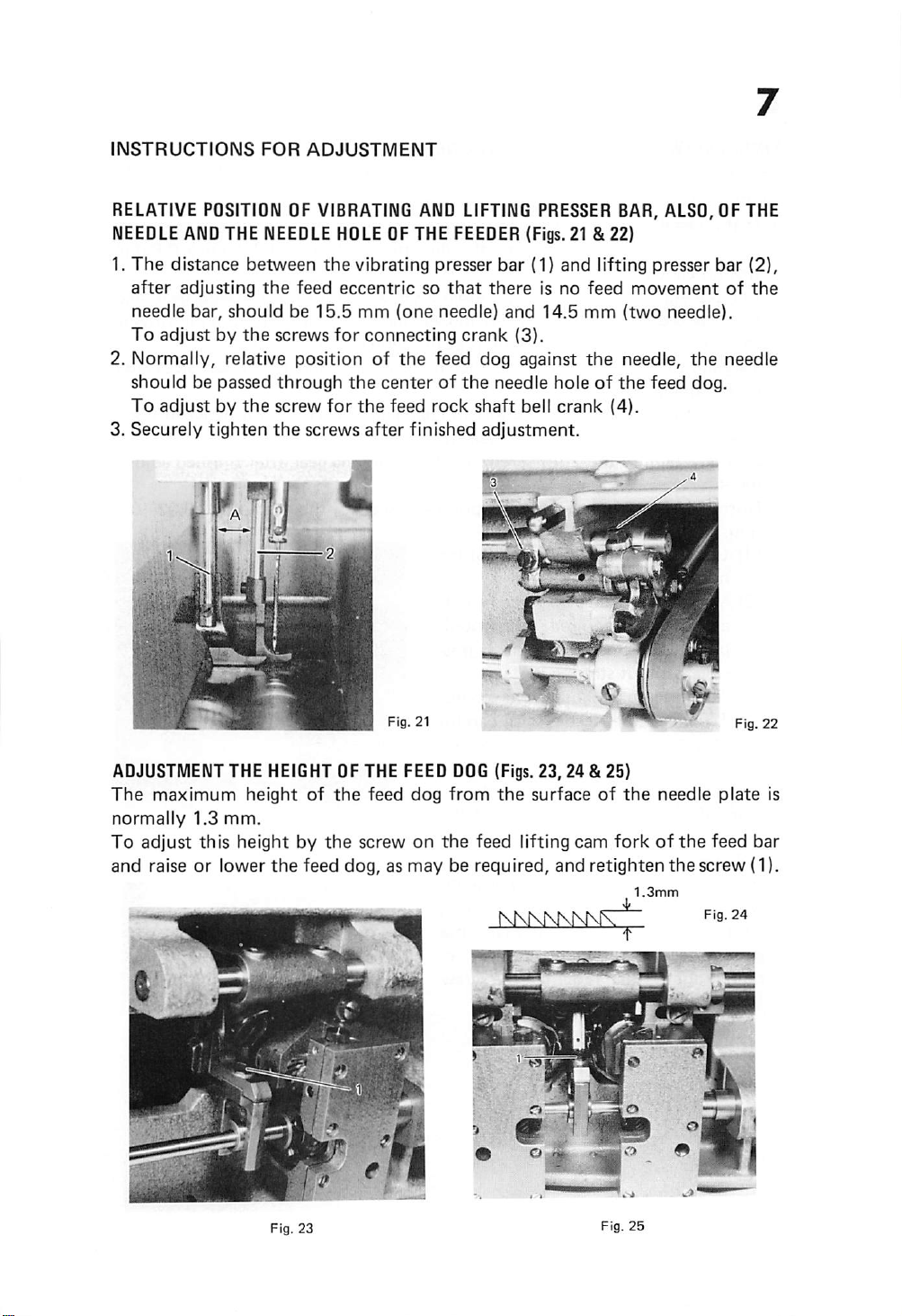

RELATIVE

NEEDLE

1.

The

after

needle

To

POSITIOlU

AND

THE

distance

between

adjusting

bar,

should

adjustbythe

OF VIBRATING AND LIFTING PRESSES BAR, ALSO, OF THE

NEEDLE

the

screws

HOLE

the

vibrating

feed

eccentricsothat

be

15.5

mm

for

connecting

2. Normally, relative position of

should

To

3.

Securely

be passed

adjustbythe

tighten

A I.

through

screw

the

screws

for

the

the

after

OF THE

(one

the

FEEDER

presser

needle)

crank

feed dog against

centerofthe

feed

rock

finished

(Figs.21 &

bar

(1)

there

is no

and

14.5

(3).

needle

shaft

bell

adjustment.

22}

and

lifting

feed

mm

(two

the

needle,

holeofthe

crank

(4).

presser

movement

needle).

the

feed

dog.

bar

of

needle

(2),

the

ADJUSTMENT

The

maximum

normally

To

adjust

THE

height

1.3

mm.

this height by

and raiseorlower

HEIGHT

of

the

feed dog, as

OF THE

the

the

screw on

A»*

1 t

\mii\l~T

rT

uJ-'

feed

: "Vr

FEED

DOG

(Figs.

23,24

dog

from

the

surfaceofthe

the

feed lifting cam

may

be required, and retighten

NKNNKNKfV

& 25)

forkofthe

1.3mm

^

needle

thescrew

F'S-

plate

feed

is

bar

(1).

24

Page 10

TIIVlliyG

Set

length

1. If

BETWEEN

the

feed

eccentric

between

the

needle

will

beatthe

from

the

lowest

For

the

adjustment

tap

this gear to

shaft

until

the

Tappingtothe

hook

timing.

Except

driving gear (2)

Securely

ment.

the

above case, to adjust in changing gear

tighten

THE

HOOK

with

vibrating

bar

and sewing

center

of

point.

of timing, loosen 2 screws (1) for

the

rightorleft in clearanceof2 mm on

pointofthe

right gives

and

hook

the

2 set screws

and

the

2. Normal clearance between

AND

THE

NEEDLE

the

buttonatno feeding

lifting

presser

hook

are correctly timed,

needle

hookIsat

on

shaft

hook

when

earlier

gear (3).

for

point

the

hook

hook driving gear

and scarfofthe

(Fig.26)

position,

bar

shouldbe15.5

the

needle

centerofthe

timing,

andtothe

condition

the

raised

hook

needle.

after

needle is In

and

confirm

mm.

pointofthe

3.8

mm±0.5

driving gear, and

the

hook

driving

left gives

between

finished adjust

0.02

the

hook

mm

later

hook

• 0.1

(1) Loosen

hook

two

saddle.

screws (4)

and

(2) Move hook saddle to right or left,

as

may

be

point

sible

(3)

Then

(4)

To

attention

adjustment.

3. Height of

Normal

eye

of

2.2

mm.

In case

set, loose

stud

pinch screw (A)

needle

quired

(A).

above,

required,

is as closetoneedle as

without

striking

securely tighten

check

the

bar

the

free

the

needle

clearance

needle and

the

needle

the

needle bar connecting

in

correct

then

needle

from

bar

between

bar

retighten

until

it.

two

with

bent

(Fig. 27).

topofthe

hook

point

is incorrectly

and

place

position

the

(5)

for

hook

pos

screws.

careful

before

the

as re

screw

'A

is

Fig.

26

Page 11

ADJUSTMENTOFBOBBIN

1.

Turn

the

machine

openerislocatedatthe

CASE

pulleyorhand

distance

2. In this position, adjust it so

opener

3.

Securely

(A)

tighten

and

the

topofthe

the

screw (B)

. . f r

..:

Fig.

28

OPENER

(Fig.28)

wheel

from

that

the

clearance between

hookisabout

after

finished

(Fig. 31 D & E)

the

needle

0.3-0.8

adjustment.

plate.

until

the

mm.

13

Fig.

the

topofthe

inside edge of

29

the

ADJUSTMENTOFTHE

Normal

ser

When

lever

1.

2.

3.

Position

by

position

distance

footatstopped

step

(B).

To

change

above

condition.

The

height

presser

Normal

(Dar

the

bar

distance

position guide (4) is 7 mm.

of

screw (2)

guide

on

the

the

of

lifting

the

bracket.

between

lifting

relative lift

lift of

vibrating

for

HEIGHTOFTHE

the

surfaceofthe

positionofthe

pedal,

of

the

presser

bracket.

between

presser

presser

presser

bar

PRESSER

needle

stop

lever

(C) is19mm.

the

stop

lever (C) willbereleasedbythe

the

presser

feet,

feetisadjustable

bar

position

foottoshiftinleft

lifting

bracket

and

FEET

guide

(Figs.

plate

loosen

by moving

bracket

and

the

screw (5)

29,30 & 31)

(A)

and

vibrating

the

screw (1)atthe

the

(3)

and

rightistobeadjusted

for

pres-

lifting

screw

presser

presser

I .^v.

of

bar

'it.--

Fig.

30

Page 12

10

TIMING

The

should

being

OFTHE

amountofliftofthe

be

sewn.

VIBRATING

regulated

accordingtothethickness

AND

LIFTING

vibrating

PRESSER

and

lifting presser

FEET(Fig. 32)

of

materials

feet

The feet should lift just enoughto clear the materials. 0

As a rule,

an

equal

they

To

change

screw (A)

ting

securely

the

vibrating

height,

liftanunequal

presser

tighten

but

the

relative liftofthe

for

lifting

bar

the

some

height.

rock

upward

screw (A),

and

lifting presser

gradesofwork

shaft

crank

or

downward

feet

should

may

require

presser feet, loosen

and

move

the

vibra

as

required,

lift

that

the

then

9

© o

%

Upper

Fig.

Surface

32

ADJUSTMENT

FEET (Fig. 33)

PRESSER

The

ser

To

increase

to

the

The

imum,sothat

als

The

by

amount

feet

aretobe

decrease

the

required

clearance

being

sewn.

timing

Fig.

32.

FEET-Fig. 32)

position

DF

THE

CLEARANCE

(RE-ADJUSTMENT

of

the

liftofthe

adjustedbythe

the

movementinsetting

movementinsetting

position,

for

the

vibrating

the

clearanceofthem

for

the

alternating

securely

and

vibrating

FDR

THE

VIBRATING

THE

TIMING

feed

lifting bell

the

tighten

lifting

shouldbeadjusted

and

crank

the

stud

stud

(1)atthe

the

stud

presser

lifting presser

OF THE

for

the

link screw

(1)atthe

(1)

feet

AND

VIBRATING

vibrating

stud

upper

lower

position.

with

nut

are

being

accordingtothe

feet

should

LIFTING

and

position,

(2).

adjustedatmax

PRESSER

AND

LIFTING

lifting

(1).

and

After

setting

materi

be regulated

pres

to

Page 13

ADJUSTMENT

1.

For

more

of

the

2. To strengthen

OF THE

controller

controller

the

spring stud screw (4) at

slightly to

and

securely retighten

the

left with a screwdriver,orlighten its

THREAD

actiononthe

and

set

the

action of

the

the

CONTROLLER

thread,

stop

lever, and

the

controller spring on

rear of

spring

the

stud

SPRING

loosen

for

the

less

stop screw and

screw.

(Fig.34)

set

action

the

turn

action

screw (1) at

set

the

stop

thread, loosen

the

spring stud (5)

turntothe

the

higher.

Fig.

right

the

right

34

REPLACEMENT

A.When

placing

the

purposesofthe

lowings: (Figs.

1.

Turn

the

at

the

2.

Turn

the

driving

ing

shaft

the

upper

OF

THE

connection

35&36)

machine pulley

highest

shaft

position.

hook

bushing

bushing

and

lower

shaft

CDNNECTIGN

belt

removed

parts,itshould

toward

with

the

collar

(1)

are

directly

pulley.

(2)

BELT

fingers

and

from

the

be

replaced

yousothat

until

the

red

In line.

Then

pulley

placed

the

point

for

adjusting

by

the

the

take-up

arrow

mark

markonthe

replace

the

andorre

processes, as fol-

lever (A)

on

the

hook

hook

driv

belt

over

the

Fig.

Fig.

35

36

Page 14

12

B. Replacement of

1.

Remove

2. Slide

the

3. Loosen

the

machine pulley (3),

4. Loosen

ing (6).

5. Lift

the

the

the

upper

connection

the

machine pulley

the

three

belt up through

far as possible and draw it

the

bushing.

6. Replace

7. Securely

looseness.

the

connection

tighten

connection belt when damaged. (Figs. 37 & 38)

arm

plate

and

reservoir.

belt

(A)

off

then

screws in

all

the

screws, so astofit

from lower

adjustment

remove

the

the

arm cap hole after removed

out

arm

through

the

shaft

beltasopposite

and

upper

screw (2) and

belt

two

pulley,

set-screws

machine pulley.

bushing (5) and remove

the

bushing (6) as

the

space normally occupied by

processes as above for removing it.

the

arm shaft, firmly, free from

the

for

bush

I- • - < /

Fig.

Fig.

37

38

Page 15

13

TO RE-ENGAGETHE SAFETY

The

hook

driving

the

hook from getting

shaft

pulley prevents damage in

releasing

Take

1.

the

locking lever in

out

jammed

thread

and

out

CLUTCH

the

of time.

the

the

from

(Figs. 39 & 40)

shaftofthe

The

sewing

hook

are spllnedtoprevent

safety clutch located In

the

lower belt

event of thread jamming in the sewing hook by

pulley.

the

hook.

2. To re-engage the clutch, press down the lock stud (A), near the base of

arm by left hand and

then

the

safety

the

3. In

(B) for lower

To increase

the

case easily releasing

belt

the

pressure in

turn

the

machine pulley backward slowly by right hand,

clutch

willbereleased.

the

pulley

after

removed

pressure in turning

turning

the

screw (B)tocounter-clockwise.

safety

clutch,

the

adjust

connection

the

pressurebythe

belt (C).

screw (B)toclockwise andtodecrease

the

screw

Fig.

39

Page 16

14

ADJUSTMENT

Adjust

for

Remove

for

or

the

volumeofwinding

the

winderinturningittoupand

the

the

winder

left.

OF THE

plate

by

BUILT-IN

(2)onthe

the

winder

BOBBIN

threadtothe

frontofthe

driving gear (3) in

WINDER

down.

arm

u o 'l

V

(Figs.41 & 42)

bobbinbythe

and

adjust

the

arm

.V

adjustment

the

slipageofthe

shafttoshifting

screw (1)

shaft

right

ADJUSTMENT

Loosen

the

oil adjustment dial (2). Maximum oil supply at

point

mark (1)

oil

supplyatthe

the

OF THE

screw

on

OILING

for

the

the

vertical

FORTHE

oil

adjustment

hook

saddle

positionofthe

and

HOOK

dial (3)

the

center

SADDLE

and

center

lineofthe

(Fig.43)

adjust

line of

oil

the

directly in line of

the

dial (2).

supplybyturning

dial (2).

Stop

the

the

Page 17

15

TREADLE

a.

Construct

b. Chain 1 , 2 , 3

ASSEMBLY

treadle

are

COMPLETE

assembly

strained

c. Chain 3 is hooked crank

the

hole

drilled

Chain 3 is used as

stand

horizontal

stoppertoprevent treadle 4 is

d. Screw 6 is drived tightly

complete

tightly.

one

side, and

after

crank

SET

setasshown.

plate.

set up

the

other

correctly.

hook of chain 3 is

not

hit

by camfollower.

dinged

CompletionofTreadle

Set

Page 18

-MEMO-

Loading...

Loading...