Seiko H-2BL-AE Instruction Manual

g-s

HI—

I

ML.

M M

INSTRUCTION

MANUAL

I

SEIKO

SEWING

MACHINE

CO.,

LTD.

Thank

you

very

much

for

buyingaSEIKO

instructions belowand the explanations given in the instruction manual.

With

industrial

as

the

needle

parts.

Follow

atingthe

sewing

and

the

machine

machines,itis

thread

take-up

instructions

so that you

normaltocarry

lever,

from

training'peVspnnel

will

knovv

sewing

and

consequently

howto use it

machine.

out

work

Before

while

positioned

using

thereisalwaysadangerofinjury

and

instructors

correctly.

regarding

your

new

directly-in

safe

machine,

frontofmoving

that

and

correct

please

read

the

parts

safety

such

canbecausedbythese

operation

before

oper

Q]

Safety indications

This

instruction

ensure

The

safe

operation

meanings

ofthese

Indications

A

Q/I^UTION

Symbols

0

SAFETY

and

their meanings

manual

...

andthe

ofthis

indications

Thissymbol

indicates

(For

example,

This

symbol

This symbol

natureofthe

(For example, the symbol at left

indications

machineiandtoprevent

and

symbols

The

instructions

instructions

ment

and

surroundings.

(A)

indicatessomething that you should be careful of.The pictureinsidethe triangle

the

natureofthe

the

symbol

((S))

indicates

(#)

indicates something that you must do. The picture inside the circle Indicates the

thing

that

INSTRUCTIONS

and

syrnbols

are

given

which

could

cause

caution

at left

means

something

mustbedone.

means

thatare

accidents

follow

injury

that

and

Below.

this

term

when

must

be

"bewareofinjury".)

that

you

"you

must

used

on the

injurytoyourself

indicate

using

taken.

must

make the ground connection".)

machine.itself

or other

situations

the

machineorphysical

not

do.

where

are

providedInorder to

people.

failuretofollow

the

damagetoequip

Notes

a

on

safety

AeAUTJON

Environmental

•

Use

the

sewing

free

from

sourcesof

as

high-frequency

Sourcesofstrong

problems

• Any

fluctuationsinthe

shouldbewithin

the

machine.

Voltage fluctuations which are greater than this

may

cause

• The

power

than

the

requirements

electrical

Insufficient

problems with correct operation.

consumption.

with

correct

problems

supply

power

machine

welders.

electrical

±10% of

supply

ii},^ari;.area

strong'ele^'riSal

operation.

power

the

with

correct

capacity

for

the

capacity

whic^

nofse

noise

may

supply

rated

shouldbegreater

sewing

voltage

voltage

operation.

machine's

may

.*'Ni

siicfr'r'

cause

for

cause

:y.>f'

requirements

f.The

HJfSVlfahgeof5®Cto35°C

ambient

Temperatures which

this

may

tion.

•

The

relative

o

o

0

range of 45% to 85% during use, and no

formation

Excessively dry or humid environments

dew

formation

rect operation.

• Avoid exposure to direct sunlight during

Exposure to direct sunlight may cause

lems

with

• In

the

power and disconnect the power cordfrom the

wall

outlet.

Lightning may cause problems with correct op

eration.

temperature

cause

humidity

should

may

correct

eventofan

problems

occurinany

operation.

electrical

should be within

during

are

cause

use.

lower or higher

with

should

problems

storm,

correct

be within

devices.

with

turn

the

than

opera

the

dew

and

cor

use.

prob

off

the

0

o

A

CAUTION

Installation

•

Machine

by a qualified technician.

• Contact your

trician for any electrical work that may need to

be

•

The

The

or

• Do not connectthe power cord untilinstallation

is

complete,

ateifthe

could

• Be

connection

receiving a serious electric shock, and problems

with

installation

done.

SEIKO

should

only be carried

dealer or a qualified elec

sewing machine weighs more than 35 kg.

installation

more

people.

shouldbecarried

otherwise

the

machine

outbytwo

may

oper

treadle is pressed by mistake, which

resultininjury.

sure

to connect

is not secure, you run a high risk of

correct

operation

the

ground. If

may

also

the

occur.

ground

out

o

0

o

o

0

• All

cords

should

away from any moving parts. Furthermore, do

not

excessiveiy

too

firmly with

danger

•

Install

motor.

the

that

belt

be

bend

the

staples,

secured

at

least

cordsorsecure

otherwise

thereisthe

25

mm

them

fire or electric shocks could occur.

coverstothe

machine

head

and

• If using a work table which has casters, the

casters

they

• Be

when handling

gets into your eyes or onto your skin, othenvise

inflammation

Furthermore;donot

cumstances,

arrhoea.

Keep

shouldbesecuredinsuchawaysothat

cannot

suretowear

move.

protective

the

lubricating oil,sothat

can

result.

asitcan

^

the

oil outofthe reach of children.

drink

cause

goggles

the

oil

vomiting

and

under

gloves

no oil

any

cir

and

di

0

0

A

A

Sewing

• This'sewihg machine'shbuld only be used by"

operators

traininginsafe

•

The

any

e

Turn

times,

the

treadleIspressed

result

•

When

• -When replacing

•

When

ing

•

When

keep

switched

tia.

starting

•

Attach

ing

these

who

sewing

applications

off

machine

the

otherwise

in injury.

threading

power

not using

the

machine

using a

turning

offasa

Wait

until

work.

all safety

machine. If

devices

have

received

use

beforehand.

should

other

than

switchatthe

the

machine

by mistake, which

the

needle

the

needle

the

machine and when leav

unattended

clutch

motor,

even

resultofthe

the

motor

devices

the

machine is used without

attached,

injury

the

not be

sewing.

may

and

after

the

stops

before using

may

necessary,

•

following

operate

bobbin

the

motor

power

motor's

fully

result.

used

before

the

for

if

could

will

is

iner

sew

Cleaning

A

.lii

r %

'Z.i

T ..1>trV

If

casters

they

• Do

usihg*^a

not

work'table which

shouldbesecuredinsuchawaysothat

cannot

touch

move.

anyofthe

•

has

moving

casters, the

partsorpress

any objects against the machine whiie sewing,

as this

to

e

For

not

may

• Ifanerror

noisesorsmejls

off

est

• If

your nearest

the

machines

touch

result.

the

SEIKO

the

nician.

may

result in personal injuryordamage

machine. ;

with

automatic

the

solenoid

occurs

power

machine

switch. Then

dealerora qualified technician.

SEIKO

section,

in machine,..pir if

are

noticed, immediately turn

developsaproblem,

dealer or a qualified tech

presser

otherwise

contact

lifter,

abnormal

your

contact

do

burns

near

• Be

sure

to wear protective goggles and gloves

can

the oil out of the reach of children.

A

•

Turn

off

the

power

cleaning,

if

the

result

otherwise

treadle is pressed by mistake, which could

in injury.

switch before carrying

the

machine may

operate

• When using a clutch motor, the motor will

keep

switched

tia.

Wait

starting

turning

work.

offasa

until

even

resultofthe

the

motor

after

stops

the

motor's

fully

power

before

out

iner

0

when handling the lubricatingoil,so that nooil

gets into youreyes or ontoyourskin,otherwise

inflammation

Furthermore, do

is

circumstances,asit

diarrhoea.

Keep

result.

not

can

drink

the

cause

oil

under

vomiting

any

and

A

CAUTION

•

Maintenance

chine

(S)

• Ask

o

• Turn off

A

should

technician.

your

cian to

tionofthe

power cord from the wall outlet at the follow

ing times, otheryrise

carry

the

ifthetreadle is pressed by

result

in injury.

•

When

and

•

When

the

•

When

keep

switched

tia.

starting

carrying

maintenance

replacing

rotary

usingaclutch

turning

Wait

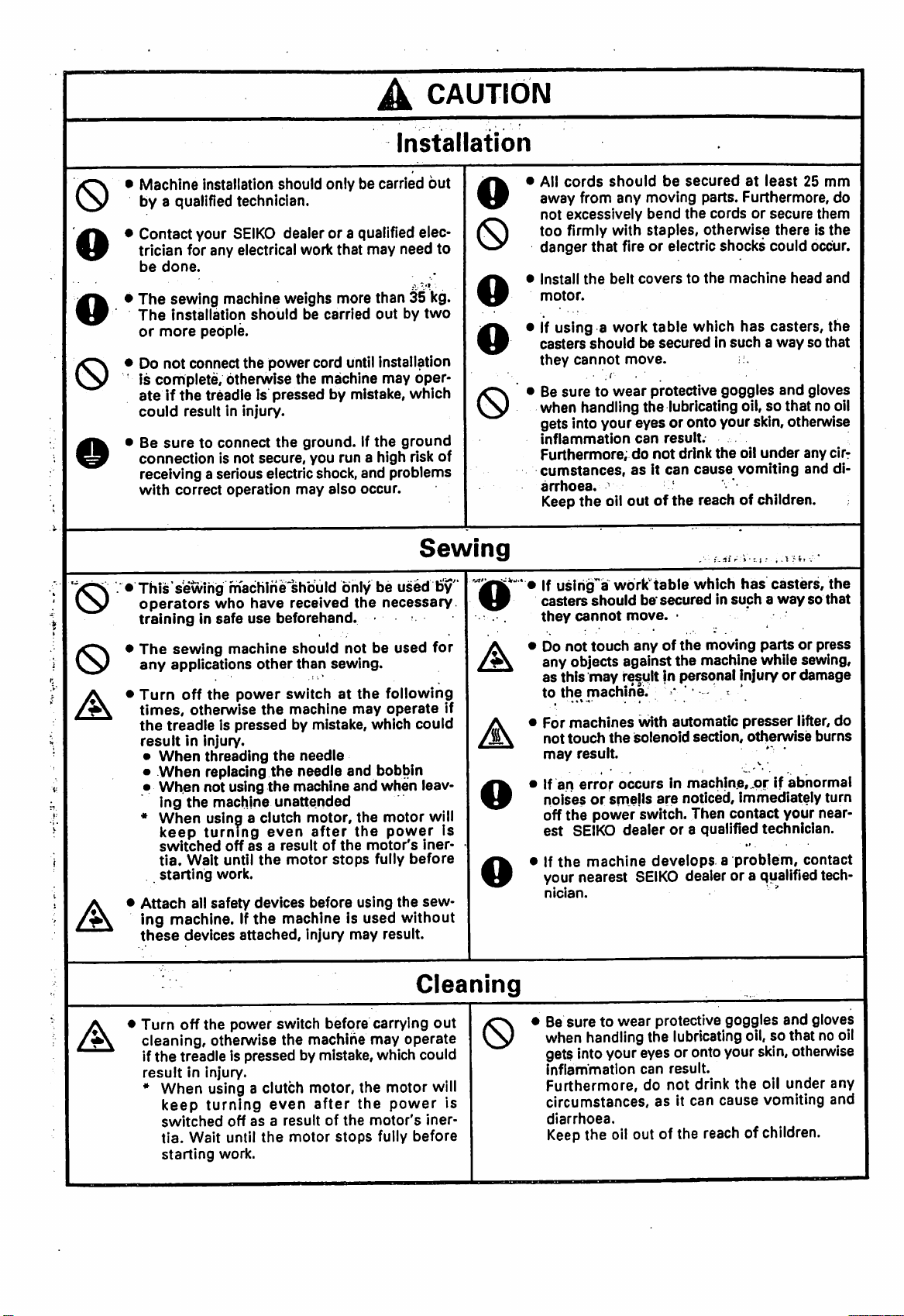

Q] Warning labels

and

inspection of

only be carried

SEIKO

electrical

work.

dealer or a qualified electri

out

any

power

switch

out

consumable

hook

even

offasa

until

the

Maintenance

the

sewing

out

by a qualified

maintenance

system.

and

the

machine

mistake,

inspection,

..

motor,

after

resultofthe

motor

disconnect

may

parts

the

the

motor's

stops

and

which

adjustment

motor

power

fully

ma

inspec

the

operate

cbutd

such

as

will

iner

before

is

and

A

O

O

•A,-

Inspection

• If

the

power

carrying

careful to

• Use only the proper replacement parts as speci

fied by SEIKO.

any

• If

absolutely

nal

positions

rectly

• Any

problemsinmachine

sult

from

•machine will

switch

out

some

observe

safety

before

devices

suretoreinstall

and

using

unauthorized

notbecoveredbythe

needstobe

adjustment, be extremely

all

safety

have

check

that

the

machine.

modifications

left on

precautions.

been

removed,

themtotheirpagi

they

operate

operation

which re

warranty.

when

cor

to

the

be

* The following warning labels appear on the seWlhg machine.

Please follow the instructions on the labels at all times when using the machine. Ifthe labels have been re

movedorare

1

A

Safety

difficult to read, please contact your nearest

A

CAUTION

Moving

parts

maycause

Operate

Tum

threading,

andneede,

devices

Injury.

with

safety

changing

cleaning

dewces.

bobbin

etc.

offmain switch before

SEIKO

i

dealer.

•

Directionofoperation

• Be

sure

the

run

to connect

ground

the

shock.

riskofreceiving a serious

If

you

electric

the

connectionisnot

ground.

O Finger guard

O Thread take-up cover

O Belt cover, etc.

secure,

1.

NAMES

2.

MACHINE

3.

WORK

3-1.

3r2.

4.

INSTALLATION

4-1.

4-2.

4-3.

4-4.

OF

MAJOR

SPECIFICATIONS

TABLE

Work

Table

Motor

Installing

Installing

installing

Adjusting

4-5. Installing the bejt

4-6.•Installing

4-7.

Installing

4-8.

Installing

4-9.

Ground

4-10.

Lubrication

4-11.

Checking

rotating

4-12.

Test

5.

PREPARATION

5-1.

Removing

Winding

5-2.

5-3.

Threading

5-4. Installing

5-5.

Threading

5-6.

Adjusting

wire

direction

operation

AND

the

the

the

the

the

the

the

cotton

connections

the

BEFORE

the

the

lower

the

the

needle

the

the

PARTS

MOTOR

oil

pan

machine

knee

knee

bobbin

belt

machine

bobbin

lower

upper

stitch

head

lifter

assembly.....

lifter 5

winder

cover

stand

pulley

SEWING

case

thread

thread

thread

length

7^.^^

CONTENTS

1

7. THREAD

1

2

8. STANDARD

2

2

3

3

4

5

5

6

6

8

9

9

9

10

11

11

11

12

12

13

13

9.

10.TROUBLESHOOTIN

TENSION

7-1. Adjusting

7-2. Adjusting

8-1. Adjusting

8-2. Adjusting

and

angle

8-3. Adjusting

8-4.

Adjusting

feed

mechanism

8-5.

Adjustirig

rotary

hook

8-6. Adjusting

8-7.

Adjusting

8-8.

Adjusting

the

forward

lengths

8-9.

Adjusting

8-10.

Adjusting

arid

presser

8-11.

Adjusting

lubrication

8-12.-

Adjusting

CLEANING

the

the

thread

presser

tension

foot

ADJUSTMENTS

the

the

the

the

presser

feed

needle

needle

foot height 16

dog

bar

and

timing

the needle and

timing

the

arm

the

and

the

the

foot21

the

amount..

the

..................... 19

thread

difference

tension

walking

rotary

oil

tension

thread

guide

backtack

release.......

foot

hook

pump

G 25

pressure..

.; 16

height

height^... 18

spring..

R 20

between

stitch

15

15

15

17

16

19

20

20

22

22

23

6.

SEWING

14

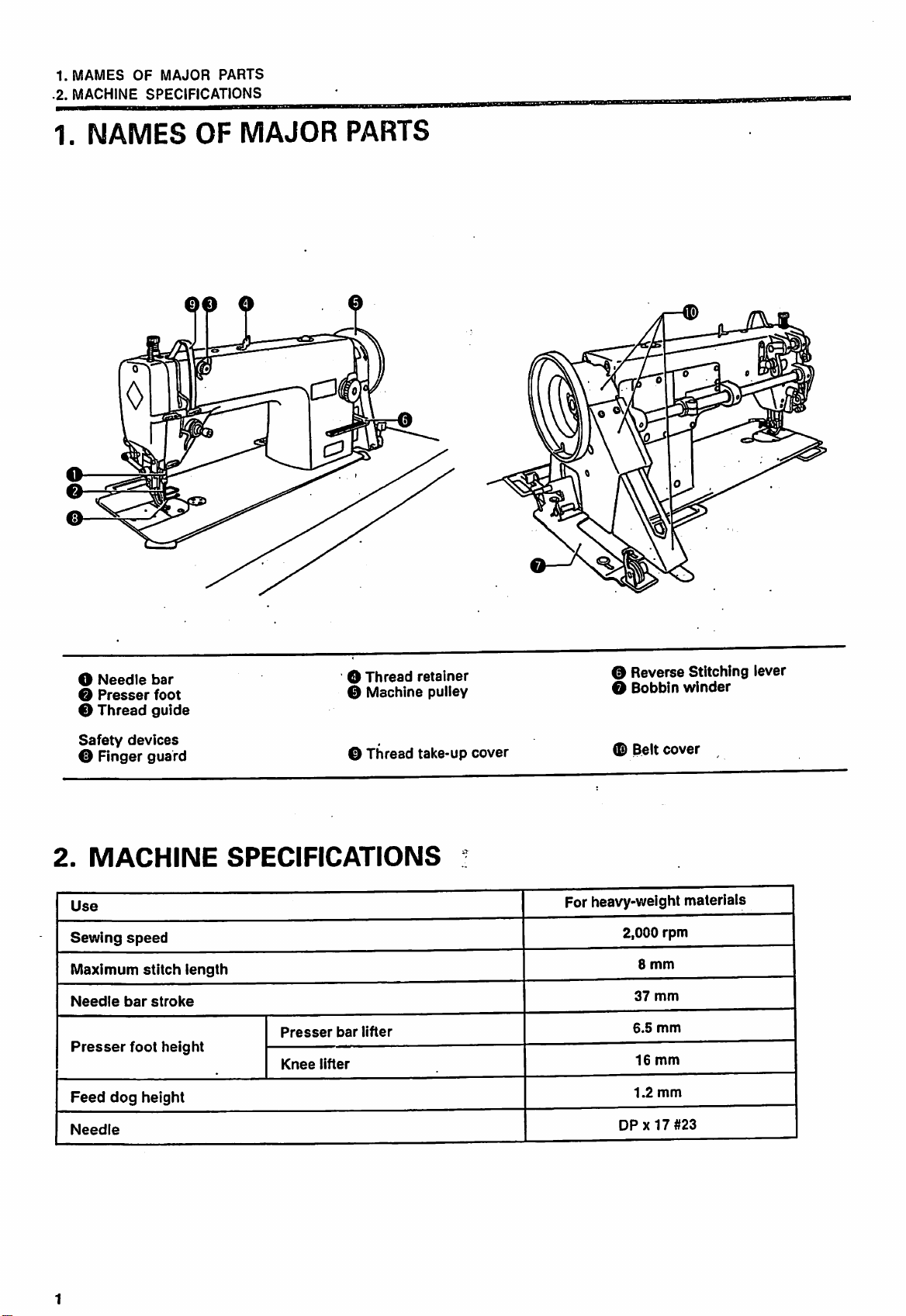

1.MAMES

.2.

MACHINE

1.

NAMES

OF

MAJOR

SPECIFICATIONS

PARTS

OF

MAJOR

PARTS

O

Needle

O

Presser

O

Thread

Safety

O Finger

2.

MACHINE

Use

Sewing

Maximum

Needle

Presser

Feed

dog

Needle

bar

guide

devices

guard

speed

stitch

bar

stroke

foot

height

foot

height

SPECIFICATIONS

length

Presser

Knee

lifter

O

0

0

bar

Thread

Machine

Thread

lifter

retainer

pulley

take-up

cover

0

Reverse

O

Bobbin

0

Belt

Stitching

winder

cover

For heavy-weight materials

2,000

rpm

8

mm

37

mm

6.5

mm

16

mm

1.2

mm

DPX17

#23

lever

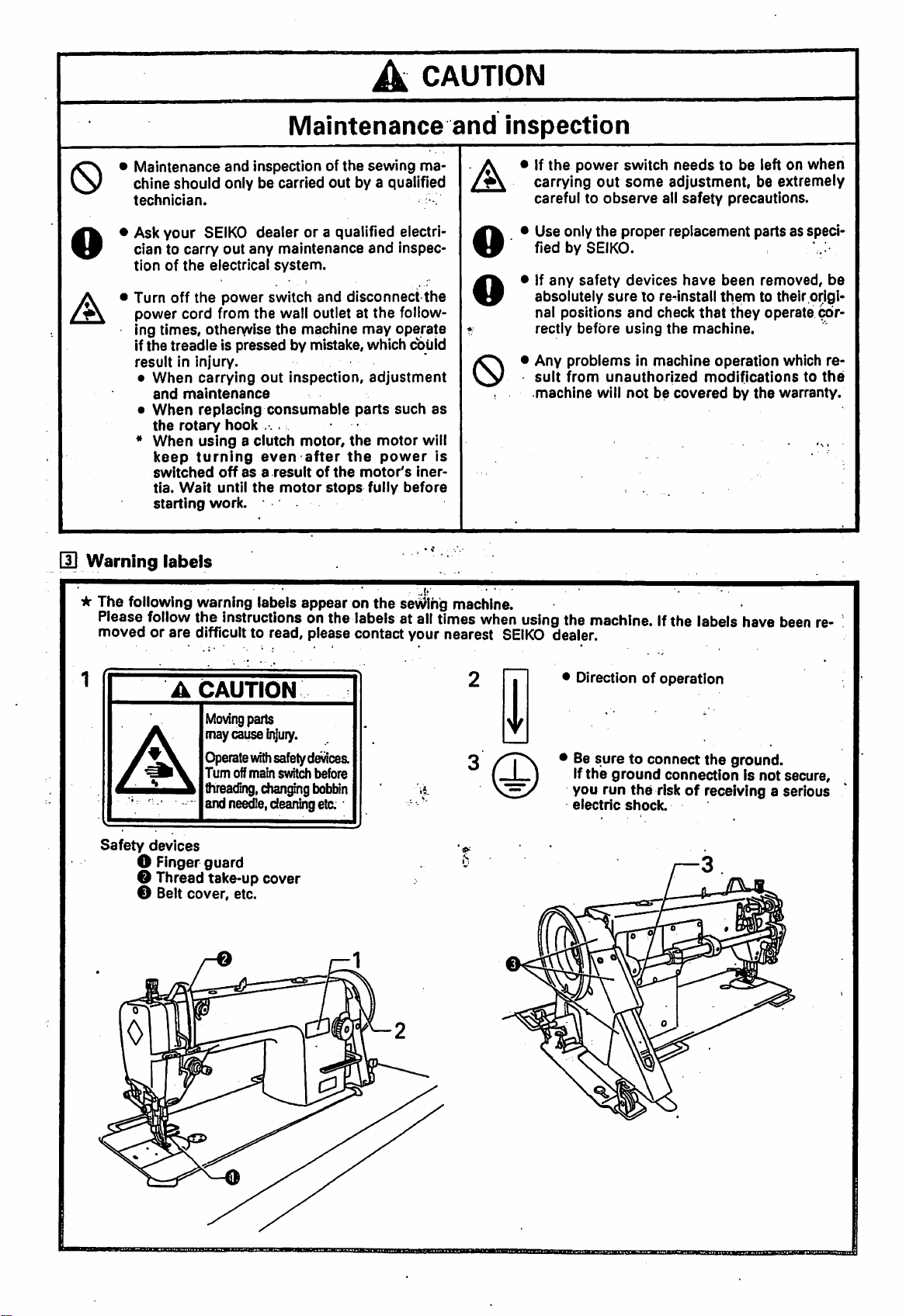

3.

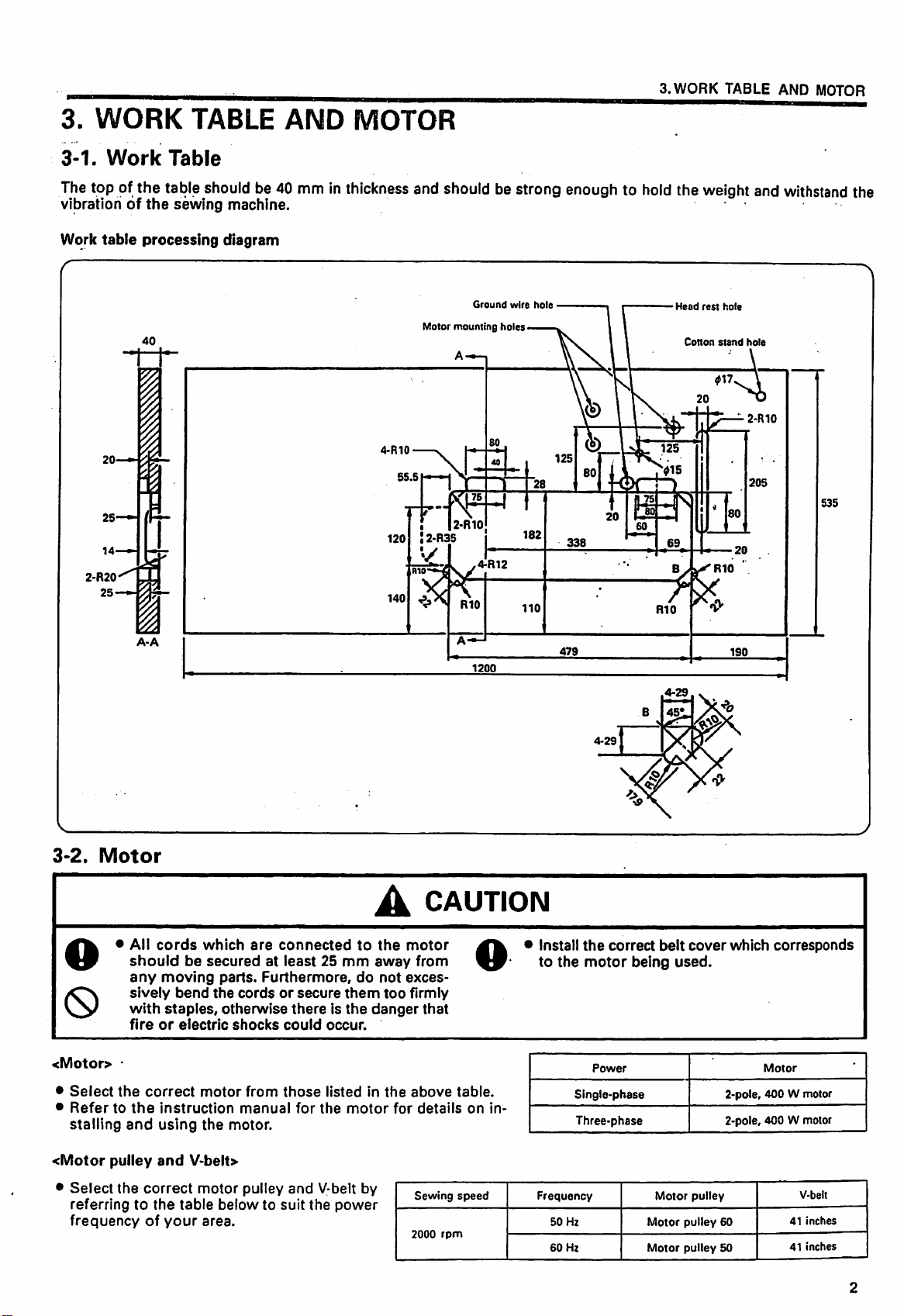

WORK

3-1.

Work

The

top of the table should be 40 mmin

vibrationofthe

Work

table

processing

TABLE

Table

sewing

machine.

diagram

AND

MOTOR

thickness

and should be strong enoughto

Motor

Ground

mounting

wire

holes.

hole

3. WORK TABLE AND MOTOR

hold

the

Head

weight

rest

Cotton

hole

stand

and

hole

withstand

the

3*2.

2-R20

Motor

4-R10

2-R3S

2-R10

4-R12

4-29

vvi

B

45*^

X

2-R10

•

All

O

should

any

sively

0

<Motor>

•

Select

•

Refer

stalling

<Motor

•

Select

with

fireorelectric

•

the

to

the

and

pulley

the

correct

referringtothe

frequencyofyour

cords

moving

bend

staples,

correct

instruction

using

and

which

are

connected

be

securedatleast25mm

parts.

Furthermore,

the

cordsorsecure

otherwise

motor

the

motor.

shocks

manual

from

thereisthe

could

those

for

V-belt>

motor

pulley

and

table

belowtosuit

area.

them

occur.

listedinthe

the

motor

V-belt by

the

power

A

to

away

do

danger

CAUTION

the

motor

from

not

exces

too

firmly

that

above

for

details

Sewing

2000

table.

speed

rpm

on

o

Install

the

correct

to

the

motor

in

Single-phase

Three-phase

Frequency

50

Hz

60

Hz

being

Power

belt

Motor

Motor

Motor

cover

used.

pulley

pulley

pulley

which

corresponds

Motor

2-poie,

400

W motor

2-pole, 400 W motor

V-belt

41

60

50

inches

41

inches

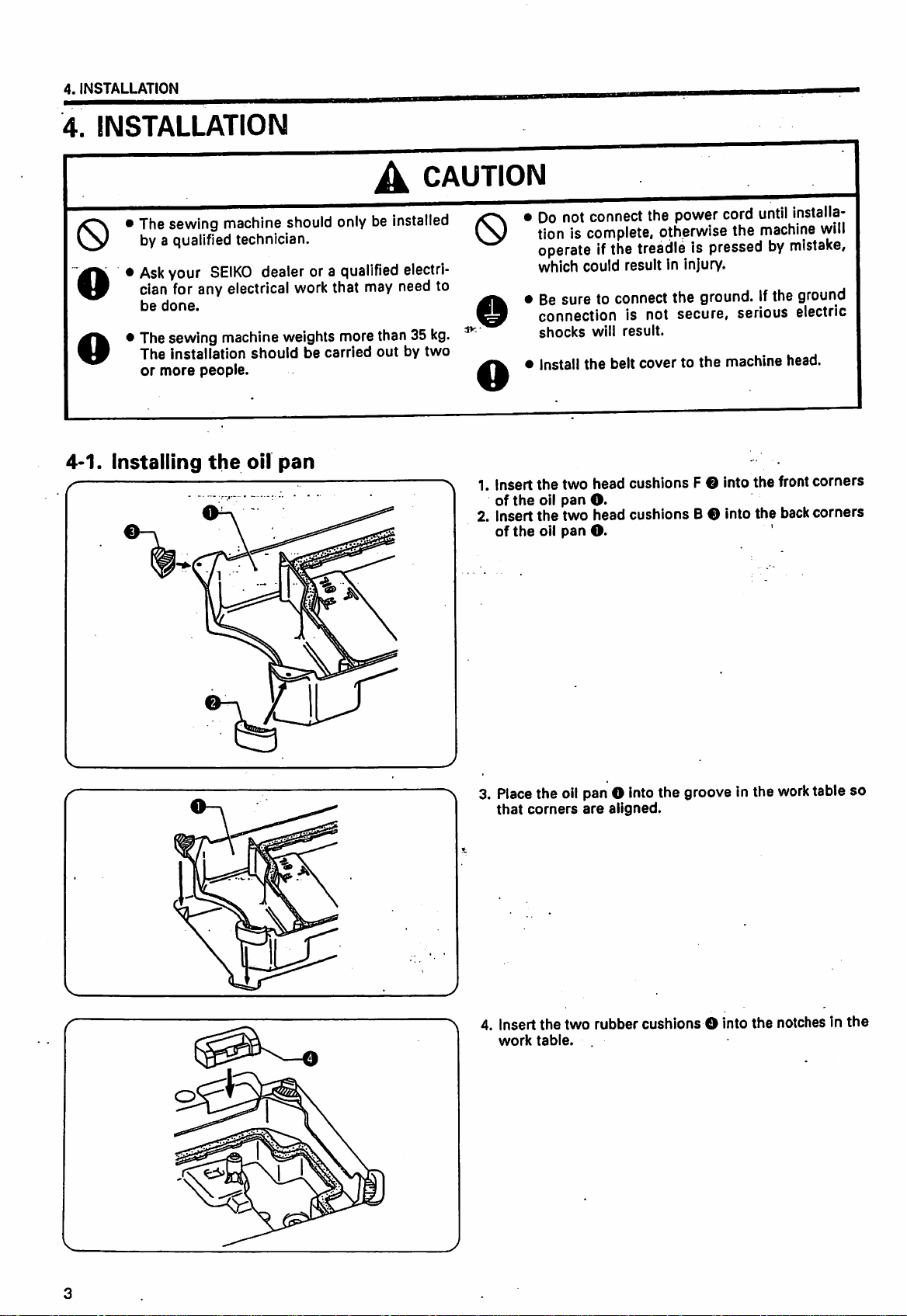

4.

INSTALLATION

4.

INSTALLATION

4-1.

r

A

by a qualified technician.

•

Ask

your

SEIKO

cian for any electrical workthat may need to

be

done.

• The sewing machine weights more than 35

The

Installation

or

more

people.

Installing

{

^

-

---V-

VI

the

dealer or a

shouldbecarried

oil

pan

qualified

-

outbytwo

CAUTION

(S)

electri

o

kg.

o

\

1. Insert

of

the

2. Insert

of

the

•

Do

not

connect

tioniscomplete,

operateifthe

which

could result in injury.

•

Be

sure to connectthe ground. Ifthe ground

the

power

otherwise

cord

the

until

installa

machine

treadleispressedbymistake,

connection is not secure, serious electric

shocks

• Install the belt cover to the machine head.

the

oil

the

oil

will

result.

two

head cushions F O into

pan

O.

two

head

pan

cushions

O.

B 0 into

the

the

front

back

will

corners

corners

V

(

nlL-—

V

J

3. Place the oil pan O into the groove in the worktable so

that

4. Insert

work

corners

table.

the

two

are

rubber

.

aligned.

cushions

O into

the

notches in

the

V

J

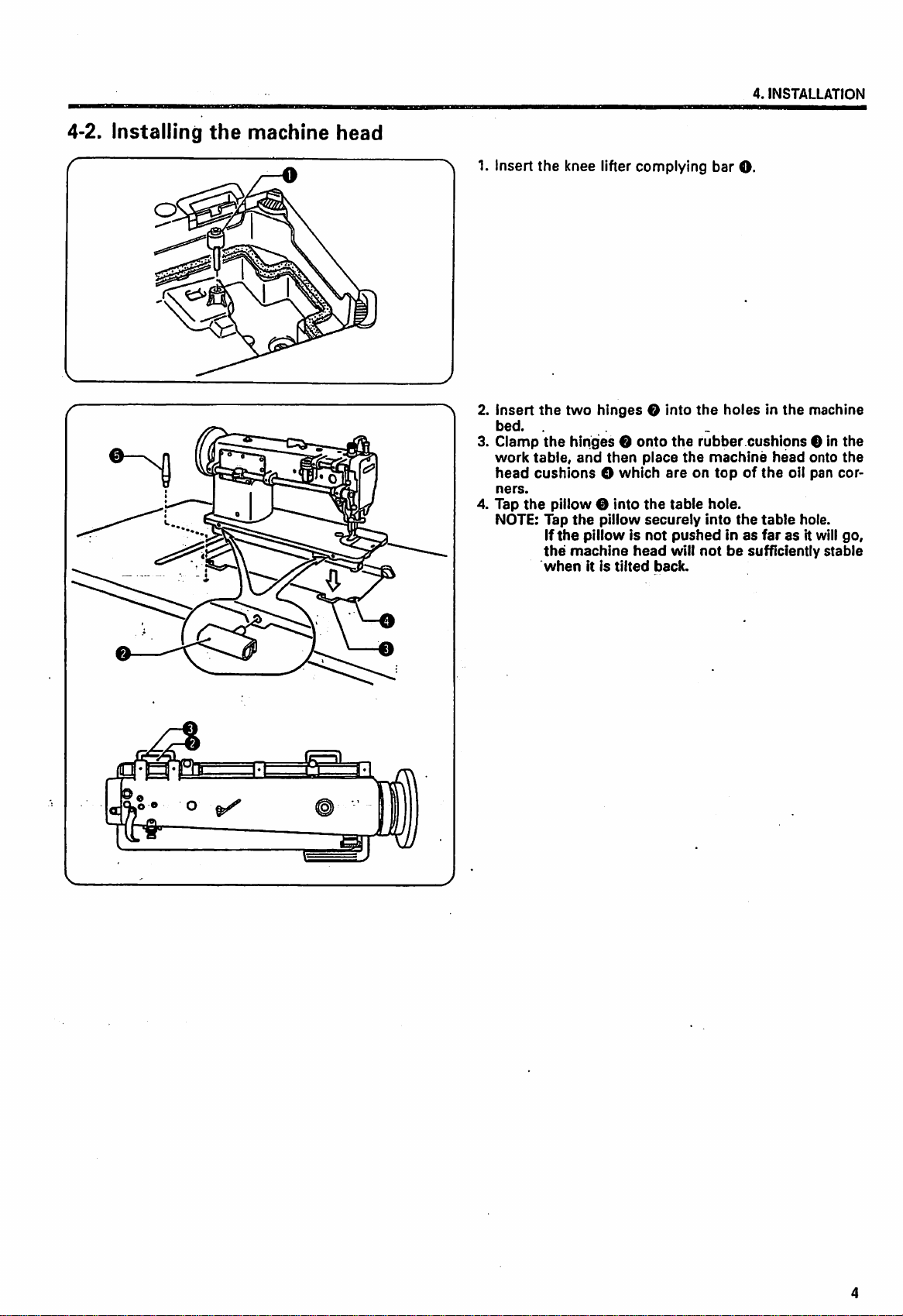

4-2.

Installing

the

machine

head

4.

INSTALLATION

1. insert

2.

insert

bed.

3.

Clamp

work

head

ners.

4.

Tap

NOTE:

the

knee lifter complying

the

two

hingesOinto

the

hingesOonto

table,

and

then

cushionsOwhich

the

pillowOinto

Tap

the

pillow

If

the

pillowisnot

the

machine

whenitis

tilted

the

the

rubber

place

the

areontopofthe

the

table

securely

pushedinas

head

will

notbesufficiently

back.

bar

O.

holesInthe

cushions

machine

hole.

into

the

machine

0 in

head

onto

oil

pan

table

hole.

farasit will

stable

the

the

cor

go,

4.

INSTALLATION

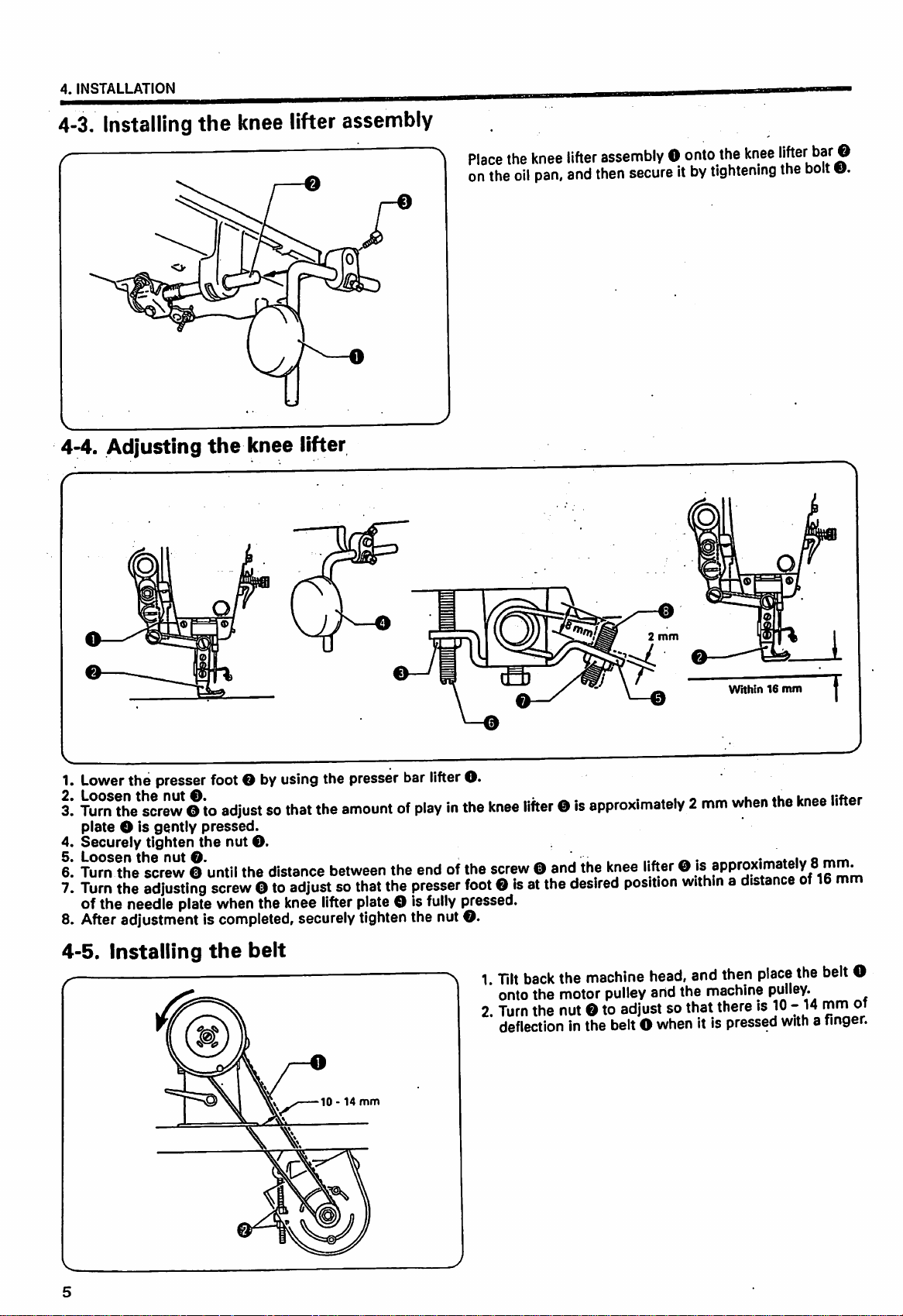

4-3.

Installing the

V.

4-4. Adjusting

knee

the

knee lifter

lifter assembly

Place

on

the

the

oil

knee

pan,

lifter

assembly0onto

and

then

secureItby

the

knee

tightening

'ijter

the

bar

bolt

©

O.

1.

Lower

3.

Turn

plate

4.

Securely

6.

Turn

7.

Turn

of the needle platewhen the knee

8. Afteradjustment is completed, securelytightenthe nut©.

4-5.

the presser footO byusing the presser bar

the^screw©to

O is

gently

tighten

the

screw©until

the

adjusting

Installing

adjustsothat

pressed.

the

nut

©.

the

screw©to

the

belt

the

distance

between

adjustsothat

lifter

amountofplayInthe

plate

the

the

O is

presser

lifter

O.

endofthe

foot©isatthe

fully

pressed.

knee

lifter©Is

screw©and

1.

Tilt

back

onto

the

2.

Turn

the

deflection

2

mm

Within16mm

approximately

the

knee

lifter

desired

the

motor

nut

inthe beltO whenit is pressed

position

machine

pulley

©to

adjustsothat

2

mm

when

© f

withinadistanceof16

head,

and

then

andthe

machine

there

the

knee

place

the

belt

pulley.

10-14mmof

withafinger.

lifter

m

O

14

mm

Loading...

Loading...