Page 1

Operating

Instructions

For

CH

CH-2B

CH-2B/DF

CH-6B

CH-7B

CH-8B

Series

CH-2-RF

<f

h

SEIKO

SEWING

TOKYO•JAPAN

MACHINE

CO.,

LTD.

Page 2

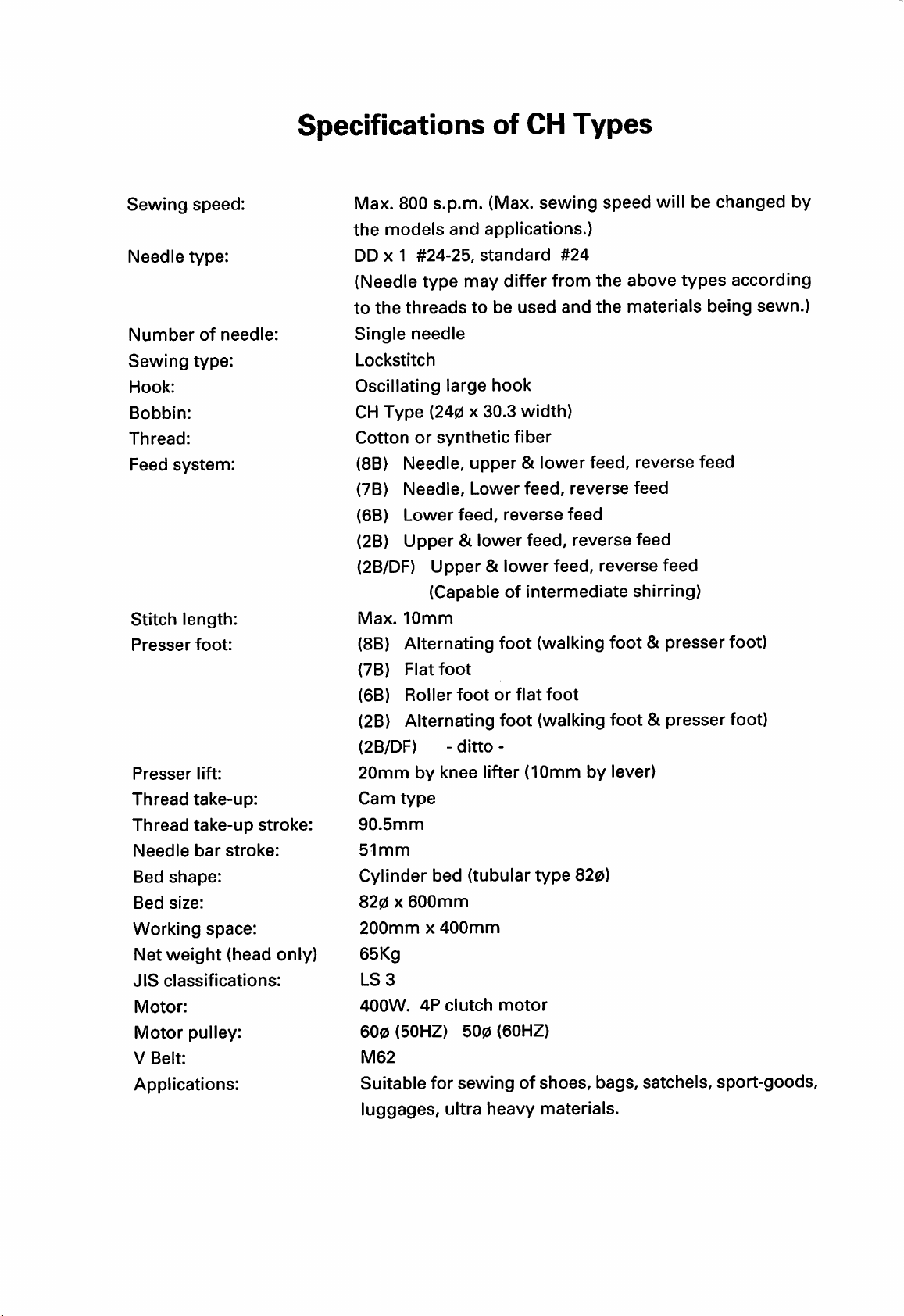

Specifications

of

CH

Types

Sewing

Needle

Number

Sewing

Hook:

Bobbin:

Thread:

Feed

Stitch

Presser

Presser

Thread

Thread

Needle

Bed

Bed

Working

Net

JIS

Motor:

Motor

V

speed;

type:

of

type:

system:

length:

foot:

lift:

take-up:

take-up

bar

shape:

size:

space:

weight

classifications:

pulley:

Belt:

Applications:

needle:

stroke:

(head

stroke:

only)

Max. 800

the

models

DD X 1

(Needle

to

the

Single

Lockstitch

Oscillating

CH

Type

s.p.m.

and

applications.)

#24-25,

type

standard

may

threadstobe

needle

large

(240 x 30.3

Cottonorsynthetic

(SB) Needle,

(7B)

(6B)

(2B)

Needle,

Lower

Upper&lower

(2B/DF)

upper&lower

Lower

feed,

Upper&lower

(Capableofintermediate

Max.

10mm

(SB) Alternating

(7B)

Flat

foot

(6B)

Roller

footorflat

(2B) Alternating

(2B/DF)

20mm

Cam

90.5mm

51mm

Cylinder

820X600mm

200mm

65Kg

LS3

400W.

6O0(5OHZ)

M62

Suitable for

luggages,

by

type

-

ditto

knee

lifter

bed

(tubular

x

400mm

4P

clutch

5O0(6OHZ)

sewingofshoes,

ultra

(Max.

differ

used

hook

width)

fiber

reverse

foot

foot

-

motor

heavy

sewing

#24

from

and

feed,

reverse

feed

feed,

reverse

feed,

(walking

foot

(walking

(10mm

type

materials.

speed

the

the

feed,

will

above

types

materials

reverse

feed

be

changed

being

feed

according

sewn.)

feed

reverse

feed

shirring)

foot&presser

foot&presser

by

lever)

foot)

foot)

820)

bags, satchels, sport-goods,

by

Page 3

Contents

1 Lubrication 1

2 Needle 1

3 Thread 1

4 Insertion

and

Removal 2

5 Winding the Bobbin Thread 3

6 Upper Threading 3

7 Tension of Bobbin Thread and Needle Thread 4

Adjusting Needle Thread Tension 4

Adjusting Bobbin Thread Tension 4

8 Pressure of Presser Foot 5

9 Adjustmentof Stitch Length 5

10 Timing of Thread Tension Releasing Mechanism 6

11

Removal of Shuttle Race Body 6

12 Adjusting on

(A)

(B)

(C)

(D)

the

Each Points 7

Adjusting Needle Position Against Needle Hole of 7

the

Feed

Dog

{7B & 8B

Types)

Adjusting of Feed Dog Height 7

Adjusting theForward and Backward Position of q

Needle

BarFrame

Timing of Needle and Hook 8

13

14

CH-2B/DF

a. Use of

b. Adjusting Upper Feed Length Against Lower Feed 11

CH-2-DF

Positioning of

Adjusting

Adjusting

needle

the

height of needle bar 9

the

position of

and

tip of

the

Clearance between needle

Each timing for up/down strokes of

foot

the

Length

Adfusting

Adfudting

Positioning

Adjustment

Adjusting

(2B & SB

Differential Feed Mechanism 10

Types

Upper

Lower

Up/Down

Feed

Feed

Upper

only)

Length

Length 12

Feed

Dog 13

Amount

the

hook 9

tip of hook 9

and

tip of hook 9

presser

of

Upper

Feed

10

11

11

14

14

Positioning

presser

Bar

15

Page 4

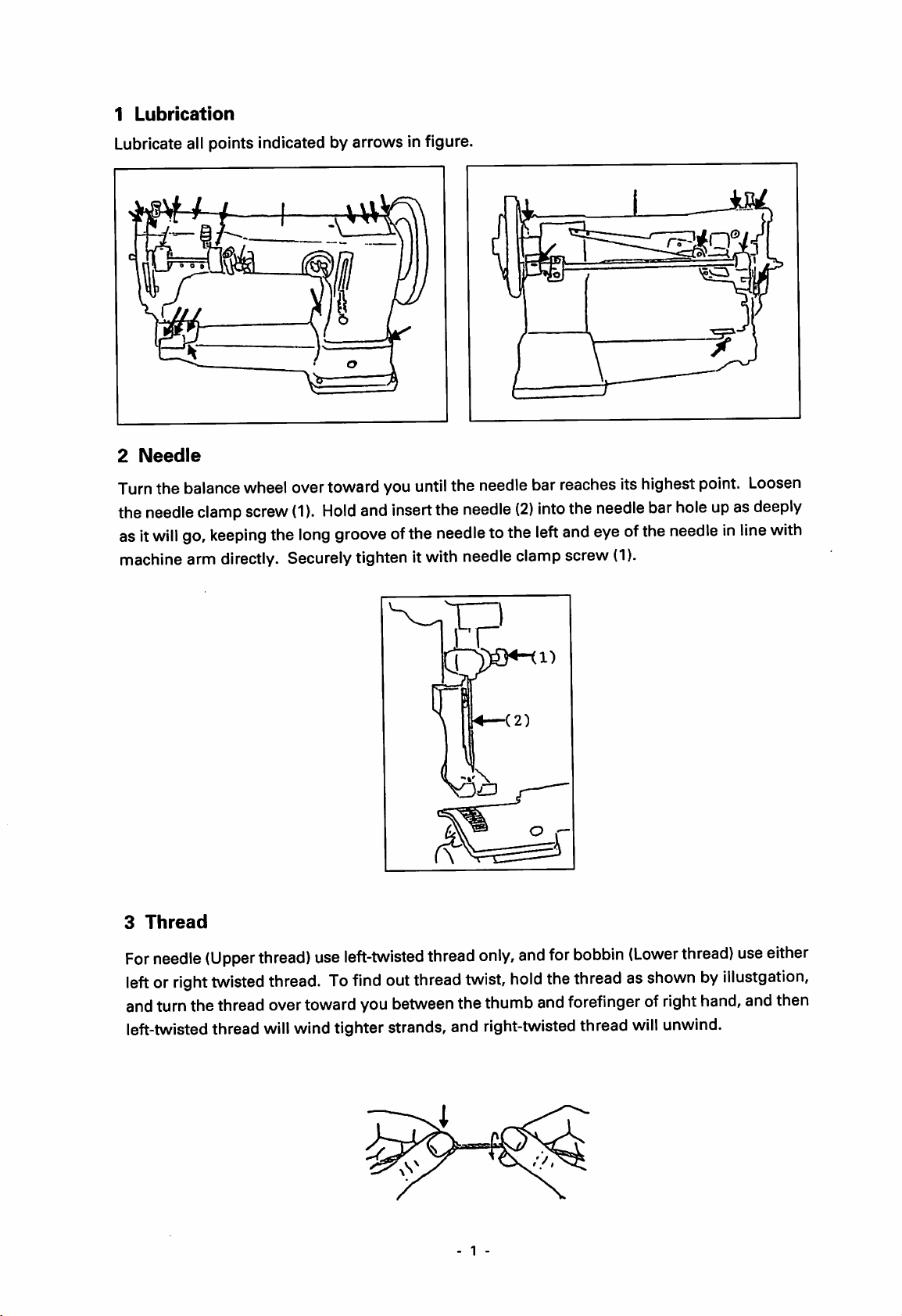

1

Lubrication

Lubricate all points indicated by arrows in figure.

2

Needle

Turnthe balance wheel over toward you untilthe needle bar reaches its highest point. Loosen

the

needle

asit

machine arm directly. Securelytighten itwith needle clamp screw

will

clamp

go,

screw

keeping

the

(1).

long

Hold

groove

and

insert

ofthe

the

needle

needle

(2)

tothe

into

left

the

and

needle

bar

eyeofthe

(1).

holeupas

deeply

needleinline

with

3

Thread

For

needle

leftorright

andturnthe thread overtowardyoubetweenthe thumbandforefinger of

left-twistedthread

(Upper

twisted

thread)

will

use

left-twisted

thread.

To

find

wind tighter strands, and right-twistedthread

out

thread

thread

only,

twist,

1 -

and

hold

for

bobbin

the

threadasshownbyillustgation,

(Lower

will

thread)

right

hand,andthen

unwind.

use

either

Page 5

4

Insertion

§

RemovalofBobbin

and

Removal

of

Bobbin

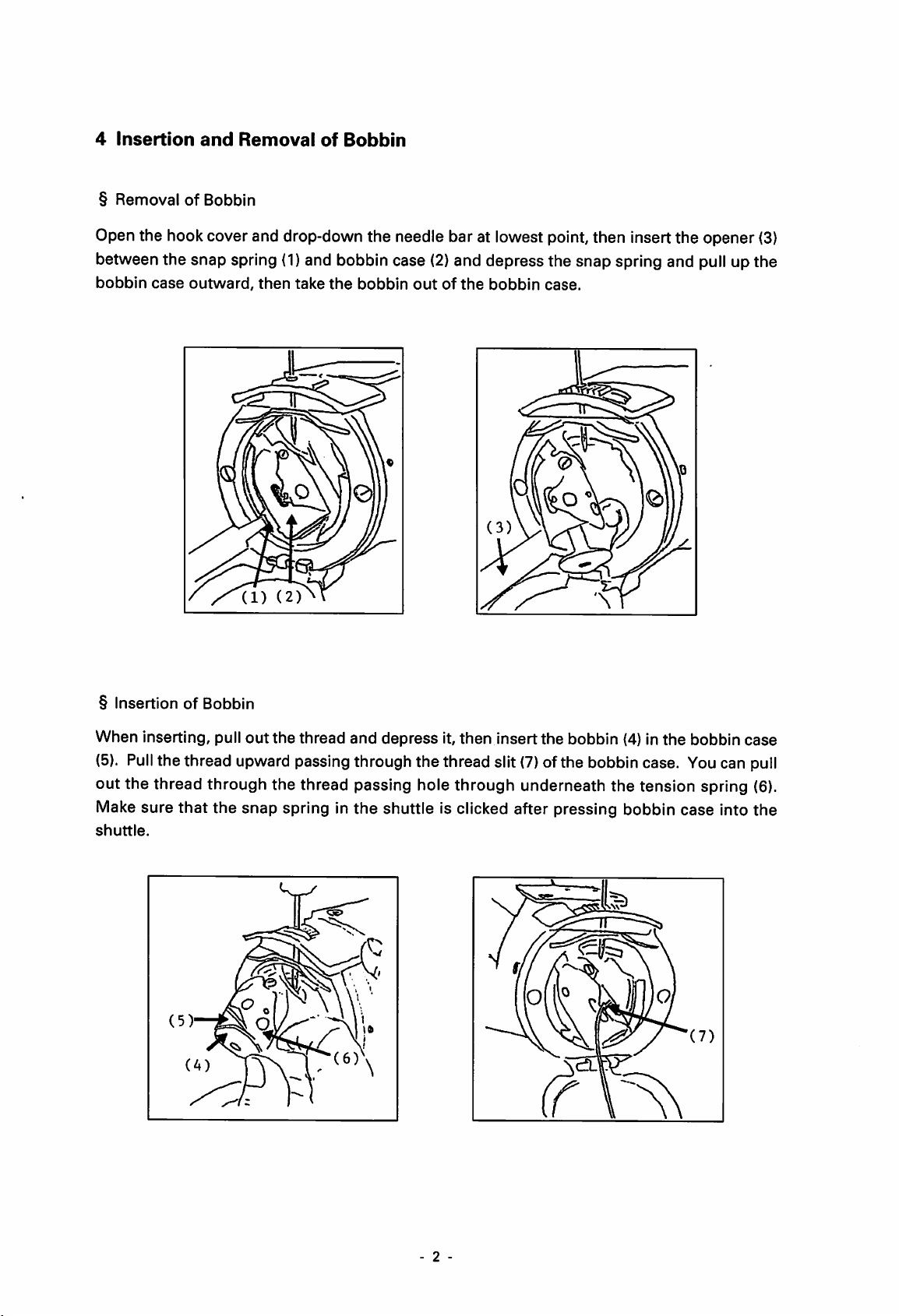

Open the hook cover and drop-down the needle bar at lowest point,then insert the opener (3)

between the snap spring

bobbin

case

outward,

then

(1)

and bobbin case

take

the

bobbin

(2)

and depress the snap spring and pull up the

outofthe

bobbin

case.

§

InsertionofBobbin

When inserting, pull

(5).

Pull

the thread upward passing through the thread slit

out

the

thread

and

depress

it,

then

insert

the

bobbin (4) in

(7)

of the bobbin case. Youcan pull

the

bobbin

case

out the thread through the thread passing hole through underneath the tension spring (6).

Make sure

shuttle.

that

the snap spring in the shuttle is clicked after pressing bobbin case into the

2 -

Page 6

5

Winding

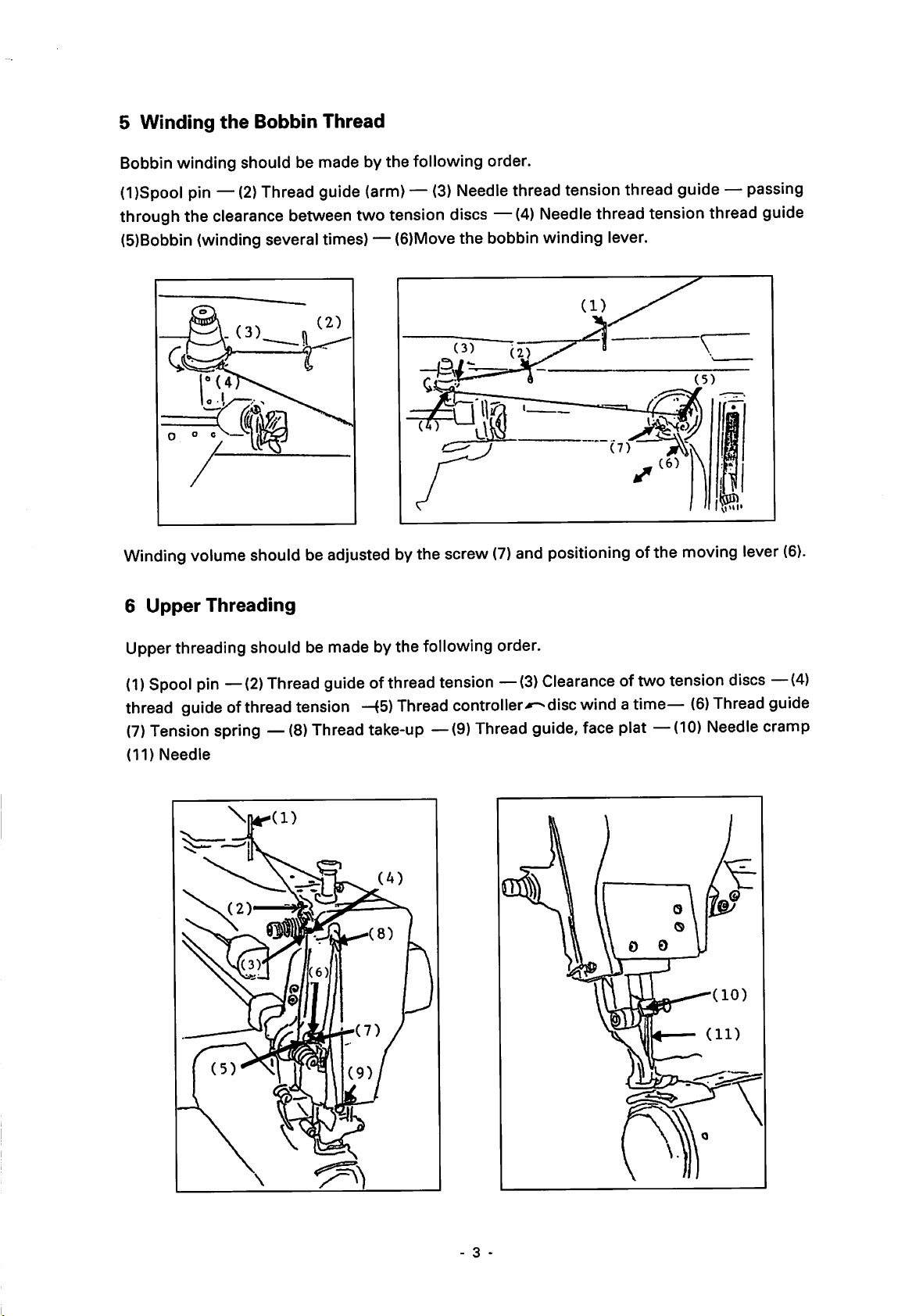

Bobbin winding should be made by the following order.

the

Bobbin

Thread

(l)Spool pin —

(2)

Thread guide

(arm)—(3)

Needle

thread tension thread guide — passing

through the clearance betweentwo tension discs —(4)

(5)Bobbin (winding several times) — (6)Move

Winding

6

Upper

volume

Threading

shouldbeadjusted

bythe

the

bobbin winding lever.

screw

(7)

and

Needle

thread tension thread guide

A

positioning

ofthe

moving

lever

(6).

Upper threading should be made bythe following order.

(I)

Spool

thread guideofthreadtension

(7)

Tensionspring —

(II)

Needle

pin

—(2)

\|1^(1)

Thread

guide

ofthread

—(5)

(8)

Thread take-up —(9)Thread guide, face plat —(10) Needlecramp

Thread

tension

—(3)

controller-*^disc

Clearanceoftwo

wind

a time—

tension

(6)

discs

Thread

—(4)

guide

- 3 -

Page 7

7

Tension

(A)

When stitch tension is well balanced, the bobbin thread is engaged with the needle thread

at

the

center of given material thickness, as

of

12^

Bobbin

Thread

and

Needle

shown

Thread

(A)

(B)

Balanced

by Fig.

Tight

needleofloose

tension

(A)

bobbin

thread

tension

(B) Fig. (B)

(C)

Fig.

shows

(C)

shows unbalanced tension, loose needle thread or tight bobbin thread.

unbalanced

tension,

§ Adjusting Needle Thread Tension

n

To adjust tension of needle thread, turn Tension Regulating

Thumb.

By

increases'-^.

By

tension

tight

turning

turning

decreases-*^.

needle

the

the

thread

(C) Loose

knurling

knurling

or loose

needleortight

nut

clockwise,

nut

counter-clockwise,

bobbin

bobbin

needle

thread.

thread

thread

needle

tension

tension

thread

§ Adjusting Bobbin Thread Tension

To

adjust

Regulating

By

regulating

be

tightened

adjusted.

By

turning

tension

clockwise'^,

loosen

increases,

tensionofthe

Screw.

set

screw

screw

the

(2).

after

tensionofthe

set

screw

The

and

bobbin

thread

bobbin

(1)

clockwise—^,

turning

set

thread,

and

screw

the

tension

turn

adjusting

(1)

should

bobbin

bobbin

set

screw

decreases.

Tension

tension

thread

counter

- 4

exactly

was

thread

Page 8

8

Pressure

By

turning

pressure

Tension

Adjustment

9

regulating

Adjustment

of

Presser

the

pressure

regulating

should

Foot

regulating

thumb

nut

be

of

screw

shouldbetightened

madetosuit

Stitch

Length

thumb

counter-clockwise^^,

for

screw

the

clockwise'-^,

after

pressure

materials

pressure

being

was

sewn.

pressure

decreases.

adjusted.

increase,

and

turning

By pull-up t feed regulating lever (1), reverse stitch is performed, and push-down feed I

regulating

By

turning

(2) & (3)

Knurling

lever

(1),

forward

knurling

counter-clockwise<«^,

nut

(2) & (3)

nut

(2) & (3)

shouldbetightened

stitchisperformed.

clockwise'^,feed

feed

length

increases.

each

other

length

after

decreases,

desired

and

turning

stitch length

knurling

was

determined.

nut

(Note)

When

regulating

should

upward

leverisloosened,

be

tightened.

- 5

&

downward

moving

feed

of

adjustin

the

screw

feed

(4)

Page 9

10 Timing of Thread Tension Releasing Mechanism

(a)When moving the liftinglever (1)for knee

lifter,

upper

(b)

Adjustment

thread

is adjusted to loosen.

Pull-up

the

presser

bar

lifter (3),

clearance

should be made over 1 mm between tip of

the

tension releasing plate

and

then

tighten

tension

releasing

11 Removal of

the

plate.

Shuttle

and

screws

Race Body

tension disc,

(2)

on

the

Tighten the shuttle race back spring screw

screws (2)and remove

(Note)

the

shuttle race body and shuttle hook.

(1),

then loosen and take offthe two shuttle race

In

caseofthe

removal of

shuttle

race body,

U

without tightening of shuttle race back spring

screw

(1),

spring

the

shuttle

shuttle

may

race

run

out

race body.

back

and/or

and

may

shuttle

difficult to

race

back

set

The shuttle race backspring screw (1)is surely

loosened, while the materials are being sewn.

Page 10

12

Adjusting

(A)

Adjusting

Needle

with

(a)

(b)

on

Needle

should

the

feed

Loosen

moving

Loosen

holeoffeed

feed

(push-inorpull

feed

the

Each

Position

be

positionedatthe

dog.

(upper)

(upper)

dog,

then

Points

Against

shaft

out)offeed

shaft

connector

tighten

Needle

centerofneedle

connecting

(upper)

(A)

the

screw

Hole of

screw

shaft

screw

(3).

the

Feed

holeoffeed

(2),

upper

connector

(3),

and

Dog. {7B & 8B

dog

feed

length

(B) (1).

needle

setatthe

Types)

and

moved

will

differbythe

centerofneedle

together

(Needle

setatthe

of

(B)

Taking

The

lowest

In 6B. 2B

The

lowest

dropping

center

the

feed

AdjustingofFeed

off

the

heightoffeed

pointofneedle

types;

heightoffeed

pointofneedle

dog.)

pointisto

of

needle

Dog

needle

in 7B

dogisadjusted

barbyfeed

dogisadjusted

bar.

be

hole

Height

and

(Note)

Feed

(upper)

is

tightened

rightward.

8B.

1.3mm-1.5mm

dog

height

1.3mm

shaft

for

the

adjustable

-1.5mm

connector

(A) (4) is fixed

preventionofthe

above

above

the

surfaceofthe

screw

(1).

the

surfaceofthe

n

and

movingofleftward

throat

troat

the

screw

plate,atthe

plateatthe

(3)

and

RefertoRemovalofShuttle

Race

Body

m

l.Smm

-

1.5nim

- 7

Page 11

(C) Adjusting

the

Forward

and

Backward Position of Needle Bar Frame

Correct position

between

presser

between

bar

and

needle

needle

bar

bar

being

frame

and

16mm

Adjustment

needle

baristobemade

presser

under

of

the

barisdeterminedbythe

the

stitch length being "0"

clearance

by

between

the

screws

presser

(1).

distance

mm.

bar

and

(D)

TimingofNeedle

Positioningofneedle

When

should

Adjusting

Loosen

adjust

the

needle

meet

the

the

screwofbar

the

needle

bar

the

center

Distance

the

heightofneedle

bar

and

Hook

and

tipofthe

has

risen

4.5mm-5.5mm

Lineofthe

between

hook

shall

be

bar

connecting

(3)(upward

hook

needle.

U

the

upper

2.5mm-3mm.

stud

(2) by

and

downward.

from

2.5imD~3nn

4.5inD~5.5min

tipofthe

wrench

its

lowest

needle-eye

position,

which inserts to

and

the

the

the

hole (1) of

tipofthe

tip

of

hook

arm

and

Adjusting

Loosen

then

Tighten

the

the

screw

determine

the

screw

positionofthe

(5) of

the

forwardnessorbackwardness

(5)

after

the

shaft

adjustment.

tipofhook

crankbythe

spanner

- 8

which

(high

speedorlow

insertstothe

speed)ofthe

hole

(4) of

the

tipofhook.

head,

Page 12

©

T

Clearance

In 7B & 8B

Loosen

needle

and

needle

rock

the

needle

After

hinge

bar

rock

And,

frame

If

the

resultedinthe

between

types;

the

set

bar

rock

also

the

bar

rock

frame

leftward

bar

determination

stud,

and

frame

put

the

(2),

and

looseness

needle

Determinationofthe

screw

frame

set

screw

frame

and

(1)ofthe

hinge

(7)ofthe

hinge

& rightward-**,

and

adjust

then

position

needle

then

of

breakingofneedle,

the

of

the

put

the

bracket

bar

rock

turn

the

the

leftward&rightward-*-^of

tip

of hook;

needle

stud

(small) (4)

needle

stud

(large)

and

clearance

clearance,

needle

(8).

frame

hinge

balance

stitch

0.05mm-0.3mm

positionofneedle

bar

rock

frame

positioned

bar

rock

frame

(6)torightward

turn

the

balance

between

tighten

bar

wheel

rock

the

frame

stud

(large)

and

tighten

skipping.

needle

set

hinge

(6)tothe

the

hinge

lower

hinge

wheel,

and

screw

stud

the

needle

0.05mm

bar

rock

frame.

stud,

and

partofneedle

stud

(large) (6).

and

also

determines

tipofthe

(2) of

the

(small)

side

faceofthe

each

screws

bar

the

set

bar

Then,

moving

smooth

hook.

needle

(4)toslightly

exactly.

should

happen,

screw

rock

the

bar

needle

(5)ofthe

frame

moving

needle

position

rock

frame

the

needle

bar

it will

(2),

the

bar

of

rock

be

0.3mm

Page 13

Each

timing

a.

Timing

to

feed

you.

Adjsutmentismadebythe

for

up/down

of walking

dog,

after

strokesofpresser

footisadjuted

downing

the

two

foot

walking

foot

leverofpresser

stopper

screwsofcam

(2B & 8B

types

reachtofeed

bar

lifter,

(1) {upward &

only)

dog

turning

before

the

balance

needle-eye

wheel

downward).

reaches

Byup &down the presser cam (upward & downward) fI , walkingfoot against needle is

touchingtofeed

As for 2B

of

the

b.

For

crank

Adjustmentistobemade

throat

the

pinch

type,

setting

dog

speedily

adjusting feed

plate.

walking

screw

(2) is tobeadjusted.

foot

by

and

dog

and

the

slowly.

and

presser

presser

materials

foot

being

foot to

set

equivalent,

sewn.

equivalent

the

lifting

point on

eccentric

the

upper

connection

toward

face

c. Up/down strokes of walking foot and

screw

(3),

the

stroke increases,

downIthe

s

presser

foot is loosened by the screw (3) and up f

screw

(3),

the

stroke

decreases.

the

a.

Useofthe

Pull-down

volume

Pull-down

length.

(e.g..

Lower

Adjusting

Turn

the

Turn

the

Fixed

positionoffeed

Differential

the

the

feed:

Upper

chain

chain

10mm,

Feed

(1),

(1),

Length

Feed

upper

upper

Upper

dial (2) clockwise'-^.,

dial (2)

counter-clockwise-^,

lengthisadjustedbystopper

Mechanism

feed

feed

feed:

upper

volume

length

18mm)

feed

length

upper

increases

increases

decreases.

feed

length

10

(3)

by

maximum

by

maximum

increases.

and

stopper

80%

nut

80%

(4)

against

against

lower

lower

feed

feed

Page 14

b. Adjusting Upper Feed Length Against Lower Feed Length

For adjusting equivalent

Adjustment

Turn

the

Turn

the

(Note)

Over

turningofstopper

that

the

is to be

stopper

stopper

topoffeed

madebythe

screw

screw (3)

adjusting

the

upper feed length against lower feed length.

stopper

(3) clockwise^-'^,

counter-clockwiseupper

screw

(3) &

lever

touch

screw

upper

stopper

with

(3)

and

stopper

feed length increases.

feed length decreases.

nut

(4)

counter-clockwise

the

feed

upper

shaft

nut

(4).

connector.

will

cause

the

troubles

CH-2-DF

© Adjusting Upper Feed Length

1.

Coarse

regardless

stitchofupper

of

lower

feed.

feed

length

canbeperformed

r

(A)

by pull

down

the

lifting

nB

lever

(A),

11

Page 15

2.

Upper

*{C)

*The

feed

position

comes

position

position

shouldbeset

in

contact

of shirring

can

be fixed by (B) & (C).

equivalently

with

(C).

amount

for

the

with

lower

materials

feed

being

length

sewn

on

the

canbeset

condition

by (B). (Fig. a & b)

that

pin

(D)

large

\

^1

3

1

small/ I

rr

II

0

Fig. a

Fig.b

3. In case of unifying of shirring amount and/or general sewing (equivalent with lower feed),

pin (D)

should

be fixed by

pinching

(B) & (C). (Fig. d)

© Adjusting Lower Feed Length

Loosen

turn

the

feed adjusting nuts

them

counter-clockwise,

(A)&(B)

feed

length

and

turn them clockwise, feed length decrease and

increase.

Fig. d

After

pulled

machine

touches

adjustment,

down

on

the

with

plate

the

exactly,

condition

(C).

lever

then

should

operate

that

nut

be

the

(A)

0

Lever

-

12

«

Pull

down

Page 16

©

Adjustment

Loosen

made by

groove

Set

the

change

position (B).

screw

set

screw,

(A)

shouldbetightened

(turn)

adjustment

the

can

be

screw driver

without

any rattle or the leftward & rightward of

the

upper

feed

arm

(C).

@

Wrong

©

Adjusting

Loosen

(8)

^ a

nut

(A),

clockwise,

decrease, turn

up/down

After

tightened

amount

adjustment,

exactly.

Up/Down

turn

the

it^b

increase.

nut

AmountofUpper

adjusting

up/down

counter-clockwise,

(A)

screw

amount

should

be

Feed

(K)

More

than

(A)

(B)

-

14

-

Page 17

© Positioning of

Presser

Bar

Clearance

and

presser

Lay

<E)

(F)

and

Clearance

1,

5mm

between

bar

guide

& (F)onarm,

(G)

should

(H)

should

upper

should

clearance

be

2mm.

be

more

feed

arm

be

1.5mm.

between

than

(C)

3mm.

u

1.

5inni

15

Page 18

SEIKO

SEWING

MACHINE

CO.,

LTD.

Head Office : 11-3,

Show

Room

Osaka

Branch

Show

Room

Telex:

: 21-7,

: 5-10,

: 5-10,

Imado

1-chome,

2657148

Asakusa

Terada-cho

Terada-cho

Talto-ku, Tokyo 111,

SEIKOJCable:

1-chome,

Taito-ku, Tokyo 111,

2-chome,

2-chome,

Japan

SEIKOSEWMCO

Japan

Tennoji-ku,

TennojI-ku, Osaka 543,

Osaka

543,

TOKYO

Japan

Japan

Tel:

03-3872-6173-4

Telefax:

Tel:

Tel:

Tel:

03-3873-6596

03-3872-6493

06-779-7578

06-779-7578

(Export

Dept.)

96033000

<E)

Loading...

Loading...