Page 1

PARTS CATALOGUE / TECHNICAL GUIDE

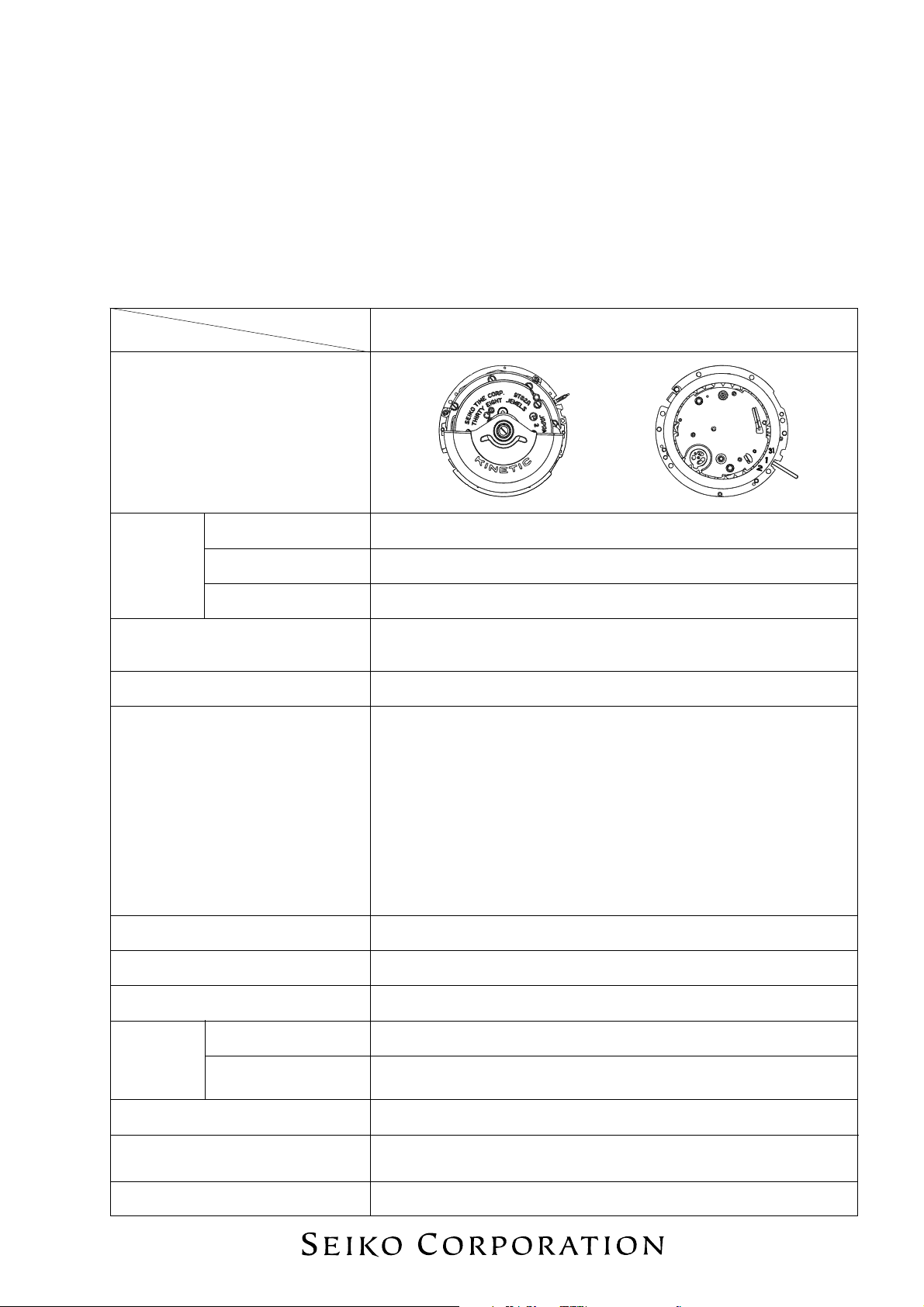

Cal. 9T82A

(For Movement Replacement)

[SPECIFICATIONS]

Cal. No.

Item

Movement

Movement

size

Time indication • Time: Hour, minute and second hands

Driving system Step motor (Load compensated driving pulse type)

Additional mechanism

Outside diameter ø33.0 mm

Casing diameter ø30.0 mm

Height 6.8 mm

• Stopwatch: Stopwatch hour, minute, second and 1/10 second hands

• Automatic generating system

• Stopwatch function with stopwatch hour, minute, second and 1/10

second hands

• Overcharge prevention function

• Energy depletion forewarning function

• Electronic circuit reset switch

• Train wheel setting device

• Date calendar

• Instant setting device for date calendar

• Instant date change mechanism

9T82A

(x 1.0)

Loss/gain Monthly rate at normal temperature range: less than 15 seconds

Regulation system

Measuring gate by quartz tester Use 10-second gate.

Power

supply

Electricity Storage

Unit (E.S. Unit)

Operating voltage range 0.45 V ~ 2.2 V

Duration of charge

Jewels 38 jewels

Logical regulation system

Automatic generating systemPower generator

Titanium lithium ion rechargeable battery

From full charge to stoppage: Approx. 1 month (when the stopwatch

is used for less than 3 hours a day)

1

Page 2

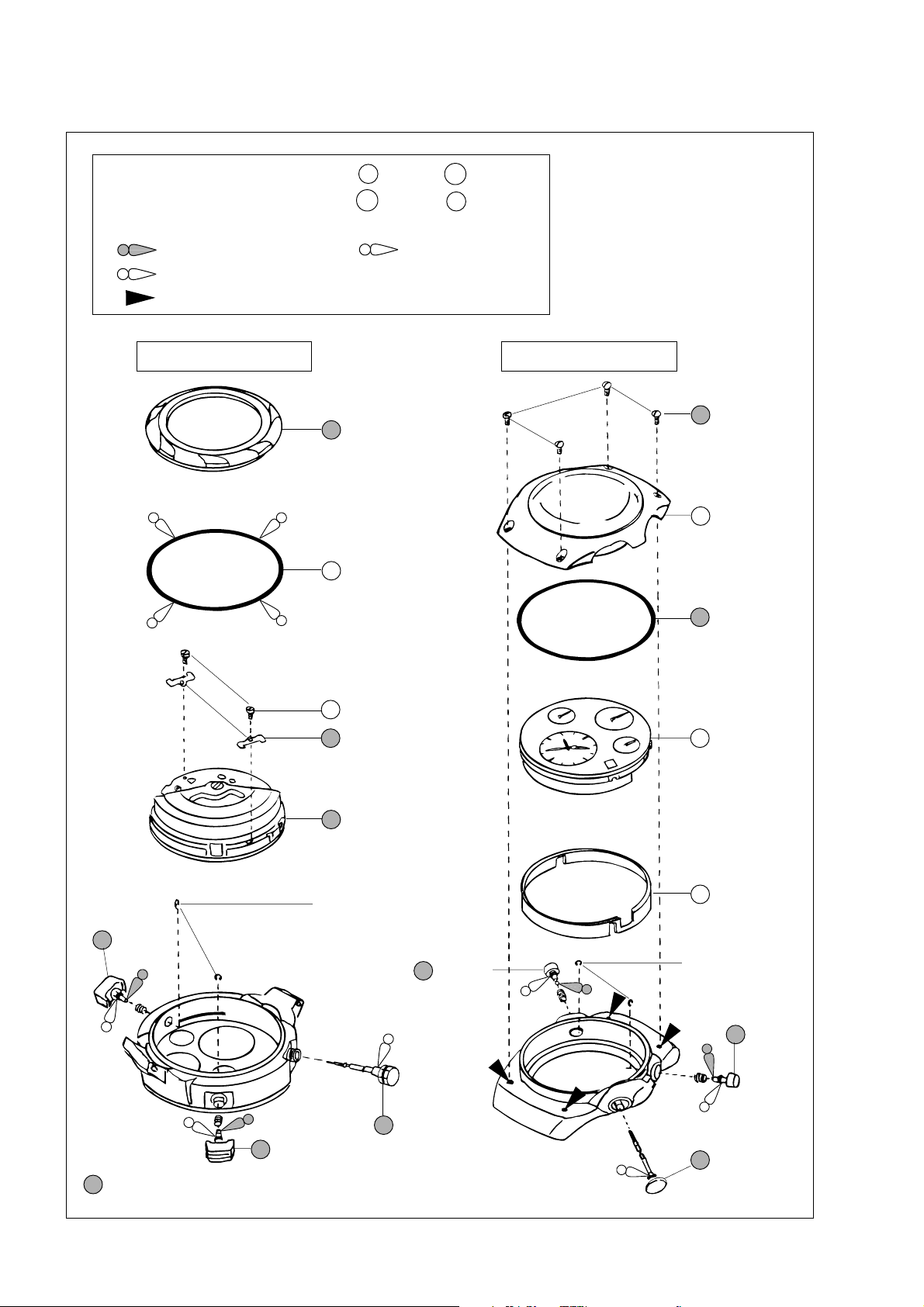

PARTS CATALOGUE

Disassembling procedures Figs. : 1 → 12

Reassembling procedures Figs. : 12 → 1

Lubricating: Types of oil Oil quantity

SEIKO Watch Oil S-6 Normal quantity

Silicone oil 500,000 c.s.

Adhesive (LOCTITE 241)

1 Case back

(page 4)

Cal. 9T82A

One-piece case typeConventional type

1 Bezel screw

(page 5)

2 Bezel

7 Button A

(page 6)

2 Case back gasket

3 Casing clamp screw

4 Casing clamp

(page 4)

6 Movement

(page 5)

Button spring clip

7 Button A

3 Bezel gasket

(page 6)

5 Movement

6 Casing ring

Button spring clip

(page 6)

7 Button B

(page 6)

5 Winding stem

7 Button B

(page 6)

Please see the page shown after the part name.

➡

with crown

(page 5)

4 Winding stem

with crown

(page 6)

2

Page 3

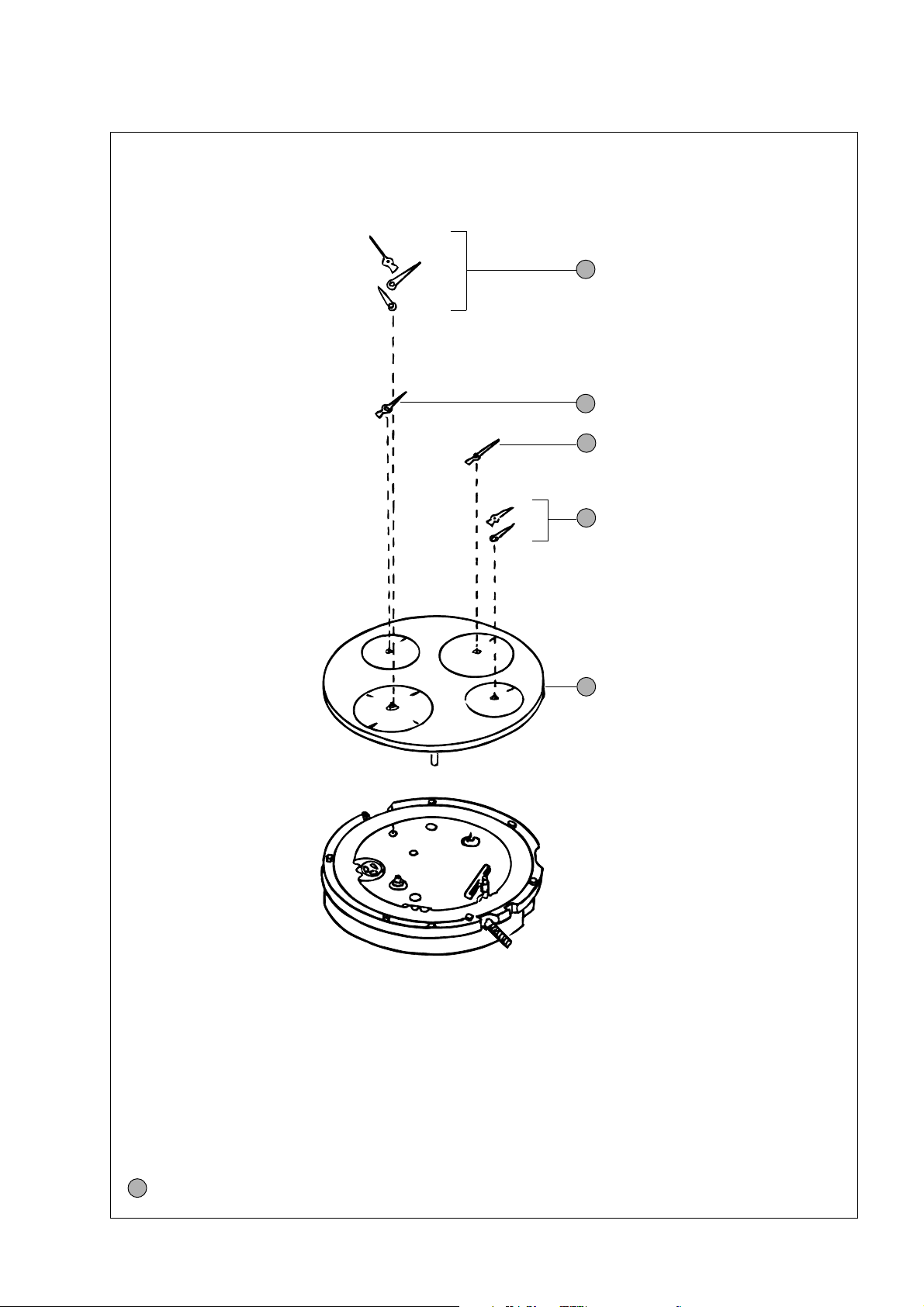

PARTS CATALOGUE

Cal. 9T82A

8 Hour, minute and second hand

(page 6)

9 Stopwatch 1/10 second hand

(page 7)

10 Stopwatch second hand

(page 7)

11 Stopwatch hour and minute hands

(page 7)

12 Dial

(page 7)

* When reassembling the watch, be sure to use a new set of stopwatch hands.

If the old stopwatch hands are reused, they may come off from the shock when they are reset to “0”

position.

Please see the page shown after the part name.

➡

3

Page 4

TECHNICAL GUIDE

I. REMARKS ON DISASSEMBLING AND REASSEMBLING

For conventional type

1 Case back

· To fix the case back to the case, the case back itself is screwed into the case, or the case back screws

are used, depending on models.

· For the models using the case back screws, use the adhesive “LOCTITE 241” to prevent them from

loosening.

Note: Never use an adhesive other than “LOCTITE 241” for fixing the case back screws.

Cal. 9T82A

• How to fix the case back with the case back screws and the adhesive

Case back screw

1. Wipe any adhesive, oil, dust or dirt off the screws and the

holes for screws on the case with alcohol.

2. Before setting the case back to the case, apply a proper

amount of the adhesive to the holes for screws as shown

at right.

3. Set the case back to the case and then, tighten the case

back screws firmly.

* Tighten the screws one by one in diagonal direction.

* After tightening once, give the screws another turn to

fix them securely.

4. Leave the watch untouched at room temperature for

about one day until the adhesive is completely hardened.

Notes:

Adhesive

* Apply only a necessary amount of adhesive to the hole lest it should come out on the case.

* Take care not to let the adhesive stick to the inner surface of the case.

4 Casing clamp

• How to remove

A

Loosen the casing clamp screws at the 3 and 9

o’clock sides and remove the casing clamps.

Case back

Case

Casing clamp

• How to install

Set the casing clamps at the 3 and 9 o’clock positions

as shown in the illustrations at right, and tighten the

B

▼

9 o’clock side

casing clamp screws securely.

Note: The movement is fixed to the case by fitting

B

“A” and “B” portions of the casing clamp

securely in the groove of the case. When

setting the casing clamp to the movement,

therefore, check that “A” and “B” portions

are equally protruded from the movement

▼

A

edge, and then, tighten the casing clamp

screw firmly.

3 o’clock side

4

Page 5

TECHNICAL GUIDE

5 Winding stem with crown

The crown gasket is attached inside the stem pipe of

the case.

• Lubricating

Apply the silicone oil to the portion of the crown as

indicated in the illustration at right. Insert the

winding stem into the stem pipe, and turn the crown

so that the silicone oil is spread thoroughly over the

crown gasket.

6 Movement

When installing the movement into the case, first set its 12 o’clock side to the case and then, other sides.

Otherwise, the movement may not be fitted in smoothly.

For one-piece case type

Cal. 9T82A

1 Bezel screw

• Remarks on the adhesive

· An adhesive is used to fix the bezel screws.

· Be sure to use the adhesive “LOCTITE 241” to fix the bezel screws.

Note: Never use an adhesive other than “LOCTITE 241” for fixing the bezel screws.

• How to fix the bezel screws with the adhesive

1. Wipe any adhesive, oil, dust or dirt off the

screws and the holes for screws on the case with

alcohol.

2. Before setting the bezel to the case, apply a

proper amount of the adhesive to the holes for

screws as shown at right.

3. Set the bezel to the case and then, tighten the

bezel screws firmly.

* Tighten the screws one by one in diagonal

direction.

* After tightening once, give the screws another

turn to fix them securely.

4. Leave the watch untouched at room temperature

for about one day until the adhesive is completely

hardened.

Adhesive

Bezel screw

Bezel

Case

Notes:

* When tightening the bezel screws, use a screwdriver having a flattened tip of a size corresponding

to that of the screws. Take care not to damage the slots of the bezel screws, bezel or case.

* Apply only a necessary amount of adhesive to the hole lest it should come out on the case.

* Take care not to let the adhesive stick to the inner surface of the case.

Lubricating: : Silicone oil 500,000 c.s.

5

Page 6

TECHNICAL GUIDE

3 Bezel gasket

Never apply the silicone oil to the bezel gasket. Otherwise, the silicone oil may spread to the dial or other

parts, causing malfunctions.

4 Winding stem with crown

• How to remove

Push the lever for unlocking stem between the dial and the case vertically down with tweezers, and

remove the winding stem with crown.

For both types

7 Buttons

• Lubricating

Cal. 9T82A

Apply SEIKO Watch Oil S-6 to the end portions of the buttons that touch the lever.

8 Hour, minute and second hands

• How to install the hour hand

The watch is provided with the instant date change mechanism. In order for the date to change at

the exact time, install the hands following the procedure below.

1. Slowly turn the crown counterclockwise.

Stop turning the crown when the date has

changed.

2. Install the hour hand so that it points slightly

ahead of the 12 o’clock marker (See the

illustration at right).

3. Install the minute and second hands so

that they point exactly to the center of the

12 o’clock marker.

Notes:

* Check clearance among the hands at the 12,

3, 6 and 9 o’clock positions lest they should

touch one another.

* Some models have hands coated with

LumiBrite. When handling the hands,

therefore, take care not to damage the

LumiBrite coating.

Install the hour hand so that

its tip points to the right end

of the 12 o’clock marker.

Hour hand

6

Lubricating: : SEIKO Watch Oil S-6

Page 7

TECHNICAL GUIDE

9 Stopwatch 1/10 second hand

10 Stopwatch second hand

11 Stopwatch hour and minute hands

* When reassembling the watch, be sure to use a new set of stopwatch hands.

If the old stopwatch hands are reused, they may come off from the shock when they are reset to “0”

position.

• How to install

1. Reset the stopwatch to “00”.

When the stopwatch is properly reset to “00”, the hammer appears in the eyehole “A” as shown

below.

Cal. 9T82A

Hammer

▼

When the stopwatch

[]

is reset to “00”

2. Set all the stopwatch hands accurately to the 12 o’clock position, and push them in completely.

Notes:

* Push in the hand securely until the lower end of the

hand installing pipe (“A” in the illustration) reaches

below the “D”-shaped notch of the arbor.

* Check that the stopwatch hour and minute hands do

not touch each other.

12 Dial

The dial is fitted to the movement by fixing the two dial

legs with the eccentric posts.

• How to remove

Turn the eccentric posts counterclockwise to release

the dial legs, and remove the dial.

“D”-shaped notch

Eccentric post

When the stopwatch

[]

is not reset to “00”

A

• How to install

Set the dial in position. While pressing down the dial

at the 12 o’clock side so that the dial is well-seated on

the movement, turn the eccentric posts clockwise to

fix the two dial legs.

Note: If metal chips are generated from the eccentric

posts, be sure to remove them.

7

Page 8

TECHNICAL GUIDE

II. VALUE CHECKING AND ADJUSTMENT

● Resetting the stopwatch hands to “0” position

Repeat “START” – “STOP” – “RESET” of the stopwatch several times to check if each of the three

stopwatch hands returns to “0” position securely.

● Checking the time period of date change

Specified time period of date change: 0:00 a.m. ~ 0:03 a.m.

With the crown at the second click, advance the hour and minute hands until the date changes. Check if

the date changes within the time period specified above.

● Remarks on measuring time accuracy

To measure the time accuracy, be sure to reset the stopwatch to “00”. If the accuracy measurement is made

while the stopwatch is counting, stable measurements may not be obtained.

Cal. 9T82A

● Current consumption

Current consumption measurement of Cal. 9T82A requires special tools, and the movement could be

damaged during the procedure of current consumption measurement. We do not recommend, therefore,

that you measure the current consumption for checking. It can be assumed that the current consumption

is within the standard range as long as the movement is kept under proper conditions.

8

* Printed on recycled paper. 2001-2 Printed in Japan

Loading...

Loading...