Page 1

PARTS CATALOGUE/TECHNICAL GUIDE

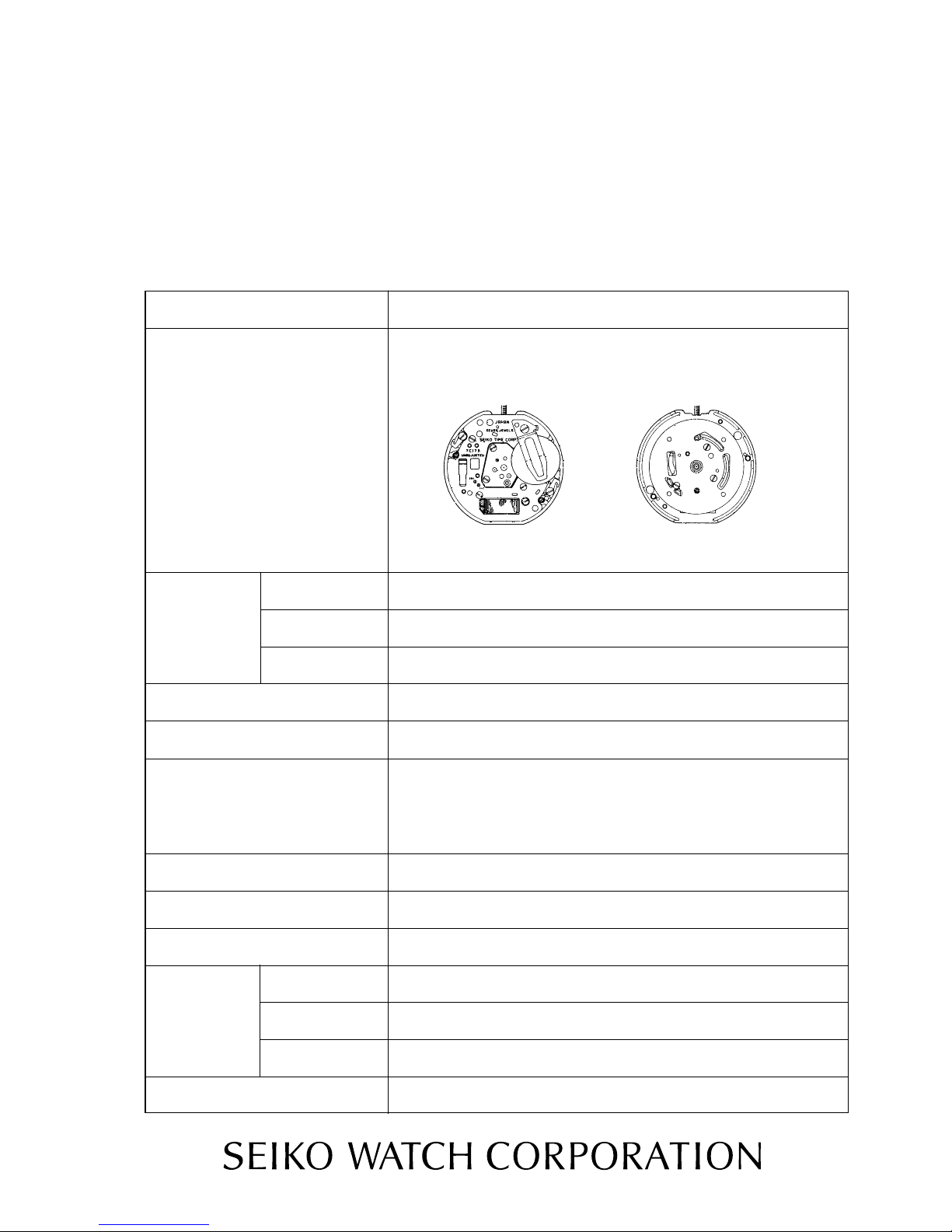

Cal. 7C17B

(×1.0)

Movement

Cal.No.

Movement size

(mm)

Outside diameter

Casing diameter

5.2 mm

2 hands

φ28.6 mm×27.0 mm between 3 o'clock and 9 o'clock sides

φ27.0 mm×25.4 mm between 3 o'clock and 9 o'clock sides

Time indication

Step motor (Load compensated driving pulse type)

Driving system

Electronic circuit reset switch

Additional mechanism

Monthly rate at normal temperature range : less than 15 secondsLoss/gain

Pattern cutting systemRegulation system

Use 10-second gate.Measuring gate by quartz tester

SEIKO SR43SW,Maxell SR43SW, U.C.C. 301, SONY EVEREADY 301 Battery type

Pressure 1.55V

approximately 5 yearsBattery life

7 jewels

Jewels

Battery

1/6

Height

[SPECIFICATIONS]

7C17B

Page 2

Disassembling procedures Figs.

Moebius A

SEIKO Watch Oil S-6

Normal Quantity

0022 493

Coil block screw

Antimagnetic shield plate

screw

0022 648

Battery clamp screw

1Case back

7Movement

8Bezel gasket

9Case (with bezel)

6Winding stem

(with crown)

2Case back gasket

4Casing clamp screw (2 pcs.)

0022 421

18

Minute wheel

0261 935

17

Setting wheel

2081 925

15

Dial sheet

0105 925

16

Hour wheel

0271 927

14

Dial sheet screw

(3 pcs.)

0022 257

13

Dial washer

0491 706

11Dial

10Hour and minute

PARTS CATALOGUE

12

Holding ring for dial

→Please see the remarks on the following pages.

5Casing clamp (2 pcs.)

0399 601

0022 421

Casing clamp screw

0022 257

Dial sheet screw

2/6

144

Lubricating: Types of Oil Oil quantity

Reassembling procedures Figs.

44

1

44

0866 544

hands

Train wheel bridge screw

Contact point spring

3

4281 514

Cal. 7C17B

→

→

Page 3

Cal. 7C17B

Eccentric dial pin

Tube for circuit block spacer A

Tube for circuit block spacer B

Tube for casing clamp screw

Setting lever pin

Tube for antimagnetic shield plate screw

Tube for traon wheel bridge

Casing clamp screw

Tube for coil block screw

3/6

29

Train wheel bridge

screw (2 pcs.)

30

Train wheel bridge

0125 925

31

Fourth wheel and

pinion 0241 927

32

Third wheel and

pinion 0231 935

33

Fifth wheel and

pinion 0701 925

34

Step rotor

4146 555

35

Train wheel setting

lever 0391 925

36

Setting lever spring

0388 925

37

Setting lever

0383 925

38

Yoke

0384 926

39

Winding stem

40

Clutch wheel

0282 926

41

Center wheel bridge

0122 925

42

Center wheel and

pinion 0221 938

20

Battery clamp

4225 555

24

Circuit block

4000 617

25

Circuit block spacer

4408 555

26

Battery connection (-)

4270 555

12 Holding ring for dial 0866 544 39

WWinding stem 0351 926

The types of these parts depend on the design of each model.

Refer to " SEIKO Casing Parts Catalogue" to choose corresponding parts.

Remarks:

19 Battery clamp screw

21

Battery (See the front page.)

22

Antimagnetic shield plate screw

0022 493

23

Antimagnetic shield plate

4259 506

0022 468

27 Coil block screw

0022 493

28 Coil block

4002 555

43

Rotor stator

4239 723

44

Main plate

0101 927

0022 493

Page 4

Use the universal movement holder for disassembling and reassembling.

5Casing clamp

●Setting position

Cross section

Bezel gasket

Casing clamp

Case middle

7

●When you remove the movement, push the movement

out of the back lid side to the bezel. When you build it

in, push it from the bezel side.

9

Bezel

Glass

3How to install the contact point spring

●Push the center of the contact spring, see the drawing,

until it touches winding stem. Be careful not transform

4/6

Center contact point spring

Cal. 7C17B

TECHNICAL GUIDE

●The explanation here is only for the particular points of Cal. 7C17B.

●For the repairing, checking and measuring procedures, refer to the "TECHNICAL GUIDE, GENERAL

I. REMARKS ON DISASSEMBLING AND REASSEMBLING

Install the casing clamp screw so that

this bent position is securely placed on

the step of the case middle.

Movement

the control point spring.

8

Bezel gasket

● Please refer to the illustration.

Case (with bezel)

●

•@Lubricate the pointed portion, see the illustration.

●

Do not lubricate bezel gasket.

INSTRUCTION".

Page 5

Cal. 7C17B

Eccentric dial pin

Eccentric dial pin

12

Holding ring for dial

Holding ring for dial

Protrusion

11Dial

Be sure to set the protrusion of the holding ring

for dial in place.

Movement

The foot of the dial has been tightened with

the eccentric dial pin. Turn the screw driver

right and tighten to attach, and turn left and

loosen to remove it.

Hole for dial leg

Hole for dial leg

31

Fourth wheel and pinion

5/6

38

Yoke

Setting lever spring

Train wheel setting lever

Setting lever

35

Train wheel setting lever

36

Setting lever spring

37

Setting lever

Setting lever spring

Setting lever

Yoke

Clutch wheel

40

Clutch wheel

*eccentric dial pin is non-supply parts, therefore

please do not lose it.

Page 6

Cal. 7C17B

41

Center wheel bridge

39

Winding stem

To prevent any crack onto the main plate, gently set the winding stem while turning it.

Lubricating

II. VALUE CHECKING

●Coil block resistance

2.0〜2.5kΩ

●Current consumption

For the whole of the movement:less than 1.30μA

For the circuit block alone: less than 0.20μA

Remarks:

When the current consumption exceeds the standard value for the whole of the movement but is less

than the standard value for the circuit block alone, overhaul and clean the movement parts and then

measure current consumption for the whole of the movement again. The driving pulse generated to

2006. June

6/6

compensate a heavy load that may apply on the gear train, etc. is considered to cause excessive current

consumption for the whole of the movement.

Loading...

Loading...