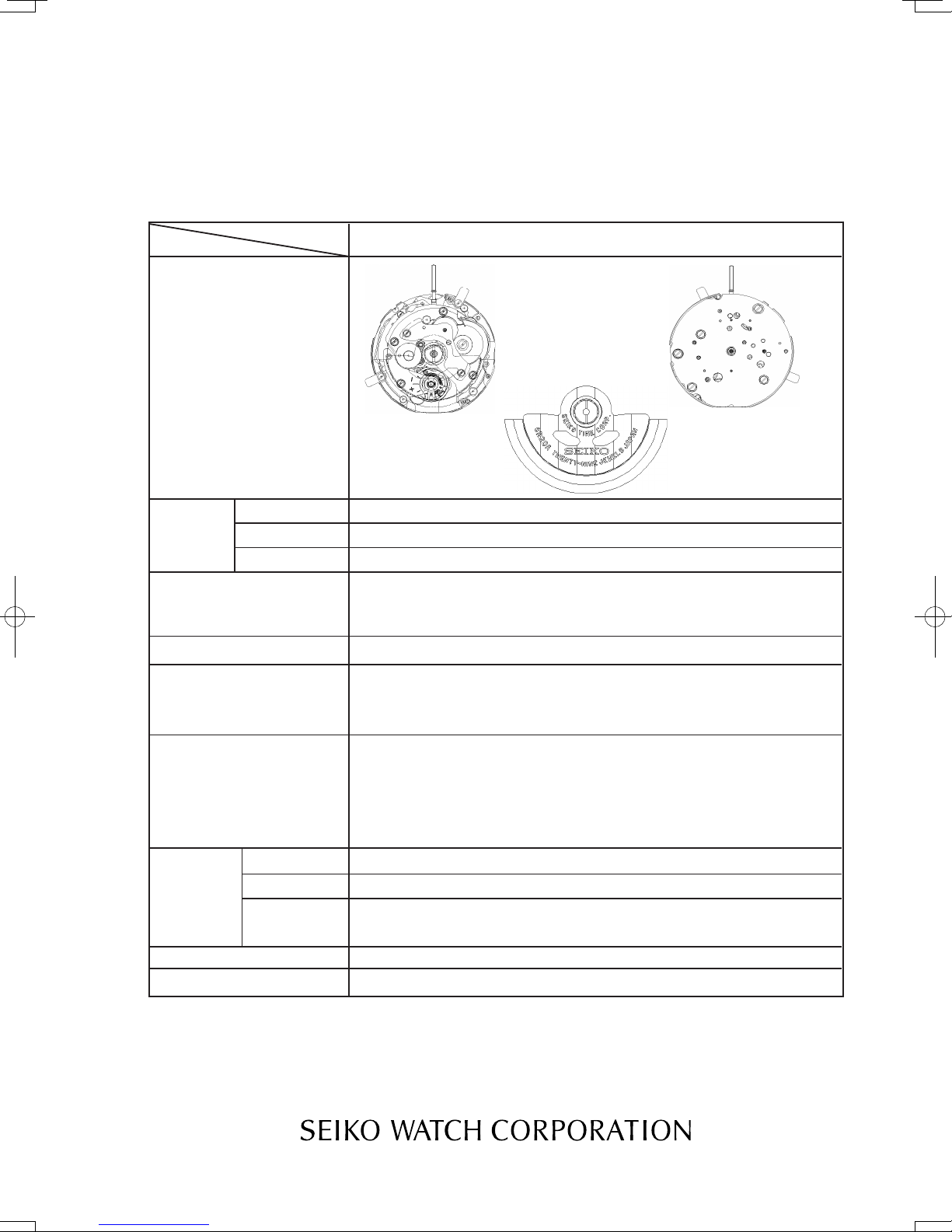

Seiko 6R20A Technical Manual & Parts Catalogue

PARTS CATALOGUE / TECHNICAL GUIDE

Cal. 6R20A

[SPECIFICATIONS]

Cal. No.

Item

Movement

Movement

size

Time indication

Outside diameter

Casing diameter

Height

Additional mechanism

Loss /gain

Number of Jewels

Basic mechanism

Crown

operation

Original

First click

Second click

Vibration per hour

1/24

28,800 Hz/hour (8 beats per second)

6.15 mm

l

Mechanical watch

l

3 hands

l

Automatic winding with auxiliary hand winding mechanism

(x 1.0)

Ø 27.4 mm

Ø 27.0 mm

l

Date hand, Day hand, and Power reserve indicator

l

Date/Day correction function

l

Second hand stop mechanism

l

Clearance adjustment

Manual winding (turn clock wise)

Date correction (turn counterclockwise)/Day correction (turn clockwise)

Time setting (turn clockwise to move forward and counterclockwise to

move back)

Second hand stops on the spot

Between -15 seconds and +25 seconds per day

29 jewels

6R20A

l

3 hands (hour, minute and second hands)

l

Date/Day indication

l

Power reserve indicator

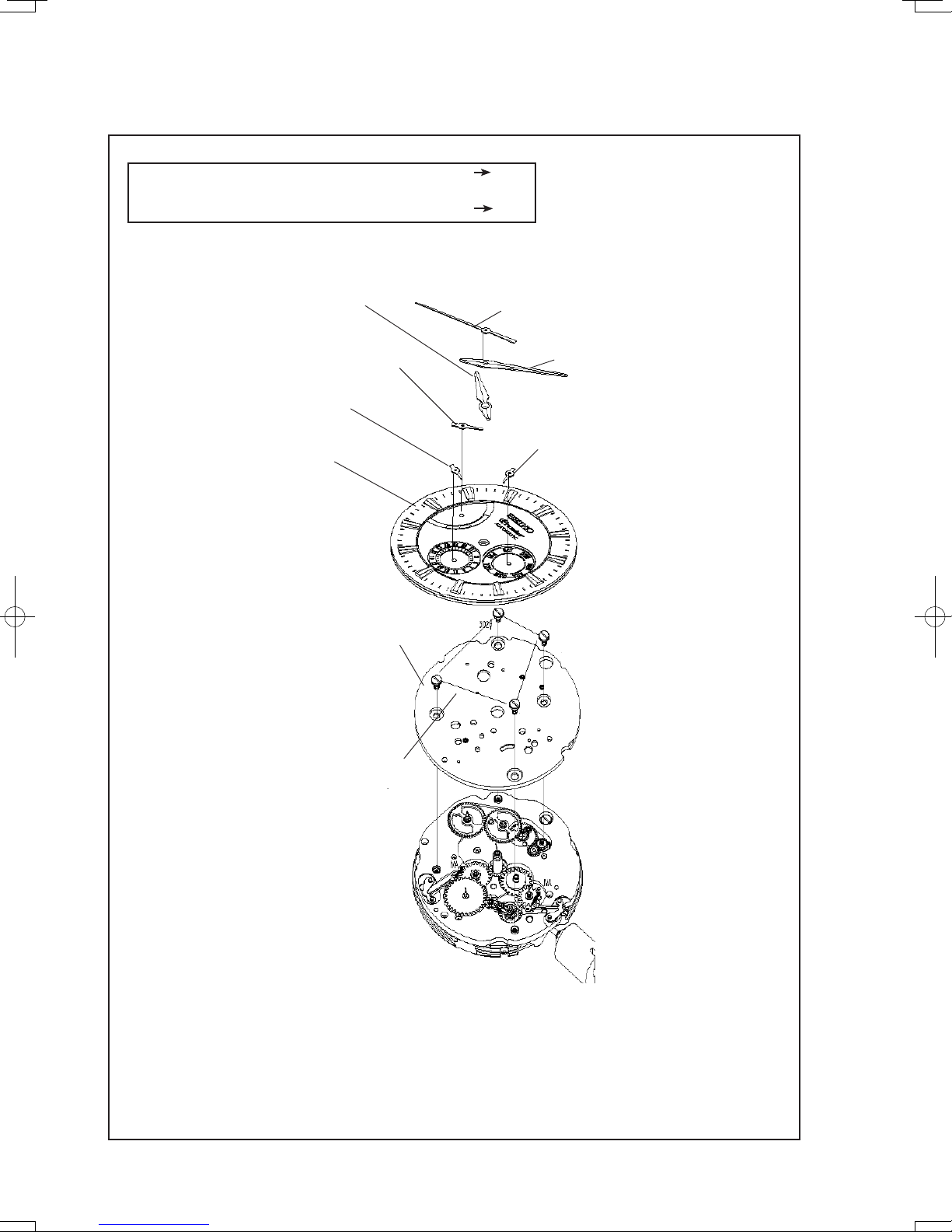

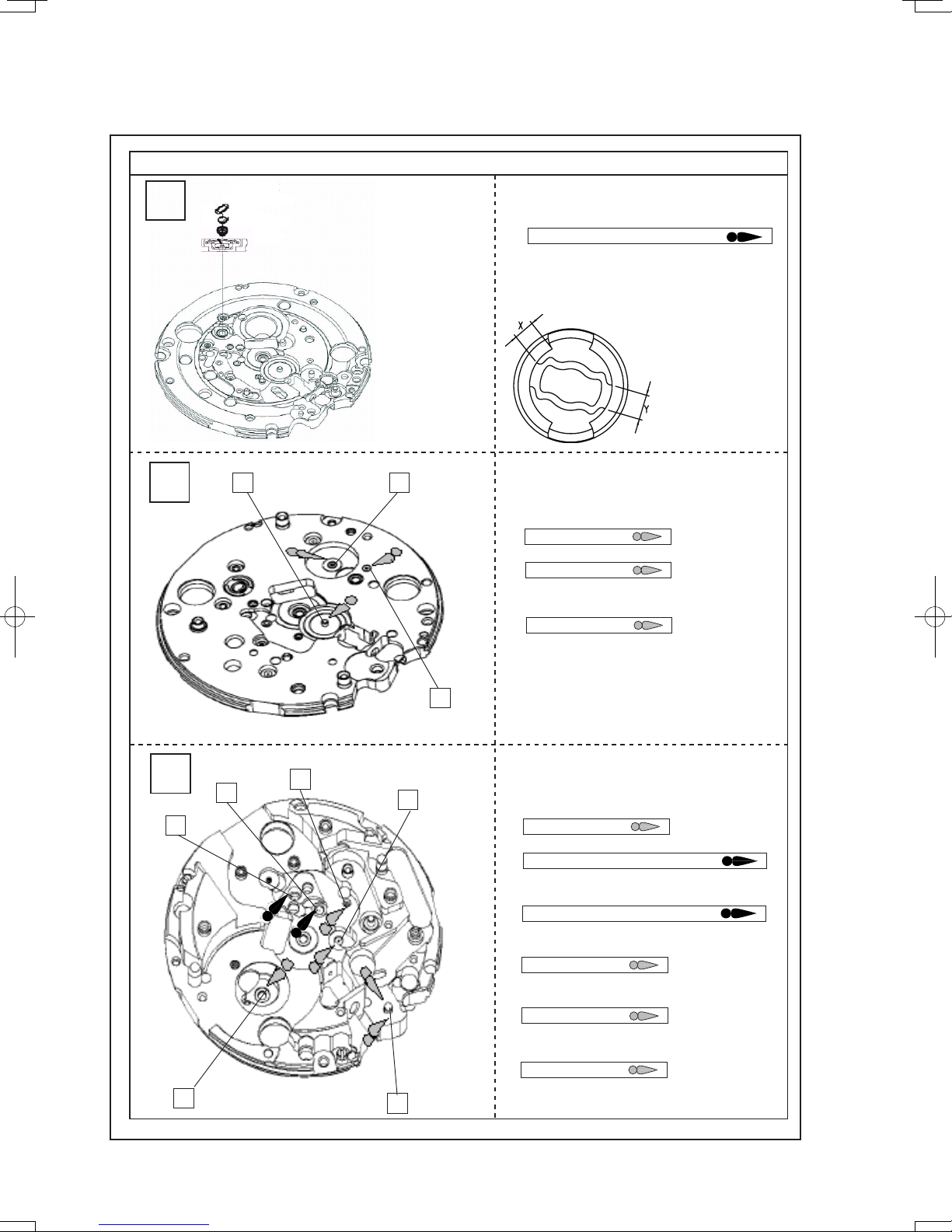

Cal. 6R20A

PARTS CATALOGUE

3

Hour hand

4

Power reserve indicator

5

Date hand

1

Second hand

2

Minute hand

6

Day hand

9

Auxiliary train wheel

bridge

0126 025

8

Auxiliary train wheel

bridge screw (4 pcs.)

0012 201

7

Dial

Disassembling procedures Figs.:

1

yh

Reassembling procedures Figs.:

yh

1

2/24

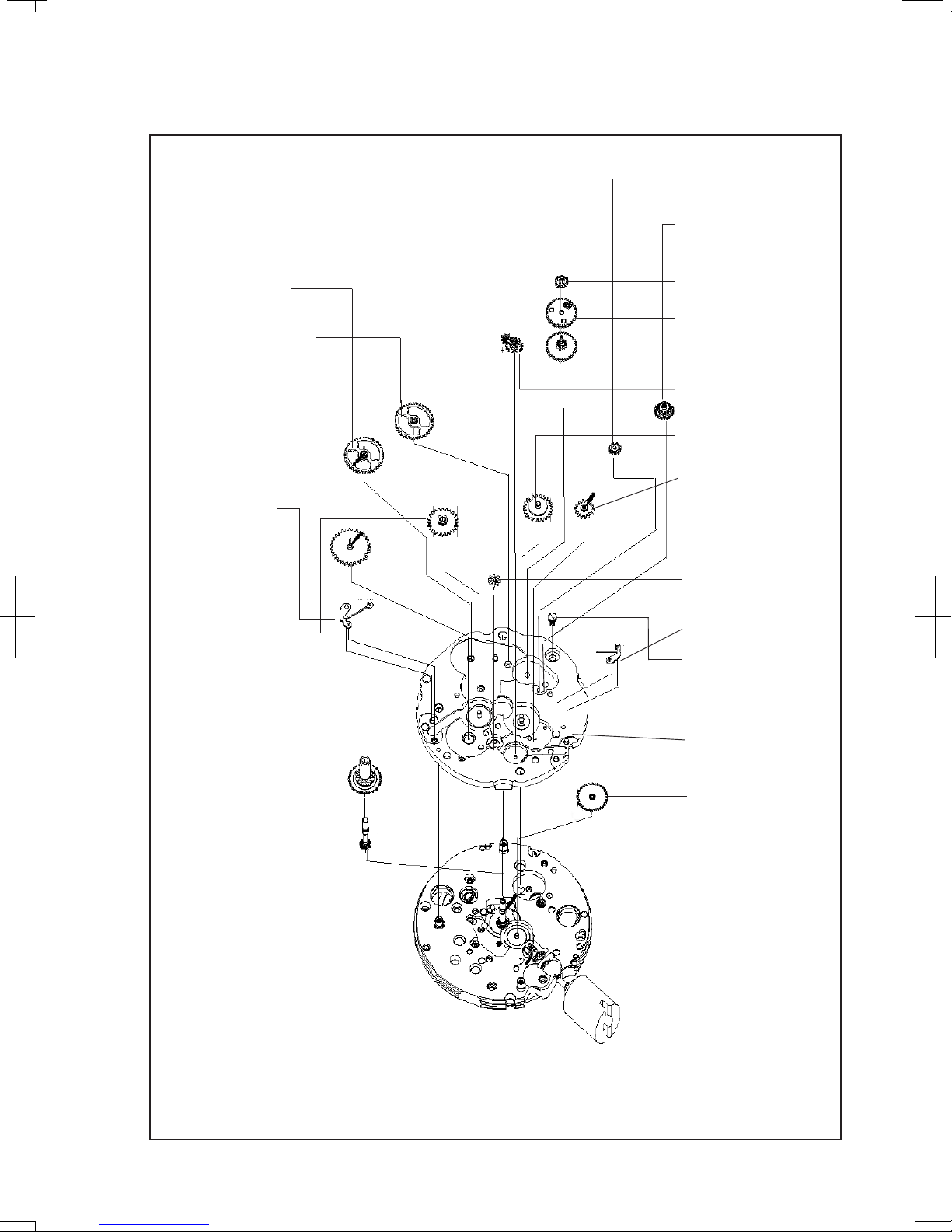

PARTS CATALOGUE

Cal. 6R20A

qf

Second sun wheel

1009 004

ql

Date indicator

driving wheel

0802 036

ws

Day-date corrector

setting unit

1001 029

qa

Intermediate power

reserve wheel

0817 047

q;

Power reserve

wheel

1019 002

qg

Sun and planet unit

1001 025

qh

Sun wheel

1009 003

qd

Planetary reduction

wheel

1026 002

qs

Barrel arbor pinion

1010 267

wj

Minute wheel and

pinion

0261 006

wl

Cannon pinion

wf

Day star

0970 003

wd

Day driving wheel

0898 001

wa

Date jumper

0810 017

wh

Auxiliar y main plate

0102 023

w

k

Hour wheel

qj

Day jumper

0810 017

q

k

Date star

0970 002

wg

Auxiliar y main plate

screw

0012 201

w

;

Date corrector

setting wheel

0737 002

3/24

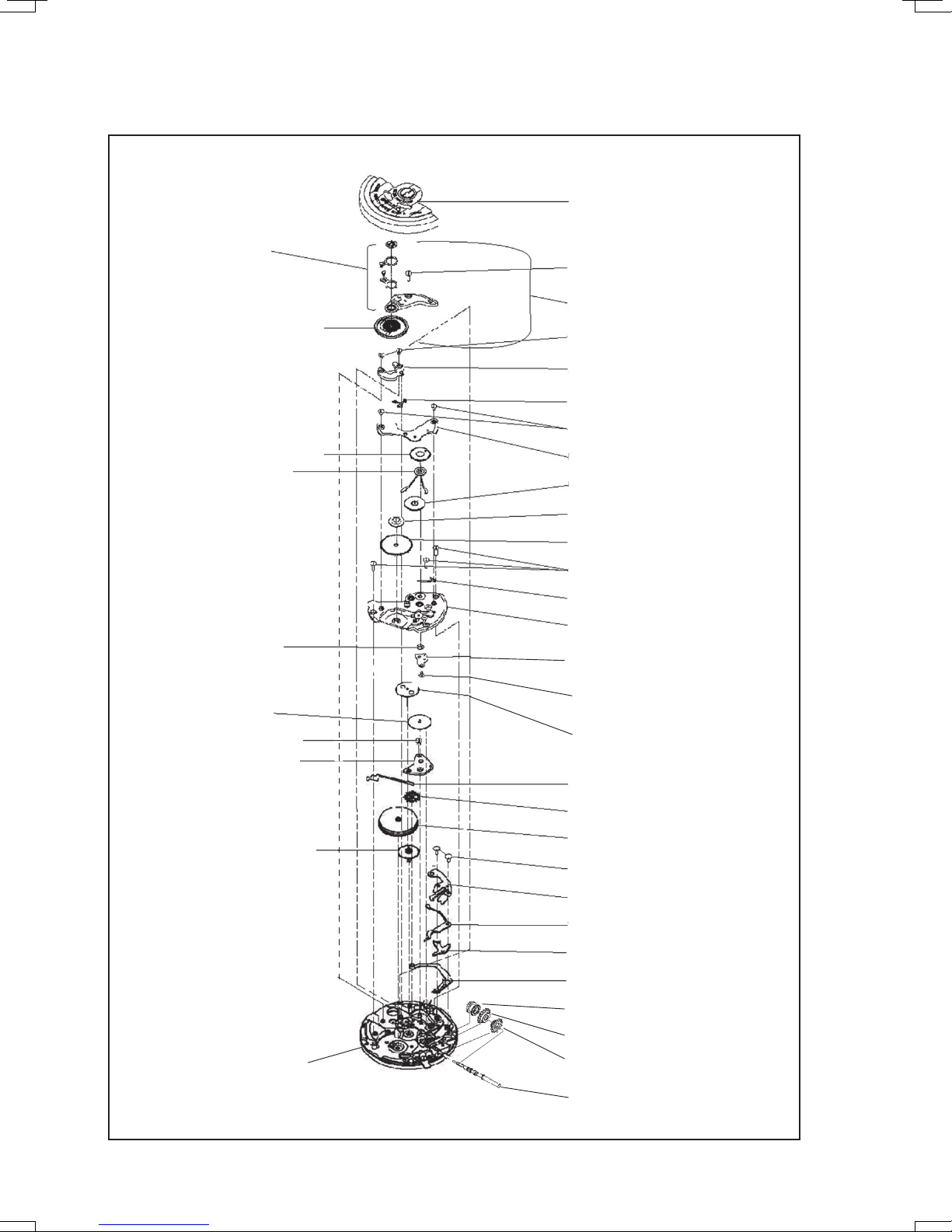

ea Balance bridge screw

0012 420

e;Oscillating weight

0509 266

es Balance staff (balance complete

with stud and balance bridge)

edPallet bridge screw (2pcs.)

0012 354

efPallet bridge

0161 310

egPallet fork

0301 310

ehAutomatic train wheel screw

(2pcs.) 0012 354

ej Automatic train bridge

0191 025

el Ratchet wheel screw

0012 919

r; Ratchet wheel

0285 051

ra Barrel & train wheel bridge screw

(3 pcs.) 0012 420

rs Ratchet sliding wheel spring

0363 156

rd Barrel & train wheel bridge with

upper hole jewel with frame

0112 365

rk Lower plate for barrel & train

wheel bridge

0436 001

rjLower plate for barrel & train

wheel bridge screw

0012 354

rl Fourth wheel & pinion

0241 216

ta Click

0381 004

tsEscape wheel & pinion

0251 310

tdBarrel complete

0201 074

tjYoke spring screw (2pcs.)

0012 168

tkYoke spring

0388 071

tlYoke

0384 061

y;Setting lever

0383 060

yaBalance stop lever

0601 010

yh Main plate

ek Second reduction wheel & pinion

0514 010

thCenter wheel & pinion

0221 085 (Standard type)

* Remove the cannon pinion

on the back side of the

main plate before removing

the center wheel.

tgCenter wheel bridge

0122 302

tfCenter wheel bridge screw

0012 354

t;Third wheel & pinion

0231 070

rfReduction wheel holder

0836 002

rh Pawl lever

0831 010

rgFirst reduction wheel & arbor

0511 010

Balance complete set without stud

0310 048

Balance bridge

(complete set)

0171 117

ys Clutch wheel

0282 040

yd Winding pinion

0283 020

yf Intermediate wheel for calendar

correction A

0962 021

ygWinding stem

Cal. 6R20A

PARTS CATALOGUE

4/24

0012 919

0012 354

Ratchet wheel screw

Lower plate barrel & train wheel bridge screw

Center wheel bridge screw

Pallet bridge screw (2pcs.)

Automatic train wheel screw (2pcs.)

Date indicator maintaining plate screw A (3 pcs.)

Parts code Parts name

Yoke spring screw (2pcs.)

Barrel & train wheel bridge screw (3 pcs.)

Balance bridge screw

Casing clamp screw (2 pcs.)

0012 168

0012 420

0012 067

CROSS-SECTION VIEW OF THE SCREW PARTS

0012 201

Auxiliary main plate screw

Auxiliary train wheel bridge screw (4 pcs)

The correct parts for the following are determined based on the design of the cases.

Re fer to " S EIKO Watch Par ts Catalogu e ( S EIKO WATCH S ERVI C E SITE) " to c hoos e

corresponding parts.

l Holding ring for dial

l Date indicator

l Winding stem

Remarks

PARTS CATALOGUE

Cal. 6R20A

5/24

How to remove

How to install

1. Initial phase

Set the balanc e complete with stud and balance bridge

to the main plate.

PREPARATION

HOW TO REMOVE AND INSTALL THE BALANCE STAFF

2. Move the stud suppor t toward the balance bridge until it

is attached to the balance bridge.

* When doing so, mak e su re that the ou ter en d of the

hairspring is not removed from the r egula tor arm.

4. R e mo ve the b al anc e b r id ge a nd rep la ce the bal a nce

complete with stud with a new one.

3. Temporarily set the stud to the stud suppor t.

Make sure that the hairspring passes outside the pin o f

the regulator arm.

* Be careful not to damage the hairspring.

1. Initial phase

Set a new balance comple te with stud to the main p late.

2. S et the bal ance bridge and tight en the balan ce bridge

screw.

4. Using s turdy tweezers, set the stud to the stud suppor t

and pre ss it down.

Ma ke sure that th e ou te r en d of the hairs pr ing passes

through the regulator slot of the regulator arm.

* Be careful not to damage the hairspring.

3. Using sturdy tweezers, p ush the stud out war d from the

direc tion of the arrow shown in the illustration until it is

remove d from the stud support.

TECHNICAL GUIDE

Cal. 6R20A

6/ 24

PREPARATION

PREPARATION

1. Lubricate the lower shock absorbing cap

jewel, and set it to the lower hole jewel

with frame.

2. Set the lower hole jewel with frame (with

the cap jewel attached) to the main plate

with lower shock absorbing frame.

3. Set the shock absorbing spring.

Lubricate at the three points on the rear

of the main plate as illustrated.

1. Lower hole jewel for the minute wheel

pin

2. Lower hole jewel for the sun wheel

3. Lower hole jewel for the planetary

reduction wheel

Type of oil: S-6

Lubricate at the six points on the surface

of the main plate as illustrated.

1. Lower hole jewel for the barrel

complete

2. Lower hole jewel for the pallet fork.

3. Lower hole jewel for the escape wheel

and pinion

4. Lower hole jewel for the first

reduction wheel

5. Lower hole jewel for the third wheel

and pinion

6. Setting lever pin and sliding face of

setting lever

3 1

Type of oil: S-6

Type of oil: S-6

Type of oil: S-6

Type of oil: AO-3 (Moebius A)

Type of oil: AO-3 (Moebius A)

Type of oil: AO-3 (Moebius A)

1

Type of oil: S-6

Type of oil: S-6

Type of oil: S-6

TECHNICAL GUIDE

Cal. 6R20A

1

2

3

TECHNICAL GUIDE

Cal. 6R20A

2

7/24

2

3

4

5

6

PREPARATION

4

5

6

1. Set the rachet sliding wheel spring.

1. Lubricate the lower hole jewel for the

second reduction wheel and pinion.

Type of oil: S-6

2. Lubricate at the two points in the rachet

sliding wheel.

1

2

Type of oil: S-6

TECHNICAL GUIDE

Cal. 6R20A

TECHNICAL GUIDE

1. Lubricate the upper hole jewel for the

third wheel bridge and set the upper hole

jewe l with f rame. Th en, s et the upper

sho c k absorbin g sprin g for the thir d

wheel bridge.

Type of oil: AO-3 (Moebius A)

2. Lubr ica te the up per hole jewel for the

es c a p e wh e el a n d pi nion and set the

upper hole jewel frame with frame. Then,

set the upper shock absorbing spring for

the escape wheel and pinion.

Type of oil: AO-3 (Moebius A)

8/ 24

Loading...

Loading...