Page 1

Customer Display

DM-D500

Installation Manual

401156101

Page 2

CAUTIONS

❏ This document shall apply only to the product(s) identified herein.

❏ No part of this document may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without the prior written permission of Seiko Epson

Corporation.

❏ The contents of this document are subject to change without notice. Please

contact us for the latest information.

❏ While every precaution has been taken in the preparation of this document,

Seiko Epson Corporation assumes no responsibility for errors or omissions.

❏ Neither is any liability assumed for damages resulting from the use of the

information contained herein.

❏ Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser

of this product or third parties for damages, losses, costs, or expenses incurred

by the purchaser or third parties as a result of: accident, misuse, or abuse of this

product or unauthorized modifications, repairs, or alterations to this product, or

(excluding the U.S.) failure to strictly comply with Seiko Epson Corporation's

operating and maintenance instructions.

❏ Seiko Epson Corporation shall not be liable against any damages or problems

arising from the use of any options or any consumable products other than

those designated as Original EPSON Products or EPSON Approved Products by

Seiko Epson Corporation.

TRADEMARKS

EPSON® is a registered trademark of Seiko Epson Corporation.

Microsoft®, MS®, MS-DOS®, Windows

of Microsoft Corporation.

General Notice: Other product and company names used herein are for

identification purposes only and may be trademarks of their respective companies.

Copyright © 1999, 2000 by SEIKO EPSON CORPORATION

®,

Windows NT® are registered trademarks

Page 3

Engli

h

Safety Precautions

This document presents important information intended to ensure safe and effective use

of this product. Please read this document carefully, and store it in an accessible location

near your installation.

s

Precaution Headings

This document uses the two headings shown below to call attention to potential hazards.

Failure to observe the information provided under or alongside these headings may lead

to injury or property damage. Be sure that you understand the meaning of each heading

before you proceed.

WARNING:

Indicates a potentially lethal hazard. Failure to observe a WARNING

may result in severe injury or death.

CAUTION:

Failure to observe a CAUTION may result in personal injury, or in damage

to equipment or other property.

Safety Precautions

WARNING:

❏

Shut down your equipment immediately if it produces smoke, a

strange odor, or unusual noise. Continued use may lead to fire or

electric shock. Immediately turn the power off and contact your

dealer or a SEIKO EPSON service center for advice.

❏

Never attempt to repair this product yourself. Improper repair work

can be dangerous. Tampering with this product may result in injury,

fire, or electric shock.

❏

Be sure to use the specified power source. Connection to an

improper power source may cause fire or shock.

❏

Do not allow foreign matter to fall into the equipment. Pene tration

of foreign objects may lead to fire or shock.

❏

If water or other liquid spills into this equipment, immediately turn the

power off and contact your dealer or a SEIKO EPSON service center

for advice. Continued usage may lead to fire or shock.

1

Page 4

CAUTION:

❏

Do not plug the cable differently from the instruction in this manual.

Wrong connection may cause equipment damage and fire.

❏

Be sure to set this equipment on a firm, stable, horizontal surface.

Product may be damaged or cause injury if it falls.

❏

Do not use in locations subject to high humidity or dust levels.

Excessive humidity and dust may cause equipment damage, fire, or

shock.

❏

Do not place heavy objects on top of this product. Equipment may

be damaged and cause injury if it falls.

❏

Do not attach plural extension supports. Product may be damaged

or cause injury if it falls.

❏

A stopper limits the horizontal rotation of the display. Do not try to

force it to turn beyond the limits of the stopper. Doing so may

damage the equipment.

EMC and Safety Standards Applied

Product Name: DM-D500

Type Name: M151A

The following standards are applied only to the display that is so labeled. (EMC is tested

using the EPSON PS-170 power supply.)

❏ Europe: CE Marking

Safety: EN60950

❏ North America: EMI: FCC/ICES-003 Class A

Safety: UL 1950/CSA C22.2 No.950

❏ Japan: EMC: VCCI Class A JEIDA-52

❏ Oceania: EMC: AS/NZS 3548 (CISPR22) Class B

CE Marking

The display conforms to the following Directies and Norms

Directive 89/336/EEC EN55022 Class B

EN55024

IEC 61000-4-2

IEC 61000-4-3

IEC 61000-4-4

IEC 61000-4-5

IEC 61000-4-6

IEC 61000-4-11

2

Page 5

Engli

h

WARNING

You are cautioned that changes or modifications not expressly approved by SEIKO

EPSON Corporation could void your authority to operate the equipment.

FCC COMPLIANCE STATEMENT FOR AMERICAN USERS

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

FOR CANADIAN USERS

This Class A digital apparatus complies with Canadian ICES-003.

s

Cet appareil numérique de la classe A est conforme

à

la norme NMB-003 du Canada.

About This Manual

Cautions and Notes

CAUTION:

Cautions must be observed to avoid minor injury to yourself or damage

to your equipment.

Note:

Notes have important information and useful tips on the operation of your display.

3

Page 6

Contents

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cautions on Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Precautions when connecting to a TM printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assembling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Attaching to the IR Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Attaching to the TM-H5000II/TM-J8000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Attaching to the TM-U375/TM-U950. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Attaching to the TM-H6000/TM-U675 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Attaching to Other TM Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Attaching to the DM-D stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Part Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DIP Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

DIP Switch Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Turning and Tilting the DM-D500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Self Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Check Items of Self test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Performing Self test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

General Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Character Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Reliability Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4

Page 7

Engli

h

This manual explains how to set up the DM-D500.

installati

l

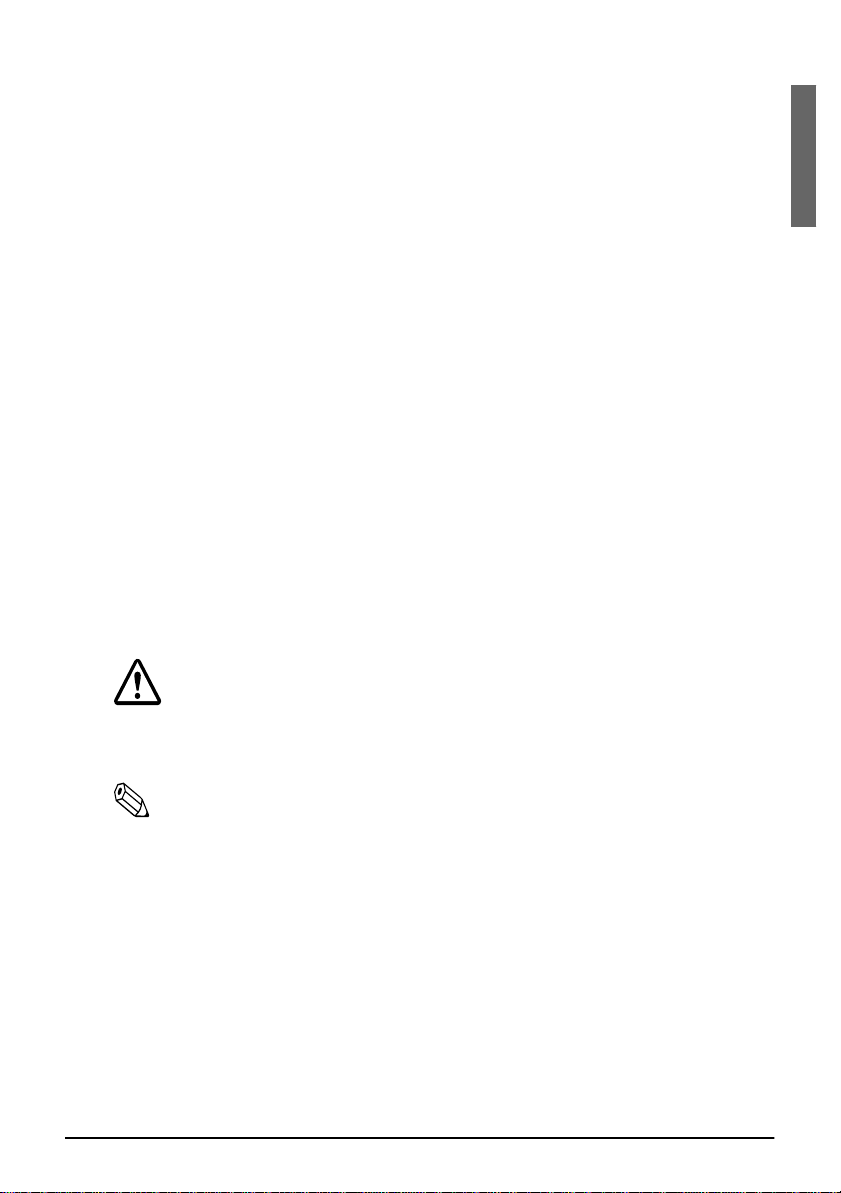

Unpacking

s

The following items are in the box.

warranty card

(201 model only)

on manua

display (DM-D500)

Make sure that you have all the items shown above, and that none has

been damaged. If you find anything missing or damaged items, please

contact your DM-D500 dealer.

Cautions on Handling

When you use the DM-D500, be sure to note the following points:

❏ Avoid locations that are subject to high temperature and humidity.

❏ Avoid dirty and dusty locations.

❏ Avoid locations that are unstable or are subject to high levels of

vibration.

❏ When connecting or disconnecting cables, make sure that the

power switch of the DM-D500 and printers connected to the

DM-500 are turned off.

❏ Do not drop the DM-D500, because you may damage the built-in

vacuum fluorescent display.

5

Page 8

Usage

The DM-D500 can be used with the following equiment.

❏ IR Series. You can attach the DM-D500 to the IR Series using the

“DM-D pole unit for IR” (DP-504). (See page 8.)

❏ TM-H5000II/TM-J8000 printers. You can attach the DM-D500 to

TM-H5000II/TM-J8000 printers using the “DM-D pole unit for TM

printers (Type B)” (DP-503). (See page 10.)

❏ TM-U375/TM-U950. You can attach the DM-D500 to the TM-U375/

TM-U950 printers using the “DM-D pole unit for TM printers

(Type A)” (DP-502). (See page 13.)

❏ TM-H6000/TM-U675. You can attach the DM-D500 to TM-H6000/

TM-U675 printers using the “DM-D pole unit for TM printers

(Type A)” (DP-502). (See page 16.)

❏ Other TM printers. You can attach the DM-D500 using the “DM-D

pole unit for TM printers (Type A)” (DP-502) and Velcro tapes or

screws. (See page 21.)

❏ DM-D stand. You can attach the DM-D500 to the DM-D stand

directly using the “DM-D stand unit for DM-D500” (DP-501). When

using the DM-D stand, an optional power supply unit (PS-170) is

required. Also, if you want to extend the length of the DM-D500, an

optional extension support unit (DP-105) is required. (See page 24.)

6

Page 9

Engli

h

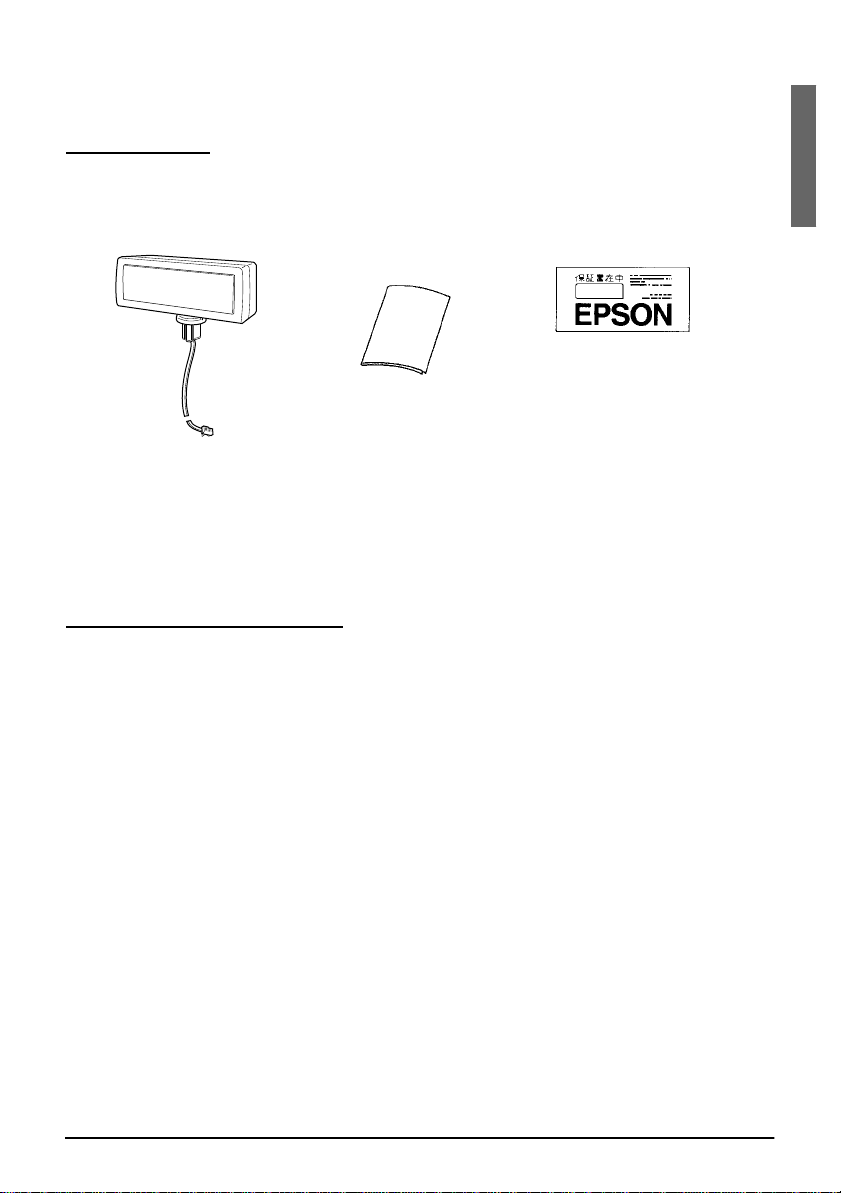

Precautions when connecting to a TM printer

When the DM-D500 is connected to a TM printer, be sure to check the serial

number on the label affixed to the re ar or bottom of the TM prin ter. If the serial

number is one of the numbers indicated below it can be used immediately. If

the serial number is not listed below, however, the DM-D500 cannot be

connected to the TM printer as it is. In this case, please purchase and install the

latest model of the UB-S01 board (Part code: C8233610200) before using the

DM-D500 with that printer.

If your TM or other printer is not listed below, it may be connected to the DMD500 without any special modifications (continued on back).

Printer Model Serial No. Printer Model Serial No.

TM-H5000 - None *1 TM-U590 101 ART0 010001 and higher

TM-H5000II 001 AR30 010001 and higher 111 ARU0 003001 and higher

011 AR40 040001 and higher ARU0 510001 and higher

AR40 530001 and higher 131 ARY0 003001 and higher

021 AR50 040001 and higher ARY0 510001 and higher

AR50 510001 and higher 141 BUV0 000001 and higher

031 AR60 040001 and higher BUV0 510001 and higher

AR60 510001 and higher TM-H6000 001 BMQ0 020001 and higher

041 AR70 040001 and higher 011 BMR0 020001 and higher

AR70 510001 and higher 021 BMS0 020001 and higher

091 BFX0 000001 and higher 031 BMT0 020001 and higher

BFX0 510001and higher 041 BV40 020001 and higher

161 BKS0 000001 and higher 061 BX50 020001 and higher

BKS0 510001 and higher 071 B7R0 020001 and higher

181 BNV0 000001and higher TM-U675 001 BMK0 020001 and higher

BNV0 510001and higher 011 BML0 020001 and higher

201 B430 000001 and higher 021 BMM0 020001and higher

B430 510001 and higher 061 BX30 020001 and higher

211 B5X0 000001 and higher TM-T285 001 2XT0 010001 and higher

B5X0 510001 an d higher TM-J8000 011 AQS0 010001 and higher

*1: If your printer is a TM-H5000, always purchase the latest model of the UB -S01 befor e using it with

the DM-D500.

If an old model of the UB-S01 (Part code: C8233610000)is connected to the

TM printer, please purchase and install the latest model of the UB-S01 board

(Part code: C8233610200).

s

The TM printer and UB-S01 used with the DM-D500 will have one of the

following markings on the RS-232C connector mounting plate. This marking

indicates whether of not the printer can be connecte d to th e DM-D500.

Blue seal

Scribed square

7

Page 10

Assembling

Attaching to the IR Series

The DM-D500 can be attached directly to the IR Series using the “DM-D

pole unit for IR” (DP-504).

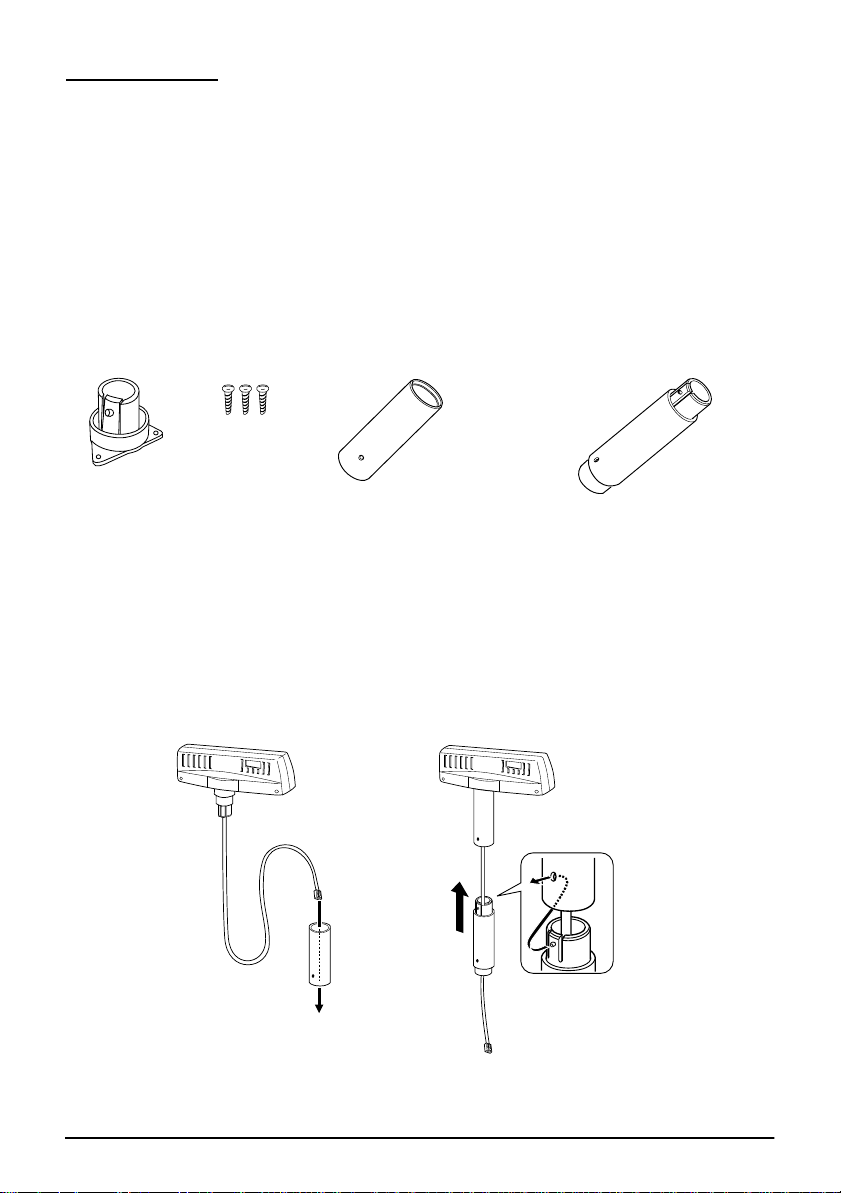

Required items

The following items are used to attach the DM-D500 to the IR Series.

These items are packed with the “DM-D pole unit for IR” (DP-504).

fixing screws

base

support A

Assembling steps

1. Pass the cable for the DM-D500 through support A, and attach

support A to the DM-D500.

When using support B for extension, insert the tab on support B

into the hole on support A until you feel it click.

support B

(for extension)

When using support B for

extension

8

Page 11

Engli

h

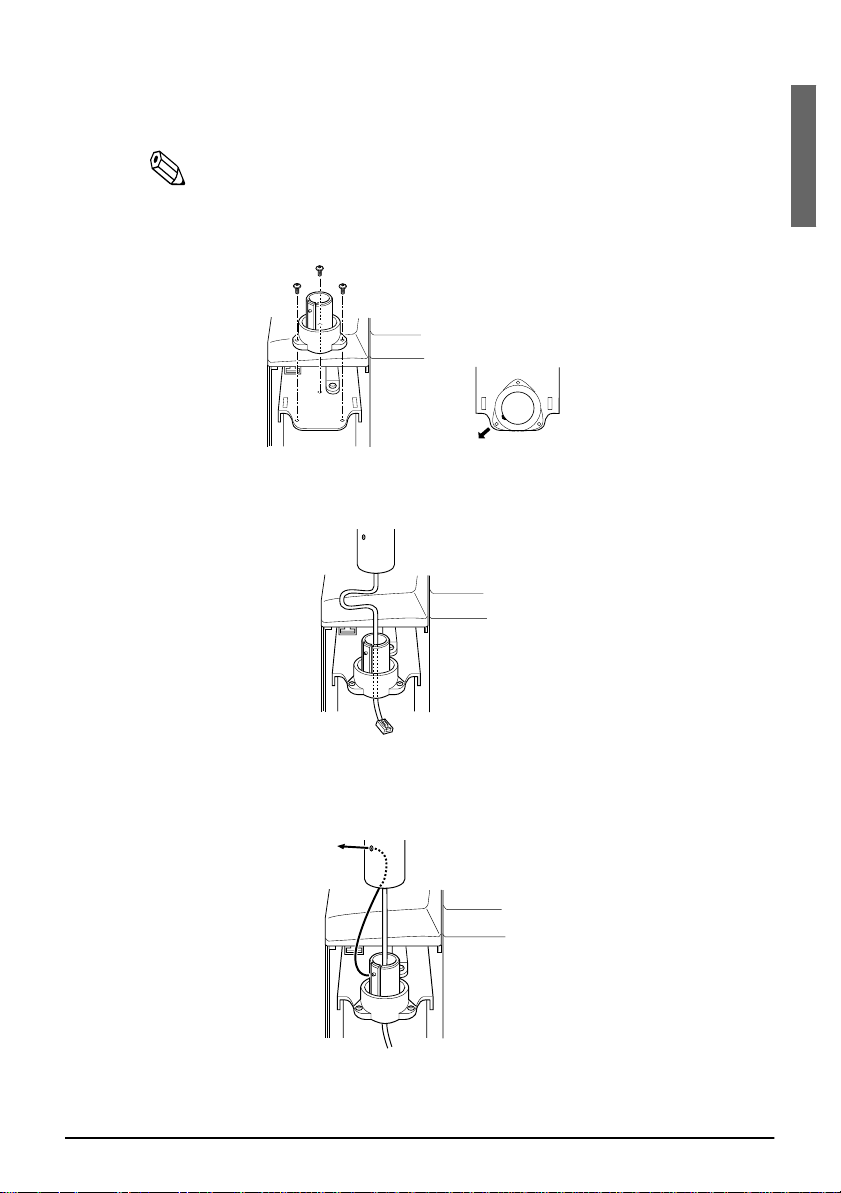

2. Attach the base to the setting position on the IR Series, and secure it

with the screws.

Note:

When attaching the base, note that the corners of the base are set as shown

below.

3. Pass the cable for the DM-D500 through the base.

s

4. Insert the tab on the base into the hole on the support until you feel

it click.

.

9

Page 12

5. Connect the cable for the DM-D500 to the DM connector on the IR

Series.

Attaching to the TM-H5000II/TM-J8000

The DM-D500 can be attached directly to the TM-H5000II/TM-J8000

printers using the “DM-D pole unit for TM printers (Type B)” (DP-503).

Required items

The following items are used to attach the DM-D500 to the

TM-H5000II/TM-J8000 printers. These items are packed with the

“DM-D pole unit for TM printers (Type B)” (DP-503).

fixing screws

10

base

support B

(for extension)

support C

Page 13

Engli

h

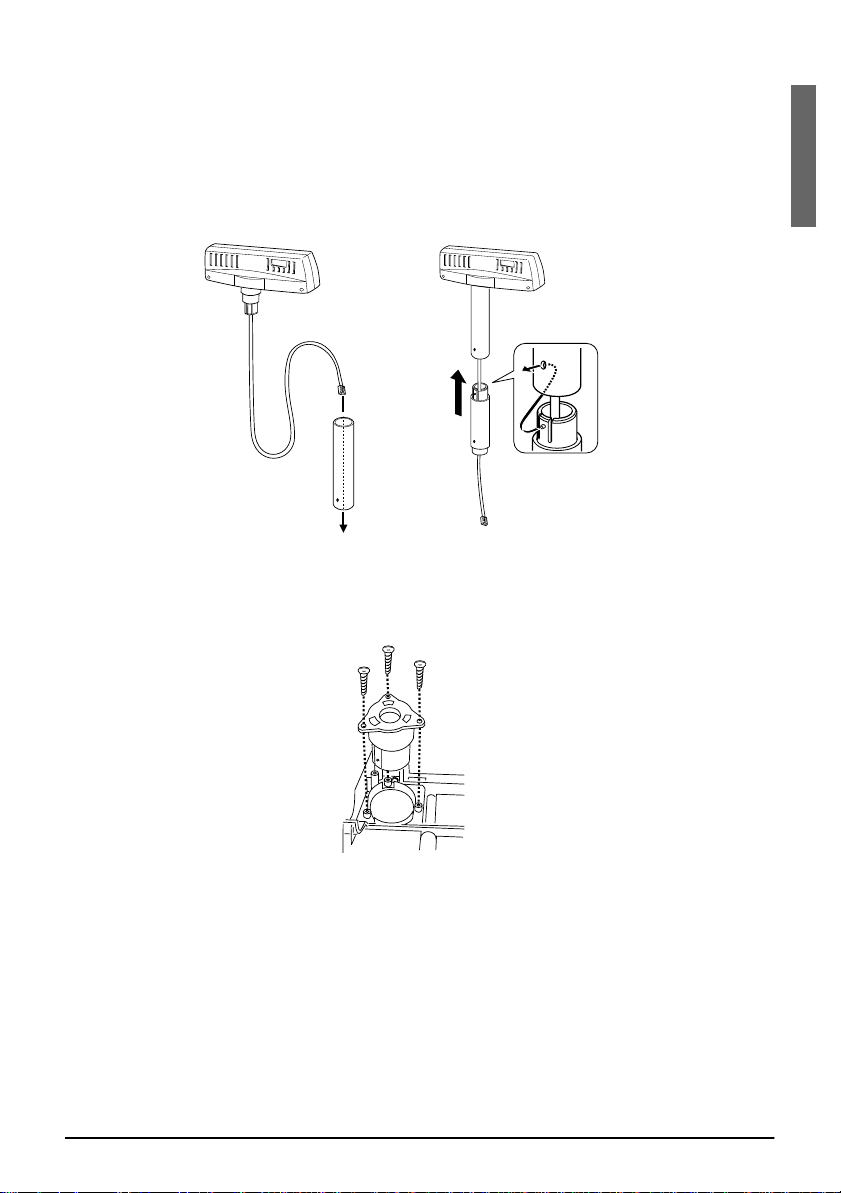

Assembling steps

1. Pass the cable for the DM-D500 through support C, and attach

support C to the DM-D500.

When using support B for extension, insert the tab on support B

into the hole on support C until you feel it click.

When using support B for

extension

2. Attach the base to the setting position on the TM printer and secure

it with the screws.

s

11

Page 14

3. Pass the cable for the DM-D500 through the base.

4. Insert the tab on the base into the hole on the support until you feel

it click.

5. Connect the cable for the DM-D500 to the DM connector on the TM

printer.

12

Page 15

Engli

h

Attaching to the TM-U375/TM-U950

t

f

fixi

The DM-D500 can be attached directly to the TM-U375/TM-U950

printers using the “DM-D pole unit for TM printers (Type A)”

(DP-502).

Required items

The following items are used to attach the DM-D500 to the TM-U375/

TM-U950 printers. These items are packed with the “DM-D pole unit

for TM printers (Type A)” (DP-502).

<For TM-U375>

rubber feet

(square)

fixing screws

for rubber feet

(large)

rubber fee

(large)

ixing screws

for metallic

portion

<For TM-U375 and TM-U950>

<For TM-U950>

rubber feet

(square)

ng screws

for plastic position

s

support B

for extension

support C

fixing plate A

13

Page 16

Assembling steps

1. Pass the cable for the DM-D500 through support C, and attach

support C to the DM-D500.

When using support B for extension, insert the tab on support B

into the hole on support C until you feel it click.

When using support B

for extension

2. Attach the rubber feet to the printer.

14

[TM-U375]

[TM-U950]

Page 17

Engli

h

3. Pass the cable for the DM-D500 through the hole on fixing plate A,

and fix the cable at the bottom as shown below.

4. Connect the cable for the DM-D500 to the DM connector on the TM

printer.

s

5. Adjust the length of the cable and secure fixing plate A to the

printer with screws.

[TM-U375] [TM-U950]

15

Page 18

6. Store any excess cable in the support, and attach the DM-D500 to

fixing plate A.

Attaching to the TM-H6000/TM-U675

The DM-D500 can be attached directly to the TM-H6000/TM-U675

printers using the “DM-D pole unit for TM printers (Type A)”

(DP-502). You can attach fixing plate A on either side of the

TM-H6000/TM-U675. After attaching it, you can slide the display

freely.

Required items

The following items are used to attach the DM-D500 to the TM-H6000/

TM-U675 printers. These items are packed with the “DM-D pole unit

for TM printers (Type A)” (DP-502).

stopper

fixing screws for

rubber feet (small)

16

support C

fixing screw

for stopper

rubber feet (small)

support B

for extension

angle fixing

screw

fixing plate B

fixing screws for

fixing plate B

fixing plate A

Page 19

Engli

h

Assembling steps

1. Pass the cable for the DM-D500 through support C, and attach

support C to the DM-D500.

When using support B for extension, insert the tab on support B

into the hole on support C until you feel it click.

When using support B

for extension

2. Attach the rubber feet to the printer.

s

3. Attach fixing plate B to the printer.

17

Page 20

4. Pass the cable for the DM-D500 through the hole on fixing plate A,

and fix the cable at the bottom as shown below.

5. Connect the cable for the DM-D500 to the DM connector on the TM

printer.

6. Attach fixing plate A to the TM printer using the stopper. When

you attach the stopper, insert the projections on the stopper into the

holes of fixing plate B. Fixing plate A can be attached on either side

of the printer. (The illustration below shows fixing plate A attached

to the right side of the printer.)

18

Page 21

Engli

h

7. The horizontal rotation mechanism of fixing plate A can be

adjusted. To secure the location of the display, set fixing plate A to

either one of the following four positions and secure it with the

angle fixing screw.

s

19

Page 22

Note:

The paper roll cover may not open if the position of the display is

inappropriate. Before securing the position of the display, make sure that

you can open the paper roll cover.

paper roll cover

8. Store any excess cable in the support and attach the DM-D500 to

fixing plate A.

9. Connect the power cable of the printer. To avoid disconnection,

hook the cable to the tabs on fixing plate B, as shown below.

20

Page 23

Engli

h

Attaching to Other TM Printers

When using with other TM printers, the DM-D500 can be attached to a

desk or other surface, using the “DM-D pole unit for TM printers

(Type A)” (DP-502), and Velcro tapes or screws.

Required items

The following items are used when the DM-D500 is used with other

TM printers. These items are packed with the “DM-D pole unit for TM

printers (Type A)” (DP-502).

Velcro tapes

support B (for extension)

fixing plate A

fixing screws for

wood position

Velcro tapes

support C

Assembling steps using Velcro tapes

s

1. Attach Velcro tapes to the bottom of fixing plate A.

21

Page 24

2. Pass the cable for the DM-D500 through support C, and attach

support C to the DM-D500.

When using support B for extension, insert the tab on support B

into the hole on support C until you feel it click.

When using support B

for extension

3. Pass the cable for the DM-D500 through the hole on fixing

plate A, and fix the cable at the bottom as shown below.

22

4. Connect the cable for the DM-D500 to the DC connector on the

TM printer.

Page 25

Engli

h

5. Store any excess cable in the support, and attach the DM-D500

to fixing plate A.

6. Peel off the Velcro tapes, and attach the display to the setting

position.

Assembling steps using screws

1. Follow steps 2 and 3 in “Assembling steps using Velcro tapes.”

2. Secure fixing plate A to the setting position with fixing screws.

s

3. Attach the DM-D500 to fixing plate A.

23

Page 26

Attaching to the DM-D stand

>

The DM-D500 can be attached directly to the DM-D stand using the

“DM-D stand unit for DM-D 500” (DP-501). The DM-D500 with the

DM-D stand can be connected to a TM printer, or be used as a stand

alone product.

Required items

The following items are used to attach the DM-D500 to the DM-D

stand. Note that an optional power unit (PS-170) is required when

using the DM-D stand. Also, another optional extension support

(DP-105) is required if you want to extend the length of the DM-D500.

Please get them separately from the DM-D stand unit (DP-501).

<DM-D stand unit for DM-D500 (DP-501)>

DM-D stand

extension cable for

power supply

<extension support (DP-105)

Velcro tapes

extension support

interface connector

base plate

RS-232C connector installation screw

(mm type)

<power supply unit (PS-170)>

power

supply unit

AC cable

24

Page 27

Engli

h

Connectors for the DM-D stand

The connectors for the DM-D stand are as follows:

computer connector

power supply unit connector

display connector

printer connector

extension cable connector

Note:

The DM-D stand comes with inch-type hexagonal lock screws installed to

secure the interface cable to the interface connector for RS-232. If you plan to

use an interface cable which requires millimeter-type lock screws, replace the

inch-type screws with the included millimeter-type screws using a hex

screwdriver (5mm). To distinguish the two types of screws, see the illustration

below.

notch (one or more lines)

inch-type

millimeter-type

RS-232C connector

installation screw

s

25

Page 28

Jumper setting

Set the jumpers on the DM-D stand as follows:

JP1 JP2 Contents

1-2 1-2 Set the jumpers as in the left columns when connecting both the TM

printer and the DM-D stand. (Default setting)

2-3 2-3 Set the jumpers as in the left column when using the DM-D stand as

stand alone. (TM printer is not connected.)

The jumpers are located as follows:

Precautions on using the power supply unit

To avoid damage to the DM-D500 and the power supply unit, make

sure to note the following points.

❏ Use the optional Seiko Epson products, PS-170, or PA-6508,

PA-6511, PA-6513, PB-6509 or PB-6510 as the power supply.

❏ Never connect the DC cable to the power supply unit when the

power supply unit is connected.

❏ Unplug the DC cable by holding the connector part. If you pull the

cable to unplug, it may be damaged.

26

Page 29

Engli

h

Assembling steps

1. Pass the cable for the DM-D500 through the DM-D stand.

When extending the length of the DM-D stand, attach the extension

support (DP-105) to the DM-D stand.

When using the

extension support

(DP-105)

2. Insert the tab on the DM-D500 (or the extension support) into the

hole on the DM-D stand until you feel it click.

s

3. Connect the cable for the DM-D500 to the display connector on the

DM-D stand until you feel it click.

27

Page 30

4. Connect one end of the computer interface cable to the computer

connector on the DM-D stand; then connect the other end to the

RS-232 connector on the computer. Tighten the screws on both ends

of the cables to fasten them.

computer

5. When using as a stand alone, go to step 6.

When using with the printer, connect one end of the printer

interface cable for the printer to the printer connector on the DM-D

stand; then connect the other end to the connector on the printer.

Tighten the screws on both ends of the cable to fasten them.

28

printer

Page 31

Engli

h

6. When not using the extension cable for power supply packed with

e

the DM-D stand, go to step 7.

When using the extension cable, connect it (with the arrow mark

up) to the extension cable connector indicated with “POWER OUT”

on the DM-D stand; then connect the other end to the power

connector on the printer.

extension cabl

connector

extension cable for

power supply

7. Connect the DC cable of the power supply unit (with the arrow

mark up) to the power supply unit connector indicated with

“POWER IN” on the DM-D stand.

power supply unit

connector

DC cable of power

supply unit

s

8. When using as a stand alone product, set the jumpers. (See “Jumper

setting” on page 26.)

29

Page 32

9. Arrange the cables as shown below. Put the cables for the DM-D500

inside the DM-D stand.

10. Attach the base plate to the DM-D stand following the number of

the arrow shown below. At this time, push the base plate until it is

locked by the hook on the DM-D stand.

11. When the extension support (DP-105) is used, attach Velcro tapes to

the four corners of the plate to avoid falling down.

12. Connect the cord of the power unit to the socket.

30

Page 33

Engli

h

Part Names and Functions

Exterior

s

DIP switch

(rear side of the display)

display

power switch

(bottom of the display)

❏ Display: Characters are displayed.

❏ Power switch: The power is turned on/off.

❏ DIP switch: The functions of the DM-D500 are changed.

(See “DIP switch” for details.)

Note:

When turning on the DM-D500 again after turning it off, wait for at least

3 seconds.

31

Page 34

DIP Switch

DIP Switch Functions

The DM-D500 has two groups of DIP switches. The functions of the

DIP switches are as follows:

DIP switch 1

DSW1 No. Function ON OFF Default setting

1-1 Data receive error Ignored Displays “?” OFF

1-2 Hand shaking XON/XOFF (*1) DTR/DSR OFF

1-3 Data length 7 bits 8 bits OFF

1-4 Parity on or off Parity No parity OFF

1-5 Parity type Even Odd OFF

1-6

1-7 OFF

1-8 ON

(*1)XON/XOFF is effective only when the DM-D500 is connected with a stand alone.

Change transmis-

sion speed

See “Transmission speed.”

Transmission speed

ON

SW1-6 SW1-7 SW1-8 Transmission speed (bps)

ON ON ON 2400

OFF ON ON 4800

ON OFF ON 9600

OFF OFF ON 19200

ON ON OFF 38400

OFF ON OFF 57600*

ON OFF OFF 115200*

*Cannot be set to 57,600 or 115,200 when using the IR Series.

32

Page 35

Engli

h

DIP switch 2

DSW2 No. Function ON OFF Default setting

2-1 Y-connection (*1) Enable Disable OFF

2-2 Self test selection (*2) Perform self test Do not perform OFF

2-3 20 column and 2 line

mode selection (*3)

2-4 Device selection

default setting

2-5 Address 0 The display device number

2-6 Address 1 OFF

2-7 Address 2 OFF

2-8 Reserved (*5) - Fixed to OFF OFF

(*1)The “Y-connection enable” is set when a TM printer with no modular jack for the

DM-D is connected with this product, using one COM port to connect both TM

printer and DM display. In this case, an optional DM-D stand (DP-501) and a

connecting cable are required. In the cases other than above, choose

“Y-connection disable” (default setting).

(*2)This function can select whether or not you perform self test when turning on the

power. See “Self Test” for details.

(*3)When selecting “20 column and 2 line mode,” this product can be used like the

DM-D105/106/205/206. In this case, the graphic display and the original functions

for the DM-D500 cannot be used, but when selecting “256 × 64 dots mode,” they

can be used.

(*4)When setting to “Printer is selected,” data is sent to the TM printer, but is not

displayed on the display. When setting to “Display is selected,” data is displayed

on the display but is not output from the TM printer.

The selection can be changed using <ESC=> command.

(*5)Stay at OFF setting.

20 column and

2 line mode

Printer is

selected

(1-7) corresponds to Address number 0 to 2.

(All OFF are regarded as no display number.)

256 ¥ 64 dots

mode

Display is

selected

OFF

OFF

OFF

s

Note:

❏

The changes in the DIP switch setting are effective when the power is

turned on again.

❏

The data transmission setting, such as data length, transmission speed,

must be the same on both your computer and printer.

33

Page 36

Setting the DIP switches

CAUTION:

Turn off the DM-D500 while removing the DIP switch cover to

prevent electrical damage to the DM-D500.

1. Turn off the power for the DM-D500.

2. Remove the DIP switch cover.

DIP switch cover

3. Change each setting of the switches with a pointed object, such as a

pen tip or small screwdriver.

4. Close the cover, and turn the power on.

34

Page 37

Engli

h

Turning and Tilting the DM-D5 0 0

You can turn or tilt the display while holding the support. The display

can be moved easily, so do not move any further if it stops. If you move

it by force, you may damage it.

With the “DM-D pole unit for IR” (DP-504) and the “DM-D pole unit

for TM printers (Type B)” (DP-503), the display area maynot face the

direction you desire. In this case, remove the base, change the position

of the tab ob the base so that the display faces to the direction you

desire, and reattach it to the base.

48°

45° for left

(you can turn the same angle for right.)

The display area has the following range of movement:

❏ Tilt: 48° max. (4 steps, 5 positions)

s

❏ Horizontal rotation: 90° max. (45° for each left and right)

35

Page 38

Self Test

The DM-D500 has a self test function. If you want to perform a self test,

you must change the setting of the DIP switch.

Check Items of Self test

The following items are checked during the self test:

❏ Control ROM version

❏ DIP switch settings

❏ Example of display characters

❏ Example of each function, such as brightness, flashing, and scroll

Performing Self test

To perform the self test, follow the steps below.

1. Turn off the power for the DM-D500.

2. Set the SW 2-2 of the DIP switch 2 to ON, and turn on the power.

Note:

If the contents of the self test are not displayed, the DM-D500 may be

malfunctioning. Please contact your DM-D500 dealer for assistance.

When the self test is finished and no error occurs, the cursor is

displayed at the home position; then the DM-D500 is ready to receive

data.

36

Page 39

Engli

h

Specification

General Specifications

❏ Height, Width, Depth and Weight

<DM-D500 and DM-D stand>

213 mm

s

DM-D500

DM-D stand (DP-501)

200 mm

90°

• DM-D500:

Height: 83 mm

Width: 213 mm

Depth: 51 mm

Weight: 460 g

• DM-D stand (DP-501):

Height: 65 mm

Width: 200 mm

Depth: 118 mm

Weight: 440 g

83 mm

65 mm

51 mm

48°

118 mm

37

Page 40

DM-D pole unit for IR

Series (DP-504)

<DM-D pole units>

DM-D pole unit for

TM printer (Type B)

(DP-503)

DM-D pole unit for

TM printers (Type A)

(DP-502)

50 mm

129 mm

53 mm

base

248 mm

78 mm

260 mm

164 mm

• Base and support A of the “DM-D pole unit for IR Series”

(DP-504):

Height: 129 mm

Width: 50 mm

Depth: 53 mm

Weight: 60 g

• Base and support C of the “DM-D pole unit for TM printers

(Type B)” (DP-503):

Height: 248 mm

Width: 50 mm

Depth: 53 mm

Weight: 116 g

38

• Fixing plate A and support C of the “DM-D pole unit for TM

printers (Type A)” (DP-502):

Height: 260 mm

Width: 78 mm

Depth: 164 mm

Weight: 264 g

Page 41

Engli

h

❏ Tilt angle Max 48° (4 steps, 5 positions)

❏ Horizontal rotation

Max 90° (for each left and right at 45°)

❏ Vacuum fluorescent display

• Total number of dots: 256 (W) × 64 (H) dots

• Dot pitch: 0.55 × 0.55 mm

• Number of characters: 32 column × 4 lines max.

(When using Font A)

• Number of characters: 42 column × 8 lines max.

(When using Font B)

• Display color: Green (505 nm)

• Brightness: 300 (cd/m

Electrical Specifications

❏ Type PS-170, PA-6508, PB-6509, PB-6510,

PA-6511, PA-6513 (when using the DM-D stand)

❏ Rated voltage DC 11.4 to 48 V

❏ Rated current 0.53 A (at 11.4V) (max.)

s

2

)

Environmental Specifications

❏ Operation environment

Temperature: 5°C to 40°C

Humidity: 30% to 85% (No condensation)

❏ Storage environment

Temperature: −10°C to 50°C

Humidity: 30% to 90% (No condensation)

39

Page 42

Character Specifications

❏ Type of character

• Alphanumeric characters: 95

• International characters: 37

• Extended graphics: 128 characters × 12 pages

• Kanji characters (The Kanji character model supports printing

with one of the following character sets.):

❏ Character grid

• Font A: 8 × 16 dot

• Font B: 5 × 7 dot

• Kanji: 16 × 16 dot

❏ Character style

• Black/White reverse and emphasis

• Size change, character spacing, and line spacing

(Only for the window on the graphic mode)

Japanese Kanji (JIS Level 1 and 2)

Chinese Kanji (GB2312)

❏ Emulation mode

• Cursor (except the window on the graphic mode):

• Period, comma: DM-D20x emulation

• Annunciator: DM-D20x emulation

Reliability Specification

❏ MTBF (vacuum fluorescent display only)

40

DM-D10x emulation

30,000 hours

(a half-value period of the brightness)

Loading...

Loading...