Page 1

1

VERTICAL MACHINING CENTER

VS50/60

INSTRUCTION MANUAL

OPERATION

SEIKI-SEICOS Σ16M/18M

Version 1.01

BO-2782-1-0221-E-1-01

Page 2

1

Introduction

Thank you for your having purchased the machine, favoring our product lines for your use.

This manual contains fundamental information on the machine operation. Please read and fully

understand the contents for your safe machine operation.

In particular , the contents of the items concerning safety in this manual and the descriptions on the

“caution plates” attached to the machine are important. Please follow the instructions contained

and keep them always in mind to ensure safe operation.

The reference record papers on adjusting setting values such as a parameter list are attached to

the machine unit and enclosed in the packing. These are necessary for maintenance and

adjustment of the machine later on. Please keep them safely not to be mislaid.

The design and specifications of this machine may be changed to meet any future improvement.

As the result, there may arise some cases where explanations in this manual could become partly

inconsistent with the actual machine. Please note this point in advance.

In this manual, items on the standard and optional specifications are handled indiscriminately.

Please refer to the “delivery note” for the detailed specification of your machine confirmation.

Page 3

i

CONTENTS

OPERATION OF MACHINE...................................................................... 1 -1

1. Daily Maintenance and Inspection.......................................................................................1 -1

2. Outline of Main Operation Panel and NC Operation Panel ..................................................1 -1

2-1 Operation by Using the Main Operation Panel and Sub-operation Panel...................... 1 -1

2-2 NC Operation Panel................................................................................................. 1 -15

3. Operational Procedures....................................................................................................1 -18

3-1 When St arting the Machine...................................................................................... 1 -18

3-2 Warming-up Operation of Spindle ............................................................................1 -19

3-3 Zero Return Procedures .......................................................................................... 1 -20

3-4 When Completing the Daily Operation.....................................................................1 -21

4. Manual Operation..............................................................................................................1 -22

4-1 Each Axial Feed .......................................................................................................1 -22

4-2 Rapid Traverse ........................................................................................................ 1 -22

4-3 Mounting and Dismounting the Tool ......................................................................... 1 -23

5. Manual Data Input (MDI) Operation...................................................................................1 -24

5-1 Each Axial Feed .......................................................................................................1 -24

5-2 Coolant .................................................................................................................... 1 -24

5-3 Spindle Speed Change and Spindle Revolution........................................................ 1 -24

5-4 Spindle Positioning................................................................................................... 1 -25

6. Registration of Program .....................................................................................................1-26

6-1 Registration from an External Device .......................................................................... 1-26

6-2 Manual Registration by the Address/Numeral Keys..................................................... 1-27

7. Program No. Search...........................................................................................................1-29

7-1 Search by Key in a Program No. ................................................................................. 1-29

7-2 Search to Utilize the Program List. .............................................................................. 1-30

8. Edition of Program.............................................................................................................. 1-31

8-1 Preparation in Advance at the Time of the Edition of Program..................................... 1-31

8-2 Search of Word ........................................................................................................... 1-32

8-3 Edition of Program .......................................................................................................1-33

8-4 Back Ground Editing ....................................................................................................1-39

8-5 Copy of Program ......................................................................................................... 1-41

8-6 Editing Procedure of Range Designation (Expanded Tape Editing/Option) ................. 1-42

8-7 Alteration of Word (Expanded Tape Editing)................................................................. 1-43

8-8 Deletion of Program..................................................................................................... 1-45

8-9 Arrangement of Program ............................................................................................. 1-46

8-10 Process After Edition ................................................................................................. 1-47

9. Output of Program.............................................................................................................. 1-48

Page 4

ii

10. Automatic Operation ........................................................................................................1-50

10-1 When Machining the First Workpiece, Checking the Newly Created Program.......... 1-50

10-2 Program Memory Operation ...................................................................................... 1-50

10-3 When Inserting Manual Operation in Automatic Operation......................................... 1-51

10-4 When Performing MDI Operation in Automatic Operation.......................................... 1-51

1 1 . Operation of Automatic Tool Changer (A TC)................................................................... 1 -52

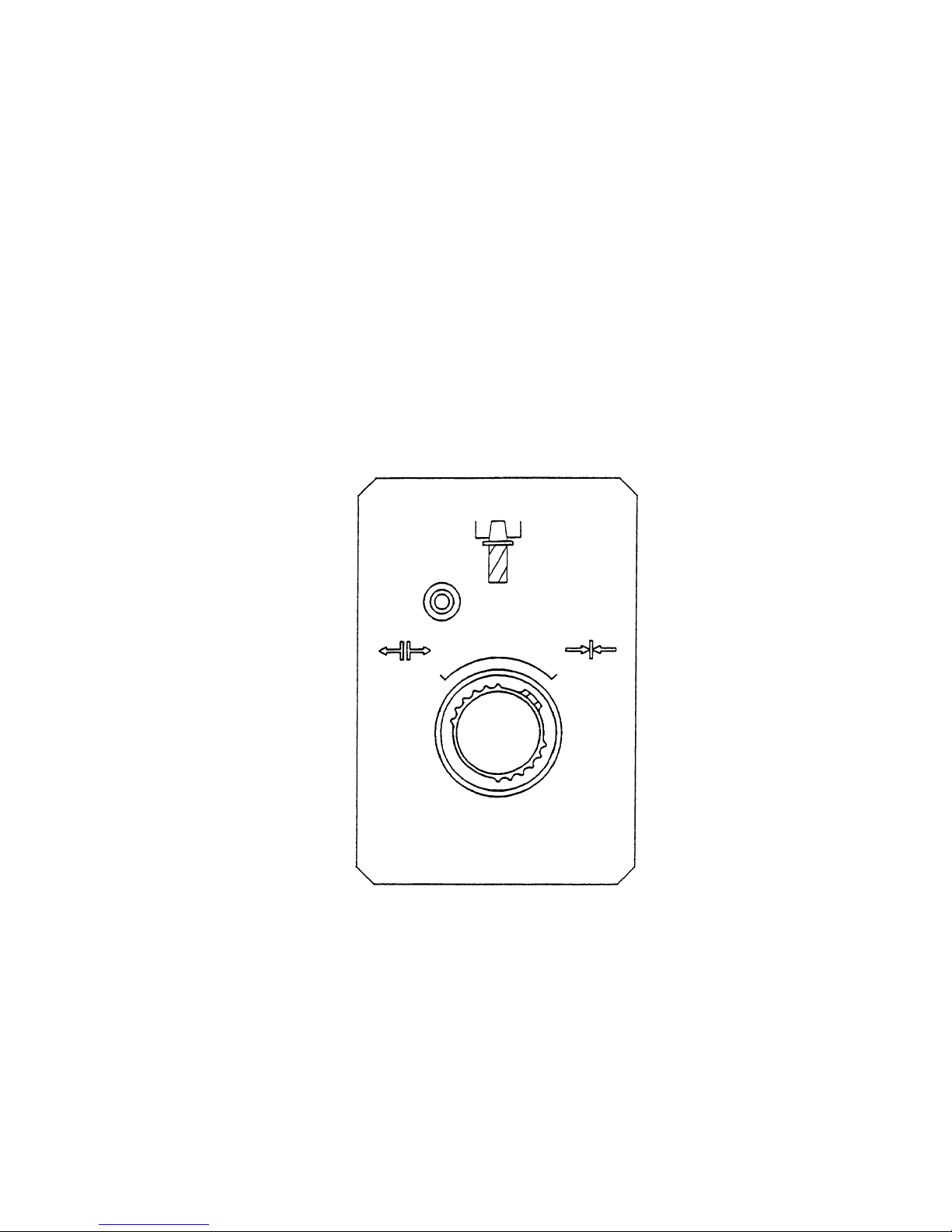

11-1 Names of ATC Each Section.................................................................................. 1 -52

1 1-2 Explanation of Actions ............................................................................................ 1 -53

1 1-3 Rot ation of Tool Storage Magazine (at Single Mode) ..............................................1 -56

11-4 Attachment and Detachment of Tools .................................................................... 1 -57

1 1-5 Relation Between Spindle Nose Key and A TC........................................................ 1 -58

1 1-6 Attention When Using Oil Hole T ool........................................................................ 1 -58

11-7 ATC Program Operation......................................................................................... 1 -59

11-8 Condition Check During ATC Execution ................................................................. 1 -60

12. Setting (Data).................................................................................................................... 1-62

12-1 Outline ....................................................................................................................... 1-62

13. Time Measuring, Data.......................................................................................................1-64

13-1 Time Measuring ......................................................................................................... 1-64

13-2 Date and Time ........................................................................................................... 1-65

14. Animated Drawing.............................................................................................................1-66

14-1 Outline ....................................................................................................................... 1-66

14-2 Drawing Parameter.................................................................................................... 1-67

15. Parameter Setting.............................................................................................................1-70

16. Operations Concerning W-Setter ...................................................................................1 -74

16-1 Outline.................................................................................................................... 1 -74

16-2 Input Signal and V arious Operations...................................................................... 1 -74

16-3 Operation for Setting of Work Setter Reference Surface....................................... 1 -75

16-4 Operation for Setting of Work Setter Reference Hole ............................................1 -76

16-5 Operation for Setting of Work Setter Coordinate Modification................................ 1 -77

16-6 Manual Overwriting of Work Zero Point Offset Amount. .........................................1 -78

16-7 Setting Operation of Tool Setter ............................................................................. 1 -78

16-8 Tool Length Measuring Mode, Tool Diameter Measuring Mode .............................. 1 -80

16-9 Parameter.............................................................................................................. 1 -81

16-10 Others.................................................................................................................... 1 -82

17. Safety Guard.....................................................................................................................1-84

17-1 Safety Guard (Tool Length) ........................................................................................1-84

17-2 Safety Guard (Comparison)....................................................................................... 1-88

18. Tool Life Management .......................................................................................................1-92

18-1 Tool Life Management ................................................................................................ 1-92

18-2 Sp are Tool Management ............................................................................................ 1-94

18-3 Premachining Tool Check .......................................................................................... 1-95

18-4 Tool Skip and Tool Reset............................................................................................ 1-96

18-5 Tool Life Management Program ................................................................................. 1-96

18-6 Tool Life Management Operation ............................................................................. 1-100

Page 5

iii

18-7 Tool Life Screen ....................................................................................................... 1-101

18-8 Spare Tool Screen.................................................................................................... 1-105

18-9 Tool Status List Screen ............................................................................................1-108

18-10 Tool Life Management Parameters and Their Setting ............................................ 1-109

18-1 1 Alarms .................................................................................................................... 1-110

19. Cutting Monitoring Unit .................................................................................................... 1-111

19-1 Outline ......................................................................................................................1-111

19-2 Monitoring Method .....................................................................................................1-111

19-3 Monitoring Functions................................................................................................ 1-112

19-4 Cutting Monitoring Program ..................................................................................... 1-115

19-5 Data Setting ............................................................................................................. 1-118

19-6 Cutting Monitoring Operation.................................................................................... 1-120

19-7 Set Load Screen ......................................................................................................1-124

19-8 Load Graph Screen.................................................................................................. 1-127

19-9 Life Graph Screen.................................................................................................... 1-128

19-10 Display and Setting of Parameters ........................................................................ 1-129

19-1 1 Alarms .................................................................................................................... 1-133

Page 6

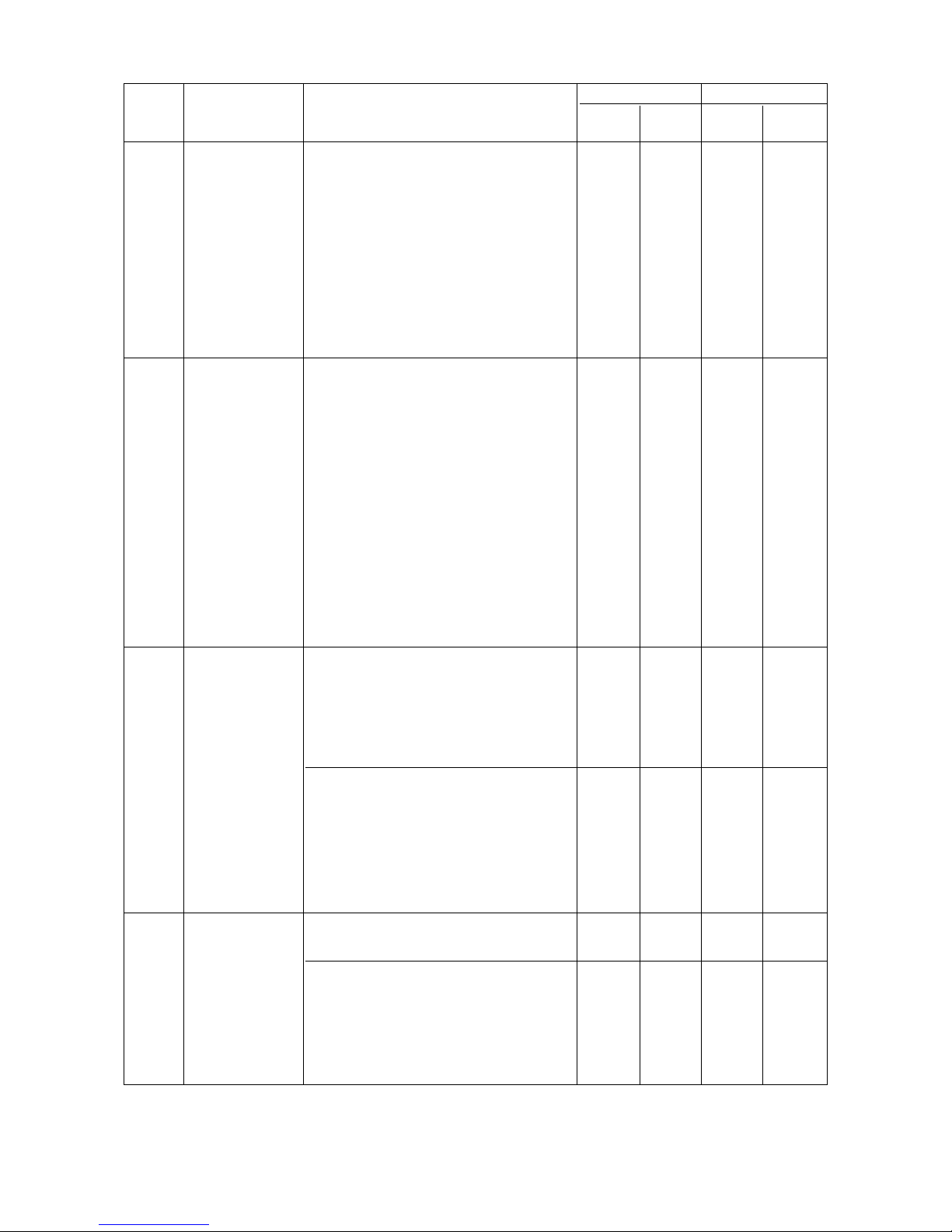

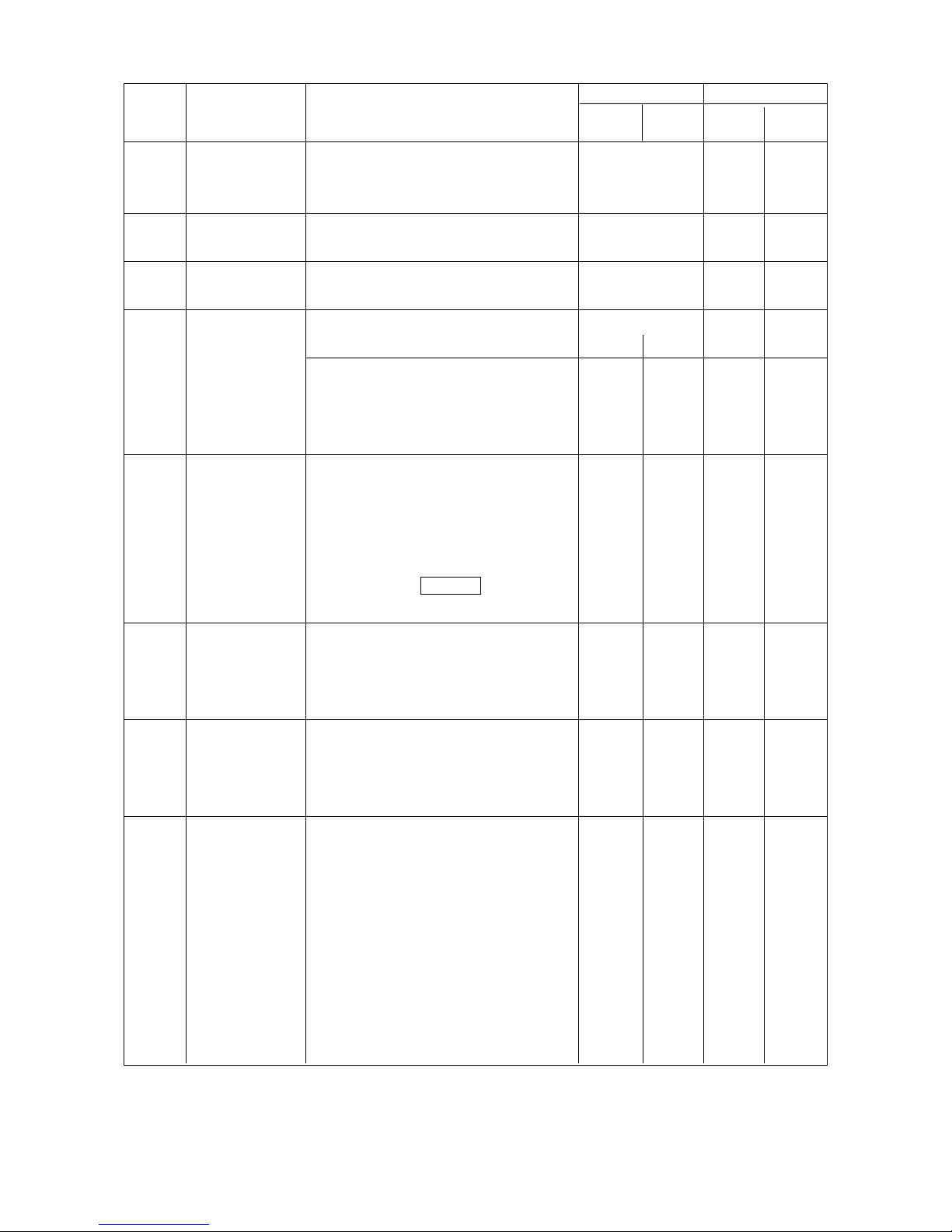

1 - 1

Note : When you operated a function which the specifications do not allow, the lamp of that push

button switch blinks, and the alarm lamp [8] and call light are turned on. Also, “NO

OPTION” is displayed on the CRT.

[1]

[2]

These are used for selecting

operation modes: “MDI”, “PROGRAM

EDITING”, “MEMORY AUTOMA TIC

OPERATION” and “TAPE

AUTOMATIC OPERATION”.

CANCEL Z... A machine lock

condition is applied to the Z axis only .

It is convenient if used for a program

test run.

MACHINE LOCK... Only a display

proceeds omitting axial moves of the

machine.

This function enables checking of

program coordinate values without

moving the axes.

DRY RUN... A manual jog feed rate

become valid instead of a feed rate

specified by the program

Operation method

Push

button

Lamp

Effective mode

Auto. Manual

Mode selector

switches

Function

selector

switches (Push

a necessary

function switch

with the

SELECT”

switch

pressed.)

UseName

Group

No.

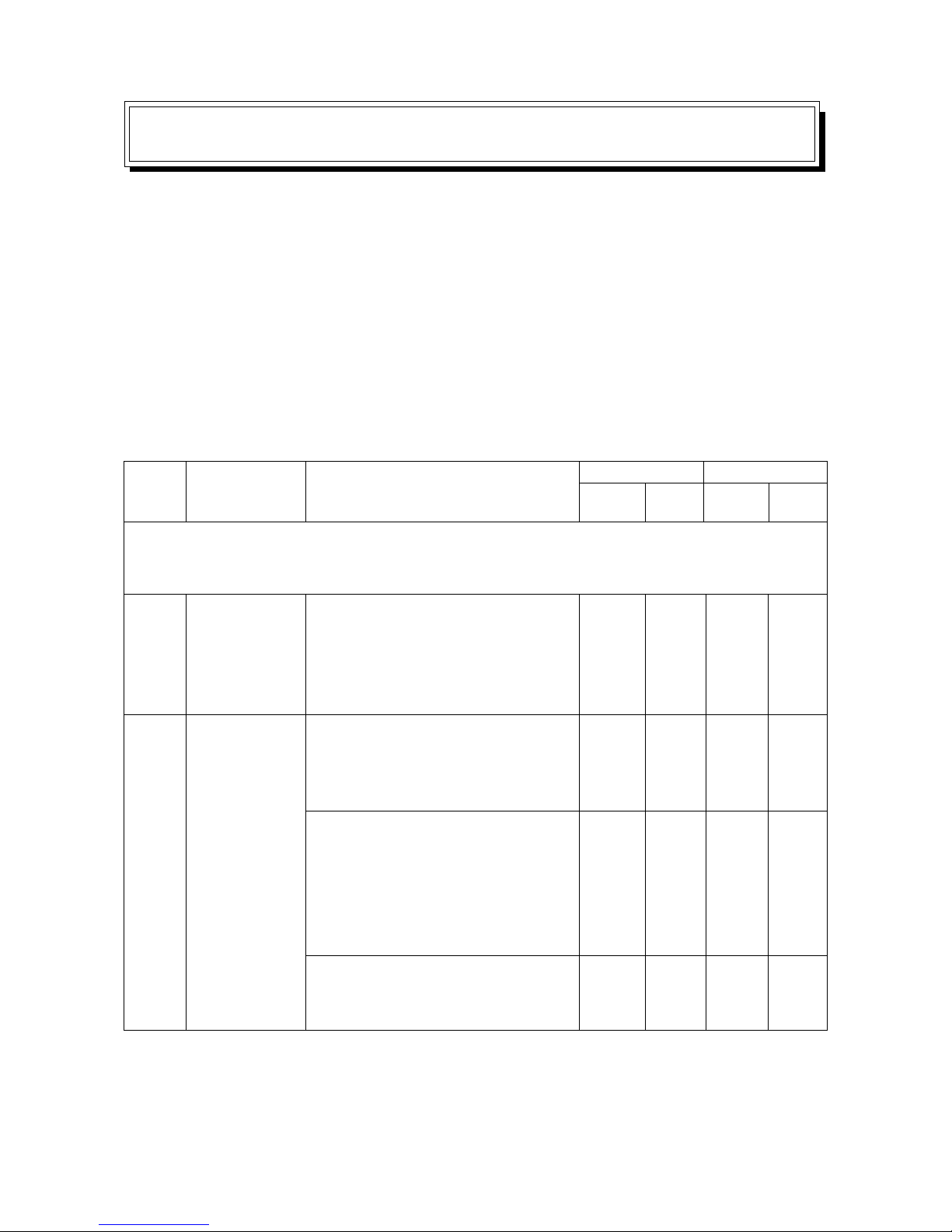

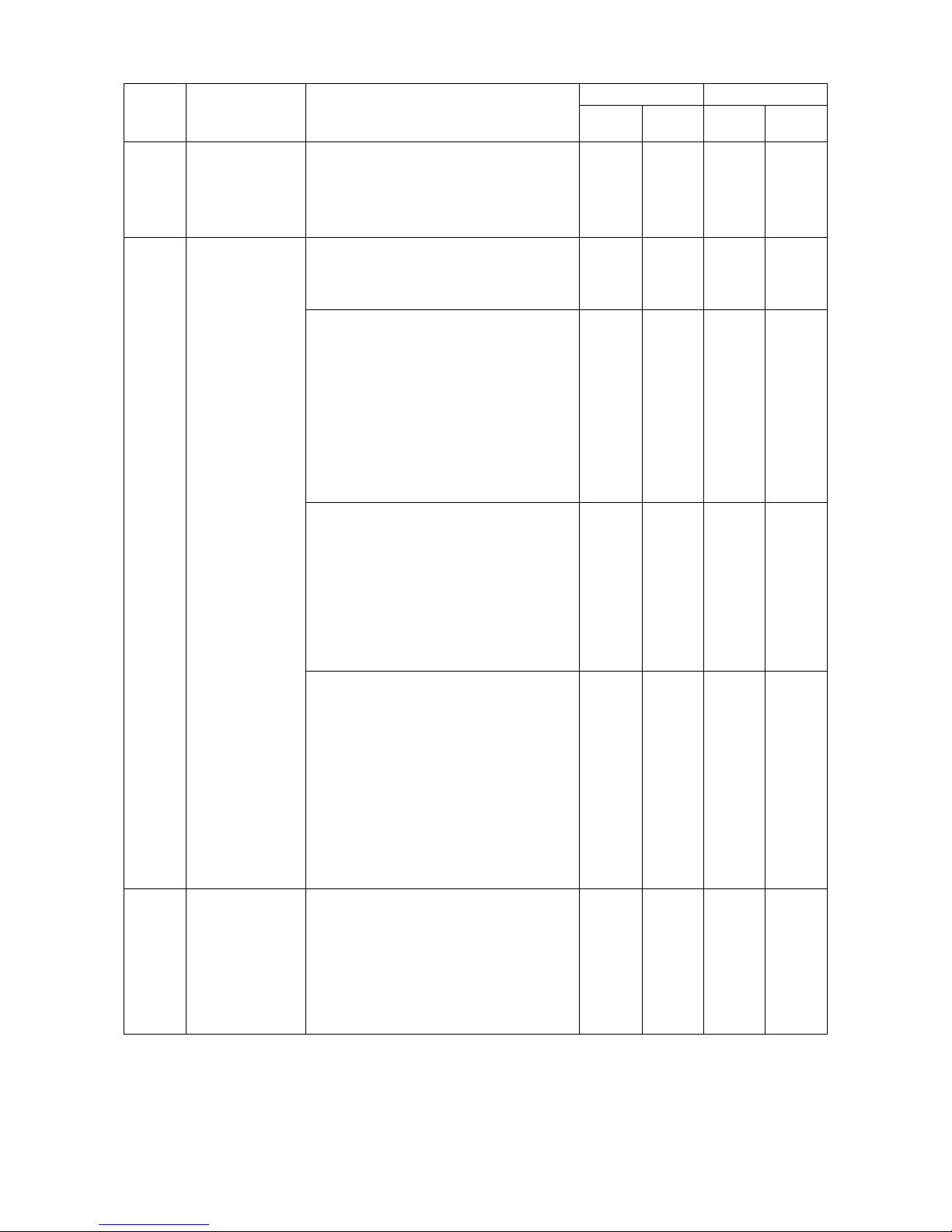

OPERATION OF MACHINE

1. Daily Maintenance and Inspection

To prevent trouble with the machine and keep it always in a good operating condition, daily check

is as important as the periodic maintenance and inspection. As for the daily maintenance, refer to

Chapter 2 “Daily Inspection Item List” of the “Maintenance Manual” and carry out necessary

inspections accordingly.

2. Outline of Main Operation Panel and NC Operation Panel

2-1 Operation by Using the Main Operation Panel and Sub-operation Panel

O

O

O

O

O

O

O

O

O

O

O

O

O

O

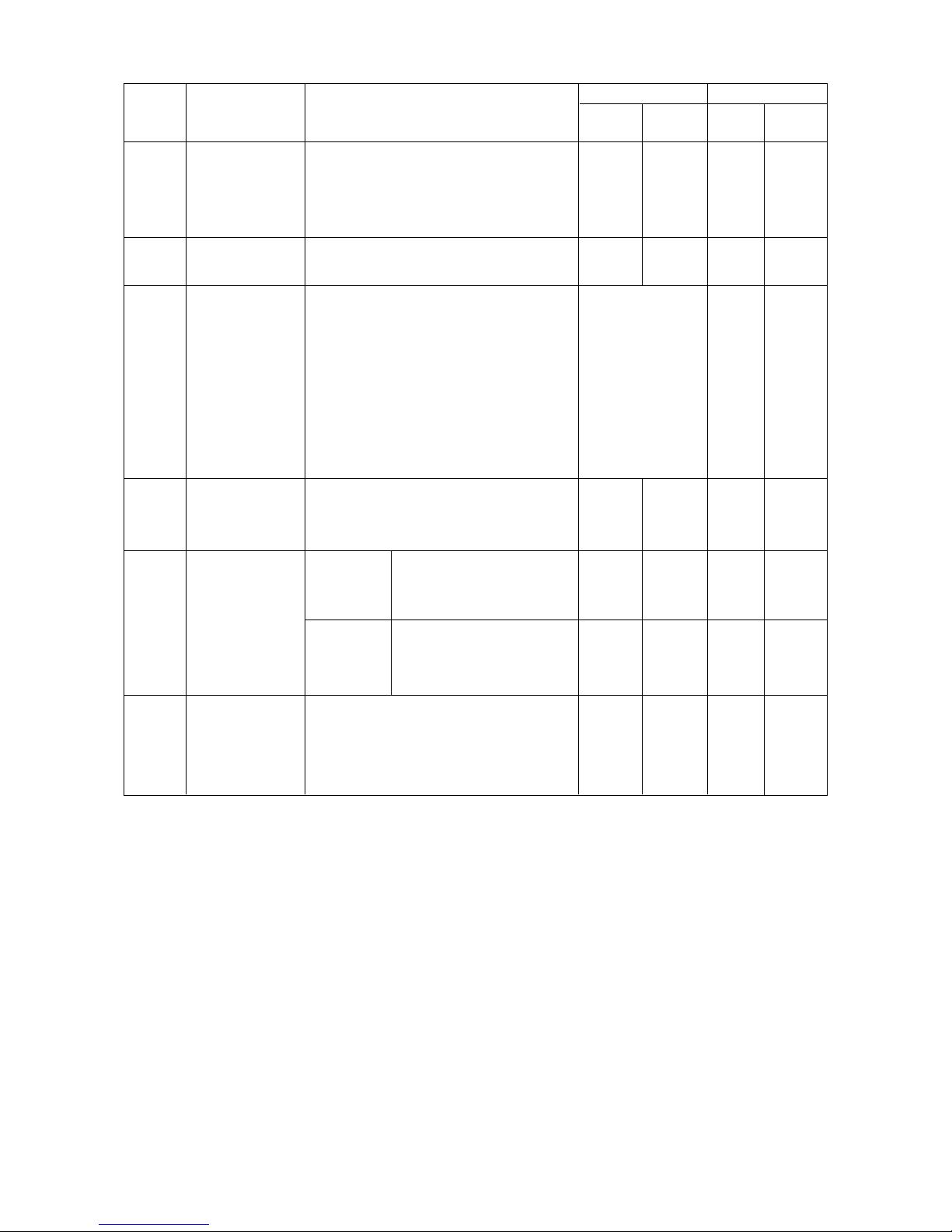

Page 7

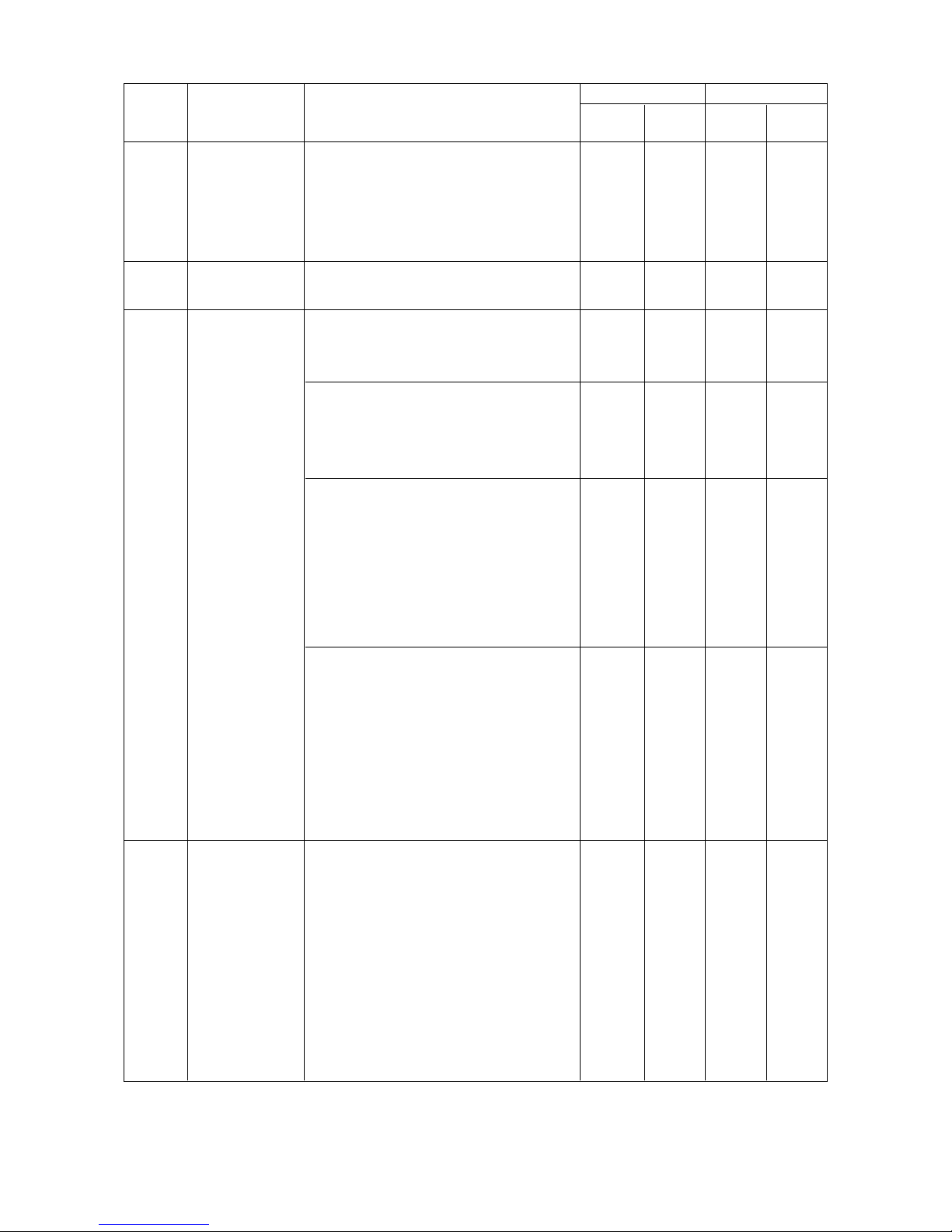

1 - 2

[3]

[4]

[5]

Spindle rotation

effective key

Mode selector

switches

Program START

/ FEED HOLD

switches

These push button switches start

and stop the spindle.

(It is necessary to specify a spindle

speed in advance.)

These are used for selecting

operation modes: “FEED”, and

“ZERO RETURN”.

FEED... This mode enables a

manual continuous feed. A feed axis

and its direction are selected by the

axis move push button switches [6],

and a feed rate by the FEEDRATE

[19] switches. Rapid traverse is

available by the rapid traverse

button.

RAPID... This mode enables a rapid

traverse. A rapid traverse axis and

its direction are selected by the push

button switches [6] and a rapid

traverse rate (override) by the

RAPID OVERRIDE push button

switches [17].

ZERO RETURN... This mode

enables zero return. For an axis to

be returned to the zero point, select

with the push button switches [6].

For a feed rate, an override of 25%

is applied.

When zero return is completed,

green lamp at [6] is lighted up, from

the blinking state.

START... IN the AUTO or MDI mode,

this push button switch start the

program. While this push button

switch is pressed and the program is

running, a lamp located above lights

up.

Operation method

Push

button

Lamp

Effective mode

Auto. Manual

Use

Name

Group

No.

O

O

O

O

O

O

O

O

O

O

O

OO

O

O

O

O

O

Page 8

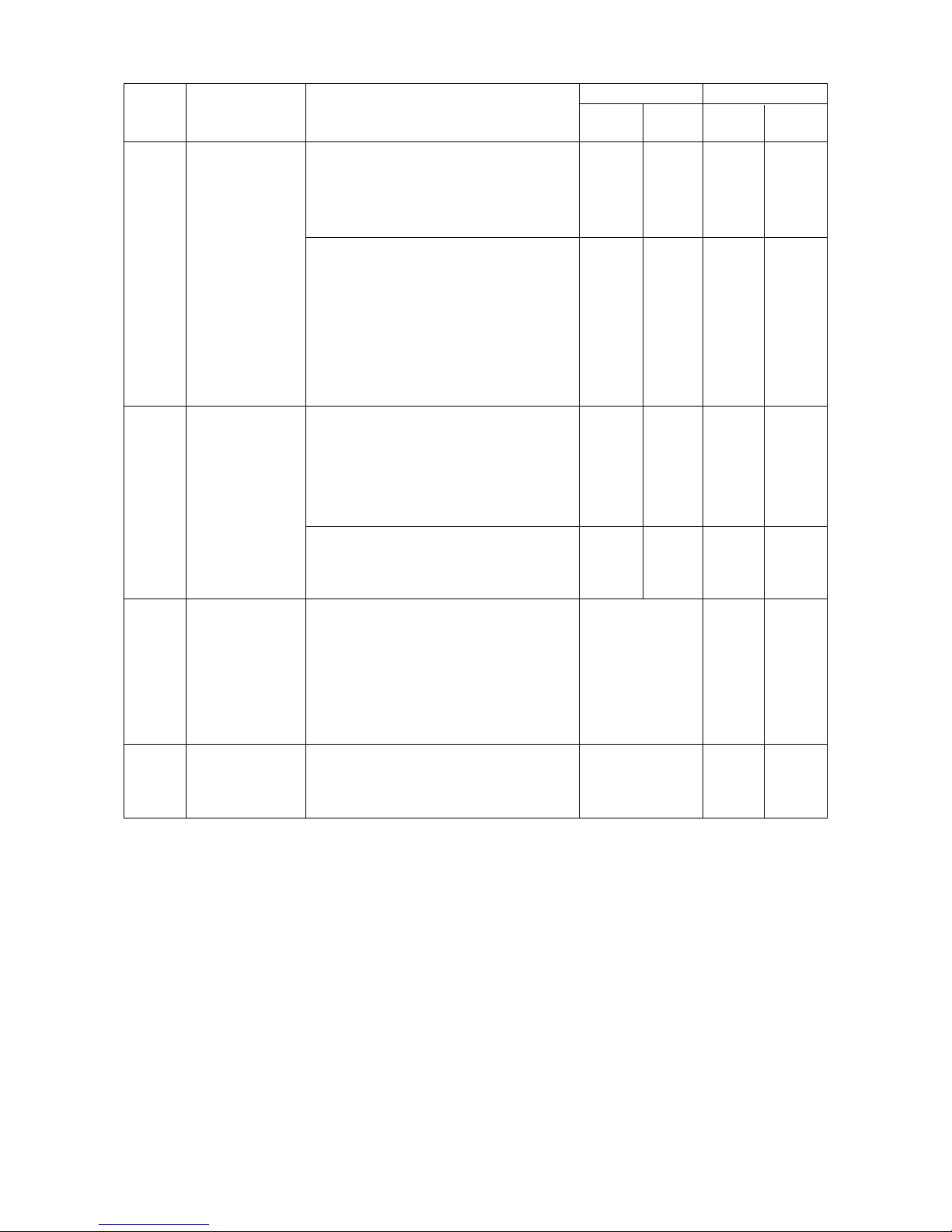

1 - 3

Program

START / FEED

HOLD switches

Axis move

switches

Initial position

check

Status display

lamp

[5]

[6]

[7]

[8]

Operation method

Push

button

Lamp

Effective mode

Auto. Manual

Use

Name

Group

No.

FEED HOLD.. This push button

switch suspends a program’s

progress. An axis being operated

stops and a red lamp located above

lights up. During operation by an

auxiliary command (M, S or T), the

program’s progress stops after

executing the remaining action of

respective command.

These push button switches move

the X, Y, Z and A (optional) axes

respectively.

Axis selection and its moving

direction abide by the indication

given on the respective push button

switches.

For a feed rate, select among the

FEEDRATE switches [22].

When executing rapid traverse, push

the rapid traverse button at the some

time.

APC INITIAL POSITION... This lamp

indicates that each machine section

is located at its specified position,

when executing an automatic. pallet

change (APC) command.

ATC INITIAL POSITION... This lamp

indicates that each machine section

is located at its specified position,

when executing an automatic tool

change (ATC) command. During T

cycle operates, this lamp lights up.

ALARM ... A red lamp lights up when

an alarm occurred.

PROGRAM STOP... When M00 or

M01 is executed during operation in

an automatic mode, a red lamp lights

up. It is lit off by starting or

continuing the program.

O

O

O

O

O

O

O

O

O

O

O

O

O

O

Page 9

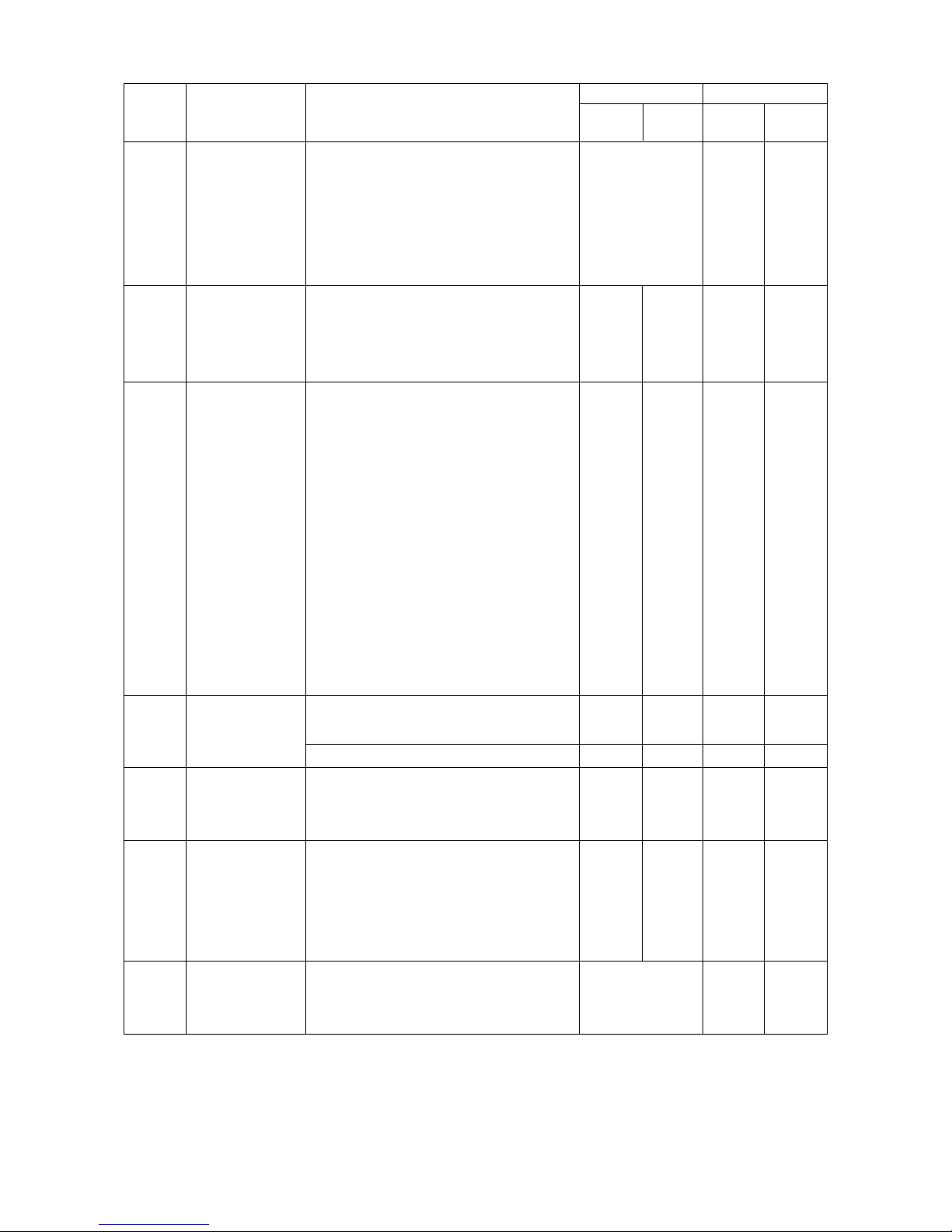

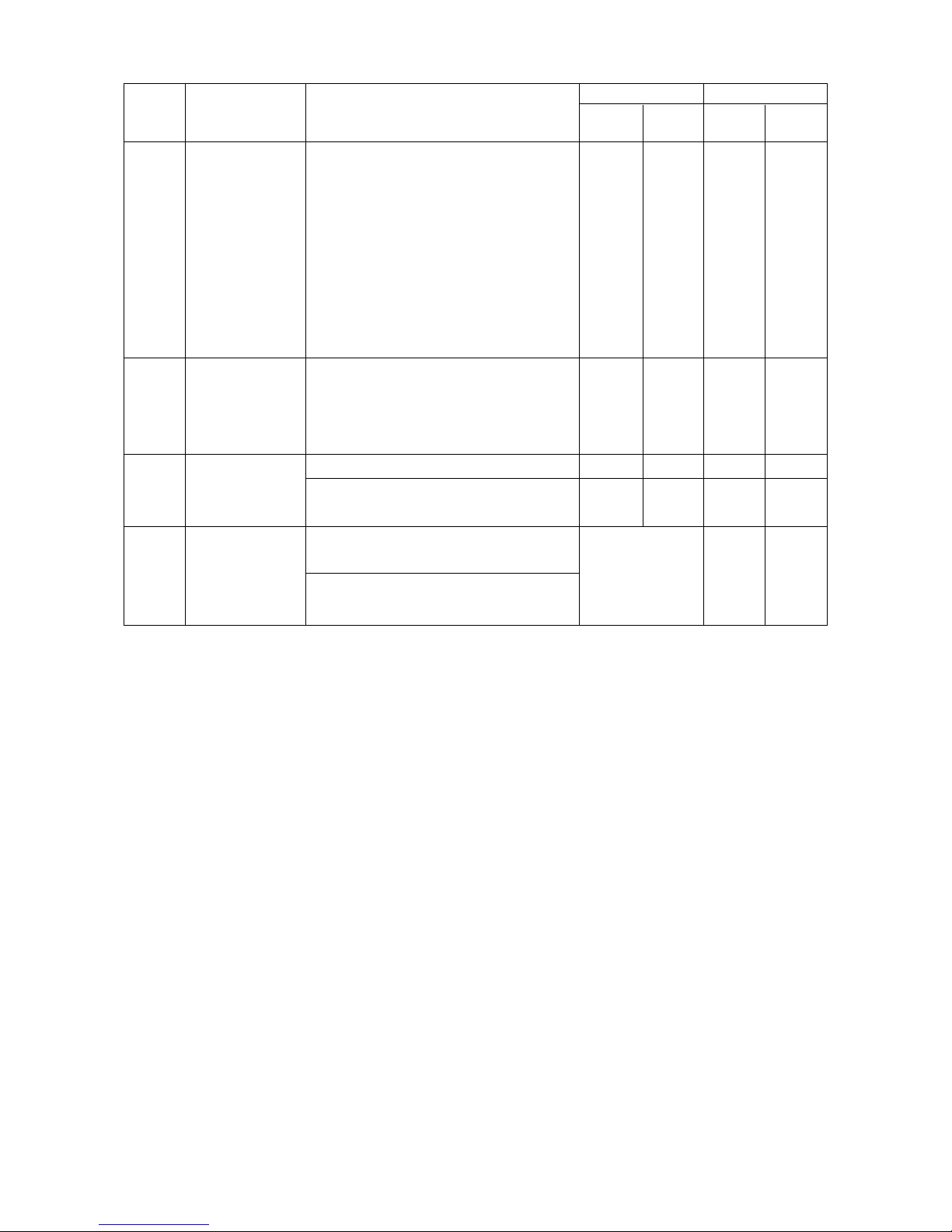

1 - 4

Automatic

power shut-off

switch

Call right off

switch

Work setter

Safety check

Operation method

Push

button

Lamp

Effective mode

Auto. Manual

Use

Name

Group

No.

[9]

[10]

[11]

[12]

This makes the automatic power

shut-off function effective. After

machining cycle is completed, the

power is automatically shut-off by

M30 when no pallet exists.

This switches off the lighting call

light (yellow lamp melody horning.

Makes the following functions

effective, making use of a reference

touch tool

TOOL SETTER... Measures a tool

length and a tool diameter and

automatically sets their offset

amounts in the offset memory.

REF. SURFACE, REF. HOLE ...

Measures the coordinate system

shift amounts of the reference

surface and hole against the

machine coordinate system and

sets them in the coordinate system

shift memory.

COORD ALIGN... By measuring 3

points on the orthogonal or jig

located on the X-Y plane,

differences in rotation angle with the

X and Y axes are calculated and

stored, thus compensating X-axis

and Y-axis program coordinate

values.

Measure a machining tool length by

the 1st program start. Measure the

workpiece at an actual machining

position with the reference touch

tool mounted to the spindle by the

2nd program start. A workpiece-tool

interference check is made by Zaxis approach (G00) command,

adding the tool offset amounts used

for these two information.

O

O

O

O

O

O

O

O

O

O

OO

O

O

O

Page 10

1 - 5

Operation method

Push

button

Lamp

Effective mode

Auto. Manual

Use

Name

Group

No.

[12]

[14]

[15]

[16]

Safety check

Override

Feedrate

override

switches

Spindle

override

switches

TOOL LENGTH... Measures and

stores the length of the tool used for

an actual machining program.

COLLATION... Sets the Z axis to a

machine lock state, operates the

machine with an actual machining

program and checks whether there

is an interference between the

workpiece and tool when Z axis

approaches.

MEMORY... Memorizes optimum

override values (feed rate, spindle

speed) found in trial cutting, etc.,

making them corresponding to the

tools used.

AUTO. ... The override values

memorized are automatically input

to a program.

These push button switches apply

an override (ranging from 0 to

200%) to a feed rate in automatic

(cycle) operation. During a canned

cycle for tapping, the override is

ignored, resulting in 100%.

These push button switches apply

an override (ranging from 50 to

150%) to a spindle speed command.

O

O

O

O

O

O

O

O

O

O

O

O

O

OO

(Rotary switch)

(Rotary switch)

Page 11

1 - 6

Operation method

Push

button

Lamp

Effective mode

Auto. Manual

Use

Name

Group

No.

[17]

[18]

[19]

[20]

Rapid override

switches

Conveyor

switch

Work light

switch

Coolant

switches

These push button switches apply

an override (ranging from 0 to

100%) to a specified rapid traverse

rate. When the power is turned ON,

the override value becomes less

than 25%. In the manual operation,

the rapid traverse rate becomes

0~25%.

Note)The manual feed is not

available in 0%.

This push button switch runs the

chip conveyor.

This push button switch turns on a

work light.

These push button switches work

various kinds of coolant indicated

on them respectively. Each kind of

coolant can be turned ON/OFF

manually even during automatic

operation.

O

O

O

O

O

O

O

O

O

O

O

O

O

O

(Rotary switch)

Page 12

1 - 7

Operation method

Push

button

Lamp

Effective mode

Auto. Manual

Use

Name

Group

No.

[21]

[22]

[22]

[24]

[25]

[26]

[27]

Feedrate

switches

Optional block

skip

Restart of

block

Power

Standby

Emergency

stop

(Main/Suboperation

panel)

Memory

These push button switches select a

manual jog feed rate between 0 mm/

min and 5,000 mm/min.

(In case of the A-axis, it becomes

between 10 deg/min and 1,400 deg/

min.)

This switch makes the block skip

function command by program

effective. During programming, the

slash “/” used.

The RESTART OF BLOCK becomes

effective by pressing this switch and

the indication lamp lights up. This

becomes ineffective by repressing

this switch and the indication lamp

goes out. When the RESET OF

BLOCK is not provided as option,

this switch becomes ineffective and

the indication lamp puts out.

Through designating a sequence No.

that is not restarted by this functions,

the machining can be restarted from

that block.

ON ... turns on the main power to the

NC unit.

OFF ... Turns off the main power.

Drive preparation state as for the NC

unit to make the machine ready for

operation.

Stops the machine completely. All

motors are stopped and the NC unit

is reset.

LOCK... Protects the information

stored in the NC unit. Normally, shift

this switch to “LOCK”.

O

O

O

O

O

O

O

O

O

O

O

_

_

_

O

O

O

_

_

_

O

(Rotary switch)

(Key)

Page 13

1 - 8

Operation method

Push

button

Lamp

Effective mode

Auto. Manual

Use

Name

Group

No.

[28]

[29]

[30]

[31]

[32]

[33]

[34]

[35]

Memory

Speed meter

Load meter

Tool clamp/

unclamp

Optional stop

Single block

Program restart

Manual pulse

generator

(Portable)

WRITE ... Shift this switch to

“WRITE” when writing or correcting

memory information.

Indicates a spindle speed.

Indicates a spindle load to a motor’s

rated power in terms of percentage.

CLAMP ... Clamp a tool to the

spindle.

UNCLAMP ... Unclamp the spindle

tool. When the tool is unclamped, a

yellow lamp lights up and you

cannot run the spindle.

When M01 is commanded in the

tape, tape operation stops after all

the commands in the block are

completed. The indication lamp

lights up. This is released by

repressing the START button and

indication lamp puts out.

Program commands are executed

one block by one block. However,

canned cycles are executed one

cycle by oneb cycle.

The program restarts.

The indication lamp lights up. This

is released by repressing the button

and the indication lamp puts out.

Get the handle mode by the push

button and select the feed axis by

the rotary switch. For a feed rate,

you can select 1 pulse/graduation

(1/1), 10 pulses/graduation (10/1)

and 100 pulses/graduation (100/1).

Since it is portable, you can draw it

out to a convenient position for use.

For inch specifications, you can

select 1/1, 10/1 and 50/1.

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

(Key)

(Meter)

(Meter)

(Toggle

switch)

Page 14

1 - 9

Operation method

Push

button

Lamp

Effective mode

Auto. Manual

Use

Name

Group

No.

[36]

[37]

[38]

[39]

[40]

[41]

State OK

indication

Cutting monitor

Cutting monitor

Block skip

AIR BLOW

Magazine

rotation (ATC)

Information such as mode, override,

interlock, and spindle tool No.

necessary for machining can be

monitored.

The screen of the cutting monitor

can be monitored.

Monitoring data is automatically set

by the “AUTOMATIC SETTING”

teaching cutting data.

Select switch

INEFFECTIVE ... makes the cutting

monitor function ineffective.

EFFECTIVE ... makes the cutting

monitor function effective.

This makes the block skip 2~9

effective.

“/(2~9)” is used in the program.

Tool nose Air is spouted out from

the nozzle directed to the

tool nose

Through Air is spouted out from

the through coolant

nozzle.

The ATC magazine rotates to index

tools.

Forward rotation: CW

Reverse rotation: CCW

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

(Select switch)

Page 15

1 - 10

Operation method

Push

button

Lamp

Effective mode

Auto. Manual

Use

Name

Group

No.

[42]

[43]

[44]

[45]

O

(Key switch)

Manual

indexing

A TC initial

position return

Auto door

DOOR

INTERLOCK

Replacement of tools can be done

even when automatic operation is

going on.

ON ... “FORWARD” and

“REVERSE” buttons are effective.

OFF ... The above buttons are not

effective. To switch off manual

interrupt, keep pressing on the

“OFF” switch for at least 3 seconds.

This is a push button for making the

restoration easy after emergency

stop or power failure etc. during

ATC.

OPEN ... The door is opened.

CLOSED ... The door is closed.

‘‘Effective’’ : Interlock of door

open becomes effective.

‘‘Ineffective’’ : Interlock of door

open becomes ineffective.

O

O

O

OO

O

O

O

O

Page 16

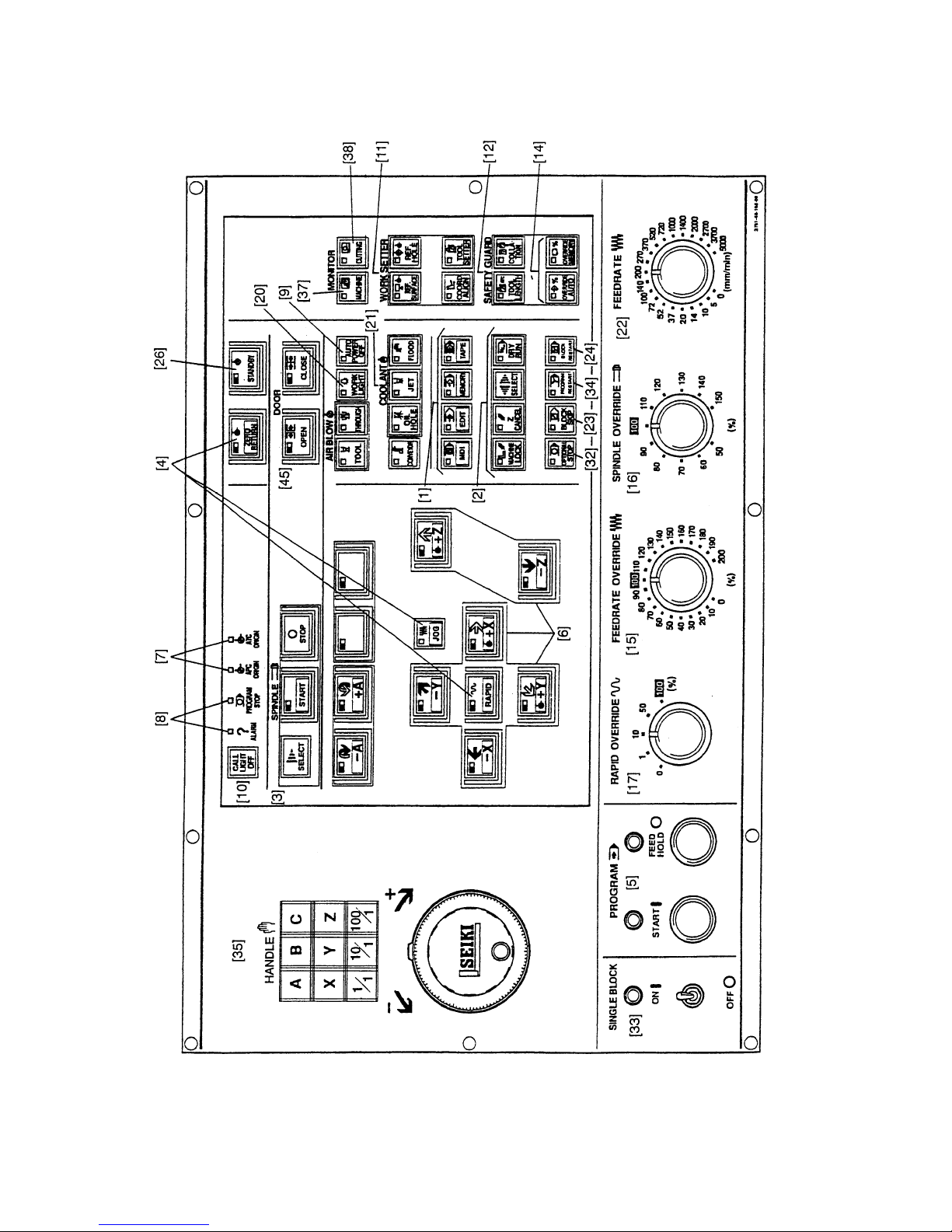

1 - 11

Main operation box (I)

[41]

Page 17

1 - 12

Fig.4-2 Main operation box (II)

Page 18

1 - 13

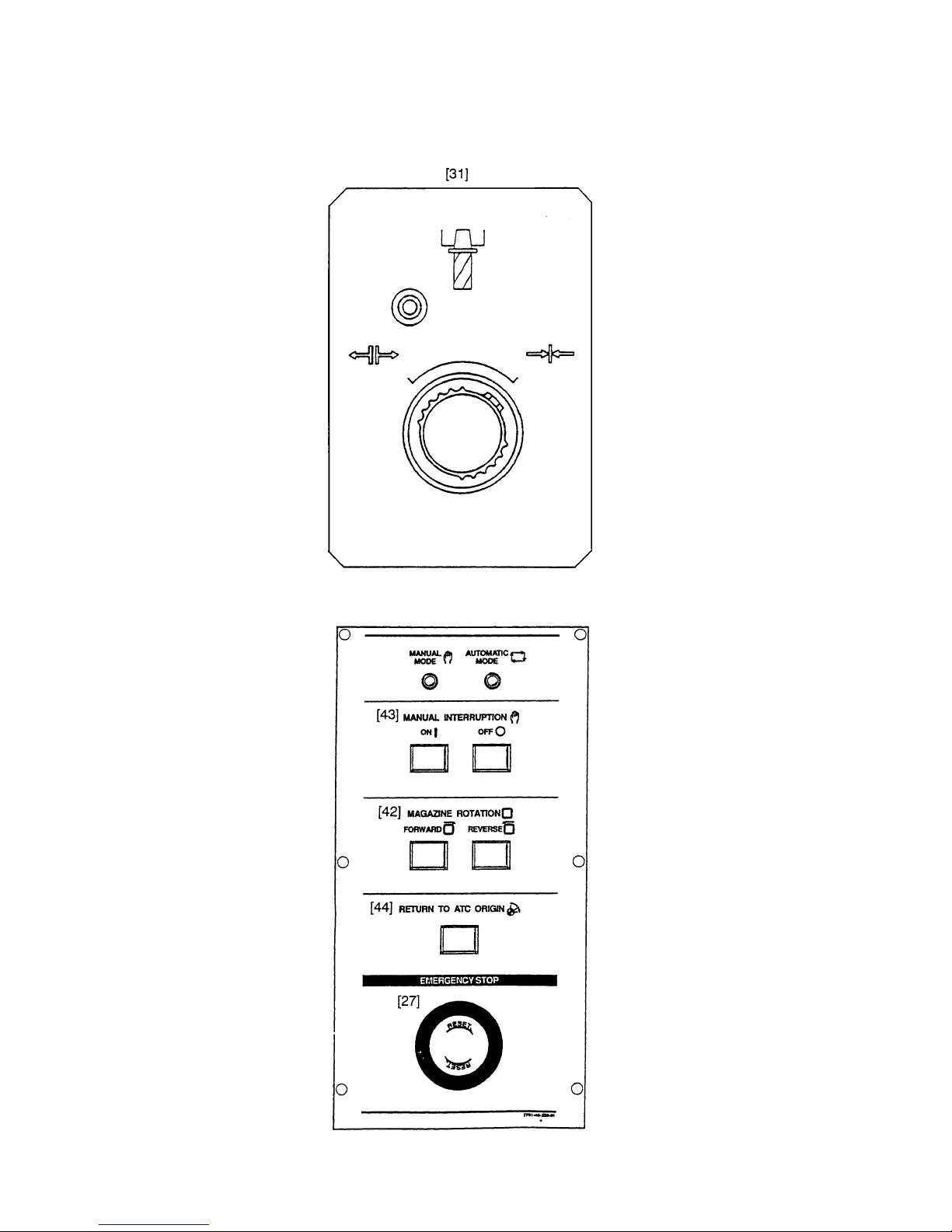

Auxiliary operation box (I)

Spindle tool clamp/unclamp

Auxiliary operation box (II) — ATC magazine

Page 19

1 - 14

Handle operating panel

Magnification of

handle

Manual pulse

generator

Axis selection

Handle mode selection

Page 20

1 - 15

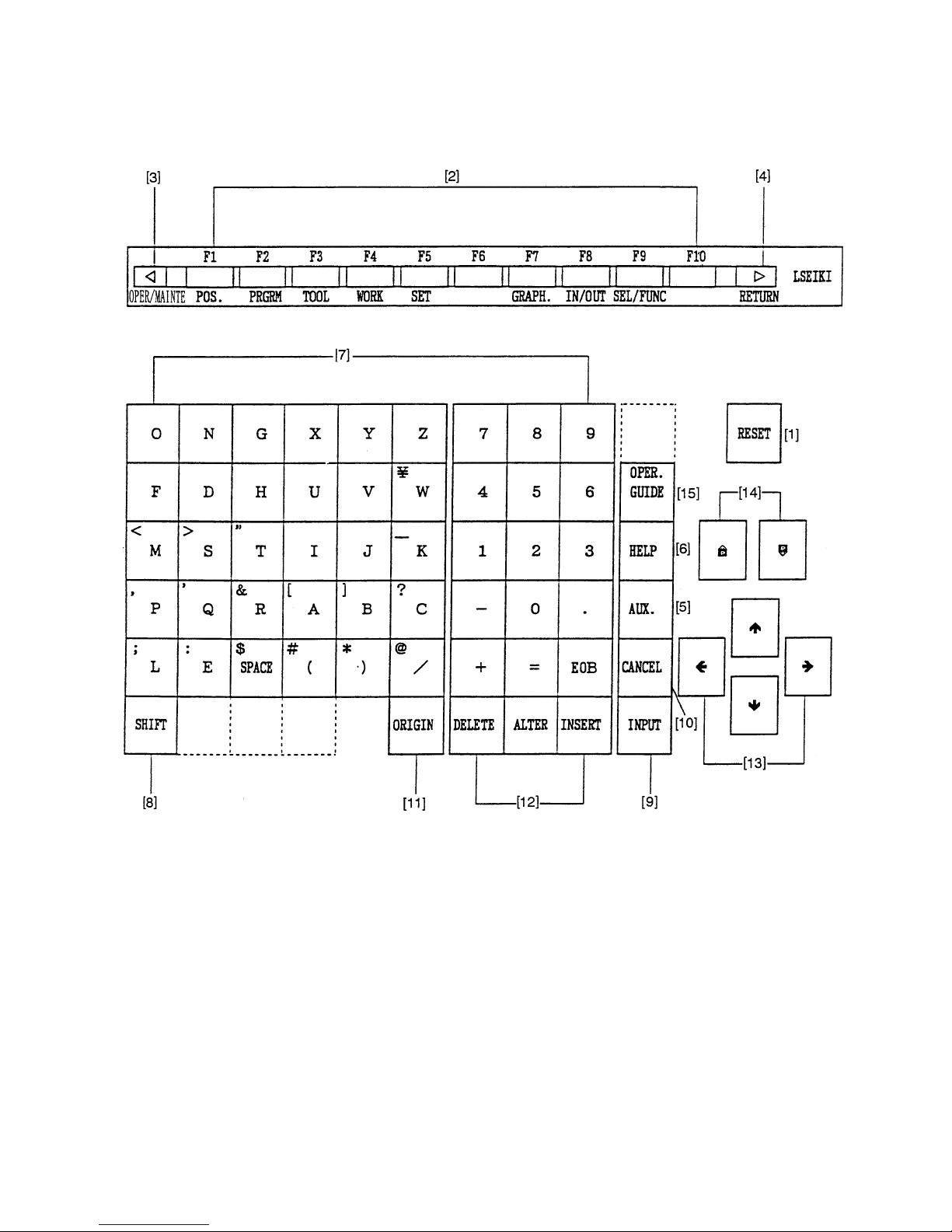

2-2 NC Operation Panel

Page 21

1 - 16

NC Operation Panel

Page 22

1 - 17

No.

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

Name

RESET key

Function keys

OPER/MAINTE

RETURN key

AUX. Key

HELP key

Address and Numerical

keys

SHIFT key

INPUT key

CANCEL key

ORIGIN key

DELET ALTER and INSRT

keys

Cursor move key

Page key

OPER. GUIDE

Description

Press this key when resetting the CNC unit in order to reset

an alarm so on.

When the function menu is displayed at the bottom of the

CRT, there are the keys to select the menu. When the

menu is not displayed, they serves as the keys to select the

Position, Program, Tool, Work Coordinate, Setting, Plot and

I/O screens. Press the F9/SEL/FUNC key when displayed

the function menu at the bottom of the CRT.

Press this key when displaying the PC, Alarm or

Maintenance screen. Pressing it once displays the function

menu at the bottom of the CRT, and pressing it again

erases the menu.

Press this key when you want to return to the Overall

screen.

Used to input the alphabet, numbers, etc.

There are some address keys which have 2 characters

marked on them. If you press the address key after the

SHIFT key, upper left character is input.

If the address or numerical key is pressed, it is input into

the key input buffer once, and then, displayed on the CRT.

Press the INPUT key when actually setting the data input

into the key input buffer.

Press this key when deleting the characters or symbols

input into the key input buffer.

This key is used to clear the Plot screen.

Used to perform deletion, alteration and insertion in editing

the program.

The alter key is also used for restoring F menu screen after

having selected an item on the F menu.

There are 4 keys which are used to move the cursor up/

down and right/left.

There are 2 keys which are used to page in the forward and

backward directions.

NC Operation Keys

Page 23

1 - 18

Caution

Caution

3. Operational Procedures

3-1 When Starting the Machine

(1) Turn on the supply power Switch.

(2) Turn on the power switch on the electric cabinets

(3) Press the POWER ON push button switch located on the upper part of the main operation

panel.

The main panel and NC cabinet are enclosed lest the open air should enter

directly. Therefore, do not leave each door open for a long time while the power

is turned on. Check on the display and that cooling fan motors inside and

outside the cabinet are started.

(4)

Release EMERGENCY STOP button on the main operation panel.

(5)

Press the STANDBY push button switch located of the main operation panel. (A green

lamp lights up.)

(6) Before starting daily operation, reciprocate the X, Y and Z axes several times. (When this

is done, be careful not to have the axes overtravelled.)

(7) Return each axis to the zero point (refer to the description for zero return). By performing

zero return, a basic machine coordinate system is set and stored stroke limits are made

effective.

(8) Turn on the conveyor switch.

Do not make operation under the state that massive chips are cast in the trough.

Page 24

1 - 19

Caution

Caution

3-2 Warming-up Operation of Spindle

3-2-1 Warming-up at the Time of Starting Daily Operation

It is necessary to keep the bearing lubrication in a good condition for getting the normal

spindle revolution. If the spindle is suddenly rotated at a high speed without warmingup, there is a danger of the oil film being cut and the bearing is burnt stuck. To have

the spindle operated correctly in full capacity, warming up operation is necessary of

which the following should always be practiced practice.

Warming-up before starting daily operation (30 minutes)

[1] 30% of maximum spindle revolution (10 minutes)

↓

[2] 50% of maximum spindle revolution (10 minutes)

↓

[3] 80% of maximum spindle revolution (10 minutes)

Practice warming in the order of [1] , [2] , [3] .

3-2-2 Warming-up When the Machine Was Not Operated for More Than One Week or

Longer

In case of starting the spindle of oil air lubrication, after it has not been used for more

than one week, warming-up must be practiced taking a longer time than usual, as oiling

into bearing is necessary. In this case, please make sure up practice warming-up

according to the following schedule.

1. #50 - Spindle of 10,000min

-1

specification (oil air lubrication)

Warming-up after the spindle has not been used for more than

one week (minimum warming-up time 4 hours)

[1] By 2,500min

-1

for 1 hour or longer

↓

[2] By 5,000min-1 for 1 hour or longer

↓

[3] By 7,500min-1 for 1 hour or longer

↓

[4] By 10,000min-1 for 1 hour or longer

Practice warming in the order of [1] , [2] , [3] , [4] .

Page 25

1 - 20

Caution

2. #40 - Spindle of 20,000min

-1

specification (oil air lubrication)

Warming-up after the spindle has not been used for more than

one week (minimum warming-up time 4 hours)

[1] By 5,000min

-1

for 1 hour or longer

↓

[2] By 10,000min-1 for 1 hour or longer

↓

[3] By 15,000min-1 for 1 hour or longer

↓

[4] By 20,000min-1 for 1 hour or longer

Practice warming in the order of [1] , [2] , [3] , [4] .

3-3 Zero Return Procedures

Be sure to perform manual zero return so that you may set the basic machine coordinate

system after turning on the power.

Display on the pushbutton for zero point direction of each axis flickers.

(1) Operate the mode switching push button for “Zero return”.

(2) Of the push button switches for the axis desiring “Zero return”, press the one with the origin

mark ( ).

(3) By the specified speed of the rapid feed override, the axis returns to the zero point in the

rapid feed speed, and stops at zero point. Then, the zero point position confirmation lamp

of the axis is lit on.

(4) When the lamp lights up, release the switch.

Even when unhanded during decelerated speed movement, the axis stops after zero point

is generated.

The above operations will complete zero return.

1. Make zero return operations for each axis one by one.

2. When the axis for which zero return is intended is already located close to the zero

point, move axis once to the opposite side of the zero point by about 50mm then

move it again to the direction of the designated zero return point.

Page 26

1 - 21

3-4 When Completing the Daily Operation

(1) Confirm that START display lamp on the main operation panel is lit off.

(2)

Press EMERGENCY STOP button on the main operation panel.

(3) Clean the machine.

(4) Release EMERGENCY STOP button on the main operation panel.

(5) Set operation preparation, and drive the conveyor.

(6) Stop the conveyor after all of cutting chips in the bed are discharged.

(7) Move each axis to the stop position.

X-axis ......... center of the stroke

Y-axis.......... center of the stroke

Z-axis.......... the head upward movement end

(8)

Press EMERGENCY STOP button on the main operation panel.

(9)

Press POWER OFF button of the main control panel to cut out the control device power.

(10) Cut out power of the high voltage control panel.

(11) Cut out supply power.

Page 27

1 - 22

4. Manual Operation

4-1 Each Axial Feed

— In case of manual jog feed —

(1) Select the operation mode selector push button switch “JOG”.

(2) Press the FEEDRATE push button switch to set an appropriate feed rate. Pressing the

manual jog feed push button switch for a desired axis, move the machine in a desired

direction.

When it comes to a specified position, release the switch.

(The machine moves only while the switch is pressed.)

Applications : • Warming-up operation

• When bringing close to the zero point

• When cutting by manual operation

• Work rearranging operation

— In case of handle feed —

(1) Select the operation mode selector push button switch “HANDLE”.

(2) Select an axis with the axis selector push button switch.

(3) With the manual handle, you can move the machine by 0.001 mm (0.0001 inch) per

graduation (when 1/1 is selected) or by 0.01 mm (0.001 inch) per graduation (when 10/1 is

selected).

Applications: • When moving the machine by a very fine amount, such as when setting

the zero point by centering a workpiece or fixture

4-2 Rapid Traverse

(1) While pushing the rapid traverse mode switch, press the push button switch for the axis

you want to move at a rapid traverse rate (rapid traverse is applied only while the push

button switch is pressed). At this time, an override of 0, 1, 10, 50 or 100% can be applied

to a specified rapid traverse rate.

(2) Releasing rapid traverse push button switch changes the rapid traverse to normal feed.

Page 28

1 - 23

4-3 Mounting and Dismounting the Tool

(1) Stop the spindle head at an arbitrary position.

(2) Select one of manual operation modes; JOG, RAPID, HANDLE or ZERO RETURN.

(3) Holding a tool firmly, shift to UNCLAMP the TOOL CLAMP/UNCLAMP selector push button

switch, which is located on the front of the spindle head, and press it.

When the tool has been mounted, if the push button switch is released, the tip of the

drawbar will push the pull-stud bolt, thus removing the tool from a spindle taper hole (hold

the tool firmly lest it should drop). While the tool is unclamped, the yellow lamp located on

the upper left part lights up.

(4) When mounting the tool, eliminate dust completely from the taper section of the tool shank.

Clean the spindle taper hole properly with an accessory cleaner.

(5) Insert the tool shank into the spindle hole, and shift the TOOL CLAMP/UNCLAMP selector

push button switch to CLAMP and press it. The tool is automatically mounted to the

spindle and the yellow lamp lights off.

Page 29

1 - 24

5. Manual Data Input (MDI) Operation

5-1 Each Axial Feed

(1) After pressing RETURN button to get the general screen, set the mode selection

pushbutton switch to [MDI].

(2) General (MDI) is displayed on the display unit.

(3) Select the axis, which you want to mode, with the address keys, and enter the sign and the

numerical value by the numerical keys then press the RETURN key.

(4)

Press the INSERT button.

(5) Repeating the steps (2) and (3), input one block worth of data.

(6) Press the PROGRAM START button.

5-2 Coolant

(1) After pressing RETURN button to get the general screen, set the mode selection

pushbutton switch to [MDI].

(2) General (MDI) is displayed on the display unit.

(3)

Press the address key M .

(4)

Enter 0 and 8 by operating the numerical keys then press the RETURN key.

(5)

Press the INSERT button, and then, the PROGRAM START button.

Coolant is discharged from the nozzle at the spindle head.

(6) If you give M09 by similar operation, the coolant will stop.

5-3 Spindle Speed Change and Spindle Revolution

(1) After pressing RETURN button to get the general screen, set the mode selection

pushbutton switch to [MDI].

(2) General (MDI) is displayed on the display unit.

(3)

Press the address key S .

(4)

Input the spindle revolution speed by the numerical keys then press the RETURN key.

(5)

Press the INSERT button.

(6) Similarly, input an M code for spindle forward revolution or reverse revolution.

(7) Press the PROGRAM START button.

(8) To stop the spindle, give M05 by similar operation.

Example

MDI → S → 1 5 0 0 → EOB → M → 0 3 →

INSERT → PROGRAM START

Page 30

1 - 25

5-4 Spindle Positioning

(1) After pressing RETURN button to get the general screen, set the mode selection

pushbutton switch to [MDI].

(2) General (MDI) is displayed on the display unit.

(3)

Press the address key M

(4)

Enter 1 and 9 by operating the numerical keys then press the RETURN key.

(5)

Press the INSERT button, and then, the PROGRAM START buttons, the spindle runs at

a low speed and stops at its home position.

Page 31

1 - 26

6. Registration of Program

There are following two methods to register a program into the NC unit.

1. Registration from an external input device

2. manual registration by the address/numeral keys

6-1 Registration from an External Device

1) Connect an input device RS-232-C terminal

and make a possible condition of

transmission.

2) Set a mode to [EDIT].

3) Set the memory key to [WRITE].

4) Press the function key

F8/IN-OUTPUT .

A right sketch is displayed.

5)

Press the F1/INPUT key.

• Start reading from the first EOB of the NC program and continue until the % code.

• The program No. is registered the 0 No. registered in the input device.

• Display at the program No. list after completion of reading.

• At the time of input, the ISO/EIA information is recognized automatically.

Note) If the program No. already registered is inputted, it becomes an alarm condition.

Page 32

1 - 27

6-2 Manual Registration by the Address/Numeral Keys

1) Set a mode [EDIT].

2) Set the memory key to [WRITE].

3) Press the F2/PRGRM key.

4) Key in a desired program No. and press the

INSERT key.

Example: 0 1 2 3 4 INSRT

5) Set the cursor to; by the cursor key.

Page 33

1 - 28

6) Input a program according to the order of

the NC program.

Example:

Data>G91 G28 X0;

•

The EOB key must be inputted at the

end of one block.

• Press the CANCEL key when the data

which has inputted want to be deleted.

A word deletes one by one.

7)

Press the RETURN key and return to the

initial screen after input of all program is

completed.

G 9 1 G 2 8 X 0

EOB INSRT

Page 34

1 - 29

7. Program No. Search

There are following two methods to search a program.

1. Search by key in a program No.

2. Search to utilize the program list.

7-1 Search by Key in a Program No.

1) Set a mode to the [MEMORY] or [EDIT].

2) Set the memory key to [WRITE].

3) Press the function key

F2/PRGRM .

4) Key in the program No. to be searched and

press the

key.

Example: O 1 2 3 4

Calling up program is displayed.

O 1 2 3 4

Page 35

1 - 30

7-2 Search to Utilize the Program List.

1) Set a mode to the [MEMORY] or [EDIT].

2) Set the memory key to [WRITE].

3) Press the function key

F2/PRGRM .

4) Press the F7/PROGRAM LIST key.

5) Set the cursor to the program No. to be

searched by the cursor key and press the

INPUT key.

Calling up program is displayed.

Page 36

1 - 31

8. Edition of Program

The keys to edit a program are as follows;

INSERT : Insert a content of key input after the cursor.

ALTER : Alter a content of key input at a section of the cursor.

DELETE : Delete a section of the cursor.

Use it deletion of program as well.

8-1 Preparation in Advance at the Time of the Edition of Program.

To edit a program, the following conditions should

be made.

1) Set a mode [EDIT].

2) Set the memory key to [WRITE].

3) Press the function key

F2/PRGRM .

Page 37

1 - 32

8-2 Search of Word

A word can be searched by the following method.

1) A method by means of the page and cursor

keys.

[1] Press the page key and display the

page to be edited.

[2] Press the cursor key and move the

cursor to the word to be edited.

• The cursor moves at a block unit by

the

keys.

• The cursor moves at a word unit by

the

keys.

2) A method by means of word or address

search.

Since a message is displayed as “Not found”

if it is not found, try it again.

[1] Word search, No. search

Key in the address and numerals to be

searched and press

key.

Example: M06

M 0 6

Page 38

1 - 33

When searching a section above the

current position of cursor, press the

key

[2] Block search

Check a word in a block and search a

block which contains a relevant word

only.

Key in all address and numerals of one

block then press EOB and key.

Example: When searching a block of

M06 T06;

Note)

The EOB should be inputted at the

end of a block.

8-3 Edition of Program

(1) Insertion of word, block

New word is inserted just after the word

currently located the cursor.

[1] Designate a word immediately

before a section to be inserted.

[2] Key in a new data to be inserted

then press the INSERT key.

Example: when inserting Y 100.0 after

X-250.0

M 0 6 T 0 6

EOB

Y 1 0 0 .

0 INSRT

Page 39

1 - 34

[3] When inserting one block, key in data

of one block and press EOB and

INSERT key.

Page 40

1 - 35

(2) Alteration of word

Alter a word, the cursor located currently, to

the new word.

Alteration is done by a word unit.

[1] Set the cursor to the word to be altered.

[2] Key in the new word then press the

ALTER key.

Example: Alter S1000 to S2000.

After alteration

S1000 replaces S2000.

S 2 0 0 0

ALTER

Page 41

1 - 36

(3) Deletion of word, block

A word currently located the cursor or a

certain boundary of a program can be

deleted.

(a) Deletion of word

[1] Set the cursor to a word to be deleted.

[2]

Press the DELETE key.

Example: When deleting Z-200.0

Set the cursor to Z-200.0

then press the

DELETE key.

After deletion

Z-200.0 is deleted.

Page 42

1 - 37

(b) Deletion of block

It can be deleted one block at a time.

[1] Set the cursor to the head of the block

to be deleted.

[2]

Press the EOB and DELETE .

Example: When deleting a block G04

X 10.0;

Set the cursor to G04 and

press the EOB and

DELETE key.

After deletion

The block G04... is deleted and

program moves upward.

Page 43

1 - 38

(c) Boundary deletion

Delete blocks after the cursor to before the

designated sequence No.

[1] Set the cursor to the head word to be

deleted.

[2] Key in the sequence No. just after the

last block to be deleted and press the

DELETE key.

Note) Search the sequence No. before

deletion and check how far is it

deleted.

Example: When deleting

S1000 M03;

G28 X0 Z0 M19;

Set the cursor to S1000 and press

N 3 DELETE key.

~

After alteration

The program

moves upward.

Page 44

1 - 39

8-4 Back Ground Editing

Generally, “Editing” means front side editing, however this editing could not watch contents of

program and also edition is not available while executing a program.

In fact, giving a possibility to edit a program while executing a program is a back ground editing.

• An editing is available to other than currently executing program.

• A program under back ground editing can not execute.

• Editing can be done both manual and automatic mode.

1) Turn the memory key to [WRITE].

2) Press the F2/PROGRAM key.

3) Press the

F2/BACK GRD EDIT key.

A title of the screen becomes a “Back

ground editing”.

Page 45

1 - 40

Caution

4) Search a program wanted to edit.

A procedure of search is exactly same

as a (front) editing.

Never execute a reset operation, since the machine will stops if reset is done during

machine operation at the time of back ground editing.

5) Execute edition of program.

A procedure of edition is exactly same

as a (front) editing.

Page 46

1 - 41

6) End of back ground editing

[1]

Press the F2/BACK GRD EDIT key.

A title of screen becomes a “Program”.

It becomes normal editing screen.

8-5 Copy of Program

A program being displayed can be copied on the

other number and displayed.

1) Display a program wanted to be copied.

2) Key in a new program No. and press

INPUT key.

Example: When altering to O2001

O 2 0 0 1 INPUT

Page 47

1 - 42

8-6 Editing Procedure of Range Designation (Expanded Tape Editing/Option)

Designate a range of program and this “Insertion”, “Deletion” or “Storage” can be done at the

program screen.

• Starting of range editing

Operation...... Press the F3/RANGE EDIT key.

The function changes into that for range editing.

• Designation of range

Operation...... Press the F4/RANGE SET key.

The cursor becomes a frame.

A cursor range increases by moving this. That is a range.

• Release a designation of range

Operation...... Press the F4/RANGE SET key and F3/EXIT key.

It becomes a normal cursor and a range is released.

• Storage of range

Operation...... Press the F5/RANGE STORE key.

A part of range is stored.

If a size of range exceeds 2,048 characters (approx. 5m), “Range exceeds a limit.” is

displayed and not stored.

It can be used by the range insertion at any time, since it is stored until a power turned

off.

• Insertion of range

Operation...... Press the F6/STORE→INSERT key.

Insert a part of storage after the cursor by storage of range.

• Deletion of range

Operation...... Press the F7/RANGE DELETE key.

A part designated by range is deleted.

If the size of range exceeds 2,048 characters (approx. 5m), a message “Range exceeds

limit” is displayed and the storing is ineffective.

While the source power is kept on, the stored data is maintained and the data is

available by F8/DELETE→INSERT whenever desired.

• Inserting deletion

Operation...... Press the F8/DELETE→INSERT key.

The portion stored by range deletion is inserted at the cursor position.

Page 48

1 - 43

8-7 Alteration of Word (Expanded Tape Editing)

At the program screen, search a designated word to be altered in the program and rewrite it to a

word to be altered.

There are following two methods for alteration of word.

1) Search one word each and alter if after confirmation.

2) Alter words collectively (or after words continuously with display an altering condition).

The words to be altered collectively are maximum 400,000 words.

A method to search a word is the same as the word search, words combined one character of

alphabet (or “#” mark) and numerals becomes the number search as words showing the numeral

value and recognize it with or without a decimal point.

For example, of changing “X.1” to “X.5”, a row of characters such as “X0.1”, “X0.100”, “X00.10”,

“X.1” or “X.100” which coincide with “X.1” as numeral value, become the object of alteration and

change all to “X.5”.

Also, if adding a “?” mark on the word to be changed as “X.1?” such as changing “X.1?” to “X.5”,

a row of characters “X.1” becomes the object of alteration, then “X1” becomes “X.5” and “X.100”

becomes “X.500”, however, “X.01”, “X0.100” and “X00.10” does not have the row of character

“X.1” so it does not become an object of alteration.

Outline of operation

[1]

Start alteration of word by pressing the F5/WORD CONVT. key.

INPUT in the order of a word to search and alter then a word to replace it.

If replacing word is blank, it becomes a deletion.

[2] When searching a word one by one, designate a searching direction by the cursor

,

and press the Y key if found a word to be altered.

[3] For altering a word contained in many places of the file collectively, designate the

searching direction by the function menu. Confirm that such overall alteration is

unmistakable, then press Y key.

Once word alteration starts, it goes on to the beginning or end of the file, depending

on the searching direction. For suspending the alteration,

Press the F5/EXIT key.

In case of the alteration of words collectively as mentioned item [3], alter it except a

row of characters in the comment. To change inside of comment, alter it by the

method [2].

Page 49

1 - 44

OPERATION MESSAGE

F5/WORD CONVT. ........................................ “INPUT a word to be altered.”

Input the word to be altered ........................... “Input the word to be altered.”

Input the word to be replaced ....................... “Alter word from....to....”

The words are to be searched by cursor using

,

keys. “Alter word from....to....”

... INPUT as it is blank ................................. “Delete a word......”

...Alteration of word will be completed even if pressing the CANCEL key from • mark.

...Designate a searching direction of word by

, key.

...If it is not found ........................................... “Not found”

...“Search by cursor

, .”

...If it is found ................................................. “Alter a word....to....”

...Alter by Y key.

F1/BLANKET ALL Regardless of cursor position, searching starts with the

program head.

F2/BLANKET BEFORE Searching takes place in the forward part following the

cursor including the word with the cursor.

F3/BLANKET AFTER Searching takes place in the backward part preceding

the cursor including the word with the cursor.

...By operating , keys collective alteration starts.

...Alteration is executed by pressing Y key.

When alteration has be completed ................ “Word replaced”

When the word is not found........................... “Not found”,

.............. “0 word replaced”

Press F5/EXIT key. ...................................... “Alteration suspended”

Page 50

1 - 45

8-8 Deletion of Program

There are following two methods to delete a program.

1. Delete it by the program list screen.

2. Delete it by key input at the program screen.

1) Deleting method by the program list screen.

[1]

Press the F7/ PROGRAM LIST key at

the program screen.

[2] Set the cursor at the program to

be deleted by the program list.

Press the cursor key.

[3] Press the DELETE key.

[4] Against a message “Is it all right

to delete?”, press the Y key if

you agree.

A program which is designated

by the cursor is deleted.

Page 51

1 - 46

2) Deleting method by key input

[1] Display the program screen.

[2] Key in the program No. to be deleted

and press the DELETE key.

Example: In case of deleting O100

O 1 0 0 DELET

[3] Against a message “Is it all right

to delete?”, press the Y key if

you agree.

A program keyed in is deleted.

3) Continuous deletion by Program No.

[1]

Press F7/PROGRAM LIST .

[2] Place the cursor at the Program No. to

be deleted then press the SPACE bar.

An asterisk marked at the head of the

Program Nos. selected.

Example: Screen display shown below

is the case of deleting

Program

Nos. O100, O111, O169, O200.

[3]

Press the DELETE key.

For deleting the entire program, press

ORIGIN and DELETE keys.

8-9 Arrangement of Program

When editing a program, a size of program becomes larger than actual size occasionally. In this

case, available memory can be increased a little by arrangement of program. This operation is

called “Condensation”.

Operation

... Confirm that it is in the editing mode, not background editing, and NC is in reset

condition. (When there is secondary series or background drawings, it must also

be in reset condition.)

Press the F1/CONDENSE key.

A comment message “Condensing program” appears on the display, then after a

while, it changes to “Condensation complete”.

It takes several seconds to several minutes to complete program condensation,

depending on the size of memory and the condition of memory usage. If any key is

touched during the midst of this process, the comment message “Condensing

program” disappears and the process is suspended.

Page 52

1 - 47

Caution

If source power is switched off during “Condensation”, the program is destroyed.

When a program is found to be abnormal, initialize the program memory, and input the

program anew.

8-10 Process After Edition

Press the RETURN key.

Return to the initial screen.

Page 53

1 - 48

9. Output of Program

NC program can be outputted to the external in/output equipment.

1) Connect an output device to the RS-232-C

terminal and make it ready.

2) Make a mode selection to [EDIT].

3)

Press the function key F8/IN/OUT .

Note) When “Dondon FD” is on the screen

display, press the

F5/DONDON FD COMPLETE

key, and get the “Data Output”

screen.

A right sketch is displayed.

Refer to the instruction manual of output

device.

Page 54

1 - 49

4)

By pressing F7/ LIST CHANGE , switch

over the screen display from “Program No.

List” to “Program No. Detail”.

• To select Program No.

Place the cursor at the Program No. to be

select then press the SPACE .

An asterisk is marked at the head of the

Program No. selected. When selecting all

programs, repeat pressing “ORIGIN”

several times until the mark “*” is

displayed.

Example: O5, O6, O7.

5)

Press the RETURN key after completion of

output and return to the original screen.

Page 55

1 - 50

!

WARNING

Caution

10. Automatic Operation

10-1 When Machining the First Workpiece, Checking the Newly Created Program

(1) Go through the steps (1) through (5) mentioned in 4-6-2 “Program Memory Operation”

(2) Turn on the [SINGLE BLOCK] switch. (When this is done, it is recommended to set a

rapid override value to 10% for safety.)

(3)

Press the PROGRAM START button.

(4)

Check one block worth of functioning, press the PROGRAM START button again to

sequentially advance a program.

10-2 Program Memory Operation

Close the front door and the ATC magazine door.

(1) Check that the ALARM lamp on the main operation panel is not lit up.

(2) Check and correct tool length and tool compensation data, if necessary.

(3) Set the mode selector switch to “MEMORY”. For normal operation, at this time, turn

off the DRY RUN, OPTIONAL STOP, MACHINE LOCK, BLOCK SKIP and SINGLE

BLOCK switches, and set the FEEDRA TE OVERRIDE, SPINDLE OVERRIDE and

RAPID OVERRIDE switches to 100%.

(4)

Press the RESET button on the setting operation panel.

(5) Call the PROGRAM AUTOMATIC to the display screen by pressing the

F2/PRGRM button to check the initial state.

In order to suspend the machine durintg operation, press STOP button on the

operation panel or turn [ON] SIGNAL BLOCK switch.

In case of emergency, press the EMERGENCY STOP button to immediately stop the

machine on the operation panel.

Page 56

1 - 51

Caution

Caution

10-3 When Inserting Manual Operation in Automatic Operation

(1) Press the PROGRAM STOP push button switch (while program operation is suspended, a

red lamp lights up.) or suspend the machine operation by turnig [ON] SINGLE BLOCK

switch.

(2) Select the operation mode selector push button switch either [HANDLE] or [JOG] and

perform manual operation.

(3) On completion of manual operation, return the mode selection to [MEMORY].

(4) Press the PROGRAM START button to restart the program.

Even when the PROGRAM STOP button is pressed, the M, S and T functions

continue until their actions are completed. Manual operation is available only after these

actions are completed.

10-4 When Performing MDI Operation in Automatic Operation

(1) Turn on the [SINGLE BLOCK] switch on the operation panel.

(2) Shift the mode selection switch do [MDI] after the machine stops.

(3)

Press RETURN button to get the general screen.

(4) Enter necessary actions with the address keys and numerical keys, and press the

INSERT button.

(5)

Press the PROGRAM START button after confirming the data of one block has

been input.

(6) To restart the automatic operation, shift the mode selector switch to [MEMORY] or

[TAPE] and turn off the SINGLE BLOCK switch.

(7)

Press the PROGRAM START button.

1. When an auto command immediately before is a canned cycle and you specify an

action other than the canned cycle by MDI operation, be sure to specify a

necessary G code.

2. When MDI operation is inserted in the state mentioned in Note 1, you must specify

hole machining data preceding MDI insertion, if you want to execute the auto

command again.

!

After you enter actions by MDI operation, if you forget to execute them (due to a certain

reason such as leaving a work site) and restart automatic operation, the machine

functions in an unexpected way and endangers you, because buffer contents for

automatic operation have been replaced with unexecuted MDI buffer contents. Be full

aware of it.

WARNING

Page 57

1 - 52

11. Operation of Automatic Tool Changer (ATC)

11-1 Names of ATC Each Section

Bed

Magazine

Servo motor

(Magazine rotation)

Tool change position

Tool setting position

Tool feed hand

Proximity switch

(Tool feed hand open/close)

LS603A, 603B

Air cylinder

(Hand forward and backward movement)

Proximity switch

(Waiting grip, tool ready or not)

LS54A

Proximity switch

(Hand forward and backward movement)

LS92A, 92B

Twin arms

Tool grip

Cum box

(Twin arms rotates,

goes up and down.)

Solenoid valve

(Backup pump)

SOL636

Photo macro

(LS637A,

637B, 637C)

Solenoid valve

(Tool feed hand)

SOL603A, 603B

Solenoid valve

(Hand forward and backward movement)

SOL92A, 92B

Inverter motor

(Twin arms rotates, goes up and down.

Tool lock oil hydraulic)

Page 58

1 - 53

11-2 Explanation of Actions

ATC operates continuously according to command contents.

1. Change Spindle and Waiting Tool……M06 Operation

Note) (M1**) in the figures operates only at the maintenance mode.

Z-axis second original point

Third original point position

Tool loosened

Arm downward

movement

Arm rotation

Arm upward

movement

Tool fastened

1) Open the shutter, and move to the

spindle orientation Z-axis second

original point.

4) Move to X-axis second original point, and

index magazine of waiting tool number.

Shutter closed

(M100)

Second original point

Shutter closed

(M101)

2) Move to X-axis third original point (tool

change position).

3) Tool change action (M117)

5) Shutter is closed.

Page 59

1 - 54

2. Call Tool to Waiting Position………….T01~T20 (T30 Option)

Note) (M1**) in the figures operates only at the maintenance mode.

1) Index magazine of waiting tool number. 5) Index magazine of T code number.

(M104)

2) Feed hand is closed (M102).

3) Move feed hand to magazine side.

4) Feed hand is open (M103).

6) Feed hand is closed (M102).

7) Move feed hand to twin arms side

(M105).

8) Feed hand is open (M103).

9) Index magazine of spindle tool number.

Page 60

1 - 55

3. Return Waiting Tool to Magazine……….T00 Action

Note) (M1**) in the figures operates only at the maintenance mode.

1) Index magazine of waiting tool number. 5) Index magazine of spindle tool number.

(M104)

2) Feed hand is closed (M102).

3) Move feed hand to magazine side.

4) Feed hand is open (M103).

6) Feed hand is closed (M102).

7) Move feed hand to twin arms side

(M105).

8) Feed hand is open (M103).

Page 61

1 - 56

11-3 Rotation of Tool Storage Magazine (at Single Mode)

The magazine is rotated while the pushbutton switch on the ATC single operation panel is being

pressed. When requested pot No. comes close to the specified position, release the

pushbutton, which makes the magazine decelerate, position and stop.

Page 62

1 - 57

Caution

11-4 Attachment and Detachment of Tools

Attachment and detachment of tools are accomplished through the tool attachment/

detachment window on the right side of the machine. The procedures are as follows.

[1] Keep pressing manual indexing button “ON” on ATC control panel until the button is lit on.

[2] Index the magazine to be attached or detached to the tool attachment/detachment position.

(Operate until this stage, keep closing the tool attachment/detachment window.)

Tool attachment

[3] Align the tool holder V groove and the magazine grip.

(Refer to the next section for tool key grooving method.)

[4] Push a tool horizontally into the magazine side.

(Pay attention to the spring of the magazine clip section when pushing.)

Tool detachment

[5] Hold the taper section of the tool holder and the tool shank section firmly with both hands,

and pull them out horizontally towards you.

[6] Close the tool attachment/detachment window

[7] Press the manual indexing button “OFF” on ATC control panel for three seconds or more.

Magazine manual indexing is executed by normal/reverse rotation selection button on ATC

control panel. It rotates per pitch by inching operation, and rotates continuously by keeping

pressing the button.

When attaching and detaching, give full attention to edges of tools and weight for

safety operation.

Tool attachment/detachment

method Tool attachment/

detachment position

Tool holder V groove

Guide for attachment/detachment

Tool attachment/detachment window

Page 63

1 - 58

11-5 Relation Between Spindle Nose Key and ATC

When turning edges of tools which have directionality such a boring bar in the direction of key

of the magazine grip, the edges, attached to the spindle by ATC action, turn to the left from the

machine front.

11-6 Attention When Using Oil Hole Tool

• When attaching an oil hole tool, attach it so that the pilot plunger (positioning pin) may

come in the direction of the key of the magazine clip.

• When using an oil hole tool, cutting chips attached to oil hole block side may cause

troubles in insertion and positioning of pilot plunger of a tool into block. Regardless of

manual or automatic operation, turn “ON” oil hole coolant, or blow down coolant tentatively

by M50 command before attachment. After cleaning the block like this, change tools.

* Be sure to use an oil hole tool exclusively for HITACH SEIKI VS50/60.

Spindle center

Key of tool grip

Change position

Tool change diagram

Tool attachment/detachment

position

View from spindle end face

Page 64

1 - 59

11-7 ATC Program Operation

(1) Block operation by the program (automatic mode)

The ATC carries out the following block operations, depending on the program:

T ; Calls the tool No. from the tool magazine to an arm “standby

position”.

M06 ; Replace the tool in the spindle with that located at the arm standby

position.

T M06 ; Calls the tool No. from the magazine to the “spindle”. (ATC

canned cycle)

T00 ; Returns to the tool magazine the tool located at the arm standby

position.

(2) ATC Single Block Stop

When single block is on, ATC action by M06 goes on by each step shown in M06 action (1)

- (5) of ATC action explanation.

Page 65

1 - 60

11-8 Condition Check During ATC Execution

1) • Tool No. on the spindle

• Tool No. at the ATC arm standby position are displayed on the general screen.

2) • Tool No. commanded in a program is displayed on the commanded value screen.

How to display each screen is as follows:

1) How to display the general screen

When pressing the RETURN key, the general screen appears.

Page 66

1 - 61

2) How to display the commanded value screen

Display the general screen → Press the F1/POSITION key → Press the function key

F4/COMMAND VALUE for commanded values → The commanded value screen appears.

Page 67

1 - 62

Caution

12. Setting (Data)

12-1 Outline

Various setting data required to operate the machine can be set.

The setting (Data) screen is displayed by pressing the F5/SET key.

In this screen, parameters frequently used are classified together by item or purpose for easy

setting.

An option is not displayed if it is not provided.

Since it consist of several pages, change it by pressing the page key

or alphabetical key

corresponding a menu at the left side of the screen.

The number search also available.

Setting (Data)

(1) Display and setting

In case of a selection such as “Do/Don’t”,

marks are on at the side of setting has done if

you want.

Set the cursor by the cursor key and press the INPUT key.

Further, when the cursor key is pressed, it moves at the side of mark. The

HITACHI SEIKI’s standard is the left side.

Numeral data is set through the key input area. Needless to say, calculation and absolute/

increment value input are also available.

Input limit for writing key etc. is not applied on the setting screen is different from the

parameter screen, change it with fully attention by an operator himself.

Page 68

1 - 63

N

(2) Number search

Since all pages have serial number, a page or cursor can be moved at once by the number

search. A search executes by pressing a cursor key after inputting N and

following numerals.

Example N: Number = 12

(Move to No. 12)

N: Number = 1 + 10

(Move to No. 11)

(3) Setting method

1. Set the key switch for writing of

memory to “write side”.

2. Select the setting data screen.

Press the RETURN key.

Press the F5/SET key.

3. Set the cursor to the item to be

changed by the page and cursor key

or number search.

Press the page key and

display a section to be

changed.

4. Key in a desired numeral and press

the INPUT key.

5. press the RETURN key and display

the initial screen after completion of

setting.

or, input the setting number.

Page 69

1 - 64

13. Time Measuring, Data

Machining time and cutting time are displayed at the lower right of the general screen. It can be

displayed by pressing the RETURN key.

13-1 Time Measuring

Four type of time is measured at the lower right of the screen. It can be measured in the limit

of less than 10,000 hours.

Input in here execute by moving the cursor after pressing the F9/SEL/FUNC key

Example: (Hour/Minute/Second) = 0 (Set to zero)

(Hour/Minute/Second) = 1 (Input as 1:00:00)

(Hour/Minute/Second) = 1/2 (Input as 1:02:00)

(Hour/Minute/Second) = 1/2/3 (Input as 1:02:03)

(1) Prearrangement of completion

Advance notice of completion becomes effective when “SET END TIME” on the operation

panel of the machine is “ON”.

A time of a prearrangement of completion is a time from start to the time of a advance

notice of completion at the automatic operation.

If an operator inputs a time of a prearrangement of completion of a program, inform it by

call light when a machining time reaches to the prearrangement of completion.

Page 70

1 - 65

(2) Machining time

Accumulate a time during machining. (A time of the start lamp is being on.)

(3) Cutting time

Accumulate a time during cutting feed. (A time during cutting feed by G01, G02 or G03)

(4) Lap time

Measure a lap time between a tool and tool. At the time of tool change set it to zero

automatically. Measurement does not execute while the NC is stand by condition.

13-2 Date and Time

The date and time is displayed by the clock builted in.

The date shows by A.D. and time shows by 24 hours. (1 p.m. is 13 hours.)

Since it is backed up by a battery, it moves even if the power is turned off.

Do not change it unnecessarily, however, if discrep ancy of the time has occurred from one cause

or another, it should be set correctly because it uses at the time of periodical check.

Page 71

1 - 66

14. Animated Drawing

14-1 Outline

When the F7/GRAPH key is pressed, the animated drawing screen is displayed.

Animated drawing of a locus of a tool is executed here. Also, the following data are displayed for

the reference of animated drawing.

Animated drawing plane of parameter

Tool tip position

Rotation S, Feed F, Tool command T

Machining time, Cutting time

List of programs currently under execution

A locus is drawn based on a value of the tool tip coordinate system. Since a moving point becomes