Page 1

User Manual

Segway® Robotics Mobility Platform

210/220

Page 2

RMP 210/220

Contents

Copyright, Disclaimer, Trademarks, Patent, and Contact Information .................................................................... 6

Introduction

Safety.......................................................................................................................................................................... 8

Abbreviations ........................................................................................................................................................... 10

RMP 210 and 220

Included Components............................................................................................................................................... 11

Capabilities ................................................................................................................................................................12

Coordinate System ...................................................................................................................................................13

Physical Characteristics – 210 .................................................................................................................................14

Physical Characteristics – 220 ................................................................................................................................15

Mounting Locations — 210 .......................................................................................................................................16

Mounting Locations — 220 .......................................................................................................................................16

Turn Envelope ............................................................................................................................................................ 17

User Interface Panel ..................................................................................................................................................18

Powerbase Connections ...........................................................................................................................................19

Performance Specifications .................................................................................................................................... 20

Environmental Specifications..................................................................................................................................20

Transportation and Shipping ....................................................................................................................................21

Balancing

Payload Gain Schedules .......................................................................................................................................... 23

Balance Mode Requirements .................................................................................................................................. 24

Entering Balance Mode ............................................................................................................................................ 24

Exiting Balance Mode............................................................................................................................................... 25

Performance Limits ................................................................................................................................................. 25

Interaction With The Environment .......................................................................................................................... 27

Balance Mode Faults .................................................................................................................................................31

Hardware Balance Request ......................................................................................................................................31

Velocity Filter .............................................................................................................................................................31

Electrical Overview

System Architecture ................................................................................................................................................32

System Power ........................................................................................................................................................... 32

System Components ............................................................................................................................................... 33

Copyright © 2014 Segway Inc. All rights reserved.

2

Page 3

RMP 210/220

Operational Model

Operational States ................................................................................................................................................... 35

Faults ........................................................................................................................................................................36

Initialization ..............................................................................................................................................................36

Diagnostic Mode ...................................................................................................................................................... 37

Bootloader Mode...................................................................................................................................................... 37

Standby Mode .......................................................................................................................................................... 37

Tractor Mode ............................................................................................................................................................ 37

Balance Mode ........................................................................................................................................................... 37

Disable Mode ............................................................................................................................................................38

Decel To Zero (DTZ) Mode .......................................................................................................................................38

Charging

Using the External Power Supply ............................................................................................................................39

Charge Status LEDs .................................................................................................................................................39

Powering On/Off

Powering On .............................................................................................................................................................40

Powering Off ............................................................................................................................................................. 40

Connecting

Connector I ................................................................................................................................................................41

Starter Breakout Harness ........................................................................................................................................42

Connector II ..............................................................................................................................................................43

Disable Button ..........................................................................................................................................................43

Additional Signals ....................................................................................................................................................43

Connector IV.............................................................................................................................................................44

Connecting To the RMP ............................................................................................................................................ 45

Communication

General Command Structure ..................................................................................................................................48

Standard Motion Commands ..................................................................................................................................50

Configuration Commands ........................................................................................................................................51

Standard Input Mapping .......................................................................................................................................... 62

RMP Response .........................................................................................................................................................66

IEEE754 32-bit Floating Point and Integer Representation .................................................................................... 77

Cyclic Redundancy Check (CRC)-16 ....................................................................................................................... 78

Fault Status Definitions ...........................................................................................................................................82

Copyright © 2014 Segway Inc. All rights reserved.

3

Page 4

RMP 210/220

Internal Connections

Centralized Control Unit ..........................................................................................................................................88

Auxiliary Battery Board ............................................................................................................................................89

Smart Charger Board ............................................................................................................................................... 90

Communication.........................................................................................................................................................91

Hardware Controls ................................................................................................................................................... 97

Mode Selection ........................................................................................................................................................98

Status Indicators ...................................................................................................................................................... 98

CCU Input Power ...................................................................................................................................................... 99

CCU Battery Supply ................................................................................................................................................. 99

Coin Cell Battery ......................................................................................................................................................99

Included Software

Installing the Software ........................................................................................................................................... 100

RMP CCU Bootloader Application ..........................................................................................................................101

OCU Demo Application .......................................................................................................................................... 102

Software License Agreement .................................................................................................................................107

Maintenance

Fastener Torque ...................................................................................................................................................... 108

Tire Pressure .......................................................................................................................................................... 108

Parts List — 210 .....................................................................................................................................................109

Use the diagram and table below to identify part names and numbers. ............................................................. 109

Parts List — 220 ......................................................................................................................................................110

Use the diagram and table below to identify part names and numbers. .............................................................. 110

Removing Wheel Assemblies ...................................................................................................................................111

Replacing Wheel Assemblies ...................................................................................................................................111

Cleaning ....................................................................................................................................................................111

Software Updates .....................................................................................................................................................111

Batteries

Replacing Batteries ................................................................................................................................................. 112

Installation and Removal Instructions ...................................................................................................................113

Transportation and Shipping .................................................................................................................................. 113

Proper Disposal ....................................................................................................................................................... 113

Copyright © 2014 Segway Inc. All rights reserved.

4

Page 5

RMP 210/220

Troubleshooting

Reporting Problems to Segway .............................................................................................................................. 114

Extracting the Faultlog ............................................................................................................................................ 114

Reading the Faultlog ............................................................................................................................................... 115

Faults .......................................................................................................................................................................116

Charging Faults ...................................................................................................................................................... 120

Other Issues ........................................................................................................................................................... 120

Copyright © 2014 Segway Inc. All rights reserved.

5

Page 6

RMP 210/220

Copyright, Disclaimer, Trademarks, Patent, and Contact Information

Copyright © 2014 Segway Inc. All rights reserved.

Disclaimer

The Segway RMP is not a consumer product. Usage examples shown on rmp.segway.com have not necessarily been reviewed nor

approved by Segway Inc. ("Segway"). Segway is not responsible for end customer modifications or additions.

Trademarks

Segway owns a number of trademarks including, but not limited to, Segway and the Segway "Rider Design" logo that have been registered

in the United States and in other countries. Those trademarks followed by ® are registered trademarks of Segway. All other marks are

trademarks or common law marks of Segway. Failure of a mark to appear in this guide does not mean that Segway does not use the mark,

nor does it mean that the product is not actively marketed or is not significant within its relevant market. Segway reserves all rights in its

trademarks. All other trademarks are the property of their respective companies.

Xbox® is a registered trademark of Microsoft Corporation.

Logitech® is a registered trademark of Logitech International SA.

Segway Patent Information

The Segway RMP is covered by U.S. and foreign patents. For a patent listing, see http://rmp.segway.com/RMPPatents.pdf.

Contact Information

For support, please contact Segway Customer Care or use the RMP forum at http://rmp.segway.com/forum.

Segway Customer Care: 866-4SEGWAY (866-473-4929)

Fax: 603-222-6001

E-mail: technicalsupport@segway.com

Website: http://rmp.segway.com

Copyright © 2014 Segway Inc. All rights reserved.

6

Page 7

RMP 210/220

Introduction

The Segway Robotics Mobility Platform (RMP) is a robotic vehicle chassis and power-train designed to be integrated with additional

components to create robotic products. It is intended to be the mobility component for any number of robotic applications and as such

was designed with versatility, durability, and performance in mind.

Segway engineers have led the way with electric drive propulsion systems in the fields of battery management, advanced sensing, driveby-wire control, and dynamic stabilization. The RMP benefits from some of the same proprietary technology that has been deployed and

proven around the world as part of the Segway Personal Transporter (Segway PT) line of products.

The RMP can handle high payloads, a variety of environmental conditions, and a wide range of operational scenarios. The chassis is

designed to handle a certain amount of abuse consistent with operation over rough terrain and in industrial environments. Control

parameters can be tweaked to make it easy to drive slowly around obstacles, at high speed in open spaces, or in any environment in

between.

Control of the RMP occurs via command and response messages sent over Ethernet, CAN, or USB interfaces. Commands are used to

control movement, set configuration parameters, and control response data. Response messages provide detailed information about

the current status of the RMP. Segway has chosen to allow users to control overall RMP movement, but not individual wheels/motors.

This frees users to treat the RMP as a single unit rather than a collection of components, and allows Segway to provide a more robust,

predictable mobility platform.

To allow for the greatest possible control over the RMP's behavior, a variety of configuration parameters can be modified. However, it is

possible to set these parameters to unsafe values, so care must be taken when setting parameters to reduce the risk of damage or injury.

It is the user's responsibility to set configuration parameters to safe values. Be sure to follow all safety instructions in this document.

This manual describes the capabilities of the RMP and explains how to communicate with it. Integrators and engineers can use this

information to mount equipment on the RMP and write software for controlling the RMP.

Copyright © 2014 Segway Inc. All rights reserved.

7

Page 8

RMP 210/220

Safety

Improper use of the RMP can cause personal injury, death and/or property damage from loss of control, collision, and falls. To reduce risk

of injury, read and follow all instructions and warnings in this manual.

The following safety messaging conventions are used throughout this document:

WARNING!

CAUTION!

NOTICE

WARNING!

• Keep out of reach of children and pets. Unanticipated movement by the RMP could result in death or serious injury.

• Do not sit, stand, or ride on the RMP. Doing so could result in death or serious injury.

• Do not drive the RMP at people or animals. A collision could result in death or serious injury.

• Always alert people in the vicinity when an RMP is operating. An unexpected collision with the RMP could result in death or

serious injury.

• Avoid powering off on a slope. The RMP cannot hold its position when powered off and may roll downhill, causing serious

injury, death, or property damage.

• The RMP can accelerate rapidly. It is recommended that the RMP be securely raised so the wheels are off the ground (or

remove the wheels) until the user becomes familiar with the controls. Unanticipated movement by the RMP could result in

death or serious injury.

• Be careful when working with the DC power connections. You could shock yourself and/or damage the RMP.

• Remove batteries before working inside the RMP. You risk serious bodily injury from electric shock as well as damage to the

RMP.

• Do not submerge the RMP, batteries, or powerbases, in water. Do not use a power washer or high-pressure hose to clean

a RMP. Avoid getting water into any of the connectors. If you suspect the batteries or powerbase have been submerged or

experienced water intrusion, call Segway Technical Support immediately at 1-866-473-4929, prompt #2. Until you receive

further instructions, store the RMP upright, outdoors, and away from flammable objects. Failure to do so could expose you

to electric shock, injury, burns, or cause a fire.

• Unplug or disconnect the RMP from AC power before removing or installing batteries or performing any service. Never work

on any part of the RMP when it is plugged into AC power. You risk serious bodily injury from electric shock as well as damage

to the RMP.

• The cells within the batteries contain toxic substances. Do not attempt to open batteries. Do not insert any object into the

batteries or use any device to pry at the battery casing. If you insert an object into any of the battery's ports or openings

you could suffer electric shock, injury, burns, or cause a fire. Attempting to open the battery casing will damage the casing

and could release toxic and harmful substances, and will render the battery unusable.

• As with all rechargeable batteries, do not charge near flammable materials. When charging, the batteries heat up and could

ignite a fire.

• Do not use a battery if the battery casing is broken or if the battery emits an unusual odor, smoke, or excessive heat or leaks

any substance. Avoid contact with any substance seeping from the battery. Batteries contain toxic and corrosive matrials

that could cause serious injury.

• Observe and follow all safety information on the warning label found on the battery. Failure to do so could result in death,

serious injury, or property damage.

• Do not use cables that are frayed or damaged. You could shock yourself and/or damage the RMP.

• Use only Segway approved fasteners on the RMP. Other fasteners may not perform as expected and may come loose. Failure

to do so could expose you to risk of personal injury or property damage.

• Use assistance when moving or lifting the RMP. Single person lifting could result in serious injury.

Warns you about actions that could result in death or serious injury.

Warns you about actions that could result in minor or moderate injury.

Indicates information considered important, but not related to personal injury. Examples include

messages regarding possible damage to the RMP or other property, or usage tips.

Copyright © 2014 Segway Inc. All rights reserved.

8

Page 9

RMP 210/220

CAUTION!

• Be responsible about setting performance parameters. Read the relevant sections of this manual before changing any

performance parameters. The RMP follows commands issued to it, and it is the responsibility of the user to properly

safeguard their controls.

• Read and understand the Balancing chapter of this manual before operating the RMP in Balance Mode. The RMP's behavior

while balancing is not always intuitive and may result in unexpected or undesired motion.

• Failure to charge the batteries could result in permanent damage to them. Left unplugged, the batteries could fully

discharge over time, causing permanent damage.

• Use only charging devices approved by Segway and never attempt to bypass or override their charging protection circuits.

• Always protect against electrostatic discharge (ESD) when working inside the RMP. The RMP could become damaged.

NOTICE

• This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an output on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

• This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe b est conforme à la norme NMB-003 du Canada.

• Modifications not expressly approved by Segway may void the user's authority to operate this device under FCC regulations

and must not be made.

Copyright © 2014 Segway Inc. All rights reserved.

9

Page 10

RMP 210/220

Abbreviations

ABB Auxiliary Battery Board — a PCB used to gather and report performance information from the auxiliary battery.

BCU Battery Control Unit — a PCB inside the battery pack that manages the charge of the individual cells.

BSA Balance Sensor Assembly — a group of PCBs used to obtain information about the vehicle's orientation.

CAN Controller Area Network — a message-based protocol used for communication between microcontrollers.

CCU Centralized Control Unit — a PCB that houses the SP, UIP, and NVM; it controls the RMP and handles communication.

CRC Cyclic Redundancy Check — a type of error-detection used to verify the accuracy of transmitted data.

DLC Data Length Code — a part of the CAN message header that specifies the size of the data packet being sent.

DTZ Decelerate To Zero — an operational mode in which the RMP comes to a stop and powers down.

LE Large Enclosure — a unified chassis/enclosure for 4-wheeled RMP models.

MCU Motor Control Unit — a PCB that controls the electric motors that turn the wheels.

NVM Non-Volatile Memory — a type of digital memory that can retain the stored information even when not powered.

OCU Operator Control Unit — software and hardware that provide an interface between the user and the RMP.

PCB Printed Circuit Board — a thin board with conductive pathways and electronic components mounted on it.

PSE Pitch State Estimate — a 3-axis inertial estimate of the orientation of the RMP.

RMP Robotics Mobility Platform — a propulsion system that can be used as a platform for making mobile robots.

SCB Smart Charger Board — a PCB that controls battery charging functions.

SE Small Enclosure — a box that contains all of the electrical components of the RMP.

SID Standard ID — a CAN identifier that indicates the type of message being sent.

SOC State Of Charge — a measurement of battery charge from 0% (empty) to 100% (full).

SP Segway Processor — a microcontroller on the CCU that contains proprietary Segway code for controlling the RMP.

SPI Serial Peripheral Interface — a synchronous serial data link standard that operates in full duplex mode.

UDP User Datagram Protocol — a simple, transaction-oriented network protocol on top of TCP/IP.

UDFB User Defined Feedback Bitmap — a stored value that indicates what feedback data should be sent to the user.

UI User Interface — the means by which an operator interacts with a device.

UIP User Interface Processor — a microcontroller on the CCU that communicates with the OCU.

USB Universal Serial Bus — an industry-standard bus for communication and power supply between computers and peripherals.

VAB Vicor Adapter Board — a PCB that interfaces with Vicor DC-DC converters.

Copyright © 2014 Segway Inc. All rights reserved.

10

Page 11

RMP 210/220

RMP 210 and 220

The RMP 210 and RMP 220 are battery-powered Robotics Mobility Platforms (RMPs) meant to be used as the propulsion systems for

robotic products. The major difference between the two models is the number of Motor Control Units (MCUs) in the powerbase and the

presence or absence of a Balance Sensor Assembly (BSA). The RMP 210 has one MCU, one propulsion battery, and no BSA. The RMP

220 has two MCUs, two propulsion batteries, and a BSA. The second MCU provides component-level redundancy: one MCU can fail and

the platform will continue to operate. The second battery provides additional range and operational time. The BSA contains sensors that

provide the orientation data necessary for balancing.

The RMP 210 is a compact, non-balancing platform with three wheels: two propulsion wheels and one caster wheel. It has only one Motor

Control Unit (MCU) and one propulsion battery, making it suitable for low payload applications that don't require redundancy.

The RMP 220 is taller than the 210 and is capable of running in either Tractor Mode (with a third wheel) or in Balance Mode (balancing

on two wheels). When in Balance Mode it operates much like the Segway PT, leaning slightly in the direction of movement. The platform

has two MCUs and two propulsion batteries, allowing it to operate at higher payloads and over longer distances. With two MCUs the

propulsion system is completely redundant, allowing one MCU to fail without losing control of the platform. At the top of the RMP 220 is a

mounting plate with drilled and tapped holes for users to mount their equipment.

The powerbase contains the MCUs and Balance Sensor Assembly (BSA). Additional electrical components are mounted inside a User

Interface (UI) box located above the powerbase. Propulsion batteries are mounted to the bottom of the powerbase. The auxiliary battery

is mounted to the top of the UI box.

The on/off switch, external connectors, and indicator lights are mounted on an interface panel at the front of the machine.

Communication with the RMP can occur over Ethernet, CAN, and USB.

Inside the UI box are the Centralized Control Unit (CCU), Auxiliary Battery Board (ABB), Smart Charger Board (SCB), and Power

Converter(s). A cable runs from the UI box to the powerbase.

Figure 2: RMP 220Figure 1: RMP 210

Included Components

The RMP 220 comes with a Disable Button, Starter Breakout Harness, and External Power Supply. The Disable Button must be connected

for the RMP to power on and enter Standby Mode. When pressed, the Disable Button will cause the RMP to immediately shut down. The

Starter Breakout Harness provides Ethernet, CAN, and USB connectors as well as leads for DC power. The External Power Supply is used

to charge the RMP. When connected, indicator lights on the UI box show the charge status of each battery.

Figure 3: Disable Button Figure 4: Starter Breakout Harness Figure 5: External Power Supply

Copyright © 2014 Segway Inc. All rights reserved.

11

Page 12

RMP 210/220

Capabilities

The RMP is meant to be used by integrators when creating mobile robotic products. As such, the RMP was designed with flexibility and

expandability in mind.

Driving

The RMP can drive forward, reverse, and can turn in place. A variety of parameters can be adjusted for easier driving in different

circumstances, making it possible to have fine control at slow speeds and at high speeds. Adjustable parameters include maximum

velocity, maximum acceleration, maximum deceleration, maximum turn rate, and maximum turn acceleration.

Velocity control can either be velocity-based (m/s) or acceleration-based (m/s2). With velocity-based control the user continually

sends the desired velocity command (e.g. by holding a joystick steady to achieve a steady velocity). With acceleration-based control,

acceleration commands are sent until the RMP reaches the desired speed. Then an acceleration of zero is commanded in order to

maintain that speed. This is similar to using cruise control on the highway. See "Standard Input Mapping," p. 62, for more information

on the different types of control.

For safety, a disable button is provided with the RMP. When pressed, the disable button will cause the RMP to shut down. A Decel To Zero

(DTZ) command can also be sent, either by hardware button (not supplied) or by software command. This command causes the RMP to

decelerate and come to a stop before powering down.

Payload

Users can mount equipment to the rails along the sides of the RMP. Mounting holes are provided along the tops of the rails and on the

ends of the rails. On the RMP 220, users can mount equipment to the mounting plate at the top of the RMP.

The maximum total payload is 180 kg (400 lbs), evenly distributed.

Communication

Communication with the RMP can occur over Ethernet, CAN, or USB. If using Ethernet the IP address, port number, subnet mask, and

gateway can all be configured. For both Ethernet and USB communications, a Cyclic Redundancy Check (CRC) is performed, which

verifies the accuracy of the transmitted data.

The RMP communicates via a polling method: the user sends a command and the RMP responds. Commands can be either motion

commands (that tell the RMP to move) or configuration commands (that set user-configurable parameters). Some of these parameters —

the User Defined Feedback Bitmaps — control what information is sent in the RMP response, allowing the user to receive only the relevant

data.

The RMP expects to receive commands within a frequency range (0.5 Hz - 100 Hz). If commands are issued too frequently the RMP will

ignore them. If commands are updated too slowly the RMP will slew the commands to zero.

Power

With the auxiliary battery, the RMP can provide power for additional equipment. Each RMP has space for two Power Converters. For more

information see "Power Converter," p. 34.

Control Interface

The user is responsible for creating an interface for communicating with and controlling the RMP. Details on how to communicate with

the RMP and interpret its responses are described later in this document (see "Communication," p. 47).

To make this process easier, Segway provides an OCU Demo Application and source code (see "OCU Demo Application," p. 102). This

application is fully functional, but is not intended to be an end solution. Instead it is meant to be used as a functional example of how to

interface with the RMP.

Copyright © 2014 Segway Inc. All rights reserved.

12

Page 13

RMP 210/220

Coordinate System

The Balance Sensor Assembly (BSA) uses accelerometers and gyroscopes to determine the position and movement of the RMP, all of

which are used to create the Pitch State Estimate (PSE). This data is available to the user.

The RMP has a coordinate system relative to forward/reverse, pitch, roll, and yaw. This coordinate system is used when controlling the

RMP. The diagrams below show the RMP's axes and coordinate system.

Both the RMP 210 and 220 share the same coordinate system. An RMP 210 is pictured below.

Z

Ψ'

Figure 7: RMP Roll Axis, Rear View

Figure 6: RMP Axes

Φ

Φ'

Θ'

Figure 8: RMP Pitch Axis, Right Side View

Y

(Forward)

X

Θ

The variables listed below provide momentary information about the state of the RMP. For information on how to receive this data see

"User Defined Feedback Bitmaps," p. 66.

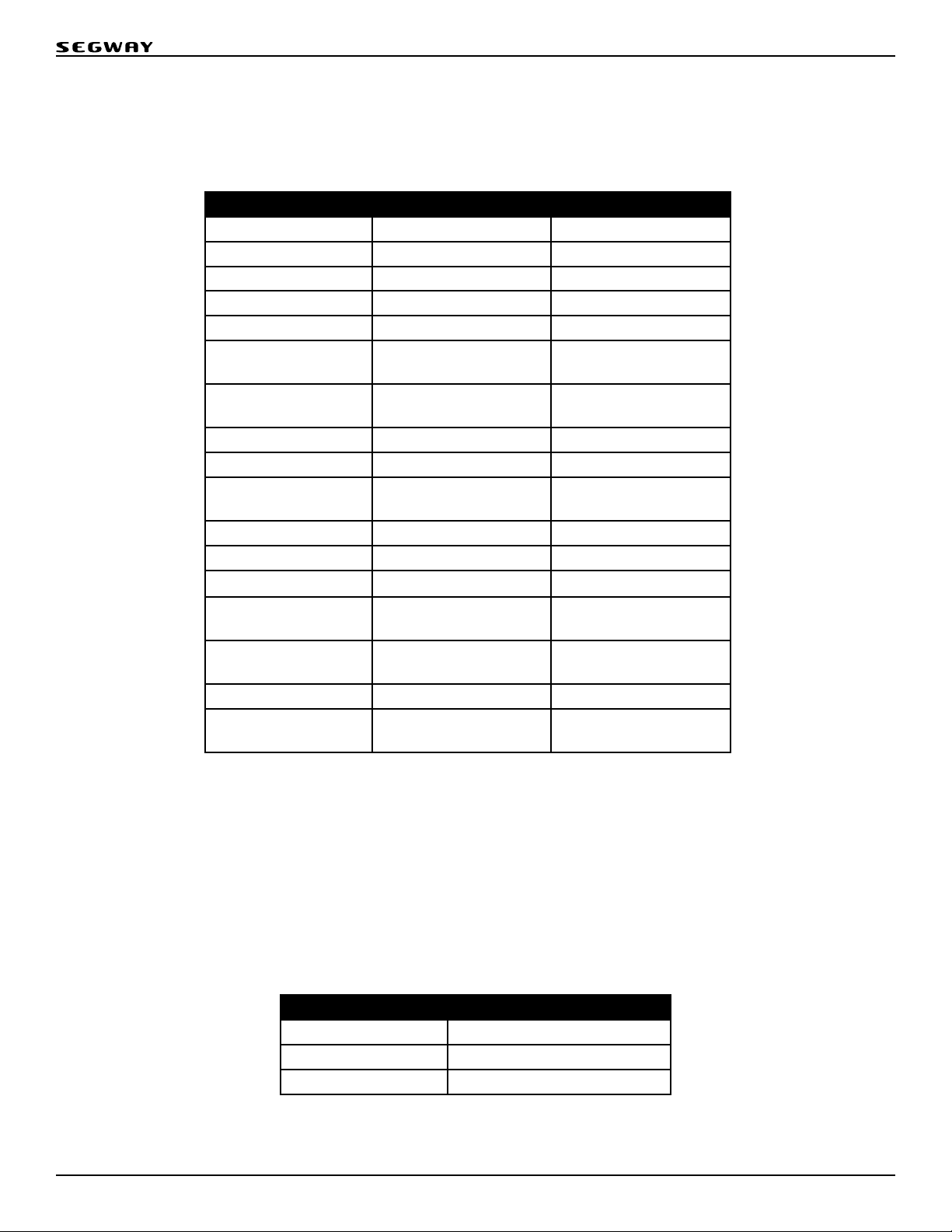

Table 1: BSA and PSE Variables

UDFB Variable Symbol Measurement Units

inertial_x_acc_g X Linear Acceleration g

inertial_y_acc_g Y Linear Acceleration g

inertial_x_rate_rps X Angular Velocity rad/s

inertial_y_rate_rps Y Angular Velocity rad/s

inertial_z_rate_rps Z Angular Velocity rad/s

pse_pitch_deg

pse_pitch_rate_dps

pse_roll_deg

pse_roll_rate_dps

pse_yaw_rate_dps

Copyright © 2014 Segway Inc. All rights reserved.

Θ

Θ'

Φ

Φ'

Ψ'

Angle (From Normal) deg

Angular Velocity deg/s

Angle (From Normal) deg

Angular Velocity deg/s

Angular Velocity deg/s

13

Page 14

RMP 210/220

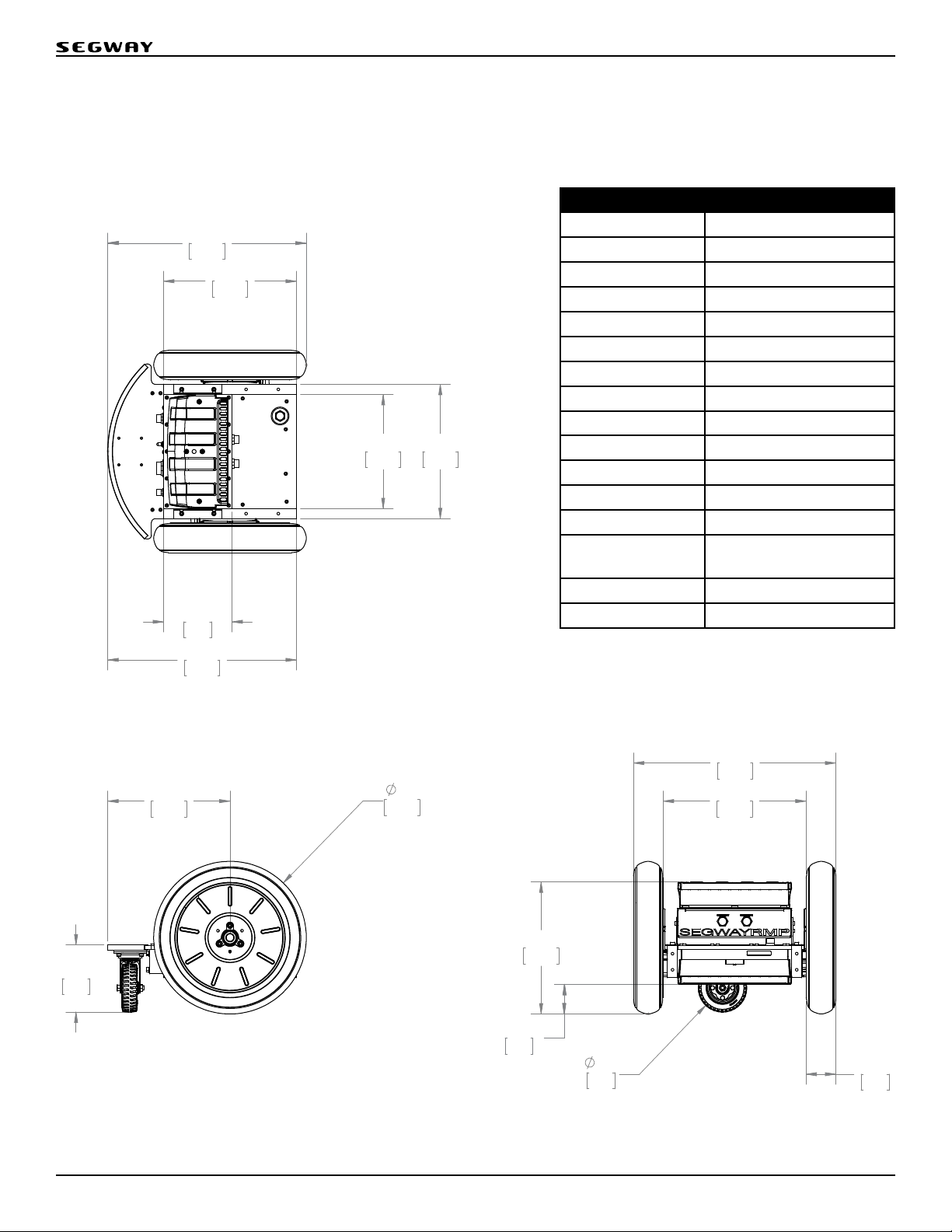

Physical Characteristics – 210

For product dimensions, please refer to the diagrams below. A summary of the major dimensions is provided in Table 2.

NOTICE

Product options may change the characteristics of the RMP.

625

24.6

419

16.5

360

14.2

216

8.5

594

23.4

423

16.7

Table 2: RMP 210 Physical Characteristics

Characteristic Value

Overall

Length 625 mm (24.6 in)

Width 637 mm (25.1 in)

Height 481 mm (18.9 in)

Chassis

Length 419 mm (16.5 in)

Width 423 mm (16.7 in)

Height 212 mm (8.3 in)

Clearance 93 mm (3.7 in)

Tires

Tire Size 19 in Segway i2 Tire

Wheel Base N/A

Track Width 544 mm (21.4 in)

Recommended

Tire Pressure

6–15 psi

Other

Weight 52 kg (115 lbs)

Figure 9: RMP 210 Top View

637

25.1

385

15.2

212

8.3

Figure 10: RMP 210 Side View Figure 11: RMP 210 Rear View

481

18.9

450

17.7

416

16.4

93

3.7

152

6.0

94

3.7

Copyright © 2014 Segway Inc. All rights reserved.

14

Page 15

RMP 210/220

Physical Characteristics – 220

For product dimensions, please refer to the diagrams below. A summary of the major dimensions is provided in Table 3. The RMP is shown

here with a caster plate attached; the caster plate is an optional accessory for non-balancing RMPs.

NOTICE

Product options may change the characteristics of the RMP.

665

26.2

626

24.6

76

3.0

76

3.0

559

22.0

419

16.5

Figure 12: RMP 220 Top View

423

16.7

Table 3: RMP 220 Physical Characteristics

Characteristic Value

Overall

Length 664 mm (26.1 in)

Width 637 mm (25.1 in)

Height 761 mm (30.0 in)

Chassis

Length 419 mm (16.5 in)

Width 423 mm (16.7 in)

Height 212 mm (8.3 in)

Clearance 93 mm (3.7 in)

Tires

Tire Size 19 in Segway i2 Tire

Wheel Base N/A

Track Width 544 mm (21.4 in)

Recommended

Tire Pressure

6–15 psi

Other

Weight 73 kg (161 lbs)

481

18.9

212

8.3

385

15.2

Figure 13: RMP 220 Side View

343

13.5

279

11.0

761

30.0

555

21.8

Figure 14: RMP 220 Rear View

6.0

152

430

16.9

366

14.4

450

17.7

637

25.1

215

8.5

93

3.7

Copyright © 2014 Segway Inc. All rights reserved.

15

Page 16

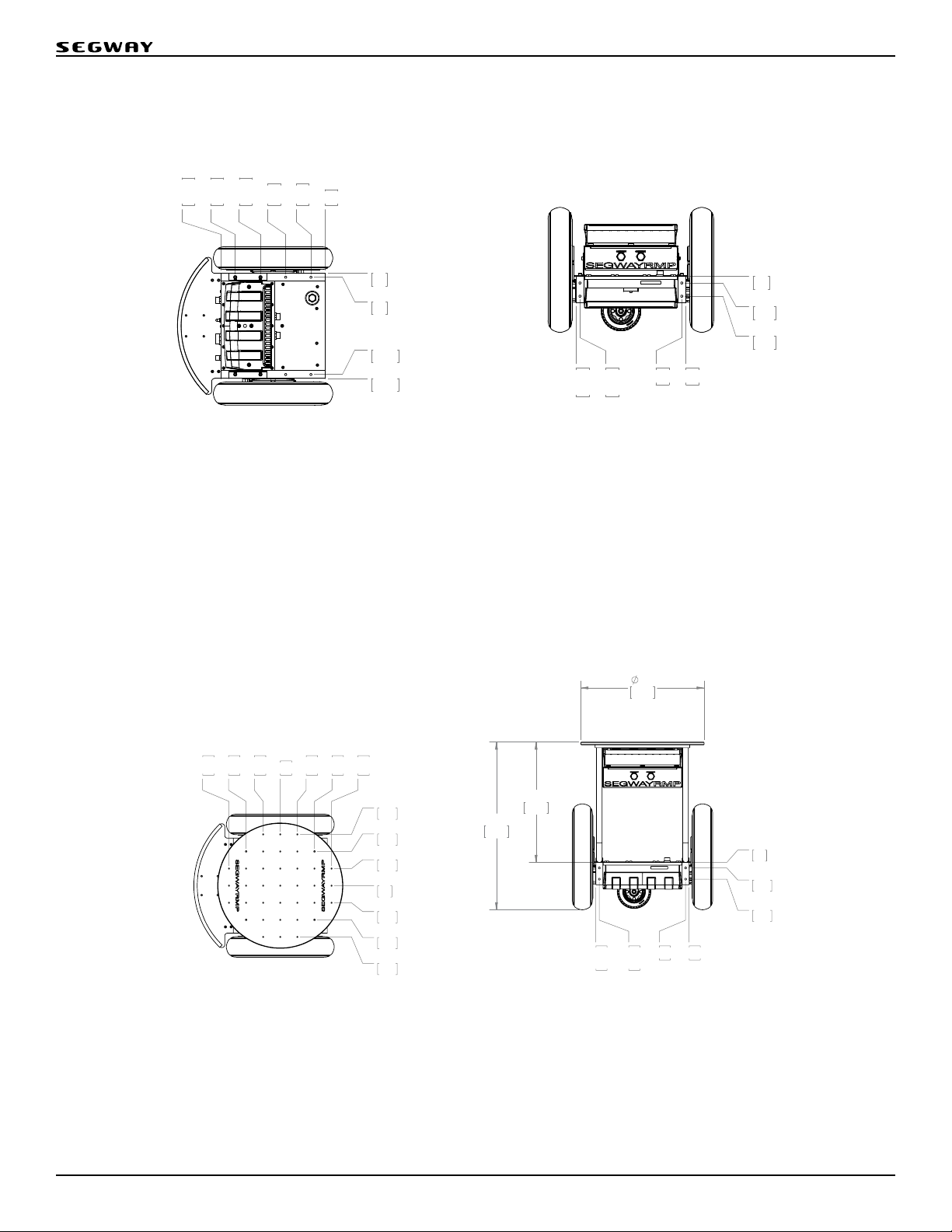

RMP 210/220

419

229

Mounting Locations — 210

Equipment can be mounted to the RMP using the provided mounting locations. Tapped holes are located on the tops and ends of the rails.

Tapped holes are M8x12. Dimensions are mm [in].

260

362

14.3

16.5

Figure 15: Top Mounting Holes

NOTICE

Only mount equipment via the provided mounting locations. Drilling holes in the enclosure or other modifications to the RMP may

adversely affect the FCC rating, IP rating, and/or structural integrity of the RMP.

10.3

159

6.3

0

57

.0

2.3

0

.0

16

.6

407

16.0

423

16.7

16.0

0

.6

.0

16

423

16.7

407

0

.0

25

1.0

76

3.0

Figure 16: End Mounting Holes

Mounting Locations — 220

The RMP 220 has all the same mounting locations as the 210. In addition, it includes a mounting plate at 761 mm (30.0 in) high. Tapped

holes are M8 through holes. Dimensions are in mm [in].

559

22.0

3.0

152

6.0

229

9.0

761

30.0

546

21.5

0

.0

25

1.0

76

3.0

423

16.7

407

16.0

0

.6

.0

16

229

9.0

152

6.0

76

3.0

0

0

.0

.0

76

3.0

152

6.0

229

9.0

Figure 18: End Mounting Holes

9.0

152

6.0

0

76

0

.0

3.0

.0

Figure 17: Mounting Plate

76

Copyright © 2014 Segway Inc. All rights reserved.

16

Page 17

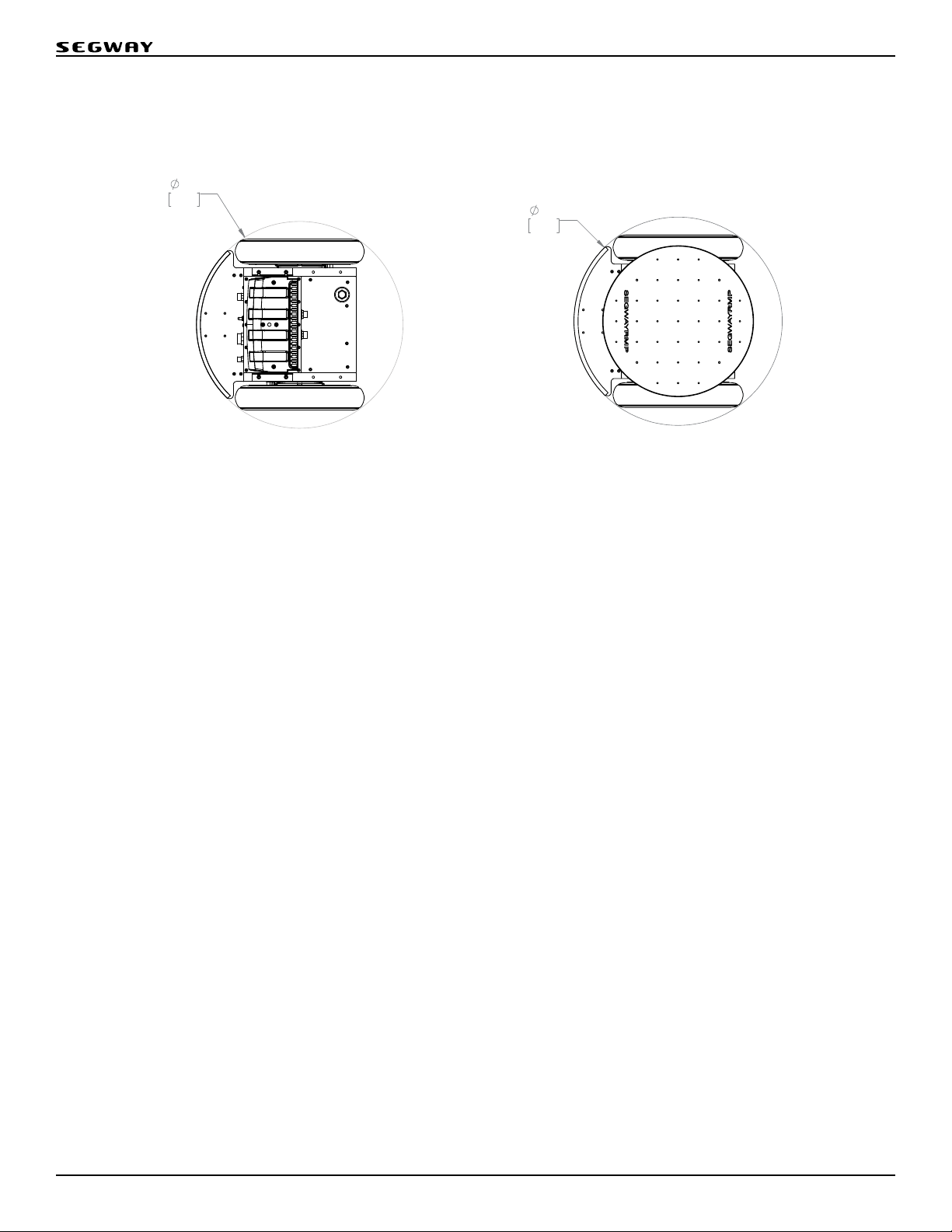

Turn Envelope

771

The RMP can turn in place, so its turn envelope is very small. Both the 210 and the 220 have the same turn envelope.

The caster plate is designed to fit within the turn envelope.

RMP 210/220

30.4

Figure 19: Turn Envelope, RMP 210

771

30.4

Figure 20: Turn Envelope, RMP 220

Copyright © 2014 Segway Inc. All rights reserved.

17

Page 18

RMP 210/220

User Interface Panel

The power switch, LEDs, and external connectors for the RMP are all located on the User Interface Panel on the rear of the RMP. Users

should familiarize themselves with the various connectors and LEDs. For information on the connectors and what plugs into them see

"Connecting," p. 41.

Figure 21: Interface Panel

ON/OFF Switch

Use this switch to power on and off the RMP.

Power and Status LEDs

These two LEDs indicate what mode the RMP is in. They can be used to troubleshoot startup issues. See "Powering On/Off," p. 40, for a

list of what the LEDs indicate.

Connector I

This connector is used for communication and for auxiliary power. Communication available through this connector includes Ethernet,

USB, and CAN. Auxiliary power available depends on the Power Converters installed. Up to two different DC voltages can be made

available. The Starter Breakout Harness connects here.

Connector II

The Disable Button connects here. The Disable signal must be sent for normal operation. Other signals include: the Decel Request, used

to initiate a Decel to Zero (DTZ); the Boot1 signal, used to enter Diagnostic mode; and the Boot2 signal, used to enter Bootloader mode.

Connector IV

This connector is used in conjunction with the External Power Supply for charging the batteries of the RMP. For more information on

charging see "Charging," p. 39.

Charge Status LEDs

When charging the batteries, the Charge Status LEDs will light up, indicating the status of each of the batteries. Each LED corresponds to

a specific battery. For more information see "Charging," p. 39.

Auxiliary Battery

Auxiliary Battery

Front

Figure 22: Battery Locations, 210

Copyright © 2014 Segway Inc. All rights reserved.

Battery 0

Front

NOTICE

Caster Plate is not

standard on the RMP 220.

Battery 0 Battery 1

Figure 23: Battery Locations, 220

18

Page 19

RMP 210/220

Powerbase Connections

On the side of the enclosure there are two powerbase connectors. The left-hand connector goes to the powerbase; the right-hand one

is unused. If two powerbases are used, the right-hand connector goes to the rear powerbase. The powerbase must be plugged into the

proper connector for the charge status LEDs to be correct.

Figure 24: Powerbase Connections

Connector V

Connect the powerbase to this jack.

Connector VI

Cover this jack with the protective cap.

Copyright © 2014 Segway Inc. All rights reserved.

19

Page 20

RMP 210/220

Performance Specifications

The RMP is driven by two independent and fully redundant brushless DC drive motors. It can operate both outdoors and indoors.

Traversable terrain includes asphalt, sand, grass, rocks, and snow.

Table 4: Performance Specications

Characteristic 210 220

Mobility

Max. Speed 8.0 m/s (18 mph) 8.0 m/s (18 mph)

Max. Speed Balancing N/A 4.5 m/s (10 mph)

Turn Radius 0 minimum 0 minimum

Turn Envelope 771 mm (30.4 in) 771 mm (30.4 in)

Max. Slope

Peak Torque

1

20°

50 N-m (37 lb-ft) 100 N-m (74 lb-ft)

(Each Wheel)

Maximum Range

2

25 km (15 mi) 50 km (30 mi)

Power

Batteries

Run Time

3

1 Propulsion Battery

1 Auxiliary Battery

Up to 24 hours Up to 24 hours

Charge Time 2-3 hours 2-3 hours

Battery Chemistry LiFePO

Propulsion Battery

4

380 Wh each 380 Wh each

Capacity

Auxiliary Battery

380 Wh 380 Wh

Capacity

Payload

Max. Payload 400 lbs

10° non-balancing

5° balancing

2 Propulsion Batteries

1 Auxiliary Battery

LiFePO

4

100 lbs4 (Balance Mode)

400 lbs (Tractor Mode)

1

Based on an unloaded platform.

2

Based on an unloaded platform with 15 psi tires travelling in a straight line on level pavement. Actual performance may vary.

3

Run time based on a stationary RMP running on internal battery power. Extended run time is possible with charger connected.

4

Maximum payload in Balance Mode is determined by the gain schedule (page 23). It is possible to use higher payloads with custom gain schedules.

Environmental Specifications

The Segway RMP was designed to withstand environmental conditions both indoors and outdoors.

Table 5: Environmental Specications

Characteristic Value

Operating Temp. Range 0°–50° C

Storage Temp. Range -20°–50° C

Ingress Protection

4

Batteries must be installed in order for enclosure to be fully sealed.

Copyright © 2014 Segway Inc. All rights reserved.

4

Designed to meet IP66 / NEMA 4

20

Page 21

RMP 210/220

Transportation and Shipping

NOTICE

Lithium-ion batteries are regulated as "Hazardous Materials" by the U.S. Department of Transportation. For more information, contact the

U.S. Department of Transportation at http://www.phmsa.dot.gov/hazmat/regs or call 1-800-467-4922.

To prevent damage to your RMP, always ship it in the original crate it came in. The crate disassembles for storage. If you do not have the

original crate, contact Segway for a replacement (see "Contact Information," p. 6).

Copyright © 2014 Segway Inc. All rights reserved.

21

Page 22

RMP 210/220

Balancing

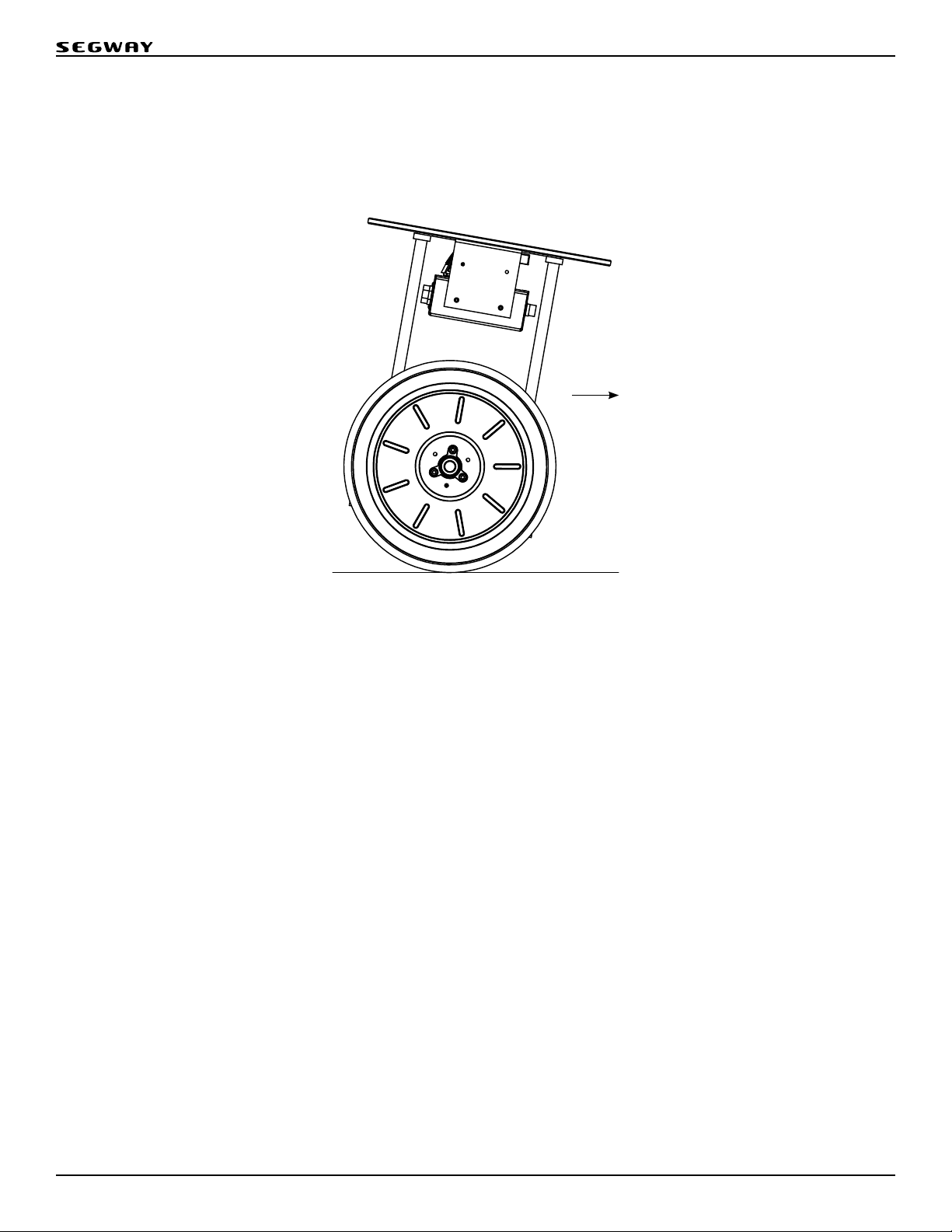

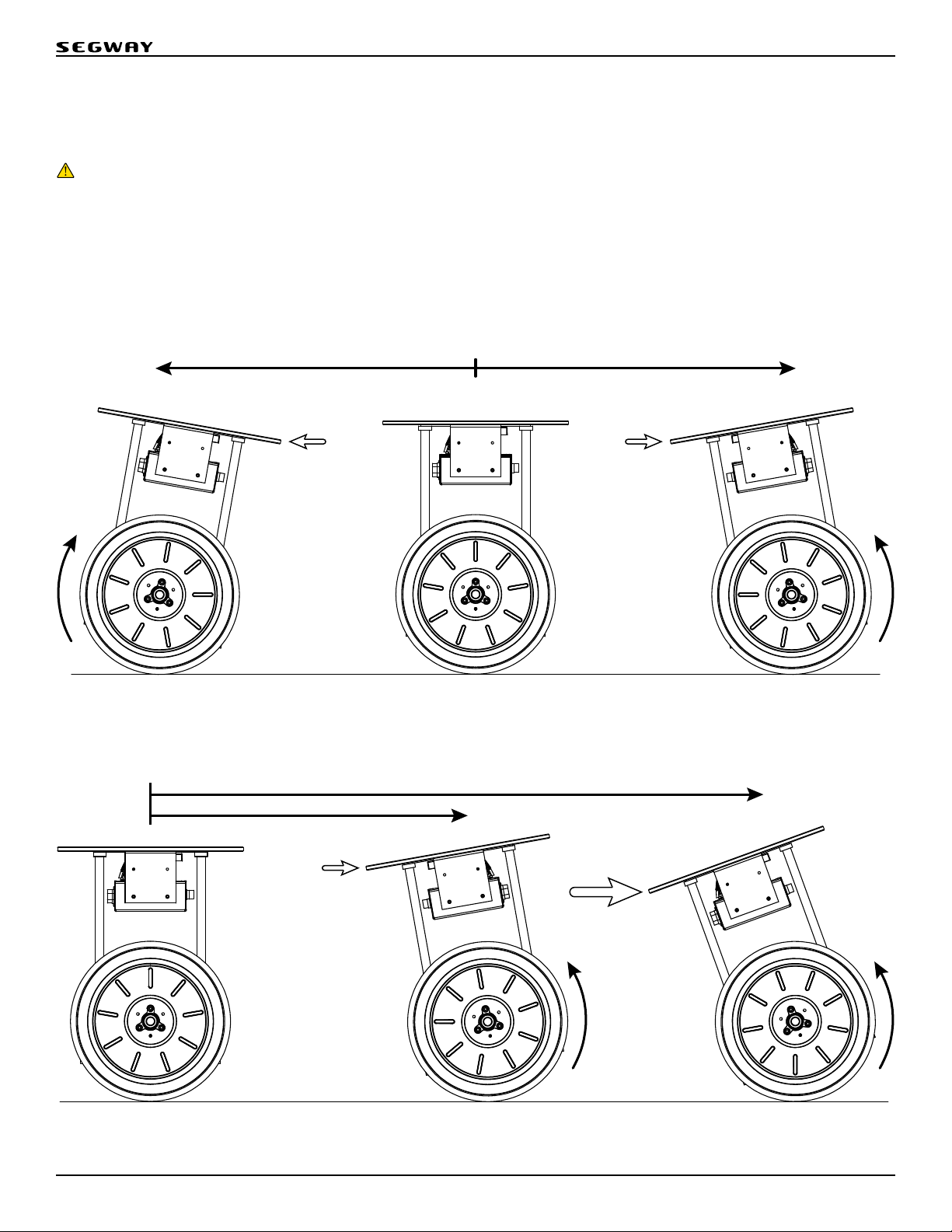

In Balance Mode the RMP balances on two wheels and accepts motion commands. As in Tractor Mode, it can be commanded to drive

forward, backward, and turn left/right. When moving, the RMP tilts slightly in the direction of motion (see Figure 25).

Figure 25: Driving to the Right

In order to enter Balance Mode a mode transition is commanded (see "RMP_CMD_SET_OPERATIONAL_MODE," p. 59). Then the RMP

is tipped upright. When it is vertical, the RMP will begin balancing. At this point the RMP may rock back and forth as it gains its balance.

Do not hold onto the RMP or restrict its movement in any way. Allow it to balance on its own.

NOTICE

When standing still, the RMP may rock forward and backward slightly. This is normal. The RMP is simply maintaining its balance.

Any outside force applied to the RMP while it is balancing will cause it to react. For example, if the RMP is standing still and you press

down on the front of the mounting plate the RMP will tilt. The RMP will push back, attempting to drive forward and tipping the front of the

mounting plate up. For more information on how the RMP will act in a variety of situations, read the rest of this chapter.

Copyright © 2014 Segway Inc. All rights reserved.

22

Page 23

RMP 210/220

Payload Gain Schedules

In order to balance safely and accurately the controller's gain schedules must be precisely tuned for a given payload and weight

distribution. Four pre-defined gain schedules can be selected, and Segway can create custom gain schedules for specific applications.

CAUTION!

The Tall configuration requires extra care. Small tilt angles can result in large relative displacements of the wheel and upper payload.

Each gain schedule has been optimized for a particular payload at a particular height. For best performance, the user should endeavor to

combine their payload with ballast to reproduce mass properties that are close to the configurations defined below.

In general, all gain schedules operate with a wide range of payloads. Choosing the gain schedule that best fits a user's payload has one

main advantage: the handling and dynamics of the RMP will be better damped and more predictable. While each of the gain schedules

can balance a wide variation in payload, the degree of oscillation and control activity will change as the payload is altered. For example,

both the Light and Heavy gain schedules can handle a 75 lb payload on the mounting plate, however the response of each controller will

be slightly different in the presence of disturbances. Note that the Tall payload configuration will not balance with the Light or Heavy gain

schedules.

The gain schedule is assigned when the RMP enters Balance Mode. Changes to the gain schedule cannot be performed while in Balance

Mode. The RMP will have to enter Tractor Mode for the gain schedule to change.

25 lbs

750 mm

25 lbs

Figure 26: Unloaded Figure 27: Light Figure 28: Tall Figure 29: Heavy

Unloaded (Default)

Use this gain schedule for an RMP with no additional mass loaded

onto it. This is the default gain schedule.

NOTICE

This physical playform configuration represents the minimum

mass ballast required for safe operation in Balance Mode.

Light

Use this gain schedule for an RMP with a 50 lb (22.7 kg) payload

mounted directly on the mounting plate.

Tall

Use this gain schedule for an RMP with 25 lbs (11.3 kg) mounted

on the mounting plate and an additional 25 lbs (11.3 kg) mounted

Custom

Custom gain schedules can be created for specific applications

and payloads. The gain schedule parameters are stored in NVRAM

so they will not be forgotten across reboots. Contact Segway for

more information ("Contact Information," p. 6).

750 mm (29.5 in) above the mounting plate.

Heavy

Use this gain schedule for an RMP with 100 lbs (45.4 kg) mounted

directly on the mounting plate.

100 lbs50 lbs

Copyright © 2014 Segway Inc. All rights reserved.

23

Page 24

RMP 210/220

Balance Mode Requirements

In order to safely balance, the RMP must meet the following requirements.

• Ability to tip to 45° (to safely allow the RMP full maneuverability).

• Correct weight distribution as per the gain schedule selected (see "Payload Gain Schedules," p. 23).

CAUTION!

The Balance Frame Assembly (Tube Frame, U-Bracket for high mounting of User Interface Box, and Mounting Plate) provides the

minimum mass ballast required for operating in Balance Mode and must be installed as shown before entering Balance Mode. Optional

brackets for mounting the User Interface Box low are available, but are not compatible with Balance Mode operation.

Also, before entering Balance Mode the Balance Enable Bit must be set to 1. See "RMP_CMD_SET_INPUT_CONFIG_BITMAP," p. 55. The

purpose of this bit is to lock out Balance Mode in situations where it would be unsafe to enter Balance Mode.

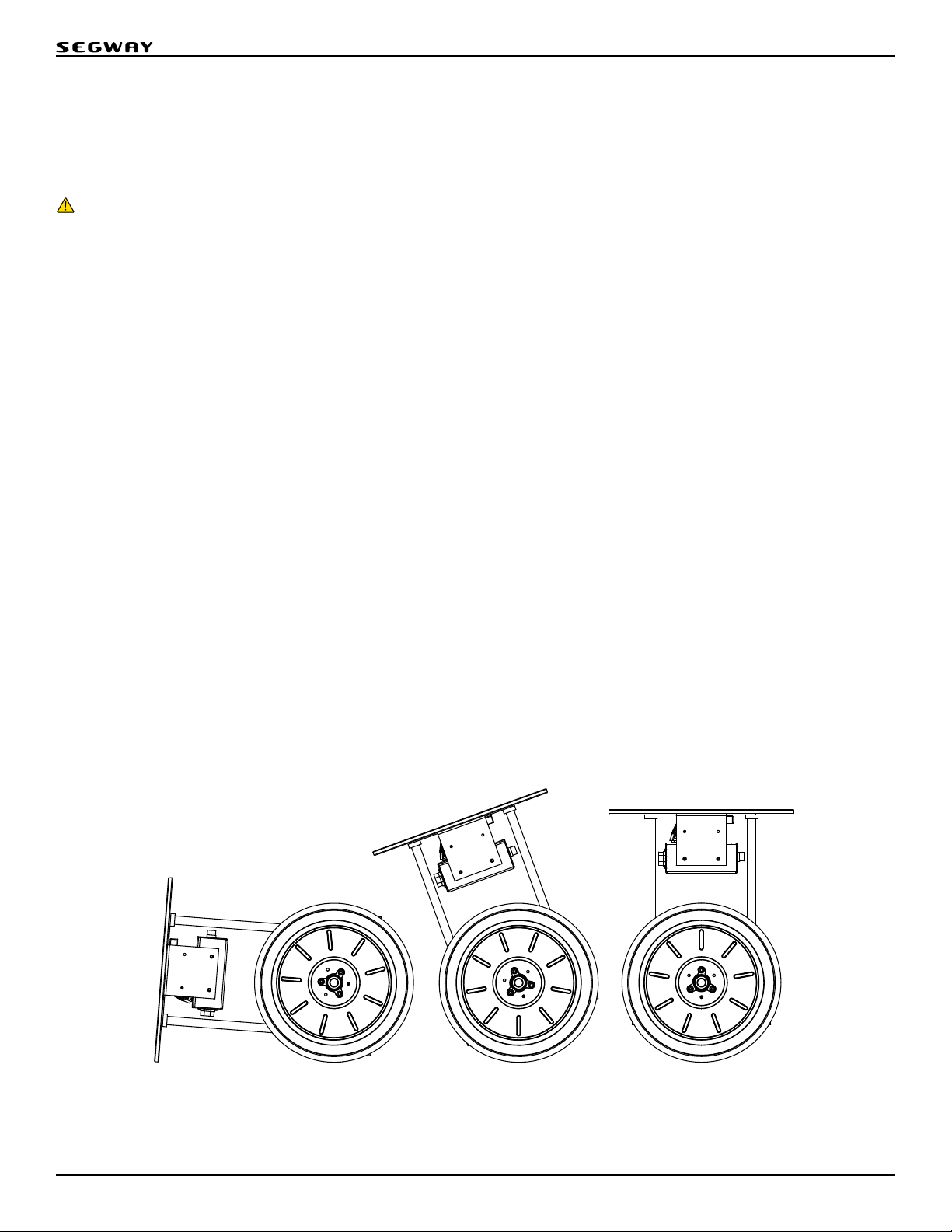

Entering Balance Mode

The RMP will enter Balance Mode if:

• Balance Mode is enabled (see "RMP_CMD_SET_INPUT_CONFIG_BITMAP," p. 55).

• A Balance Mode transition is commanded.

• The BSA is initialized.

• The RMP crosses the vertical axis.

The BSA initializes when the RMP is within 30° of vertical and takes a few seconds to occur. During this time the RMP should remain

stationary.

1. Verify that the RMP meets the Balance Mode Requirements.

2. Turn on the RMP.

3. Command a transition to Balance Mode (see "Hardware Balance Request," p. 31 and

"RMP_CMD_SET_OPERATIONAL_MODE," p. 59).

The RMP will make a emit a beep-beep sound if the BSA is not initialized.

4. Tip the RMP upright until it is vertical (see Figure 30).

Once the BSA initializes, the beep-beep sound will change to a repeating beep.

The RMP will beep with increasing frequency as it approaches vertical.

5. Allow the RMP to balance on its own.

You can now send motion commands.

Copyright © 2014 Segway Inc. All rights reserved.

Figure 30: Tip the RMP Upright When Entering Balance Mode

24

Page 25

RMP 210/220

Exiting Balance Mode

When exiting Balance Mode the RMP will stop balancing and will tip over. Be prepared to catch the RMP if you do not want it to slam into

the ground.

1. Bring the RMP to a stop.

2. Exit Balance Mode by commanding a mode transition (see "RMP_CMD_SET_OPERATIONAL_MODE," p. 59).

3. Catch the RMP as it begins to tip over.

WARNING!

Do not let the RMP fall onto your foot or other part of your body. The mounting plate is heavy and could cause injury.

The RMP can exit Balance Mode in a variety of ways. Any mode transition out of Balance Mode will cause the RMP to stop Balancing

(transitioning to Standby Mode, Tractor Mode, Disable Mode, etc.). Also, toggling the Power Switch OFF will cause the RMP to stop

balancing.

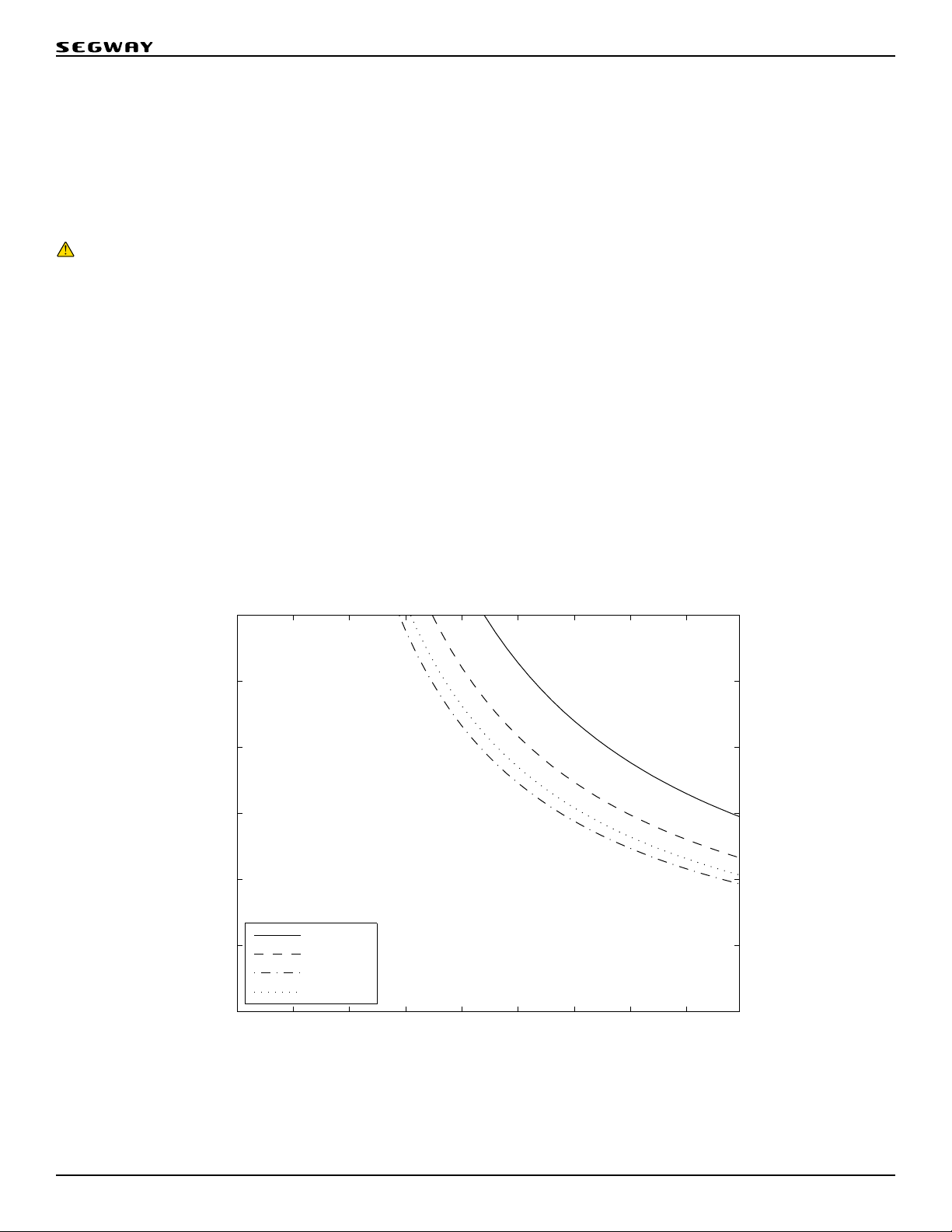

Performance Limits

Roll Over

In order to balance the RMP needs to have its payload mounted relatively high. This is because the RMP operates as an inverted

pendulum while balancing. Unfotunately, the property that helps the RMP to balance (a high center of mass) also makes the RMP more

likely to roll over.

Figure 31 shows how velocity and yaw rate combine to make the RMP roll over. The area above the curve(s) is where the RMP is likely to

roll over. This graph assumes that the RMP is operating on level ground. Any slope, however slight, will increase the likelihood of roll-over.

Roll Over Performance Limits

3

2.5

2

1.5

yaw rate [rad/s]

1

0.5

0

0 0.5 1 1.5 2 2.5 3 3.5 4

Unloaded

Light

Tall

Heavy

velocity [m/s]

4.5

Copyright © 2014 Segway Inc. All rights reserved.

Figure 31: Roll Over Performance Limits

25

Page 26

RMP 210/220

Turn Radius

The RMP's speed and yaw rate can be used to calculate the turn radius. Higher speeds increase the turn radius while higher yaw rates

decrease it. Be sure not to exceed the Roll Over limit described above.

R =

V

Y

Where,

R = Turn Radius (m)

V = Velocity (m/s)

Y = Yaw Rate (rad/s)

This equation provides the turn radius to the center of the RMP. To calculate the radius to the outside of the RMP just add half of the

RMP's width (~0.32 m) to the final radius.

Using this equation and the Roll Over limit, the minimum safe turn radius can be determined for a variety of speeds.

Stopping Distance

Changing the deceleration limit can have a big effect on how far the RMP travels as it slows to a stop. If the RMP cannot stop soon enough

it may collide with obstacles. If it stops too quickly it may tip far enough and fast enough to jostle equipment or startle bystanders.

Because of this it is important to reach a balance between stopping distance and tip angle.

These same principles also apply to the DTZ deceleration limit and the acceleration limit. The DTZ decleration limit controls the rate at

which the RMP will come to a stop when a DTZ command is issued or when a fault triggers a DTZ response. The acceleration limit affects

how far the RMP travels while coming up to speed. Remember to set the DTZ deceleration limit high enough to stop the RMP quickly in

case of an emergency.

To calculate the stopping distance from the velocity and deceleration rate, use the following formula:

2

D =

Where,

D = Distance Travelled (m)

V = Initial Velocity (m/s)

A = Acceleration/Deceleration Rate (m/s2)

V

2A

Copyright © 2014 Segway Inc. All rights reserved.

26

Page 27

RMP 210/220

Interaction With The Environment

When the RMP makes contact with other objects in the environment, the results can be counter-intuitive at first. For recommended tire

pressure please refer to page 108.

WARNING!

Read and understand this section before operating an RMP in Balance Mode. Proper understanding of how the RMP will act is necessary

to avoid personal injury and property damage.

Displacement

If the RMP is displaced from its desired position, it will lean against the displacement force, creating a new equilibrium position. The

harder it is pushed, the more it will lean.

∆X ∆X

Desired Position

Desired Position

Figure 32: Displacement Direction

2∆X

∆X

Copyright © 2014 Segway Inc. All rights reserved.

Figure 33: Displacement Magnitude

27

Page 28

RMP 210/220

Unable to Right Itself

If an external force causes the RMP to tip forward or backward, the RMP will attempt to right itself. This simple concept can have some

surprising consequences.

If a downward force is applied to the mounting plate, the RMP will drive in the direction that it is tipped. This could occur if someone

presses down on the mounting plate, or if the payload center of gravity is off-center. See Figure 34.

Figure 34: Downward Force

Something similar happens when the RMP gets caught under something, as is shown in Figure 35 where the mounting plate is caught

under a table. In this case the RMP will push up against the table in an attempt to right itself. The force applied by the RMP can be quite

strong, lifting the table or tipping it over.

Copyright © 2014 Segway Inc. All rights reserved.

Figure 35: Caught Under a Table

28

Page 29

RMP 210/220

Unable to Right Itself (cont.)

The situation shown in Figure 36 is very different from a dynamic standpoint, but the controller cannot differentiate between this

configuration and the ones in Figure 34 and Figure 35. In this case the RMP will accelerate faster and faster to the right trying to bring the

machine to a level equilibrium. It will quickly trip the position error limit of 12 feet and Disable.

Figure 36: Caster Wheel

A caster wheel can cause the RMP to accelerate rapidly even if it does not normally contact the ground. If the RMP hits an obstacle or

encounters a slope, the caster wheel will tip the RMP and start it accelerating in the opposite direction.

Copyright © 2014 Segway Inc. All rights reserved.

Figure 37: Caster Wheel on a Slope

29

Page 30

RMP 210/220

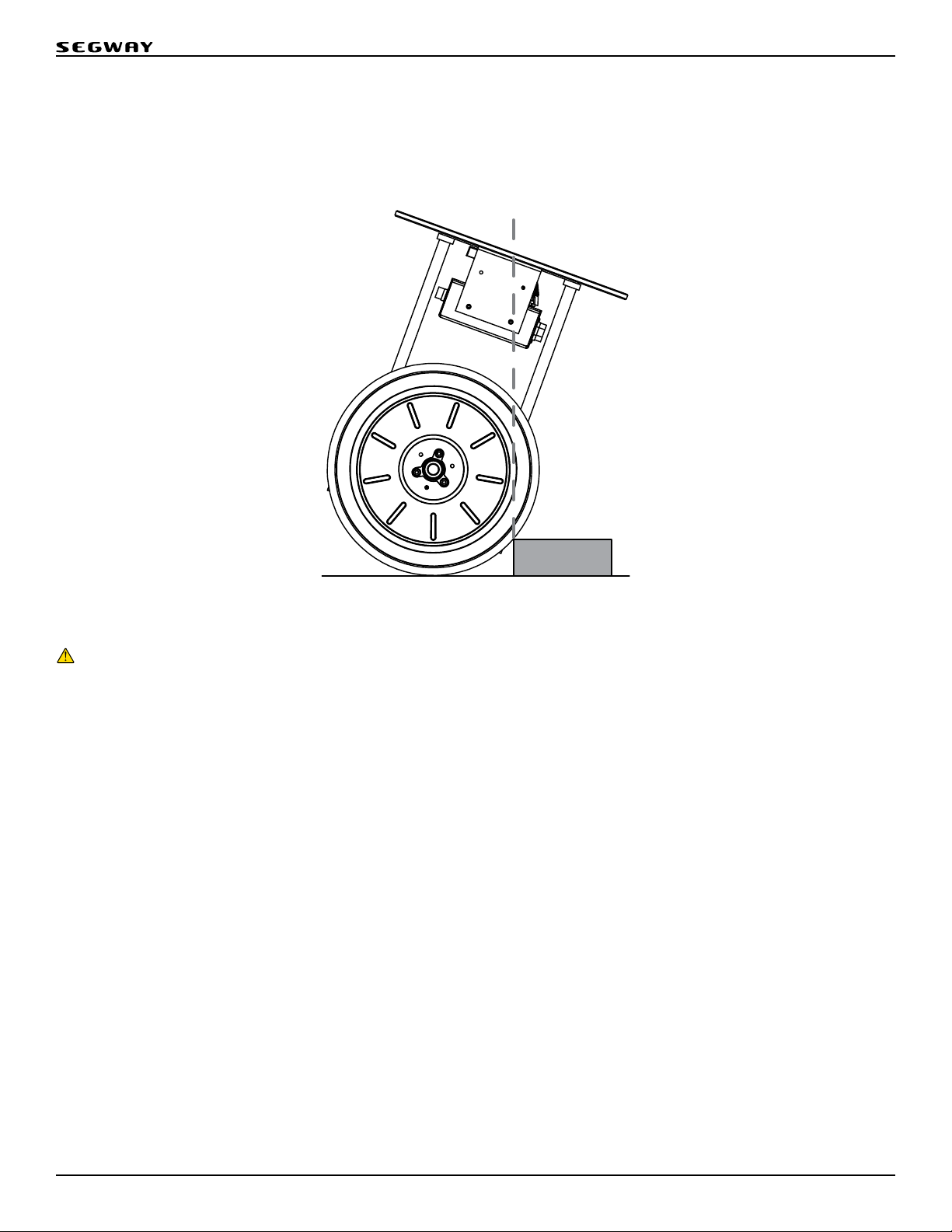

Obstacles

When the RMP needs to roll over an obstacle, the CG of the RMP must tilt forward over the contact point. When the tire makes contact

with the obstacle, it stops rolling and the frame tilts forward. Once the CG is over the contact point with the obstacle, the RMP will roll over

the obstacle (provided the obstacle is small and sufficient traction exists). Because torque is required to hold the tilted position, there is a

tendency to overshoot the obstacle. Approaching obstacles with a small initial velocity typically helps in traversing obstacles.

Figure 38: Crossing an Obstacle

WARNING!

• If the RMP is traveling too fast over an obstacle, the wheels could leave the ground. When this happens the RMP will have

difficulty maintaining its balance and will move very quickly trying to right itself. This could result in death or serious injury to

bystanders, or property damage.

• If there are multiple obstacles in a row, the RMP must be able to catch its balance after each one. When obstacles are too close

together the RMP will not be able to maintain its balance and will move very quickly trying to right itself. This could result in

death or serious injury to bystanders, or property damage.

Copyright © 2014 Segway Inc. All rights reserved.

30

Page 31

RMP 210/220

Balance Mode Faults

There are some faults that occur only in Balance Mode. For information on how the RMP will respond to other faults, see "Faults," p. 36

and "Fault Status Definitions," p. 82.

Pitch Angle Exceeded

If the RMP tips forward or backward greater than 30° from normal (see Θ, page 13), the RMP will Disable and power off. This is

because the BSA's Pitch State Estimate is only accurate within this range. Furthermore, if the RMP tips past 30° it is likely that it will be

difficult or impossible for it to right itself.

Roll Angle Exceeded

If the RMP tips sideways greater than 30° from normal (see Φ, page 13), the RMP will Disable and power off. This is because the RMP

will not be able to right itself and is in the process of falling over.

Speed Limiter Hazard

In order to maintain its balance the RMP must sometimes move very quickly. Usually this is acceptable, however if the RMP tries to move

too fast it is an indicator that the RMP is having difficulty righting itself. When the actual speed exceeds the the speed limiter value, the

RMP will Disable and power off.

Position Control Failed

During normal operation, the RMP will attempt to hold position when no movement is commanded. If the RMP is unable to hold position

for any reason and the wheels rotate too far from the original resting location (an equivalent of 12 feet of displacement), the RMP will

Disable and power off. This could happen if the wheels are slipping, a force pushes the RMP away from the equilibrium position, or some

other condition is preventing the RMP from reaching its equilibrium position (e.g. the RMP is lifted off the ground).

Velocity Control Failed

During normal operation, the RMP will attempt to match the commanded velocity (or hold position if no velocity is commanded). If the

RMP's actual velocity moves outside of the acceptable range, the RMP will Disable and power off. This could occur if the RMP is trying to

regain its balance after losing traction, or if some condition is preventing the RMP from reaching its equilibrium position (e.g. the RMP is

lifted off the ground).

Hardware Balance Request

A Balance Mode transition can also be commanded via a hardware button. While in Standby Mode or Tractor Mode, momentarily sending

a Boot1 signal will initiate the Balance Mode request.

A Boot1 signal is sent by connecting pins D and E on Connector II. See "Connector II," p. 43.

Sending a Boot1 signal while in Balance Mode will not cause a transition out of Balance Mode. Instead a mode request must be made to

transition to Standby Mode, Tractor Mode, Disable Mode, or DTZ.

Velocity Filter

When in Balance Mode the RMP can tip quite suddenly, especially when large changes in velocity are commanded. To mitigate this a

velocity filter can be applied that smooths velocity transitions by limiting the rate at which the acceleration rate can change. For more

information see "Velocity Filter," p. 65.

Copyright © 2014 Segway Inc. All rights reserved.

31

Page 32

RMP 210/220

Electrical Overview

This section describes the components of the RMP and shows how they interact.

System Architecture

The RMP combines the robustness of the Segway powerbase with a versatile Centralized Control Unit (CCU). The powerbase is the same

proven technology used in the Segway PT. It controls the wheels, senses the RMP's orientation, and provides a mounting location for the

batteries. The Centralized Control Unit coordinates the RMP's movement and controls communication among all the components. It acts

as the interface between the RMP and the outside world. The diagram below shows how these components communicate with each other.

Figure 39: System Architecture Diagram

System Power

The RMP runs on rechargeable batteries. Power is routed from the batteries to the various components of the system. DC power is

available for customer use.

Figure 40: System Power Diagram

Copyright © 2014 Segway Inc. All rights reserved.

32

Page 33

RMP 210/220

Front

System Components

A brief overview of each component is provided to help you become familiar with these components and their functions.

Centralized Control Unit

The Centralized Control Unit (CCU) contains the Segway Processor (SP)

and the User Interface Processor (UIP). These processors use synchronized

timing to control the RMP in real time. They communicate via a Serial

Peripheral Interface (SPI) link.

Segway Processor

The SP controls essential system functions including timing

management, control algorithms, safety kernel functions, redundancy

management, estimation algorithms, and Segway hardware interfaces.

In addition, a real time clock and Non-Volatile Memory (NVM) allow for

diagnostic fault logging.

User Interface Processor

Figure 41: Centralized Control Unit

The UIP controls the interaction between the user and the RMP. It allows the user to command RMP motion, configure machine

parameters, and access faultlog information.

The UIP consists of four layers: System layer, I/O layer, Toolkit layer, and Application layer.

1. The System layer manages hardware-specific functionality like interrupts and timing.

2. The I/O layer manages all processor I/O including GPIO, ADC, DAC, CCP, USB, UDP, CAN, RS232, TTL Serial, and the SPI link.

The I/O layer is responsible for gathering all raw UIP data and presenting it to the Toolkit layer.

3. The Toolkit layer abstracts the information gathered by the I/O layer and interprets it into meaningful system level data. The

Toolkit layer then relays that information to various interfaces for consumption by the user.

4. The Application layer consists of an application stump for future expansion and development of the system.

Powerbase

The powerbase is one of the main components of the Segway PT and has been leveraged for use as the propulsion unit of the RMP.

Each RMP 220 has one powerbase that controls both wheels. Inside the powerbase are two Motor Control Units (MCUs) and a BSA. The

powerbase is not serviceable by the user; this information is provided for completeness only.

Motor Control Unit

The MCU is a Segway motor drive. It utilizes the robustness of the

Segway PT propulsion system as a motor drive. Each MCU has two motor

drives that drive half of a dual hemisphere Segway motor. Each MCU

performs its own internal fault detection and communicates with the SP

via CAN interface. The user does not have access to the MCU interface.

MCU 0

Balance Sensor Assembly

The BSA provides redundant raw three-axis inertial data to the SP. The

SP uses this information to compute the Pitch State Estimate (PSE). The

PSE algorithm estimates the machine orientation and movement based

on the combined raw inertial information and wheel odometry.

BSA

MCU 1

Copyright © 2014 Segway Inc. All rights reserved.

Figure 42: Segway Powerbase

NOTICE

Caster Plate is not standard on the RMP 220.

33

Page 34

Smart Charger Board

The Smart Charger Board (SCB) distributes charging current from the

External Power Supply to the ABB and both powerbases. It controls multiple

high current smart chargers and manages charging. It has 5 monitored

channels at 100 VDC each and can perform fault detection down to the level

of the power supply, board, and battery.

Auxiliary Battery Board

The Auxiliary Battery Board (ABB) monitors voltage, current, state of charge,

and battery flags of the auxiliary battery pack. It has software protected

outputs to prevent over-discharge of the battery. The board can act as a

standalone unit or can connect to the CCU. It interfaces with the UIP via CAN

and provides real-time battery data and status information for the auxiliary

battery pack. The ABB can communicate via CAN, USB, and RS232.

If the fuse blows, the entire board must be replaced.

RMP 210/220

Figure 43: Smart Charger Board

Power Converter

The RMP 220 accommodates up to two Power Converters. Each Power

Converter accepts 72 VDC input power and provides DC output power at a

different voltage. One Power Converter provides 12 VDC power for internal

use and customer use. The other Power Converter is selectable at time of

purchase. Output voltage options include 5 VDC, 12 VDC, 24 VDC, 36 VDC,

and 48 VDC.

Figure 44: Auxiliary Battery Board

Figure 45: Power Converter

Copyright © 2014 Segway Inc. All rights reserved.

34

Page 35

Operational Model

This chapter describes powering on, powering off, and the various modes of operation.

Operational States

At any given time, the RMP will be in one of the following operational states:

• Initialization

• Diagnostic Mode

• Bootloader Mode

• Standby Mode

• Tractor Mode

• Balance Mode

• Disable Mode

• DTZ Mode

• Off

Figure 46 shows how these states interact. Each of these states is discussed in more depth on the following pages.

RMP 210/220

Figure 46: System State Diagram

Copyright © 2014 Segway Inc. All rights reserved.

35

Page 36

RMP 210/220

Faults

Faults occur in response to events that impact the RMP. This could include anything from receiving a user-commanded DTZ signal

to detecting a failed battery. Sometimes faults are the result of a problem that needs to be resolved. Other times they are merely

informative.

In response to a fault the RMP may simply log the fault or it may take an action. There are four types of fault responses:

• No fault response — fault is logged. No change in RMP behavior.

• DTZ response — fault initiates a Decel To Zero. RMP comes to a stop, logs the fault, and maintains position. Transitions to

Balance Mode or Tractor Mode are disabled.

• Disable response — fault causes RMP to power off. RMP logs the fault and powers off immediately.

• Disable MCU response — fault causes a single MCU to go down. RMP will continue to balance (if applicable) and hold position.

Initialization

Initialization is composed of three sub-states: Init Hardware, Init Propulsion, and Check Startup Issues. First, the hardware is initialized;

this includes the CCU and ABB. Then, propulsion is initialized (the MCUs and BSA). If there are no issues with the system, the RMP

transitions to Standby Mode. Otherwise it shuts down.

If the BOOT1 or BOOT2 signal is pulled low the RMP will enter Diagnostic Mode or Bootloader Mode, respectively.

Init Hardware

During Init Hardware, the following steps are performed:

1. UIP and SP initialize hardware, interrupts, and software.

2. UIP and SP synchronize their timing.

3. UIP-SP communication is established.

4. SP reads configuration parameters from NVM, initializes dependent data, and passes the parameters to the UIP for UIP

dependent data initialization.

5. UIP and SP verify configuration validity.

6. SP extracts the faultlog from NVM and relays the faultlog array to the UIP for user access.

Init Propulsion

During Init Propulsion the SP initializes each MCU using a state machine. Each state verifies a certain MCU operational status. If any MCU

is not operating as expected, the RMP will transition to Disable Mode and power off. Information regarding the failure is stored in the

faultlog

Check Startup Issues

In this sub-state the SP checks for various parameters that will gate entry to Standby Mode. When the RMP detects an issue, Standby

Mode entry is gated and the RMP will emit a tone and blink the LEDs for five seconds before failing initialization. If the issue is corrected in

this time, the transition to Standby Mode will be allowed.

The following issues will gate transition to Standby Mode:

• An MCU declares a fault.

• The RMP is charging (this can be overridden: see "RMP_CMD_SET_INPUT_CONFIG_BITMAP," p. 55).

• An MCU battery open circuit voltage is below the operational threshold.

• An MCU battery state of charge is below the operational threshold.

• 7.2 VDC battery (if present) has low or high voltage.

• Any detected machine motion (RMP moving un-commanded).

• Tractor mode request is present from the user.

• BSA communication has not been established.

Copyright © 2014 Segway Inc. All rights reserved.

36

Page 37

RMP 210/220

Diagnostic Mode

In Diagnostic Mode the RMP stays in the Init System state without transitioning to Standby Mode. In this mode the RMP has initialized

the CCU and ABB, but has not initialized propulsion. The user can communicate with the RMP but cannot command it to move. This mode

allows the user to update configuration parameters and extract the faultlog without fully initializing the RMP; this is useful when a fault

causes the RMP to shutdown before entering Standby Mode.

In this state the RMP will remain on as long as power is available.

To enter Diagnostic Mode:

1. Turn the RMP off.

2. Connect pins D and E on the 6-pin connector (for the full pinout, see "Connector II," p. 43).

3. Use the USB cable to connect the RMP to the computer. The RMP will power on.

This will pull the BOOT1 signal low. The RMP will begin initialization but will stop at Init System and remain there.

Bootloader Mode

In Bootloader Mode, the RMP remains in the bootloader stage without continuing on to the RMP applications. The user can then load new

applications into either of the processors using the Bootloader Application (see "RMP CCU Bootloader Application," p. 101).

In this state the RMP will stay powered as long as USB power is available.

To enter Bootloader Mode:

1. Turn the RMP off.

2. Connect pins D and F on the 6-pin connector (for the full pinout, see "Connector II," p. 43).

3. Use the USB cable to connect the RMP to the computer. The RMP will power on.

This will pull the BOOT2 signal low. The RMP will stop at the bootloader stage without loading any applications or beginning initialization.

Standby Mode

In Standby Mode the RMP is fully functional with the exception that motion commands are not executed. The MCUs are enabled, the

controllers are initialized, and the RMP is holding its position. Any motion commands issued will not be executed by the platform.

Standby mode is entered automatically after successful initialization. From here the user can initiate a transition to tractor mode or

disable the RMP.

Tractor Mode

In Tractor Mode the RMP will accept motion commands from the user. In this mode the RMP can be commanded to move. The MCUs are

enabled and the controllers are running. Motion commands issued by the user will be accepted.

Tractor Mode can only be entered from Standby Mode as the result of a user mode request (see "RMP_CMD_SET_INPUT_CONFIG_

BITMAP," p. 55). From here the user can initiate a transition back to Standby Mode or can disable the RMP.

Balance Mode

In Balance Mode the RMP will balance on two wheels and will accept motion commands from the user. The RMP's actions in Balance