Page 1

420-6796-02UK REV 0

SERVICE MANUAL

TWIN TYPE

Before using this product, read this SERVICE MANUAL carefully to understand the contents stated herein.

After reading this manual, be sure to keep it available nearby the product or somewhere convenient in order to

be able to refer to it whenever necessary.

Manufactured in the UK by

Page 2

CONTENTS

1.

BEFORE USING THIS PRODUCT................................ ..................................................................5

1.1. Inspections Immediately After Transporting The Product To The Location.......................................6

2.

INTRODUCTION TO THIS SERVICE MANUAL................................................................................8

3.

INSTALLATION AND SERVICE INSTRUCTIONS .............................................................................9

3.1. Handling and Installation Precautions ..........................................................................................9

3.2. Coin Handling.........................................................................................................................11

3.3. Name of Parts.........................................................................................................................12

3.4. Accessories ...........................................................................................................................13

3.5. Shipping the Game Board ........................................................................................................ 14

3.6. Shipping the GD -ROM Drive .....................................................................................................16

3.7. Assembly Instructions.............................................................................................................17

3.7.1. Applying the Play Instructions ...........................................................................................18

3.7.2. Assembling the Cockpit ................................ .................................................................... 19

3.7.3. Securing In Place (Leg Adjuster Adjustment)......................................................................20

3.7.4. Billboard Installation..........................................................................................................22

3.7.5. Installing The AC Covers (Wire Covers )..............................................................................23

3.7.6. Coin Handling Installation ..................................................................................................24

3.7.6.1. Wiring Connections....................................................................................................25

3.7.7. Communication Cables.....................................................................................................26

3.7.8. Connection To The Power Supply.......................................................................................27

3.7.9. Assembly Check ..............................................................................................................29

3.7.9.1. CRT Test ..................................................................................................................29

3.7.9.2. Memory Test.............................................................................................................30

3.7.9.3. Input Test..................................................................................................................31

3.7.9.4. Output Test...............................................................................................................32

3.7.9.5. Sound Test ...............................................................................................................32

3.7.10. Moving The Machine ......................................................................................................33

3.8. Fuses ................................ .................................................................................................... 34

3.9. Maintenance...........................................................................................................................35

3.9.1. Handle Mecha ..................................................................................................................36

3.9.1.1. Removing the Handle Mecha ....................................................................................... 36

3.9.1.2. Replacing and Adjusting The Handle Mecha’s V.R........................................................36

3.9.1.3. Adjusting the VR ................................ .......................................................................37

3.9.1.4. Replacing the VR.......................................................................................................37

3.9.1.5. Greasing...................................................................................................................38

3.9.2. Accelerator & Brake .........................................................................................................39

3.9.2.1. Removing the Accelerator & Brake. .............................................................................39

3.9.2.2. Adjusting the V.R......................................................................................................40

3.9.2.3. Replacing the V.R......................................................................................................41

3.9.2.4. Greasing...................................................................................................................41

3.10. Shift Lever...........................................................................................................................42

3.11. Replacement of Fluorescent Lamp and Other Lamps ..............................................................43

3.11.1. Fluorescent Lamp Replacement .....................................................................................43

3.12. Cleaning the Cabinet Surfaces ..............................................................................................44

3.13. Seat (Greasing to Seat Rail Portion) ...................................................................................... 44

3.14. Troubleshooting ...................................................................................................................45

3.14.1. Troubleshooting (When No Error Message Is Shown) ........................................................45

3.15. Gameboard.........................................................................................................................48

3.15.1. Removing the Board ......................................................................................................48

3.15.2. Removing The GD-ROM Drive .........................................................................................49

3.15.3. Removing The Game Board................................ ............................................................ 51

3.15.4. Composition of the Game Board .....................................................................................52

3.15.4.1. Replacing The Main Board Battery ..............................................................................53

3.15.4.2. Replacing The Media Board Battery Pack................................ .................................... 54

3.15.5. Shipping The Game Board.............................................................................................57

3.15.6. Shipping The Media Board.............................................................................................59

3.15.7. Shipping The GD -ROM Drive ..........................................................................................60

3.15.8. Machine Set Up ............................................................................................................61

3.15.8.1. Network Play ................................ ............................................................................ 62

2

Page 3

3.16. Periodic Check and Inspection..............................................................................................67

4.

HOW TO PLAY..........................................................................................................................68

4.1. Basic Controls................................ ........................................................................................ 68

4.2. Game Outline.........................................................................................................................68

4.3. Game Flow.............................................................................................................................69

4.3.1. Versus Mode Entry ...........................................................................................................69

4.3.2. Car Selection ...................................................................................................................69

4.3.3. Transmission Selection.....................................................................................................71

4.3.4. Mode Selection ................................................................................................................71

4.3.4.1. OutRun Mode................................ ............................................................................ 71

4.3.4.2. Heart Attack Mode.....................................................................................................72

4.3.4.3. Time Attack Mode.....................................................................................................74

4.4. Versus Play................................ ............................................................................................ 76

4.4.1. Versus Mode Game Play ..................................................................................................76

4.4.2. Special Versus Mode Commands ......................................................................................76

4.4.2.1. No Handicap Mode................................ .................................................................... 76

4.4.2.2. Player Only Mode ......................................................................................................76

4.5. Gameplay Techniques and Secret Commands ...........................................................................77

4.5.1. How to Drift......................................................................................................................77

4.5.2. Mid-game Quit Command..................................................................................................77

4.6. Character Introductions ............................................................................................................78

5.

MAINTENANCE INSTRUCTIONS.................................................................................................79

5.1. Explanation of Test and Data Display ........................................................................................ 79

5.1.1. VTS Assembly .................................................................................................................80

5.2. System Test Mode .................................................................................................................. 81

5.2.1. RAM Test ................................ ........................................................................................ 82

5.2.2. JVS Test.........................................................................................................................82

5.2.3. Sound Test......................................................................................................................83

5.2.4. C.R.T Test .......................................................................................................................83

5.2.5. System Assignments .......................................................................................................84

5.2.5.1. Coin Assignments.....................................................................................................84

5.2.5.2. Coin/Credit Setting (Coin Chute Common Type) ............................................................85

5.2.5.3. Coin/Credit Setting (Coin Chute Individu al Type) ............................................................ 86

5.2.5.4. Manual Setting ..........................................................................................................87

5.2.5.5. Sequence Setting ......................................................................................................88

5.2.5.6. Bookkeeping.............................................................................................................89

5.2.5.7. Backup Data Clear.....................................................................................................89

5.2.5.8. ROM BD Test ............................................................................................................90

5.2.5.9. Clock Setting................................ ............................................................................ 90

5.3. Game Test Mode................................ .................................................................................... 91

5.3.1. Input Test ................................ ........................................................................................ 92

5.3.2. Output Test......................................................................................................................93

5.3.3. Drive Board Test...............................................................................................................94

5.3.4. Game Assignments..........................................................................................................95

5.3.5. Bookkeeping................................ .................................................................................... 97

5.3.6. Backup Data Clear ...........................................................................................................99

6.

COIN MECH INSTALLATION AND CREDIT BOARD SET UP........................................................ 100

6.1. Introduction........................................................................................................................... 100

6.1.1.

6.1.2.

6.1.3. Price Of Play Settings Austria-Czech-Denmark-Norway-Israel-France2............................... 105

7.

8.

8.1. Assembly Structure............................................................................................................... 107

8.2. ORT-00001UK TOP ASSY OUTRUN2 TWIN............................................................................ 108

8.3. ORT-10001UK ASSY COCKPIT 1P ......................................................................................... 110

8.4. DUT-1120UK ASSY SUB MAIN BASE .................................................................................... 113

8.5. ORT-1550UK ASSY MONITOR COVER L 2P ................................ ..........................................114

8.6. APC-1560 ASSY SPEAKER L...............................................................................................115

8.7. ORT-1555UK ASSY MONITOR COVER R 2P ..........................................................................116

Price of Play Settings UK ............................................................................................... 103

Price Of Play Settings Euro ............................................................................................ 104

DESIGN RELATED PARTS .......................................................................................................106

PARTS LIST ............................................................................................................................ 107

3

Page 4

8.8. APC-1565 ASSY SPEAKER R..............................................................................................117

8.9. ORT-2000UK ASSY CONTROL PANEL ..................................................................................118

8.10. SPG-2500 ASSY HANDLE MECHA .................................................................................... 120

8.11. ORT-2100UK-ASSY SW PLATE ......................................................................................... 122

8.12. ORT-1100UK ASSY PEDAL BASE ORT................................ ..............................................123

8.13. SPG-2200 ASSY BRAKE & ACCELL................................ ..................................................124

8.14. ORT-1600UK ASSY SEAT TWIN 1P ................................................................................... 126

8.15. ORT-4500UK ASSY MAIN BD ............................................................................................ 128

8.16. ORT-4600UK ASSY ELEC BD ............................................................................................129

8.17. FRI-1510UK ASSY BASE LID R......................................................................................... 131

8.18. ORT-INST-TW ASSY INSTALLATION KIT ORT TWIN............................................................ 132

8.19. ORT-0200UK ASSY BILLBOARD........................................................................................ 133

8.20. FRI-0300UK ASSY COINCHUTE TOWER FRI................................ ......................................134

8.21. ORT-0500UK ASSY WIRE COVER ORT TWIN .................................................................... 135

8.22. ORT-0400UK ASSY AC BRKT MAIN ...................................................................................136

8.23. ORT-0700UK ASSY AC BRKT SUB .................................................................................... 137

8.24. ORT-4560UK ASSY LAN COM2 ......................................................................................... 138

9.

APPENDIX A - ELECTRICAL SCHEMATIC ................................................................................. 139

9.1. Wire Colours .........................................................................................................................139

9.2. Electrical Schematic ............................................................................................................. 139

4

Page 5

1. BEFORE USING THIS PRODUCT

To ensure the safe usage, be sure to read the following before using the product. The following instructions are

intended for the use of QUALIFIED SERVICE PE RSONNEL ONLY.

If any activity is carried out on the product, this should be done only after carefully reading and sufficiently

understanding the instructions.

Only qualified service personnel should carry out maintenance on the product.

Depending on the potential risk, terms such as” WARNING!” “CAUTION” and “IMPORTANT!” are used where an

explanation is given that requires special attention. SEGA is not responsible for injury or damage caused by use in a

manner contrary to the instructions given in this document.

In order to prevent accidents warning stickers and printed instructions are applied in the places where a potentially

hazardous situation relating to the product could arise. Be sure to comply with these warnings.

Indicates that mishandling the product by disregarding this warning will cause a potentially

hazardous situation that can result in death or serious injury.

Indicates that mishandling the product by disregarding this caution will cause a potentially

hazardous situation that can result in personal injury and or material damage.

This is cautionary information that should be complied with when handling the product.

Indicates that mishandling the product by disregarding this will cause a potentially

hazardous situation that may not result in personal injury but could damage the product.

Be sure to turn off the power and disconnect from the mains supply before working on the machine.

Ensure that the correct fuses are fitted to the machine. Details of these are enclosed in the Service Manual.

Ensure that only qualified Service Engineers perform any maintenance work on the machi ne.

Specification changes, removal of equipment, conversion and/or additions not designated by SEGA are not permitted

and will invalidate this product’s CE conformity.

Warning labels or safety covers for personal protection etc, are component parts of the product. A potential hazard

will be created if the machine is operated while any parts have been removed. Do not operate the product if any

doors, lids or protective covers become damaged or lost. SEGA is not liable in any whatsoever for any injury and/or

damage caused by specification changes not designated by SEGA.

Before installing the product, check for the Electrical Specification Sticker, SEGA products have a sticker on which the

electrical specifications are detailed. Ensure that the product is compatible with the power supply voltage and

frequency requirements of the location in which the machine is to be installed.

Install and operate the machine only in places where appropriate lighting is available, allowing warning stickers to

be clearly read.

To ensure maximum safety for customers and operators, stickers and printed instructions describing potentially

hazardous situations are applied to potentially hazardous locations. Ensure that the product’s operating location has

sufficient lighting to allow any warnings to be read. If any sticker or printed warning is removed or defaced, do not

operate the machine until an identical item has replaced it.

Exercise great care when handling the monitor (applies only to product with monitor). Some of the monitor (TV) parts

are subject to high -tension voltage. Even after turning the power off some components are liable to high-tension

voltage. Only qualified service engineers should perform monitor repair and replacement.

In cases where commercially available monitors and printers are used, only the items relating to this product are

contained in this manual. Some commercially available equipment will have functions and reactions not referred to

in this manual. This manual should be read in conjunction with the spec ific manufacturer’s manual for such

equipment.

Descriptions contained herein may be subject to change without prior notification.

The contents described herein are fully prepared with due care. However, should any question arise or errors be

found please contact SEGA AMUSEMENTS EUROPE LTD.

Descriptions contained herein may be subject to change without prior notification.

5

Page 6

The contents described herein are fully prepared with due care. However, should any question arise or errors

be found please contact SEGA.

1.1. Inspections Immediately After Transporting The Product To The

Location

• Only QUALIFIED SERVICE PERSONNEL should carry out inspection.

Normally, at the time of shipment, SEGA products are in a state to allowing usage immediately after

transporting to the location. Nevertheless, an irregular situation may arise during transportation preventing this.

Before turning on the power, check the following points to ensure that the product has been transported

safely.

• Are then any dented parts or defects (cuts, et c.) on the external surfaces of the product?

• Are castors and leg adjusters present and undamaged?

• Do the power supply voltage and frequency requirements meet with the local supply?

• Are all wiring connectors correctly and securely connected? Unless connected in the correct direction,

connector connections cannot be made successfully. Do not insert connectors forcibly.

• Are all IC’s of each IC BD firmly inserted?

• Does the power cord have any cuts or dents?

• Do fuses meet the specified rating?

• Are such units such as monitors, control equipment, IC BD, etc. firmly secured?

• Are all earth wires connected?

• Are all accessories available?

• Can all doors and lids be opened with the accessory keys and/or tools?

6

Page 7

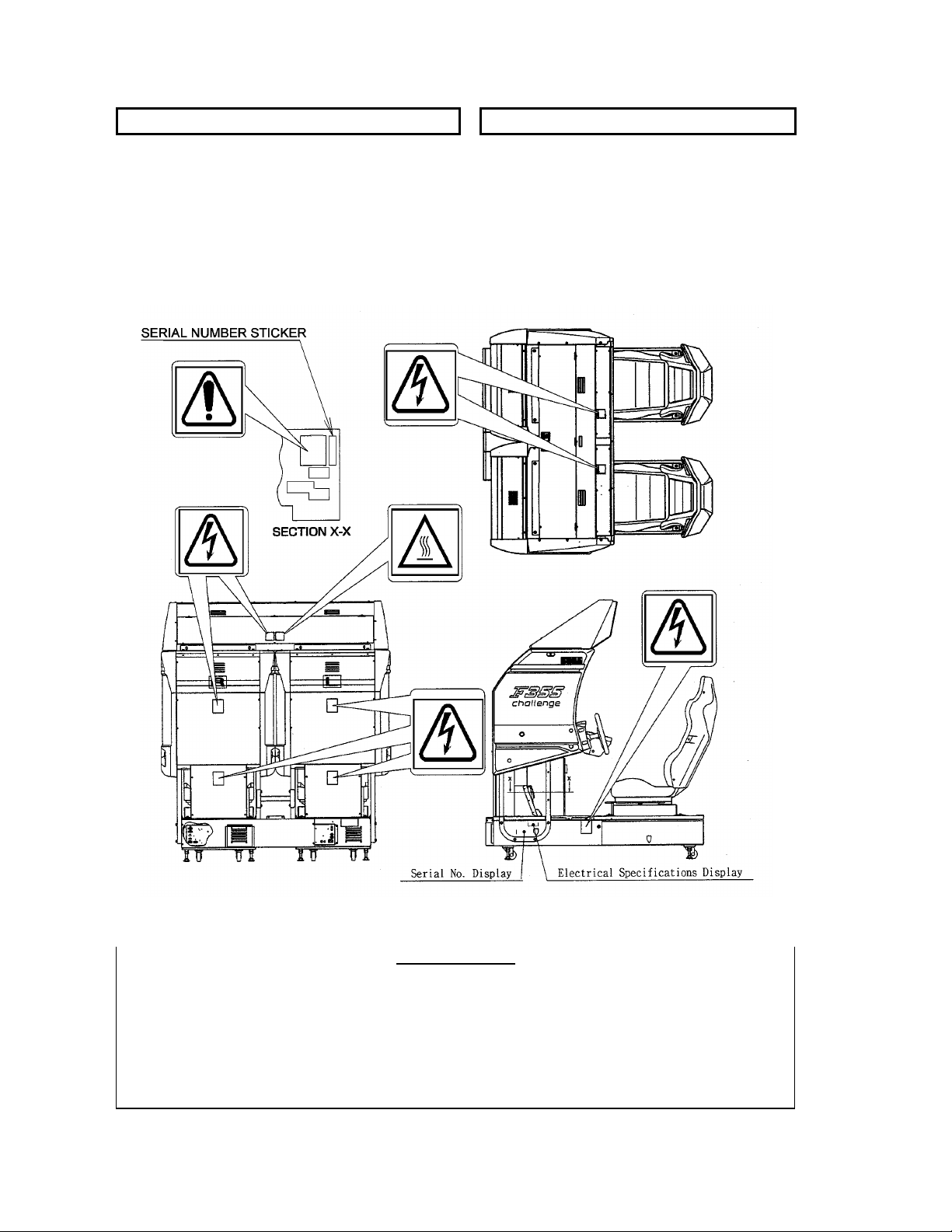

CONCERNING THE STICKER DISPLAY CONCERNING WARNING STICKERS

SEGA product has stickers describing the product

manufacture number (Serial Number) and electrical

specification. If you require service assistance you

will require the Serial Number. Identical machines

may have different parts fitted internally. Only by

quoting the Serial Number will the correct parts be

identified.

SEGA product has warning displays on

stickers, labels or printed instructions

adhered/attached to or incorporated in the

places where hazardous situations can arise.

The warning displays are intended for the

accident prevention of customers and service

personnel.

SPECIFICATIONS

Installation Space (cm): 164 x 170

Height (cm): 187

Weight (kg): 510

Power consumption (max): Rated Voltage (V.AC): 220-240 VAC

Rated Current (A): 3 Amps.

Note: Descriptions in this manual are subject to change without prior notice.

7

Page 8

2. INTRODUCTION TO THIS SERVICE MANUAL

SEGA ENTERPRISES LTD. supported by its experience in electronic high technology of VLSI’s,

microprocessors et c. and with a wealth of experience, has for more than 30 years been supplying various

innovative and popular games to the world market. This Service Manual is intended to provide detailed

descriptions together with all the necessary information covering the general operation of electronic

assemblies, electro-mechanicals, servicing controls, spare parts, etc. as regards this new SEGA product.

This manual is intended for those who have knowledge of electricity and technical expertise especially in IC’s,

CRT’s, microprocessors etc. Carefully read this manual to acquire sufficient knowledge before working on the

machine. Should there be any malfunction, non -technical personnel should under no circumstances touch the

internal systems. Should such a situation arise contact our head office.

SEGA AMUSEMENTS EUROPE LTD./ SEGA SERVICE CENTRE

Suite 3a

Oaks House

12 - 22 West Street

Epsom

Surrey

United Kingdom

KT18 7RG

8

Page 9

3. INSTALLATION AND SERVICE INSTRUCTIONS

• Only QUALIFIED SERVICE PERSONNEL should carry ou t installation and

commissioning.

3.1. Handling and Installation Precautions

When installing or inspecting the machine, be very careful of the following points and pay attention to ensure

that the player can enjoy the game safely.

The game must NOT be installed under the following conditions:

• Outside, the game is designed for indoor use only.

• In areas directly exposed to sunlight, high humidity, dust, excessive heat, or extreme cold.

• In locations that would present an obstacle in the case of an emergency i.e. near fire equipment or

emergency exits.

• On unstable surfaces or surfaces subject to vibration.

• Where liquids, other than routine cleaning, may come into contact with the game.

Important:

• Only Qualified Service Personnel should install this machine.

• Be sure to switch the supply power OFF and remove the mains supply plug from the machine before any

work is carried out on the machine.

• Do not attempt to repair the PCB’s (Printed Circuit Boards) yourself. This will void the warranty. The PCB’s

contain static sensitive devices that could be damaged.

• Always return a faulty part to your distributor with adequate packaging and protection.

• When removing the plug from the mains always grasp the plug not the cable.

• Do not use a fuse that does not meet the specified rating.

• Make sure all connections are secure before applying power.

9

Page 10

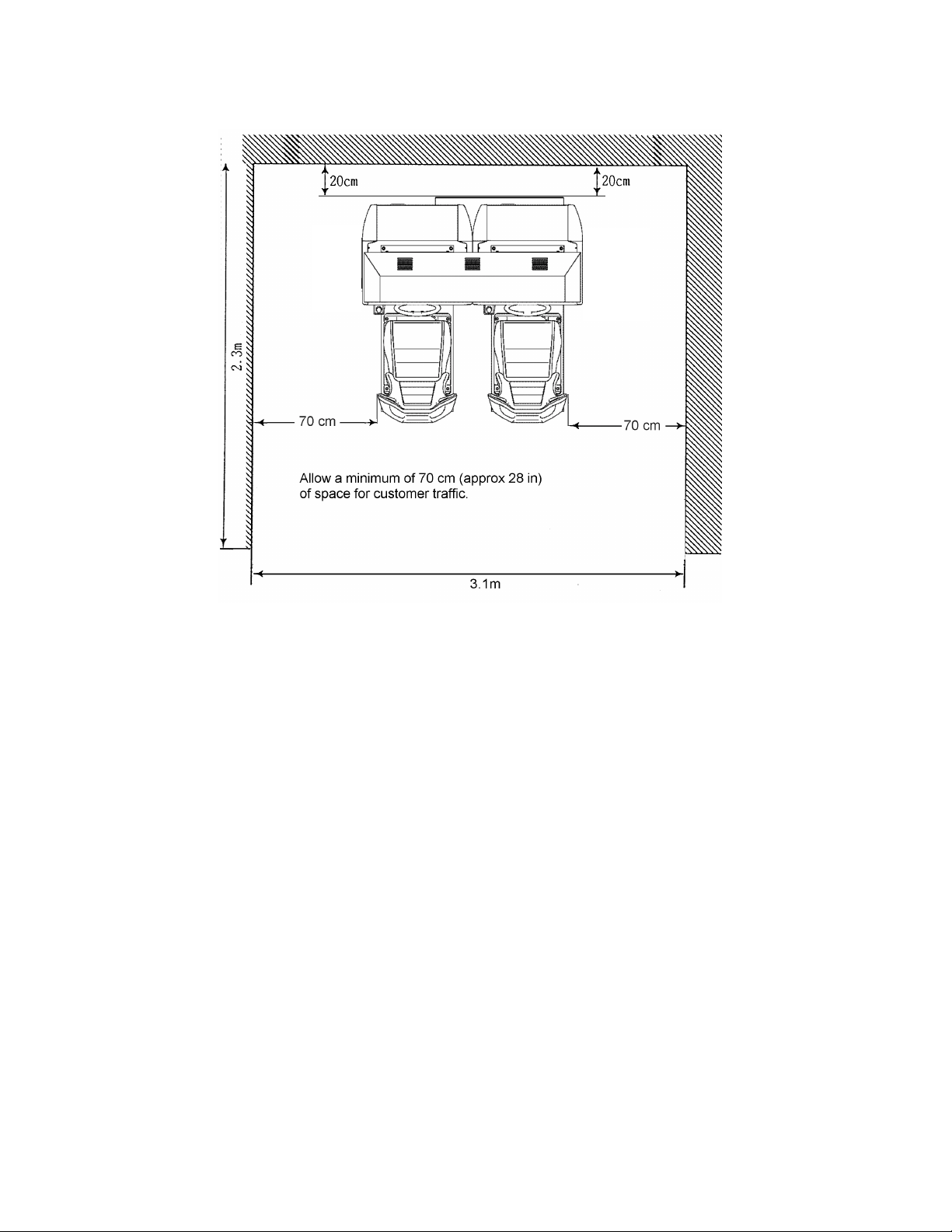

Installation Space

10

Page 11

Ensure that the power supply is fitted with circuit protection. Using the power supply

• Ensure that the mains lead is not damaged. If the mains lead is damaged in any

way there could be a danger of electric shock or a fire hazard.

•

without circuit protection is a fire hazard.

3.2. Coin Handli ng

Standard Sega machines are fitted with a SR3 coin mechanism, however, as a service to our customers Sega

machines can be supplied with no coin mechanism or door allowing the customer to fit a coin handling option

from the approved list. Fit only the coin handling arrangements detailed below and follow the instructions

provided in Section 3.7.6. Failure to fit the coin handling options detailed or failure to follow the installation

instructions will render the machine, under the CE marking directive, void.

Approved coin handling options:

• Coin controls SR3

• Generic mechanical

• Mars (MS111B1 and ME115)

• SECI RM4-G20

11

Page 12

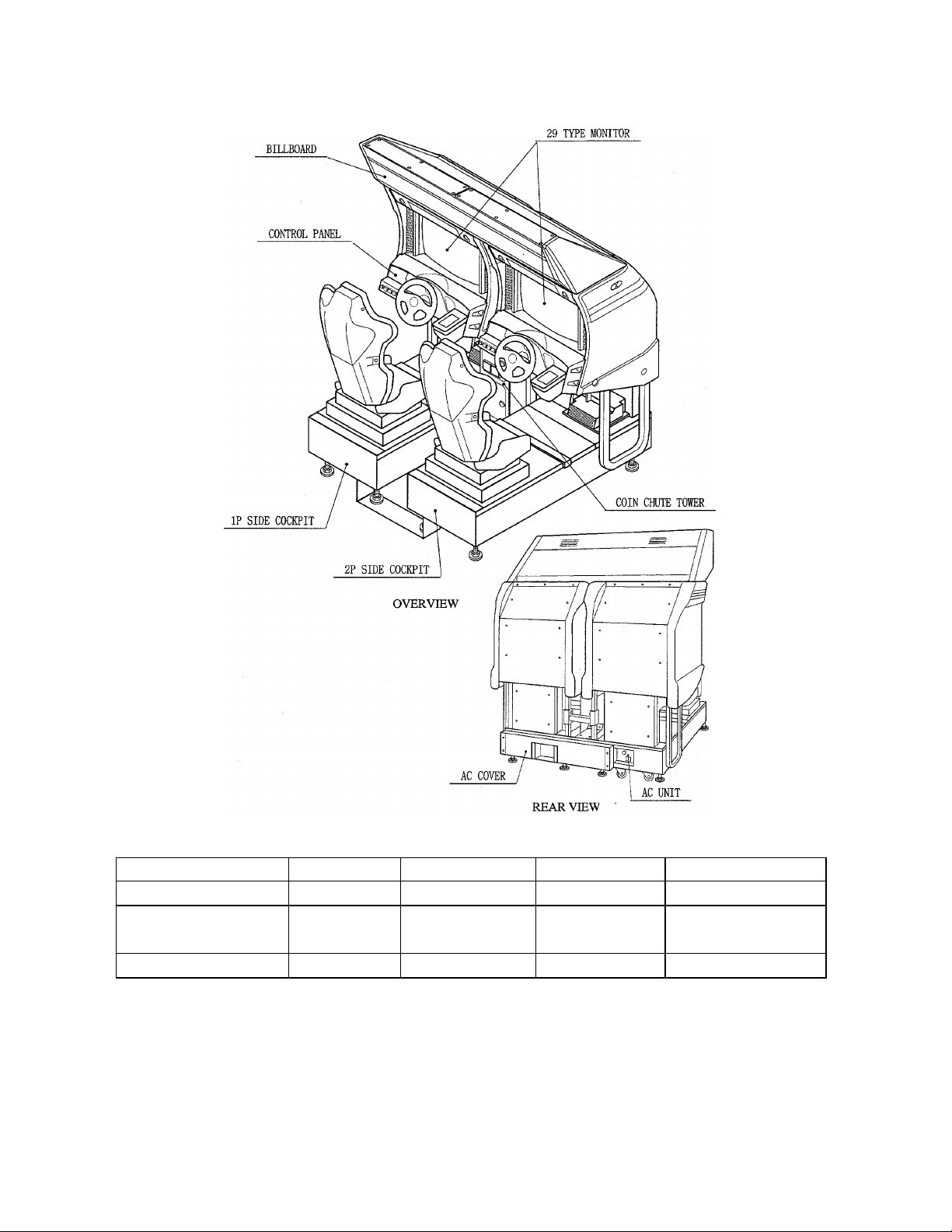

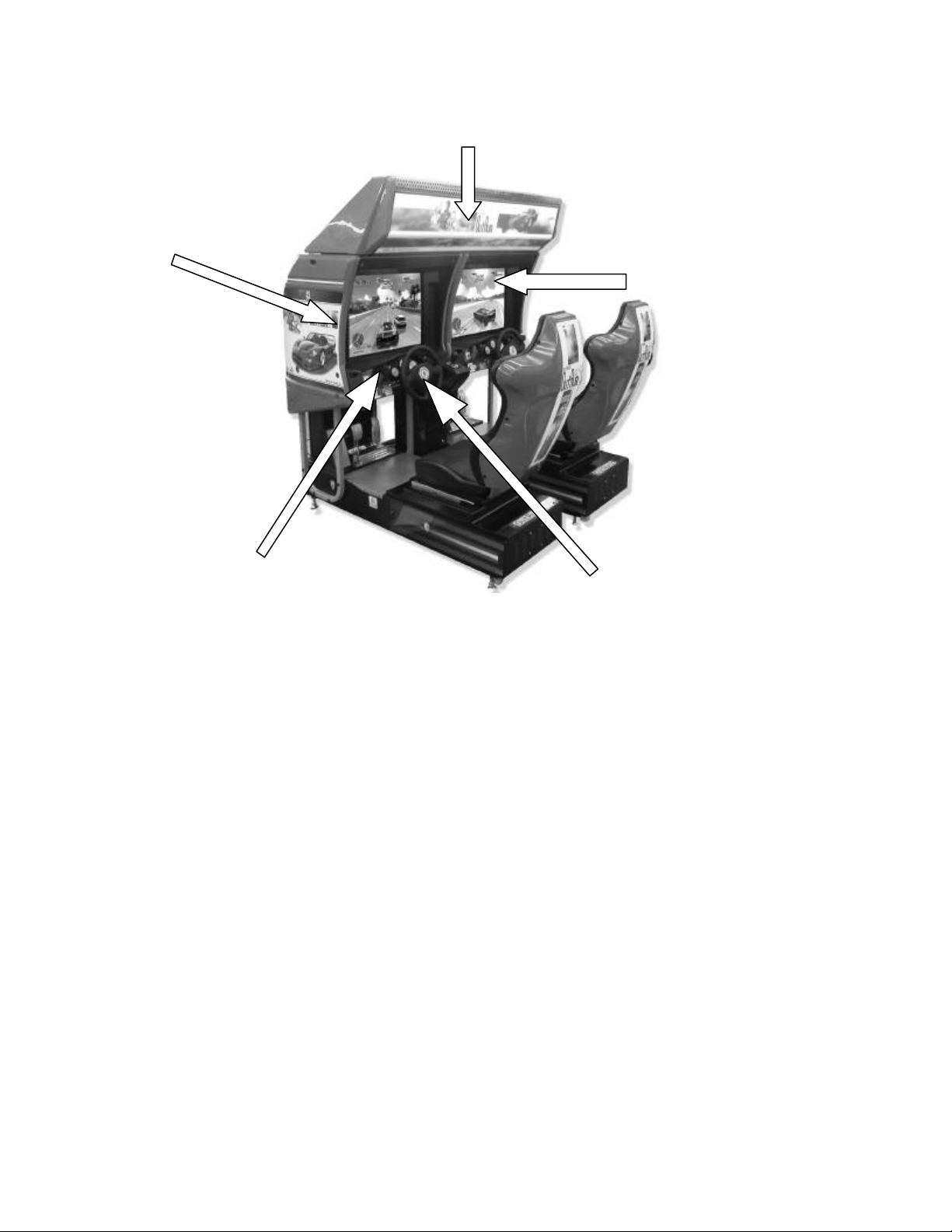

3.3. Name of Parts

Width (cm) Length (cm) Height (cm) Weight (kg)

COCKPIT 82 164.5 152 228

COIN CHUTE TOWER 30.5 51.5 570 15

BILLBOARD 160.9 61.7 35.4 36

When Assembled 163.2 170 186.4 507 approx

12

Page 13

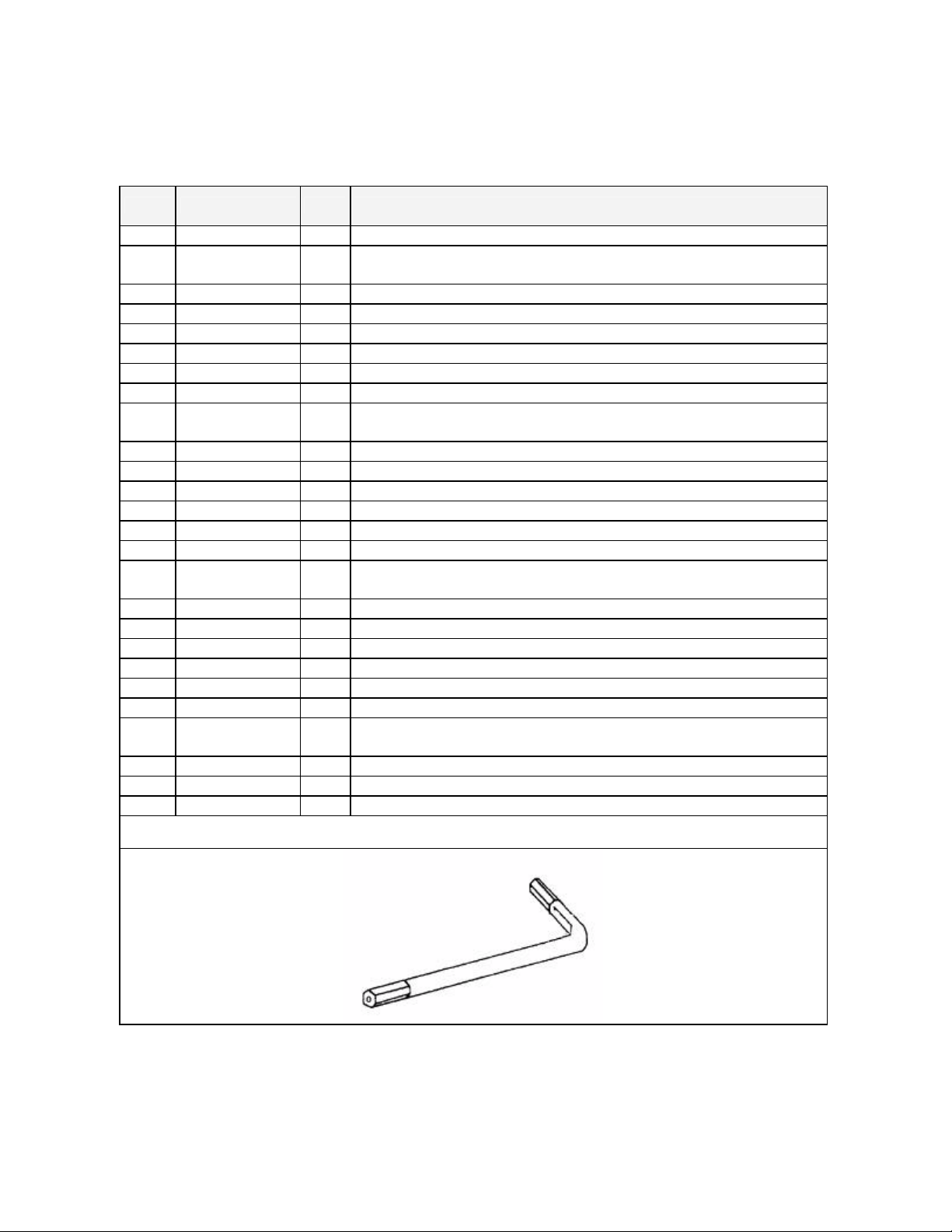

3.4. Accessories

The machine is supplied with an installation kit. Please ensure the follow ing parts are supplied:

ITEM PART NO. QTY DESCRIPTION

1 ORT-0200UK 1 ASSY BILLBOARD

2 FRI-0300UK 1 ASSY COINCHUTE TOWER FRI

3 ORT-0500UK 1 ASSY WIRE COVER ORT TWIN

4 DYN-0013 1 JOINT PIPE

5 DYN-0006XUK 1 AC COVER B

6 SRT-0018UK 1 AC COVER C

7 DYN-0019UK 1 AC COVER D

8 RAL-XXXX-14UK 1 TIE BRACKET RALLY

9 SPG-0008 2 BILLBOARD HOLDER

10 422-0922UK 1 PLAY INSTR SH ORT TWIN MULTI

11 422-0923UK 1 SUB INSTR SH ORT TWIN MULTI

13 PK0344 1 INST KIT BOX ORT TWIN

18 220-5753 1 VOL CONT B-5K OHM (TOCOS)

19 PK0343 0.5 PALLET INST KIT

101 440-CS0186UK 2 STICKER C EPILEPSY MULTI

201 030-000825-SB 20 M8X25 BLT W/S BLK

202 068-852216-0B 20 M8 WSHR 22OD FLT BLK

203 000-P00412-WB 15 M4X12 MSCR PAN W/FS BLK

204 050-F00400 3 M4 NUT FLG SER PAS

401 420-5827 1 SERVICE MANUAL SANWA 31K

402 420-6796-02UK 1 SERVICE MANUAL ORT TWIN

403 OS1019 2 SELF SEAL BAG 9X12.3/4

404 540-0006-01 1 WRENCH M4 TMP PRF

405 540-0007-01 1 WRENCH M5 TMP PRF

406 540-0009-01 1 WRENCH M8 TMP PRF

407 220-5484 1 VOL CONT B-5K OHM

408 SAECE-xxx 1 DECLARATION OF CONFORMITY

409 514-5078-5000 2 FUSE 5X20 CERAMIC SB 5000mA

411 420-6620UK 1 SERVICE MANUAL GD ROM SYSTEM

416 509-5704 1 SW MICRO TYPE (OMRON K3L13)

Item 404-406 - Tamper-proof TORX wrench.

13

Page 14

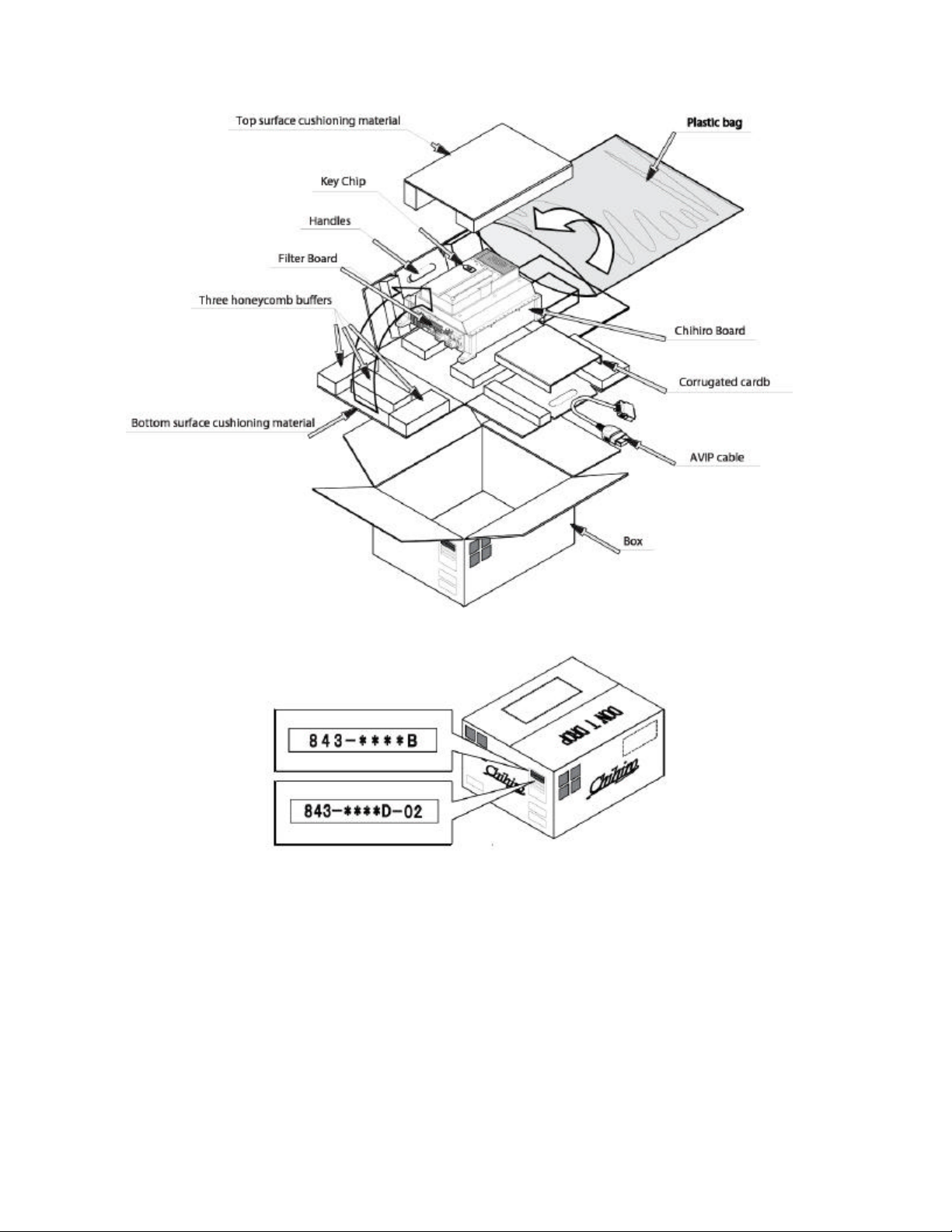

3.5. Shipping the Game Board

Replacement or repair of the Game Board (Chihiro) for this product should be undertaken at

the appropriate repair centre. Be sure to follow the specifications below when requesting

repairs/sending the board to the repair centre. Not following the specifications may result in

the board not being accepted or in extra charges being made.

• Put the game board in the carton box as is. Do not carry out any disassembly or part

removal other than that specified.

• Follow the procedure and instructions regarding direct ion below when placing the Game

Board in the carton box.

• When packing the game board with the Media Board attached, do not remove the Key

Chip.

• When packing the game board with the Media Board detached, be sure to include the

AVIP Cable.

• When packing, attach the accessory stickers in the specified places on the Game Board

and carton box.

INSTRUCTIONS

1. Wrap the Chihiro Board in a plastic bag.

2. Place it on top of the bottom surface cushioning material. Turn the Filter Board to face the side with

the three honeycomb buffers. Packing it in the opposite direction may cause damage to the Filter

Board.

3. Insert corrugated cardboard into the space between the lateral honeycomb buffers of the bottom

surface cushioning material and stow the AVIP cable inside.

4. Place the Chihiro Board wrapped in the bottom surface cushioning material into the carton box. Use

the handles on the bottom surface cushioning material.

5. Place the upper surface cushioning material on top of the Chihiro Board. Be sure to align it in the right

direction, as it will not fit otherwise.

6. Close the top of the carton box and seal it tightly with adhesive tape.

14

Page 15

15

Page 16

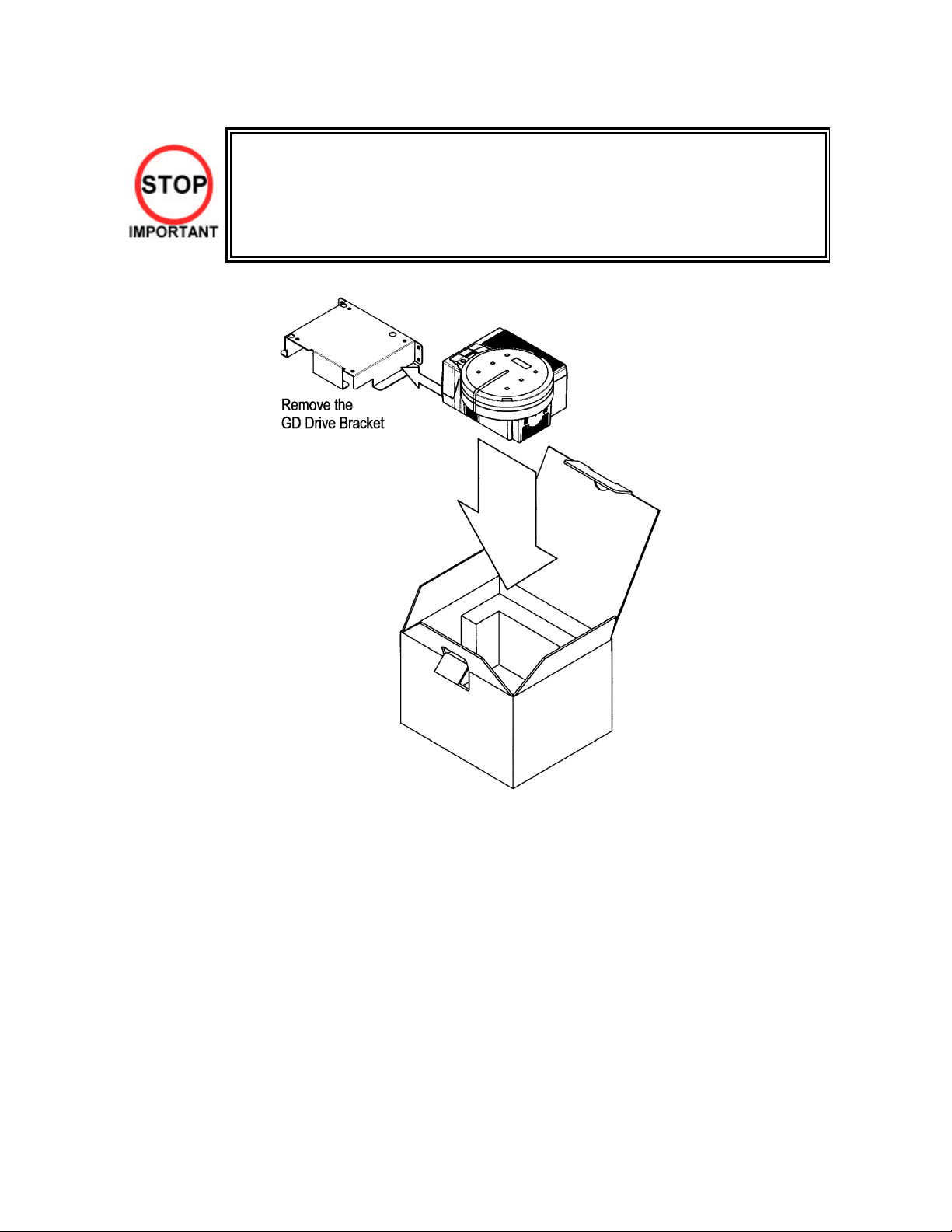

3.6. Shipping the GD-ROM Drive

• When returning the GD -ROM DRIVE for repair or replacement, be sure to package it in

the original card transit box - THERE ARE NO USER-SERVICEABLE PARTS INSIDE.

• Ensure the GD -ROM Disk is removed and the GD -ROM Drive Lid is replaced on the unit,

with fixing screw, before packaging. Also, remove the GD-ROM Drive Bracket and store

with the four screws for reuse.

• Failure to return the GD -ROM DRIVE in this manner may invalidate the warranty.

16

Page 17

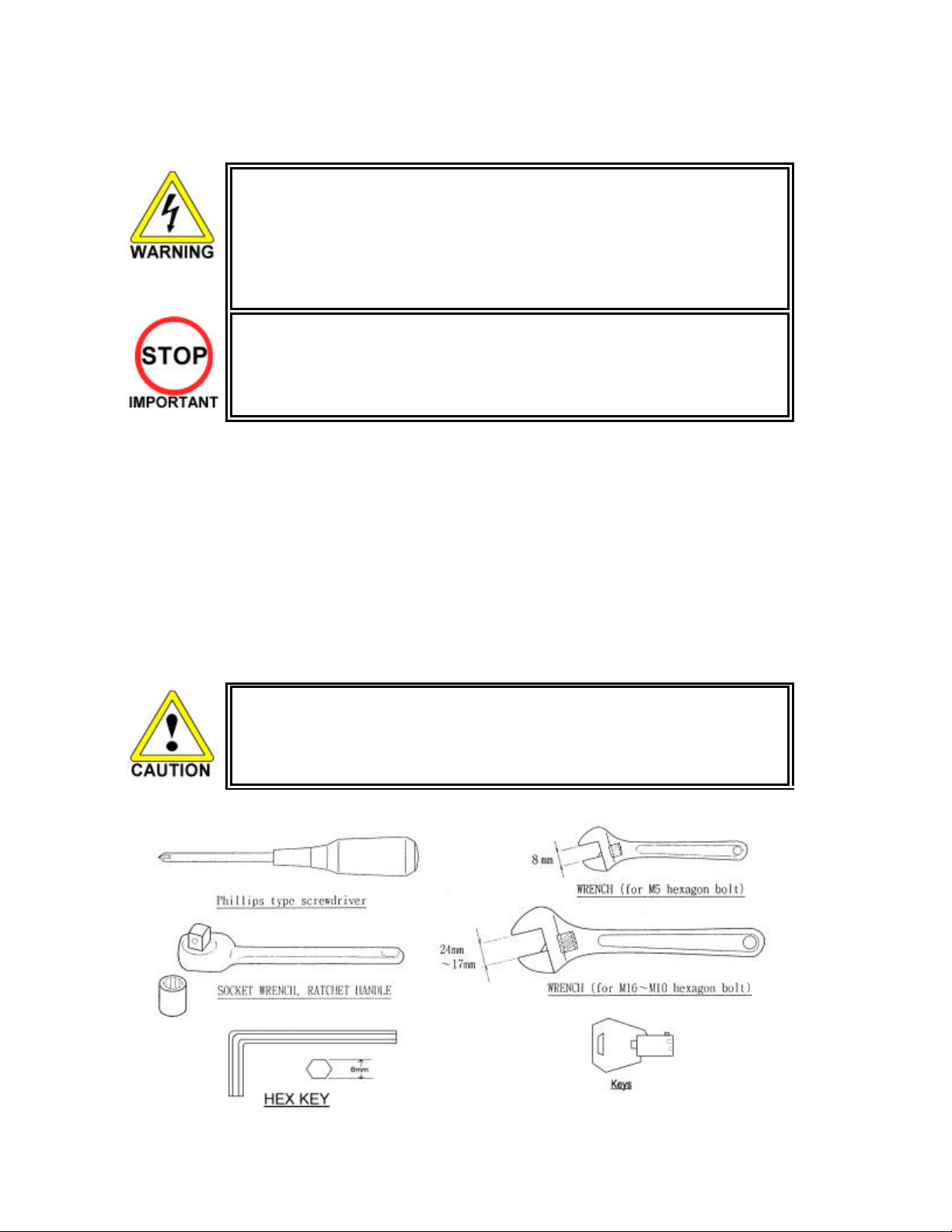

3.7. Assembly Instructions

• Perform the assembly by following the procedure herein stated. Failure to comply

with the instructions, for example, inserting the plug into an outlet at a stage not

mentioned in this manual can cause an electric shock

• Assembling should be performed as per this manual. Since this is a complex

machine, erroneous assembling can cause damage to the machine, or malfunction

to occur.

• Do not attempt to complete this work alone, a minimum of 2 people are required.

• Only QUALIFIED SERVICE PERSONNEL should carry out assembly.

When carrying out the assembly work, follow the procedure in the following 7 item sequence

STEP 1 ASSEMBLING THE COCKPIT

STEP 2 SECURING IN PLACE (LEG ADJUSTER ADJUSTMENT)

STEP 3 BILLBOARD INSTALLATION

STEP 4 INSTALLING THE AC COVERS (WIRE COVERS)

STEP 5 COIN HANDLING INSTALLATION

STEP 6 CONNECTION TO POWER SUPPLY

STEP 7 ASSEMBLY CHECK

Note that the parts contained within the installation kit are required for the assembly work.

• Fit all fixings loosely first as detailed in step 1, then position all components before

finally tightening fixings at step 6.

17

Page 18

3.7.1. Applying the Play Instructions

• Only QUALIFIED SERVICE PERSONNEL should carry out this operation.

Supplied in the installation kit are 4 sets of play instructions in 5 languages. Select the language of your

choice and apply in the following areas:

1. 422-0922UK: Instructions (on Monitor Mask)

2. 422-0923UK: Instructions (on Control Panel)

18

Page 19

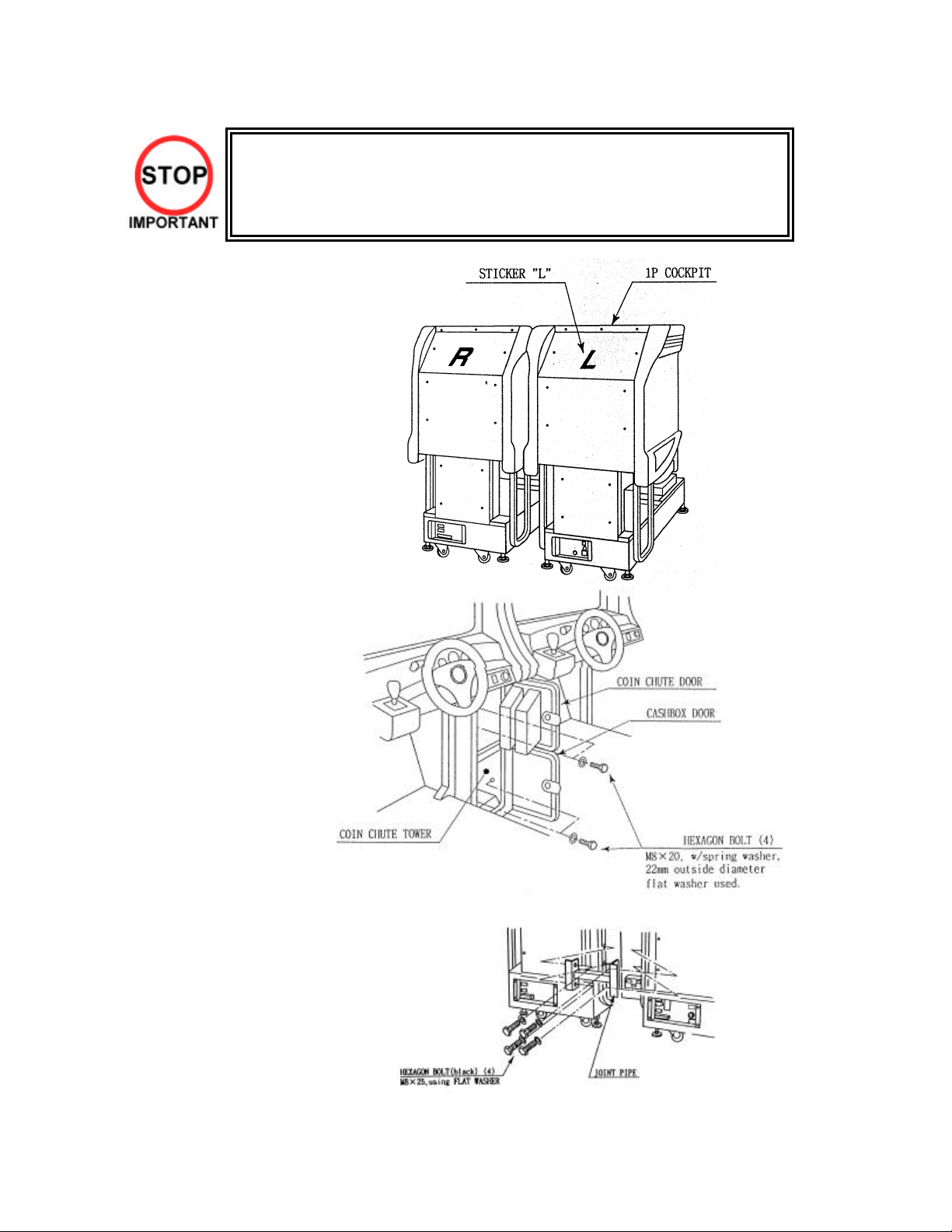

3.7.2. Assembling the Cockpit

• Only QUALIFIED SERVICE PERSONNEL should carry out this operation.

1. Place the two cockpits

side by side. Position the

1P cabinet, which has the

IEC inlet at the left hand

side when viewed facing

the monitor. STICKER L is

attached to the back of the

1P cabinet and STICKER

R on the back of the 2P

cabinet

2. Install the coin chute tower

in between both cabinets.

Open the coin chute door

and the cash door and

secure with the 4 hexagon

bolts from inside the

doors. At this time, make

sure the bolts are only

loosely fitted.

Note: Door may open in opposite way to that shown above

3. Install the joint pipe on the

rear-side of both cabinets

by securing with 4

hexagon bolts, at this time

loosely.

19

Page 20

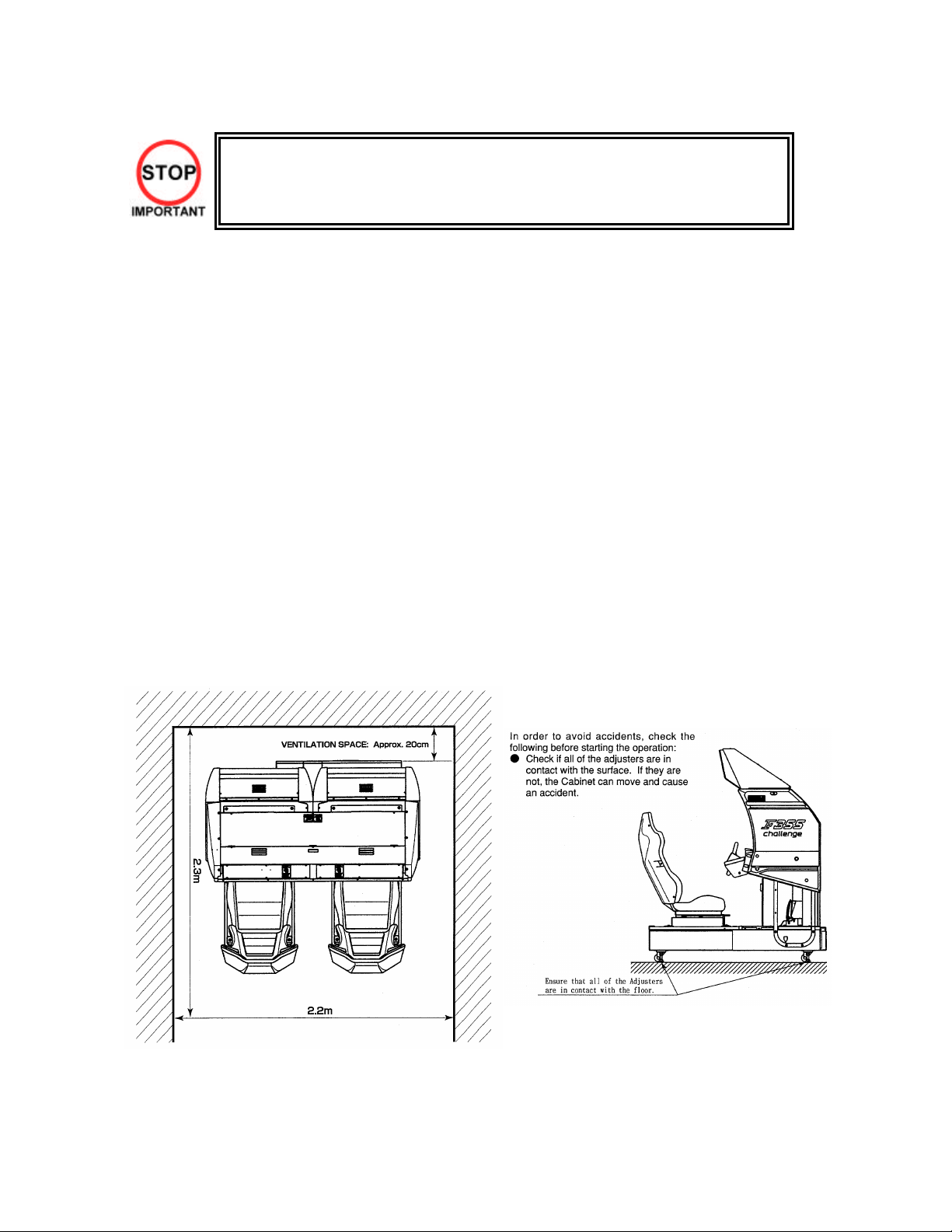

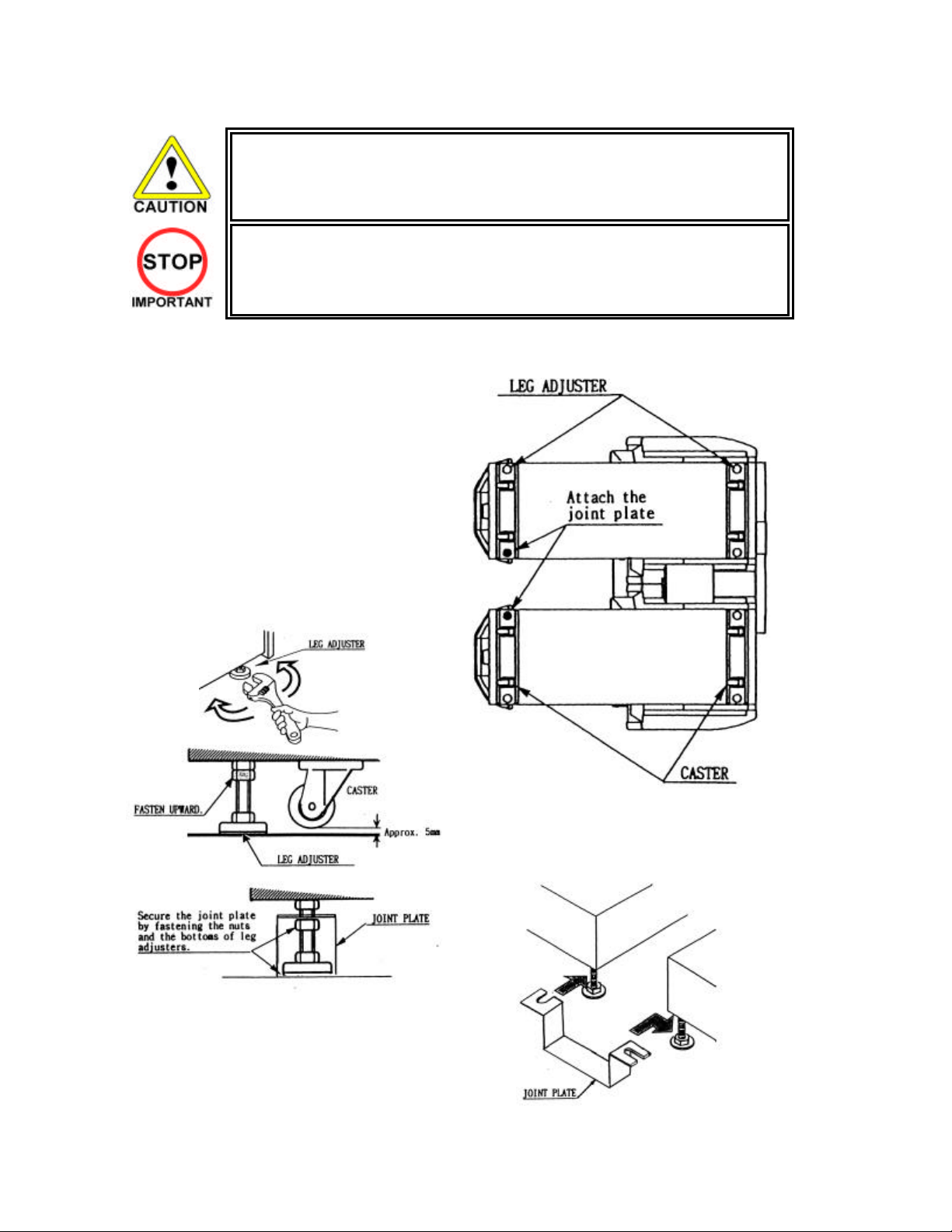

3.7.3. Securing In Place (Leg Adjuster Adjustment)

• Make sure all of the leg adjusters are in contact with the floor. If they are not the

machines may move and cause injury. This operation requires 2 people.

• Only QUALIFIED SERVICE PERSONNEL should carry out this operation.

This machine has eight castors and eight leg adjusters. When the installation position is decided, unscrew

the leg adjusters so that they raise each caster a minimum of 5mm from the floor. Make sure the machine is

level.

1. Move the machine to the installation position.

When installing against or close to a wall, be

sure to allow an adequate space to allow the

player access to the machine.

2. Make the leg adjusters contact the floor.

Adjust using a spanner as shown below so

that a minimum of 5mm e xists between the

casters and the floor. Make additional

adjustment so that the machine is level.

3. Slide the joint plate onto the shafts of the

indicated leg adjusters. Tighten the lock nut on

all eight leg adjusters. This will secure the joint

plate.

After securing the leg adjuster bolts, fully tighten all bolts temporarily attached in STEP 1 above.

20

Page 21

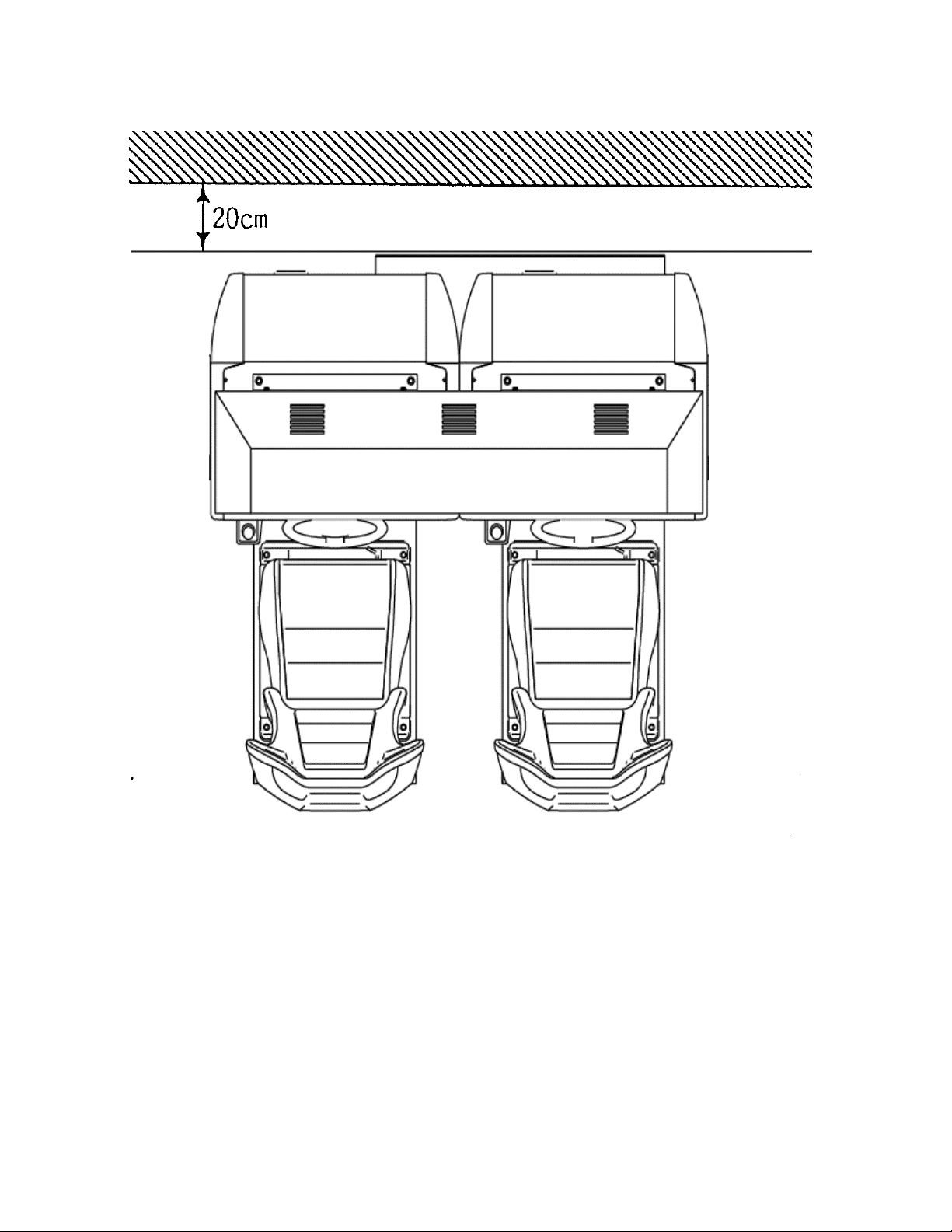

Ensure adequate ventilation is maintained as detailed below

21

Page 22

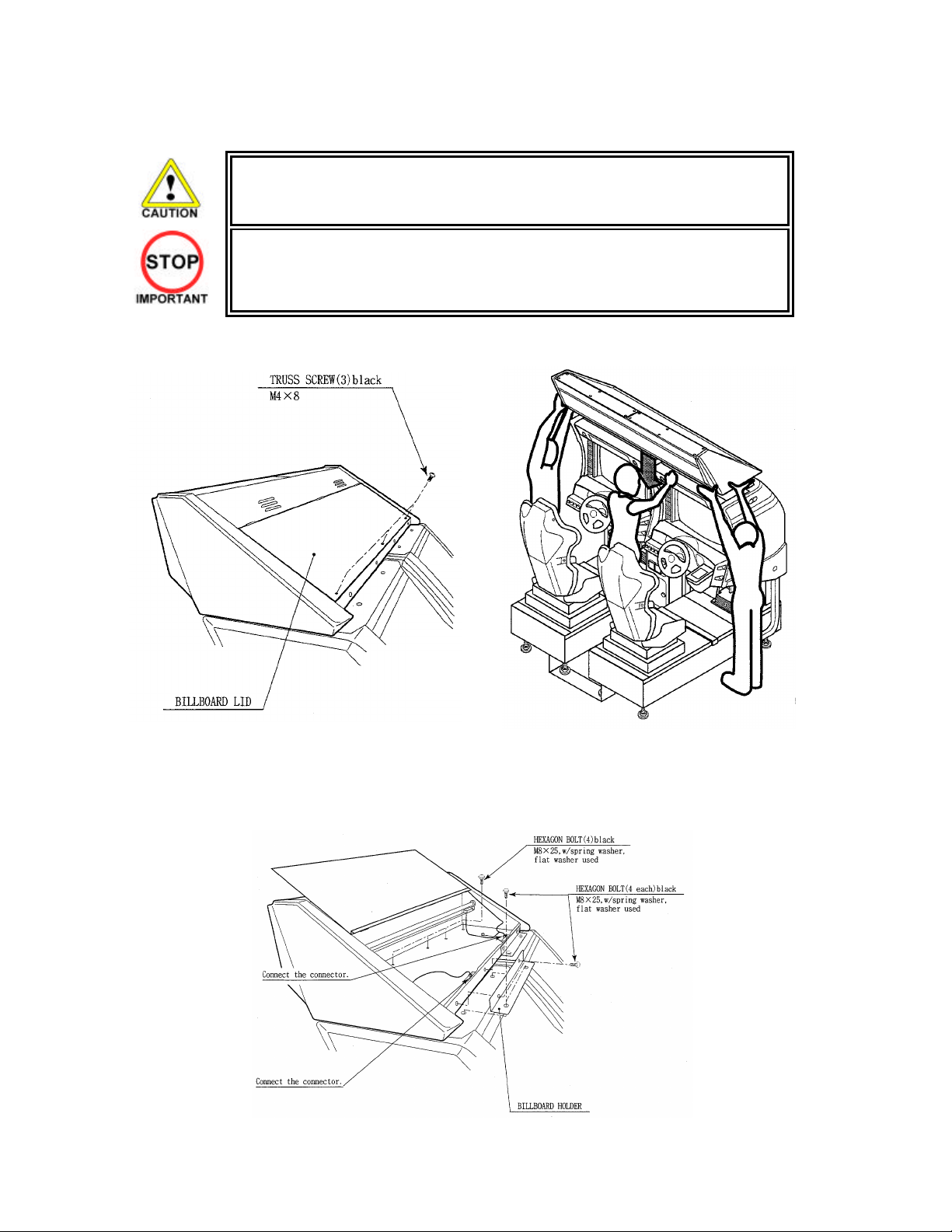

3.7.4. Billboard Installation

• One person alone cannot perform the installation of the billboard assembly. Seek

assistance before attempting this operation

• Only QUALIFIED SERVICE PERSONNEL should carry out this operation.

1. Install the billboard base over the two cockpits.

2. Mount the billboard by fitting it onto the billboard base.

3. Install the billboard holders using 2 hexagon bolts each to secure them to the cabinets.

4. Connect the wire connectors from the billboard box to the connectors on the cabinets and install the

connector covers using two screws for each.

22

Page 23

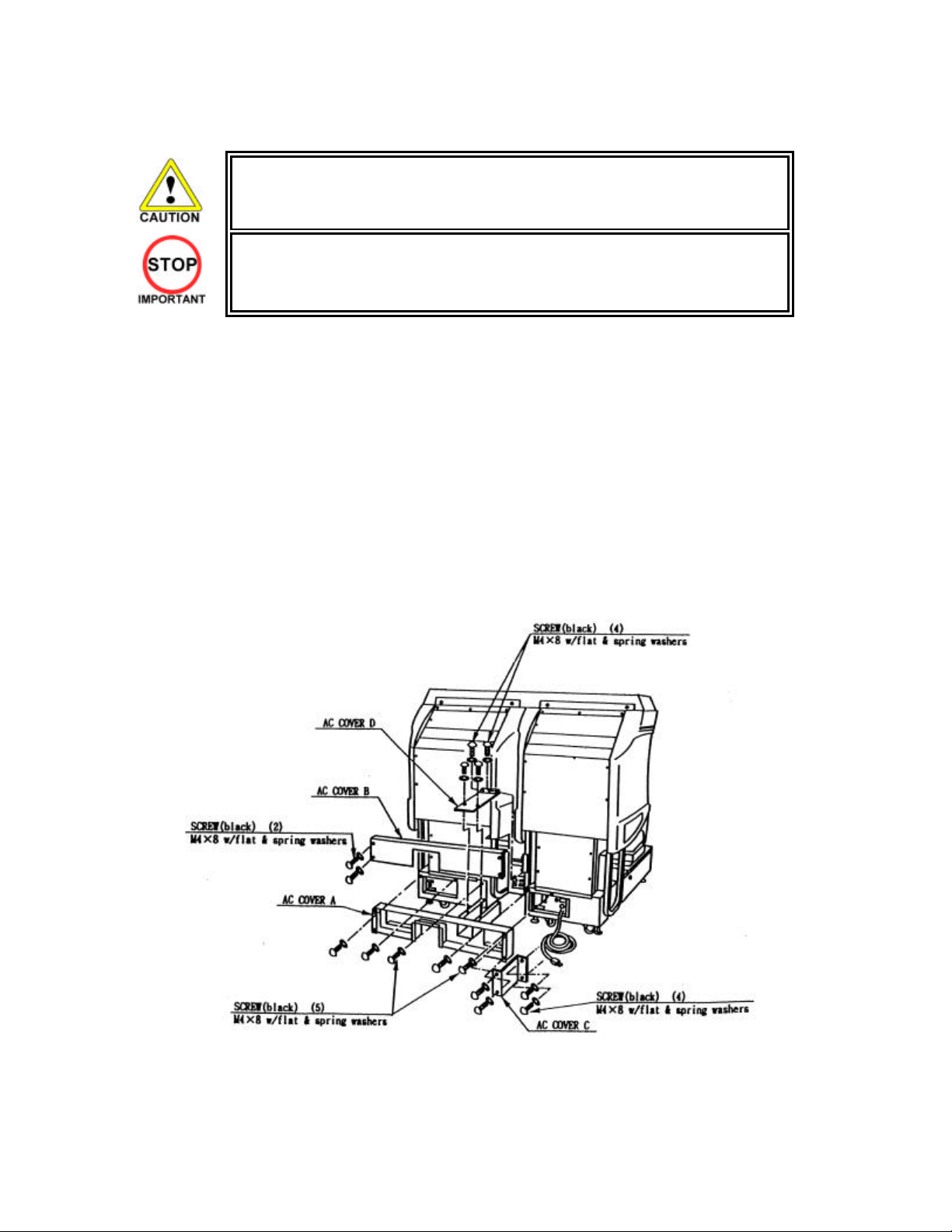

3.7.5. Installing The AC Covers (Wire Covers )

• Be sure that the machine is not connected to the mains supply before attempting

this operation.

• Only QUALIFIED SERVICE PE RSONNEL should carry out this operation.

The AC Wire Covers are used for protecting the interconnecting wiring and the fibre optic cables. When

carrying out this operation be very careful so as not to trap any wire between the covers. Pay attention when

handling the fibre optic cables as excessive bending may cause damage.

1. Attach AC Cover A to the rear of the cabinet using 5 screws.

2. Make all the wiring connections between the two cockpits and the Coin Chute Tower. The wiring

connectors are colour coded and cannot be fitted into the wrong size connectors. Do not force any

connectors together.

3. Connect the earth wires between the two AC Brkts, the AC Covers and the Coin Chute Tower.

4. Insert the fibre optic cables into the fibre optic connectors. Ensure that the “RX” connection on the 1P

cockpit is connected to the “TX” connector on the 2P cockpit. The other fibre optic connects the “TX”

connector of the 1P cockpit to the “RX” connector of the 2P cockpit.

5. Insert AC Cover B into AC Cover A from above and secure using 2 screws. Be sure not to trap any

cables.

6. Secure AC Cover C and AC Cover D using 4 screws each.

23

Page 24

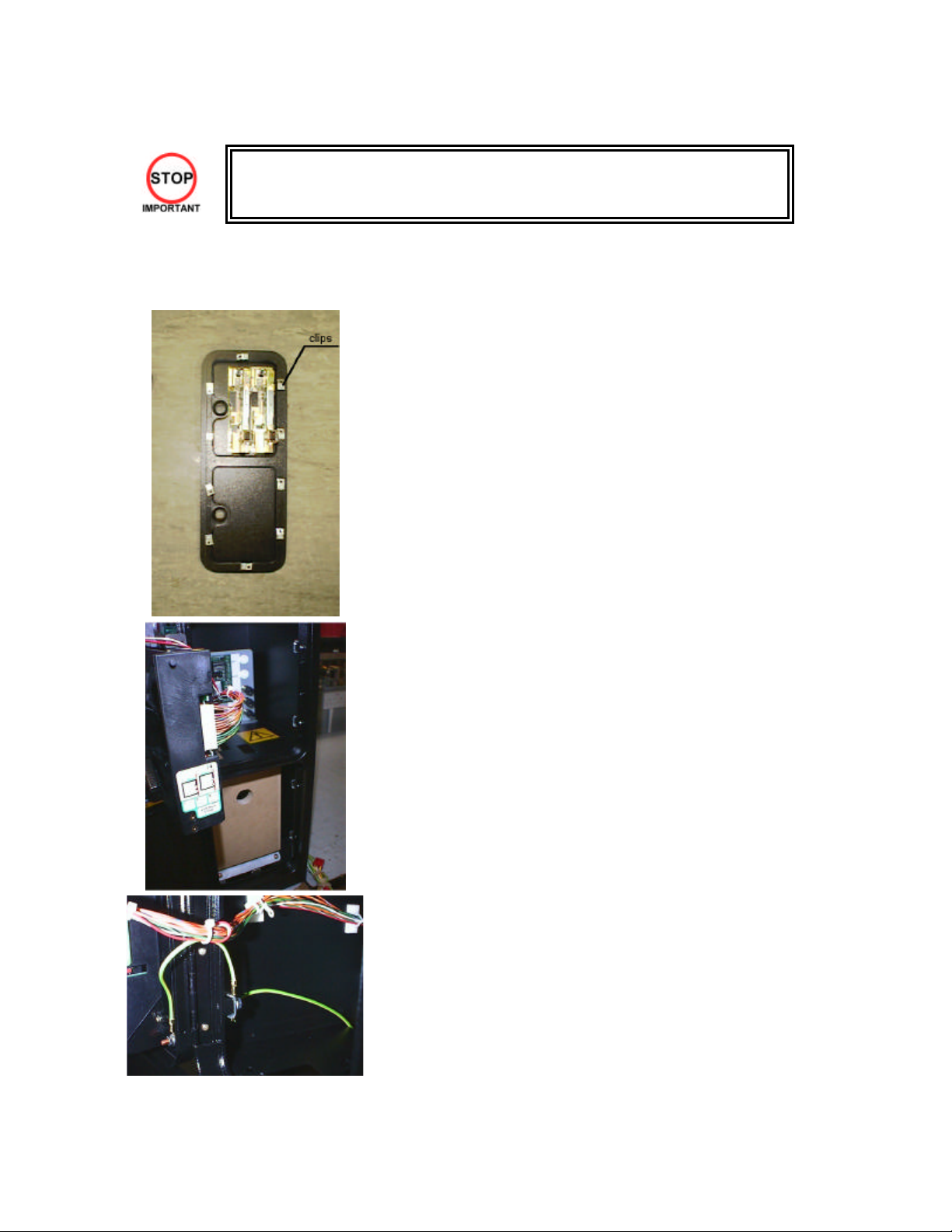

3.7.6. Coin Handling Installation

• Only QUALIFIED SERVICE PERSONNEL should carry out this operation.

When fitting the coin mechanism to the door please refer to the specific manufacturers installation instructions

for that coin mechanism. To fit the door to the machine, follow the procedure below.

• Loosen all of the bolts on the frame, which secure the clips.

• Turn all clips in towards the door.

• Position the door into the aperture in the machine.

• Turn the clips around so that they will hold the door in the

machine.

• Tighten all of the bolts.

• Ensure that the door is earthed to the frame and the frame is

earthed to either the VTS bracket or the coin chute tower.

24

Page 25

3.7.6.1.Wiring Connections.

COIN MECH LOOM INSTALLATION

C220B LM1006IDC

LM1006LAMP-0.1

GENERIC

MECHANICALS

MARS MS111B1

MARS ME115

SECI, C120,

SR3

LM1008

LM1008-LAMP

LM1007

LM1008-LAMP

OWN LOOM AND

LM1006LAMP-0.1

• Attach the lamp holder to the bracket on the coin return

button.

• Attach one 15 -way connector to the C220 coin mech.

• Attach the other 15 -way connector to Validator A on the

credit board.

• Attach the 2-way connector to ‘LAMP’ on the VTS board.

• Fit the two lamp holders behind the coin return buttons.

• Attach the blue cable and orange cable to one mech’s

microswitch switc h.

• Attach the blue/green cable and orange/green cable to

the other mech’s microswitch.

• Attach the 2-way mate and lok plug to the 2-way mate

and lok cap provided.

• Attach one 15 -way connector to Validator A and the other

to Validator B on the credit board

• Fit the lamp holder to the bracket behind the coin return

button.

• Fit one of the 13 -way connectors to the coin mech.

• Fit the other 13-way connector to Validator A on the

credit board. Note the 13 -way connector is keyed and

this key must coincide with the key on the credit board.

• Attach the lamp holder to the bracket on the coin return

button.

• Attach the 2- connector to ‘LAMP’ on the VTS board.

• Attach the validator’s own l oom to position A on the credit

board

VTS credit board assembly

25

Page 26

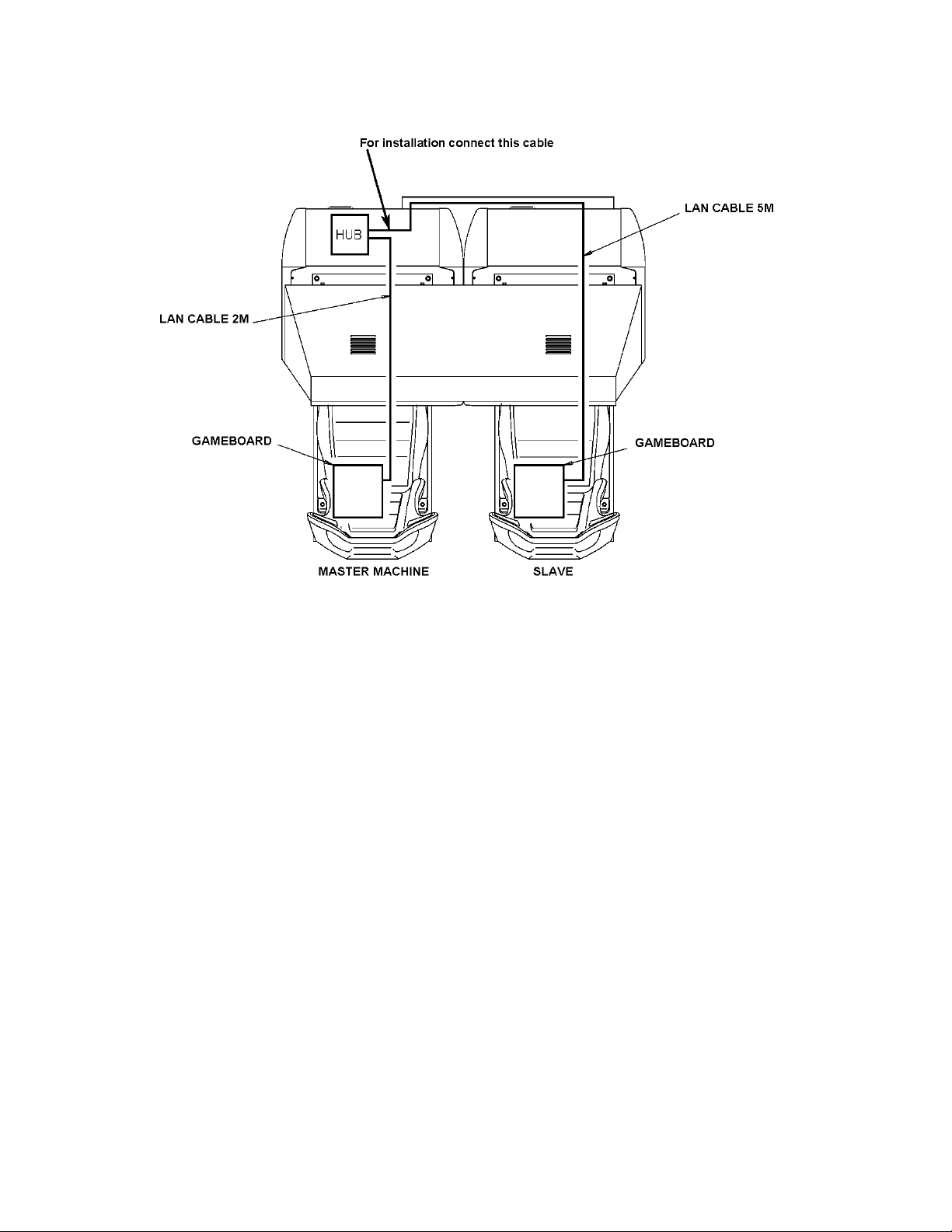

3.7.7. Communication Cables

The master (left) machine’s LAN cable will come pre -connected to hub.

Connect the slave machine’s LAN cable (bundled up at the back in a loop) across via the AC cover to the hub

of the master machine and connect to one of the hub’s ports.

For machine set -up refer to section 3.15.8.1.

26

Page 27

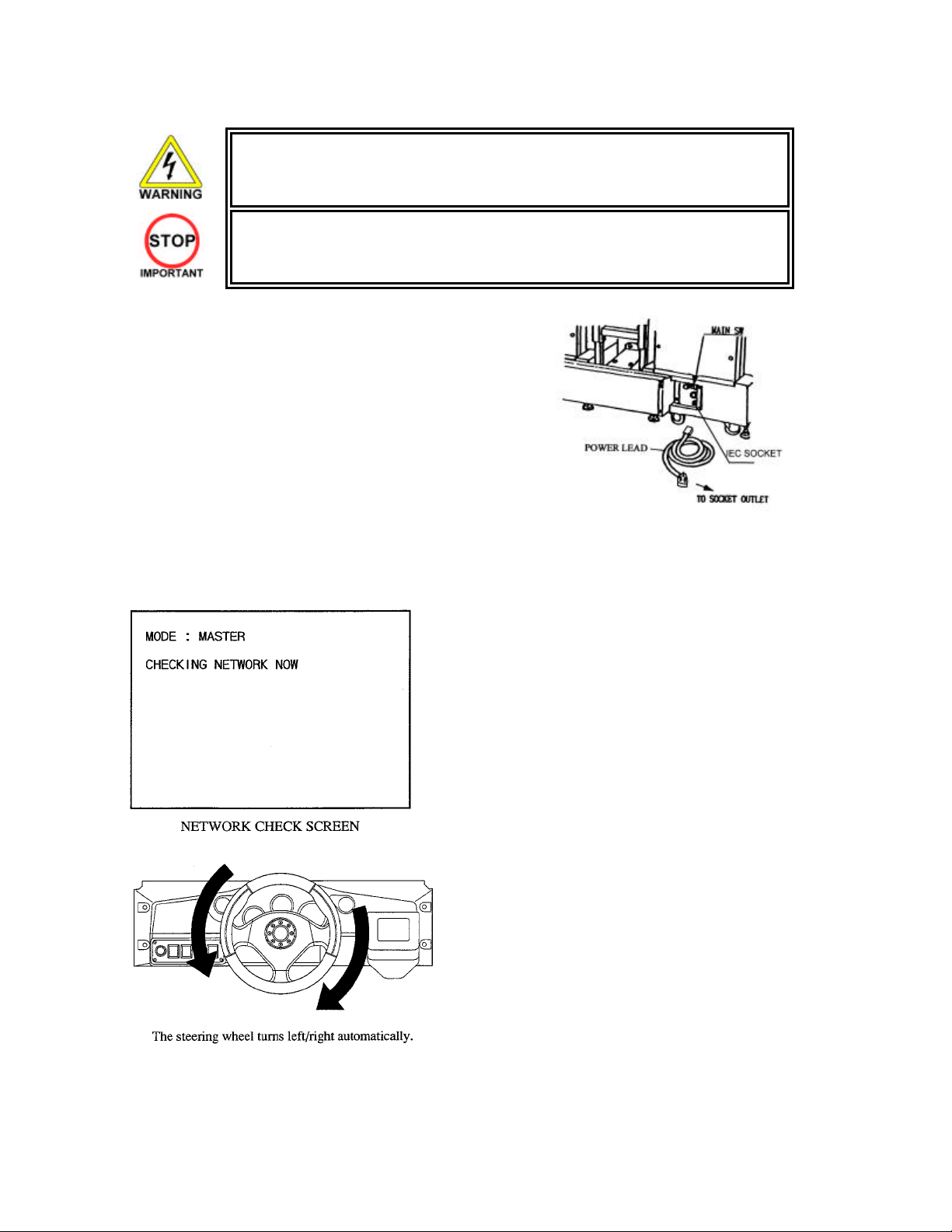

3.7.8. Connection To The Power Supply

• This operation may only be carried out once the machine has been completely

assembled.

• Only QUALIFIED SERVICE PERSONNEL should carry out this operation.

The AC Unit is located on the rear of the 1P cockpit. Using the

power lead supplied connect this to the mains socket at the wall.

1. Turn the mains switch on.

2. Turn the switch on the AC bracket on

3. The machine will start up and go through an initialisation

procedure where the steering wheel turns left and right.

4. DO NOT TOUCH THE MACHINE DURING INITIALISATION. If

the wheel is touched during this time, it could upset the motor

settings and affect the feedback performance during

gameplay.

5. The gameboard will now be checked for approximately one

minute.

6. The network check then starts. After this the attract mode will

appear. If after 30 seconds or so, the network check has not

finished, check the IR communication connections.

27

Page 28

Sound is

emitted

Fluorescent lamps are always lit

On screen

images are

output

Control Panel

Steering wheels turn both

directions

28

Page 29

3.7.9. Assembly Check

In the Test Mode, ascertain that the assembly has been made correctly and IC BD is satisfactory (see

section 5.2.1).

In the test mode perform the following test:

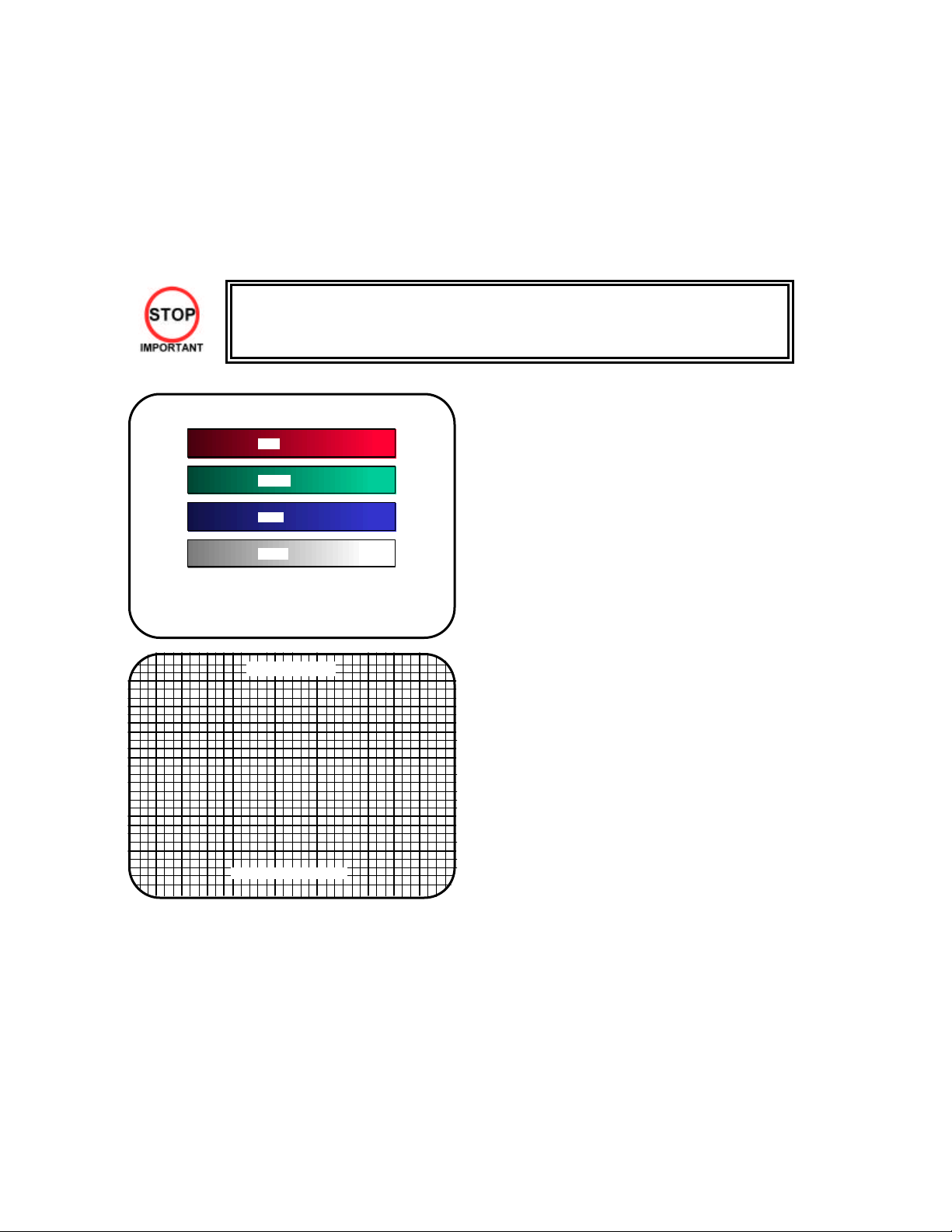

3.7.9.1.CRT Test

• Only QUALIFIED SERVICE PERSONNEL should carry out this operation.

C.R.T. TEST 1/2

C.R.T TEST

PAGE 1/2

RED

GREEN

BLUE

WHITE

In the TEST mode select CRT test to check the

screen is satisfactory.

Although the projector has been set up at the factory

before shipment, check to see if the screen needs

adjustment.

PRESS TEST BUTTON TO CONTINUE

C.R.T. TEST 2/2

PRESS TEST BUTTON TO EXIT

29

Page 30

3.7.9.2.Memory Test

Selecting RAM TEST or MEDIA BOARD TEST from

the menu screen in System Test mode will cause the

machine to automatically perform a test of memory

on the game boards. If GOOD is displayed next to

the number of each memory segment, the game

boards are working properl y.

Select SYSTEM INFORMATION to display

information on the main game board and the media

board. If the information is displayed correctly, this

indicates that the game boards are functioning

properly.

MEDIA BOARD TEST 1/2

DIMM BOARD(TYPE 3)

VERSION ****

STATUS GOOD

CHECKING 100%

DIMM TEST

DIMM0 - GOOD

DIMM1 - NONE

GD- ROM - GOOD

PRESS TEST BUTTON TO EXIT

SYSTEM INFORMATION

MAIN BOARD

REGION ****

BOOT VERSION ****

FIRM VERSION ****

FPGA VERSION ****

SERIAL NO. ***************

MEDIA BOARD

DIMM BOARD(TYPE 3) + GDROM

MEMORY SIZE 512MB

FIRM VERSION ****

SERIAL NO. ***************

NETWORK BOARD

FIRM VERSION *****

PRESS TEST BUTTON TO EXIT

RAM TEST

AUX MEMORY GOOD

TEST BUTTON TO EXIT

MEDIA BOARD TEST 2/2

NETWORK BOARD TEST

RAM CHECK _ GOOD

-- COMPLETED --

PRESS TEST BUTTON TO EXIT

NETWORK BOARD

VERSION ****

STATUS GOOD

CHECKING 100%

30

Page 31

3.7.9.3.Input Test

Select INPUT TEST from the menu screen in either System Test mode or Game Test mode.

JVS TEST

INPUT TEST

NODE 1/1

SYSTEM 00

PLAYER 1 1 0000

PLAYER 2 2 0000

COIN 1 1 0000

COIN 2 2 0000

ANALOG 1 0000

ANALOG 2 0000

ANALOG 3 0000

ANALOG 4 0000

ANALOG 5 0000

ANALOG 6 0000

ANALOG 7 0000

ANALOG 8 0000

Test the STEERING, GAS (ACCEL) and BRAKE controls to ensure that they are functioning properly and that

the parameters change smoothly as each input device is operated.

Display N, UP and DOWN using the GEAR POSITION. N displays that there is no control input. Verify that

both UP and DOWN display in sync with the position of the shift knob.

Press the START, CHANGE VIEW, SERVICE and TEST Buttons. If functioning correctly, each indicator will

switch from OFF to ON.

Press the SERVICE and TEST B uttons simultaneously to return to the Game Test Menu screen.

31

Page 32

3.7.9.4.Output Test

Select OUTPUT TEST to display the following screen and check the status of each lamp.

This test should be used periodically to check that the lamps are functioning correctly.

On this screen the cursor will switch automatically between items, lighting up the respective lamps.

• START BUTTON : Lights up the START button.

• VIEW CHANGE BUTTON: Lights up the View Change button.

Press the TEST Button to return to the Game Test Menu screen.

3.7.9.5.Sound Test

OUTPUT TYPE STEREO

RIGHT SPEAKER OFF

LEFT SPEAKER OFF

à EXIT

SELECT WITH SERVICE BUTTON

SOUND TEST

In the system test mode, selecting SOUND TEST

causes the screen (on which sound related BD and

wiring connections are tested) to be displayed.

Check if the sound is satisfactorily emitted from each

speaker and the sound volume is appropriate.

32

Page 33

Page 34

3.8. Fuses

• Never touch places other than those specified. Touching places other than those

specified can cause electric shock and short circuit. Disconnect the machine from

the supply before attempting the replacement of any fuse.

• Only QUALIFIED SERVICE PERSONNEL should replace FUSES.

There are a number of fuses used on this machine to protect the user and the machine from damage. Only

replace the fuse once you have remove the cause of its failure. Detailed below is a list of the fuses used, their

location and if relevant PCB reference:

PART NUMBER LOCATION TYPE & DETAILS QTY PER COCKPIT

514-5078-10000 IEC INLET (EP1302) 5X20 HRC SB 10000 mA 1 (PER TWIN)

514-5078-6300 838-11856CE-02 5X20 HRC SB 6300 mA 1

514-5078-6300 838-13578(F1) 5X20 HRC SB 6300 mA 1

514-5080-15000 838-14174(F1) 32X6.35 HRC SB 15000 mA 1

514-5078-2500 838-14174(F2) 5X20 HRC SB 2500 mA 1

There are also fuses located on the Monitor PCB. Refer to the relevant Monitor manual supplied to reference

these fuses.

RATED VOLTAGE: 220-240 VAC

RATED CURRENT: 3 Amps.

34

Page 35

3.9. Maintenance

• Only Qualified Service Personnel must carry out maintenance.

• Ensure that the mains power is switch OFF and disconnected before attempting any

work.

• The CONTROL PANEL ASSEMBLY is heavy and may cause injury or damage to the

machine if dropped. Use an assistant when removing a nd replacing it.

• In order to prevent an electric shock and short circuit, be sure to turn power off before

performing work by touching the interior parts of the product.

• Be careful not to damage the wires. Damaged wires may cause electric shock or short

circuit or present a fire risk.

• Do not touch undesignated places. Touching places not designated can cause electric

shock or short circuit.

• This work should be performed by the site maintenance individual or other skilled

professional. Performing work by non -technical personnel can cause electric shock

hazard.

• Do not perform work other than those specified in this Manual in order to prevent

accidents during performing work and operation after performing work. Performing work

not specified in this Manu al may require special training for this product. If performing

work other than those stated in this manual is required for repair, contact the offices

herein stated in this manual or where you purchased the product from and ask for repair

or inquire how to repair.

• Be very careful when soldering. Handling a soldering iron carelessly may result in a fire or

a burn.

• Be extremely careful when heating the heat-shrinkable tube. Failure to do so may result

in a fire or burns.

• Do not drop parts when removing them. Dropping parts may damage them or cause

sudden accidents.

• To prevent accidents, more than one person must perform these operations.

• Exercise extreme caution when handling the internal parts of the Control Panel. Watch

out for damage, warping and loss. The loss of just one piece may result in damage to or

lead to faulty operation of the entire unit.

• When securing the plastic -made parts, do not excessively fasten screws and nuts.

Failure to observe this may damage the parts and cause injury due to fragments resulting

from damage.

• Be sure to perform volume's move value setting in the Volume Setting in the Test Mode

after replacing or adjusting the Volume. (See 5.3.1)

35

Page 36

3.9.1. Handle Mecha

In the TEST MODE, if the steering whe el V.R. variations are not within the allowable limit, the V.R. installation

position requires adjustment or the V.R. needs replacement. Also be sure to apply grease every 3 months.

3.9.1.1.Removing the Handle Mecha

1. Turn the POWER switch OFF

2. Remove a total of 4 tamperproof screws from

the Control Panel

3. Wiring connectors are connected inside the

Control Panel. Carefully withdraw the control

panel in a manner so as not to damage the

wiring.

4. Disconnect the wiring connectors and earth

harness.

3.9.1.2.Replacing and Adjusting The Handle Mecha’s V.R.

• Never touch places other than those specified. Touching places other than those

specified can cause electric shock and short circuit.

• After the replacement or adjustment of the V.R. be sure to set the Centre of Steer in the

DRIVE BOARD TEST.

36

Page 37

3.9.1.3.Adjusting the VR

Remove the CONTROL PANEL as detailed above. Locate the V.R. on the rear surface of the HANDLE

MECHA.

1. Using a screwdriver, loosen the 2 machine screws which secure the V.R. Bracket. Move the V.R.

Bracket so as to disengage the gears.

2. Gently rotate the V.R. until its value is within the range of the centring position. Position the steering

wheel in the centre position.

3. Mesh the gears together. Make sure that a correct amount of backlash is maintained between the gears.

4. If the V.R. value is still not correct make fine adjustments by loosening the 2 machine screws on the

V.R. gear. Rotate the gear holder until the correct value is obtained.

5. The value should be adjusted such that with the steering wheel in the centre position the value read

during INPUT TEST shall be 80H±10H.

6. Re-set the centre of steer as described in the game test mode (output test).

3.9.1.4.Replacing the VR

1. Remove the CONTROL PANEL as detailed above. Locate the V.R. on the rear surface of the HANDLE

MECHA

2. Using a screwdriver, remove the 2 machine screws which secure the V.R. Bracket. Remove the V.R.

Bracket so as to disengage the gears.

3. Loosen the hexagon drive grub screws in the collar and gently slide off the V.R.

4. Reassemble is the reverse procedure of steps 1 and 2 above.

5. When complete you must readjust the V.R. in accordance with the paragraph above.

37

Page 38

3.9.1.5.Greasing

• Be sure to use a good quality, synthetic lubricant. Using a mineral-based lubricant will

cause damage to the plastic parts.

• Do not apply lubricant to parts other than those specified. Doing so may cause damage

Apply lubricant to gear mesh portions once every 3 months.

or deterioration of parts.

38

Page 39

3.9.2. Accelerator & Brake

• Only Qualified Service Personnel must carry out maintenance. Ensure that the

mains power is switched OFF and disconnected before attempting any work.

In the TEST MODE, if the brake or accelerator V.R. variations are not within the allowable limit, the V.R.

installation position requires adjustment or the V.R. needs replacement. Also be sure to apply grease to all

moving parts every 3 months.

3.9.2.1.Removing the Accelerator & Brake.

1. Turn the POWER switch OFF

2. Remove a total of 4 screws securing the

covers over the ACCELERATOR & BRAKE

3. Fine adjustment of the V.R. values is

accomplished with just these covers removed.

4. Coarse adjustment requires the

ACCELERATOR & BRAKE mounting bolts to

be removed. If this is necessary, remove the

bolts from the unit, but do not remove the unit

from the machine. Take extreme care when

operating the unit in this condition as damage

to other components can occur.

39

Page 40

3.9.2.2.Adjusting the V.R.

• Never touch places other than those specified. Touching places other than those

specified can cause electric shock and short circuit.

• After the replacement or adjustment of the V.R. be sure to set the values in the

INPUT TEST.

1. Remove the cover panels as detailed above.

2. Fine Adjustment - By using a screwdriver loosen

the 2 machine screws that secure the V.R. arm.

Move the V.R. arm to adjust the V.R. value within

the relaxed range.

3. Coarse Adjustment - Remove the four hexagon

bolts detailed above and remove the side covers

of the Accelerator & Brake.

4. Loosen the two machine screws holding the V.R.

rack

5. Move the V.R. rack away so as to disengage the

V.R.

6. Gently rotate the V.R. until its value is within the

range of the centring position.

7. Mesh the gears together. Make sure that a

correct amount of backlash is maintained.

8. If the V.R. value is still not correct make fine

adjustments as detailed above.

The required values are:

GAS PEDAL: Under 30H ⇒ Over C0H

BRAKE PEDAL: Under 30H

(THE PEDAL RELEASED)

⇒ Over C0H

(THE PEDAL

PRESSED)

40

Page 41

3.9.2.3.Replacing the V.R.

1. Loosen and withdraw the V.R. rack as detailed above.

2. Using a hexagon key loosen the two grub screws holding the V.R. gear onto the V.R.

3. Remove the V.R. gear

4. Using a spanner remove the nut holding the V.R. in position.

5. Gently remove the V.R. and its wire harness.

6. Refit is the reverse of removal.

7. When complete you must readjust the V.R. in accordance with the paragraph above.

3.9.2.4.Greasing

• Be sure to use a good quality, synthetic lubricant. Using a mineral -based lubricant

will cause damage to the plastic parts.

• Do not apply lubricant to parts other than those specified. Doing so may cause

damage or deterioration of parts.

Apply lubricant to gear mesh portions once every 3 months.

41

Page 42

3.10. Shift Lever

Remove the 2 Tapping Screws to replace the

In the Test Mode, if the SHIFT LEVER's SW can not be inputted satisfactorily, replace the Switch. Apply

greasing to the Mechanism's sliding portion once every 3 months.

When performing the above work, remove the Shift Lever Unit.

• Before starting to work, ensure that the Power SW is OFF. Failure to observe this

can cause electric shock and short circuit hazards.

• Use care so as not to damage wirings. Damaged wiring can cause electric shock

and short circuit hazards.

REMOVING THE SHIFT LEVER

A) Turn the Power SW off.

B) Remove the 4 Tamperproof Screws to lift the

Shift Lever Unit.

C) Disconnect the Connector to remove the

Shift Lever Unit.

D) When reinstalling, follow the procedure

opposite as when removing. At this time,

ensure that "DOWN" display appears on the

upper part as shown.

E) After reinstalling, be sure to check INPUT

TEST in the test mode. (TEST.)

SWITCH REPLACEMENT

A) Disconnect the wiring Connector of the

Switch to be replaced.

B)

Microswitch.

GREASING

Apply greasing once in 3 months to the s pecified

portions.

For spray grease, use NOK KLUBER L 60 or

Grease Mate (Part No. 090 -0066).

42

Page 43

3.11. Replacement of Fluorescent Lamp and Other Lamps

• Never touch places other than those specified. Touching places other than those

specified can cause electric shock and short circuit. Disconnect the machine from

the supply before attempting the replacement of any lamp.

• Prepare a secure step when working on the upper parts of the machine.

• Only QUALIFIED SERVICE PERSONNEL should replace lamps.

3.11.1.Fluorescent Lamp Replacement

1. Turn the POWER switch OFF.

2. Take out the 3 screws and open the Billboard lid.

3. Remove the end caps from the fluorescent tube.

4. Pull the tube out of the clips with a twisting action.

43

Page 44

3.12. Cleaning the Cabinet Surfaces

When the cabinet surfaces are badly soiled, remove stains with a soft cloth dipped in water or diluted

(with water) chemical detergent and squeezed dry. To avoid damaging surface finish, do not use such

solvents as thinner, benzine, etc. other than ethyl alcohol, or abrasives, bleaching agent and chemical

dustcloth.

3.13. Seat (Greasing to Seat Rail Portion)

Move the Seat to the rearmost position and

apply spray greasing to the portion shown

at the right once every 3 months by using

NOK KLUBER L60 or GREASE MATE

SEGA PART No. 090-0066.

After greasing, move the Seat a few times

forward and backward so as to allow the

grease to be applied all over uniformly. Be

sure to wipe grease which attaches to the

surfaces of the PROTECT RUBBER on the

Seat Rail, or any excess grease.

44

Page 45

3.14. Troubleshooting

turned ON, the machine is

After eliminating the cause of overload,

• Only QUALIFIED SERVICE PERSONNEL should carry out these procedures.

3.14.1.Troubleshooting (When No Error Message Is Shown)

• In order to prevent electric shock and short circuit, be sure to turn power off before

performing work.

• Be caref ul so as not to damage wirings. Damaged wiring can cause electric shock or

short circuit.

• After removing the cause of the functioning of the Circuit Protector, reinstate the

Circuit Protector. Depending on the cause of the functioning, using the Circuit

Protector as is without removing the cause can cause generation of heat and fire

hazard.

• In the event that a problem cannot be resolved by employing the procedures listed in

this Manual, be sure to request service from the office shown on this Manual or the

dealer from whom the product was originally purchased. Attempts to employ

procedures other than those specified in this Manual can cause electrical shock,

shorting, or fire.

• In the event of a problem that is not described here, be sure to contact the office

shown on this Manual or the dealer from whom the product was originally purchased.

Careless attempts at repair can result in electrical shock, shorting, or fire.

If a problem occurs, first check to make sure that the wiring connectors are properly connected.

PROBLEM CAUSE COUNTER MEASURES

When the main SW is

not activated.

Fluorescent lamp inside

FL box doesn't light up.

The power is not ON. Firmly insert the plug into the outlet.

Incorrect power source/voltage. Make sure that the power

supply/voltage are correct.

The fuse of the connect board was blown out

due to momentary overcurrent.

Connector connection fault. Check connector connections

Fluorescent lamp and Glow lamp need

replacement.

replace the specified rating fuse.

between the Cabinet and the FL box.

Replace the fluorescent lamp and the

glow lamp (See Section 3.7.9)

45

Page 46

Check the visual signal connector connection

ake adjustment appropriately. (See Monitor

Does not accept input from

Does not accept input from

PROBLEM CAUSE COUNTER MEASURES

Sound is not emitted.

Sounds are emitted and

the lamps are lit, but the

screen is black.

Irregular/uneven colors on

the monitor screen.

Colors on the monitor

screen are strange.

The on -screen image

sways and/or shrinks.

any switch or volume.

Sound volume adjustment is not

correct.

Faulty connections for various

connectors.

Malfunctioning BD, Amp. and

Adjust the Switch Unit's sound adjustment

volume . (See Section 5.1.1)

Check the connections for the game board,

amp, speakers and Volume connectors.

Perform SOUND TEST. (See 5.2.3)

Speaker.

Faulty connections for the visual

signal connector or the monitor power

Check the connections for the monitor and

game board connectors.

connector.

Broken monitor. Contact the company from whom the unit

was purchased.

Magnetization of the CRT. Press the Degauss. switch on the VTS

Assembly (See Section 5.1.1.)

Faulty connection for the visual signal

connector.

and make sure it is secured properly.

Screen adjustment is not appropriate. M

Manual)

The power source and voltage are no

correct.

Faulty connector connections.

Make sure that the power supply and voltage

are correct.

Check the connection for the I/O Board and

Cabinet connector.

the Shift Lever.

STEERING (Servomotor)

response is incorrect.

Check the power for the I/O Board.

Faulty connector connections. Check the connections for the connectors in

the Control Pane l and between the Control

Panel and the Cabinet.

Broken Microswitch. Replace the Microswitch

Incomplete power on check. Power on and verify that the power on check

completes properly. (See 3.7.8)

Deviation of the volume value. Adjust the volume value in the Test Mode.

Volume gear engagement fault. Adjust the engagement of the gear. (See

Section 3.9.1.3)

Volume malfunctioning. Replace the volume. (See 3.9.1.4)

Detached wires. Check for faulty wire connections around

moving parts.

When replacing wires, secure them so that

they do not touch any moving parts.

46

Page 47

PROBLEM CAUSE COUNTER MEASURES

No response from Steer ing

(Servomotor).

Steering (Servomotor) is

week in its force feedback.

Unsatisfactory Accel and

Brake operation.

Failure of power -on checking

procedure.

Faulty connector connections. Check the connections for the connectors

Thermal element in the Servodriver

is operating.

Momentary overload caused a fuse

on the Servodriver to blow.

Aging of the force feedback

mechanism.

Incorrect volume setting. Adjust the volume value in the Test Mode.

Faulty Volume attachment or adjust

gear alignment.

Faulty connector connection. Check the connections for the Accel and

Failure of the volume. Replace the volume. (See 3.9.2.3)

Reconnect the power and complete a

power-on checking procedure. (See

Section 3.7.8)

between the Game Board and Servodriver

and between the Servodriver and the

Servomotor.

Occurs when the internal temperature

reaches 70°C (158 °F) and corrects

automatically when the unit cools.

Contact the company from whom the unit

was purchased.

Reset in the Test Mode. ( See 5.3.1)

(See 3.9.2.2)

Adjust the volume attachment and verify in

Test Mode. (See Section 3.9.2.2)

Brake connectors and the connectors

between the Accel, Brake and Cabinet.

Start button and Change

View button input does not

work and they do not flash.

Start button and Change

View button input works, but

they do not flash.

Failure of the network play.

Faulty connector connections. Check the connections for the connectors

between the I/O Board, the Cabinet and

the Control Panel and those inside the

Control Panel.

Unverified settings or operation. The Start button only flashes when Free

Play is set. Check the operation in Test

Mode.

(See Section 5.3.1)

The lamp is burnt out. Replace the lamp.

Network play is wrongly set. Reset correctly. (See Section 3.15.8)

Communication cables are wrongly

connected.

Communication cables are

disconnected.

Damage of communication cables.

Reconnect the cables.

(See Sections 3.7.7 & 3.15.8)

Reconnect cables correctly. (See Section

3.15.8)

Replace the cables. Contact the company

from whom the unit was purchased.

47

Page 48

3.15. Gameboard

• Turn off the mains power and remove the power cord before opening the machine.

• The GAME BOARD should not require any work to be carried out upon it. All settings

and tests can be achieved without access to the GAME BOARD.

• All work to be carried out by QUALIFIED SERVICE PERSONNEL

3.15.1.Removing the Board

To return the game board for servicing, take out the board using the following procedure.

1. Turn the main switch OFF.

2. Unlock the base and remove the 2 M6 bolts.

3. Tip the seat carefully backwards as shown. Be careful not to damage the seat back when resting it on the

floor. Use a protective mat under the seat back to protect it on hard floors.

4. Disconnect all connectors from the game board, remove the fou r screws securing the game board to the

wooden base, and lift it out. Do not attempt to service the game board. THERE ARE NO USER

SERVICEABLE PARTS INSIDE! Return the game board to the Service Department inside the special

packaging provided.

Note.

Triforce game board is shown

however a Chihiro board is fitted.

48

Page 49

3.15.2.Removing The GD-ROM Drive

1. Turn the power off.

2. Remove 1 truss screw from each side of Base Lid R.

3. Unlock the base with the Master Key.

4. Turn the Lock Handle on Base Lid R to unlock the lid.

5. Lower the seat towards the backrest. Slowly lower the backrest until it touches the floor to prevent

damage to the seat part. Put a drop cloth on the floor to prevent damaging the surface of the seat

part.

Note:

Triforce game board is shown,

however a Chihiro is fitted .

6. Remove the GD cable connector and the power cord connector from the GD-ROM drive.

Note:

Triforce game board is shown,

however a Chihiro is fitted.

49

Page 50

7. Remove the 4 screws to remove the GD-ROM drive.

Note:

Triforce game board is shown,

however a Chihiro is fitted.

50

Page 51

3.15.3.Removing The Game Board

• When returning the game board for replacement or repair, make sure that the connectors

are attached correctly. Incorrect connections can lead to accidents such as electric

shock, short circuits, and/or fire.

• When plugging in connectors, pay close attention to the direction of the connection. The

connectors are designed to be connected in a specific direction. Attempting to plug in a

connector by applying excessive force may damage the connector or its terminal clasp,

possibly resulting in electric shock, short circuits, and/or fire.

1. Follow the above described action 1 to 5.

2. Remove all the connectors from the game board.

3. Remove the 4 screws that fix the game board.

51

Page 52

3.15.4.Composition of the Game Board

Once the Chihiro Board has the Key Chip inserted, it is this product's specialized Game Board.

ASSY CASE BOX ORT EXP 843 -0005D-02

DIP SW SETTING

Use this product with the DIP SW settings shown in the figure below.

52

Page 53

3.15.4.1.Replacing The Main Board Battery

• To prevent overheating, explosion, or fire:

• Do not recharge, disassemble, heat, incinerate, or short the battery.

• Do not allow the battery to come into direct contact with metallic objects or

other batteries.

• To preserve or to dispose of the battery, wrap it in tape or other insulating

material.

• Follow local regulations when disposing of the battery.

Improper disposal can damage the environment.

• To avoid risk of malfunction and damage:

• Make sure the positive and negative ends are aligned correctly.

• Use only batteries approved for use with this unit.

• If an error appears indicating that the battery power is very low within the first year

of use, it is usually an indication of a problem or abnormality with something other

than the battery. Be sure to inspect the board that the battery is connected to.

There is a Media Board Button Battery underneath the Media Board.

• Carefully remove the battery from its holder.

• Insert a new battery into the holder with the "+" terminal facing up.

53

Page 54

3.15.4.2.Replacing The Media Board Battery Pack

rmor may be heated and melted or

Prohibitions and Cautions to Handle the Battery Pack

• Be careful when handling the battery pack.

• We bear no responsibility for problems caused by handling clearly contrary to the content of this

manual.

• Do not disassemble the battery pack and the batteries.

• If you should fail to observe this instruction, the internal wires and/or protective

devices may be damaged; as a result the safety system may not function when

discharging and recharging, eventually causing an overheating, fire and explosion. If

you should disassemble the batteries, the generated gases may harm your throat

and the negative plate may overheat and make a fire.

• Do not make an external short circuit of the battery pack and the batteries.

If you should fail to observe this instruction, the batteries may overheat, make a

fire, and explode.

• Do not fire the battery pack and the batteries.

If you should fail to observe this instruction, the batteries may make a fire and

explode.

• Do not leave the battery pack and the batteries nearby the heat source (fire or

heater) or under the intense direct sunlight and flaming sun.

If you should fail to observe this instruction, the batteries may reduce the service

life and in the worst case may overheat, make a fire, and explode.

• Do not leave the battery pack and the batteries in water or seawater. Also do not

apply water or seawater onto the battery pack and the batteries. If you should fail to

observe this instruction, the internal wires and/or protective devices may be

damaged; as a result the safety system may not function when discharging and

recharging, eventually causing an overheating, fire and explosion. Also water may

be electrolyzed into oxygen and hydrogen, and eventually the battery's sealed

section may be corroded and the internal liquid may leak.

• Do not solder on the battery pack's terminals.

If you should fail to observe this instruction, the a

the internal wires may be damaged, eventually causing an overheating, fire and

explosion. Also, when the battery's temperature reaches to 100•Ž or more, the

battery may leak its internal liquid due to destruction of its pla stic parts (gasket,

separator, etc.), or may overheat, make a fire, or explode due to internal shortcircuit.

• Do not insert or connect the battery in a reversal polarity.

If you should fail to observe this instruction, the battery may be externally short circuited and eventually overheat, make a fire, or explode, depending on the device

you connect with.

54

Page 55

• Do not tightly seal the battery pack when installing it onto an external device.

• Flammable gas is generated from the battery when its safety mechanism has

functioned. If you should fail to observe the above -described instruction, sparks

from motors, switches, etc. may cause the gas to fire. Therefore, install the battery

pack so that the gas can be quickly released from the external device.

• Do not use the battery pack for the device/usage other than this game system.

If you should fail to observe this instruction, the battery and/or the device may be

damaged due to non -applicable specifications.

• Do not strike a nail in, hammer, step on, or apply any other forms of pressures and

shocks on, the battery.

If you should fail to observe this instruction, the battery may be deformed. As a

result, the battery may burst at its sealed sections to leak the internal liquid, or

may be short-circuited internally to overheat, make a fire, and explode.

• Do not use a battery charger because any battery charger is not usable for this

battery pack.

If you should fail to observe this instruction, the gas may be suddenly generated in

the battery and eventually the battery may overheat, make a fire or explode.

• If the battery in use or in keeping shows an abnormal indication (deformation,

change of color, bursting of the armor cover, etc.), immediately stop using or

keeping it. If it leaks and smells abnormally, immediately keep it away from fire and

put it in a safety box.

• If the liquid leaks from the battery and gets in your eyes, do not rub your eyes but

immediately wash them with clean water (city water etc.); and consult a medical

doctor for a treatment. If you shou ld fail to observe this instruction, the liquid may

harm your eyes.

• The battery pack armor (a polyvinyl chloride tube) may be damaged or deformed by

external force or heat. When transporting the battery pack or replacing it with a new

one, therefore, be careful not to drop or excessively shock it. Do not continue to

use any damaged or deformed battery pack. If you should fail to observe this

instruction, the battery may overheat, make a fore, or explode.

• The battery pack contains a printed circuit board (PCB) for protective circuitry. It

may be destroyed by the static electricity. When handling or servicing the battery

pack, therefore, take preventive measures against the static electricity.

• If your battery pack has shown destruction of a protective circuitry PCB, do not

continue to use it. If you should fail to observe this instruction, the battery may

overheat, make a fore, or explode.

• When wiring the battery pack to a device, be careful not to apply excessive force

onto the connectors and lead wires. The battery may overheat, make a fire, or

explode if the connectors and lead wires are damaged.

• When discarding the battery pack at a disposal specialist, be sure to cover the

terminals with tape or some other covering and avoid damage when packing.

55

Page 56