Seeley International Breezair Exvq User Manual

INSTALLATION MANUAL

EXVQ Evaporative Coolers

(English)

Original English Instructions

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS

Read and Save these Instructions for Future Reference 1

Warnings 1

Employer and Employee Responsibilities 1

Installer and Maintenance Contractors - Risk Assessment 1

Some Points to Consider 1

Other Important Requirements 1

QUICK GUIDE 2

INSTALLATION

Pack Out Kit Contents 4

Cooler Location 4

Access for Servicing and Maintenance 4

Installing the Roof Jack 5

Conveying the Cooler To The Roof 5

Mounting the Cooler 5

Securing the Leg Supports 6

Weatherseal and Latch 6

Electrical Requirements 7

Installing the Mains Power Cable 7

Installing the Controller Cable 7

Water Requirements 8

Water Connections 8

Coolers with Drain Valves 8

Installing the Inlet Solenoid 8

Fitting the Solenoid Cover 9

Installing the Drain Valve 9

Drain Valve Assembly 9

Connecting the MagIQtouch Controller 9

Motor Power (Amps) 10

Pulley Adjustment 10

Belt Tension 11

Motor Low Speed Setting 11

COMMISSIONING

Test Operation 12

Diagnostic LED 12

Salinity LED 12

MagIQtouch Controller Information 12

Fault Codes 13

Setting the Water Level 13

Testing the Drain Valve 14

Testing the Pump 14

Retting the Pad Frames 14

Adjusting Cooler Settings 14

Commissioning Completion Checklist 15

TROUBLE SHOOTING 16

WARNING! Failure to install and commission the product in compliance with these instructions, or failure to do

the job properly and competently, may void the customer’s warranty. Further, it could expose the Installer and/or

the Retailer to serious liability.

i |

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS FOR

FUTURE REFERENCE.

Means for all pole disconnection must be incorporated in the

xed wiring in accordance with the wiring rules.

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualied persons in

order to avoid a hazard.

The following specications for the cooler water supply are

required:

Min Water Pressure: 15psi (100kPa)

Max Water Pressure: 115psi (800kPa)

New hose sets supplied with the appliance are to be used and

old hose-sets should not be re-used.

WARNINGS

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Installation work and electrical wiring must be done by

qualied person(s) in accordance with all applicable codes

and standards, including re-rated construction.

2. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

3. Ducted fans must always be vented to the outdoors.

4. Do not use this fan with any solid-state speed control device.

EMPLOYER AND EMPLOYEE RESPONSIBILITIES

The installation and maintenance of evaporative coolers at

height has the potential to create Occupational Health and

Safety issues for those involved. Installers are advised to

ensure they are familiar with the relevant State and Federal

legislation, such as Acts, Regulations, approved Codes of

Practice and National Standards, which oer practical guidance

on these health and safety issues. Compliance with these

regulations will require appropriate work practices, equipment,

training and qualications of workers.

Seeley International provides the following information as a

guide to contractors and employees to assist in minimising risk

whilst working at height.

INSTALLER AND MAINTENANCE CONTRACTORS RISK ASSESSMENT

A risk assessment of all hazardous tasks is required under

legislation. A risk assessment is an essential element that

should be conducted before the commencement of work, to

identify and eliminate the risk of falls or to minimise these risks

by implementing control measures. There is no need for this to

be a complicated process, it just is a matter of looking at the job

to be done and considering what action(s) are necessary so the

person doing the job does not injure themselves.

This should be considered in terms of:

• What are the chances of an incident happening?

• What could the possible consequence be?

• What can you do to reduce, or better still, completely get rid of

the risk?

SOME POINTS TO CONSIDER

• What is the best and safest access to the roof and working

areas?

• If a worker is alone, who knows they are there and if they get

into diculty, how can they summon help? (Call someone on

the ground? Mobile phone? Etc.)

• What condition is the roof in? Should the trusses, underside

or surface be checked?

• Does the worker have appropriate foot wear? (Flat sole jogger

type is advisable.)

• Are all power cables / extension leads safe and appropriately

rated?

• Are all ladders, tools and equipment suitable in good

condition?

• Where ladders are to be used, is there a rm, stable base for

them to stand on? Can they be tied or secured in some way

at the top? Is the top of the ladder clear of electricity supply

cables?

• Is there a roof anchor to attach a harness and lanyard to? If

so, instruction should be issued for the use of an approved

harness or only suitably trained people used.

• Are all tools and materials being used, prevented from

slipping and falling onto a person at ground level? Is the area

below the work area suitably protected to prevent persons

walking in this area?

• Does the work schedule take into account weather conditions,

allowing for work to be suspended in high winds, thunder

storms/lightning or other types of weather giving wet, slippery

surfaces?

• Is there an on-going safety check system of harnesses,

ropes, ladders and access/lifting equipment and where they

exist on roofs, anchor points before the commencement of

work?

• Is there a system which prevents employees from working

on roofs if they are unwell or under the inuence of drugs or

alcohol?

• Are there any special conditions to consider i.e. excessive

roof pitch, limited ground area, fragile roof, electrical power

lines?

OTHER IMPORTANT REQUIREMENTS

• Never force parts to t because all parts are designed to t

together easily without undue force.

• Never drill holes in the pan (Reservoir) of the cooler.

• Check the proposed cooler location, to ensure that it is

structurally capable of supporting the weight of the cooler, or

provide an adequate alternate load bearing structure.

Ensure the installation complies with all local and national

regulations with regards to electrical, plumbing and bushre/

wildre construction requirements.

BREEZAIR EXVQ EVAPORATIVE COOLER INSTALLATION MANUAL | 1

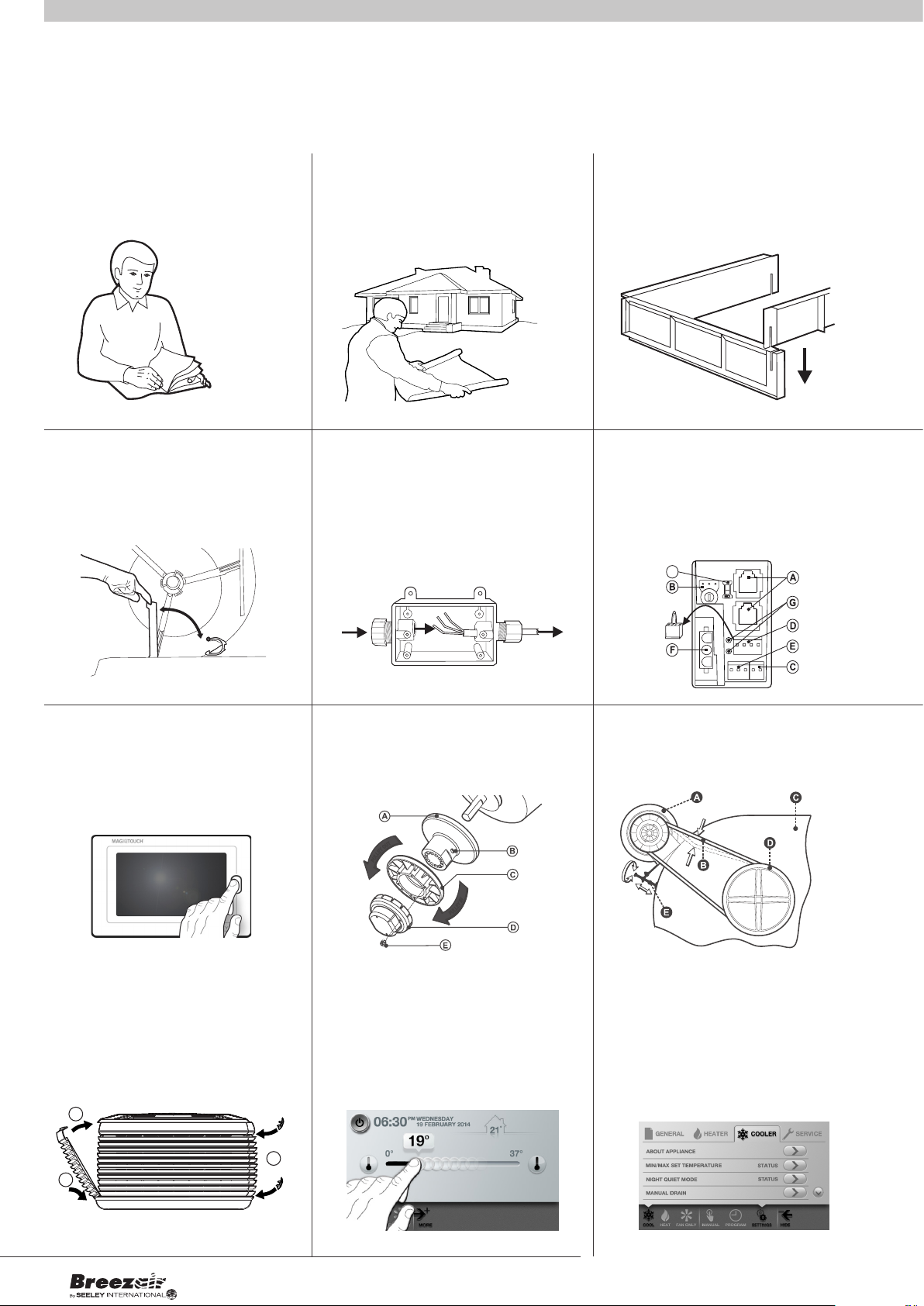

QUICK GUIDE

MAIN POWE

OX

STEP 1

SAFETY

Read & understand the safety section.

page 1i

STEP 7

WEATHERSEAL

Check operation of the Weatherseal

STEP 2

COOLER LOCATION

Check cooler location. Consider

regulations. Discuss with customer.

page 4

STEP 8

POWER CABLE

Use the main power termination box

for wiring connections inside cooler.

Terminate power cable outside of cooler

in a junction box.

R

STEP 3

INSTALL ROOFJACK

Install 24G metal roof jack and

seal before mounting.

page 5

STEP 9

CONTROLLER CABLE

Connect one end of the controller cable

to cooler electronics.

H

Shorting

Plug

ON

page 6

STEP 13

CONNECTING THE CONTROLLER

Connect the other end of the controller

cable to MagIQtouch control.

page 9

STEP 19

REFIT PAD FRAMES

Ret the pad frames before testing the

pump.

2

CONTROLB

page 7

STEP 14

SET MOTOR AMPS

page 9

STEP 20

TEST PUMP

Turn on the cooler and check the water

is evenly distributed to all pads.

page 7

STEP 15

ADJUST BELT TENSION

page 9

STEP 21

COOLER SETTINGS

Where necessary, adjust the cooler

settings to suit customer requirements

using the controller.

2 |

3

1

page 14

page 14

page 14

ON

QUICK GUIDE

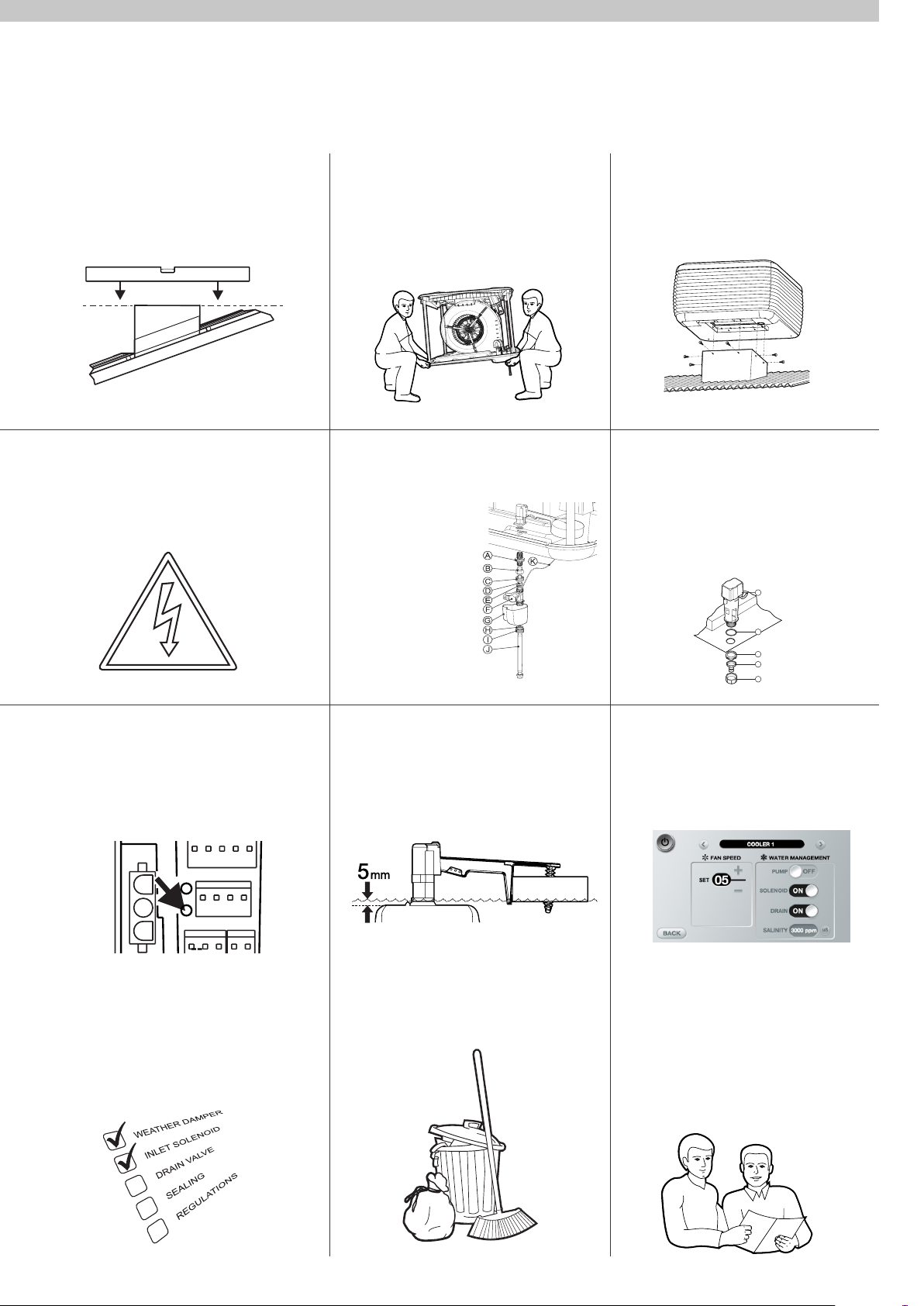

STEP 4

LEVEL ROOF JACK

Position, level, secure and seal the roof

jack.

page 5

STEP 10

REGULATIONS

Read & adhere to the local & national

electrical and plumbing regulations.

STEP 5

CONVEY COOLER

Convey the cooler to the roof.

Note! Always use 2 people when

handling manually.

STEP 11

INLET SOLENOID

Fit the solenoid.

Connect the cable.

Connect the

water supply.

Install the drain pipe.

page 5

STEP 6

MOUNT COOLER

Mount cooler to the dropper.

Check pan (reservoir) is level.

page 5

STEP 12

DRAIN VALVE

Fit the drain valve.

Connect the discharge system.

Connect the cable to the cooler

electronics.

A

page 7

STEP 16

COMMISSION THE COOLER

Test the cooler with the MagIQtouch

Controller. Check diagnostics of cooler

electronics. Test the motor.

page 12

STEP 22

FINAL CHECK

Test & complete the commissioning

checklist at the end of this document.

STEP 17

WATER LEVEL & DRAIN

Set the water level.

Test the drain valve.

page 13

STEP 23

CLEAN UP

Clean up the site!

page 8

B

C

D

E

page 9

STEP 18

SETTING THE CONTROL METHOD

Set water management method

Set salinity control method.

page 14

STEP 24

CUSTOMER HANDOVER

Show customer how to operate the

cooler. Give them both the MagIQtouch

Controller and cooler owner’s manual.

Explain maintenance requirements.

page 15

page 15

BREEZAIR EXVQ EVAPORATIVE COOLER INSTALLATION MANUAL | 3

page 15

INSTALLATION

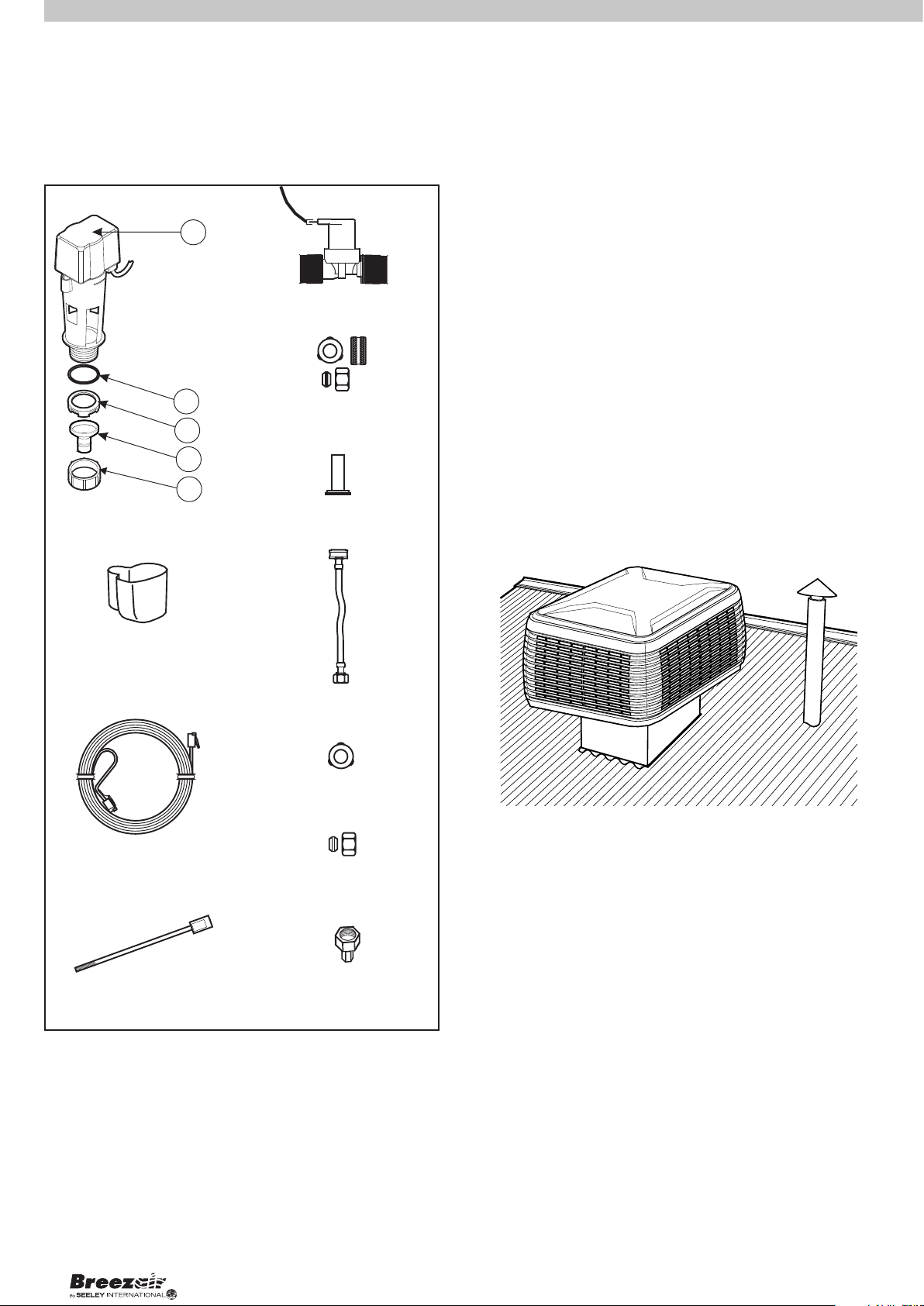

PACK OUT KIT CONTENTS

A

DRAIN VALVE

ASSEMBLY&

FITTINGS

A- Drain Valve

B -‘O’Ring

C - Nut

D - Drain Adaptor

E - Lock Nut

B

C

D

E

SOLENOID

SOLENOID

FITTINGS

STRAIGHT TUBE

(Water Inlet)

COOLER LOCATION

Check the proposed cooler location to ensure it is structurally

capable of supporting the weight of the cooler. If the roof is

structurally inadequate, provide an alternate load bearing

structure.

The ideal location for the cooler is in a central position on the

roof (away from sleeping areas and where people spend most

of their time) so that the duct runs are of approximately the

same length. Carefully consider neighbouring residences and

noise levels when locating the cooler, if necessary talk to the

customer and the neighbour before carrying out the installation.

Always locate the cooler where it will receive adequate fresh air

and not in a recess where it may be starved for air or where the

air is polluted.

Ensure location is a minimum of:

• 10’ (3m) from a solid fuel heater ue,

• 5’ (1.5m) from a gas ue,

• 17’ (5m) from a sewer vent, and

• 2’ (600mm) from a wall.

The cooler must be mounted at least 10’ (3m), preferably 17’

(5m), away from any TV antenna or antenna cables.

EXVQ MODELS

SOLENOID

COVER

CONTROL

CABLE

CABLE TIE

E

FLEXIBLE HOSE

ASSEMBLY

RUBBER

WASHER

NUT

½”BSP &

OLIVE

BRASS

ADAPTOR

½”BSP to 1/4”

COMPRESSION

ILL3385-A

ILL1204-C

Make sure the cooler is not between the antenna and the

transmission tower that is providing the television signal to the

home.

Allow adequate access to and around the cooler for

maintenance. Provision must be made for access to electricity,

water supplies and drains.

Note! Do you need to discuss the installation of items like

safety anchor points with the customer?

ACCESS FOR SERVICING AND MAINTENANCE

The cooler should be installed in a position that allows adequate

access for installation, and future maintenance and servicing

activities. This should comply with installation guidelines and

any local, State and National regulations.

Consider the following for installation location:-

• Which has clear access to and around the cooler

• Which is clear of xtures in line with below clearances

• Which is clear of fall edges (> 10’ or 3m away)

• Which is structurally capable of supporting the weight of the

cooler and service technicians

Required clearances around the cooler for future maintenance

and servicing are shown adjacent.

4 |

Loading...

Loading...