Seeley Climate Wizard CW-H10, Climate Wizard CW-H15S, Climate Wizard CW-H15, Climate Wizard CW-H15S Plus Installation & Operation Manual

(English) (CW-H15)

INSTALLATION & OPERATION MANUAL

INDIRECT EVAPORATIVE COOLER

CW-H10, CW-H15, CW-H15S, CW-H15S Plus

Original English Instructions

2 | CW-H10, H15, H15S, H15S Plus

TABLE OF CONTENTS

MAINTENANCE NOTE 3

SAFETY 4

Risk Assessment 4

Installer and Maintenance Contractors 4

Some Points to Consider 4

Other Important Requirements 4

Employer and Employee Responsibilities 4

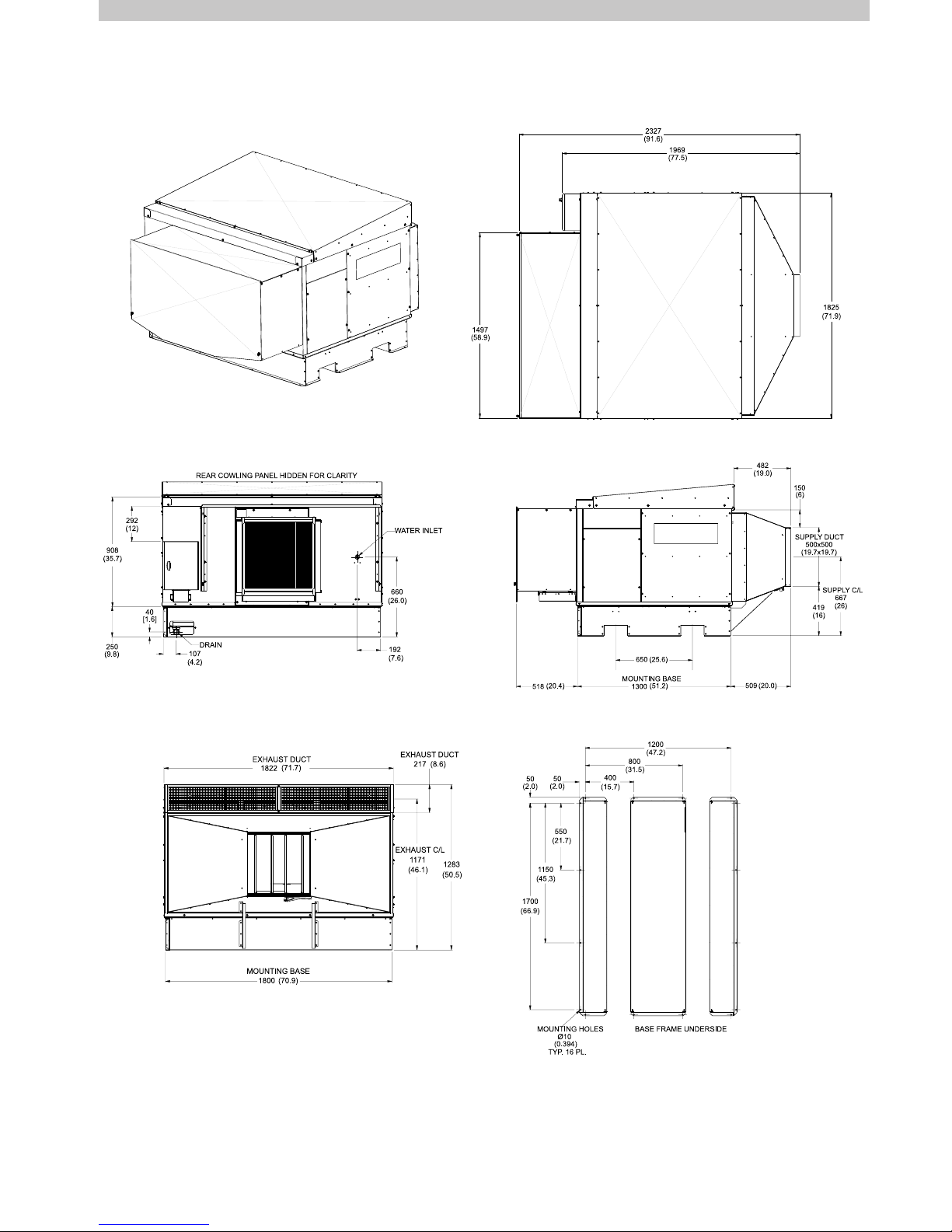

COOLER VIEWS 5

Isometric 5

Rear 5

Front 5

Top 5

Side 5

Bottom 5

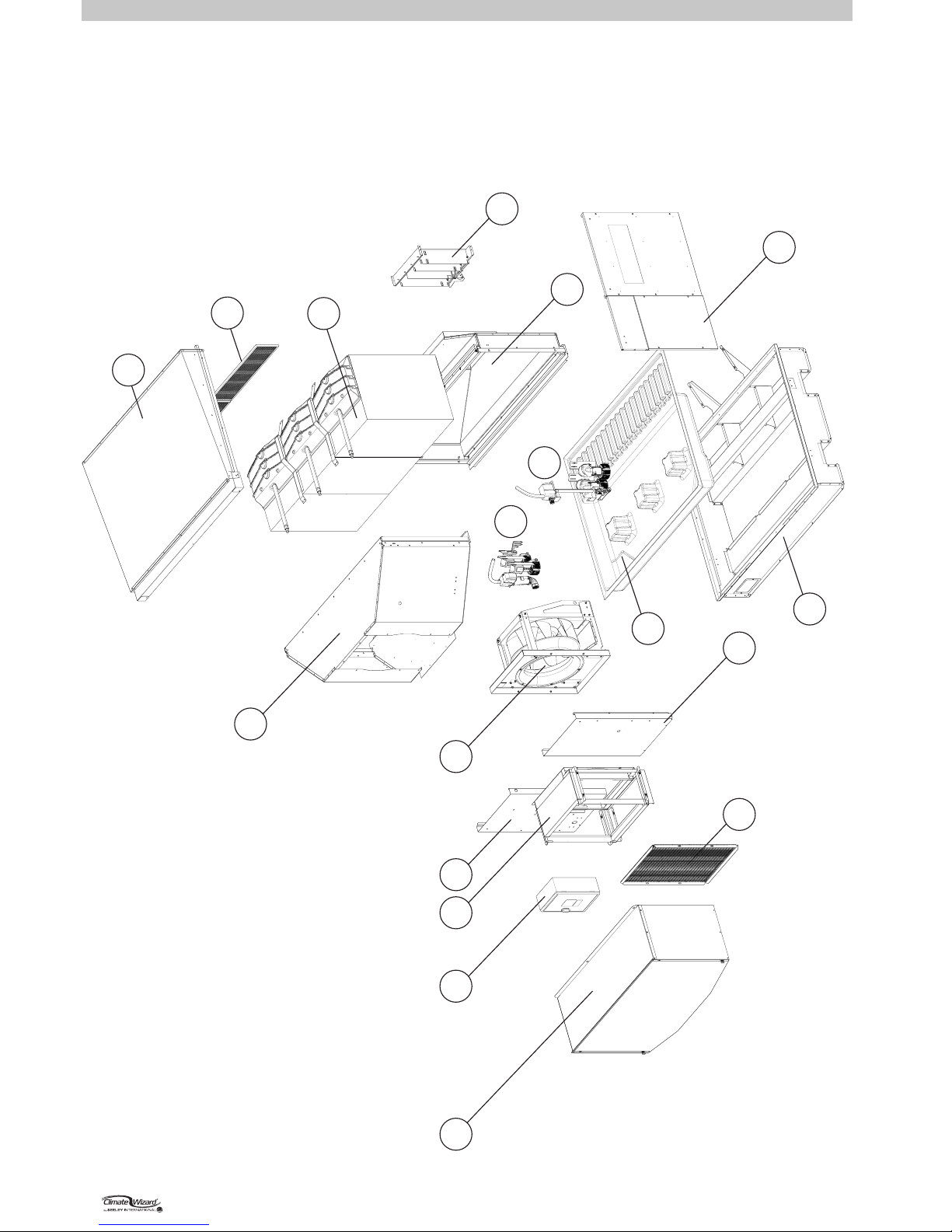

COOLER EXPLODED VIEW 6

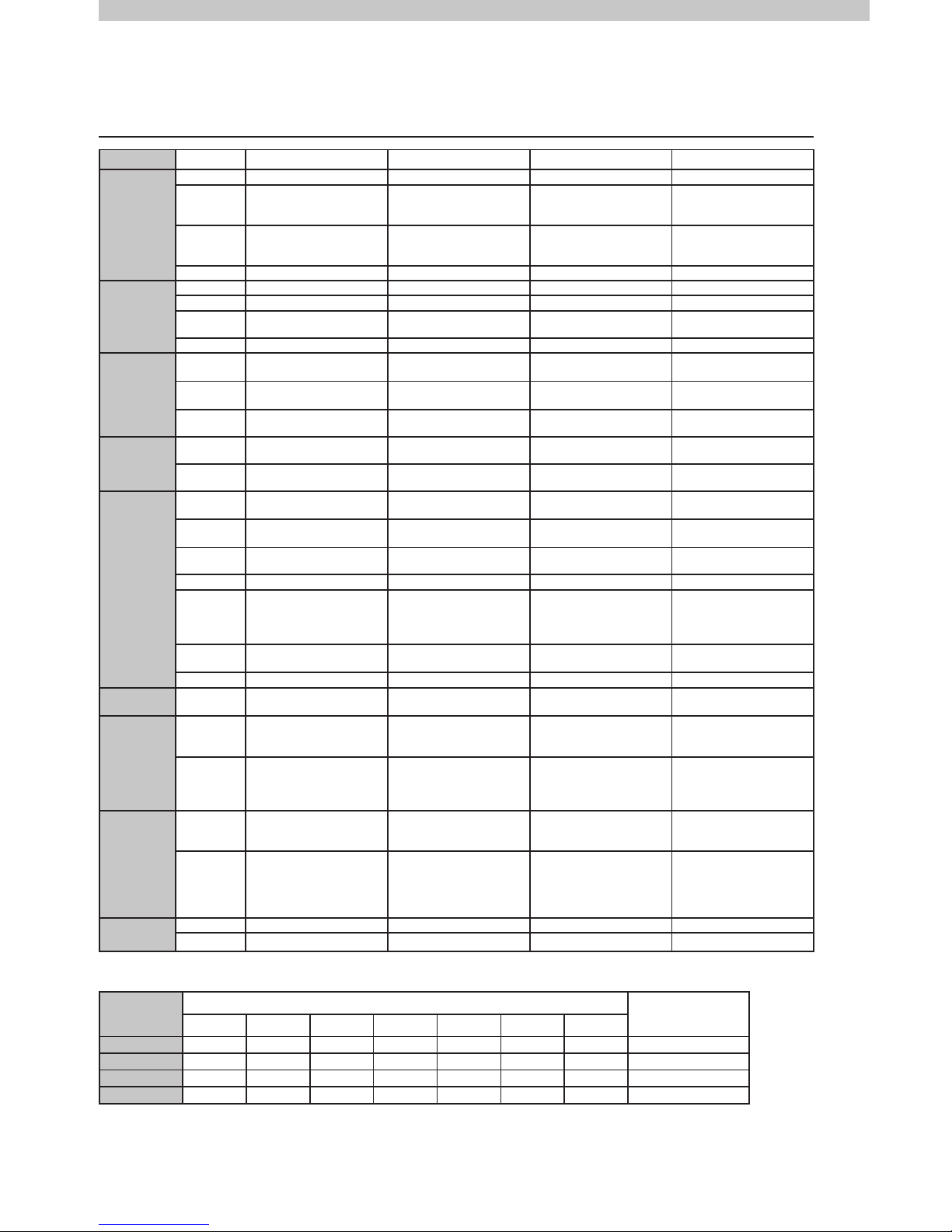

COOLER SPECIFICATIONS 7

TECHNICAL SPECIFICATIONS - METRIC MODELS 7

TECHNICAL SPECIFICATIONS - IMPERIAL MODELS 8

COOLER CONTENTS 9

Cooler Installation Components 9

Optional Components 9

INSTALLATION 10

Cooler Location 10

Mounting/Support 10

Unpacking the Cooler 10

Moving the Cooler 10

Lifting the Cooler 10

Vibration Isolation 10

Drip-Tray 10

Supply Air Duct Connections 10

Exhaust Transition Assembly 11

Exhaust Duct Connection Requirements 11

Inlet Air Filter Assembly or Safety Grille 12

Inlet Air Filter Cowling Assembly 13

Water Supply Installation 14

Water Supply Filtration 14

Water Hammer 14

Water Drain Installation 14

Electrical Supply Installation

(Australia, Europe - 3Ph 380-415V) 15

Electrical Supply Installation

(USA 3Ph, 380 - 480V) 16

Electrical Supply Installation

(USA 3Ph, 200 - 240V) 17

Electrical Supply Installation

(USA 1Ph, 200 - 240V) 18

Climate Wizard Supercool Installation 19

Relay Control Method 1: Switch 19

Relay Control Method 2: BMS 19

Relay Control Method 3: Always Run 19

CONTROL SCHEMES 20

Option 1 - Local Zone Control with Wall Control 20

Option 2 - Building Management System (BMS) Interface 20

Remote On-O (Input) 20

Cool/Vent (Input) 20

Fan Speed (Input) 20

Error Signal (Output) 20

WALL CONTROL INSTALLATION 21

Locating the Wall Control 21

Fixing the Wall Control Bracket to a Plasterboard Wall 21

Fixing the Wall Control Bracket to a Brick Wall 21

Fitting the Wall Control to the Mounting Bracket 21

Running the Wall Control Cable to the Wall Control 21

COMMISSIONING 22

Water Management System 22

Tank (Reservoir) Drain Valve Control 22

Inlet Solenoid Valve Control - Water 22

Pre-Wet Cycle 22

Pump Control 22

Salinity Control 22

Water Usage Sensing: 22

Chlorinator Control 22

Testing the Cooler 23

Changing Control Parameters 23

Setting the Air Discharge Damper 24

INSTALLATION CHECKLIST 25

OPERATING INSTRUCTIONS 26

Wall Control 26

If ‘02’ or ‘03’ is displayed 27

If ‘04’ is displayed 27

MAINTENANCE INSTRUCTIONS 28

Quarterly Inspection Procedures 28

Pump Maintenance & Replacement 28

Cleaning Pump Strainers & Impellors 28

Chlorinator Maintenance & Replacement 29

Water Management Probe Maintenance & Replacement 29

Drain Valve Maintenance & Replacement 30

Cleaning the Water Reservoir (Tank) 30

Solenoid Valve Maintenance & Replacement 30

Cleaning or Replacing Inlet Air Filters 31

Changing Cooler Cores 31

Cooler Cores - Orientation 32

Changing Cooler Chillcel Pads 33

Operating and Fault Code Diagnosis 33

MAINTENANCE SCHEDULE 36

SPARE PARTS 39

HOW TO REGISTER YOUR PRODUCT WARRANTY

(Australia only) 40

WARRANTY TERMS AND INFORMATION (Australia only) 41

SEELEY INTERNATIONAL

- INSTALLATION MANUAL | 3

MAINTENANCE NOTE

IMPORTANT

As with any product that has moving parts or is subject to wear

and tear, it is VERY IMPORTANT that you maintain your cooler

and have it regularly serviced. It is a condition of warranty cover

for your cooler that you comply with all of the maintenance

and service requirements set out in this Manual. Compliance

with these requirements will prolong the life of your cooler.

Further, it is also a condition of warranty cover that each item

in the Maintenance Schedule in the Manual is lled out (by

signing and dating it in the places indicated) when the item is

completed.

Any failure to carry out the required maintenance and servicing,

and any failure to ll out the maintenance schedule, will void

your warranty.

4 | CW-H10, H15, H15S, H15S Plus

SAFETY

RISK ASSESSMENT

Installer and Maintenance Contractors

A risk assessment of all hazardous tasks is required under

legislation. A risk assessment is an essential element that

should be conducted before the commencement of work, to

identify and eliminate the risk of falls or to minimise these risks

by implementing control measures. There is no need for this to

be a complicated process, it just is a matter of looking at the job

to be done and considering what action(s) are necessary so the

person doing the job does not injure themselves.

This should be considered in terms of:

• What are the chances of an incident happening?

• What could the possible consequence be?

• What can you do to reduce, or better still, completely

get rid of the risk?

SOME POINTS TO CONSIDER

• What is the best and safest access to the roof

and working areas?

• If a worker is alone, who knows they are there and if they get

into diculty, how can they summon help? (Call someone on

the ground? Mobile phone? etc.)

• What condition is the roof in? Should the trusses, underside

or surface be checked?

• Does the worker have appropriate foot wear?

(Flat sole jogger type is advisable)

• Are all power cables / extension leads safe

and appropriately rated?

• Are all ladders, tools and equipment suitable

in good condition?

• Where ladders are to be used, is there a rm, stable

base for them to stand on? Can they be tied or secured

in some way at the top? Is the top of the ladder clear of

electricity supply cables?

• Is there a roof anchor to attach a harness and lanyard to? If

so, instruction should be issued for the use of an approved

harness or only suitably trained people used.

• Are all tools and materials being used, prevented from

slipping and falling onto a person at ground level? Is the area

below the work area suitably protected to prevent persons

walking in this area?

• Does the work schedule take into account weather

conditions, allowing for work to be suspended in high winds,

thunder storms/lightning or other types of weather giving wet,

slippery surfaces?

• Is there an on-going safety check system of harnesses,

ropes, ladders and access/lifting equipment and where

they exist on roofs, anchor points before the

commencement of work?

• Is there a system which prevents employees from

working on roofs if they are unwell or under the inuence of

drugs or alcohol?

• Are there any special conditions to consider i.e.

excessive roof pitch, limited ground area, fragile roof,

electrical power lines?

OTHER IMPORTANT REQUIREMENTS

• Never force parts to t because all parts are designed

to t together easily without undue force.

• Never drill holes in the tank(s) of the cooler.

• This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of

the appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not play

with the appliance.

EMPLOYER AND EMPLOYEE RESPONSIBILITIES

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK OR INJURY TO OTHER PERSONS, OBSERVE THE

FOLLOWING:

Seeley International provides the following information as a

guide to contractors and employees to assist in minimizing risk

whilst working at height.

The installation and maintenance of direct and indirect

evaporative coolers at height has the potential to create

Occupational Health and Safety issues for those involved.

Installers are advised to ensure they are familiar with

the relevant State and Federal legislation, such as Acts,

Regulations, approved Codes of Practice and Local

Standards, which oer practical guidance on these health

and safety issues. Compliance with these regulations will

require appropriate work practices, equipment, training and

qualications of workers.

Seeley International provides the following information as a

guide to contractors and employees to assist in minimising risk

whilst working at height.

1. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

2. Before servicing or cleaning the unit, switch power o at

service panel and lock the service disconnecting means

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag

to the service panel.

3. Installation work and electrical wiring must be done by

qualied person(s) in accordance with all applicable codes

and standards, including re-rated construction.

4. When cutting or drilling into walls or ceilings, do not

damage electrical wiring and other hidden utilities.

SEELEY INTERNATIONAL

- INSTALLATION MANUAL | 5

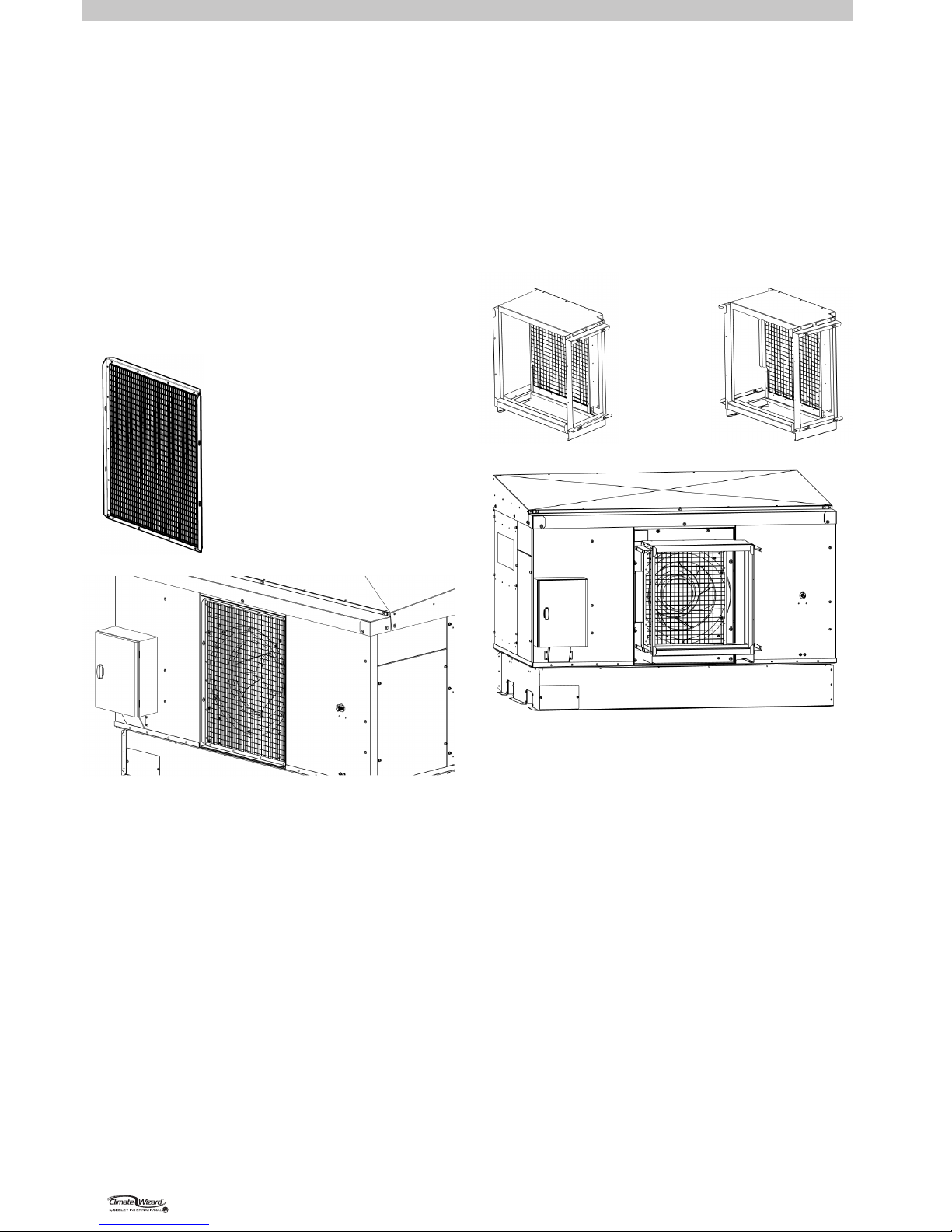

COOLER VIEWS

Dimensions are in mm (inches in brackets).

ISOMETRIC

CW-H15 views shown

TOP

REAR SIDE

BOTTOM

ILL1916-A

ILL1918-A

ILL1917-A

ILL1919-A

ILL1920-A

FRONT

ILL2422-A

6 | CW-H10, H15, H15S, H15S Plus

COOLER EXPLODED VIEW

ILL2423-A

1

2

35 6

7

4

5

12

13

14

10

11

15

16

17

8

9

INDEX

DESCRIPTION

1 COWLING ASSEMBLY

2

ELECTRONICS

BOX

3 AIR FILTER ASSEMBLY

4 INLET SAFETY GRILLE ASSEMBLY (Optional, mandatory if Inlet Filter not used)

5 FRONT PANELS

6 MOTOR AND FAN ASSEMBLY

7 INLET TRANSITION ASSEMBLY

8 PUMPS, DRAIN VALV E AND WATER PROBE

9 PUMPS, INLET SOLENOID AND CHLORINATOR

10 TANK ASSEMBLY

11 BASE FRAME ASSEMBLY

12 OUTER PANELS (RHS)

131415

16 EXHAUST GRILLE ASSEMBLY

17

OUTLET TRANSITION ASSEMBLY

DAMPER ASSEMBLY

CORE AND SPREADER ASSEMBLY

EXHAUST LID ASSEMBLY

ILL2423-A

SEELEY INTERNATIONAL

- INSTALLATION MANUAL | 7

COOLER SPECIFICATIONS

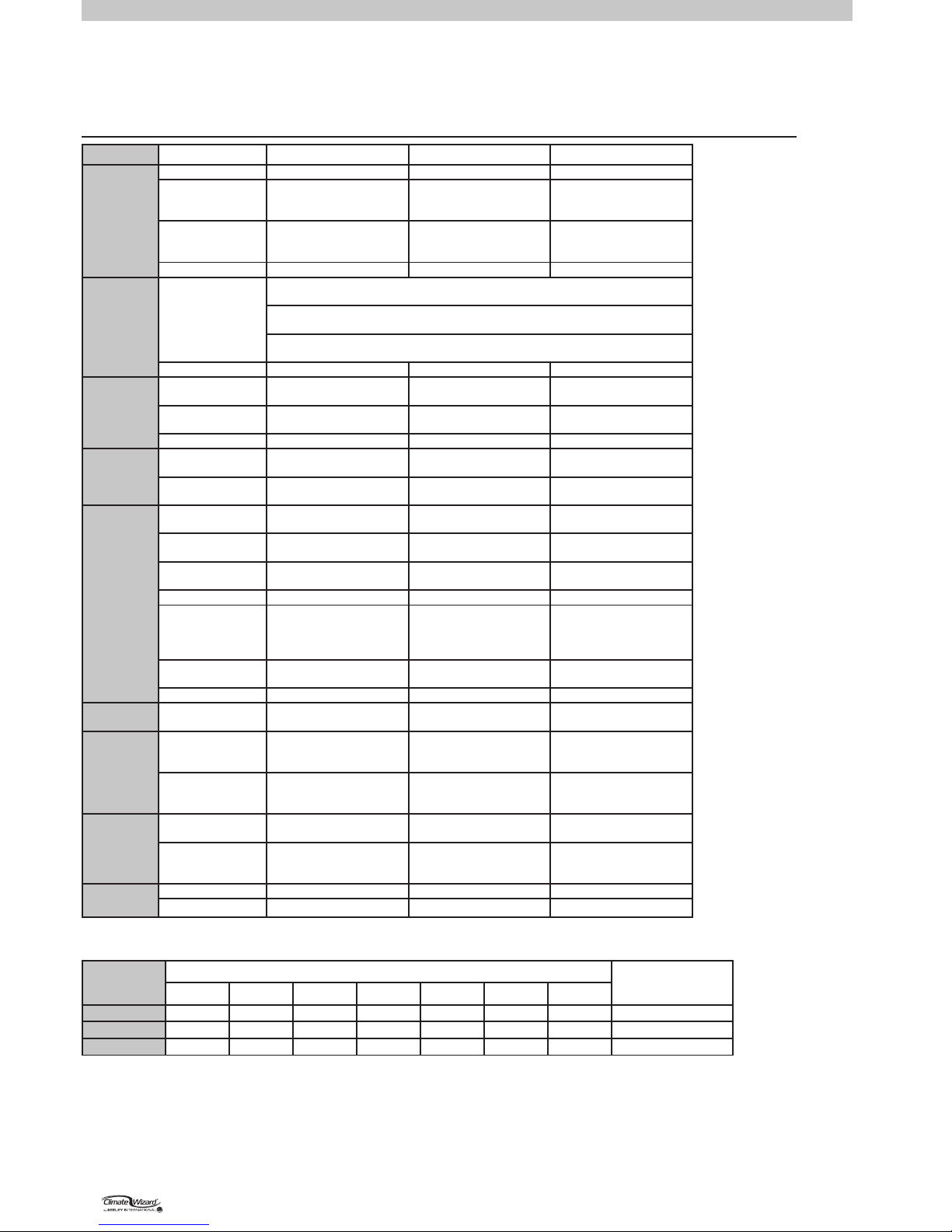

TECHNICAL SPECIFICATIONS - METRIC CW-H MODELS

Specication CW-H10 CW-H15 CW-H15S CW-H15S Plus

Capacity

Airflow

800 L/s @ 140 Pa 1100 L/s @ 150 Pa 1100 L/s @ 130 Pa 1600 L/s @ 80 Pa

Maximum

External Static

Pressure

215 Pa 215 Pa 195 Pa 155 Pa

Nominal

Cooling

Capacity*

18 kW 24 kW 28 kW 40 kW

COP

12 14 16 18

Electrical

Supply

Voltage

380-415V/3N~ 380-415V/3N~ 380-415V/3N~ 380-415V/3N~

Frequency

50 Hz 50 Hz 50 Hz 50 Hz

Rated

Current

3A 3A 3A 3A

Input Power

1.5 kW 1.8 kW 1.8 kW 2.2 kW

Fan/Motor

Type

560mm dia

Backward Curved

560mm dia

Backward Curved

560mm dia

Backward Curved

560mm dia

Backward Curved

Control

Variable Speed

ECM PWM Control

Variable Speed

ECM PWM Control

Variable Speed

ECM PWM Control

Variable Speed

ECM PWM Control

Maximum

Speed

1270 rpm 1350 rpm 1350 rpm 1460 rpm

Heat

Exchanger

Indirect

Evaporative

2 Cores 3 Cores 3 Cores 3 Cores

Direct

Evaporative

None None 3 Chillcel Pads 3 Chillcel Pads

Water

Water Supply

Min. 100kPa, Max

800kPa, 20L/min

Min. 100kPa, Max

800kPa, 20L/min

Min. 100kPa, Max

800kPa, 20L/min

Min. 100kPa, Max

800kPa, 20L/min

Inlet

1/2” male BSP

12V Solenoid

1/2” male BSP

12V Solenoid

1/2” male BSP

12V Solenoid

1/2” male BSP

12V Solenoid

Water

Consumption

44 L/hr 56 L/hr 60 L/hr 72 L/hr

Tank

45 L 65 L 65 L 65 L

Pumps

2 pumps,

13 L/min @ 1.5m head.

230V 50Hz

Input power 30W/ea

3 pumps,

13 L/min @ 1.5m head.

230V 50Hz

Input power 30W/ea

4 pumps,

13 L/min @ 1.5m head.

230V 50Hz

Input power 30W/ea

4 pumps,

13 L/min @ 1.5m head.

230V 50Hz

Input power 30W/ea

Drain

1

1/2

” male BSP

12 V motor

1

1/2

” male BSP

12 V motor

1

1/2

” male BSP

12 V motor

1

1/2

” male BSP

12 V motor

Chlorinators

1 chlorinator 1 chlorinator 1 chlorinator 1 chlorinator

Air Filters

Type G4

washable

305 * 610 * 50mm Qty 2

610 * 610 * 50 Qty 1

305 * 610 * 50mm Qty 3

610 * 610 * 50 Qty 1

305 * 610 * 50mm Qty 3

610 * 610 * 50 Qty 1

305 * 610 * 50mm Qty 3

610 * 610 * 50 Qty 1

Dimensions

Shipping

(Including

Pallet)

2050mm long

1375mm wide

1280mm high

2050mm long

2000mm wide

1280mm high

2050mm long

2000mm wide

1280mm high

2050mm long

2000mm wide

1280mm high

Operating

(Including

Filters and

Cowling)

2330mm long

1230mm wide

1610mm high

2330mm long

1825mm wide

1285mm high

2330mm long

1825mm wide

1285mm high

2330mm long

1825mm wide

1285mm high

Weight

Shipping

(Including

Pallet)

250 kg 320 kg 335 kg 335 kg

Operating

(Including

Filters,

Cowling,

Water)

255 kg 325 kg 340 kg 340 kg

Duct

Connections

Supply

500 x 500 mm 500 x 500 mm 500 x 500 mm 500 x 500 mm

Exhaust

500 x 500 mm 1825 x 220 mm 1825 x 220 mm 1825 x 220 mm

*Tested in accordance with ASHRAE 143 with conditions of 38° C Dry Bulb / 21° C Wet Bulb.

Stand alone cooling capacity may be lower, depending on application.

Frequency

(Hz)

Radiated Sound Power Level (dB(A) re 1pw) Octave Band Centre Frequency Total Sound Power

dB(A) re 1pw

125 250 500 1k 2k 4k 8k

CW-H10

70 60 58 57 54 50 42 63

CW-H15

84 68 65 62 55 51 44 70

CW-H15S

68 69 64 63 60 53 44 73

CW-H15S Plus 71 70 66 64 61 55 48 75

8 | CW-H10, H15, H15S, H15S Plus

COOLER SPECIFICATIONS

TECHNICAL SPECIFICATIONS - IMPERIAL CW-H MODELS

Specication CW-H15 CW-H15S CW-H15S Plus

Capacity

Airflow

2330 CFM @ 0.60 in WG 2330 CFM @ 0.52 in WG 3390 CFM @ 0.32 in WG

Maximum

External Static

Pressure

0.86 in WG 0.78 in WG 0.62 in WG

Nominal

Cooling

Capacity*

82,000 BTU/hr 93,800 BTU/hr 135,500 BTU/hr

EER

46 53 61

Electrical

Supply

Voltage / Frequency /

Current

Option 1 - 380-480V/3~/60Hz

3A per Phase / 8.5 MCA / 15 MOPD

Option 2 - 200-240V/3~/60Hz

6A per Phase / 14.5 MCA / 20 MOPD

Option 3 - 200-277V/1~/60Hz

8A per Phase / 11.5 MCA / 15 MOPD

Input Power

1.8 kW 1.8 kW 2.2 kW

Fan/Motor

Type

22” dia

Backward Curved

22” dia

Backward Curved

22” dia

Backward Curved

Control

Variable Speed

ECM PWM Control

Variable Speed

ECM PWM Control

Variable Speed

ECM PWM Control

Maximum Speed 1350 rpm 1350 rpm 1460 rpm

Heat

Exchanger

Indirect

Evaporative

3 Cores 3 Cores 3 Cores

Direct

Evaporative

None 3 Chillcel Pads 3 Chillcel Pads

Water

Water Supply

Min. 15 psi, Max 115 psi,

5.3 gal/min

Min. 15 psi, Max 115 psi,

5.3 gal/min

Min. 15 psi, Max 115 psi,

5.3 gal/min

Water

Consumption

15 gal/hr 16 gal/hr 19 gal/hr

Inlet

1/2” male NPT

12V Solenoid

1/2” male NPT

12V Solenoid

1/2” male NPT

12V Solenoid

Tank 17 gal 17 gal 17 gal

Pumps

3 pumps,

3.4gal/min @ 4.9’ head.

220V 60Hz

Input power 32W/ea

4 pumps,

3.4gal/min @ 4.9’ head.

220V 60Hz

Input power 32W/ea

4 pumps,

3.4gal/min @ 4.9’ head.

220V 60Hz

Input power 32W/ea

Drain

1

1/2

” male BSP

12 V motor

1

1/2

” male BSP

12 V motor

1

1/2

” male BSP

12 V motor

Chlorinators 1 chlorinator 1 chlorinator 1 chlorinator

Air Filters

MERV 8 washable 12 * 24 * 2” Qty 3

24 * 24 * 2” Qty 1

12 * 24 * 2” Qty 3

24 * 24 * 2” Qty 1

12 * 24 * 2” Qty 3

24 * 24 * 2” Qty 1

Dimensions

Shipping

including pallet

81” long

79” wide

51” high

81” long

79” wide

51” high

81” long

79” wide

51” high

Operating including

filters,

cowling

92” long

72” wide

51” high

92” long

72” wide

51” high

92” long

72” wide

51” high

Weight

Shipping

including pallet

705 lb 740 lb 740 lb

Operating including

filters,

cowling, water

715 lb 750 lb 750 lb

Duct

Connections

Supply 20 x 20” 20 x 20” 20 x 20”

Exhaust 70 x 8.5” 70 x 8.5” 70 x 8.5”

*Tested in accordance with ASHRAE 143 with conditions of 100° F Dry Bulb / 70° F Wet Bulb.

Stand alone cooling capacity may be lower, depending on application.

Frequency

(Hz)

Radiated Sound Power Level (dB(A) re 1pw) Octave Band Centre Frequency Total Sound Power

dB(A) re 1pw

125 250 500 1k 2k 4k 8k

CW-H15

84 68 65 62 55 51 44 70

CW-H15S

68 69 64 63 60 53 44 73

CW-H15S Plus

71 70 66 64 61 55 48 75

SEELEY INTERNATIONAL

- INSTALLATION MANUAL | 9

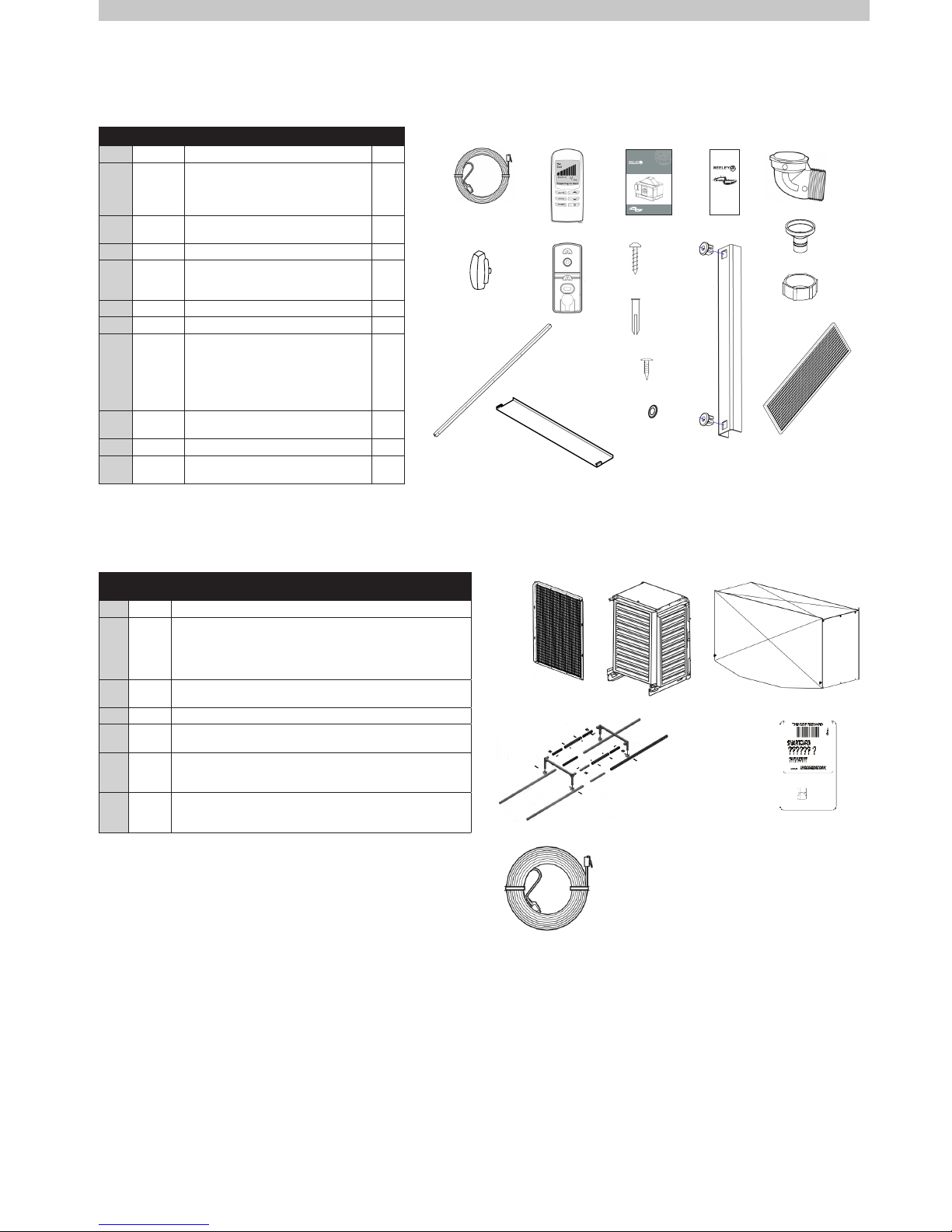

COOLER CONTENTS

COOLER INSTALLATION COMPONENTS

OPTIONAL COMPONENTS

Item Part No. Description QTY

1 834245 Control Cable 20m (65’) 1

2A

2B

2C

2D

114279

584331

804644

805306

Wall Control CW-H

Plate Mount Wall Control

Screw Pan Ph 6AB*1" ZNP

Plug Rawl Yellow 5mm Dia

1

1

2

2

3 859379

Instruction - Installation, Operation,

Maintenance

1

4 879345 Warranty Card (USA Only) 1

5A

5B

5C

861883

593104

861593

Adaptor Drain Elbow

Adaptor, Drain 32/20mm

Nut, Pipe Fitting 1.5” BSP

1

1

1

6 - Handle, Control Box 1

7 637994 Exhaust Centre Post 1

8A

8B

8C

8D

8E

8F

805597

804446

804422

864341

864385

864372

Screw 8AB x ½” Pan Phill SS

Screw SEMS HX 14*3/4" ZNP

Plastic Grommet Size 14

Screw Set SHCS M6*35mm SS

Washer Flat M6*12.5OD*1.2 SS

Washer Flat NYLON M8*16OD

10

11

5

4

4

4

9 931685 Exhaust Side Rails (1176mm Long)

(UNDER LID)

2

10 834785 Exhaust Grille (869x205) (UNDER LID) 2

11 637999

Exhaust Cap (UNDER LID)

CW-H15S Plus Only

2

Item

Seeley

Part

Description

1 120202 Inlet Air Safety Grille

2A

2B

2C

2D

120409

120379

120430

120447

Inlet Air Filter Frame inc. Filters (CW-H10)

Inlet Air Filter Frame inc. Filters (CW-H15, H15S, H15S Plus)

Bushre Rated Inlet Air Filter Frame inc. Filters (CW-H10)

Bushre Rated Inlet Air Filter Frame inc. Filters

(CW-H15, H15S, H15S Plus)

3A

3B

120416

120386

Inlet Air Filter Cowling (CW-H10)

Inlet Air Filter Cowling (CW-H15, H15S, H15S Plus)

4 094724 Control Cable 40M

5A

5B

134192

134215

Roofstand 0-10O (CW-H10)

Roofstand 0-10O (CW-H15, H15S, H15S Plus)

6A

6B

6C

094397

093970

TBC

CW-H15S Conversion 380-480V/3~

CW-H15S Conversion 220-240V/3~

CW-H15S Conversion 220-240V/1~

7A

7B

7C

094366

TBC

TBC

High Altitude Smartcard 380-480V/3~ (CW-H15)

High Altitude Smartcard 200-240V/3~ (CW-H15)

High Altitude Smartcard 200-240V/1~ (CW-H15)

ITEM 1. ITEM 2A

ITEM 2B

ITEM 9

ITEM 10

ITEM 11

ITEM 2C

ITEM 2D

ITEM 3

ITEM 4

ITEM 5A

ITEM 6

ITEM 5C

ITEM 5B

INSTALLATION,OPERATION&MAINTENANCE

(English)(CW-H15)

ClimateWizard–CW-H10,CW-H15

IndirectEvaporativeCooler

WARRANTYINFORMATION

DUCTEDINDIRECTEVAPORATIVE

AIRCOOLER

INTERNATIONAL

ITEMS 7&8C

ITEMS 8A, 8B&8D

ITEMS 8E&8F

ITEM 1 ITEMS 2A &2B

ITEM 4

ITEM 16

ITEM3

ITEM 5 ITEM 7ITEM 6

Not Shown

ILL2425-A

ILL2424-A

ITEM 4

10 | CW-H10, H15, H15S, H15S Plus

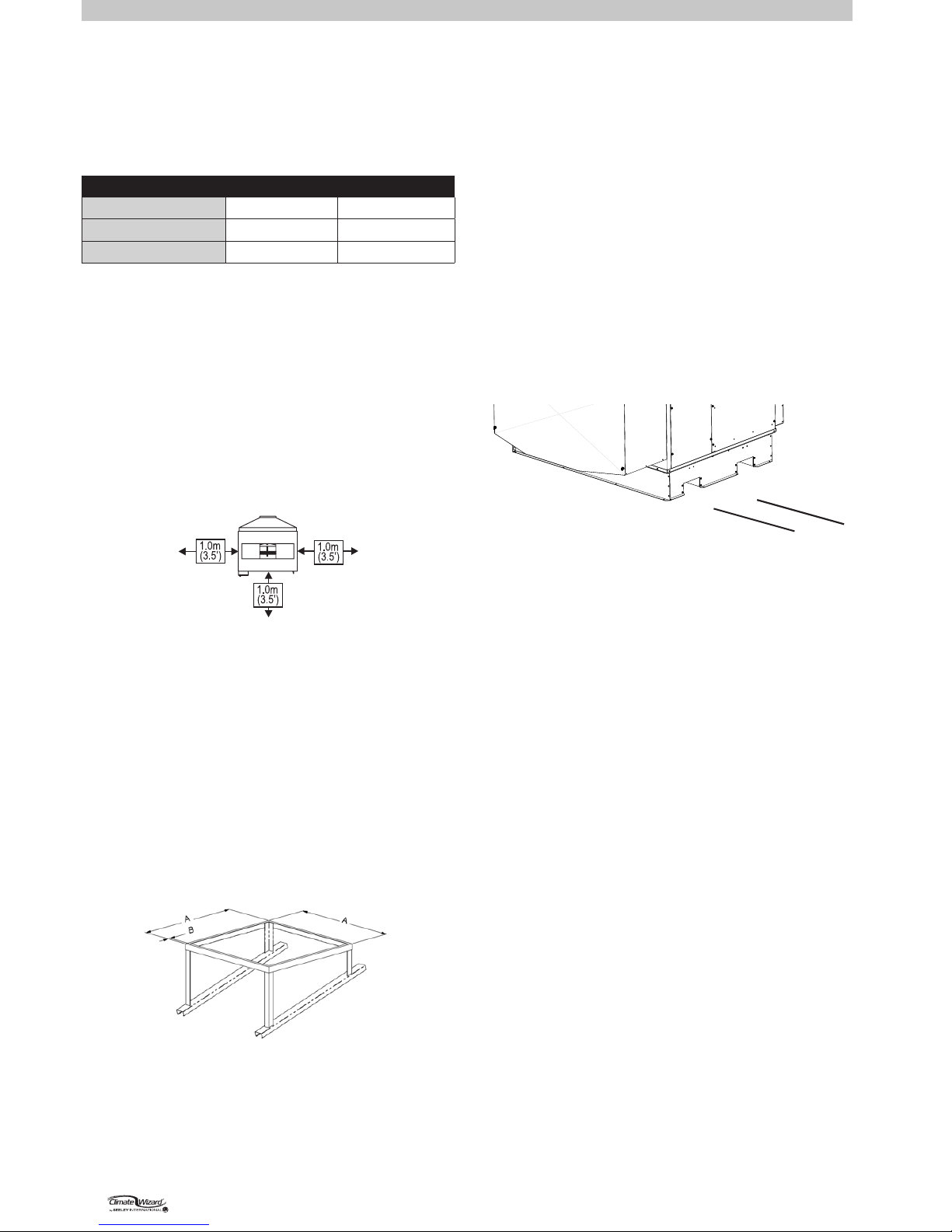

INSTALLATION

COOLER LOCATION

Check the proposed cooler location, to ensure that it is

structurally capable of supporting the weight of the cooler, or

provide an adequate alternate load bearing structure.

Model Shipping Weight Operating Weight

CW-H10 250kg (550 lb) 255kg (560 lb)

CW-H15 320kg (705 lb) 325kg (715 lb)

CW-H15S, H15S Plus 335kg (740 lb) 340kg (750 lb)

Always locate the cooler where it will receive a plentiful supply

of fresh air, NOT in a recess where it may be starved for air or

where the air is polluted.

Air exiting the exhaust hood is warm and heavily laden with

moisture. Ensure the cooler’s exhaust outlet location will not

cause corrosion or damage to other nearby items. Do not allow

exhaust air to re-circulate into the air intake of the cooler.

Ensure the location is a minimum of:

• 3.0m (10’) from a solid fuel heater ue,

• 1.5m (5’) from a gas ue,

• 5.0m (16’) from a sewer vent

• Rear = Min 1.0m (3.5’) from a wall, 1.0m (3.5’) at sides to

allow easy access for maintenance and core replacement.

ILL1925-A

Allow adequate access to and around the cooler for

maintenance. Provision must be made for access to electricity,

water supplies and drains.

Note! Do you need to discuss the installation of items like

safety anchor points with the customer?

MOUNTING/SUPPORT

Industry standard support frames can be used with this cooler.

Recommended steel specication:

50 x 50 x 3mm (2” x 2” x 1/8”) RHS Galvanized or Painted

Specic CW-H Roofstands are available for order via Seeley

International to suit cooler size and accommodating 5 or 10

degree roof pitches.

CW-H10: 0-10º - P/No. 134192

CW-H15: 0-10º - P/No. 134215

ILL2426-A

CW-H10:

A = 1300mm (51.2”) x 1206mm (47.5”)

CW-H15, H15S, H15S Plus:

A = 1300mm (51.2”) x 1800mm (70.9”)

CW-H10, CW-H15, H15S, H15S Plus:

B = 50mm min (2” min.)

Angle to match roof pitch

UNPACKING THE COOLER

The cooler will be delivered wrapped in a plastic stretch wrap

lm which will need to be removed before installation. A small

bag of installation components along with the exhaust transition

side rails and grilles can be found under the lid of the main

cabinet of the cooler. The exhaust transition will need to be

raised into place before operation.

The wall control and communications cable, along with ancillary

mount plates, fasteners and drain adaptors will need to be

placed aside for later connection.

WARNING: Once unwrapped, the exhaust transition assembly

should be tted together as soon as practicable to avoid loose

components becoming lost/damaged and/or a hazard.

MOVING THE COOLER

The cooler has in-built fork-truck tyne openings in the base for

ease of movement. The openings can also be used with lifting

straps or slings (refer diagram & see below).

ILL1916-A

Min. Fork tyne gap =

460mm (18.2”)

LIFTING THE COOLER

The cooler may be lifted either by fork-truck or crane with slings.

The method for lifting by crane is by lifting straps through the

cooler base fork-truck tyne openings. Do not attempt to lift using

any cabinet features or by retro-tting lifting lugs. The cabinet

may be damaged and/or lift safety compromised.

It is recommended to use a spreader bar on the straps or slings

and/or to protect the upper edges of the cooler with a corner

protector beneath the lifting straps to avoid any damage to the

cabinet during the lift.

VIBRATION ISOLATION

Wae pads are recommended to be used under each corner

of the cooler. Pad size approx. 200mm (8”) x 200mm (8”). Use

industry standard methods of xing to the building structure.

DRIP-TRAY

When Climate Wizard coolers are installed indoors, or

anywhere that water leakage could cause damage, install

a corrosion resistant drip tray under the whole machine.

Recommended sizes:

CW-H10:

1500w x 1300d x 50h mm (59”w x 51”d x 2”h)

CW-H15, H15S, H15S PLUS:

1500w x 1900d x 50h mm (59”w x 75”d x 2”h)

Apply silicone sealant between drip-tray and cooler base at

every xing.

SUPPLY AIR DUCT CONNECTIONS

Vibration absorbing exible connections are recommended

for all duct connections to the cooler, for any ducts that are

attached to the building structure. All ducts attached to the

exible connection must be independently supported.

SEELEY INTERNATIONAL

- INSTALLATION MANUAL | 11

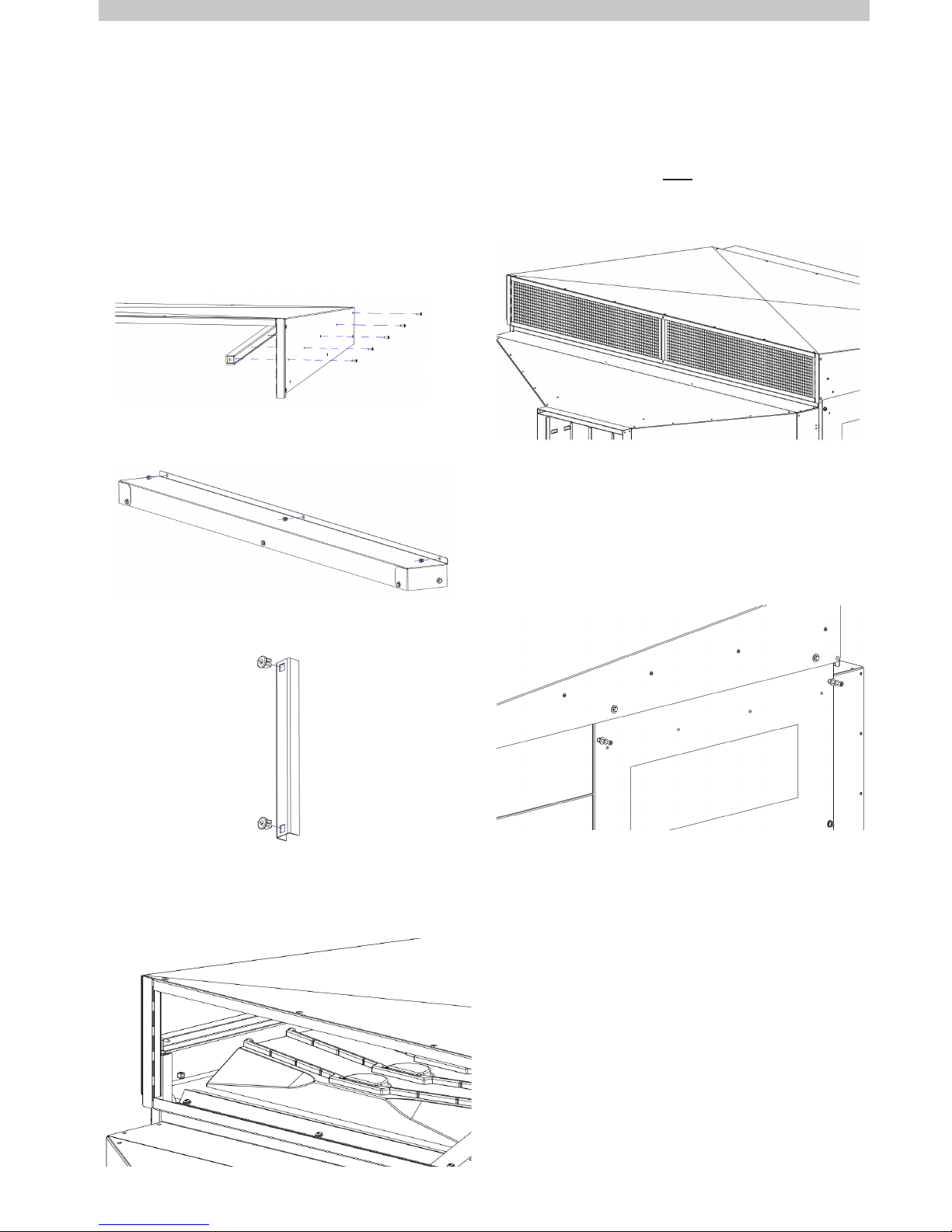

INSTALLATION cont.

8. Fit the supplied 4 x M6 x 35MM SET SCREW, STAINLESS

STEEL FLAT WASHER, NYLON FLAT WASHER to the tops

of both core access doors. Apply a liberal coat of anti-seize

paste to the screw thread prior to tment.

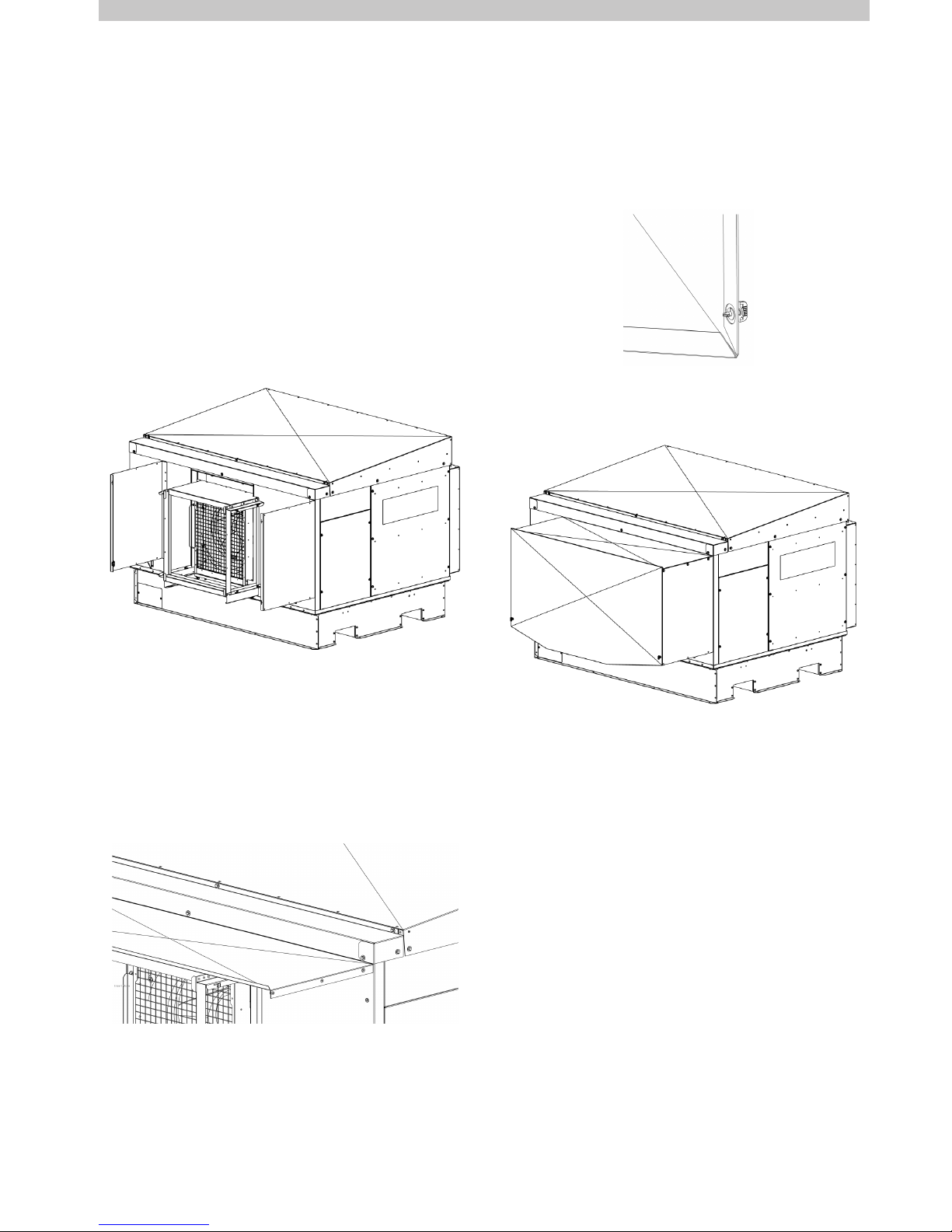

EXHAUST TRANSITION ASSEMBLY

The exhaust transition is supplied in knock-down form and its

components are to be found beneath the lid of the cooler and

inside the component kit.

1. Lift the large top panel and locate;

• 2 x EXHAUST SIDE RAILS (1176mm Long)

• 2 x EXHAUST GRILLE (869 X 205)

• 2 x EXHAUST CAPS (CW-H15S Plus Only)

2. Fit the EXHAUST SIDE RAILS to the inside vertical faces

of the large top panel with the supplied 10 x SCREW PAN

PHILLIPS 8AB*1/2” SS. Ensure the foam seal faces down.

ILL2427-A

3. Fit the supplied 3 x PLASTIC GROMMET SIZE 14 to the

rear lid panel upstand square holes.

ILL2428-A

4. Fit the supplied 2 x PLASTIC GROMMET SIZE 14 to the

EXHAUST CENTRE POST.

ILL2429-A

5. Position the large top panel over the top of the cooler, with

the rear u-channel over the top of the upstand, the side rails

sitting on the tops of the cooler side walls and the end posts

sitting on the outside of the front tray.

ILL2428-A

6. Slip the 2 x EXHAUST GRILLE and 1 x EXHAUST CENTRE

POST into position, retained inside the top panel front

u-channel.

CW-H15S Plus ONLY: Before tting to the cooler, slide an

EXHAUST CAP over the back of each EXHAUST GRILLE.

The EXHAUST CAP covers the top portion of the EXHAUST

GRILLE, and is designed to optimise the CW-H15S

Supercool performance.

ILL2431-A

7. Screw the exhaust transition assembly to the cooler body

with the supplied 11 x SCREW SEMS HEX 14 x 3/4” ZP.

3 x Rear Upstand, 3 x Left Side, 3 x Right Side, 2 x Centre

Post.

ILL2432-A

EXHAUST DUCT CONNECTION REQUIREMENTS

If required, the exhaust discharge opening may be ducted away

from the cooler. When designing the exhaust duct please note

the following;

• The exhaust air is warm and heavily laden with moisture.

Ensure the exhaust opening is located and oriented in such a

way as to avoid exhaust air re-entering the cooler inlet.

• Access to the heat exchanger cores requires the removal of

the cooler lid/exhaust transition. Ensure any additional ducting

is readily removable and/or lightweight.

• Where an installation requires extended exhaust ducts, the

increase in static load should not exceed 20 Pa (0.08 in wg).

12 | CW-H10, H15, H15S, H15S Plus

INSTALLATION cont.

INLET AIR FILTER ASSEMBLY OR SAFETY GRILLE

Climate Wizard coolers SHOULD NEVER BE INSTALLED

WITHOUT DUST FILTERS.

Use either the Inlet Air Filter Assembly supplied from the factory

or use the cooler with pre-ltered air to EN779 G4 or ASHRAE

52.2 MERV8 standards.

Should the Inlet Air Filter Assembly not be required an Inlet Air

Safety Grille is available and MUST be tted for safety reasons.

Other Safety Grilles cannot be substituted.

The Inlet Air Filter Assembly or Safety Grille is supplied in

separate cartons when shipped with the Climate Wizard.

OPTION 1 – INLET AIR SAFETY GRILLE (FOR USE WITH

PRE-FILTERED AIR ONLY)

CW-H10, CW-H15, H15S, H15S Plus: = P/N 120102

OPTION 2 - INLET AIR FILTER ASSEMBLY

CW-H10: = P/N 120409

CW-H15, H15S, H15S Plus: = P/N 120379

1. Remove the air lters from their shipping position in the

frame.

2. Fit the Inlet Air Filter Assembly using the 4 x M6 x 16mm Set

Screws and Washers pre-tted to the front face of the air

inlet recess. Ensure the frame is centred around the fan inlet

cone.

ILL2433-A

Fit the Inlet Air Safety Grille

using the 4 x M6 X 16MM SET

SCREWS AND WASHERS pre-

tted to the inside surfaces of

the air inlet recess.

ILL2434-A

3. Re-t the air lters, ensuring the sticker showing direction of

air ow is the correct way round.

ILL2436-A

ILL2437-A

CW-H10 CW-H15, H15S, H15S Plus

ILL2435-A

SEELEY INTERNATIONAL

- INSTALLATION MANUAL | 13

INSTALLATION cont.

INLET AIR FILTER COWLING ASSEMBLY

Climate Wizard coolers installed outside should be tted with an

inlet air cowling assembly to protect the air lters from exposure

to water. It features a detachable front panel for easy access to

the lters.

The Inlet Air Cowling Assembly is supplied in a separate carton

when shipped with the Climate Wizard. It contains a small bag

of fasteners required for tment to the cooler.

CW-H10: = P/N 120416

CW-H15, H15S, H15S Plus: = P/N 120386

1. Fit the 2 x Cowling Side Panels. Ensure the black plastic

tting is at the bottom of the panel.

a. CW-H15, H15S, H15S Plus: – Screw the cowling side

panels to the cooler using the supplied 6 x SCREW SEMS

HEX 14 x 3/4” ZP into the pre-tted plastic grommets tted

to the cooler body.

4. Screw the cowling side panel and the top panel to the cooler

body with supplied 6 x SCREW SEMS HEX 14 x 3/4” ZP.

5. Fit the supplied 2 x quarter-turn, self-ejecting fasteners to

the Cowling Front Panel. Ensure the supplied split washer is

tted as shown.

b. CW-H10 – Fit the right hand side panel as above.

Fit the left hand side panel using the same pre-tted M6 x

16mm Set Screws and Washers used to t the lter frame to

the cooler.

2. Fit the supplied 6 x PLASTIC GROMMET SIZE 14 to the

sides of the Cowling Top Panel

3. Remove the pre-tted centre and right hand screws from

the cooler lid back panel. Slip the long large upstand of the

Cowling Top Panel under the lip of the cooler lid back panel

and re-t the screws.

ILL2438-A

ILL2439-A

6. Rest the return fold of the cowling front panel on the lip of

the top panel. Secure the bottom corners using the quarterturn self-ejecting fasteners.

ILL2440-A

ILL2441-A

14 | CW-H10, H15, H15S, H15S Plus

INSTALLATION cont.

WATER SUPPLY INSTALLATION

Climate Wizard requires a permanent water supply to be

connected.

Installation of the water supply to the cooler must conform to

local plumbing rules, regulations and standards:

The following specications for water supply are required:

• Water Connections:

½” BSP (Aus/Eur), ½” NPT (USA)

male connection supplied suitable for a compression tting.

• Water Supply:

100kPa (15psi) - 800 kPa (115psi)

MAXIMUM @ 20L/min (5.3 gal/min)

• Water Supply Temperature:

40°C (105°F) MAXIMUM

• Water Supply Salinity:

100 to 1150µS/cm

Important! If the water pressure exceeds this maximum

specication then a pressure reducing valve is required and

must be supplied and tted by the installer.

The installer must provide a manual 1/4 turn ball type shut o

valve (do not use a stop cock) in the water supply line adjacent

to the cooler, subject to local plumbing regulations. This allows

the water supply to be isolated whenever work needs to be

done on the cooler.

In areas subject to freezing, the water line needs a drain

down facility.

WATER SUPPLY FILTRATION

Seeley International requires an inlet lter to be installed on

the water supply line, external to the Climate Wizard cooler

to prevent any debris from entering and damaging cooler

components.

Important! Flush the water pipe to remove any contaminants

(swarf, lings or dirt) before nal tting. Contaminants can lodge

in the solenoid, preventing it from functioning correctly.

Climate Wizard’s water management system is designed to

use water that is suitable to be classied as ‘potable’ and t for

human consumption. If alternative water (including rain water)

is to be used that contains high levels of salinity, hardness,

acidity or chemical contaminants, then additional ltration or

treatment systems should be employed to render the water

‘potable’.

WATER HAMMER

Not all installation pipeworks are the same, and some may

require additional prevention against water hammer.

If water hammer is a problem, it is the responsibility of the

Installer to t an appropriate water hammer arresting device

external to the cooler.

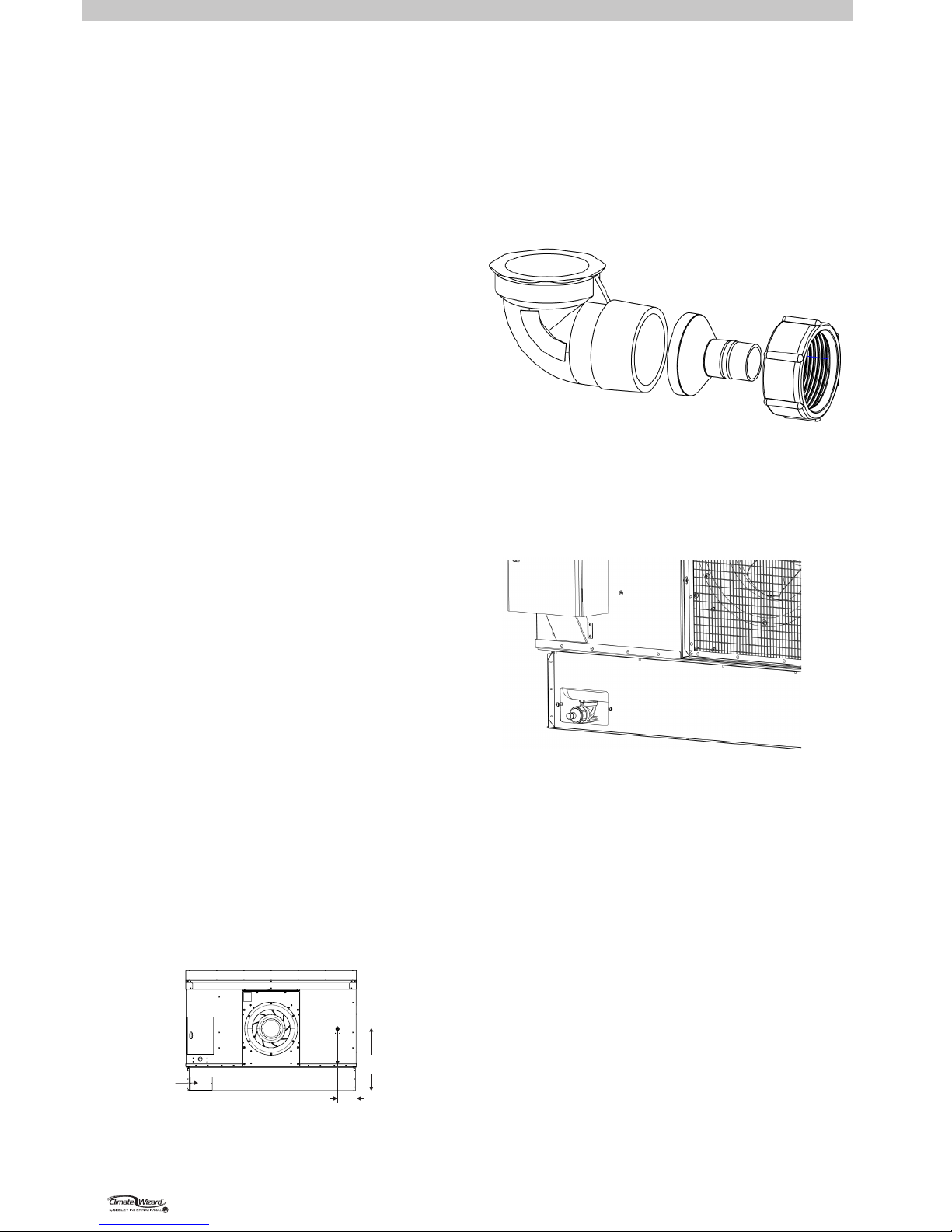

WATER DRAIN INSTALLATION

Climate Wizard coolers require a permanent water drain to

be connected. A built-in Drain Valve, controlled by the water

management system, releases water from the cooler when

required.

The cooler installation kit contains components to congure the

Drain Valve discharge to one of the following options;

ACCESS COVER

FOR DRAINVALVE

CONNECTION

WATER CONNECTION

1/2”MALE NIPPLE

(Water connection may

require an adaptor to

suit local pipe sizes)

660mm

(26”)

200mm

(7.9”)

DO NOT OVER-TIGHTEN

OR CROSS-THREAD

COMPRESSION

FITTINGS

ONTO THE PLASTIC

WATER INLET NIPPLE.

REAR VIEW

ILL1940-B

The correct drain system must be used. Water drained from

the drain valve is high in salinity and must be carried away

to a suitable discharge point on the building or property, in

accordance with local regulations. It is a requirement of

Seeley International - Never drain the water directly onto

the roof.

• Down Discharge 1.5” (40mm) BSP Male

• Down Discharge 20mm Push On Hose

• Rear Discharge 1.5” (40mm) BSP Male

• Rear Discharge 20mm Push On Hose

An access panel can be removed for rear discharge options.

ILL2442-A

ILL2442-A

Loading...

Loading...