Page 1

Installation Instructions

For CT-BNC59C Compression RG-59 BNC Connector,

Using CT-CCT-BFR1 Compression Crimping Tool

Step 1: Cable Preparation

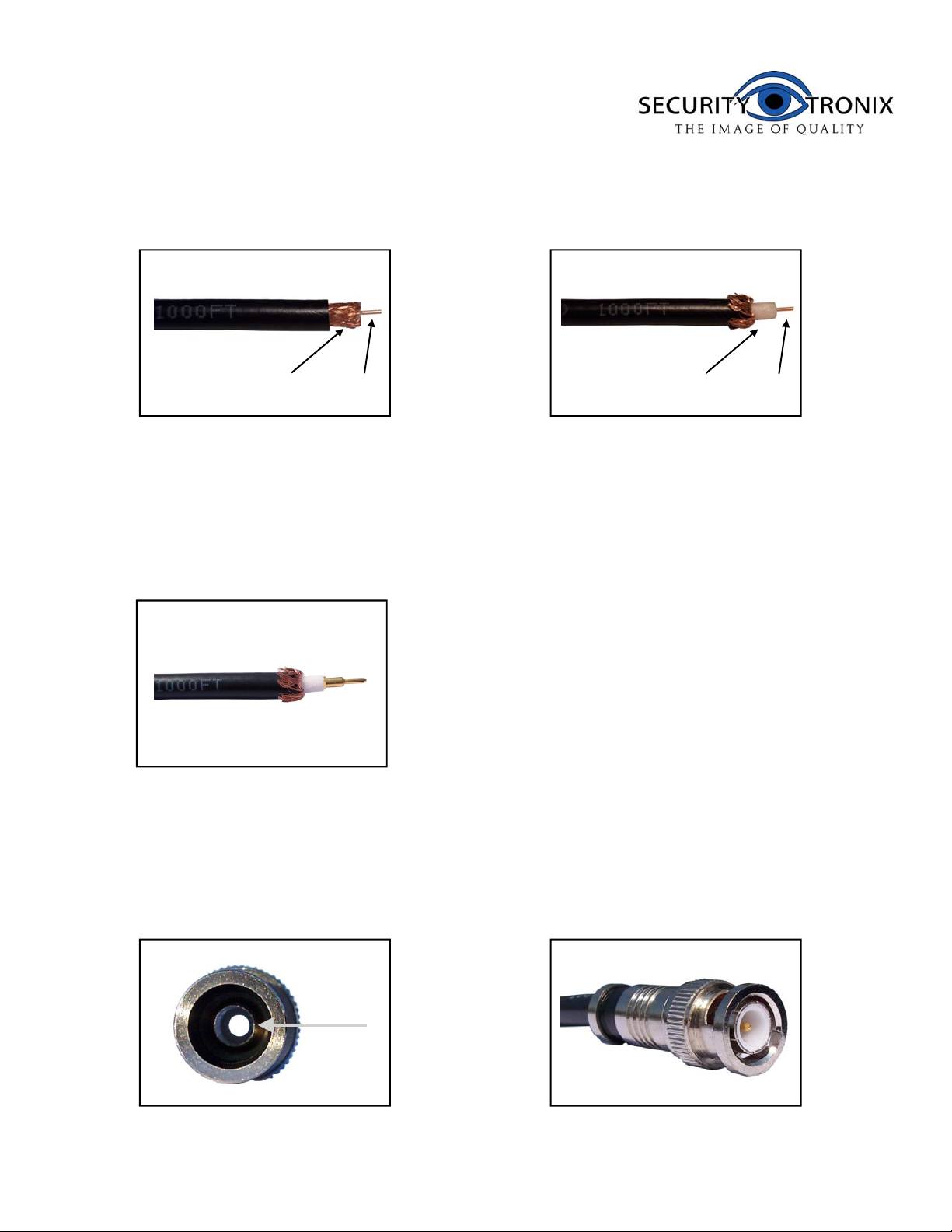

Using a two blade cable stripping tool (CT-WS568 recommended) prepare the RG-59 coaxial cable with the first

cut exposing 1/8” of the center conductor and the second cut exposing 1/4” of the cable’s foam dielectric (Figure 1).

1/4”

Figure 1 Figure 2

Fold the braiding back over the cables jacket making sure that none of the braiding strands have wrapped around

the center conductor (Figure 2). If any of the strands remain in contact with the center conductor a short will be

created causing the connection to fail.

1/8”

1/4”

1/8”

Step 2: Pin Insertion

Push the connectors pin over the cable’s center conductor making sure that the base of the pin seats snugly

against the top of the foam dielectric (Figure 3).

Figure 3

Step 3: Connector Body Insertion

Insert the pin end of the prepared cable into the center channel of the body of the BNC connector making sure that

the dielectric is inserted smoothly into the dielectric channel of the connector (Figure 4). Push the connector using

a firm twisting motion until the connector is seated snugly on the cable. The center pin should be visible in the

connection end of the BNC connector and will be slightly recessed from the end of the connector (Figure 5).

Figure 4

Figure 5

www.securitytronix.com sales@securitytronix.com

Page 1

Page 2

Installation Instructions

For CT-BNC59C Compression RG-59 BNC Connector,

Using CT-CCT-BFR1 Compression Crimping Tool

Step 4: Preparing The CT-CCT-BFR1 Crimping Tool

Set the plunger depth of the crimping tool to the #5 mark by turning the plunger until the outer edge of the plunger

is in line with the #5 mark (Figure 6). Lock the plunger in place using the set stop located at the other end of the

threaded plunger rod (Figure 7).

Figure 6 Figure 7

Step 5: Crimping The Connector

Place the end of the assembled BNC connector cable assembly onto the inside edge of the plunger (Figure 8).

Press the cable into the spring loaded jaws of the crimping tool (Figure 9). Compress the connector slowly being

sure the cable remains properly seated in the spring loaded jaws (Figure 10).

Figure 8 Figure 9

Properly Crimped Connector

Figure 11 Figure 12

www.securitytronix.com sales@securitytronix.com

Figure 10

Page 2

Loading...

Loading...