Page 1

Securitron Magnalock Corp. www.securitron.com ASSA ABLOY, the global leader

Tel 800.624.5625 techsupport@securitron.com

in door opening solutions

INSTALLATION AND OPERATING INSTRUCTIONS

For Model M38 and M68 Magnalocks

(Versions “L”, “S” and “LS” with “D” and “T” Options)

1. INTRODUCTION

Securitron’s Model M38 and M68 Magnalocks are fail safe electromagnetic locks designed for

*interior use in areas which require controlled access or egress. Each unit includes an

interlocking mounting bracket and a power and control wiring access compartment which

provides the added convenience of wiring “at-the-lock”. The sleek, low-profile design provides a

professional looking, unobtrusive integration into a wide range of architectural applications and

can be easily retrofitted to replace existing m agnetic lock systems.

* M38 and M68 Magnalocks are not designed, recommende d or approved for exterior (outdoor)

use. Interior use is described as any door installation to the interior of a building (i.e. offices,

work or storage rooms) or to the interior side

2. SPECIFICATIONS

M38:

M68:

Holding Force: 600 Lbs. [272 Kg] Holding Force: 1,200 Lbs. [544 Kg]

Dimensions:

Inches: 10-1/2”L X 2-9/16”H X 1-9/16”D

Millimeters: 267 L X 65 H X 40 D

Electrical:

12 Volts DC:

Current Requirement: 300 – 325 mA

Power Consumption: 3.6 Watts

24 Volts DC:

Current Requirement: 150 – 175 mA

Power Consumption: 3.6 Watts

3. PRODUCT OVERVIEW

Upon unpacking this product, an inventory should be made to ensure that all the required

components and hardware have been included. Along with these instructions and the

installation template, the lock assembly (M38 Shown) should include the following items:

of any perimeter exterior door.

Dimensions:

Inches: 10-1/2”L X 3-5/8”H X 1-13/16”D

Millimeters: 267 L X 92 H X 46 D

Electrical:

12 Volts DC:

Current Requirement: 250 – 275 mA

Power Consumption: 3.0 Watts

24 Volts DC:

Current Requirement: 125 -150 mA

Power Consumption: 3.0 Watts

Mounting Bracket

Strike Plate

Hardware Pack

Magnetic Lock

Housing

Sex Bolt

© Copyright, 2012, all rights reserved PN# 500-21400

Page 1 Rev. C, 05/12

Page 2

4. RECOMMENDED TOOLS

Hammer Wrench, 1/2” box-end

Center punch Pliers, vise grip

Drill motor Screwdrivers: #1 and #3 Phillips

Drill bits: 3/16”, 7/32” 3/8” and 1/2” Hex (Allen) wrenches: 1/16” (provided) & 3/16”

5. INSTALLATION INSTRUCTIONS

5.1. Pre-Installation Survey

Due to the variety of mounting configurations available with this product, it is strongly

recommended that an initial survey and assessment be made of the physical area to which

the Magnalock will be installed. A determination of the optimal method o f mounting should b e

made prior to installation with considerations made to the following:

A. Physical strength of mounting area. The structural integrity of mounting surfaces

must be strong enough to meet or exceed the holding force of the Magnalock.

B. Protection of the lock from external attack. The Magnalock and the wiring must be

protected to a reasonable degree from potential damage due to intruders or

vandals.

C. Convenience and accessibility of area to be protected. The Magnalock assembly

should be installed in a location that will not hinder or create a potential safety

hazard to authorized personnel routinely accessing the protected area.

The mounting configuration addressed in detail in this manual will be for an outswinging

door. All hardware required for the outswinging mount configuration has been included with

this unit. For the inswinging version of mounting, a bracket accessory Top Jam Kit (TJ-38 or

TJ-68 Series) is required. Both kits are available through Securitron. The following

illustrations show two basic mounting configurations:

Outswinging Door Mount

Inswinging Door Mount (with TJ-38 Kit)

The Magnalock should normally be mounted under the door frame header in the corner

furthest from the hinges. Most commonly the lock is positioned horizontally but vertical

orientation may also be considered. In some cases for example, the horizontal header on an

aluminum frame glass door is not as strong as the vertical extrusion, so vertical mounting

would obviously be preferred. This (outswinging) type of installation places the Magnalock on

the opposite side of the door as the door swings away from the lock. This configuration

should be used for all facility exit doors (otherwise the lock would be located on the outside

of the building). For interior doors, it is also recommended that the lock be mounted in this

manner unless security planning anticipates a physical assaul t on the lock from that side of

the door in which case the inswinging mounting kit (TJ-38 or TJ-68) should be obtained from

Securitron.

PN# 500-21400

Page 2 Rev. C, 05/12

Page 3

5.2. Door Lock Installation

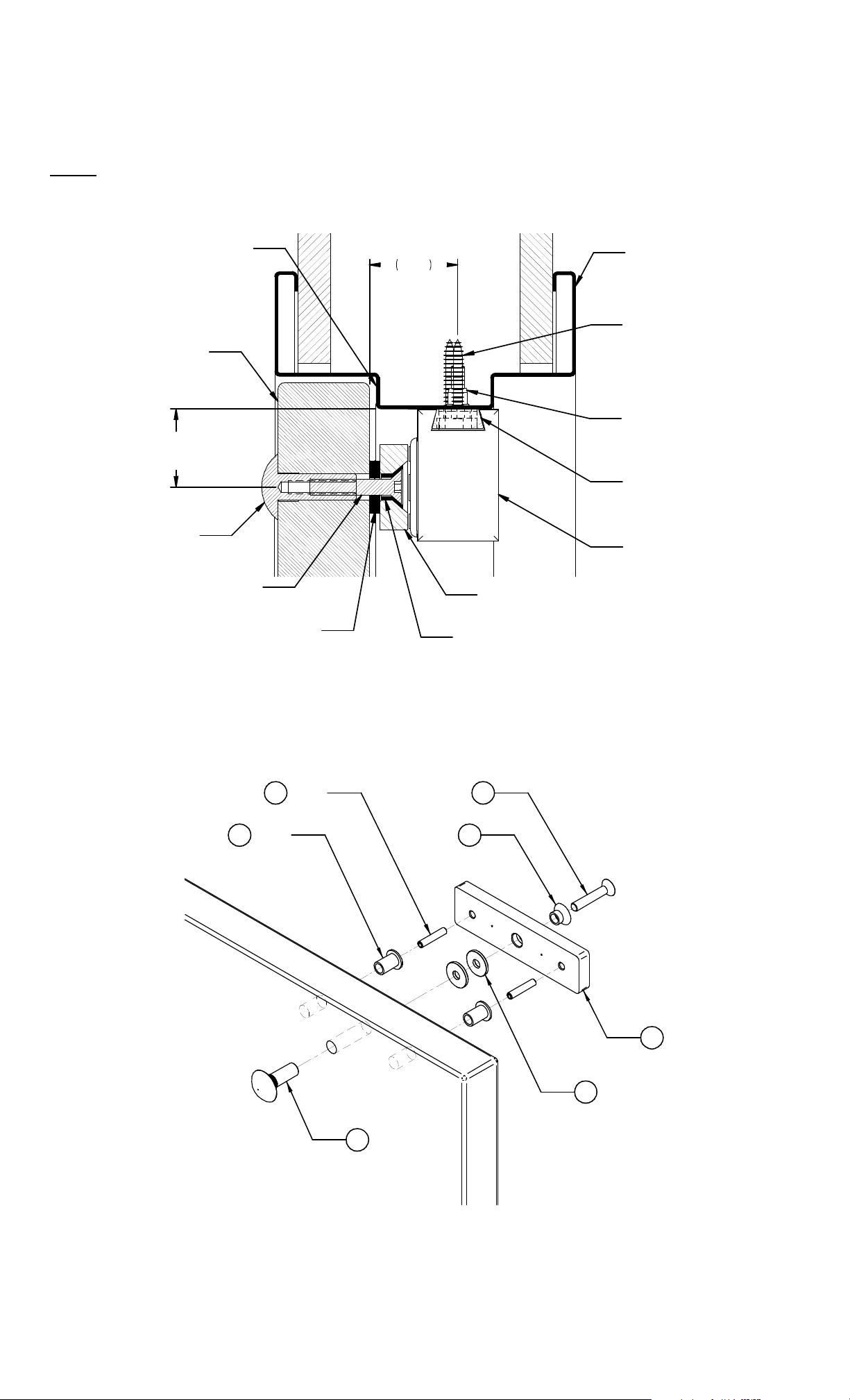

Figure 1 below is a typical cross section view of an M38 installed to a metal door frame in

the outswinging door mount configuration:

Note:

Reference dimensions are in parenthesis – see the product mounting template for

clarification.

(DOOR STOP)

(DOOR)

(1.50 [38.1mm] - M38)

(2.04 [51.8mm] - M68)

SEX BOLT

5/16" STRIKE

MOUNTING SCREW

(2-3X) RUBBER

5.2.1. Door Preparation

Figure 2 below is an exploded illustration of the assembly of the strike to the door:

WASHERS

1.74

([44.2mm])

Figure 1

(DOOR FRAME)

(METAL)

(3X) #12 X 1-1/2"

LONG TYPE "A"

SCREW

(2X) BLIND NUT &

1/4-20 X 1" LONG

MACHINE SCREW

LOCK MOUNT

BRACKET

LOCK HOUSING

(M38 SHOWN)

STRIKE PLATE

(M38 SHO WN)

STRIKE BUSHING

2(X2)

1(X2)

5

4

3

6(X3)

7

Figure 2

PN# 500-21400

Page 3 Rev. C, 05/12

Page 4

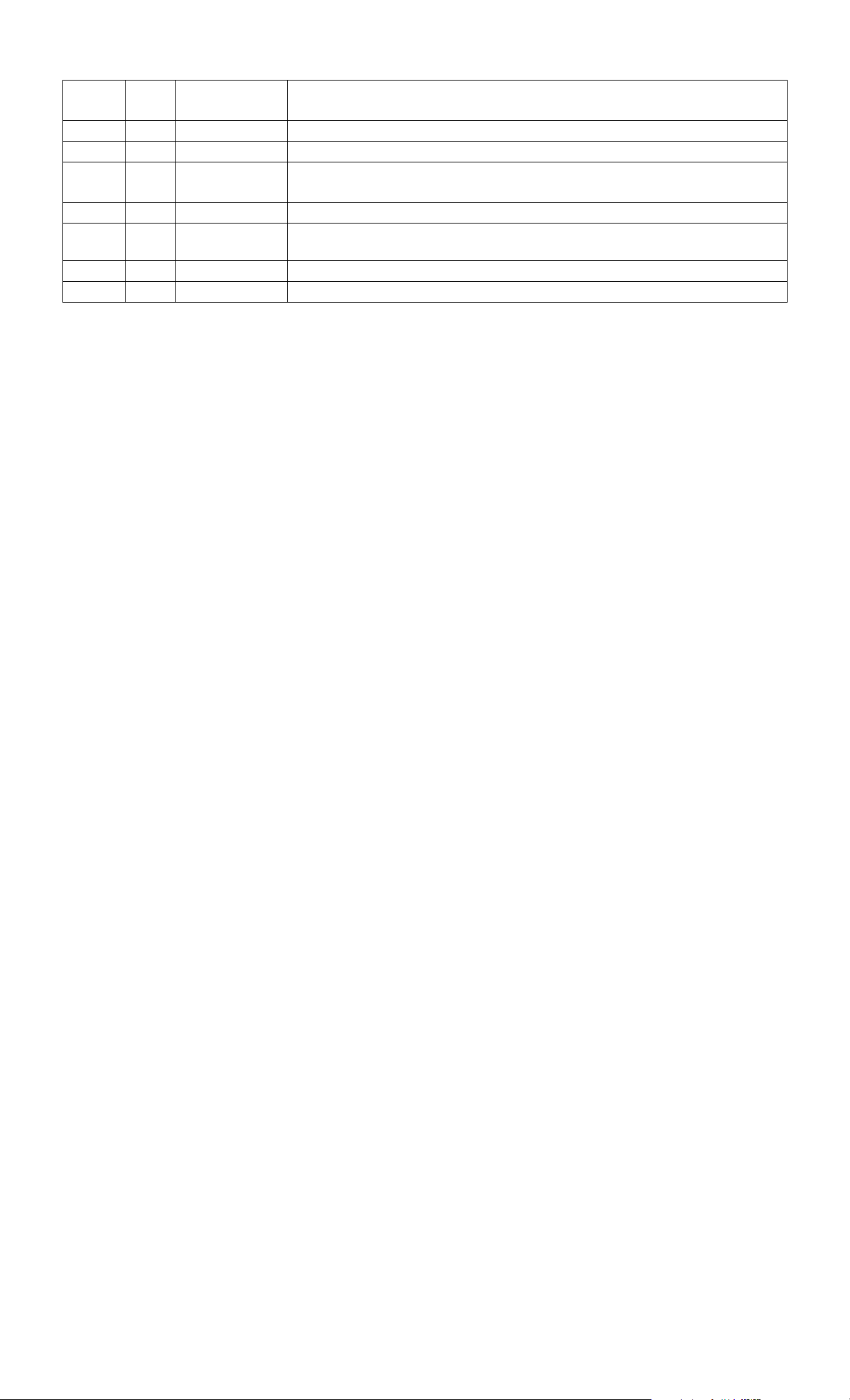

PART

ITEM QTY

NUMBER

NOMENCLATURE/DESCRIPTION

1 2 560-12050 Strike Roll Pin Bushing, Clear, Nylon

2 2 330-10800 Roll Pin, 1/4” X 1-1/4” Long, Steel (Z/P)

3 1

380-30300

775-60400

Strike Plate, M32/M38 (shown)

Strike Plate, M62/M68

4 1 330-12000 Strike Mounting Bushing, White, Delrin

5 1 300-13600

Socket Flat Head Screw, 5/16-18 UNC X 1-3/4” Long, Steel

(Z/P)

6 3 310-11100 Washer, 1” O.D. X 11/32” I.D. X 1/8” Thick, Neoprene

7 1 330-12600 Sex Bolt, 5/16-18 UNC X 1-1/2” Deep, Steel (Z/P)

5.2.1.1. Strike Installation

Using Figure 2, the template provided and the following step-by-step installat ion

instructions, complete the installation of the strike into the door.

1. Fold the template and place into position on door/frame at desired mounting

location. Mark the strike center hole on the door and the center position of the

two (2) slotted mounting bracket holes on the door frame.

2. Drill one (1) 3/8” [9.5mm] diameter hole through door (a t ma rk for strike center

hole), then drill 1/2” [12.7mm] diameter through door from opposite side for

sex bolt (Item #7).

3. From the side of the door that the strike will be mounted, drill two (2) 1/2”

[12.7mm] diameter X 1-3/8” [34.9mm] deep holes for the roll pin bushings

(Item #1).

4. Insert the two (2) strike roll pin bushings into the holes in the door (either side

of strike center hole).

5. Obtain the strike (Item #3) and place on a clean, flat surface. Using a

hammer, insert and lightly tap to install the two (2) roll pins (Item #2) into

the two (2) 1/4” [6.4mm] diameter recesse s of the strike. Note: Care should

be taken when installing roll pins into the strike. Excessive impact to the strike

or over-driving the pins into the recesses may distort the contact su rface of the

strike which will affect the holding force of the lock.

6. Insert the strike mounting bushing (Item #4) and the 5/16-18 UNC X 1-3/4”

long socket flat head screw (Item #5) through the center hole of the strike.

7. Install two (2) of the neoprene washers (Item #6) over the screw on the

opposite side (roll pin side) of the strike. Note: A third washer is provided but

is normally not used. It may be used however, if required to take up any

additional spacing that cannot be taken up by adjusting the lock mount bracket.

8. Insert the strike mounting screw (with washers) into the 1/2” [12.7mm]

diameter strike center hole in the door while aligning the roll pins of the strike

assembly into the roll pin bushings.

9. Start the sex bolt (Item #7) into the 1/2” [12.7mm] diameter hole from the

opposite side of the door. Do not fully seat the sex bolt against the surface of

the door at this time, but thread the sex bolt onto the end of the strike

mounting screw. Using a 3/16” hex wrench, continue to thread the strike

mounting screw into the sex bolt while ensuring that the assembly maintains a

straight (perpendicular) alignment to the door.

10.Using a hammer and a 3/16” hex wrench, gradually tighten the screw into the

sex bolt until it is snug, and then tap the head of the sex bolt toward the face of

the door. Keep repeating this procedure to slowly “walk” the sex bolt into place

(head against door face) – this ensures a straight (perpendicular) alignment of

the strike assembly to the door. Note: Do not ov er tighten. When the strike

is fully installed there should be some play or flexing of the strike around the

washers. This allows the lock to pull the strike into the correct alignment for

maximum holding force.

PN# 500-21400

Page 4 Rev. C, 05/12

Page 5

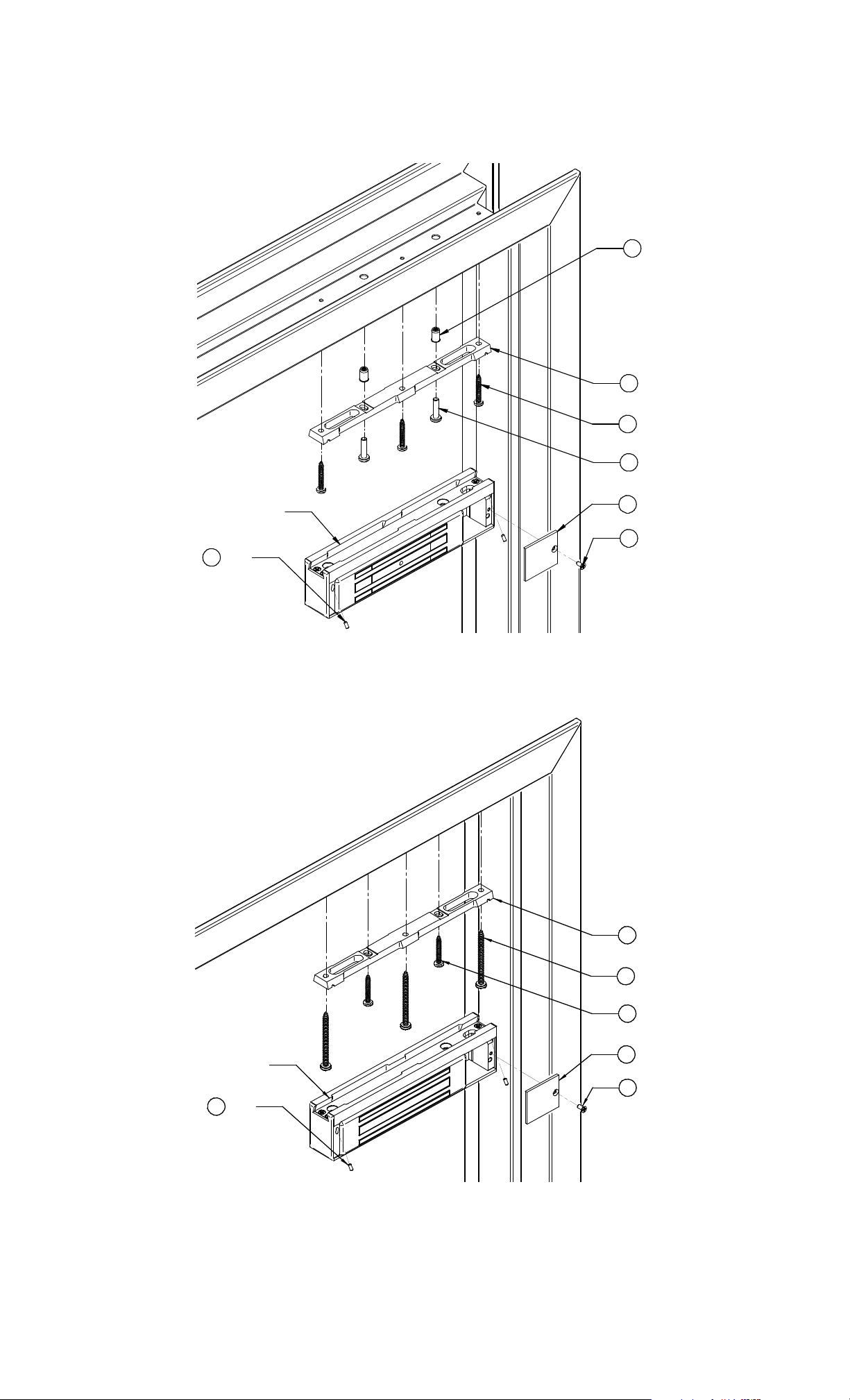

5.2.2. Door Frame Preparation

Figure 3 below is an exploded illustration of the assembly of the lock to a metal door

frame:

11 (X2)

12

14 (X3)

13 (X2)

LOCK HOUSING

10 (X2)

9

8

Figure 3

Figure 4 below is an exploded illustration of the assembly of the lock to a wood door frame:

12

15 (X3)

14 (X2)

LOCK HOUSING

10 (X2)

9

8

Figure 4

PN# 500-21400

Page 5 Rev. C, 05/12

Page 6

PART

ITEM QTY

NUMBER

NOMENCLATURE/DESCRIPTION

8 1 (Included) Phillips Flat Head Screw, 8-32 UNC

9 1 (Included) Lock Housing Front Cover

10 2 (Included) Socket Set Screw, 6-32 UNC

11 2 320-10800 Blind Nut, 1/4-20 UNC, 1-Piece

12 1 (Included) Standard Mounting Bracket

13 2 300-12403 Phillips Pan Head Screw, 1/4-20 UNC X 1” Long, Steel (Z/P)

14 3 300-13010

Phillips Pan Head Screw, #12 X 1-1/2” Long, Type “A”, Steel

(Z/P)

15 3 300-13110 Phillips Pan Head Screw, #14 X 3” Long, Type “A”, Steel (Z/P)

5.2.2.1. Lock Installation

Using Figure 3 (for metal door frames) or Figure 4 (for wood door frames) above, the

template provided and the following step-by-step installation instructions, complete the

installation of the lock onto the door frame.

1. Locate the two (2) marks applied to the door frame for the mounting bracket

using the template in the previous strike installation section (Section 5.2.1.1,

Step 1), then:

a. For Metal Door Frame:

Drill two (2) 3/8” [9.5mm] diameter holes

through the door frame at these locations.

i. Install blind nuts (Item #11) into the 3/8” [9.5mm] diameter

holes in the door frame as follows:

1. Using blind nut collapsing tool provided (with blind nut in

place), insert the end of the blind nut into the hole.

2. Using a hammer (if necessary) tap the nut in until the upper

lip seats against the door frame surface.

3. While holding the hex portion of the collapsing tool with a

1/2” box-end wrench or vise grip pliers, turn the socket head

cap screw of the tool using a 3/16” hex wrench. Note:

Maintain firm pressure toward the door frame mounting

surface while collapsing the nut.

4. Once the blind nut is adequately collapsed, remove the tool

from the nut by backing the cap screw out of the blind nut

thread.

5. Install the second blind nut onto the collapsing tool (cap

screw) and repeat sub-steps i1 through i4.

b. For Wood Door Frame:

Drill two (2) 3/16” [4.8mm] diameter holes X 1-

1/4” [31.8mm] deep (minimum) into the door frame at these locations.

2. Remove the mounting bracket (Item #12) from the top (dov etail) area of the

lock housing as follows:

a. Using a #1 Phillips screwdriver, remove the 8-32 UNC flat head screw

(Item #8) holding the lock housing front cover (Item #9) in place.

Remove cover and set screw and cover aside for later assembly.

b. Using a 1/16” hex wrench, back the two (2) 6-32 UNC socket set screws

(Item #10) out far enough to allow free (sliding) movement of the

mounting bracket. Note: It is not necessary to completely remove the

set screws to allow removal of the bracket – five (5) 360-degree

counterclockwise turns is normally far enough.

c. Slide the bracket far enough to disengage the bracket from th e top of the

lock housing. Note: The bracket/lock interface can be disengaged by

moving the lock (or bracket) 1” to 2” [25-50mm] laterally to one side or

the other, then withdrawing away vertically – you do not have to slide the

lock or bracket the full length of the housing to remove or install.

3. Place the mounting bracket onto the frame aligning the two (2) slotted holes in

the bracket with the previously installed blind nuts (for metal frame) or drilled

holes (for wood frame). Using a #3 Phillips screwdriver, lightly secure the

mounting bracket to the frame with:

PN# 500-21400

Page 6 Rev. C, 05/12

Page 7

a. For Metal Door Frame: Two (2) 1/4”-20 UNC X 1” long Philli ps pan head

screws (Item #13) provided.

b. For Wood Door Frame:

Two (2) #12 X 1-1/2” long Phillips pan head

type “A” screws (Item #14) provided.

Note: Do not fully secure (tighten) the screws at this point. Tighten

screws to “snug” and back out as necessary to provide slight movement

of bracket for adjustment.

4. Assemble the lock housing to the bracket by inserting and engaging the top

(dovetail) feature of the lock with the mounting bracket. Slide the lock into

proper position (centered on the mounting bracket).

5. Adjust the lock/bracket assembly in the slots of the bracket as necessary to

establish proper relationship with (against) the strike.

6. Carefully remove the lock housing from the mounting bracket while attempting

not to alter the position of the bracket on the door frame.

7. Using a #3 Phillips screwdriver, fully secure the two (2) screws (Item #13 or

#14) installed in Step 3 above.

8. Using the installed mounting bracket a s a guide, locate and drill three (3) holes

into the door frame corresponding to the remaining three (3) open holes in the

bracket:

a. For Metal Door Frame:

Drill three (3) 3/16” [4.8mm] diameter holes

(through).

b. For Wood Door Frame:

Drill three (3) 7/32” [5.6mm] diameter holes X

2-3/4” [69.9mm] deep (minimum).

9. Using a #3 Phillips screwdriver, install the three (3) #12 screws (Item #14 for

metal frame) or #14 screws (Item #15 for wood frame) through the bracket

and into the holes in the door frame. Tighten the screws to secure the mounting

bracket to the door frame.

10.Determine optimal location then drill a 3/8” [9.5mm ] diameter hole through the

door frame for the lock power cable. Note: This hole must align within the

large slotted “window” in the top of the lock housing when the lock is installed

on the mounting bracket.

11.After all electrical wiring has been completed, install the housing front cover

(Item #9) and secure in place using the 8-32 UNC flat head screw (Item #8).

5.3. Lock with “D” (Door Position) Option - Installation

For locks provided with the “D” (Door Position) option, the magnetic (reed) switch is factor y

installed inside the control wiring access compartment cover.

When a lock has been previously installed and it has been later determine d to upgrade to the

“D” option in the field, the template provided in the upgrade kit illustrates proper location and

installation of the switch to the inside of the compartment access cover.

Using Figure 5 below, the template provided and the following step-by-step installation

instructions complete the installation of the actuator block to the door adjacent to the strike

plate.

1. After marking the mounting holes for the actuator block on the door using the

mounting template provided with the lock (or upgrade kit), center punch these

locations. The actuator block has hardware included for mounting in two type s

of configurations. Decide which of the following choices will work best for the

application and then:

a. If Mounting Using #8 Flat Head Screws (Recommended for Solid

Core (Wood), Aluminum Frame or Hollow Metal Doors): Drill two

(2) 9/64” [3.6mm] diameter holes X 3/4” [19.1mm] deep (maximum)

into the door at the center punched locations or;

b. If Mounting Using #6 Pan Head Screws (Recommended for

Aluminum Frame, Hollow Metal or the Top Jam Z-Bracket): Drill

two (2) 1/8” [3.2mm] diameter holes X 3/8” [9.5mm] d eep (maximum)

into the door at these locations.

PN# 500-21400

Page 7 Rev. C, 05/12

Page 8

2. Using a #1 Phillips screwdriver and the screws provided secure the actuator

block to the door making sure that the arrow of the label on the backside of

the block is facing toward the mounting edge

of the lock.

Strike mounted to door

(Reference)

See Section 5.2.1

(Figure 2)

Mark & drill holes in door for

Actuator Block mounting in

accordance with installation

template (P/N 500-61050)

Actuator Block

Ensure arrow indicator of label

(on backside) of Actuator Block

is facing toward the mounting

edge of the lock when installing!

Phillips Fla t Head Screw #8 X 1-1/2" Long,

Type "A", Steel, Zinc Plated (2X) OR

Phillips Pan Head Screw #6 X 3/4" Long,

Type "A", Steel, Zinc Plated (2X) (Not Shown)

Figure 5

5.4. Inswinging Door Lock Installation

As previously mentioned, additional hardware and brackets are required for mounting the

lock system in the inswinging door configuration. The brackets, hardware and instructions

required for the installation of the lock in this arrangement are available in a Top Jam Kit (TJ38 or TJ-68 Series) which may be obtained through Securitr on Magnalock Corporation or one

of our authorized representatives.

6. OPERATIONAL INSTRUCTIONS

The M38/68 series Magnalocks are direct holding fail safe electromagnetic locks. Both

incorporate Securitron’s unique dual voltage system. Simply apply 12 or 24 volts DC observing

polarity (See Figure 6) and the locks will energize to their respective holding forces of 600 lbs.

[272 Kg] for the M38 and 1200 lbs. [544 Kg] for the M68.

The “L” option adds the ability to visually inspe ct the lock and determine via a red LED that the

lock is in fact energized.

The addition of the “S” option provides a lock status sensing signal which indicates that the lock

is secure and gives you the added ability of a SPDT dry contact that you can interface to either

the access control system or intrusion detection system (See Figure 7). The “S” option will

only report the door is secure if two criteria are met. One - the lock must be powered and two the strike armature must be in full unobstructed contact with the lock face.

Add the two options together “LS” and get both the dry contact output and a visual reference

via a bi-color LED (red = door powered and locked, green = door powered but not locked and off

= door not powered or locked).

PN# 500-21400

Page 8 Rev. C, 05/12

Page 9

Figure 6

Figure 7

The addition of the “D” option incorporates a door position sensing switch which indicat es when

the door is outside of the sensing range of the lock (3/8”-3/4”) and provides the added ability of

a SPDT dry contact that can be interfaced with either an access control system or intrusion

detection system (See Figure 8). The “D” option will report the door position whether the lock

is powered (secured) or not .

SERIES M38 OR M68 WITH "D" OPTION

(DOOR POSITION SWITCH)

"D" OPTION O UTP U T

SPDT DRY CONTACT

(RED)

NC

(WHITE)

C

(BLUE)

ACCESS CONTROL SYSTEM

DOOR POSITION STATUS INPUT

IN

REF

NO

CONTA CT RATING: 200 mA @ 24 V olts

Figure 8

The “T” su ffix option implements a smal l micro switch to create a tampe r resistant enclosure of

the control wiring access compartment. At approximately .03” movement of the access cover

away from the lock housing (usually less than a full turn of the mounting screw) a signal is

transmitted to indicate that access is being attempted to the lock control wiring compartment.

(See Figure 9 for wiring diagram).

PN# 500-21400

Page 9 Rev. C, 05/12

Page 10

SERIES M38 OR M68 WITH "T" OPTION

(TAMPER INDICATION SWITCH)

"T" OPTION OUTPUT

SPDT DRY CONTACT

(RED)

NC

(WHITE)

C

(BLUE)

ACCESS CONTROL SYSTEM

LOCK TAM PER ST ATUS INPUT

IN

REF

NO

CONTACT RATING: 2 Amps @ 24 Volts

Figure 9

The “OS” suffix option available for M68 series locks provide s a modified “Offset” strike to shift

the strike contact face 1/4” [6.4mm] further away from the door frame stop th an the standard

strike. This can be helpful in the installation to aluminum fram e glass doors where the height of

the aluminum rail at the top of the door is not sufficiently wide enough to accommodate the

standard sex bolt/strike installation. It should be noted that an approximate 10% loss in holding

force results from the use of this strike be cause of its of fset position how ever, this should n ot be

significant in that aluminum frame glass doors are not high security barriers. The offset strike is

included with locks ordered with the “OS” suffix or may be ordered separately.

A “Split Strike” configuration option is available for M68 series locks ordered with the “SS”

suffix. This allows one lock to be used to secu re two doors in a double door configuration. In

this method, a single Magnalock is mounted near the center of the header and a half size strik e

is provided for mounting to each door/leaf. This arrangement will also re duce the holding force

to about 550 Lbs. (250Kg) per door/leaf. Locks ordered with the “SS” suffix include the two

(split) strikes or they may be supplied separately.

7. MAINTENANCE

To keep the Magnalock in top working order, especially a Magnalock equipped with the “S”

(Senstat) option, we recommend taking a clean cloth and rubbing alcohol or a non-abrasive

cleaner and wiping down the face of the Magnalock and the strike once every six months.

PN# 500-21400

Page 10 Rev. C, 05/12

Page 11

8. APPENDICES

A. WIRE GAUGE SIZI NG

If the power supply is distant from the lock, voltage will be lost (dropped) in the connecting

wires so that the Magnalock will not receive full voltage. The following chart shows the

minimum wire gauge that will hold voltage drop to an acceptable 5% for different lock to

power supply distances. Proper use of the chart assumes a dedicated pair of wires to power

each Magnalock (no common negative). Note that a Magnalock operating on 24 volts is a

much better choice for long wire runs as it has 4 times the resistance of a 12 volt installation.

Also note that the correct calculation of wire sizing is a very important issue a s the installer is

responsible to insure that adequate voltage is supplied to any load. In multiple device

installations, the calculation can become quite complex so refer to the following section

“Calculating Wire Gauge Sizing” for a more complete discussion.

Distance Gauge 12V Gauge 24V

Distance Gauge 12V Gauge 24V

100 FT 24 GA 24 GA 800 FT 18 GA 22 GA

200 FT 22 GA 24 GA 1500 FT 14 GA 18 GA

400 FT 20 GA 22 GA 2000 FT 14 GA 18 GA

CALCULATING WIRE GAUGE SIZING

The general practice of wire sizing in a DC circuit is to avoid causing voltage drops in

connecting wires that reduce the voltage available to operate the device. As Magnalocks are

very low power devices, they can be operated long distances from their power sou rce. For any

job that includes long wire runs, the installer must be able to calculate the correct gauge of

wire to avoid excessive voltage drops.

This is done by taking the current draw of the lock and multiplying by the resistance of the

wire I x R = Voltage drop (i.e. 0.100A x 10.1 Ohms = 1.01 Volts dropped across the wire). For

all intents and purposes it can be said that a 5% drop in voltage is acceptable so if this were a

24 Volt system (24 Volts x .05 = 1.2 Volts) a 1.01 Volt drop would be within tolerance.

To calculate the wire resistance, you need to know the distance from the power supply to the

Magnalock and the gauge (thickness) of the wire. The following chart shows wire resistance

per 1000 ft (305 meters):

Wire Gauge Resistance/1,000 ft

Wire Gauge Resistance/1,000 ft

8 Gauge .6 Ohms 16 Gauge 4.1 Ohms

10 Gauge 1.0 Ohms 18 Gauge 6.4 Ohms

12 Gauge 1.6 Ohms 20 Gauge 10.1 Ohms

14 Gauge 2.5 Ohms 22 Gauge 16.0 Ohms

B. CONSIDERATIONS FOR MAXIMUM PHYSICAL SECURITY

M38 and M68 Magnalocks carry rated holding forces of 600 lbs. [272 Kg] and 1,200 lbs. [544

Kg] respectively. There are several installation and application variables to be considered

which affect the security level that may be obtained while using a Magnalock.

In the case of wooden doors (other than solid hardwoods), aluminum frame glass doors, and

hollow metal doors, the M38 should be employed in a “traffic control” mode. This is because a

determined assault on these types of door/lock configurations has the potential of “popping”

this model open. The M68 is generally stronger that the door itself. Users have logged

periodic cases of an assault where the door has been destroye d leaving the Magnalock intact

and still retaining the piece of the door where the strike was mounted.

A pry bar may be used to try to pry the door open. However, what generally occurs is that the

door will experience material failure. The pry b ar tears (in the case of w ood) or bends (metal)

the door material without defeating the lock. The general fact that a Magnalock mounts on the

other side of the door from the attacker is an important contributor to its strong resistance to

assault.

The concept of preferring a door that gives also affects the issue of physical security on

different door types. Oddly enough, the characteristics that make an inswinging door strong

PN# 500-21400

Page 11 Rev. C, 05/12

Page 12

can make it more difficult to secure if it is stiff or rigid. Steel doors and most particularly solid

steel doors such as may be found in prisons, transmit impact much more effectively to the lock

and as such may be defeated by repeated leg blows or by charging the door. If the end user

has such doors and/or a security environ ment where such determined at tacks can be foreseen

on the doors, it is his responsibility to ensure that the Magnalock’s strength is adequate for th e

application. Selection of the model 68 is strongly recommended with another technique being

the use of multiple locks.

These Magnalocks have been carefully designed to be installed with the included fasteners

which substantially exceed the strength of the lock. If the installer substitutes for any o f the

factory included fasteners or hardware for any reason, the strength capability of the

installation may be compromised. It should be noted that a key component to th e successful

installation of this product is the sex bolt. The head of the sex bolt is the only part of the lock

assembly that is accessible to an attacker.

It is also vital when mounting the magnet (lock housing) into a metal frame to use the

included machine screws and steel blind nuts. An alternative technique has been to use sheet

metal screws which some installers feel is easier. This is extremely ill advised as the magnet

receives a torquing force each time that the door is closed, which over tim e will work the sheet

metal screws loose. It has been determined that sheet metal screws may be considered

acceptable, although not preferred, if the frame header is made of steel. Indeed this is

mandated when Securitron’s concrete header bracket is utilized. On an aluminum header

however, mounting with sheet metal screws is dangerous as the steel screw threads will

eventually tear through the relatively soft aluminum.

To fully complete an installation that maximizes the effectiveness of the included fasteners, th e

thread locker compound (provided) should be used to prevent the threads from lo osening over

time.

PN# 500-21400

Page 12 Rev. C, 05/12

Page 13

C. TROUBLESHOOTING

PROBLEM: No magnetic attraction between magnet and strike plate.

First be sure the Magnalock is being correctly powered with DC voltage. This includes

connecting the power wires with correct polarity. Positive must go to red and negative to

black. If the magnet body is wired in reverse polarity, it will not be damaged, but it w ill not

operate. If the unit continues to appear dead, it must be electrically checked with an

Ammeter. It must be powered with the correct input voltage and checked to see if it draws th e

specified current. If the unit meters correctly, it is putting out the correct magnetic field and

the problem must lie in the mounting of the strike.

PROBLEM: Reduced holding force.

This problem usually expresses itself in terms of being able to kick the door open or to open it

with a shoulder. Check the strike and magnet face to see if some small obstruction is

interfering with a flat fit. Even a small air gap can greatly reduce the holding force. Another

possibility is if the strike plate has a dent on it from being dropped for example. Remove the

strike from the door and try to rock it on the magnet face to insure that it is flat. If the strike

and magnet are flat and clean, the cause is nearly always improper mounting of the strike in

that the strike is mounted too rigidly. The strike must be allowed to float around the rubber

washer stack which must be on the strike center mounting screw. The magnet then pulls it

into flat alignment. To correct the problem, try loosening the strike mounting screw to see if

the lock then holds properly. Another possibility is if you are operating the lock on AC instead

of DC or on half wave rectified DC (transformer + single diode). Half wave rectified DC is

unacceptable; you must at a minimum employ full wave rectified DC (transformer + bridge).

PROBLEM: The Senstat output does not report secure.

Because of the simplicity of Securitron’s patented Senstat design, this is almost always a case

of the lock status sensor doing its job. It is not re porting secure because a small obstruction

or a too stiffly mounted strike is causing the Magnalock to hold at a reduced force. The

problem is corrected by cleaning the surfaces of the magnet and strike (see Maintenance

Section 7) or establishing proper play in the strike mounting. If this does not work, you can

verify function of the Senstat feature as follows: Note that there are two (2) thin vertical lines

on the magnet face that can be said to separate the core into three (3) sections from left to

right. The Senstat output is created by the strike establishing electrical contact be tween the

leftmost and rightmost core segments. With the lock powered, use a pair of scissors and press

the points respectively into the leftmost and rightmost core segments. The Senstat output

should then report secure. This shows that the pro blem lies in the strike not making correct

flat contact with the magnet face. If the scissors technique does not cause the lock to report

secure, check to see if there is a broken Senstat wire. If this is not the case, the lock must be

returned to the factory for replacement.

PROBLEM: The lock does not release.

When power is removed from it, the Magnalock must release. Therefore the complaint of "lo ck

will not release" is either mechanical bonding via vandalism or a failure to com pletely release

power. By mechanical bonding, we simply mean that glue has been applied between the strike

plate and magnet as a prank. Failure to completely release power is generally a wiring

integrity problem. What happens is that an upstream switch removes power from the wires

going to the Magnalock, but through an installation error, the wires have their insulation

abraded between the switch and lock so that partial or full power can leak in from another

Magnalock or other DC device with similarly abraded wiring. This is most likely to occur at the

point where the wire cable leaves the Magnalock case and enters the door frame. Another

area is via an improper splice on wiring in conduit. Either a metal door frame or the metal

conduit is capable of leaking power between multiple devices with abraded wires, thereby

bypassing switches. A good way to check this electrically (as opposed to visually removing and

inspecting the wires) is to use a meter and check for leakage between the power supply

positive or negative and the door frame and conduit. Magnalocks should be powered by

isolated DC voltage without any earth ground reference to positive or negative.

PROBLEM: The lock rusts.

Both the magnet core and strike plate are plated and sealed following a military specification.

If rusting appears, the most common cause is that improper cleaning (with steel wool for

instance) has occurred and this has stripped off the relatively soft plating. Once the plating

PN# 500-21400

Page 13 Rev. C, 05/12

Page 14

has been removed, it cannot be restored in the field, so the lock will have to be periodically

cleaned and coated with oil or other rust inhibitor. A rusty Magnalock wi ll still function but at

reduced holding force. If the product is installed in a heavily corrosive atmos phere, such as

near the ocean, it will eventually rust even with non-abrasive cleaning. The only answer then

becomes continued periodic removal of the rust.

PROBLEM: Apparent electronic noise interference with the access control system.

Electric locks, being inductive devices, return voltage spikes on their power wires and also emit

microwave radiation when switched. This can interfere with access control electronics causing

malfunctions. Access control contractors often employ installation techniques designed to

isolate the access control electronics from the electric lock. These include separate circuits fo r

the lock, shielded wiring and other techniques. These techniques will vary with the sensitivity

of the access control system electronics and should, of course be followed. Note that

Magnalocks include internal electronics which suppress both inductive kickback and radiation.

They have been extensively tested and accepted by numerous access control manufacturers

and have been used in thousands of installations without incident. An apparent noise problem

is therefore usually not caused by the Magnalock. The access control equipment may be itself

faulty or have been installed improperly. One problem can arise with the Magnalock. If the

Senstat version is being used, the strike plate (which passes current) must be isolated from a

metal door and frame. Securitron supplies insulating hardware to accomplish this but the

hardware may not have been used or the strike may be scraping against the header for

instance. Check for full isolation between the strike and the door frame (when the door is

secured) with an Ohmmeter. The presence of lock voltage potential in the door frame can

interfere with the ground reference of access control system data communication and therefo re

cause a problem.

IF YOUR PROBLEM PERSISTS

CALL SECURITRON TOLL FREE

1-800-MAG-LOCK

9. MAGNACARE

For warranty information visit www.securitron.com/en/site/securitron/About/MagnaCare-Warranty/

LIFETIME REPLACEMENT WARRANTY

PN# 500-21400

Page 14 Rev. C, 05/12

Loading...

Loading...