Securitron AQU126B Installation Instructions

Tel 1.800.MAGLOCK info@securitron.com

Recommended Tools & Additional Materials

#2 Phillips Screw Driver

Wire connectors

Lead Acid or Gel Cell Batteries*

1/16” Flat head Screw Driver

6-32x1/4 Mounting Screws

Mechanical

Electrical

Environmental

Regulatory

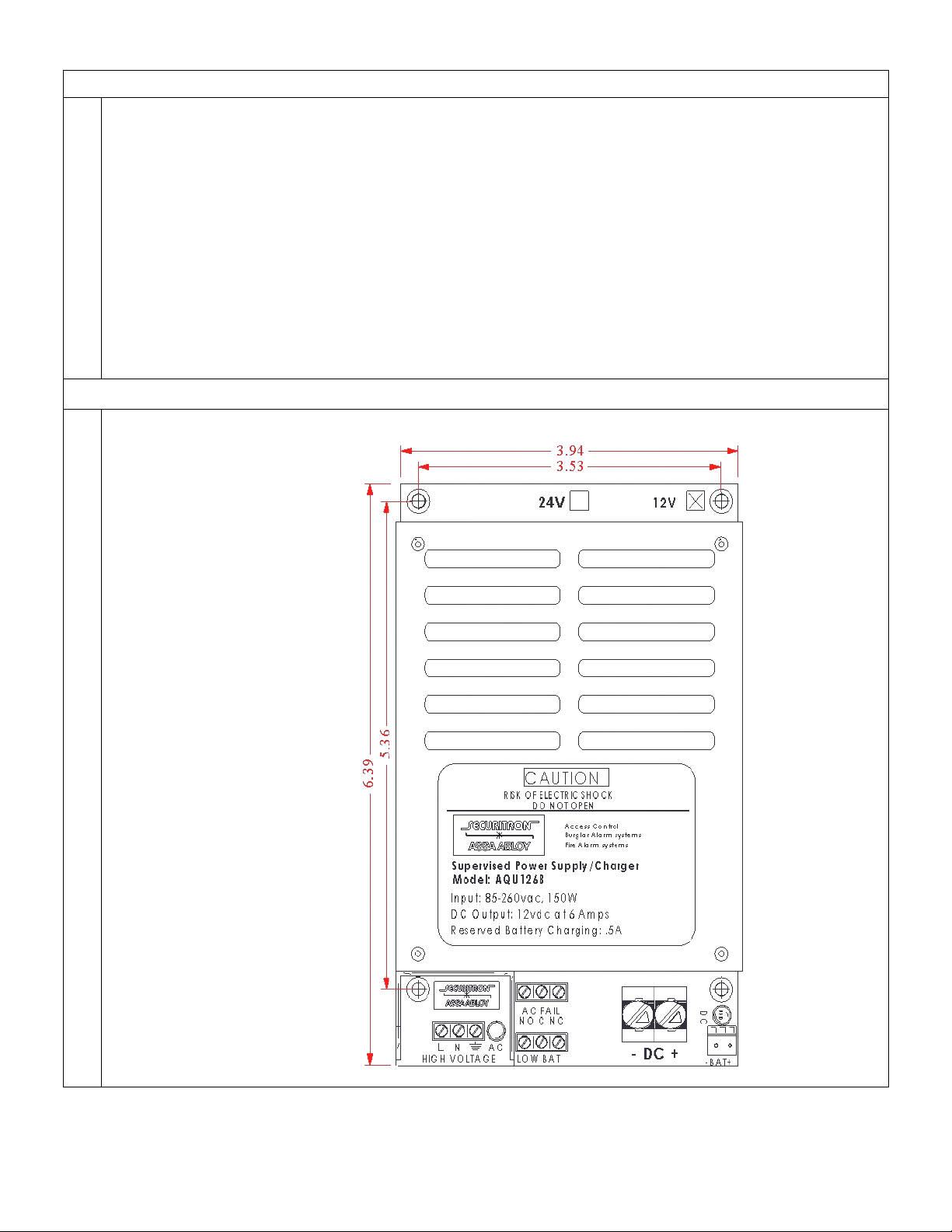

Physical Size:

Board: 3 15/16” x 6 3/8” x 2 3/8”

Mounting: : 3 9/16” x 5 3/8”

Weight*

AQU126B

1.5 lbs

Input Voltage Operating

Range

110-240VAC

47-63Hz

Maximum Output Voltage

72 VA

6 Amps @ 12VDC (±10%)

Continuous Output Voltage:

60VA

5 Amps @ 12VDC ((±10%)

Voltage Range:

9.8 -13.7 VDC/ 13.65V typical

Frequency

27KHz

Operating

Temperature

0ºF to 130ºF

[-17 to 54ºC]

Humidity

10% to 95% RH

For Indoor use

Recognized

Component:

UL294

UL603

UL1481

cUL

RoHS Compliant

1.800.624.5625 www.securitron.com

AccuPower AQU126B

Installation Instructions

*See Battery sizing guide on page 6.

© Copyright, 2013, all rights reserved Page 1 P/N 500-30035

Rev. A, 04/13

AccuPower AQU126B Specifications

Overview of AQU126B Series Power Module

The Securitron AccuPower AQU126B offers clean, steady and accurate power output for peak performance of access

control equipment plus flexibility unmatched by any power supply/battery charger on the market today.

Universal AC input with brownout tolerance to 60VAC

Tolerates and protects against input voltage fluctuations.

External LED AC power indicator

Form “ C“ contact for AC power fail notification

Dedicated voltage for battery charging even under full load

Low battery disconnect prevents deep discharge of batteries

PTC protection for Thermal Runaway and Current Overload Short Circuit and Reverse Battery protection -

will auto restart without removing load.

AQU126B and AQU126 provide a single output. The output can be divided into additional channels using any of the

optional power distribution boards: PDB4, PDB8, PDB-8F8R, PDB-8C8R, PDB-8C1R or PDB-1R.

Applications

The AQU126 Series can be used with electrified access control equipment in conjunction with access control systems

and fire/burglary systems including most electrified locking hardware and latches, card readers, keypads, electric

strikes, REX and motion detectors and more.

Pre-Installation Survey

Before installing the AQU126 Series, the mounting location should be determined and assessed for the following:

Availability of AC power service

Protection from vandalism and tampering

Sufficient clearance for air circulation and heat dispersal

CAUTION: Check with your local code inspectors to ensure your compliance with the National Electrical

Code (ANSI/NFPA 70), (Canadian Electrical Code for Canada) or equivalent and any additional licensing

and wiring requirements for your jurisdiction.

Rev. A, 04/13

Page 2 P/N 500-30035

A. Installing the Power Module

1.

Select mounting location so that AC input conduit can be aligned to maintain separation with DC power

outputs.

Ensure unit is mounted with sufficient airflow to prevent heat buildup.

IMPORTANT: AC Power input is not power limited. AC lines must be enclosed in approved

conduit. AC Input lines must be separated by at least ¼” from Class 2 power limited output

wires.

Mark board mounting hole locations and drill. Install mounting screws appropriate for the mounting

location, leaving enough hardware exposed to install standoffs. Install standoffs. Place starwheel on any

one of the three standoff locations corresponding to a mounting location on the board that has a metal ring.

Affix board to standoffs with provided metal screws.

IMPORTANT: User is responsible for observing all electrical and code requirement when

installing in self-provided enclosure or mounting location.

B. Make Electrical Connections

1.

Component Locations

Page 3 P/N 500-30035

Rev. A, 04/13

Loading...

Loading...