HW - Documentation Proxi-ESCORTE

Hardware - Documentation Proxi-ESCORTE

1 Functional description

1.1 Basic functionality

The basic function of the Standard ESCORTE is that of an intelligent data collector: Every time a

GCS data strip is read in correctly, the Data Acquisition Unit (DAU) recognises the unique 8digit number encoded in the strip and stores this number together with the time and date of the

reading in its memory. Then you can either transfer the data to a computer for further processing

using a Data Transfer Unit (DTU) or have the data evaluated in the DAU itself and check the

results in the form of well structured printouts.

Proxi–ESCORTE in addition offers the possibility to read transponders (also called tags), too.

Further processing is the same as reading a data strip.

1.2 How it works

Data strips consist of a carrier made of plastic and a ferromagnetic tape on the top of the carrier.

During the production process the barcode is mechanically engraved into the tape. The code

represents an 8 digit decimal number plus checksum.

In order to record a data strip the reading head of the Proxi–ESCORTE must be wiped over the

strip without applying to much pressure. During scanning the strip a permanent magnet placed in

the reading head magnetizes the ferromagnetic tape. At the same time a magnetic reading head

system which is mounted in the reading head of the Proxi–ESCORTE with a cardanic suspension

picks up the magnetic field emitted by the magnetic tape. A specially designed circuit amplifies

the weak signal of the magnetic head and provides a digital signal for further processing.

Processing of incoming data is done by a micro-controller. Correct readings will be

acknowledged by the unit with an acoustic and an optical signal (the LEDs will flash).

Proxi–ESCORTE additionally offers the possibly to read and also write transponders (tags).

Transponders contain an integrated circuit (chip) and an antenna – they are typically shaped as

discs. The chip contains an 8 digit identification code. In order to read out data from the chip it is

necessary to first position the head of the Proxi–ESCORTE in a maximum distance of about 1”

above the tag and then shortly press the button placed at the top of the device. This will trigger

the system and the transponder communication process will start. First a magnetic field is build

up by the antenna coil which is placed in the fixed part of the reading head of the Proxi–

ESCORTE. Then the transponder accumulates energy which it picks up with its antenna from the

radiated field of the Proxi–ESCORTE and starts to send data by load modulation. Load

modulation is detected by a special integrated circuit (reader ASIC) and a digital signal is output.

Further signal processing is done by the micro-controller. Data sent to the transponder is ASK

modulated.

An additional feature of the tags versus data strips is the write function. Read only transponders

can only be read, read/write transponders store the unit’s serial number, time and date of the last

reading in a nonvolatile memory. This information may later on be read locally by another unit,

e.g. by a supervisor, no access to a database is needed. The mode of operation is set by a flag in

the transponder memory and can be altered by GCS. The flag may be ignored if the ProxiESCORTE is set to do so. The transponder communication process for writing tags is quite

similar to reading tags. The main difference is that during programming the nonvolatile memory

page 1

HW - Documentation Proxi-ESCORTE

more energy is needed by the transponder than for reading it. Therefore the maximum

communication distance for writing is less than for reading.

The user has to keep in mind that strong electromagnetic fields may have an adverse effect on the

reading of data strips and tags, and that they shorten the lifetime of the power pack.

Communication between the DTU and the Proxi–ESCORTE is done wireless by inductive

coupling. There are separate coils for transmitting and receiving data.

Proxi–ESCORTE is powered by three alkaline batteries put together in a battery pack. For

normal use this pack usually lasts for one to two years.

1.3 Parts of the Proxi-ESCORTE

The device consists of three main parts

• electronic part

The case/body consists of two plastic parts which are glued together. Inside there are 3 PCBs:

- the reading head board with the magnetic head signal amplifier, the LEDs and the

buzzer on it

- the analog print with the circuitry for the wireless interface to the DTU, the circuits

for transponder communication and other peripheral analog circuits on it

- and the digital print with the micro-controller, memory and ‘glue logic’ on it.

• the reading head

The reading head is attached to the electronic part/body and should only be removed by

authorized persons. To remove the head first two plastic rivets have to be extracted using a

special tool. The reading head consists of:

- a fixed part which is attached to the electronic part/body (as described above) where

the antenna for the transponder communication is integrated

- a cardanic suspension for the reading head system

- the reading head system to read the magnetized strips (also containing a small

permanent magnet to first magnetize the strips)

• the power pack

The power pack is attached to the electronic part/body and should only be removed by

authorized persons. To remove the battery first two small round plastic parts have to be

removed. Then access to two screws is possible, they have to be turn out. Lastly two plastic

rivets have to be extracted using a special tool – similar to the reading head.

page 2

HW - Documentation Proxi-ESCORTE

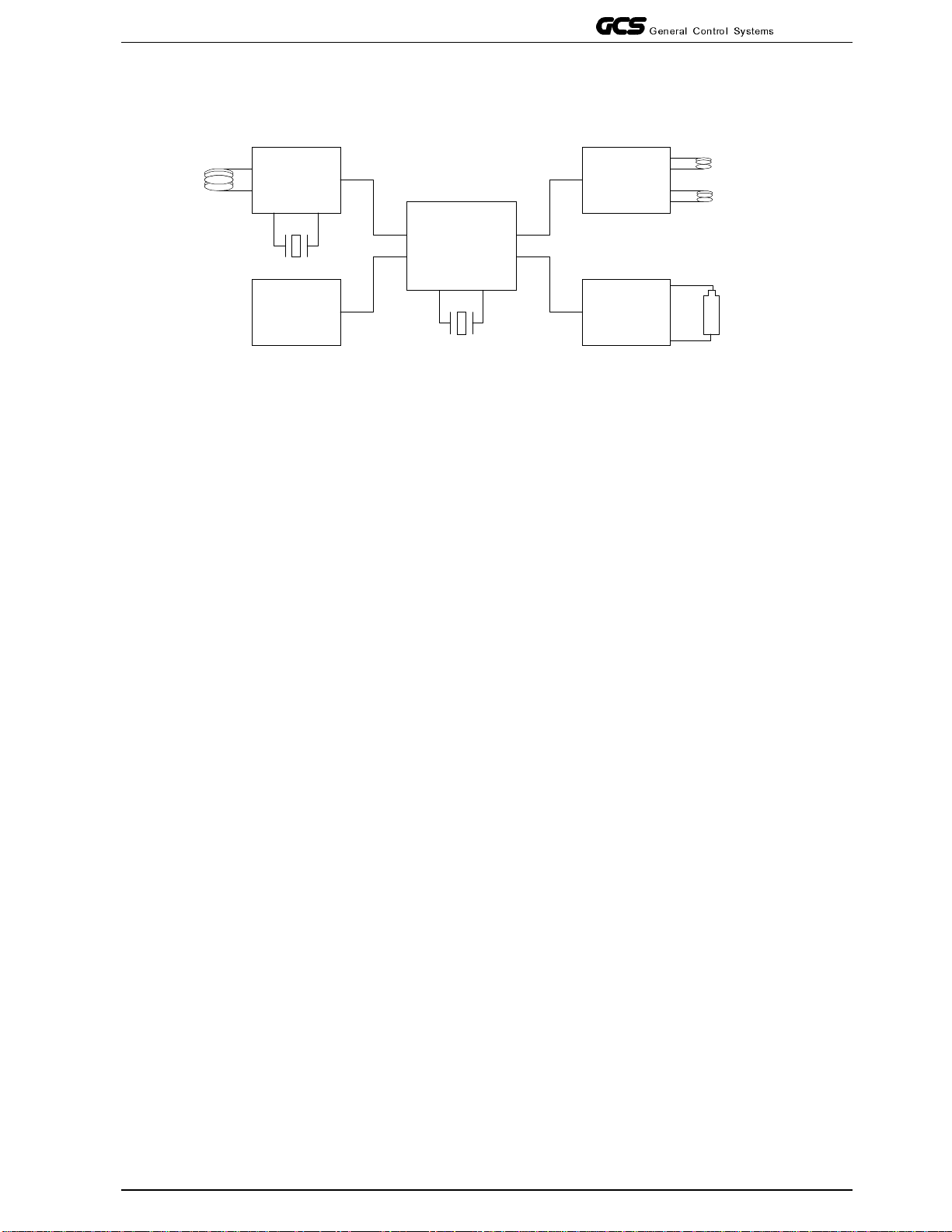

2

block diagram show i ng all relevant clock frequencies

125kHz

transponder

communic.

circuit

4MHz

Microcontroller

RAM

EEPROM

inductive

interface

600kHz

(Transmit)

800kHz

(Receive)

magnetic

barcode

reader

6MHz

power supply

3V/

5V(DCDC)

3cells

Most functions are performed by the micro-controller (80C154) operating at a clock frequency of

6MHz

. It is only active if necessary – otherwise it is in standby mode (oscillator is off).

The transponder communication circuit (reader ASIC) uses a system clock at a clock frequency

4MHz

of

. The carrier frequency for communication with transponders is

For communication from Proxi-ESCORTE to DTU a carrier frequency of

125kHz

600kHz

.

is used and

ASK modulated. For communication from DTU to Proxi-ESCORTE a carrier frequency of

800kHz

is used and ASK modulated. Communication distance is limited to approximately 0,5”.

The battery pack consists of three cells in series which result in 4.5Volts. The internal operating

voltage is 3Volts with the exception of the transponder communication circuit which operates at

a voltage of 5Volts (DC/DC converter MAX857ESA; The switching frequency depends upon the

load and the input voltage, and can range up to

500kHz

).

page 3

Loading...

Loading...